Effect of Carbon Content and Intercritical Annealing on Microstructure and Mechanical Tensile Properties in FeCMnSiCr TRIP-Assisted Steels

Abstract

1. Introduction

2. Materials and Methods

2.1. Base Material Manufacturing

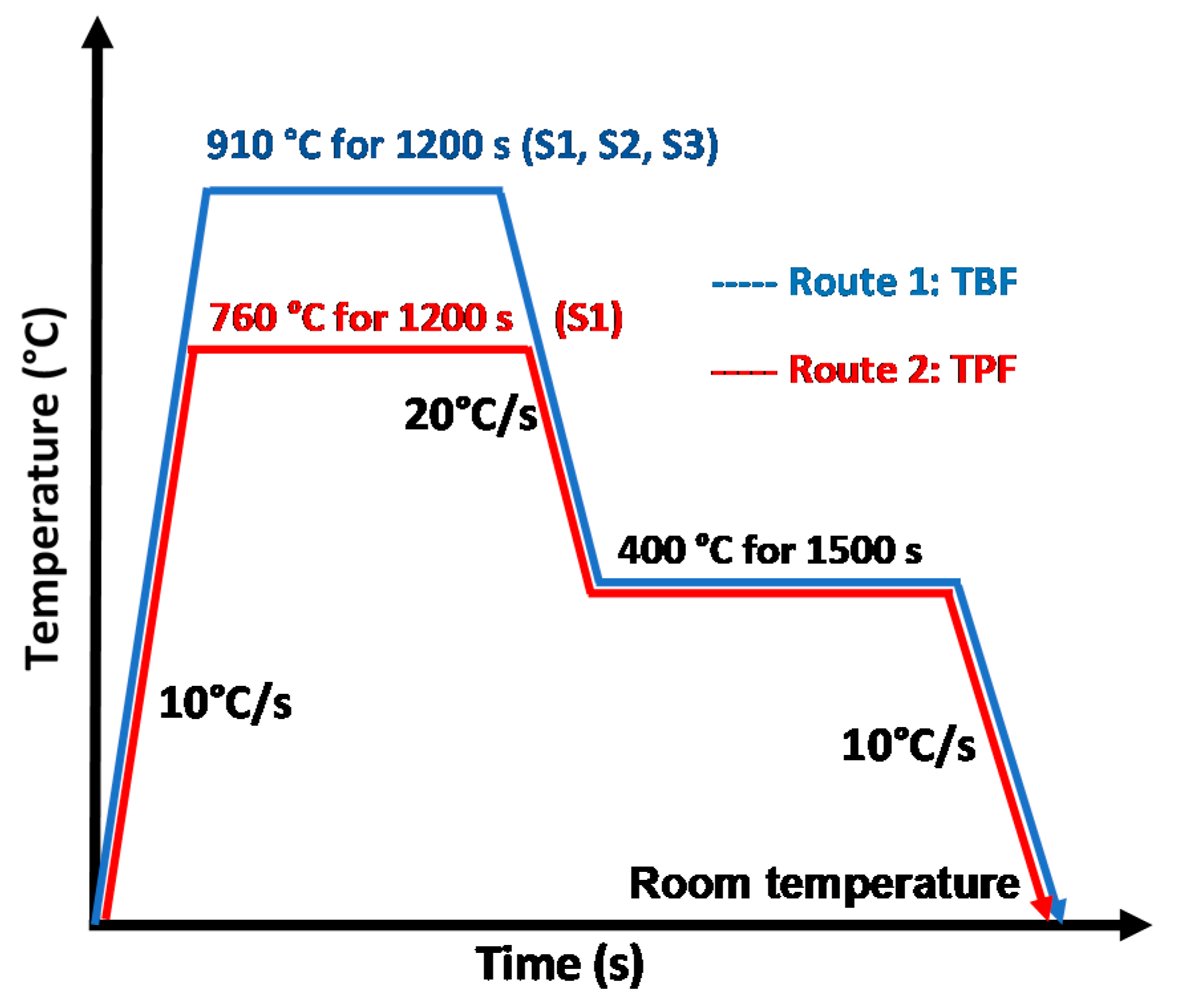

2.2. Thermal Study and Heat Treatments

2.3. Microstructural Study

2.4. Tensile Mechanical Properties

3. Results

3.1. Base Material

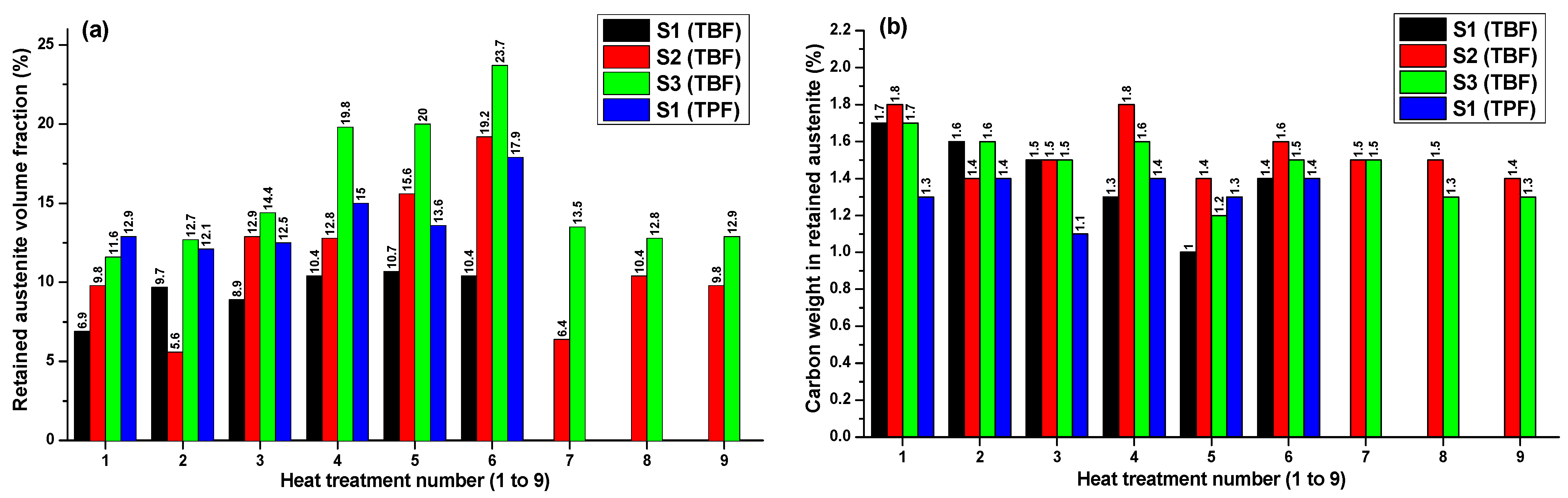

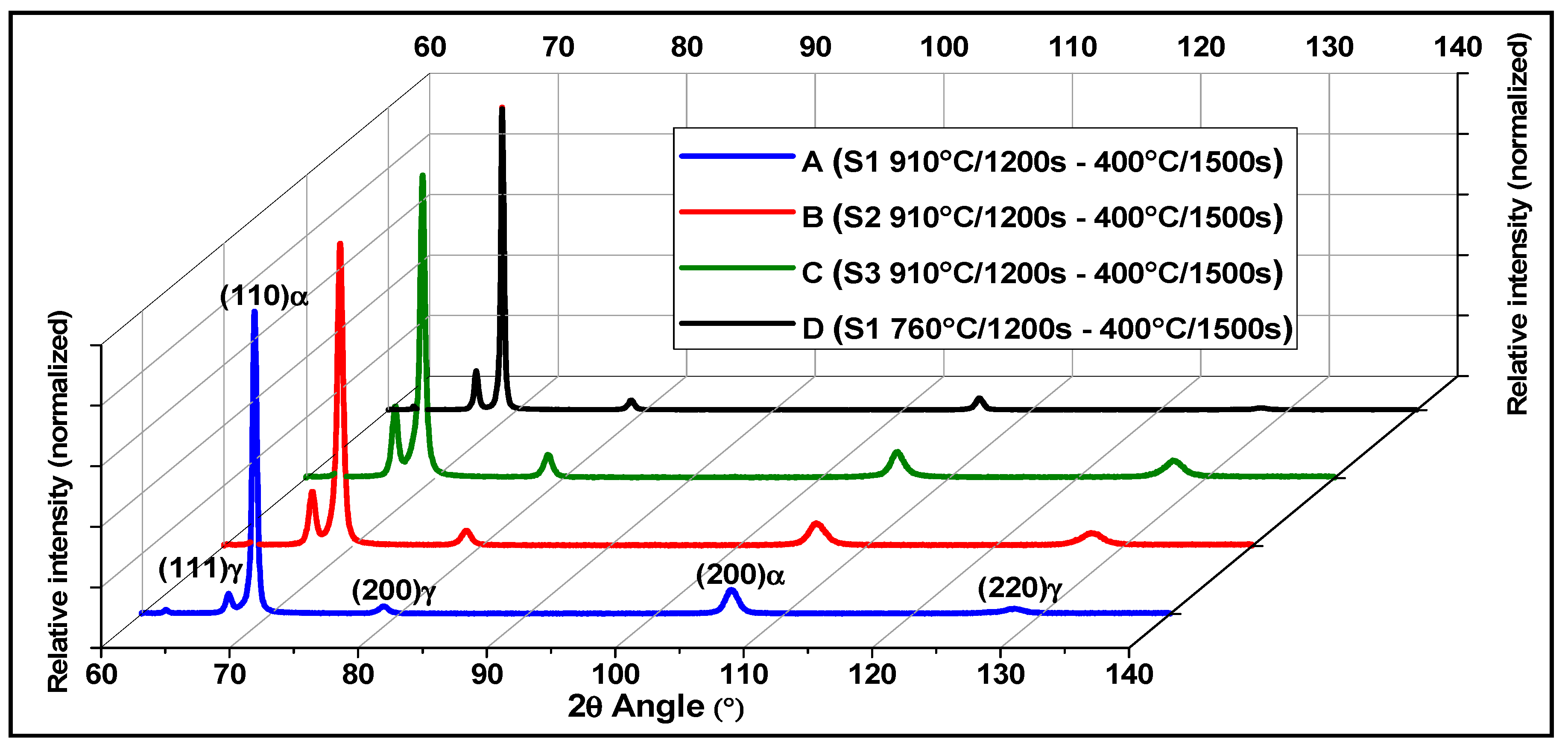

3.2. Microstructural Evolution

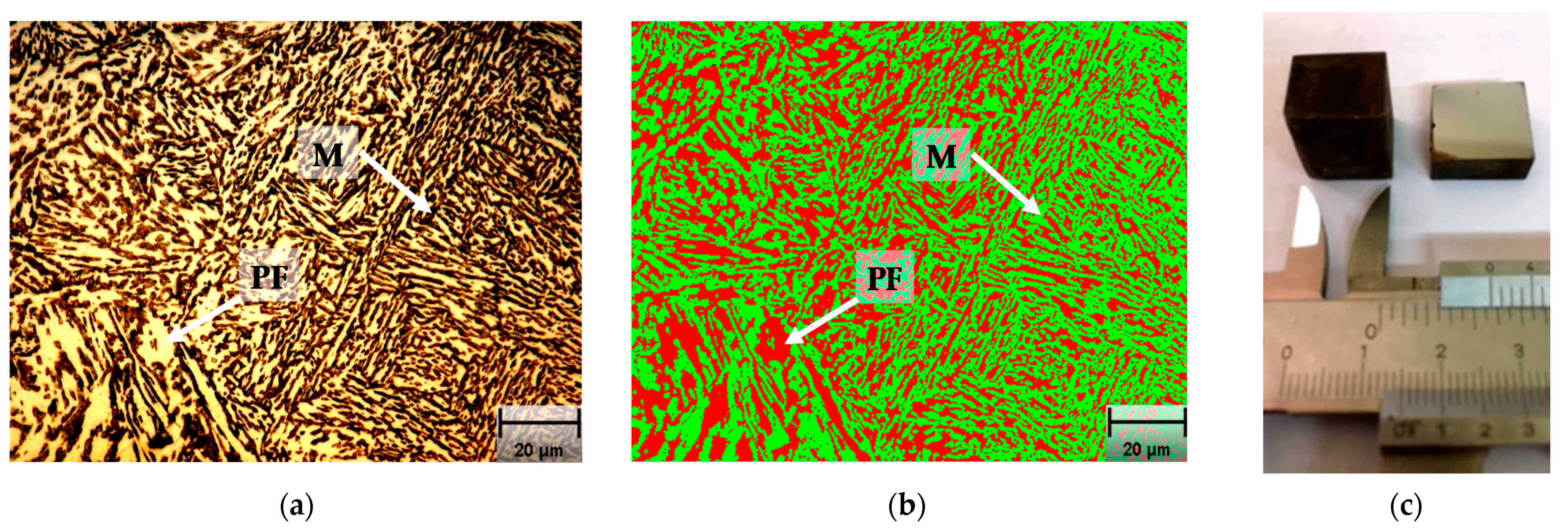

3.2.1. Optical Microscopy

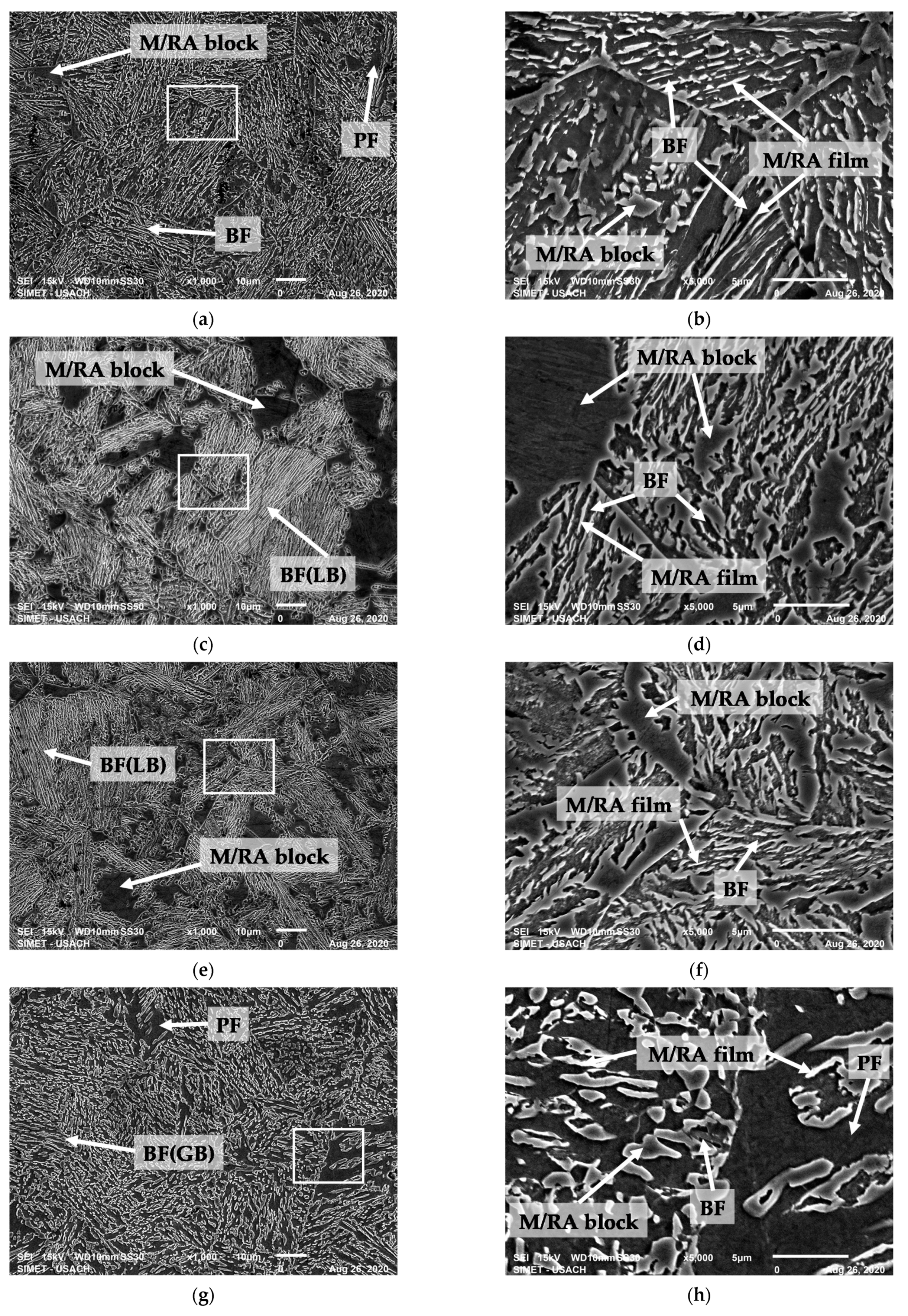

3.2.2. Scanning Electron Microscopy (SEM)

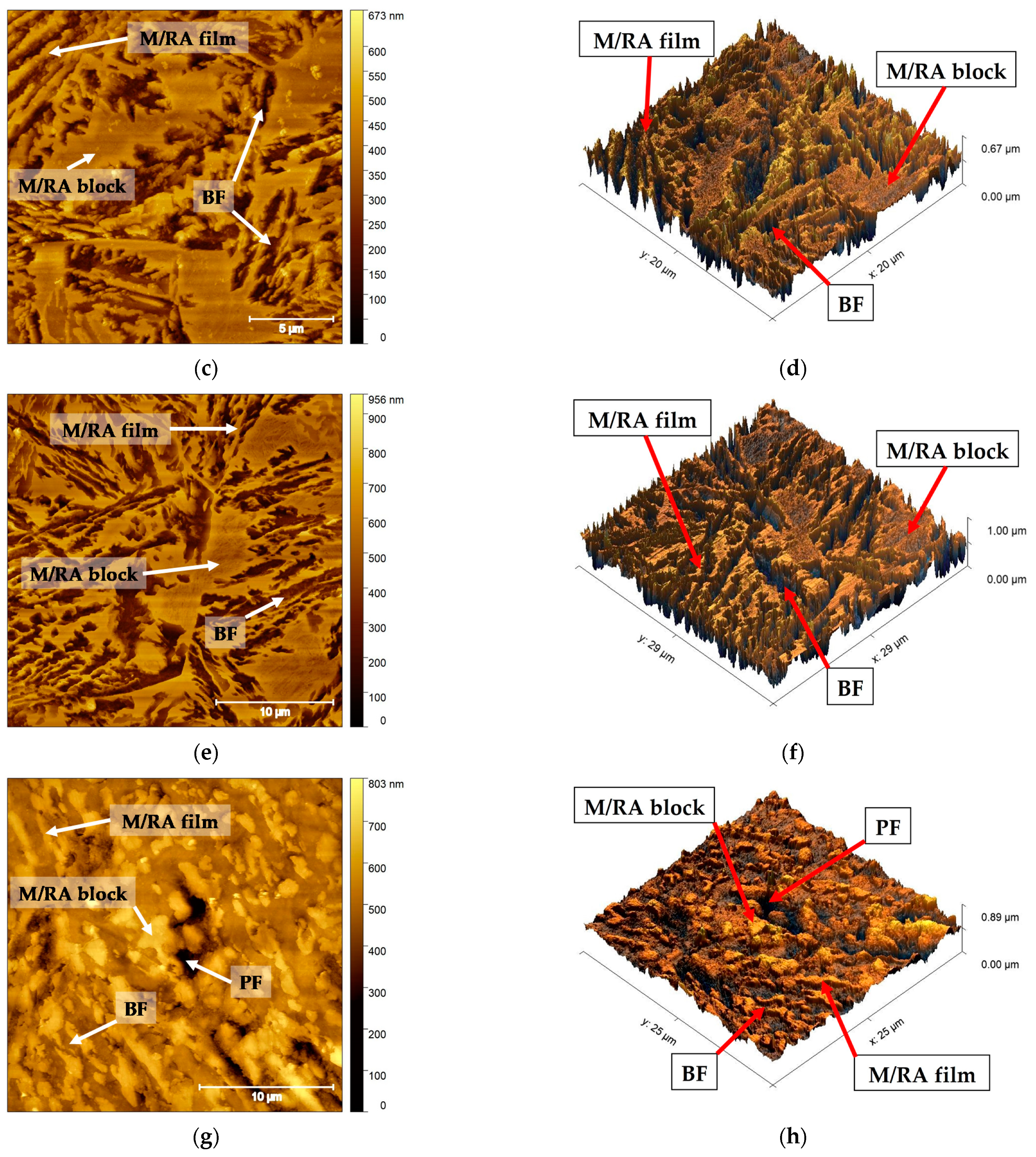

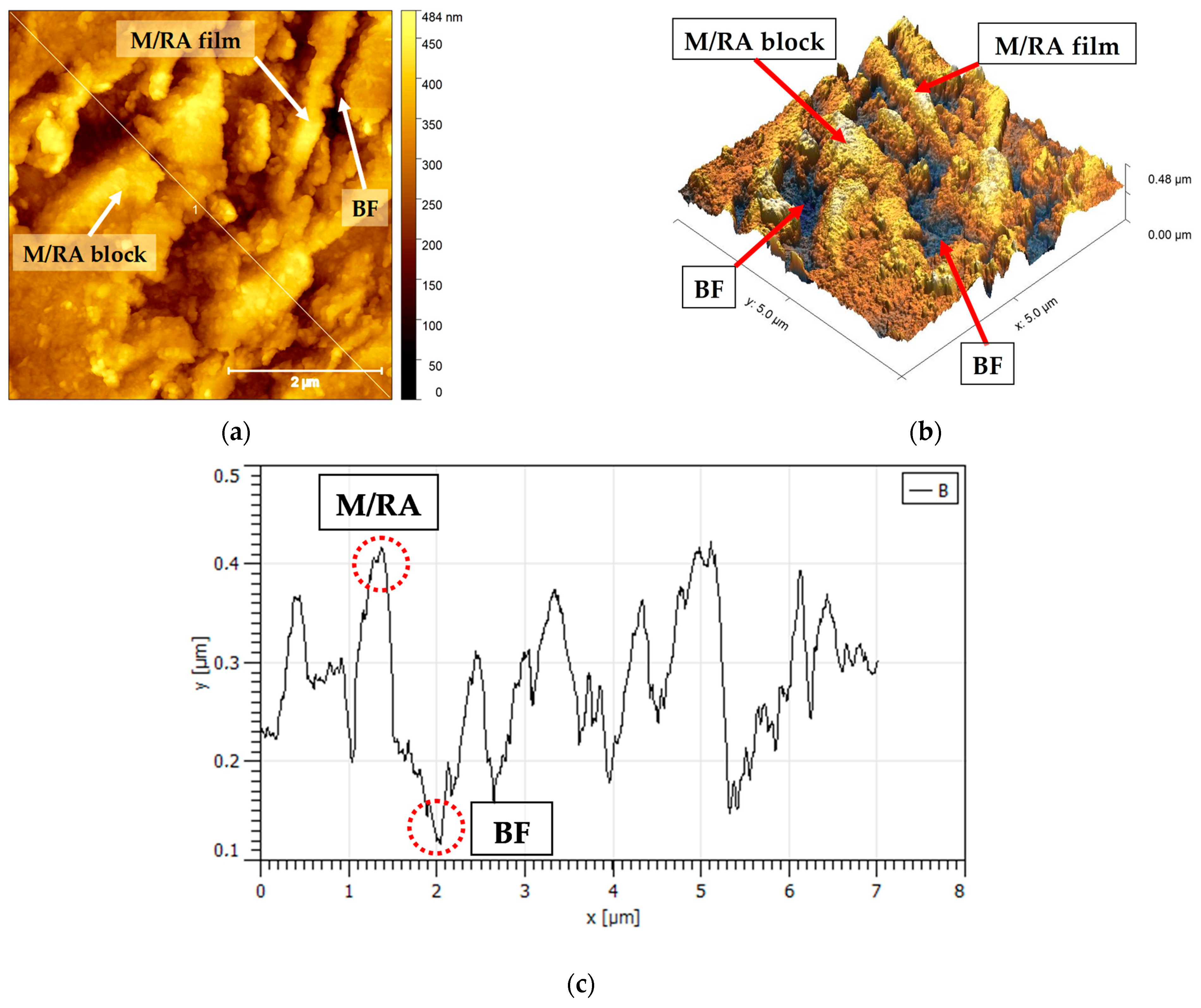

3.2.3. Atomic Force Microscopy (AFM)

3.3. Tensile Test

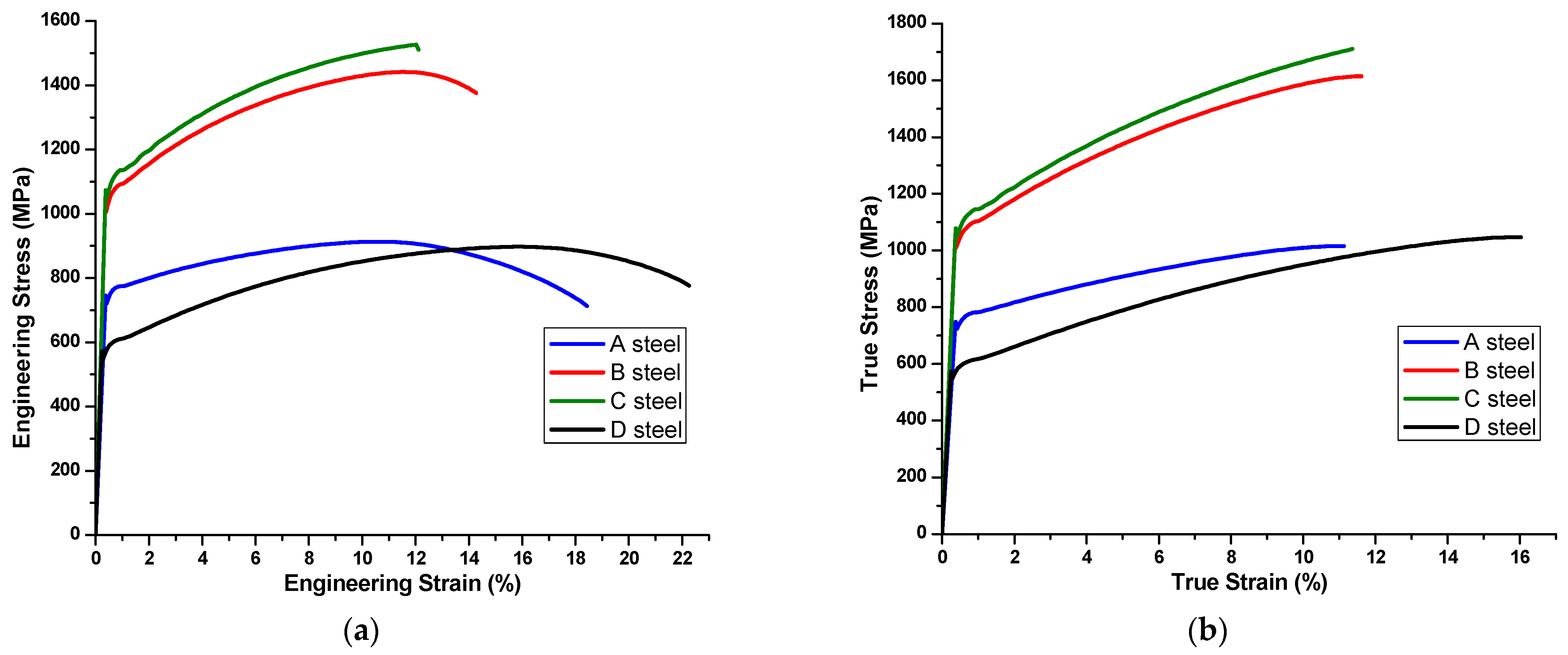

3.3.1. Mechanical Properties

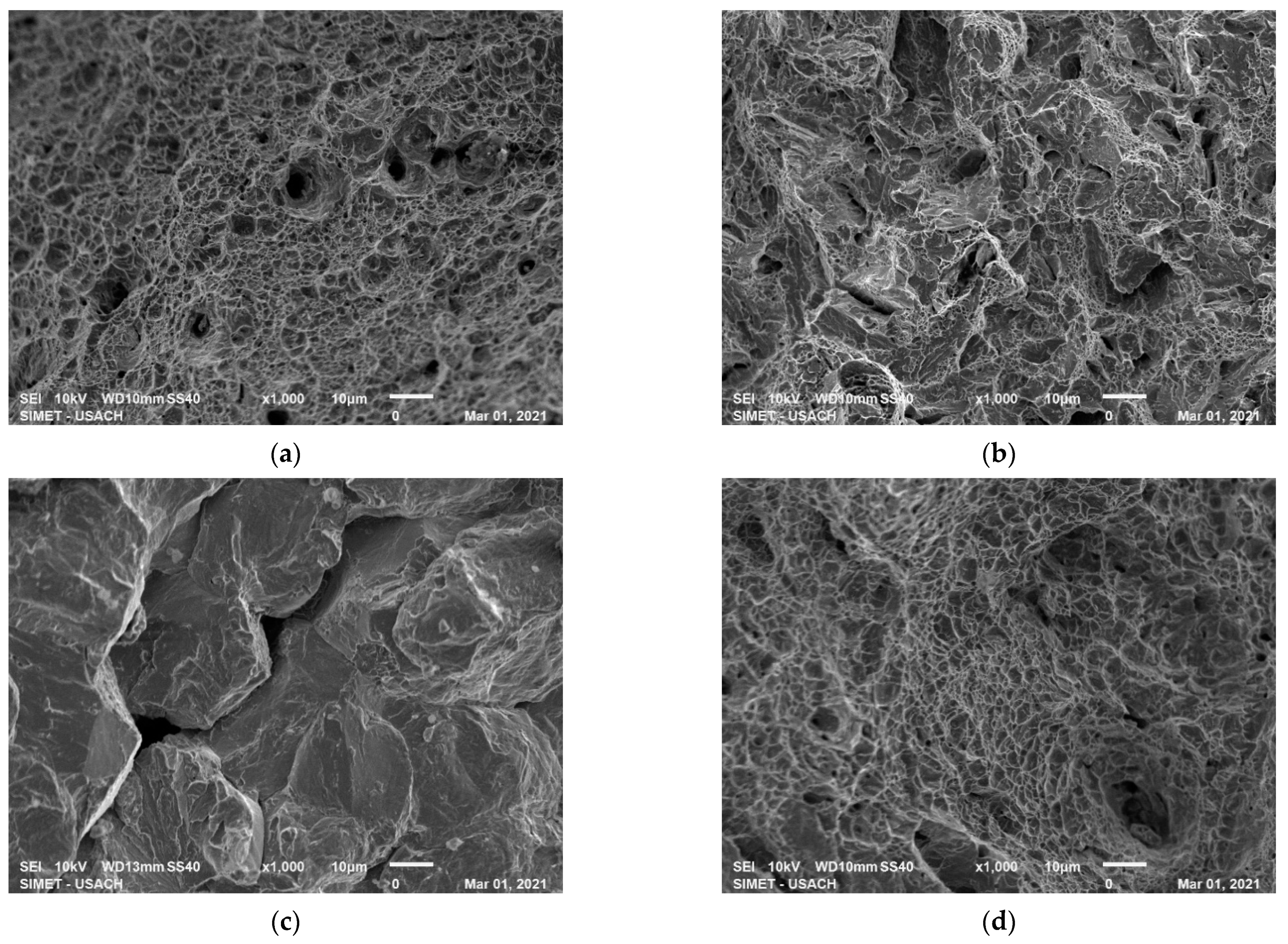

3.3.2. Fracture Surfaces

4. Discussion

5. Conclusions

- The effect of carbon was decisive in the evolution of the microstructure achieved in steels A, B and C. These were subjected to the same heat treatment to achieve TBF steels, developing between them a difference in terms of vol.% of RA, and morphology of its phases and microconstituents, which were observed by OM, SEM and AFM. As the wt.% C increased, the amount of BF decreased and the M/RA evolved from sheets to increasingly thicker blocks, perceiving an increase in its vol.% relative to BF.

- Steel D showed a granularization process of the BF and M/RA, atypical in the bainitic transformation with isothermal treatments. A possible explanation could be that with a high wt.% C in austenite, the Bs is lower than in the rest of the steels, implying that at 400 °C, IT temperature, a higher BF is obtained, less fine than the one formed at lower temperatures, which was subsequently aged after the 1500 s of bainitic transformation, evolving from plates to granules, also affecting the morphology of the M/RA, like what could occur in continuous cooling.

- Given the potential to evaluate surfaces with atomic resolution, AFM is a tool for future studies in the observation and determination of morphology for nanostructured polyphase steels, achieved with modern techniques of heat treatments for fine grain size, such as ultrafast annealing.

- In steels A, B and C, as the percentage of carbon increases, the YS and UTS rise, and the TE decreases, due to the increase in volume and thickening of the M/RA microconstituent, which is hard and brittle, confirmed with the fracture surfaces, showing an evolution from a ductile to a brittle morphology.

- Steel C, despite being the strongest and most brittle, with a large amount of M/RA in blocks, has a similar and even higher UE than steels A and B, which have less carbon and less strength. The above indicates a greater TRIP effect, due to the large amount of RA, which is evidenced by its higher “n” index.

- Steel D is a TPF steel achieved with an IA. The initial and final behavior is ductile, hardening as it progresses in homogeneous plastic strain, reaching a UTS like of steel A, but with a widely higher UE, which is confirmed too by analyzing the surface of fracture, which presents a ductile morphology.

- From the point of view of tensile toughness, the steel with the best characteristics to be used in the high-thickness structural field is D. Despite having the lowest YS, it has the best YS/UTS ratio, the highest UE, the largest “n”, and its fracture mode is mainly ductile. The higher toughness is attributed to the soft and ductile PF matrix with fine aggregates of M/RA dispersed throughout the matrix in the form of granules, which concentrate less stress than acicular morphology.

- The most important aspect of this work is that the best mechanical behavior of the high thicknesses TRIP steels studied, is related to a fine morphology of the microstructure and an adequate amount of retained austenite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zackay, V.F.; Parker, E.R.; Fahr, D. The enhancement of ductility on high strength steels. Trans. ASM 1967, 60, 252–259. [Google Scholar]

- Skálová, L.; Divišová, R.; Jandová, D. Thermo-mechanical processing of low-alloy TRIP-steel. J. Mater. Process. Technol. 2006, 175, 387–392. [Google Scholar] [CrossRef]

- Petrov, R.; Kestens, L.; Houbaert, Y. Recrystallization of a cold rolled trip-assisted steel during reheating for intercritical annealling. ISIJ Int. 2001, 41, 883–890. [Google Scholar] [CrossRef]

- De Cooman, B.C. Structure-properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 285–303. [Google Scholar] [CrossRef]

- Jacques, P.J.; Furnémont, Q.; Lani, F.; Pardoen, T.; Delannay, F. Multiscale mechanics of TRIP-assisted multiphase steels: I. Characterization and mechanical testing. Acta Mater. 2007, 55, 3681–3693. [Google Scholar] [CrossRef]

- Monsalve, A.; Guzmán, A.; De Barbieri, F.; Artigas, A.; Carvajal, L.; Bustos, O.; Garza-Montes-de Oca, N.F.; Colás, R. Mechanical and Microstructural Characterization of an Aluminum Bearing Trip Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 3088–3094. [Google Scholar] [CrossRef]

- Shan, T.K.; Li, S.H.; Zhang, W.G.; Xu, Z.G. Prediction of martensitic transformation and deformation behavior in the TRIP steel sheet forming. Mater. Des. 2008, 29, 1810–1816. [Google Scholar] [CrossRef]

- Zaefferer, S.; Ohlert, J.; Bleck, W. A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel. Acta Mater. 2004, 52, 2765–2778. [Google Scholar] [CrossRef]

- Wang, Z.C.; Kim, S.J.; Lee, C.G.; Lee, T.H. Bake-hardening behavior of cold-rolled CMnSi and CMnSiCu TRIP-aided steel sheets. J. Mater. Process. Technol. 2004, 151, 141–145. [Google Scholar] [CrossRef]

- Emadoddin, E.; Akbarzadeh, A.; Daneshi, G. Effect of intercritical annealing on retained austenite characterization in textured TRIP-assisted steel sheet. Mater. Charact. 2006, 57, 408–413. [Google Scholar] [CrossRef]

- Salinas, Á.; Celentano, D.; Carvajal, L.; Artigas, A.; Monsalve, A. Microstructure-based constitutive modelling of low-alloy multiphase TRIP steels. Metals 2019, 9, 250. [Google Scholar] [CrossRef]

- Sugimoto, K.-I. Fracture strength and toughness of ultra high strength TRIP aided steels. Mater. Sci. Technol. 2009, 25, 1108–1117. [Google Scholar] [CrossRef]

- Sugimoto, K.I.; Sato, S.H.; Kobayashi, J.; Srivastava, A.K. Effects of Cr and Mo on mechanical properties of hot-forged medium carbon TRIP-aided bainitic ferrite steels. Metals 2019, 9, 1066. [Google Scholar] [CrossRef]

- ASTM. E3-11 Standard Guide for Preparation of Metallographic Specimens Standard Guide for Preparation of Metallographic Specimens; ASTM: West Conshohocken, PA, USA, 2012; Volume 03.01. [Google Scholar]

- ASTM. E407-07 Standard Practice for Microetching Metals and Alloys; ASTM: West Conshohocken, PA, USA, 2016; Volume 7. [Google Scholar]

- ASTM. E7-17 Standard Terminology Relating to Metallography; ASTM: West Conshohocken, PA, USA, 1987. [Google Scholar]

- Gorni, A. Steel Forming and Heat Treating Handbook. Available online: www.gorni.eng.br/e/Gorni_SFHTHandbook.pdf (accessed on 16 August 2021).

- ASTM. E975-13 Standard Practice for X-ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation; ASTM: West Conshohocken, PA, USA, 2009; Volume 3. [Google Scholar]

- Onink, M.; Barkman, C.M.; Tichelaar, F.D.; Mittemeijer, E.J.; Van der Zwaag, S. The lattice parameters of austenite and ferrite in Fe-C alloys as functions of carbon concentrattion and temperature. Scr. Mater. 1993, 29, 1011–1016. [Google Scholar] [CrossRef]

- Zajac, S.; Komenda, J.; Morris, P.; Dierickx, P. Quantitative Structure-Property Relationships for Complex Bainitic Microstructures; European Communities: Luxembourg, 2005. [Google Scholar]

- ASTM. E8/E8M-16a Standard Test Methods for Tension Testing of Metallic Materials; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Vander Voort, G.F. Metallography Principles and Practice, 4th ed.; ASM International: New York, NY, USA, 2007. [Google Scholar]

- Vander Voort, G.F.; Manilova, E.P. Hints for imaging phases in steels. Adv. Mater. Process. 2005, 163, 32–37. [Google Scholar]

- ASM. ASM Metals Handbook Volume 9 Metallography and Microstructures; ASM International: New York, NY, USA, 2018. [Google Scholar]

- Caballero, F.G.; Roelofs, H.; Hasler, S.; Capdevila, C.; Chao, J.; Cornide, J.; Garcia-Mateo, C. Influence of bainite morphology on impact toughness of continuously cooled cementite free bainitic steels. Mater. Sci. Technol. 2012, 28, 95–102. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels Theory and Practice, 3rd ed.; Maney Publishing on behalf of the Institute of Materials, Minerals & Mining; Maney Publishing: Leeds, UK, 2019. [Google Scholar]

- Slama, M.B.H.; Gey, N.; Germain, L.; Zhu, K.; Allain, S. Key parameters to promote granularization of lath-like bainite/martensite in FeNiC alloys during isothermal holding. Materials 2018, 11, 1808. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Christian, J. Bainite in Steels. Metall. Trans. A 1990, 21, 767–797. [Google Scholar] [CrossRef]

- Pérez Medina, G.Y.; Hurtado Delgado, E.; Miranda Pérez, A.F.; Lopez Ferreira, H. Phases quantification in DP600 steel welded by GTAW process using SEM and atomic force microscopy1. Mater. Res. 2017, 20, 1161–1165. [Google Scholar] [CrossRef][Green Version]

- Ros-Yáñez, T.; Houbaert, Y.; Mertens, A. Characterization of TRIP-assisted multiphase steel surface topography by atomic force microscopy. Mater. Charact. 2001, 47, 93–104. [Google Scholar] [CrossRef]

- Bordone, M.; Perez-Ipiña, J.; Bolmaro, R.; Artigas, A.; Monsalve, A. Mechanical properties and microstructural aspects of two high-manganese steels with twip/trip effects: A comparative study. Metals 2021, 11, 24. [Google Scholar] [CrossRef]

- Low, J.R. The fracture of metals. Prog. Mater. Sci. 1963, 12, 3–96. [Google Scholar] [CrossRef]

- George, E. Dieter Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

| Steels | C | Mn | Si | Cr | Al | Cu | Mo | Ni | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.166 | 1.872 | 1.534 | 0.242 | 0.343 | 0.0995 | 0.017 | 0.050 | 0.005 | 0.022 | Bal. |

| S2 | 0.285 | 1.829 | 1.445 | 0.242 | 0.068 | 0.0873 | 0.017 | 0.049 | 0.005 | 0.021 | Bal. |

| S3 | 0.397 | 1.920 | 1.470 | 0.462 | 0.008 | 0.0873 | 0.013 | 0.481 | 0.016 | 0.019 | Bal. |

| Steel | Source | A1 | A3 | Bs | Ms | 50/50 |

|---|---|---|---|---|---|---|

| S1 | BBL | 728 | 866 | 581 | 389 | - |

| DSC | 713 | 855 | - | - | - | |

| DTA | 725 | 855 | - | - | - | |

| IMG | 712 | 865 | - | - | 760 | |

| S2 | BBL | 725 | 835 | 556 | 343 | - |

| DSC | 728 | 820 | - | - | - | |

| DTA | 717 | 825 | - | - | - | |

| IMG | 715 | 830 | - | - | - | |

| S3 | BBL | 720 | 796 | 473 | 228 | - |

| DSC | 730 | 822 | - | - | - | |

| DTA | 727 | 812 | - | - | - | |

| IMG | 720 | 815 | - | - | - |

| Heat Treatments for TPF Steels (S1) | Heat Treatments for TBF Steels (S1, S2, S3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| N | T (°C) IA | t (s) IA | T (°C) IT | t (s) IT | N | T (°C) AA | t (s) IA | T (°C) IT | t (s) IT |

| 1 | 760 | 1200 | 350 | 600 | 1 | 910 | 1200 | 350 | 600 |

| 2 | 760 | 1200 | 350 | 1000 | 2 | 910 | 1200 | 350 | 1000 |

| 3 | 760 | 1200 | 350 | 1500 | 3 | 910 | 1200 | 350 | 1500 |

| 4 | 760 | 1200 | 400 | 600 | 4 | 910 | 1200 | 400 | 600 |

| 5 | 760 | 1200 | 400 | 1000 | 5 | 910 | 1200 | 400 | 1000 |

| 6 | 760 | 1200 | 400 | 1500 | 6 | 910 | 1200 | 400 | 1500 |

| 7 | 760 | 1200 | 450 | 600 | 7 | 910 | 1200 | 450 | 600 |

| 8 | 760 | 1200 | 450 | 1000 | 8 | 910 | 1200 | 450 | 1000 |

| 9 | 760 | 1200 | 450 | 1500 | 9 | 910 | 1200 | 450 | 1500 |

| Steels | Final Heat Treatment | XRD Results | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) A | t (s) A | T (°C) IT | t (s) IT | vol.% RA | vol.% α | a0 (Å) RA | wt.% C RA | |||

| A | TBF | S1 | 910 | 1200 | 400 | 1500 | 10.4 | 88.3 | 3.609400 | 1.4 |

| B | TBF | S2 | 910 | 1200 | 400 | 1500 | 19.2 | 79.2 | 3.613900 | 1.6 |

| C | TBF | S3 | 910 | 1200 | 400 | 1500 | 23.7 | 74.2 | 3.613690 | 1.5 |

| D | TPF | S1 | 760 | 1200 | 400 | 1500 | 17.9 | 80.3 | 3.606854 | 1.4 |

| STEEL | Engineering Tensile Test | True Tensile Test | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| YS | UTS | YS/UTS | FS | UE | TE | Εxz | YS | UTS | YS/UTS | UE | n | K | |

| MPa | MPa | - | MPa | % | % | % | MPa | MPa | - | % | - | MPa | |

| A | 735 | 913 | 0.81 | 713 | 10.7 | 18.4 | 35.6 | 735 | 1016 | 0.72 | 11.1 | 0.12 | 757 |

| B | 1020 | 1442 | 0.71 | 1375 | 11.5 | 14.3 | 12.9 | 1020 | 1615 | 0.63 | 11.6 | 0.17 | 1045 |

| C | 1060 | 1527 | 0.69 | 1511 | 12 | 12.1 | 0.9 | 1060 | 1710 | 0.62 | 11.4 | 0.18 | 1077 |

| D | 560 | 897 | 0.62 | 777 | 15.8 | 22.3 | 29.2 | 560 | 1047 | 0.53 | 16 | 0.23 | 559 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tesser, E.; Silva, C.; Artigas, A.; Monsalve, A. Effect of Carbon Content and Intercritical Annealing on Microstructure and Mechanical Tensile Properties in FeCMnSiCr TRIP-Assisted Steels. Metals 2021, 11, 1546. https://doi.org/10.3390/met11101546

Tesser E, Silva C, Artigas A, Monsalve A. Effect of Carbon Content and Intercritical Annealing on Microstructure and Mechanical Tensile Properties in FeCMnSiCr TRIP-Assisted Steels. Metals. 2021; 11(10):1546. https://doi.org/10.3390/met11101546

Chicago/Turabian StyleTesser, Enzo, Carlos Silva, Alfredo Artigas, and Alberto Monsalve. 2021. "Effect of Carbon Content and Intercritical Annealing on Microstructure and Mechanical Tensile Properties in FeCMnSiCr TRIP-Assisted Steels" Metals 11, no. 10: 1546. https://doi.org/10.3390/met11101546

APA StyleTesser, E., Silva, C., Artigas, A., & Monsalve, A. (2021). Effect of Carbon Content and Intercritical Annealing on Microstructure and Mechanical Tensile Properties in FeCMnSiCr TRIP-Assisted Steels. Metals, 11(10), 1546. https://doi.org/10.3390/met11101546