Influence of Cooling Rate on Microstructure Formation of Si–Mo Ductile Iron Castings

Abstract

:1. Introduction

2. Experimental Procedures

3. Results

3.1. Solidification and Solid-State Transformation

3.2. Cooling Curves

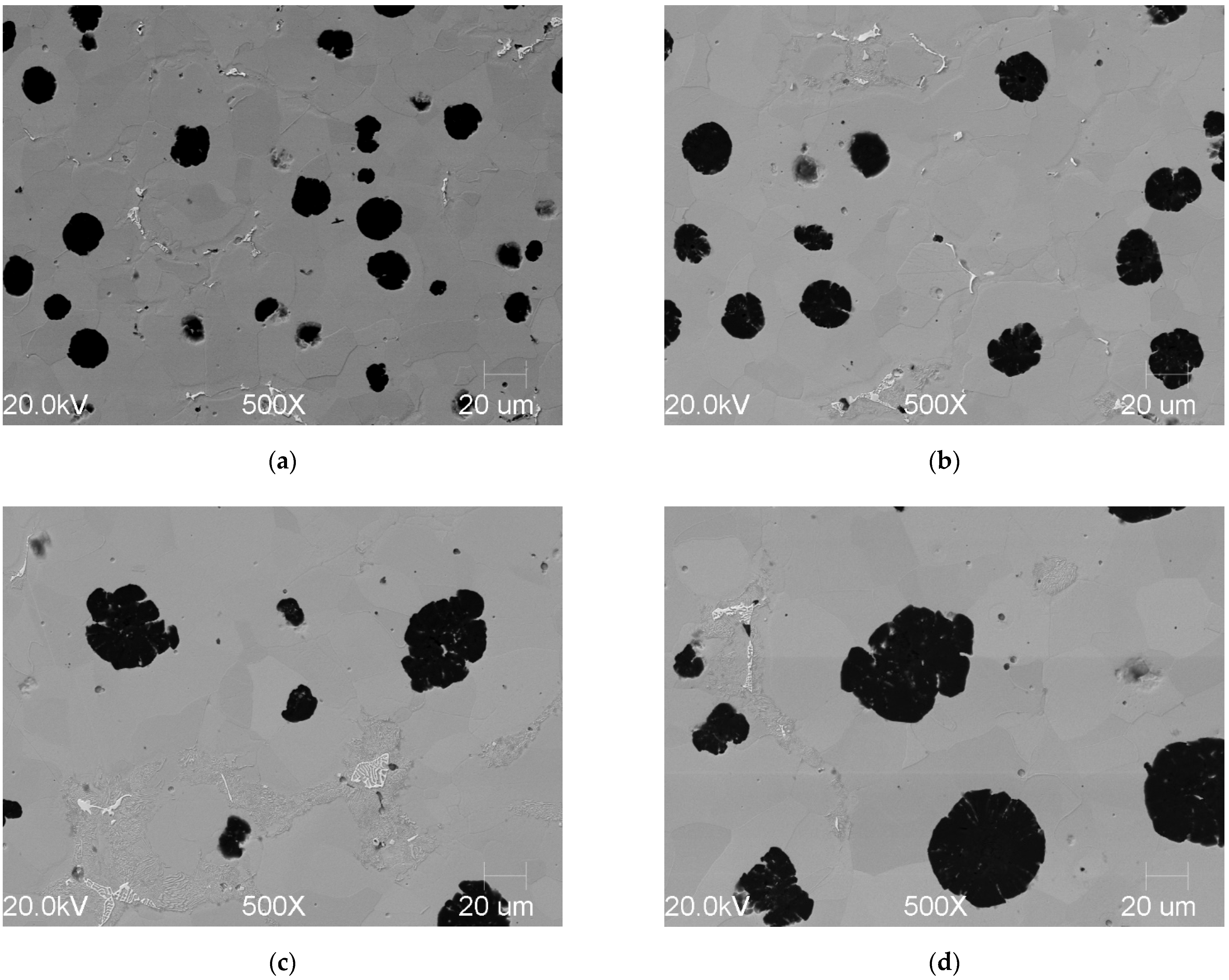

3.3. Microstructures

3.4. Ultrasonic

4. Discussion

5. Conclusions

- Different microstructures of EN-GJS-SiMo45-6 were attained for thin-walled castings with wall thicknesses of 3 and 5 mm as well as reference castings with typical wall thicknesses of 13 and 25 mm, which lead to various cooling rates that were calculated through the simulation of an actual gravity-casting system.

- The microstructures were characterized in detail, quantifying the nodule count, nodularity, average diameter of the graphitic nodules, and volumetric fractions of the graphite and ferrite as well as the average ferritic grain size. These features become finer as the solidification rate increases. A positive segregation (enrichment) of the Mo was observed in the pearlitic islands; this led to the formation of Fe–Mo carbides. The cooling rates around the eutectoid temperature were correlated with the ferritic grain size. The results suggest that the occurrence of pearlite and carbides is related to segregations during solidification rather than to cooling rates at the eutectoid temperature.

- Longitudinal ultrasonic wave velocity cL was found to be linear-dependent with the number of graphite nodules NA of the EN-GJS-SiMo45-6 ductile iron. In castings that crystallize at lower speeds due to the presence of Mo and the greater tendency towards microsegregation, the volume fraction of the carbides increases, which causes an increase in the ultrasonic wave velocity. The final effect is the relatively low sensitivity of ductile iron to changes in the values of longitudinal ultrasonic wave velocity cL when changing the wall thicknesses from 3 to 25 mm, which should result in slight variations in the mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Górny, M.; Stefanescu, D.M. Thin-wall ductile iron castings. In ASM Handbook; Stefanescu, D.M., Ed.; ASM International: Materials Park, OH, USA, 2017; Volume 1A, pp. 617–628. [Google Scholar]

- Fras, E.; Górny, M.; Lopez, H. Thin Wall Ductile and Austempered Iron Castings as Substitutes for Aluminum Alloy Castings. Int. Foundry Res. Giess. 2009, 61, 2–10. [Google Scholar]

- Stefanescu, D.M.; Dix, L.P.; Ruxanda, R.E.; Corbitt-Coburn, C.; Piwonka, T.S. Tensile Properties of Thin Wall Ductile Iron. AFS Trans. 2002, 110, 1149–1161. [Google Scholar]

- Ruxanda, R.E.; Stefanescu, D.M.; Piwonka, T.S. Microstructure Characterization of Ductile Thin Wall Iron Castings. AFS Trans. 2002, 110, 1131–1147. [Google Scholar]

- Druschitz, A.P.; Fitzgerald, D.C. Lightweight Iron and Steel Castings for Automotive Applications; SAE Tech. Pap. 2000-01-0679; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef] [Green Version]

- Xiang, S.; Jonsson, S.; Hedström, P.; Zhu, B.; Odqvist, J. Influence of ferritic nitrocarburizing on the high-temperature corrosion-fatigue properties of the Si-Mo-Al cast iron SiMo1000. Int. J. Fatigue 2021, 143, 105984. [Google Scholar] [CrossRef]

- Xiang, S. Oxidation, Creep and Fatigue Synergies in Cast Materials for Exhaust Manifolds. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2021. [Google Scholar]

- Pierce, D.; Haynes, A.; Hughes, J.; Graves, R.; Maziasz, P.; Muralidharan, G.; Shyam, A.; Wang, B.; England, R.; Daniel, C. High temperature materials for heavy duty diesel engines: Historical and future trends. Prog. Mater. Sci. 2019, 103, 109–179. [Google Scholar] [CrossRef]

- Black, B.; Burger, G.; Logan, R.; Perrin, R.; Gundlach, R. Microstructure and Dimensional Stability in Si-Mo Ductile Irons for Elevated Temperature Applications. SAE Pap. 2002, 111, 976–991. [Google Scholar]

- Li, D.; Perrin, R.; Burger, G.; McFarlan, D.; Black, B.; Logan, R.; Williams, R. Solidification Behavior, Microstructure, Mechanical Properties, Hot Oxidation and Thermal Fatigue Resistance of High Silicon SiMo Nodular Cast Irons; SAE Tech. Pap. 2004-01-0792; SAE International: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Choe, K.; Lee, S.; Lee, K. High Temperature Oxidation Behavior of Si-Mo Ferritic Ductile Cast Iron. Mater. Sci. Forum 2010, 654–656, 542–545. [Google Scholar] [CrossRef]

- Choe, K.; Lee, K.; Kim, M. Effect of Mo on the microstructure and thermal expansion of high Si ferritic heat-resistant ductile iron. In Proceedings of the International Conference on Materials, Environmental and Biological Engineering (MEBE 2015), Guilin, China, 28–30 March 2015. [Google Scholar]

- Ductile Iron Group. Ductile Iron Data for Design Engineers; Rio Tinto Iron & Titanium Inc.: Montreal, QC, Canada, 1990. [Google Scholar]

- Fras, E.; Lopez, H.F. A Theoretical and Experimental Study of the Dependence between Undercooling and Nodular Eutectic Grains Density. Arch. Metall. 1998, 43, 227–240. [Google Scholar]

- Górny, M.; Tyrała, E. Effect of Cooling Rate on Microstructure and Mechanical Properties of Thin-Walled Ductile Iron Casting. J. Mater. Eng. Perform. 2013, 22, 300–305. [Google Scholar] [CrossRef] [Green Version]

- Youssef, M.; Nofal, A.; Hussein, A. Influence of Cooling Rate on Nature and Morphology of Intercellular Precipitates in Si-Mo Ductile Irons. Mater. Sci. Forum 2018, 925, 231–238. [Google Scholar] [CrossRef] [Green Version]

- Stawarz, M. The Role of Intermetallic Phases in Silicon Cast Iron; Polish Academy of Sciences: Katowice, Poland, 2019. [Google Scholar]

- Gerval, V.; Lacaze, J. Critical Temperature Range in Spheroidal Graphite Cast Irons. ISIJ Int. 2000, 40, 386–392. [Google Scholar] [CrossRef]

- Neuman, F. The influence of additional elements on the physic-chemical behaviour of carbon in saturated molten iron. In Recent Research on Cast Iron; Merchant, H.D., Ed.; Gordon and Breach: New York, NY, USA, 1968; pp. 659–705. [Google Scholar]

- Ibrahim, M.M.; Nofal, A.; Mourad, M.M. Microstructure and Hot Oxidation Resistance of SiMo Ductile Cast Irons Containing Si-Mo-Al. Metall. Mater. Trans. B 2017, 48, 1149–1157. [Google Scholar] [CrossRef]

- Stawarz, M. SiMo Ductile Iron Crystallization Process. Arch. Foundry Eng. 2017, 17, 147–152. [Google Scholar] [CrossRef] [Green Version]

- Angella, G.; Ripamonti, D.; Górny, M.; Masaggia, S.; Zanardi, F. The Role of Microstructure on Tensile Plastic Behavior of Ductile Iron GJS 400 Produced through Different Cooling Rates, Part I: Microstructure. Metals 2019, 9, 1282. [Google Scholar] [CrossRef] [Green Version]

- Goodrich, G.M. Cast iron microstructure anomalies and their causes. AFS Trans. 1997, 105, 669–683. [Google Scholar]

- Orłowicz, W.; Tupaj, M.; Mróz, M. Quality Control by Means of Ultrasonic in the Production of Ductile Iron. ISIJ Int. 2010, 50, 906–912. [Google Scholar] [CrossRef]

- Imasogie, B.I. Spheroidal Graphite Iron. In Encyclopedia of Iron, Steel, and Their Alloys, 1st ed.; Colás, R., Totten, G.E., Eds.; Taylor and Francis: New York, NY, USA, 2006; pp. 3237–3254. [Google Scholar]

- Willcox, M. Ultrasonic Velocity Measurements Used to Assess the Quality of Iron Castings. Insight NDT. Available online: https://www.insight-ndt.com/papers/ (accessed on 8 September 2021).

| C | Si | Mn | Cu | Ni | Cr | Mg | Mo | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 3.16 | 4.63 | 0.18 | 0.01 | 0.01 | 0.02 | 0.036 | 0.65 | 0.01 | Bal. |

| g, mm | Undercooling (°C) | Cooling Rate at Te (°C/s) | Cooling Rate at Ts (°C/s) |

|---|---|---|---|

| 3 | 37.76 | 26.78 | 3.57 |

| 5 | 32.33 | 14.11 | 1.42 |

| 13 | 25.01 | 4.09 | 0.30 |

| 25 | 21.48 | 1.48 | 0.29 |

| Wall Thickness, mm | Graphite Nodule Count, 1/mm2 | Graphite Nodularity, % | Graphite Mean Diameter, µm | Ferrite Volume Fraction, % | Ferrite Grain Size, µm |

|---|---|---|---|---|---|

| 3 | 608 ± 35 | 91 | 15.32 ± 0.25 | 86 ± 2 | 20.17 ± 2.56 |

| 5 | 411 ± 28 | 90 | 19.17 ± 0.28 | 85 ± 2 | 23.23 ± 3.71 |

| 13 | 201 ± 13 | 87 | 26.27 ± 1.11 | 81 ± 2 | 34.17 ± 2.44 |

| 25 | 168 ± 15 | 85 | 27.19 ± 0.81 | 78 ± 2 | 36.73 ± 4.19 |

| g, mm | cL, m/s |

|---|---|

| 3 | 5745 |

| 5 | 5714 |

| 13 | 5698 |

| 25 | 5685 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górny, M.; Kawalec, M.; Gracz, B.; Tupaj, M. Influence of Cooling Rate on Microstructure Formation of Si–Mo Ductile Iron Castings. Metals 2021, 11, 1634. https://doi.org/10.3390/met11101634

Górny M, Kawalec M, Gracz B, Tupaj M. Influence of Cooling Rate on Microstructure Formation of Si–Mo Ductile Iron Castings. Metals. 2021; 11(10):1634. https://doi.org/10.3390/met11101634

Chicago/Turabian StyleGórny, Marcin, Magdalena Kawalec, Beata Gracz, and Mirosław Tupaj. 2021. "Influence of Cooling Rate on Microstructure Formation of Si–Mo Ductile Iron Castings" Metals 11, no. 10: 1634. https://doi.org/10.3390/met11101634

APA StyleGórny, M., Kawalec, M., Gracz, B., & Tupaj, M. (2021). Influence of Cooling Rate on Microstructure Formation of Si–Mo Ductile Iron Castings. Metals, 11(10), 1634. https://doi.org/10.3390/met11101634