Fast Image Classification for Grain Size Determination

Abstract

:1. Introduction

2. Related Work

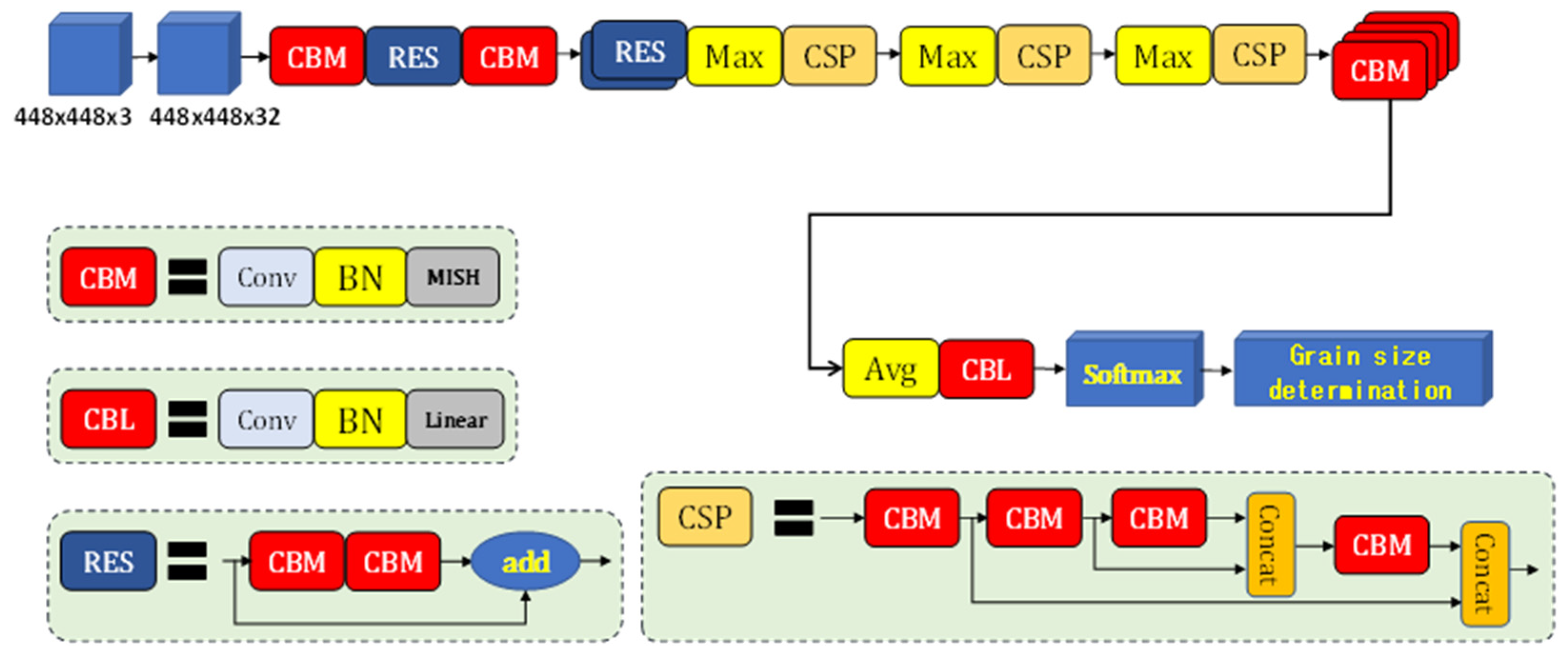

3. Fast Image Classifier

Feature Extraction Using Convolutional Neural Networks

4. Experimental Results and Analysis

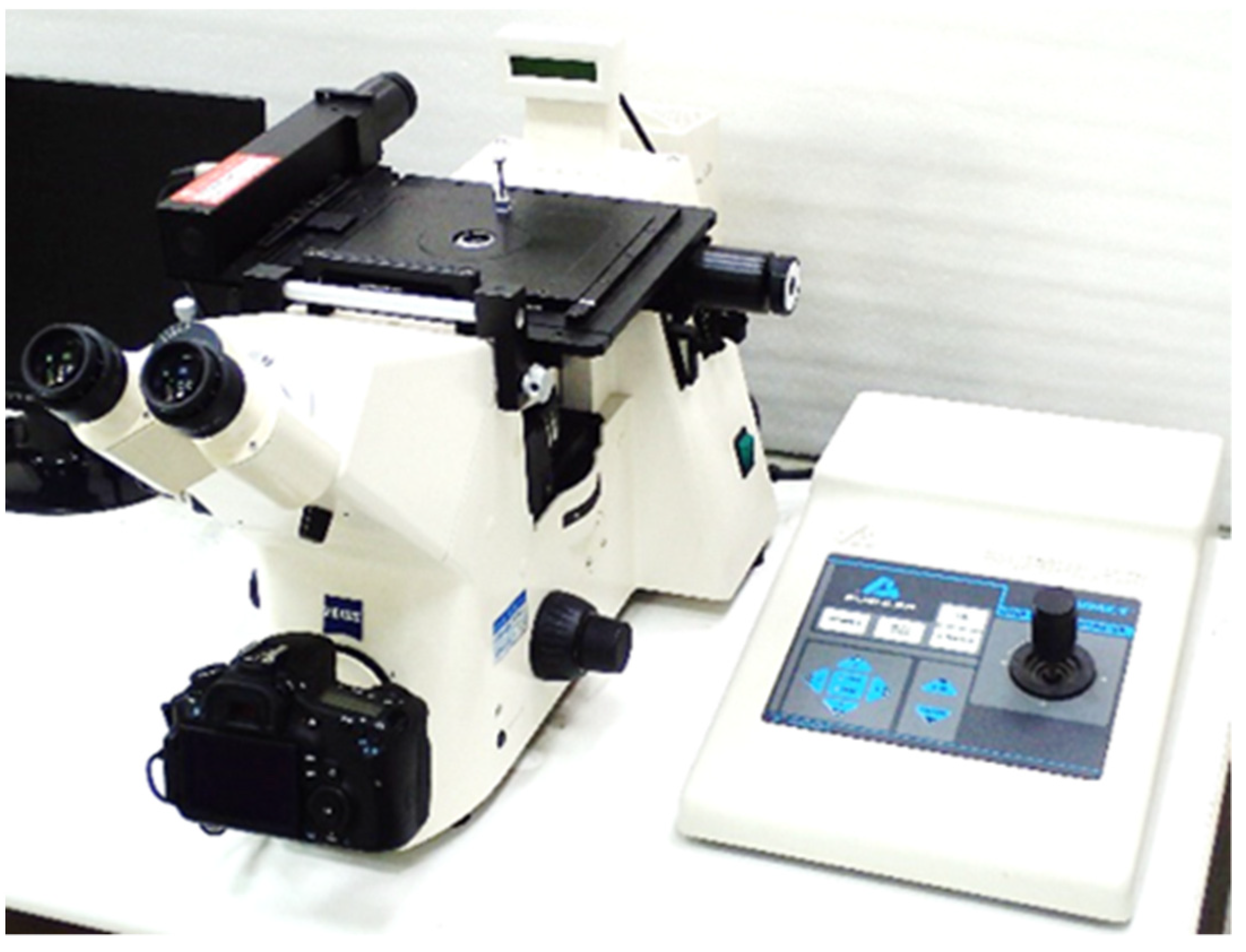

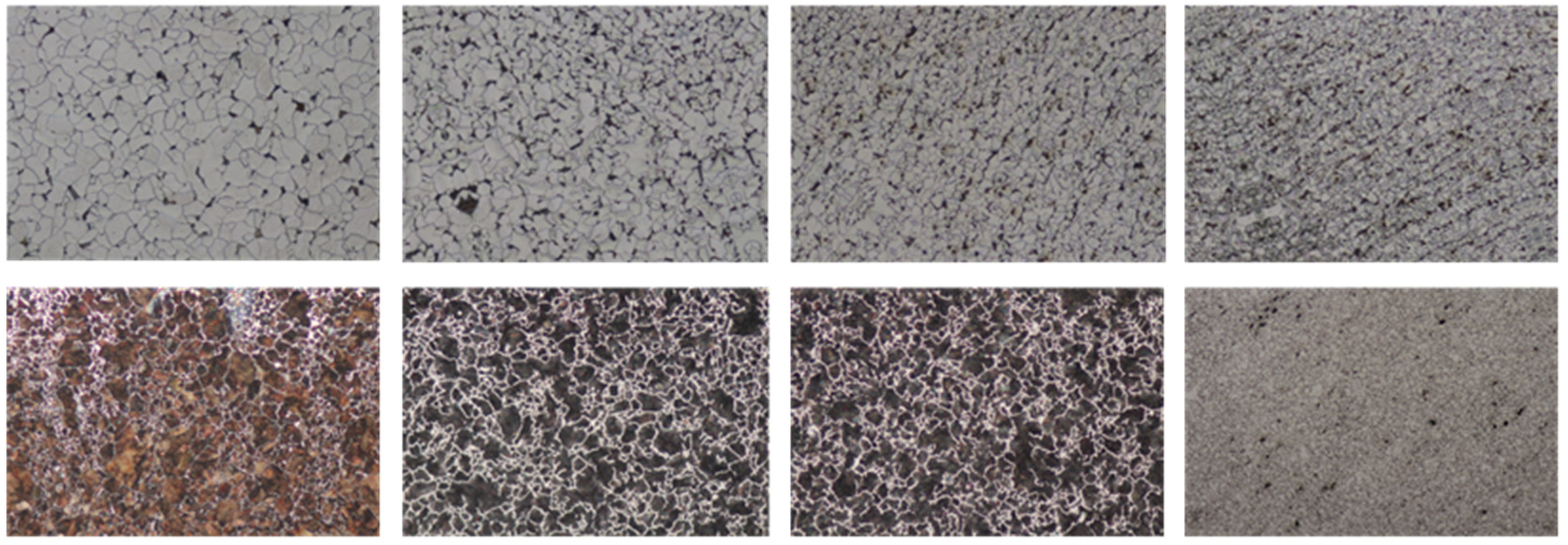

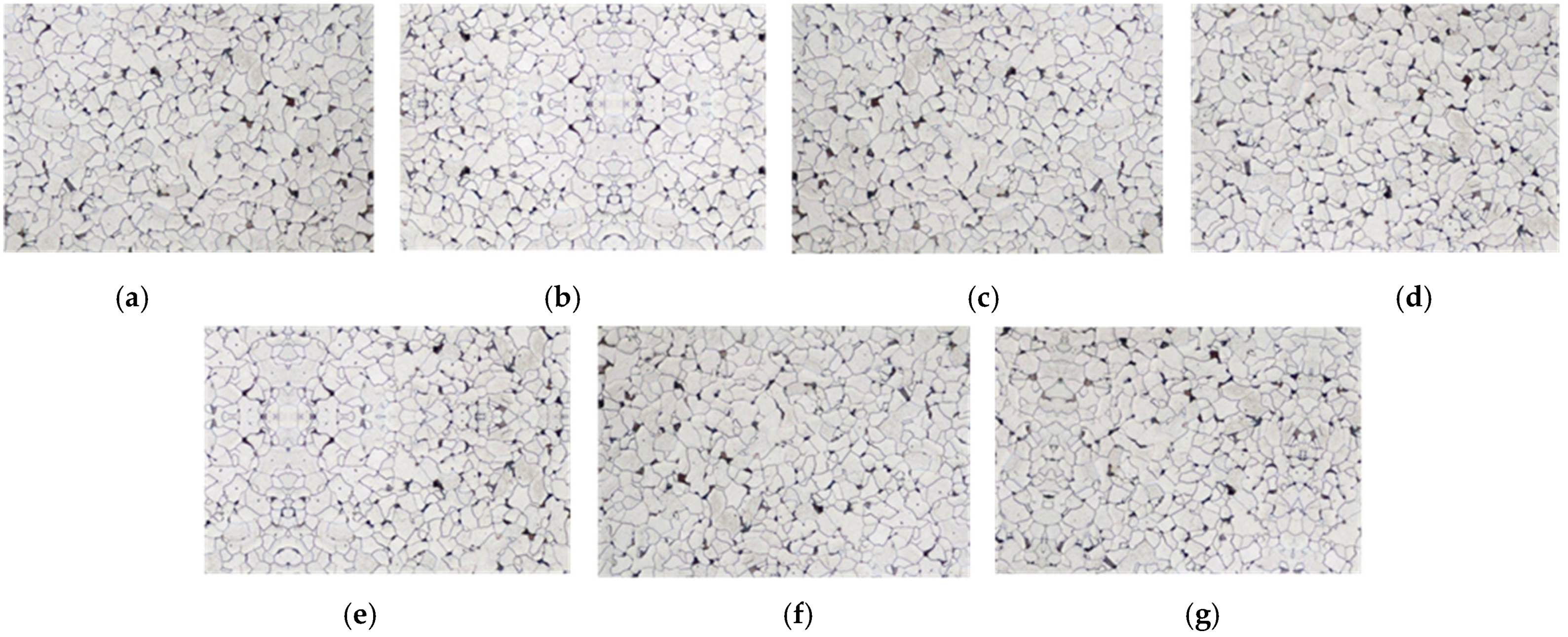

4.1. Grain Size Dataset

4.2. Validation Metrics

4.3. Experimental Results and Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Standard Test Method for Determining Average Grain Size; ASTM E112-13; ASTM International: West Conshohocken, PA, USA, 2013.

- Steels—Micrographic Determination of the Apparent Grain Size; ISO 643:2003; International Organization for Standardization: Geneva, Switzerland, 2003.

- Giumelli, A.K.; Militzer, M.; Hawbolt, E.B. Analysis of the austenite grain size distribution in plain carbon steels. ISIJ Int. 1999, 39, 271–280. [Google Scholar] [CrossRef]

- de Andrés, C.G.; Bartolomé, M.J.; Capdevila, C.; Martín, D.S.; Caballero, F.G.; López, V. Metallographic techniques for the determination of the austenite grain size in medium-carbon microalloyed steels. Mater. Charact. 2001, 46, 389–398. [Google Scholar] [CrossRef] [Green Version]

- Fuchs, N.; Bernhard, C. Potential and limitations of direct austenite grain growth measurement by means of HT-LSCM. Mater. Today Commun. 2021, 28, 102468. [Google Scholar] [CrossRef]

- Colás, R. On the variation of grain size and fractal dimension in an austenitic stainless steel. Mater. Charact. 2001, 46, 353–358. [Google Scholar] [CrossRef]

- Barreto, H.P.; Villalobos, I.R.T.; Agdaleno, J.J.; Navarro, A.M.H.; Hernández, L.A.M.; Guerrero, F.M. Automatic grain size determination in microstructuresusing image processing. Measurement 2013, 46, 249–258. [Google Scholar] [CrossRef]

- Lixin, Z.; Zhengguang, X.; Shuailing, W.; Xuechong, R.; Meiling, W. Grain size automatic determination for 7050 al alloy based on a fuzzy logic method. Rare Met. Mater. Eng. 2016, 45, 0548–0554. [Google Scholar]

- Lu, B.; Lin, Z.; Wang, H. Grain identification of polarizing images with level set method. In Proceedings of the IEEE 3rd International Conference on Communication Softwareand Networks 2011, Xi’an, China, 27–29 May 2011; Volume 45, pp. 0548–0554. [Google Scholar]

- Gajalakshmi, K.; Palanivel, S.; Nalini, N.J.; Saravanan, S.; Raghukandan, K. Grain size measurement in optical microstructure using support vector regression. Int. J. Light Electron Opt. 2017, 138, 320–327. [Google Scholar]

- Dengiz, O.; Smith, A.E.; Nettleship, I. Grain boundary detection in microstructure images using computational intelligence. Int. J. Light Electron Opt. Comput. Ind. 2015, 56, 854–866. [Google Scholar] [CrossRef]

- Ma, B.; Liu, C.; Wei, X.; Gao, M.; Ban, X.; Wang, H.; Huang, H.; Xue, W. WPU-Net: Boundary learning by using weighted propagation in convolution network. arXiv 2019, arXiv:1905.09226. [Google Scholar]

- Baggs, G.S.; Guerrier, P.; Loeb, A.; Jones, J.C. Automated Copper Alloy Grain Size Evaluation Using a Deep-learning CNN. arXiv 2020, arXiv:2005.09634. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. arXiv 2015, arXiv:1512.03385. [Google Scholar]

- Bochkovskiy, A.; Wang, C.Y.; Mark Liao, H.Y. YOLOv4: Optimal speed and accuracy of object detection. In Proceedings of the Conference on Computer Vision and Pattern Recognition CVPR, Nanjing, China, October 16–18 2020; pp. 14–19. [Google Scholar]

- Bridle, J.S. Probabilistic interpretation of feedforward classification network outputs, with relationships to statistical pattern recognition. In Neurocomputing; Springer: Berlin/Heidelberg, Germany, 1990; pp. 227–236. [Google Scholar]

- Chen, S.; Abhinav, S.; Saurabh, S.; Abhinav, G. Revisting unreasonable effectiveness of data in deep learning era. In Proceedings of the ICCV, Venice, Italy, 22–29 October 2017; pp. 843–852. [Google Scholar]

- Huang, G.; Liu, Z.; Maaten, L.V.; Weinberger, K.Q. Densely Connected Convolutional Networks. arXiv 2016, arXiv:1608.06993. [Google Scholar]

- Zhang, X.; Zou, J.; He, K.; Sun, J. Accelerating Very Deep Convolutional Networks for Classification and Detection. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 38, 1943–1955. [Google Scholar] [CrossRef] [Green Version]

| Layer | Operation Type | Input | Filter | Size/Stride | Output | Layer |

|---|---|---|---|---|---|---|

| 0 | Convolution | 448 × 448 × 3 | 32 | 3 × 3/1 | 448 × 448 × 32 | - |

| 1 | Convolution | 448 × 448 × 32 | 64 | 3 × 3/2 | 224 × 224 × 64 | - |

| 2 | Convolution | 224 × 224 × 64 | 32 | 1 × 1/1 | 224 × 224 × 32 | ResNet |

| 3 | Convolution | 224 × 224 × 32 | 64 | 3 × 3/1 | 224 × 224 × 64 | |

| 4 | Shortcut | 224 × 224 × 64 | - | - | 224 × 224 × 64 | |

| 5 | Convolution | 224 × 224 × 64 | 128 | 3 × 3/2 | 112 × 112 × 128 | - |

| 6 | Convolution | 112 × 112 × 128 | 64 | 1 × 1/1 | 112 × 112 × 64 | ResNet |

| 7 | Convolution | 112 × 112 × 64 | 128 | 3 × 3/1 | 112 × 112 × 64 | |

| 8 | Shortcut | 112 × 112 × 64 | - | - | 112 × 112 × 128 | |

| 9 | Convolution | 112 × 112 × 128 | 64 | 1 × 1/1 | 112 × 112 × 64 | ResNet |

| 10 | Convolution | 112 × 112 × 64 | 128 | 3 × 3/1 | 112 × 112 × 128 | |

| 11 | Shortcut | 112 × 112 × 128 | - | - | 112 × 112 × 128 | |

| 12 | Max pooling | 112 × 112 × 128 | - | 2 × 2/2 | 56 × 56 × 128 | - |

| 13 | Convolution | 56 × 56 × 128 | 128 | 3 × 3/1 | 56 × 56 × 128 | CSPNet |

| 14 | Route | 13 | - | - | 56 × 56 × 64 | |

| 15 | Convolution | 56 × 56 × 64 | 64 | 3 × 3/1 | 56 × 56 × 64 | |

| 16 | Convolution | 56 × 56 × 64 | 64 | 3 × 3/1 | 56 × 56 × 64 | |

| 17 | Concatenation | 15, 16 | - | - | 56 × 56 × 128 | |

| 18 | Convolution | 56 × 56 × 128 | 128 | 1 × 1/1 | 56 × 56 × 128 | |

| 19 | Concatenation | 13, 18 | - | - | 56 × 56 × 256 | |

| 20 | Max pooling | 56 × 56 × 256 | - | 2 × 2/2 | 28 × 28 × 256 | - |

| 21 | Convolution | 28 × 28 × 256 | 256 | 3 × 3/1 | 28 × 28 × 256 | CSPNet |

| 22 | Route | 21 | - | - | 28 × 28 × 128 | |

| 23 | Convolution | 28 × 28 × 128 | 128 | 3 × 3/1 | 28 × 28 × 128 | |

| 24 | Convolution | 28 × 28 × 128 | 128 | 3 × 3/1 | 28 × 28 × 128 | |

| 25 | Concatenation | 23, 24 | - | - | 28 × 28 × 256 | |

| 26 | Convolution | 28 × 28 × 256 | 256 | 1 × 1/1 | 28 × 28 × 256 | |

| 27 | Concatenation | 21, 26 | - | - | 28 × 28 × 512 | |

| 28 | Max pooling | 28 × 28 × 512 | - | 2 × 2/2 | 14 × 14 × 512 | - |

| 29 | Convolution | 14 × 14 × 512 | 512 | 3 × 3/1 | 14 × 14 × 512 | CSPNet |

| 30 | Route | 29 | - | - | 14 × 14 × 256 | |

| 31 | Convolution | 14 × 14 × 256 | 256 | 3 × 3/1 | 14 × 14 × 256 | |

| 32 | Convolution | 14 × 14 × 256 | 256 | 3 × 3/1 | 14 × 14 × 256 | |

| 33 | Concatenation | 31, 32 | - | - | 14 × 14 × 256 | |

| 34 | Convolution | 14 × 14 × 256 | 512 | 1 × 1/1 | 14 × 14 × 512 | |

| 35 | Concatenation | 29, 34 | - | - | 14 × 14 × 1024 | |

| 36 | Convolution | 14 × 14 × 1024 | 512 | 1 × 1/1 | 14 × 14 × 512 | - |

| 37 | Convolution | 14 × 14 × 512 | 512 | 3 × 3/1 | 14 × 14 × 512 | - |

| 38 | Convolution | 14 × 14 × 512 | 256 | 1 × 1/1 | 14 × 14 × 256 | - |

| 39 | Convolution | 14 × 14 × 256 | 512 | 3 × 3/1 | 14 × 14 × 512 | - |

| 40 | Avgpool | 14 × 14 × 512 | - | Global | 1 × 1 × 512 | - |

| 41 | Connected | 1 × 1 × 512 | 4 | 1 × 1/1 | 1 × 1 × 4 | - |

| 42 | Softmax | |||||

| Model | Darknet53 | DenseNet | VGG16 | ResNet50 | FIC Model |

|---|---|---|---|---|---|

| Size | 159MB | 61MB | 1729MB | 81MB | 37MB |

| BFlops | 56.88 | 32.63 | 122.79 | 28.01 | 16.33 |

| Grade | 5 | 6 | 7 | 8 | 9 | 10 |

| Ferrite | 100% | 100% | 99.13% | 99.68% | ||

| Austenite | 100% | 98.98% | 99.13% | 99.38% | - | - |

| Method | Accuracy | BFlops |

|---|---|---|

| Darknet53 | 99.81% | 56.88 |

| DenseNet201 | 97.52% | 32.63 |

| VGG16 | 45.00% | 122.79 |

| ResNet50 | 98.88% | 28.01 |

| FIC model | 99.70% | 16.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-C.; Hsu, H.-H.; Liu, S.-C.; Chen, C.-H.; Huang, H.-C. Fast Image Classification for Grain Size Determination. Metals 2021, 11, 1547. https://doi.org/10.3390/met11101547

Lee J-C, Hsu H-H, Liu S-C, Chen C-H, Huang H-C. Fast Image Classification for Grain Size Determination. Metals. 2021; 11(10):1547. https://doi.org/10.3390/met11101547

Chicago/Turabian StyleLee, Jen-Chun, Hsiao-Hung Hsu, Shang-Chi Liu, Chung-Hsien Chen, and Huang-Chu Huang. 2021. "Fast Image Classification for Grain Size Determination" Metals 11, no. 10: 1547. https://doi.org/10.3390/met11101547

APA StyleLee, J.-C., Hsu, H.-H., Liu, S.-C., Chen, C.-H., & Huang, H.-C. (2021). Fast Image Classification for Grain Size Determination. Metals, 11(10), 1547. https://doi.org/10.3390/met11101547