Experimental Investigation on Silicon Powder Mixed-EDM of Nimonic-90 Superalloy

Abstract

:1. Introduction

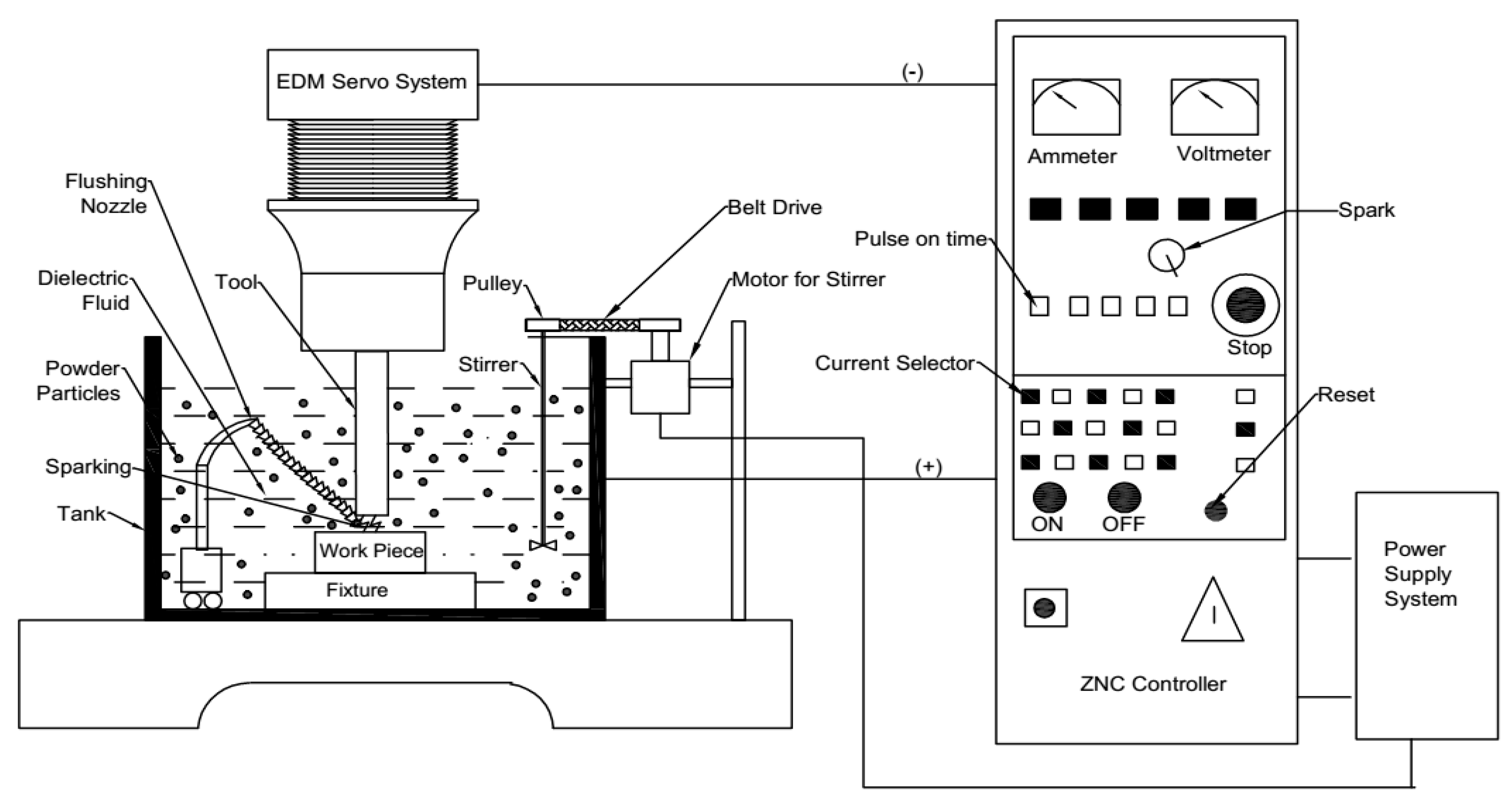

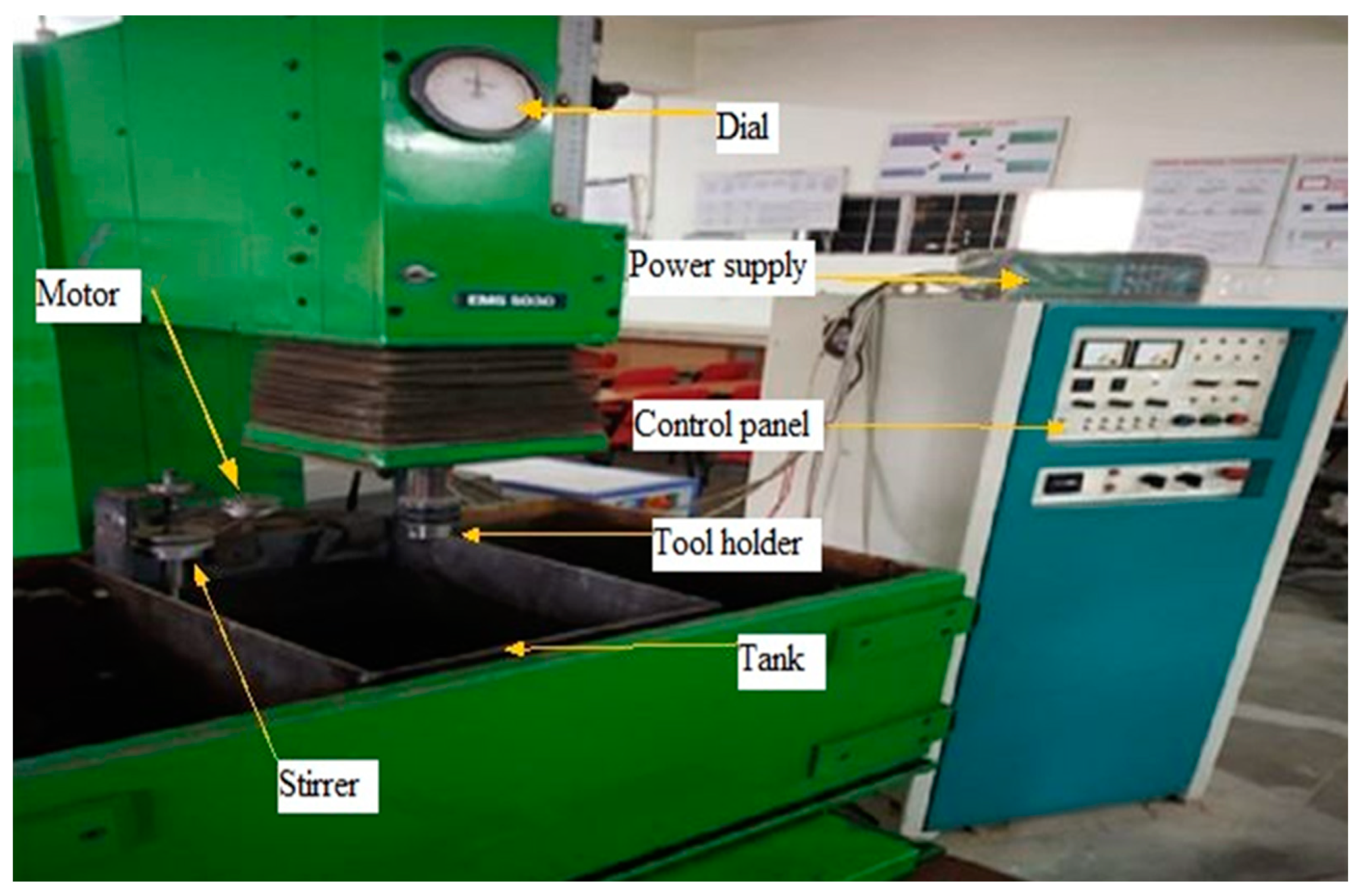

2. Materials and Methods

2.1. Materials and Experimental Details

2.2. Optimization Using Grey Relational Analysis

3. Results and Discussions

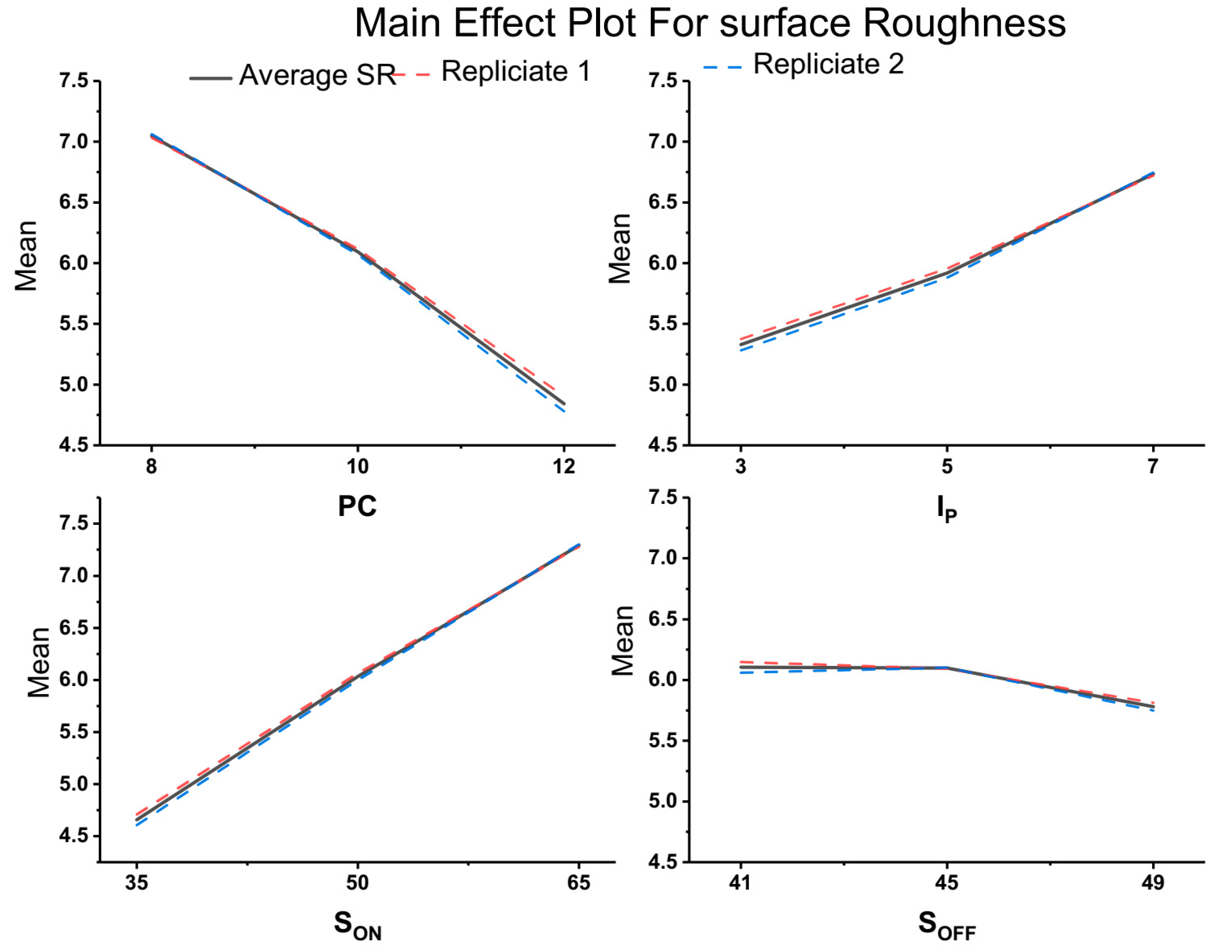

3.1. Parametric Effect on Surface Roughness

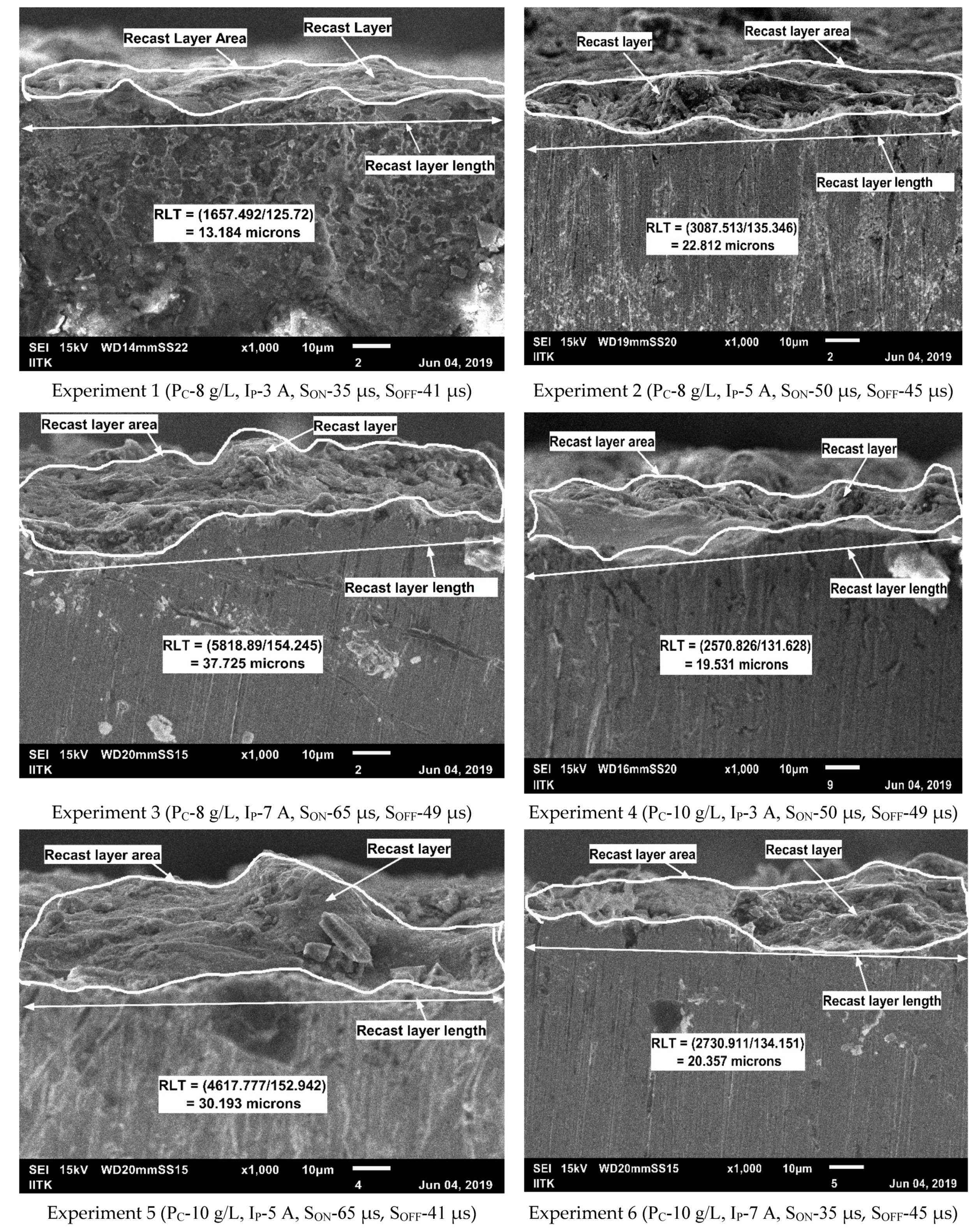

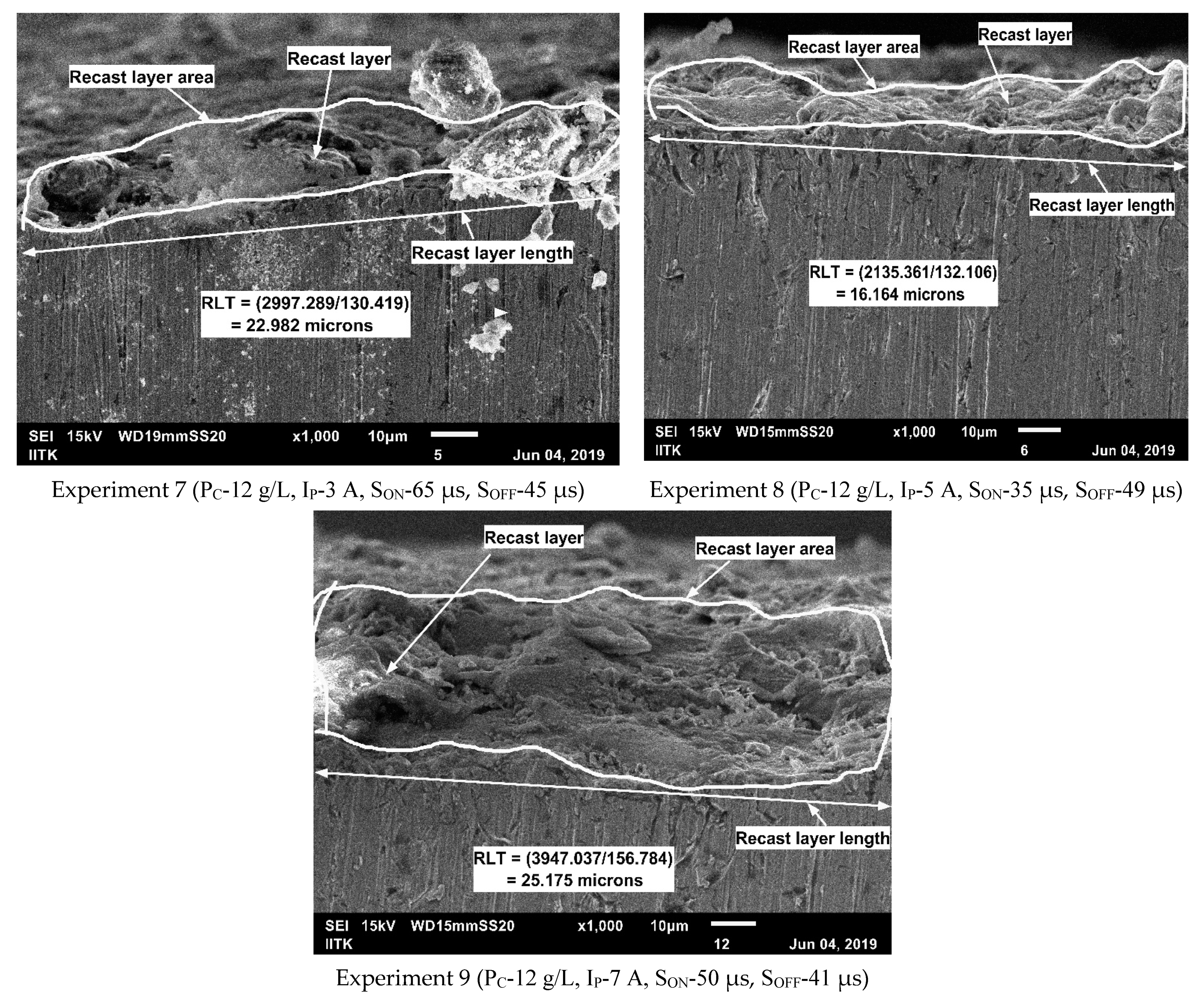

3.2. Parametric Effect on Recast Layer Thickness

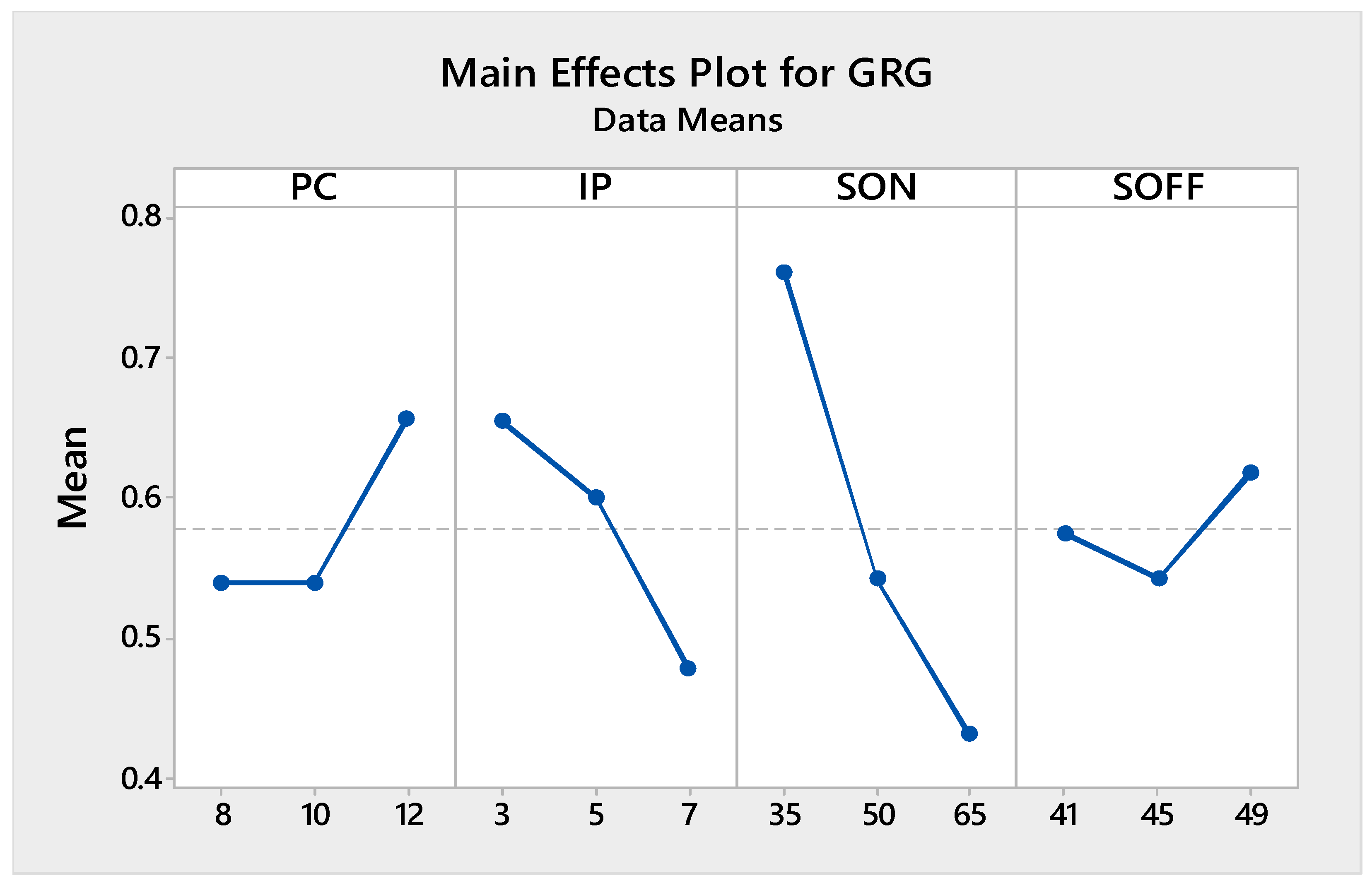

3.3. Optimization Using Grey Relational Analysis

3.4. Confirmation Test

| η = ηm + [(ηi)PC − ηm] + [(ηi)IP − ηm] + [(ηi)SON − ηm] + [(ηi)SOFF − ηm] |

| η = 0.5786 + (0.6568 − 0.5786) + (0.6557 − 0.5786) +(0.7619 − 0.5786) + (0.6185 − 0.5786) |

| = 0.9569 |

4. Conclusions

- For SR, SON was the most significant process parameter, followed by PC and IP, while the effect of SOFF was the least significant. A decrease in SR was observed with an increase in PC and SOFF, and a decrease in IP and SON;

- For RLT, SON was the most significant process parameter, followed by IP and PC. However, SOFF had a negligible effect. A decrease in RLT was noticed with an increase in PC and a decrease in IP and SON. A decrease in RLT was noticed with an increase in SOFF up to the optimum level and with further RLT increases;

- The minimum surface roughness (3.107 µm) and the thinnest recast layer (14.926 μm) was obtained at optimum process parameters i.e., PC = 12 g/L, IP = 3 A, SON = 35 μs and SOFF = 49 μs;

- Confirmatory results at optimum process parameters revealed a decrease in SR and RLT by 50.04% and 25.81%, respectively, with respect to the initial machining condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, V.; Jangra, K.K.; Kumar, V. An experimental study on trim cutting operation using metal powder mixed dielectric in WEDM of Nimonic-90. Int. J. Ind. Eng. Comput. 2016, 7, 135–146. [Google Scholar] [CrossRef]

- Kumar, V.; Jangra, K.K.; Kumar, V.; Sharma, N. GA-based optimisation using RSM in WEDM of Nimonic-90: A nickel-based super alloy. Int. J. Ind. Syst. Eng. 2018, 28, 53–69. [Google Scholar] [CrossRef]

- Pandey, A.K.; Gautam, G.D. Grey relational analysis-based genetic algorithm optimization of electrical discharge drilling of Nimonic-90 superalloy. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 117. [Google Scholar] [CrossRef]

- Kaya, E.; Akyüz, B. Effects of cutting parameters on machinability characteristics of Ni-based superalloys: A review. Open Eng. 2017, 7, 330–342. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. Experimental investigation on wire electric discharge machining (WEDM) of Nimonic C-263 superalloy. Mater. Manuf. Process. 2019, 34, 83–92. [Google Scholar] [CrossRef]

- Rouniyar, A.K.; Shandilya, P. Fabrication and experimental investigation of magnetic field assisted powder mixed electrical discharge machining on machining of aluminum 6061 alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 2283–2291. [Google Scholar] [CrossRef]

- Batish, A.; Bhattacharya, A.; Singla, V.K.; Singh, G. Study of material transfer mechanism in die steels using powder mixed electric discharge machining. Mater. Manuf. Process. 2012, 27, 449–456. [Google Scholar] [CrossRef]

- Beranoagirre, A.; Urbikain, G.; Calleja, A.; de Lacalle, L.N.L. Hole making by electrical discharge machining (EDM) of γ-TiAl intermetallic alloys. Metals 2018, 8, 543. [Google Scholar] [CrossRef] [Green Version]

- Rouniyar, A.K.; Shandilya, P. Optimization of process parameters in magnetic field assisted powder mixed EDM of aluminium 6061 alloy. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 2998–3014. [Google Scholar] [CrossRef]

- Kansal, H.K.; Singh, S.; Kumar, P. Parametric optimization of powder mixed electrical discharge machining by response surface methodology. J. Mater. Process. Technol. 2005, 169, 427–436. [Google Scholar] [CrossRef]

- Ekmekci, B.; Yaşar, H.; Ekmekci, N. A discharge separation model for powder mixed electrical discharge machining. J. Manuf. Sci. Eng. Trans. ASME 2016, 138, 1–9. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, D.; Xu, J.; Lin, J.; Lei, J.; Xu, B.; Wu, X.; Wang, X. Processing characteristics of micro electrical discharge machining for surface modification of TiNi shape memory alloys using a TiC powder dielectric. Micromachines 2020, 11, 1018. [Google Scholar] [CrossRef]

- Abdudeen, A.; Qudeiri, J.E.A.; Kareem, A.; Ahammed, T.; Ziout, A. Recent advances and perceptive insights into powder-mixed dielectric fluid of EDM. Micromachines 2020, 11, 754. [Google Scholar] [CrossRef]

- Rouniyar, A.K.; Shandilya, P. Semi-empirical modeling and optimization of process parameters on overcut during MFAPM-EDM of Al6061 alloy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 09544089211015890. [Google Scholar] [CrossRef]

- Rouniyar, A.K.; Shandilya, P. Study of surface crack density and microhardness of Aluminium 6061 alloy machined by EDM with mixed powder and assisted magnetic field. J. Micromanufacturing 2021, 251659842110164. [Google Scholar] [CrossRef]

- Jeswani, M.L. Effect of the Addition of Graphite Powder to Kerosene Used as the Dielectric Fluid in Electrical Discharge Machining. Wear 1981, 70, 133–139. [Google Scholar] [CrossRef]

- Tan, P.C.; Yeo, S.H. Investigation of recast layers generated by a powder-mixed dielectric micro electrical discharge machining processg. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1051–1062. [Google Scholar] [CrossRef]

- Rathi, M.G.; Mane, D.V. Study on effect of powder mixed dielectric in EDM of Inconel 718. Int. J. Sci. Res. Publ. 2014, 4, 1–7. [Google Scholar]

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S. Experimental investigations in powder mixed electric discharge machining of Ti–35Nb–7Ta–5Zrβ-titanium alloy. Mater. Manuf. Process. 2017, 32, 274–285. [Google Scholar] [CrossRef]

- Kumar, A.; Mandal, A.; Dixit, A.R.; Das, A.K. Performance evaluation of Al2O3 nano powder mixed dielectric for electric discharge machining of Inconel 825. Mater. Manuf. Process. 2018, 33, 986–995. [Google Scholar] [CrossRef]

- Sugunakar, A.; Kumar, A.; Markandeya, R. Effect of Powder Mixed Dielectric fluid on Surface Integrity by Electrical Discharge Machining of RENE 80. IOSR J. Mech. Civ. Eng. 2017, 14, 43–50. [Google Scholar] [CrossRef]

- Tripathy, S.; Tripathy, D.K. Grey relational analysis and its application on surface properties during EDM and powder mixed EDM. J. Eng. Sci. Technol. 2017, 12, 2374–2392. [Google Scholar]

- Patel, S.; Thesiya, D.; Rajurkar, A. Aluminium powder mixed rotary electric discharge machining (PMEDM) on Inconel 718. Aust. J. Mech. Eng. 2018, 16, 21–30. [Google Scholar] [CrossRef]

- Ramesh, S.; Jenarthanan, M.P. Investigating the performance of powder mixed electric discharge machining of Nimonic 75 by using different tool materials. World J. Eng. 2018, 15, 205–215. [Google Scholar] [CrossRef]

- Rouniyar, A.K.; Shandilya, P. Multi-Objective Optimization using Taguchi and Grey Relational Analysis on Machining of Ti-6Al-4V Alloy by Powder Mixed EDM Process. Mater. Today Proc. 2018, 5, 23779–23788. [Google Scholar] [CrossRef]

- Sahu, D.R.; Mandal, A. Critical analysis of surface integrity parameters and dimensional accuracy in powder-mixed EDM. Mater. Manuf. Process. 2020, 35, 430–441. [Google Scholar] [CrossRef]

- Farooq, M.U.; Mughal, M.P.; Ahmed, N.; Mufti, N.A.; Al-Ahmari, A.M.; He, Y. On the investigation of surface integrity of Ti6Al4V ELI using si-mixed electric discharge machining. Materials 2020, 13, 1549. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Senthilkumar, N.; Tamizharasan, T.; Anandakrishnan, V. Experimental investigation and performance analysis of cemented carbide inserts of different geometries using Taguchi based grey relational analysis. Meas. J. Int. Meas. Confed. 2014, 58, 520–536. [Google Scholar] [CrossRef]

- Meena, V.K.; Azad, M.S. Grey relational analysis of micro-EDM machining of Ti-6Al-4V alloy. Mater. Manuf. Process. 2012, 27, 973–977. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A.; Singh, G. Optimization of powder mixed electric discharge machining using dummy treated experimental design with analytic hierarchy process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 103–116. [Google Scholar] [CrossRef]

- Bains, P.S.; Sidhu, S.S.; Payal, H.S.; Kaur, S. Magnetic Field Influence on Surface Modifications in Powder Mixed EDM. Silicon 2019, 11, 415–423. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. The machining characteristics and surface integrity of Ni-rich NiTi shape memory alloy using wire electric discharge machining. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 1068–1078. [Google Scholar] [CrossRef]

- Rouniyar, A.K.; Shandilya, P. Experimental Investigation on Recast Layer and Surface Roughness on Aluminum 6061 Alloy During Magnetic Field Assisted Powder Mixed Electrical Discharge Machining. J. Mater. Eng. Perform. 2020, 29, 7981–7992. [Google Scholar] [CrossRef]

- Singh, S.; Yeh, M.F. Optimization of abrasive powder mixed EDM of aluminum matrix composites with multiple responses using gray relational analysis. J. Mater. Eng. Perform. 2012, 21, 481–491. [Google Scholar] [CrossRef]

- Majumder, H.; Paul, T.R.; Dey, V.; Dutta, P.; Saha, A. Use of PCA-grey analysis and RSM to model cutting time and surface finish of Inconel 800 during wire electro discharge cutting. Meas. J. Int. Meas. Confed. 2017, 107, 19–30. [Google Scholar] [CrossRef]

- Montgomery, D.C. Montgomery Design and Analysis of Experiments, 8th ed.; Arizona State University; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; Volume 2009, ISBN 9781118146927. [Google Scholar]

- Abidi, M.H.; Al-Ahmari, A.M.; Siddiquee, A.N.; Mian, S.H.; Mohammed, M.K.; Rasheed, M.S. An investigation of the micro-electrical discharge machining of nickel-titanium shape memory alloy using grey relations coupled with principal component analysis. Metals 2017, 7, 486. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Yan, Q.; Lu, J.; Xiong, Q.; Pan, J. Optimisation of Lapping Process Parameters for Single-Crystal 4H–SiC Using Orthogonal Experiments and Grey Relational Analysis. Micromachines 2021, 12, 910. [Google Scholar] [CrossRef]

- Suresh Kumar, S.; Uthayakumar, M.; Thirumalai Kumaran, S.; Parameswaran, P.; Mohandas, E.; Kempulraj, G.; Ramesh Babu, B.S.; Natarajan, S.A. Parametric optimization of wire electrical discharge machining on aluminium based composites through grey relational analysis. J. Manuf. Process. 2015, 20, 33–39. [Google Scholar] [CrossRef]

- Sylajakumari, P.A.; Ramakrishnasamy, R.; Palaniappan, G. Taguchi grey relational analysis for multi-response optimization of wear in co-continuous composite. Materials 2018, 11, 1743. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manikandan, N.; Raju, R.; Palanisamy, D.; Binoj, J.S. Optimisation of spark erosion machining process parameters using hybrid grey relational analysis and artificial neural network model. Int. J. Mach. Mach. Mater. 2020, 22, 1–23. [Google Scholar] [CrossRef]

- Kalyon, A.; Günay, M.; Özyürek, D. Application of grey relational analysis based on Taguchi method for optimizing machining parameters in hard turning of high chrome cast iron. Adv. Manuf. 2018, 6, 419–429. [Google Scholar] [CrossRef]

- Abhang, L.B.; Hameedullah, M. Determination of optimum parameters for multi-performance characteristics in turning by using grey relational analysis. Int. J. Adv. Manuf. Technol. 2012, 63, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Javed, S.A.; Mahmoudi, A.; Khan, A.M.; Javed, S.; Liu, S. A Critical Review: Shape Optimization of Welded Plate Heat Exchangers based on Grey Correlation Theory. Appl. Therm. Eng. 2018, 144, 593–599. [Google Scholar] [CrossRef]

- Shard, A.; Shikha, D.; Gupta, V.; Garg, M.P. Effect of B4C abrasive mixed into dielectric fluid on electrical discharge machining. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 554. [Google Scholar] [CrossRef]

- Sahu, S.K.; Datta, S. Experimental studies on graphite powder-mixed electro-discharge machining of Inconel 718 super alloys: Comparison with conventional electro-discharge machining. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2019, 233, 384–402. [Google Scholar] [CrossRef]

- Wu, K.L.; Yan, B.H.; Huang, F.Y.; Chen, S.C. Improvement of surface finish on SKD steel using electro-discharge machining with aluminum and surfactant added dielectric. Int. J. Mach. Tools Manuf. 2005, 45, 1195–1201. [Google Scholar] [CrossRef]

- Pawade, R.S.; Joshi, S.S. Multi-objective optimization of surface roughness and cutting forces in high-speed turning of Inconel 718 using Taguchi grey relational analysis (TGRA). Int. J. Adv. Manuf. Technol. 2011, 56, 47–62. [Google Scholar] [CrossRef]

| PM-EDM Setup | Properties of Nimonic-90 | ||

|---|---|---|---|

| Machine | Elektra (EMS 5030) | Density (kg/m3) | 8180 |

| Open circuit voltage (V) | 135 ± 5 | Melting point (°C) | 1370 |

| Dielectric | Kerosene | Co-efficient of thermal expansion (μm/m °C) | 12.7 |

| Machining time (mins) | 5 | Thermal Conductivity (W/m °C) | 11.47 |

| Electrode | copper | Hardness (Hv) | 270 |

| Workpiece | Nimonic-90 | Modulus of Elasticity (GPa) | 230 |

| Dielectric flow rate (L/min) | 4.2 | Electrical Resistivity (µΩ. cm) | 118 |

| Flushing condition | Side flushing (nozzle diameter 5 mm) | Poisson’s ratio | 0.28 |

| Compositions | Ni | Cr | Co | Ti | Al |

|---|---|---|---|---|---|

| At Wt. (%) | 60 | 19.3 | 15 | 3.1 | 1.4 |

| Process Parameter | Symbol | Level-1 | Level-2 | Level-3 |

|---|---|---|---|---|

| Powder concentration (g/L) | PC | 8 | 10 | 12 |

| Discharge current (A) | IP | 3 | 5 | 7 |

| Spark-on-duration (μs) | SON | 35 | 50 | 65 |

| Spark-off-duration (μs) | SOFF | 41 | 45 | 49 |

| Experimental Run | Input Process Parameter | SR (µm) | RLT (µm) | |||

|---|---|---|---|---|---|---|

| PC | IP | SON | SOFF | |||

| 1 | 8 | 3 | 35 | 41 | 5.157 | 13.184 |

| 2 | 8 | 5 | 50 | 45 | 7.116 | 22.812 |

| 3 | 8 | 7 | 65 | 49 | 8.871 | 37.725 |

| 4 | 10 | 3 | 50 | 49 | 5.256 | 19.531 |

| 5 | 10 | 5 | 65 | 41 | 7.425 | 30.193 |

| 6 | 10 | 7 | 35 | 45 | 5.601 | 20.357 |

| 7 | 12 | 3 | 65 | 45 | 5.576 | 22.982 |

| 8 | 12 | 5 | 35 | 49 | 3.216 | 16.164 |

| 9 | 12 | 7 | 50 | 41 | 5.732 | 25.175 |

| Source | DF | SS | MS | F-Value | p-Value | % Contr. |

|---|---|---|---|---|---|---|

| Regression | 4 | 20.818 | 5.2047 | 165.96 | 0.000 | |

| PC | 1 | 7.3041 | 7.3041 | 232.91 | 0.000 # | 34.87 |

| IP | 1 | 2.9610 | 2.9610 | 94.420 | 0.001 # | 14.14 |

| SON | 1 | 10.396 | 10.396 | 331.51 | 0.000 # | 49.64 |

| SOFF | 1 | 0.1571 | 0.1571 | 5.01 | 0.089 * | 0.75 |

| Error | 4 | 0.1254 | 0.0314 | 0.60 | ||

| Total | 8 | 20.9441 | ||||

| R-sq = 98.65%, R-sq (Adj.) = 97.84%, R-sq (pred.) = 94.57% | ||||||

| Source | DF | SS | MS | F-Value | p-Value | % Contr. |

|---|---|---|---|---|---|---|

| Regression | 4 | 428.11 | 107.027 | 59.55 | 0.001 | |

| PC | 1 | 14.73 | 14.727 | 8.190 | 0.046 # | 3.38 |

| IP | 1 | 126.59 | 126.592 | 70.44 | 0.001 # | 29.08 |

| SON | 1 | 282.84 | 282.838 | 157.38 | 0.000 # | 64.98 |

| SOFF | 1 | 3.9500 | 3.9500 | 2.200 | 0.212 * | 0.91 |

| Error | 4 | 7.1900 | 1.7970 | 1.65 | ||

| Total | 8 | 435.30 | ||||

| R-Sq = 97.44%, R-Sq (adj.) = 95.91%, R-Sq = 90.62% | ||||||

| Expt. Runs | Normalized | Deviation | GRC | GRG | Rank | |||

|---|---|---|---|---|---|---|---|---|

| SR | RLT | SR | RLT | SR | RLT | |||

| 1 | 0.6568 | 1.0000 | 0.3432 | 0.0000 | 0.5930 | 1.0000 | 0.7965 | 2 |

| 2 | 0.3103 | 0.6077 | 0.6897 | 0.3923 | 0.4203 | 0.5603 | 0.4903 | 7 |

| 3 | 0.0000 | 0.0000 | 1.0000 | 1.0000 | 0.3333 | 0.3333 | 0.3333 | 9 |

| 4 | 0.6393 | 0.7414 | 0.3607 | 0.2586 | 0.5809 | 0.6591 | 0.6200 | 3 |

| 5 | 0.2557 | 0.3069 | 0.7443 | 0.6931 | 0.4018 | 0.4191 | 0.4105 | 8 |

| 6 | 0.5782 | 0.7077 | 0.4218 | 0.2923 | 0.5424 | 0.6311 | 0.5868 | 4 |

| 7 | 0.5827 | 0.6007 | 0.4173 | 0.3993 | 0.5451 | 0.5560 | 0.5505 | 5 |

| 8 | 1.0000 | 0.8786 | 0.0000 | 0.1214 | 1.0000 | 0.8046 | 0.9023 | 1 |

| 9 | 0.5551 | 0.5114 | 0.4449 | 0.4886 | 0.5291 | 0.5058 | 0.5175 | 6 |

| Level | PC | IP | SON | SOFF |

|---|---|---|---|---|

| 1 | 0.5400 | 0.6557 | 0.7619 | 0.5748 |

| 2 | 0.5391 | 0.6010 | 0.5426 | 0.5425 |

| 3 | 0.6568 | 0.4792 | 0.4314 | 0.6185 |

| Delta | 0.1177 | 0.1765 | 0.3304 | 0.0760 |

| Rank | 3 | 2 | 1 | 4 |

| Parameters | Initial Process Parameters | Optimum Process Parameters | |

|---|---|---|---|

| Predicted | Experimental | ||

| Combination Level | (PC)1(IP)2(SON)2(SOFF)1 | (PC)3(IP)1(SON)1(SOFF)3 | (PC)3(IP)1(SON)1(SOFF)3 |

| SR | 6.220 | 3.116 | 3.107 |

| RLT | 20.119 | 14.904 | 14.926 |

| GRG | 0.5619 | 0.9569 | 0.9579 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhodaib, A.; Shandilya, P.; Rouniyar, A.K.; Bisaria, H. Experimental Investigation on Silicon Powder Mixed-EDM of Nimonic-90 Superalloy. Metals 2021, 11, 1673. https://doi.org/10.3390/met11111673

Alhodaib A, Shandilya P, Rouniyar AK, Bisaria H. Experimental Investigation on Silicon Powder Mixed-EDM of Nimonic-90 Superalloy. Metals. 2021; 11(11):1673. https://doi.org/10.3390/met11111673

Chicago/Turabian StyleAlhodaib, Aiyeshah, Pragya Shandilya, Arun Kumar Rouniyar, and Himanshu Bisaria. 2021. "Experimental Investigation on Silicon Powder Mixed-EDM of Nimonic-90 Superalloy" Metals 11, no. 11: 1673. https://doi.org/10.3390/met11111673

APA StyleAlhodaib, A., Shandilya, P., Rouniyar, A. K., & Bisaria, H. (2021). Experimental Investigation on Silicon Powder Mixed-EDM of Nimonic-90 Superalloy. Metals, 11(11), 1673. https://doi.org/10.3390/met11111673