Design against Fatigue of Super Duplex Stainless Steel Structures Fabricated by Wire Arc Additive Manufacturing Process

Abstract

:1. Introduction

2. Materials and Methods

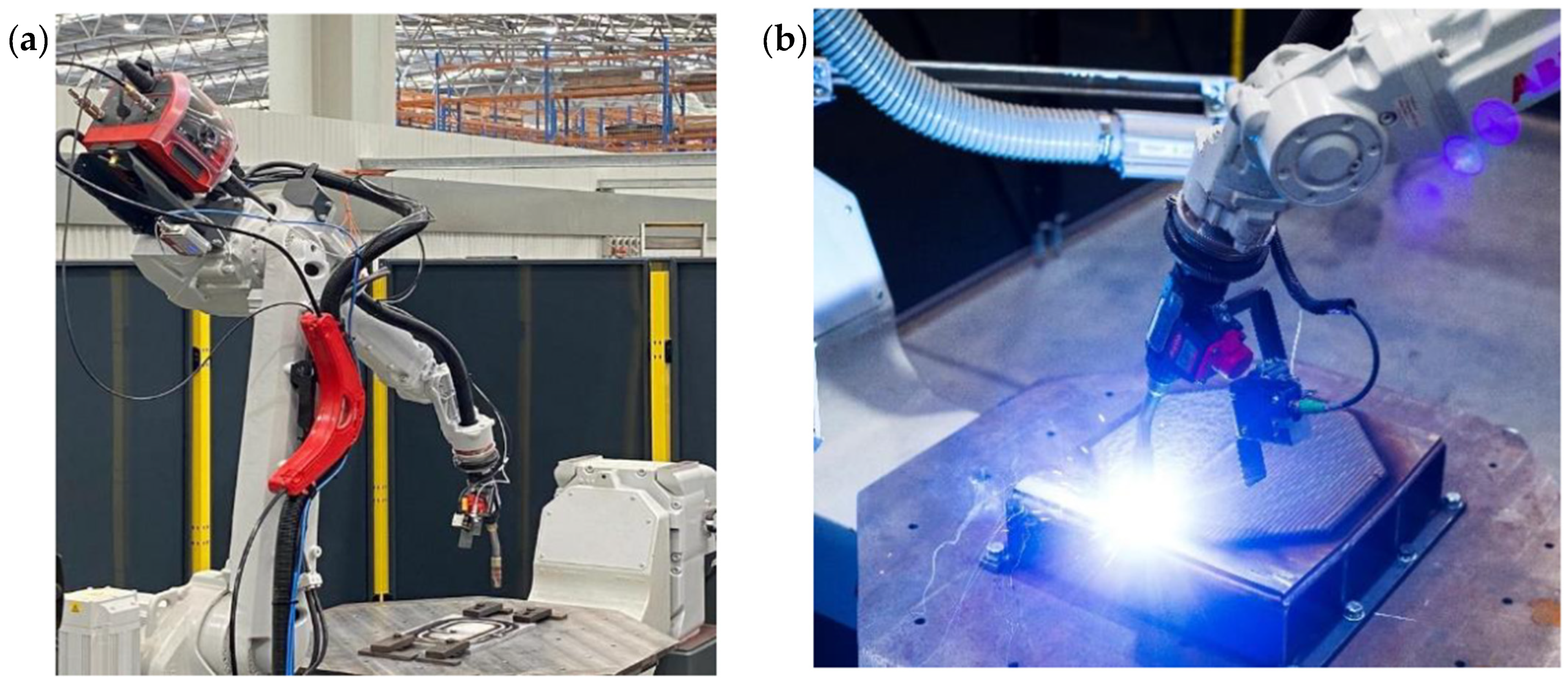

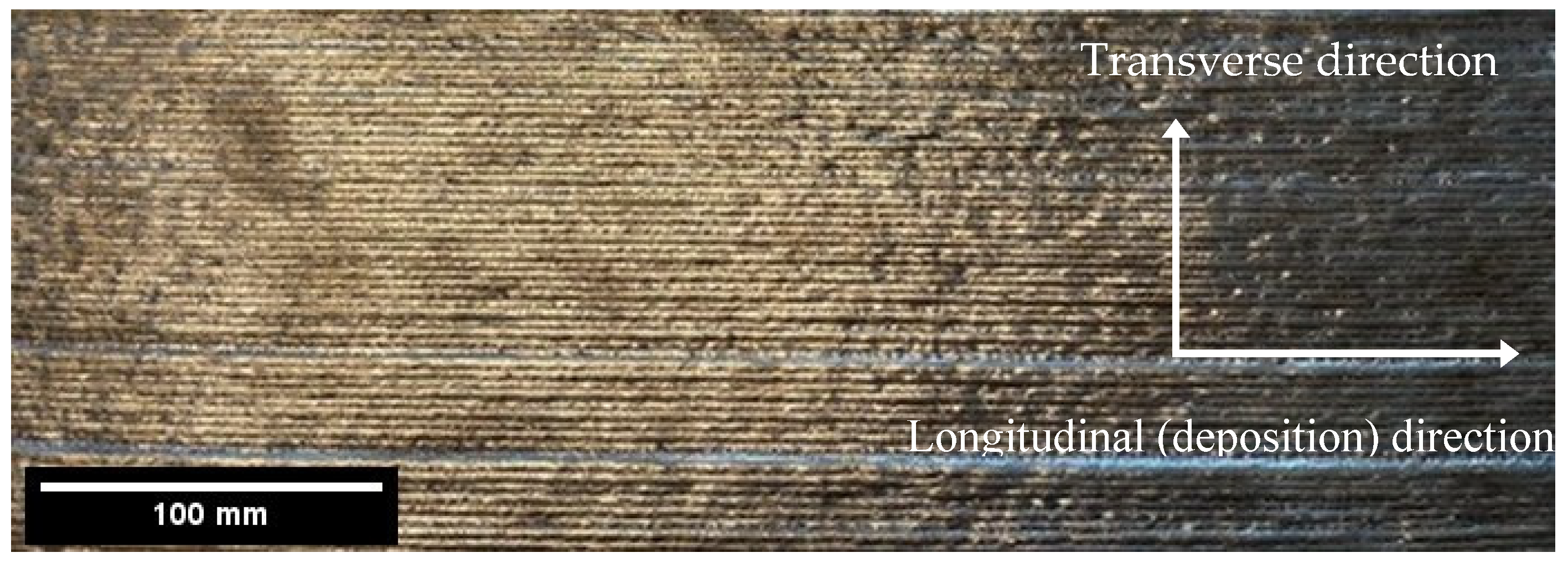

2.1. WAAM Processing

2.2. Mechanical Testing

3. Results and Discussion

3.1. Microstructure Examination

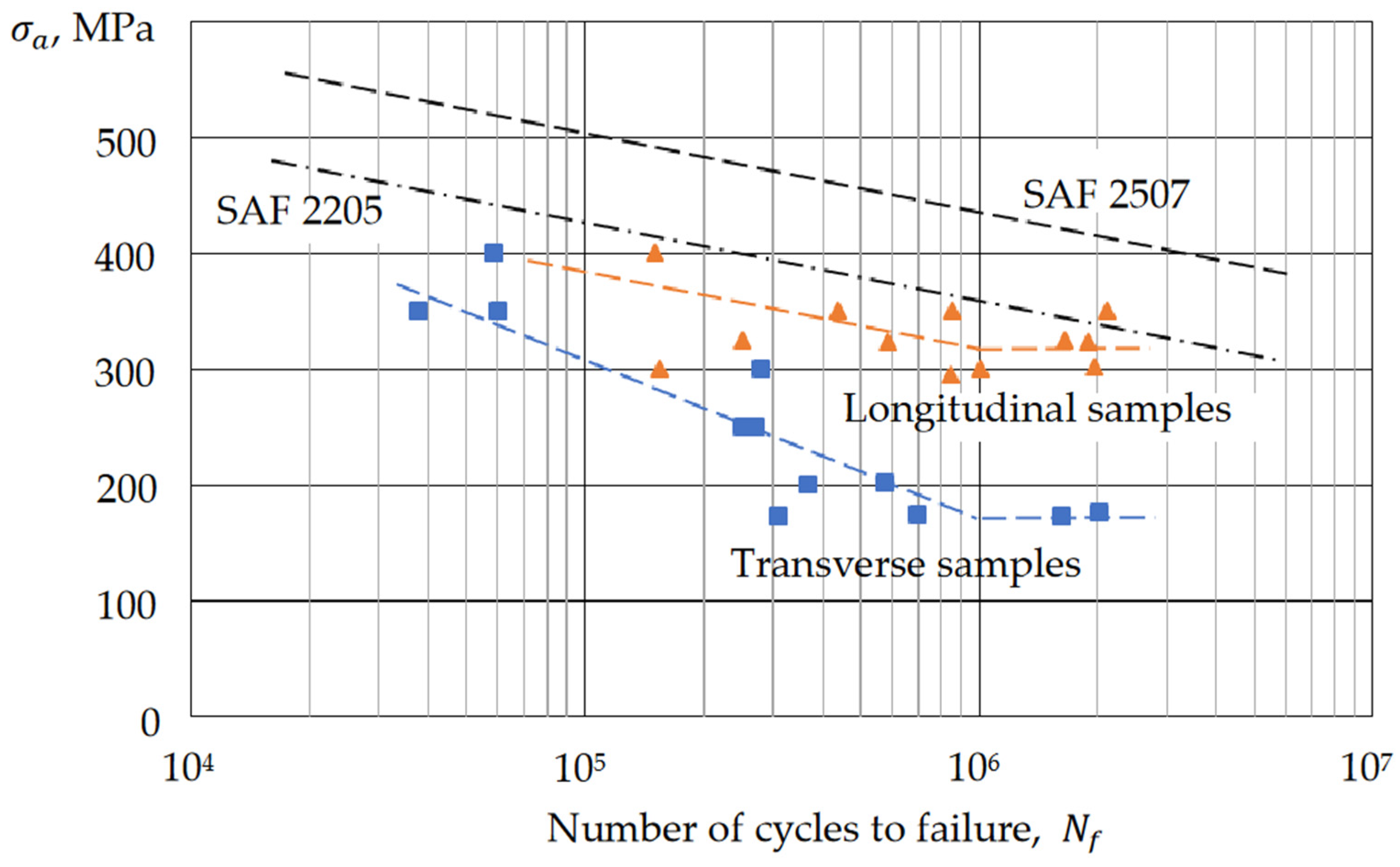

3.2. Mechanical Testing

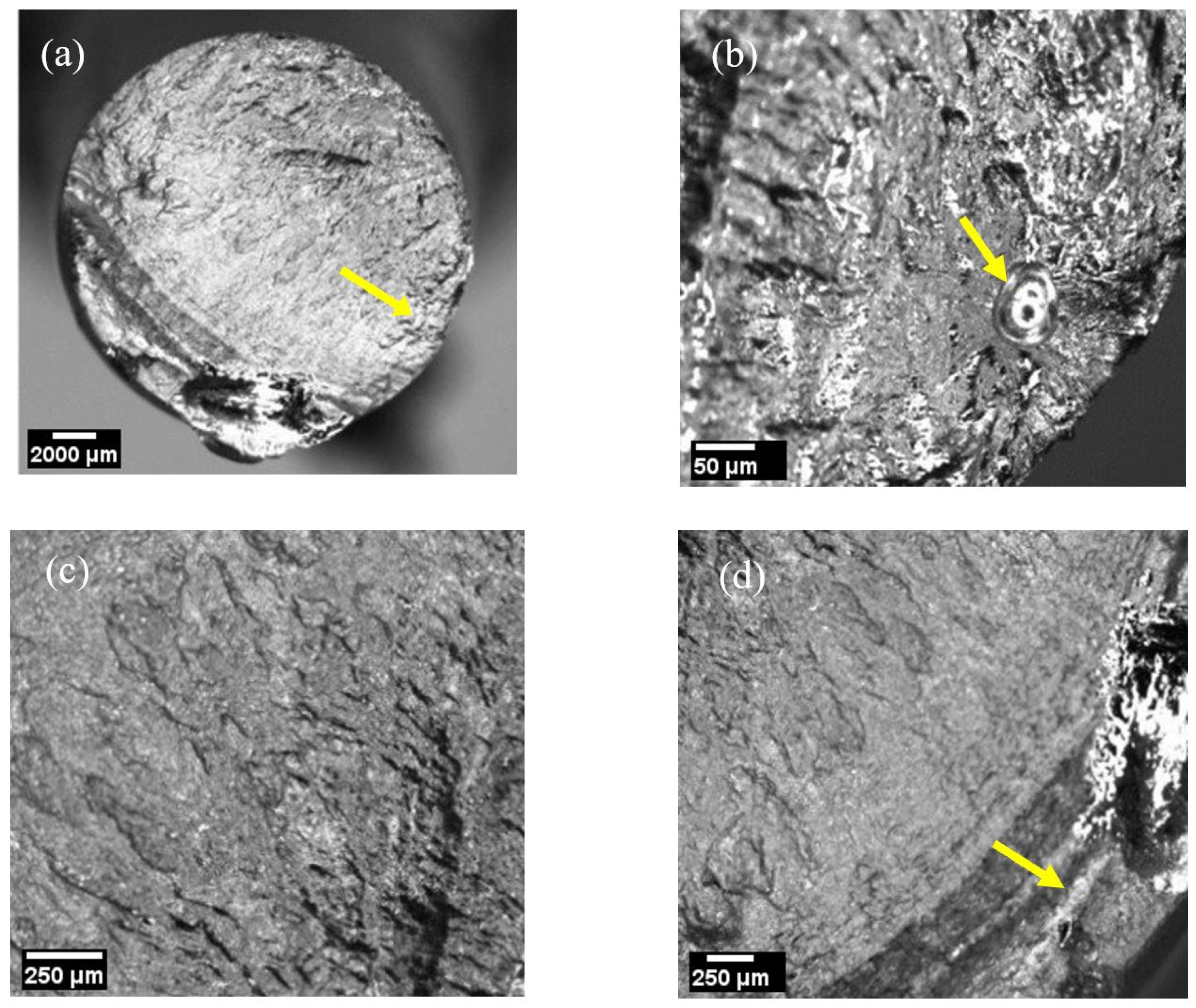

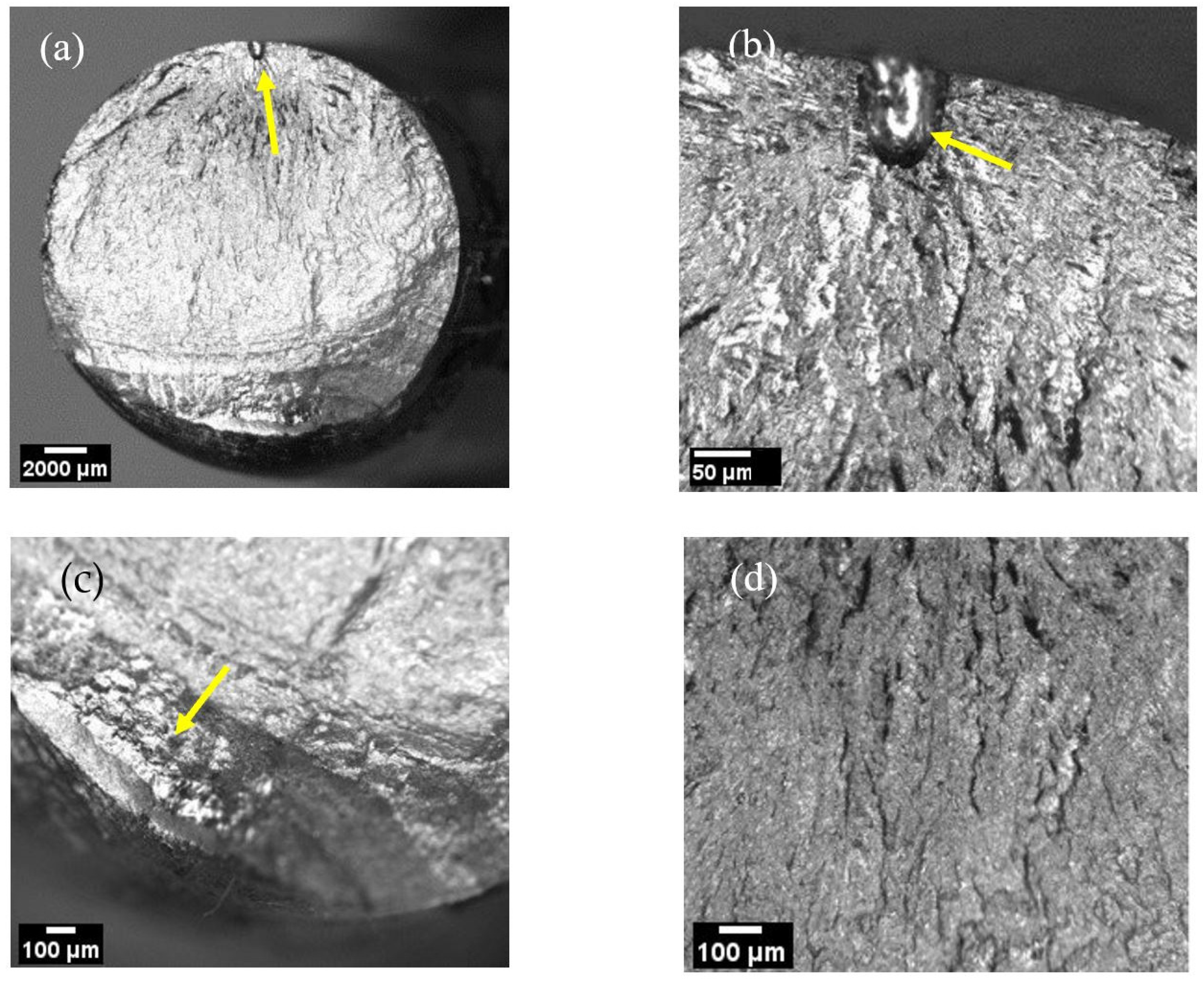

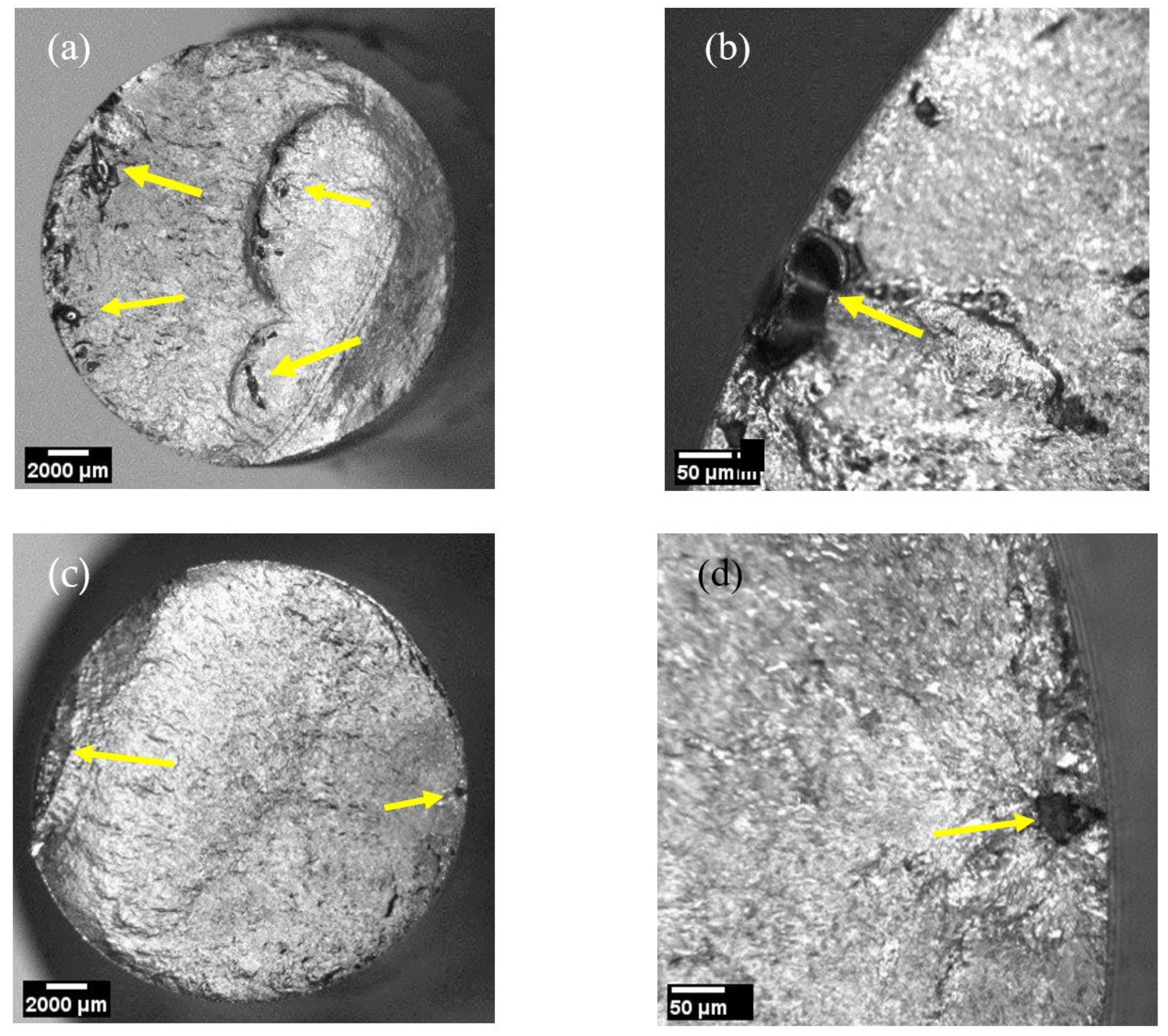

3.3. Fractography

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Murr, L.E. Global trends in the development of complex, personalized, biomedical, surgical implant devices using 3D printing/additive manufacturing: A review. Med. Devices Sens. 2020, 3, e10126. [Google Scholar] [CrossRef]

- Murr, L.; Johnson, W.L. 3D metal droplet printing development and advanced materials additive manufacturing. J. Mater. Res. Technol. 2017, 6, 77–89. [Google Scholar] [CrossRef]

- Wu, Q.; Mukherjee, T.; De, A.; DebRoy, T. Residual stresses in wire-arc additive manufacturing—Hierarchy of influential variables. Addit. Manuf. 2020, 35, 101355. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire+ arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- AWS D20.1D20.1 2019 Specification for Fabrication of Metal Components using additive manufacturing.

- PAS6010 Additive Manufacturing—Wire for directed energy deposition (DED) processes in additive manufacturing—Specification.

- ASTM F3187-16—Standard Guide for Direct Energy Deposition of Metals.

- ISO-ASTM 52900-15—Additive Manufacturing.

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Xiong, J.; Li, Y.; Li, R.; Yin, Z. Influences of process parameters on sur-face roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J. Mater. Process. Technol. 2018, 252, 128–136. [Google Scholar] [CrossRef]

- Wächter, M.; Leicher, M.; Hupka, M.; Leistner, C.; Masendorf, L.; Treutler, K.; Kamper, S.; Esderts, A.; Wesling, V.; Hartmann, S. Monotonic and Fatigue Properties of Steel Material Manufactured by Wire Arc Additive Manufacturing. Appl. Sci. 2020, 10, 5238. [Google Scholar] [CrossRef]

- Nikam, P.P.; Arun, D.; Ramkumar, K.D.; Sivashanmugam, N. Microstructure characterization and tensile properties of CMT-based wire plus arc additive manufactured ER2594. Mater. Charact. 2020, 169, 110671. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Paddea, S.; Zhang, X. Fatigue crack propagation behaviour in wire+arc additive manufactured Ti-6Al-4V: Effects of microstructure and residual stress. Mater. Des. 2016, 90, 551–561. [Google Scholar] [CrossRef]

- Dirisu, P.; Ganguly, S.; Mehmanparast, A.; Martina, F.; Williams, S. Analysis of fracture toughness properties of wire + arc additive manufactured high strength low alloy structural steel components. Mater. Sci. Eng. A 2019, 765. [Google Scholar] [CrossRef]

- Duraisamy, R.; Kumar, S.M.; Kannan, A.R.; Shanmugam, N.S.; Sankaranarayanasamy, K. Fatigue Behavior of Austenitic Stainless Steel 347 Fabricated via Wire Arc Additive Manufacturing. J. Mater. Eng. Perform. 2021, 30, 6844–6850. [Google Scholar] [CrossRef]

- Karlsson, L. Welding of duplex stainless steels—A review of current recommendations. Weld. World 2012, 56, 65–76. [Google Scholar] [CrossRef]

- Kannan, A.R.; Shanmugam, N.S.; Rajkumar, V.; Vishnukumar, M. Insight into the microstructural features and corrosion properties of wire arc additive manufactured super duplex stainless steel (ER2594). Mater. Lett. 2020, 270, 127680. [Google Scholar] [CrossRef]

- Polak, J. Cyclic Plastic Response and Fatigue Life of Duplex and SuperDuplex Stainless Steels. Kov. Mater. 2005, 43, 280–289. [Google Scholar]

- Björk, T.; Mettänen, H.; Ahola, A.; Lindgren, M.; Terva, J. Fatigue strength assessment of duplex and super-duplex stainless steels by 4R method. Weld. World 2018, 62, 1285–1300. [Google Scholar] [CrossRef]

- Akdut, N. Phase morphology and fatigue lives of nitrogen alloyed duplex stainless steels. Int. J. Fatigue 1999, 21, 97–103. [Google Scholar] [CrossRef]

- Stützer, J.; Totzauer, T.; Wittig, B.; Zinke, M.; Jüttner, S. GMAW Cold Wire Technology for Adjusting the Ferrite–Austenite Ratio of Wire and Arc Additive Manufactured Duplex Stainless Steel Components. Metals 2019, 9, 564. [Google Scholar] [CrossRef] [Green Version]

- ASTM. E8/E8M-16A Standard Test Methods for Tension Testing of Metallic Materials; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Lervåg, M.; Sørensen, C.; Robertstad, A.; Brønstad, B.M.; Nyhus, B.; Eriksson, M.; Aune, R.; Ren, X.; Akselsen, O.M.; Bunaziv, I. Additive Manufacturing with Superduplex Stainless Steel Wire by CMT Process. Metals 2020, 10, 272. [Google Scholar] [CrossRef] [Green Version]

- Mateo, A.; Llanes, L.; Akdut, N.; Stolarz, J.; Anglada, M. Anisotropy effects on the fatigue behaviour of rolled duplex stainless steels. Int. J. Fatigue 2003, 25, 481–488. [Google Scholar] [CrossRef]

- Jebaraj, A.V.; Kumar, L.A.; Deepak, C. Investigations on Anisotropy Behavior of Duplex Stainless Steel AISI 2205 for Optimum Weld Properties. Procedia Eng. 2017, 173, 883–890. [Google Scholar] [CrossRef]

| C | Mn | W | Si | Cr | Ni | Mo | N | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.014 | 0.57 | <0.01 | 0.32 | 25.36 | 9.22 | 3.99 | 0.25 | 0.08 | Balance |

| Parameters | Values |

|---|---|

| Contact tip to work distance (CTWD) | 15.0 mm |

| Wire diameter | 1.2 mm |

| Shielding gas | 80% Ar + 20% CO2 |

| Flow rate | 20 L/min |

| Inter-pass temperature | 150 °C |

| Wire-feed speed (WFS) | 9.0 m/min |

| Travel speed (TS) | 0.6 m/min |

| WFS/TS | 15 |

| Layer height (LH) | 2.5 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sales, A.; Kotousov, A.; Yin, L. Design against Fatigue of Super Duplex Stainless Steel Structures Fabricated by Wire Arc Additive Manufacturing Process. Metals 2021, 11, 1965. https://doi.org/10.3390/met11121965

Sales A, Kotousov A, Yin L. Design against Fatigue of Super Duplex Stainless Steel Structures Fabricated by Wire Arc Additive Manufacturing Process. Metals. 2021; 11(12):1965. https://doi.org/10.3390/met11121965

Chicago/Turabian StyleSales, Andrew, Andrei Kotousov, and Ling Yin. 2021. "Design against Fatigue of Super Duplex Stainless Steel Structures Fabricated by Wire Arc Additive Manufacturing Process" Metals 11, no. 12: 1965. https://doi.org/10.3390/met11121965