Critical Assessment of the Electric Effect in Electric Arc Welding

Abstract

:1. Introduction

2. The Electric Effects

2.1. Basic Consideration

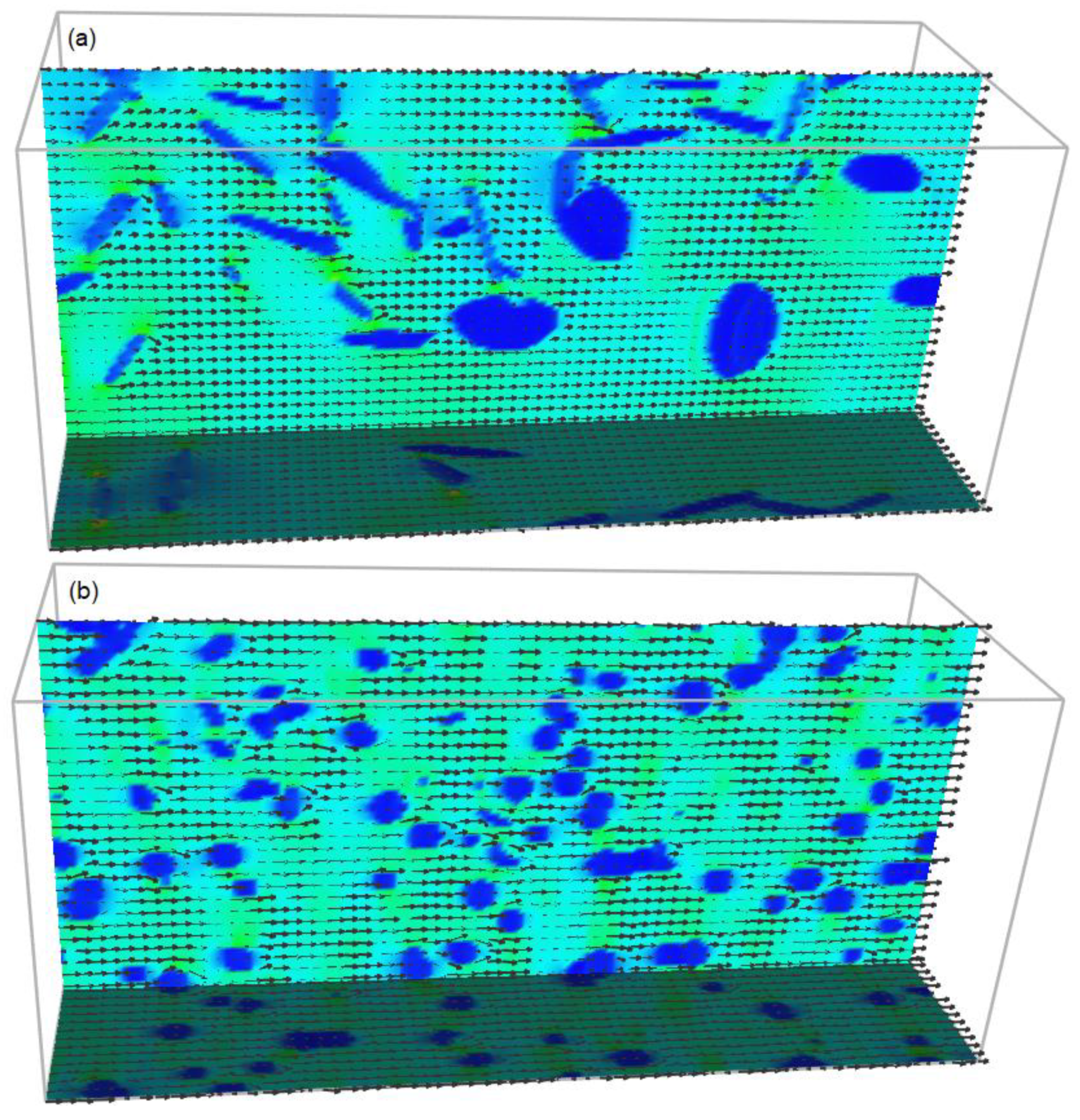

2.2. Electric Effects on Grain Growth

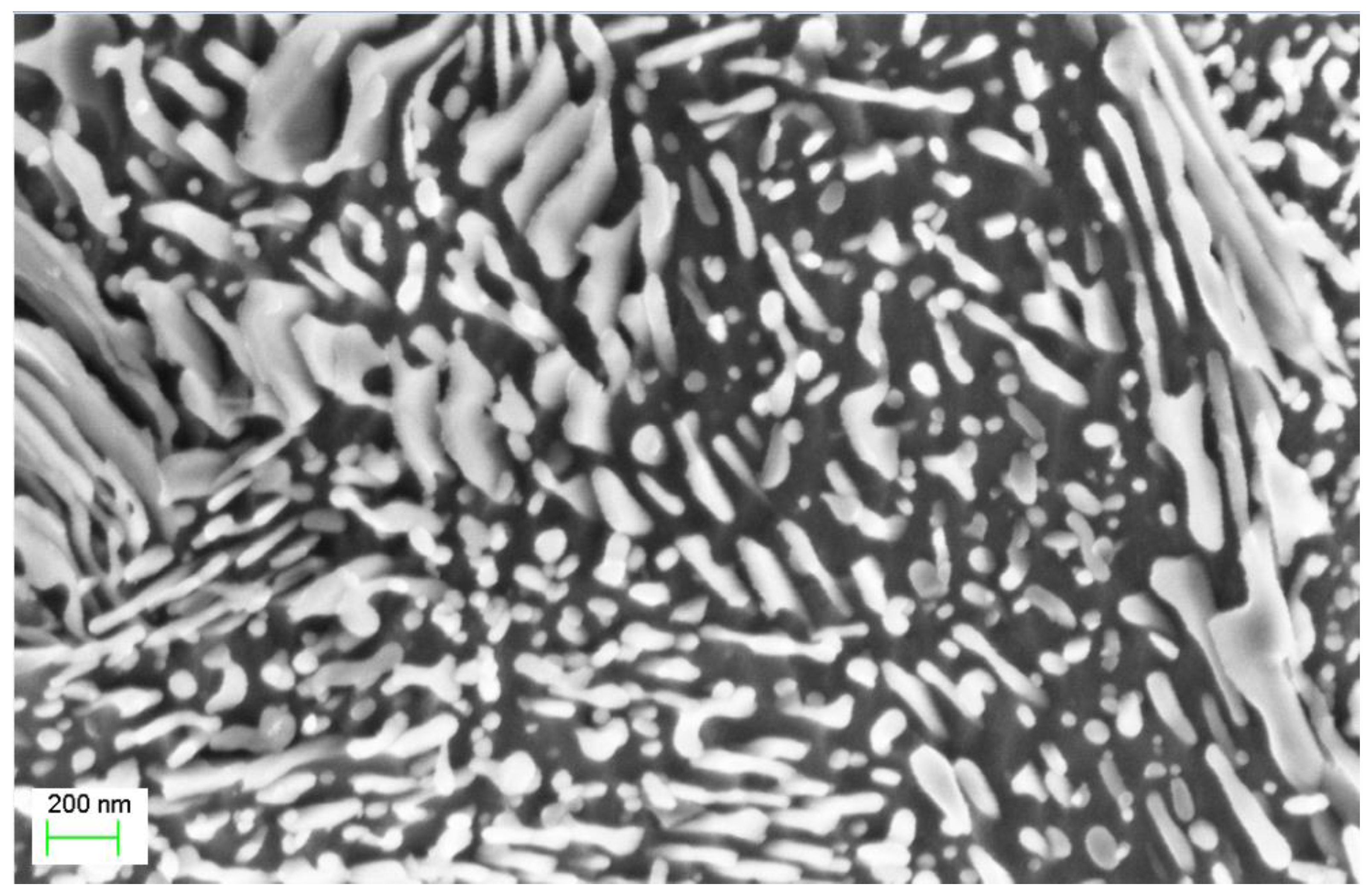

2.3. Electric Effect on Recrystallisation

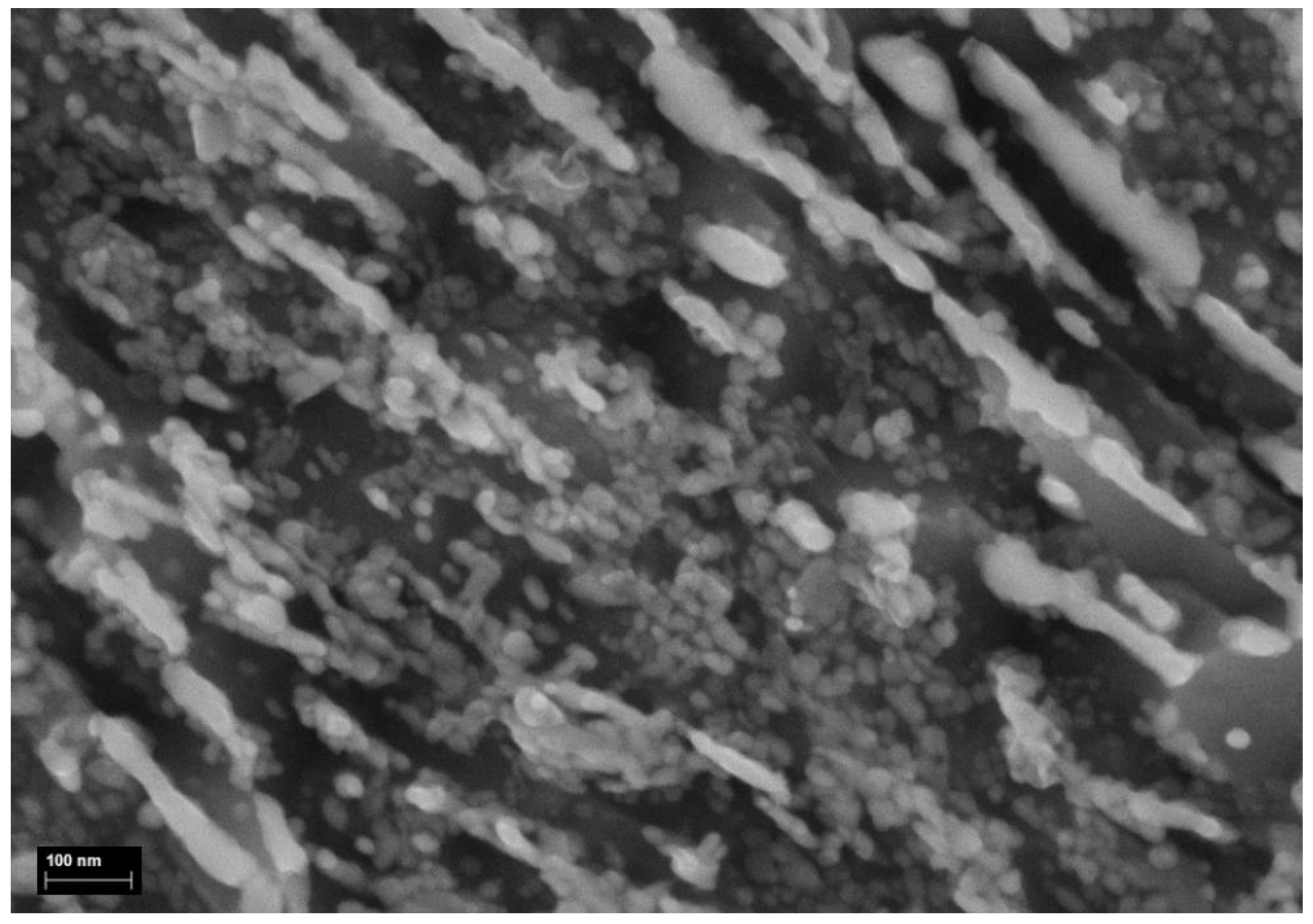

2.4. Electric Effect on Tempering

3. Optimising the Electric Effect in EAW

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amanie, J. Effect of Submerged Arc Welding Parameters on the Microstructure of SA516 and A709 Steel Welds. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2011. [Google Scholar]

- Lee, C.S.; Chandel, R.S.; Seow, H.P. Effect of welding parameters on the size of heat affected zone of submerged arc welding. Mater. Manuf. Process. 2000, 15, 649–666. [Google Scholar] [CrossRef]

- Ducharme, R.; Kapadia, P.; Dowden, J.; Thornton, M.; Richardson, I. A mathematical-model of the arc in electric-arc welding including shielding gas-flow and cathode spot location. J. Phys. D Appl. Phys. 1995, 28, 1840–1850. [Google Scholar] [CrossRef]

- Varbai, B.; Májlinger, K. Physical and theoretical modeling of the nitrogen content of duplex stainless steel weld metal: Shielding gas composition and heat input effects. Metals. 2019, 9, 762. [Google Scholar] [CrossRef] [Green Version]

- Suleimanov, R.I.; Zainagalina, L.Z.; Khabibullin, M.Y.; Zaripova, L.M.; Kovalev, N.O. Studying heat-affected zone deformations of electric arc welding. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 032053. [Google Scholar] [CrossRef]

- Nogay, H.S.; Akinci, T.C. Classification of operation cases in electric arc welding wachine by using deep convolutional neural networks. Neural. Comput. Appl. 2021, 33, 6657–6670. [Google Scholar] [CrossRef]

- Dolinsky, Y.; Elperin, T. Thermodynamics of nucleation in current-carrying conductors. Phys. Rev. B 1994, 50, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Barnak, J.P.; Sprecher, A.F.; Conrad, H. Colony (grain) size reduction in eutectic Pb-Sn castings by electropulsing. Scr. Metall. Mater. 1995, 32, 879–884. [Google Scholar] [CrossRef]

- Conrad, H. Influence of an electric or magnetic field on the liquid-solid transformation in materials and on the microstructure of the solid. Mater. Sci. Eng. A 2000, 287, 205–212. [Google Scholar] [CrossRef]

- Rahnama, A.; Qin, R.S. Electropulse-induced microstructural evolution in a ferritic–pearlitic 0.14% C steel. Scr. Mater. 2015, 96, 17–20. [Google Scholar] [CrossRef] [Green Version]

- Misra, A.K. A novel solidification technique of metals and alloys—Under the influence of applied potential. Metall. Trans. A 1985, 16, 1354–1355. [Google Scholar] [CrossRef]

- Troitskii, O.A. Electromechanical effect in metals. JETP Lett. 1969, 10, 11–14, (English version). [Google Scholar]

- Zhao, S.T.; Zhang, R.P.; Chong, Y.; Li, X.Q.; Abu-Odeh, A.; Rothchild, E.; Chrzan, D.C.; Asta, M.; Morris, J.W., Jr.; Minor, A.M. Defect reconfiguration in a Ti–Al alloy via electroplasticity. Nat. Mate. 2021, 20, 468–472. [Google Scholar] [CrossRef]

- Kim, M.J.; Yoon, S.M.; Park, S.W.; Jeong, H.J.; Park, J.W.; Kim, K.T.; Jo, J.H.; Heo, T.H.; Hong, S.T.; Cho, S.H.; et al. Elucidating the origin of electroplasticity in metallic materials. Appl. Mater. Today. 2020, 21, 100874. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, D.D.; Xu, H.; Liu, Y.B.; Cao, Z.Y.; Yang, X.H. Excellent ductility in the extruded AZ61 magnesium alloy tube induced by electropulsing treatment during tension. Metals 2021, 11, 813. [Google Scholar] [CrossRef]

- Jiang, Y.B.; Tang, G.Y.; Shek, C.H.; Zhu, Y.H.; Xu, Z.H. On the thermodynamics and kinetics of electropulsing induced dissolution of β-Mg17Al12 phase in an aged Mg–9Al–1Zn alloy. Acta Mater. 2009, 57, 4797–4808. [Google Scholar] [CrossRef]

- Kim, M.J.; Lee, K.; Oh, K.H.; Choi, I.-S.; Yu, H.-H.; Hong, S.-T.; Han, H.N. Electric current-induced annealing during uniaxial tension of aluminum alloy. Scripta Mater. 2014, 75, 58–61. [Google Scholar] [CrossRef]

- Lu, W.J.; Zhang, X.F.; Qin, R.S. Stability of precipitates under electropulsing in 316 L stainless steel. Mater. Sci. Technol. 2015, 31, 1530–1535. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; He, B.Y.; Saillet, S.; Domain, D.; Delliou, P.L.; Perez, M.; Qin, R.S. Anti-aging treatment of nuclear power plant steel. Mater. Sci. Eng. A 2018, 735, 73–80. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.B.; Lu, W.J.; Zhang, X.F. Reconstructing the decomposed ferrite phase to achieve toughness regeneration in a duplex stainless steel. Acta Mater. 2020, 183, 51–63. [Google Scholar] [CrossRef]

- Eerenstein, W.; Mathur, N.D.; Scott, J.F. Multiferroic and magnetoelectric materials. Nature. 2006, 442, 759–765. [Google Scholar] [CrossRef] [PubMed]

- Qin, R.S.; Bhowmik, A. Computational thermodynamics in electric current metallurgy. Mater. Sci. Technol. 2015, 31, 1560–1563. [Google Scholar] [CrossRef] [Green Version]

- Mohanty, U.; Rice, S.A. Theory of the electrical conductivity in the liquid vapor interface of a simple metal. J. Chem. Phys. 1983, 79, 5652–5657. [Google Scholar] [CrossRef]

- Zhang, X.F.; Qin, R.S. Electric current-driven migration of electrically neutral particles in liquids. Appl. Phys. Lett. 2014, 104, 114106. [Google Scholar] [CrossRef] [Green Version]

- Qin, R.S.; Su, S.X. Thermodynamics of crack healing under electropulsing. J. Mater. Res. 2002, 17, 2048–2052. [Google Scholar] [CrossRef]

- Liu, Z.K. Computational thermodynamics and its applications. Acta Mater. 2020, 200, 745–792. [Google Scholar] [CrossRef]

- Langer, J.S.; Müller-Krumbhaar, H. Theory of dendritic growth—I. Elements of a stability analysis. Acta Metall. 1978, 26, 1681–1687. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Problems in the welding of automotive alloys. Sci. Technol. Weld. Join. 2015, 20, 451–453. [Google Scholar] [CrossRef] [Green Version]

- Jung, G.S.; Lee, K.Y.; Lee, J.B.; Bhadeshia, H.K.D.H.; Suh, D.W. Spot weldability of TRIP assisted steels with high carbon and aluminium contents. Sci. Technol. Weld. Join. 2012, 17, 92–98. [Google Scholar] [CrossRef] [Green Version]

- Qin, R.S.; Rahnama, A.; Lu, W.J.; Zhang, X.F.; Elliott-Bowman, B. Electropulsed steels. Mater. Sci. Technol. 2014, 30, 1040–1044. [Google Scholar] [CrossRef]

- Powell, R.W. LXXX. The electrical resistivity of liquid iron. Phil. Mag. 1953, 44, 772–775. [Google Scholar] [CrossRef]

- Kannengiesser, T.; Boellinghaus, T. Hot cracking tests-an overview of present technologies and applications. Weld. World 2014, 58, 397–421. [Google Scholar] [CrossRef]

- Yousefi, N.; Gudarzi, M.M.; Zheng, Q.B.; Aboutalebi, S.H.; Sharif, F.; Kim, J.K. Self-alignment and high electrical conductivity of ultra large graphene oxide-polyurethane nanocomposites. J. Mater. Chem. 2012, 22, 12709–12717. [Google Scholar] [CrossRef]

- Yamauchi, K.; Hagio, T.; Mitsuo, T.; Iwai, K.; Itoh, T. Thermoelectric properties of crystal aligned higher manganese silicide fabricated by solidification under magnetic field. Jpn. J. Appl. Phys. 2015, 54, 117102. [Google Scholar] [CrossRef]

- Qin, R. Alignment of rods and flakes using electric field. Adv. Mater. Lett. 2019, 10, 899–902. [Google Scholar] [CrossRef] [Green Version]

- Qin, R. Electric-field-induced alignment of electrically neutral disk-like particles: Modelling and calculation. Sci. Rep. 2017, 7, 8449. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, H.X.; Zhao, J.Z.; Wang, C.P.; Liu, X.J. Effect of electric current pulses on solidification of immiscible alloys. Mater. Lett. 2014, 132, 66–69. [Google Scholar] [CrossRef]

- Jiang, H.X.; He, J.; Zhao, J.Z. Influence of electric current pulses on the solidification of Cu-Bi-Sn immiscible alloys. Sci. Rep. 2015, 5, 12680. [Google Scholar]

- Qin, R.S.; Zhou, B.L. Effect of electric current pulses on grain size in castings. Inter. J. Nonequil. Proc. 1998, 11, 77–86. [Google Scholar]

- Liu, S.H.; Poirier, D.R.; Ocansey, P.N. Resistivity of Pb and Pb-10 wt% Sn during solidification. Metall. Mater. Trans. 1995, 26A, 741–745. [Google Scholar] [CrossRef]

- Qin, R.S.; Su, S.X.; Guo, J.D.; He, G.H.; Zhou, B.L. Suspension effect of nanocrystalline grain growth under electropulsing. Nanostruc. Mater. 1998, 10, 71–76. [Google Scholar]

- Huang, K.; Loge, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Samuel, E.I.; Bhowmik, A.; Qin, R.S. Accelerated spheroidization induced by high intensity electric pulse in a severely deformed eutectoid steel. J. Mater. Res. 2010, 25, 1020–1024. [Google Scholar] [CrossRef]

- Qin, R. Using electric current to surpass the microstructure breakup limit. Sci. Rep. 2017, 7, 41451. [Google Scholar] [CrossRef]

- Qin, R.S.; Samuel, E.I.; Bhowmik, A. Electropulse-induced cementite nanoparticle formation in deformed pearlitic steels. J. Mater. Sci. 2011, 46, 2838–2842. [Google Scholar] [CrossRef] [Green Version]

- Qin, R.S.; Luo, Y.K.; Elliott-Bowman, B.; Omoigiade, O. Fabrication of nanostructured pearlite steel wires using electropulsing. Mater. Sci. Technol. 2018, 34, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Klinger, L.; Levin, L. Interface instability in an electric-field. J. App. Phys. 1995, 78, 1669–1672. [Google Scholar] [CrossRef]

- Zhao, Z.C.; Qin, R.S. Morphology and orientation selection of non-metallic inclusions in electrified molten metal. Metall. Mater. Trans. 2017, 48B, 2781–2787. [Google Scholar] [CrossRef]

- Pan, L.; He, W.; Gu, B.P. Effects of electric current pulses on mechanical properties and microstructures of as-quenched medium carbon steel. Mater. Sci. Eng. A 2016, 662, 404–411. [Google Scholar] [CrossRef]

- Lu, W.J.; Qin, R.S. Stability of martensite with pulsed electric current in dual-phase steels. Mater. Sci. Eng. A 2016, 677, 252–258. [Google Scholar] [CrossRef] [Green Version]

- Amini, K.; Akhbarizadeh, A.; Javadpour, S. Effect of carbide distribution on corrosion behavior of the deep cryogenically treated 1.2080 steel. J. Mater. Eng. Perform. 2016, 25, 365–373. [Google Scholar] [CrossRef]

- Kapoor, R.; Sunil, S.; Reddy, G.B.; Nagaraju, S.; Kolge, T.S.; Sarkar, S.K.; Biswas, A.; Sharma, A. Electric current induced precipitation in maraging steel. Scr. Mater. 2018, 154, 16–19. [Google Scholar] [CrossRef]

- Lu, W.J.; Qin, R.S. Influence of κ-carbide interface structure on the formability of lightweight steels. Mater. Des. 2016, 104, 211–216. [Google Scholar] [CrossRef] [Green Version]

- Sydorenko, Y.M.; Pashchyn, M.O.; Mykhodui, O.L.; Khokhlova, Y.A.; Khokhlov, M.A. Effect of pulse current on residual stresses in AMg6 aluminum alloy in electrodynamic treatment. Strength Mater. 2020, 5, 731–737. [Google Scholar] [CrossRef]

- Xiang, S.Q.; Zhang, X.F. Residual stress removal under pulsed electric current. Acta Metall. Sin.-Engl. 2020, 33, 281–289. [Google Scholar] [CrossRef] [Green Version]

- Song, X.D.; Wang, F.; Qian, D.S.; Hua, L. Tailoring the residual stress and mechanical properties by electroshocking treatment in cold rolled M50 steel. Mater. Sci. Eng. A 2020, 780, 139171. [Google Scholar] [CrossRef]

- Ye, Y.D.; Kure-Chu, S.Z.; Sun, Z.Y.; Li, X.P.; Wang, H.B.; Tang, G.Y. Nanocrystallization and enhanced surface mechanical properties of commercial pure titanium by electropulsing-assisted ultrasonic surface rolling. Mater. Des. 2018, 149, 214–227. [Google Scholar] [CrossRef]

- Omoigiade, O. Microstructure and Properties of Electropulsed High Carbon Steel Wire Rod. Ph.D. Thesis, Imperial College London, London, UK, 2018. [Google Scholar]

- Lawson, A.W. The effect of hydrostatic pressure on the electrical resistivity of metals. Prog. Phys. Met. 1956, 6, 1–44. [Google Scholar] [CrossRef]

- Palani, P.K.; Murugan, N. Selection of parameters of pulsed current gas metal arc welding. J. Mater. Proc. Technol. 2006, 172, 1–10. [Google Scholar] [CrossRef]

- Yang, M.X.; Bai, R.R.; Zheng, H.; Qi, B.J. Temperature monitoring and calibration in Ti-6Al-4V molten pool with pulsed arc welding. Sci. Technol. Weld. Join. 2020, 25, 369–376. [Google Scholar] [CrossRef]

- Ram, G.D.J.; Reddy, A.V.; Rao, K.P.; Reddy, G.M. Control of Laves phase in Inconel 718 GTA welds with current pulsing. Sci. Technol. Weld. Join. 2004, 9, 390–398. [Google Scholar]

- Onodera, Y.; Hirano, K.I. The effect of direct electric current on precipitation in a bulk Al-4 wt% Cu alloy. J. Mater. Sci. 1976, 11, 809–816. [Google Scholar] [CrossRef]

- Onodera, Y.; Maruyama, J.I.; Hirano, K.I. Retardation of the precipitation reaction by d.c. stress in an Al-12.5 wt% Zn alloy. J. Mater. Sci. 1977, 12, 1109–1114. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, R. Critical Assessment of the Electric Effect in Electric Arc Welding. Metals 2021, 11, 1917. https://doi.org/10.3390/met11121917

Qin R. Critical Assessment of the Electric Effect in Electric Arc Welding. Metals. 2021; 11(12):1917. https://doi.org/10.3390/met11121917

Chicago/Turabian StyleQin, Rongshan. 2021. "Critical Assessment of the Electric Effect in Electric Arc Welding" Metals 11, no. 12: 1917. https://doi.org/10.3390/met11121917

APA StyleQin, R. (2021). Critical Assessment of the Electric Effect in Electric Arc Welding. Metals, 11(12), 1917. https://doi.org/10.3390/met11121917