Microstructure and Mechanical Properties of Cast and Hot-Rolled Medium-Carbon Steels under Isothermal Heat-Treatment Conditions

Abstract

:1. Introduction

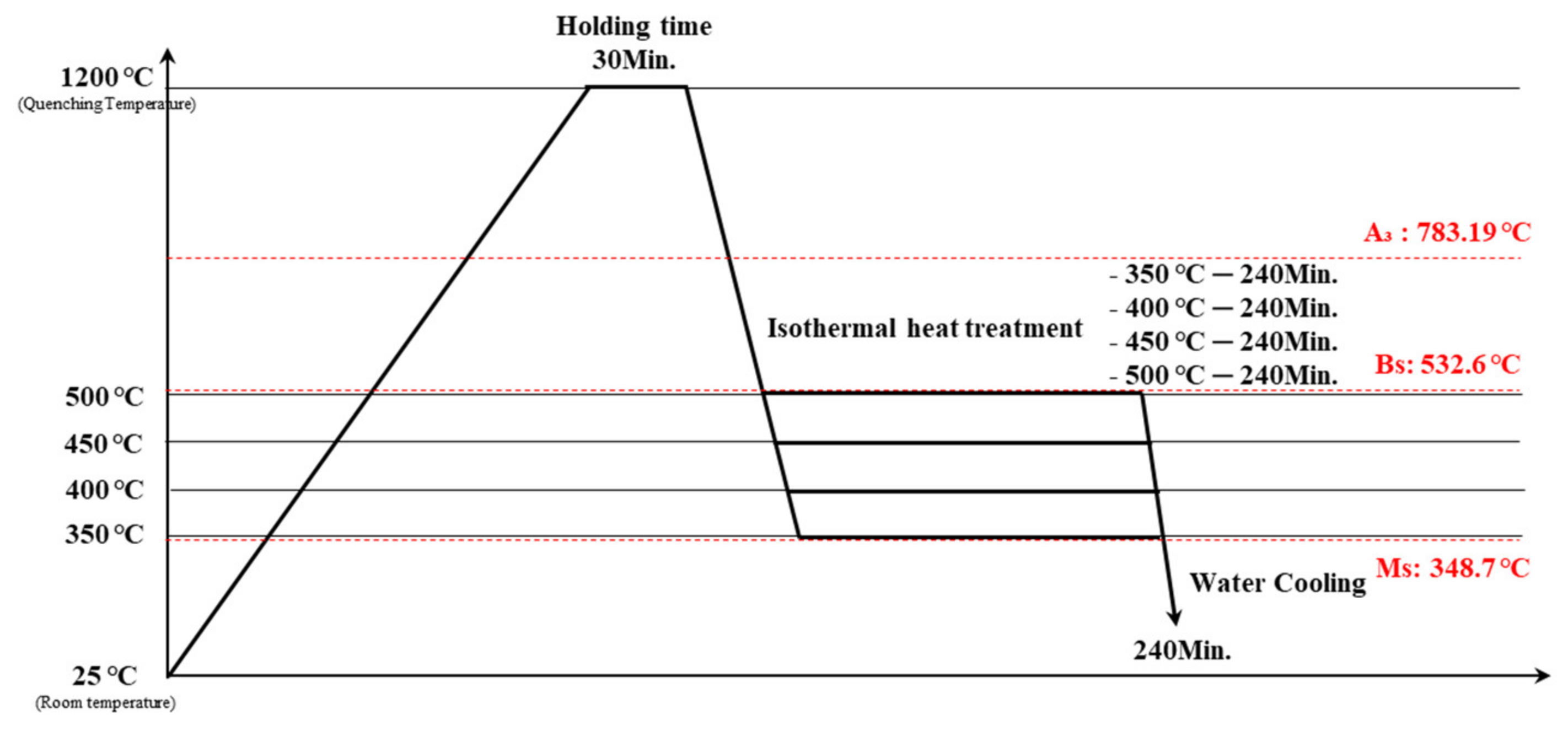

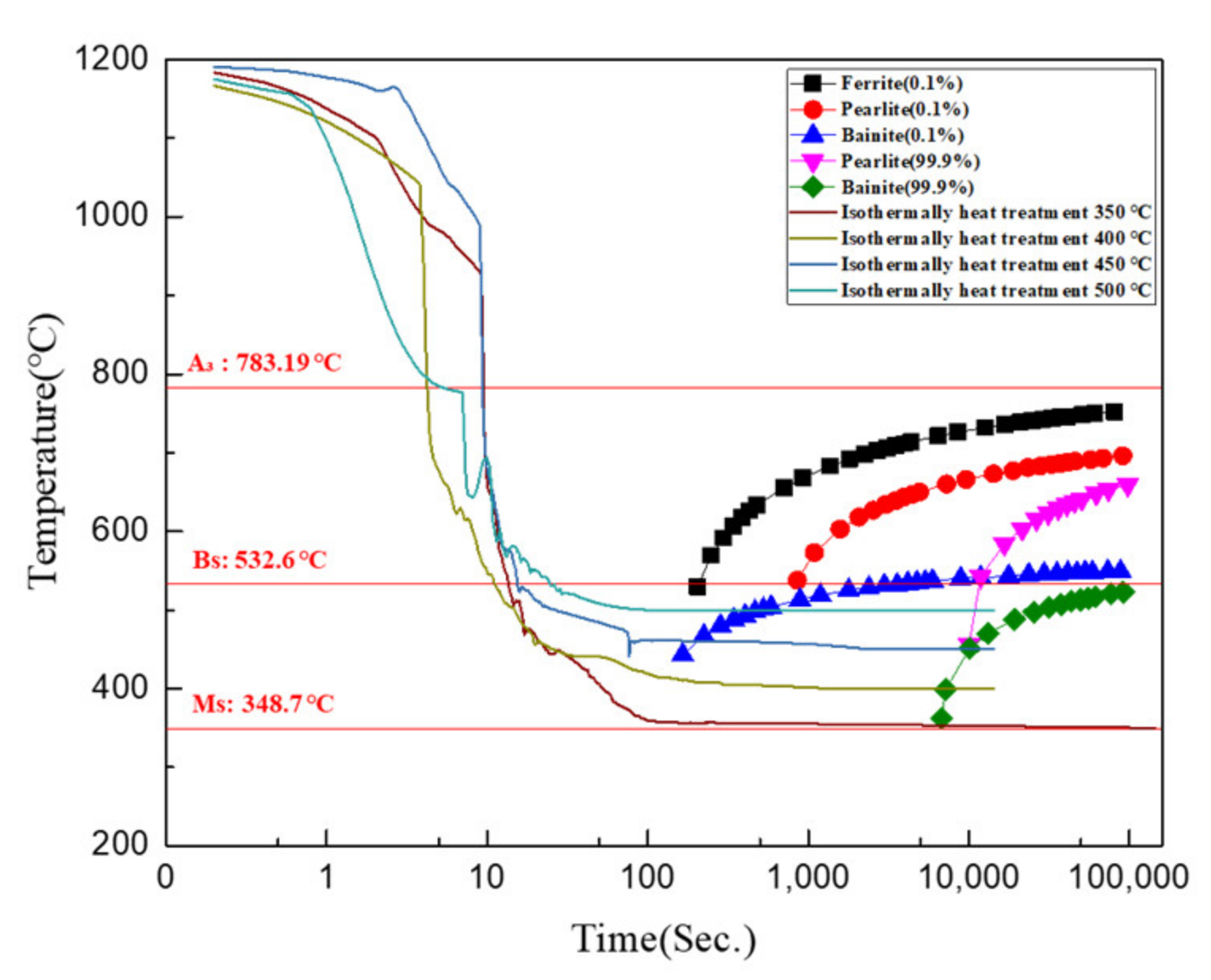

2. Materials and Methods

3. Results and Discussion

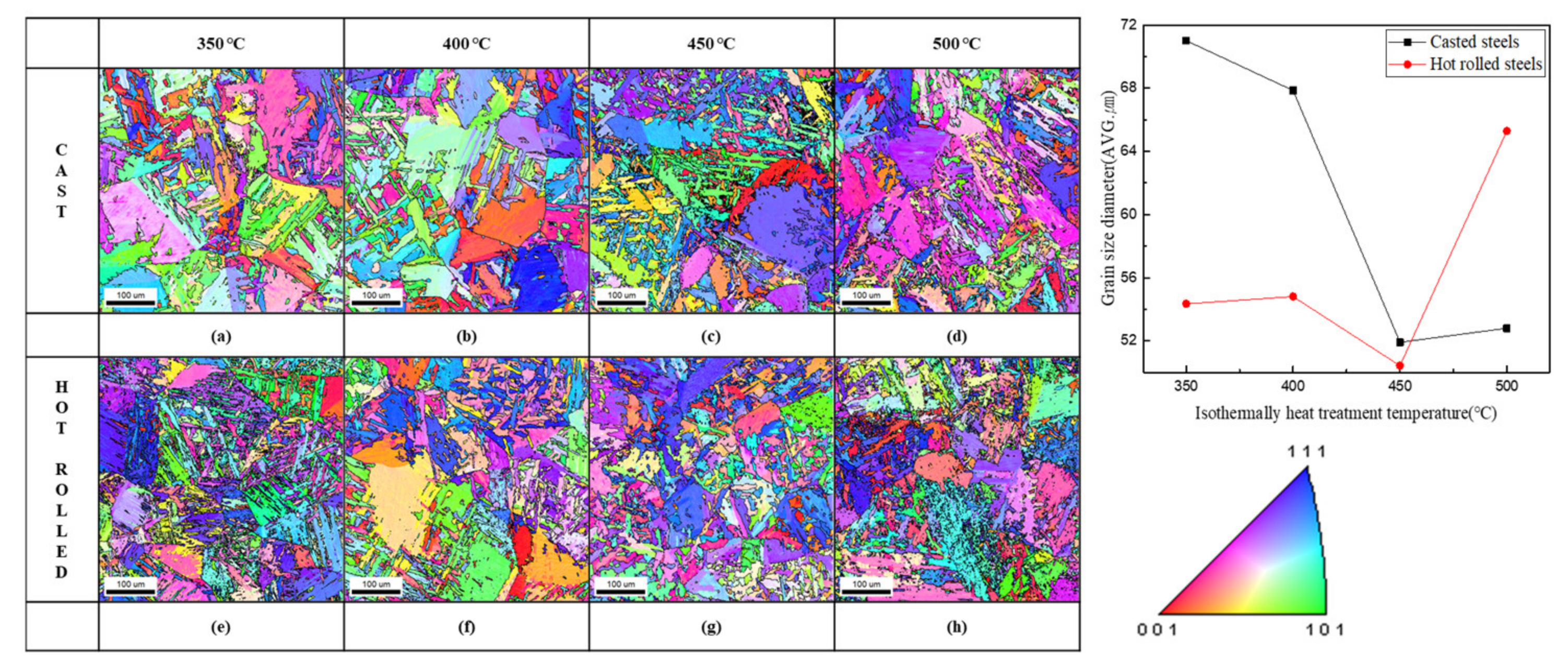

3.1. Microstructure

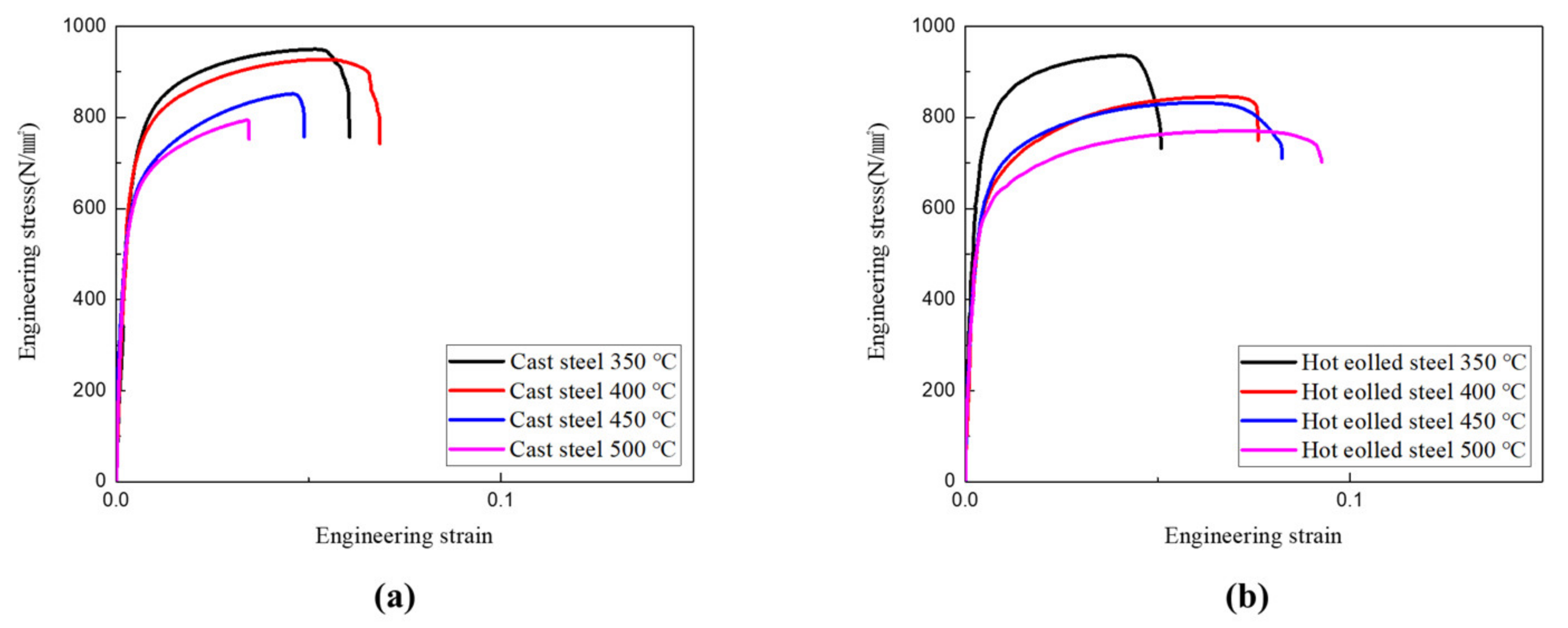

3.2. Mechanical Properties

4. Conclusions

- There was a difference in the phase transformation and phase fraction of cast steel and hot-rolled medium-carbon low-alloy steel during isothermal heat treatment at 350~500 °C for 240 min. The cast and hot-rolled steel were not completely transformed into bainitic ferrite.

- When the isothermal heat-treatment temperature decreased, the bainitic ferrite phase became more prevalent, but the opposite behavior was observed for acicular ferrite. Austenite which did not transform into bainitic ferrite during isothermal heat treatment mostly transformed into martensite.

- When the isothermal heat-treatment temperature was 500 °C, the major phases were Widmanstätten ferrite and pearlite in both the cast and hot-rolled steels.

- The average grain size of cast steel decreases rapidly from 350 to 450 °C; and at 500 °C, it is similar to 450 °C. Hot-rolled steel decreases moderately from 350 to 450 °C but increases rapidly at 500 °C. The yield strength of the cast and hot-rolled steel decreases as the isothermal heat-treatment temperature increases. The yield strength of cast steel decreases rapidly as it increases from 400 to 450 °C, and the yield strength of hot-rolled steel decreases rapidly as it increases from 350 to 400 °C. Hardness showed a similar trend to yield strength. At each isothermal heat-treatment temperature, mechanical properties depend on complex factors such as phase fractions, and grain size.

- The highest strength and hardness were exhibited at the isothermal heat-treatment temperature of 350 °C, which was similar to the Ms temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ståhlkrantz, A.; Hedström, P.; Sarius, N.; Sundberg, H.; Kahl, S.; Thuvander, M.; Borgenstam, A. Effect of Tempering on the Bainitic Microstructure Evolution Correlated with the Hardness in a Low-Alloy Medium-Carbon Steel. Metall. Mater. Trans. A 2020, 51A, 6470–6481. [Google Scholar] [CrossRef]

- Podder, A.S. Tempering of a mixture of bainite and retained austenite. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2011. [Google Scholar]

- Peet, M.J. Transformation and tempering of low-temperature bainite. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2010. [Google Scholar]

- Peet, M.J.; Babu, S.S.; Miller, M.K.; Bhadeshia, H. Tempering of low-temperature bainite. Metall. Mater. Trans. A 2017, 48A, 3410–3418. [Google Scholar] [CrossRef] [Green Version]

- He, S.; He, B.; Zhu, K.; Huang, M. On the correlation among dislocation density, lath thickness and yield stress of bainite. Acta Mater. 2017, 135, 382–389. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Peet, M.; Caballero, F.; Bhadeshia, H. Tempering of hard mixture of bainitic ferrite and austenite. Mater. Sci. Technol. 2004, 20, 814–818. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F. Ultra-high-strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef] [Green Version]

- Steven, W.; Haynes, A.G.J. The temperature of formation of martensite and bainite in low alloy steels, some effects of chemical composition. J. Iron Steel Inst. 1956, 183, 349. [Google Scholar]

- Krauss, G. Deformation and fracture in martensitic carbon steels tempered at low temperatures. Metall. Mater. Trans. B 2001, 32, 205–221. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels: Transformation, Microstructure and Properties, 2nd ed.; IOM Communications Ltd: London, UK, 2001. [Google Scholar]

- Tomita, Y. Effect of martensite morphology on mechanical properties of low alloy steels having mixed structure of martensite and lower bainite. Mater. Sci. Technol. 1991, 7, 299–306. [Google Scholar] [CrossRef]

- Tomita, Y.; Okabayashi, K. Mechanical properties of 0.40 pct C-Ni-Cr-Mo high strength steel having a mixed structure of martensite and bainite. Metall. Trans. A 1985, 16, 73–82. [Google Scholar] [CrossRef]

- Rao, T.V.L.N.; Dikshit, S.N.; Malakondaiah, G.; Rao, P.R. On mixed upper bainite-martensite in an AISI 4330 steel exhibiting an uncommonly improved strength-toughness combination. Scr. Metall. Mater. 1990, 24, 1323–1328. [Google Scholar] [CrossRef]

- Kirkaldy, J.S. Prediction of microstructure and hardenability in low alloy steels. In Proceedings of the International Conference on Phase Transformation in Ferrous Alloys, Philadelphia, PA, USA, 4–6 October 1983; AIME: Warrendale, PA, USA, 1983; pp. 125–148. [Google Scholar]

- Bramfitt, B.L.; Speer, J.G. A perspective on the morphology of bainite. Metall. Trans. A 1990, 21, 817. [Google Scholar] [CrossRef]

- Araki, T.; Kozasu, I.; Tankechi, H.; Shibata, K.; Enomoto, M.; Tamehiro, H. Atlas for Bainitic Microstructures, Continuous-Cooled Zw Microstructures of Low-Carbon Steel; ISIJ: Tokyo, Japan, 1992; Volume 1, pp. 4–5. [Google Scholar]

- Krauss, G.; Thompson, S.W. Ferritic microstructures in continuously cooled low-and ultralow-carbon steels. ISIJ 1995, 35, 937. [Google Scholar] [CrossRef]

- Koo, J.Y.; Luton, M.J.; Bangaru, N.V.; Petkovic, R.A.; Fairchild, D.P.; Petersen, C.W.; Asahi, H.; Hara, T.; Terada, Y.; Sugiyama, M.; et al. Metallurgical design of ultra-high strength steels for gas pipelines. In Proceedings of the Thirteenth International Offshore and Polar Engineering Conference; ISOPE: Honolulu, HI, USA, 2003; p. 10. [Google Scholar]

- LePera, F.S. Improved etching technique for the determination of percent martensite in high-strength dual-phase steels. Metallography 1979, 12, 263. [Google Scholar] [CrossRef]

- Zakerinia, H.; Kermanpur, A.; Najafizadeh, A. Color metallography; a suitable method for characterization of martensite and bainite in multiphase steels. ISSI 2009, 6, 14. [Google Scholar]

- Ohmori, Y.; Honeycombe, R.W.K. The isothermal transformation of plain carbon austenite. Suppl. Trans. ISIJ 1971, 11, 1160–1164. [Google Scholar]

- Quidort, D.; Bréchet, Y. The role of carbon on the kinetics of bainite transformation in steels. Scr. Mater. 2002, 47, 151. [Google Scholar] [CrossRef]

- Quidort, D.; Brechet, Y.J. A model of isothermal and non isothermal transformation kinetics of bainite in 0.5% C steels. ISIJ Int. 2002, 42, 1010. [Google Scholar] [CrossRef]

- Yin, J.; Hillert, M.; Borgenstam, A. Morphology of upper and lower bainite with 0.7 mass pct C. Metall. Mater. Trans. A 2017, 48A, 4006–4024. [Google Scholar] [CrossRef]

- Sandvik, B.P.J. The bainite reaction in Fe-Si-C alloys: The secondary stage. Metall. Trans. A 1982, 13A, 789–800. [Google Scholar] [CrossRef]

- Tsuzaki, K.; Kodai, A.; Maki, T. Formation mechanism of bainitic ferrite in an Fe-2 Pct Si-0.6 Pct C alloy. Metall. Mater. Trans. A 1994, 25A, 2009–2016. [Google Scholar] [CrossRef]

- Okaguchi, S.; Ohtani, H.; Ohmori, Y. Morphology of Widmanstätten and bainitic ferrites. Mater. Trans. 1991, 32, 697–704. [Google Scholar] [CrossRef] [Green Version]

- Aaronson, H.I.; Spanos, G.; Masamura, R.A.; Vardiman, R.G.; Moon, D.W.; Menon, E.S.K.; Hall, M.G. Sympathetic nucleation: An overview. Mater. Sci. Eng. B 1995, 32, 107–123. [Google Scholar] [CrossRef]

- Aaronson, H.I.; Reynolds, W.T.; Purdy, G.R. The incomplete transformation phenomenon in steel. Metall. Mater. Trans. A 2006, 37, 1731–1745. [Google Scholar] [CrossRef]

- Wu, K.M.; Enomoto, M. Three-dimensional morphology of degenerate ferrite in an Fe–C–Mo alloy. Scr. Mater. 2002, 46, 569–574. [Google Scholar] [CrossRef]

- Lee, E.H.; Yu, C.J.; Lee, H.B.; Kim, J.H.; Suh, D.W. Influence of Si and Al contents and isothermal treatment condition on the microstructure and tensile properties in ultra-high strength Fe-0.2C-2.0Mn martensite-bainite complex phase steels. Korean J. Met. Mater. 2021, 59, 602–612. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef]

- Lee, J.M.; Lee, S.I.; Lim, H.S.; Hwang, B. Effect of Isothermal Heat Treatment on the Microstructure and Mechanical Properties of Medium-Carbon Bainitic Steels. Korean J. Mater. Res. 2018, 28, 522. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.N.; Kang, C.Y. Effect of Thermo-mechanical Treatment on the Formation Behavior of Martensite in 316L Stainless Steel. Korean J. Met. Mater. 2018, 56, 265. [Google Scholar]

- Kang, J.; Zhang, F.; Long, X.; Lv, B. Low cycle fatigue behavior in a medium-carbon carbide-free bainitic steel. Mater. Sci. Eng. A 2016, 666, 88–93. [Google Scholar] [CrossRef]

- Sourmail, T.; Smanio, V. Low temperature kinetics of bainite formation in high carbon steels. Acta Mater. 2013, 61, 2639–2648. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Beladi, H.; Xiong, X.; Adachi, Y.; Hodgson, P.D. Nano scale microstructural characterization of a nanobainitic steel. Acta Mater. 2011, 59, 5511–5522. [Google Scholar] [CrossRef]

- Chen, C.T.; Lei, T.S. The processing window for austempering ductile iron. Mater. Tran. JIM 1999, 40, 82–85. [Google Scholar] [CrossRef]

- Sandvik, B.P.J.; Wayman, C.M. Characteristics of lath martensite: Part I. Crystallographic and substructural features. Metall. Trans. A 1983, 14, 809. [Google Scholar] [CrossRef]

- Hatem, T.M.; Zikry, M.A. A model for determining initial dislocation-densities associated with martensitic transformations. Mater. Sci. Technol. 2011, 27, 1570. [Google Scholar] [CrossRef]

- Madariaga, I.; Romero, J.L.; Gutierrez, I. Upper acicular ferrite formation in a medium-carbon micro alloyed steel by isothermal transformation: Nucleation enhance-ment by CuS. Metall. Mater. Trans. A 1998, 29, 1003–1115. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Cu | Al | Mo | Ti | V | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.314 | 0.539 | 1.321 | 0.019 | 0.011 | 0.515 | 0.252 | 0.084 | 0.028 | 0.028 | 0.002 | 0.006 | 0.015 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, B.; Kim, K.; Yi, S.; Choi, S.; Hyun, S. Microstructure and Mechanical Properties of Cast and Hot-Rolled Medium-Carbon Steels under Isothermal Heat-Treatment Conditions. Metals 2021, 11, 1950. https://doi.org/10.3390/met11121950

Shin B, Kim K, Yi S, Choi S, Hyun S. Microstructure and Mechanical Properties of Cast and Hot-Rolled Medium-Carbon Steels under Isothermal Heat-Treatment Conditions. Metals. 2021; 11(12):1950. https://doi.org/10.3390/met11121950

Chicago/Turabian StyleShin, Byungsue, Kwangyuk Kim, Sung Yi, Sanggyu Choi, and Soongkeun Hyun. 2021. "Microstructure and Mechanical Properties of Cast and Hot-Rolled Medium-Carbon Steels under Isothermal Heat-Treatment Conditions" Metals 11, no. 12: 1950. https://doi.org/10.3390/met11121950

APA StyleShin, B., Kim, K., Yi, S., Choi, S., & Hyun, S. (2021). Microstructure and Mechanical Properties of Cast and Hot-Rolled Medium-Carbon Steels under Isothermal Heat-Treatment Conditions. Metals, 11(12), 1950. https://doi.org/10.3390/met11121950