Corner Strengthening by Local Thickening and Ausforming Using Planar Compression in Hot Stamping of Ultra-High Strength Steel Parts

Abstract

1. Introduction

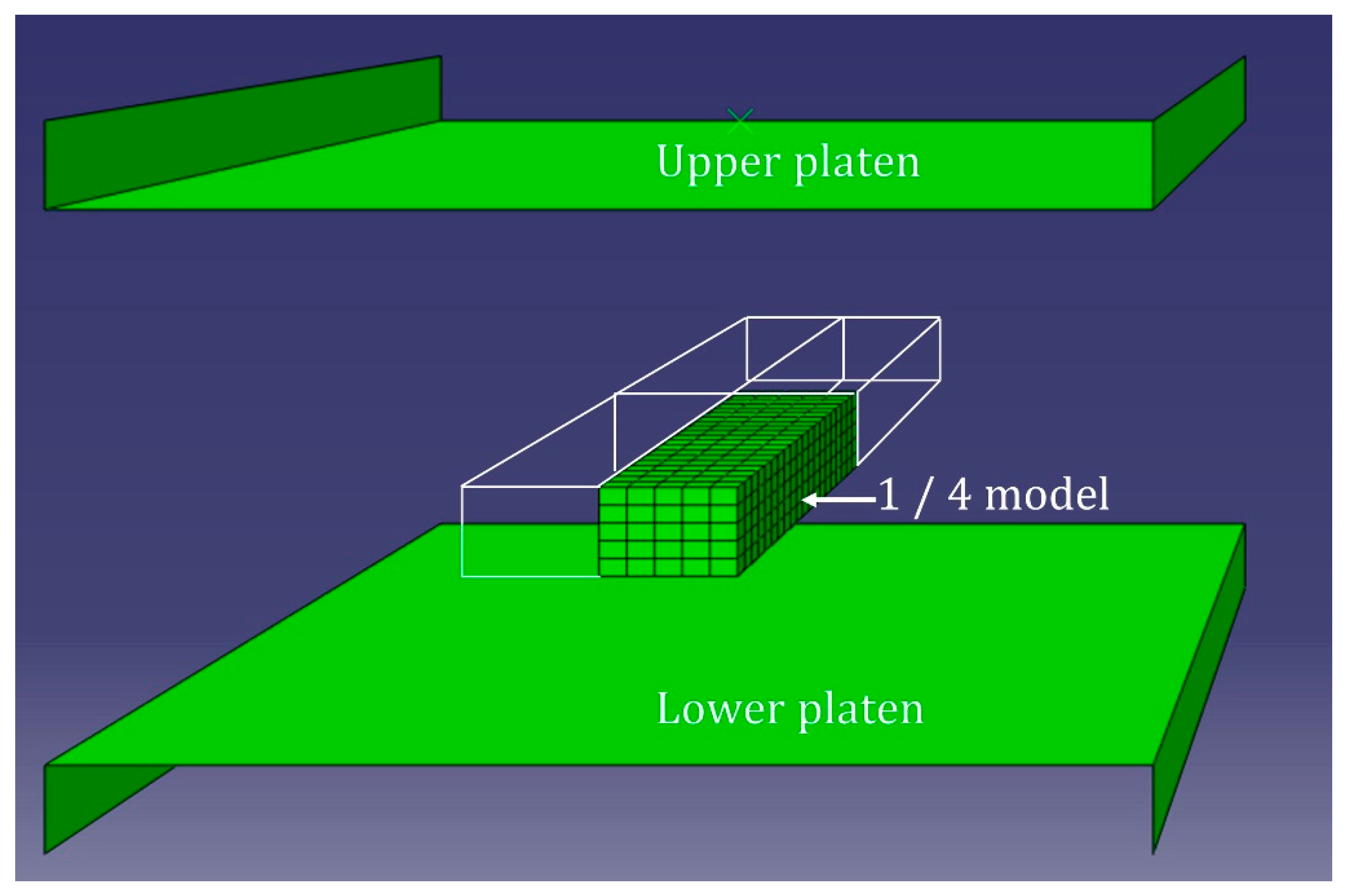

2. Corner Strengthening by Local Thickening and Ausforming Using Planar Compression in Hot Stamping

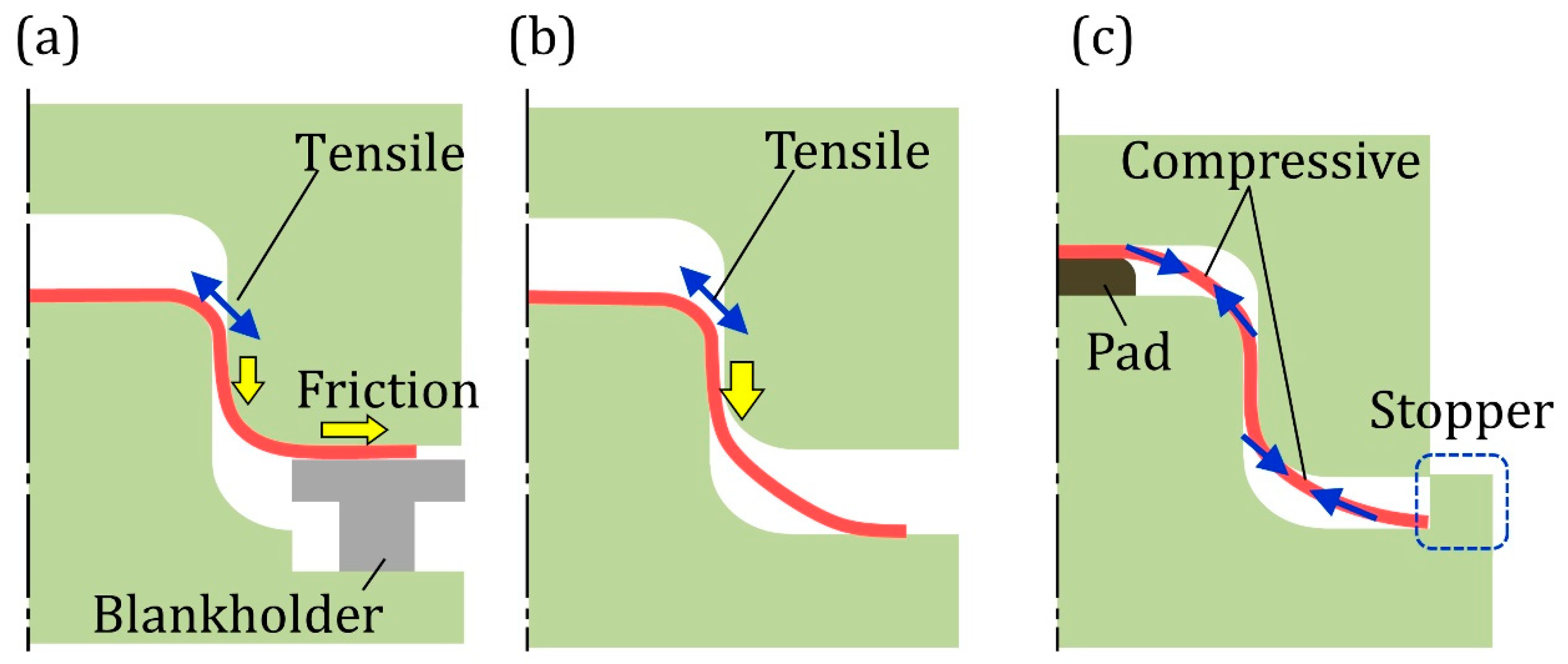

2.1. Approach of Local Thickening

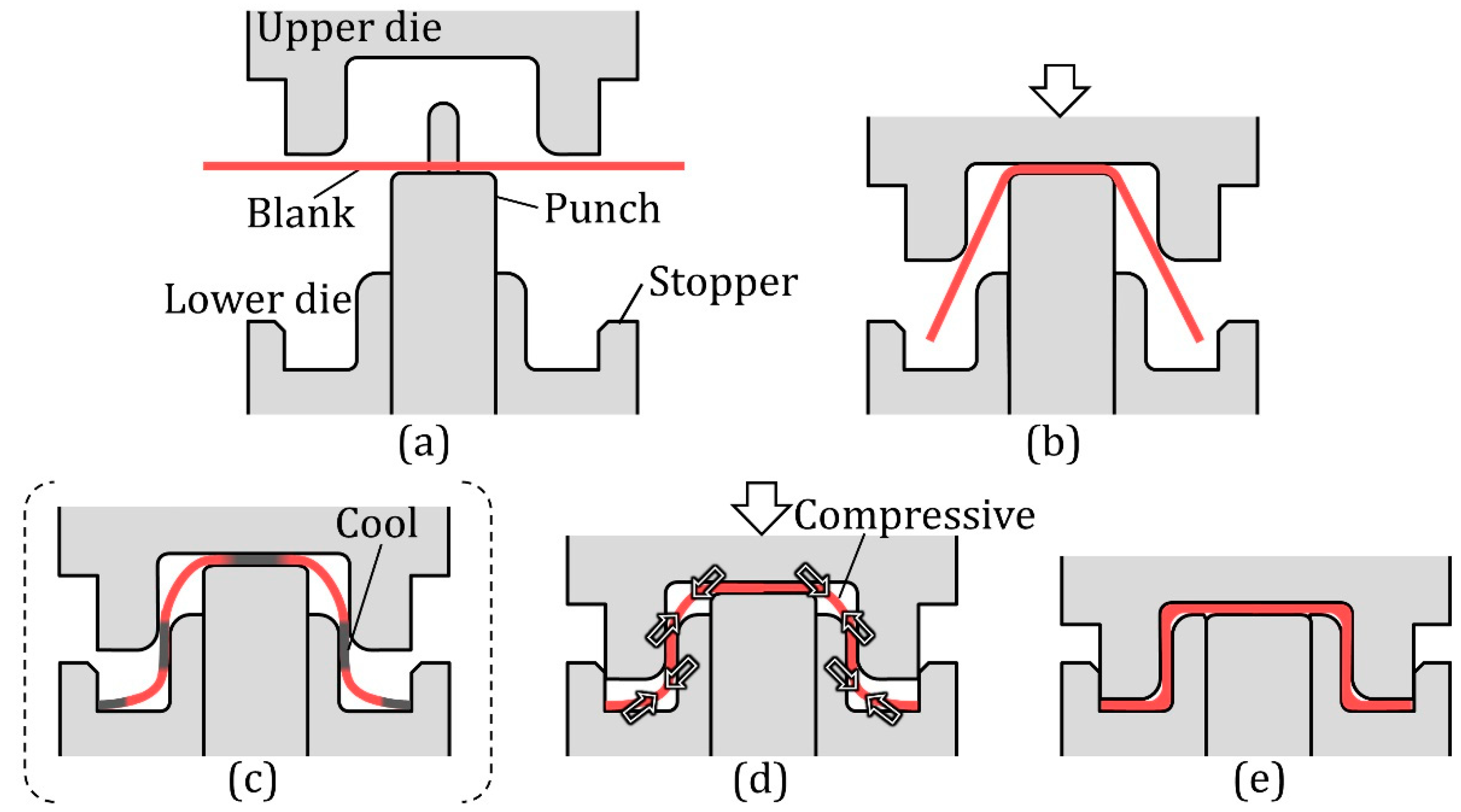

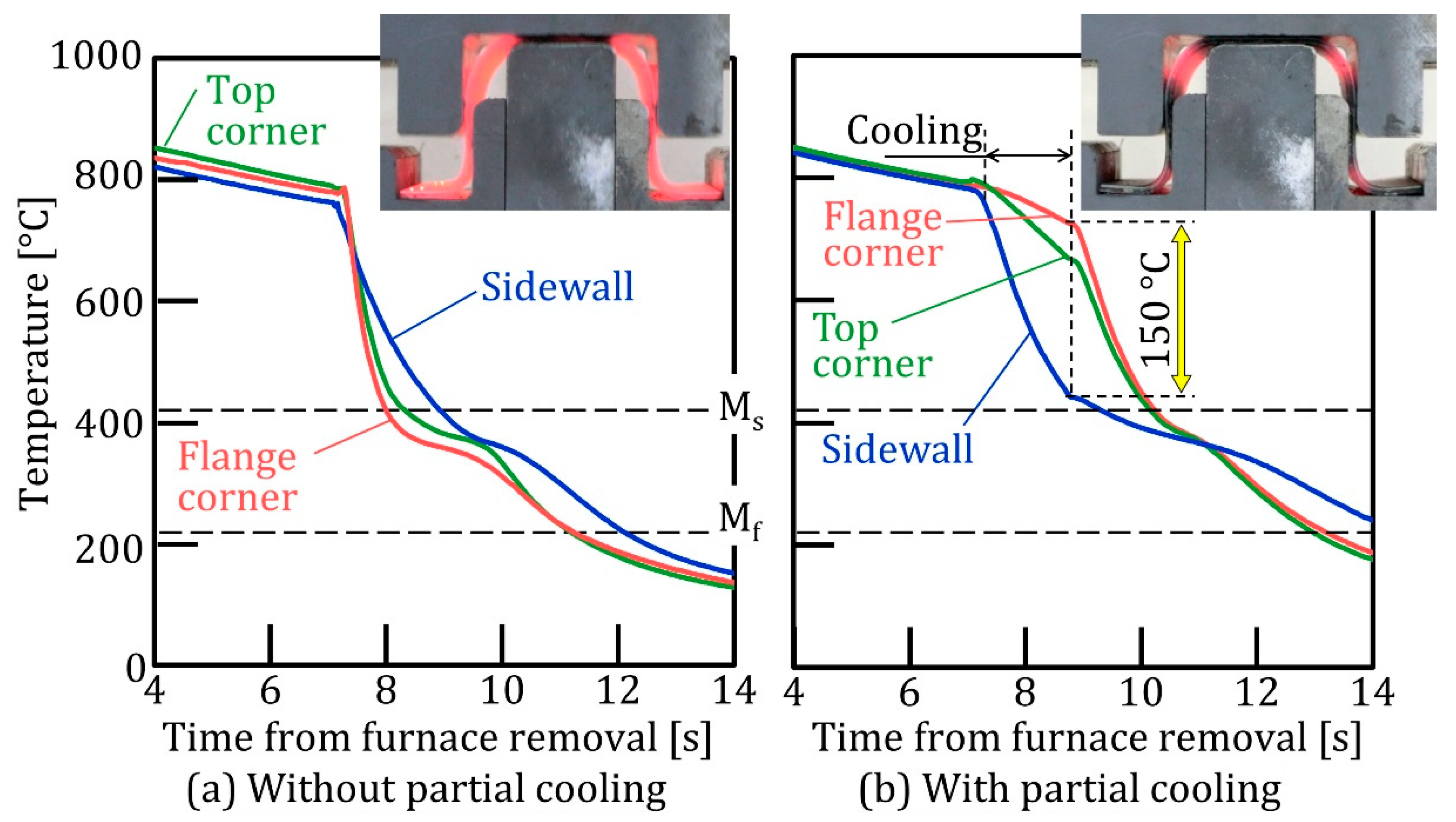

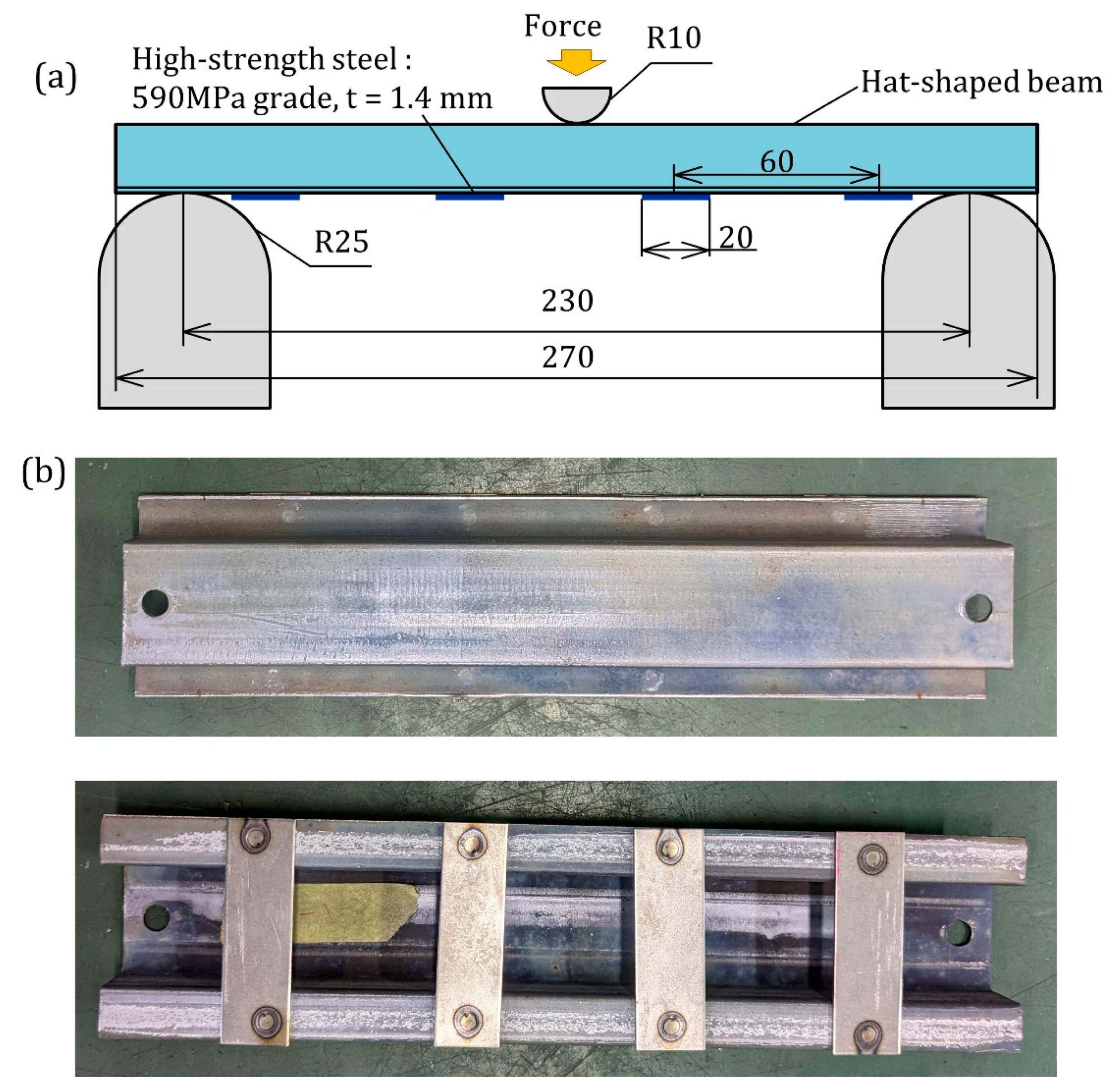

2.2. Conditions of Hot Stamping

3. Deformation Behaviour of Hot Stamping Using Planar Compression

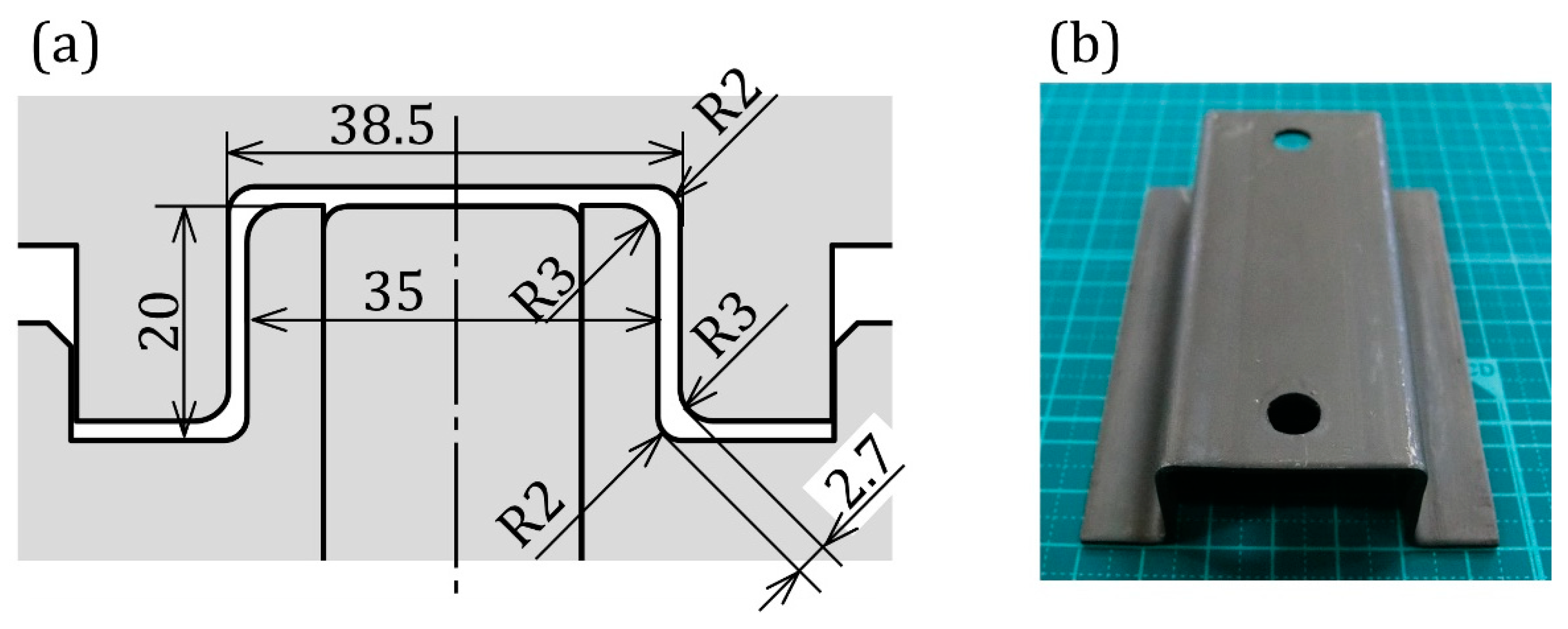

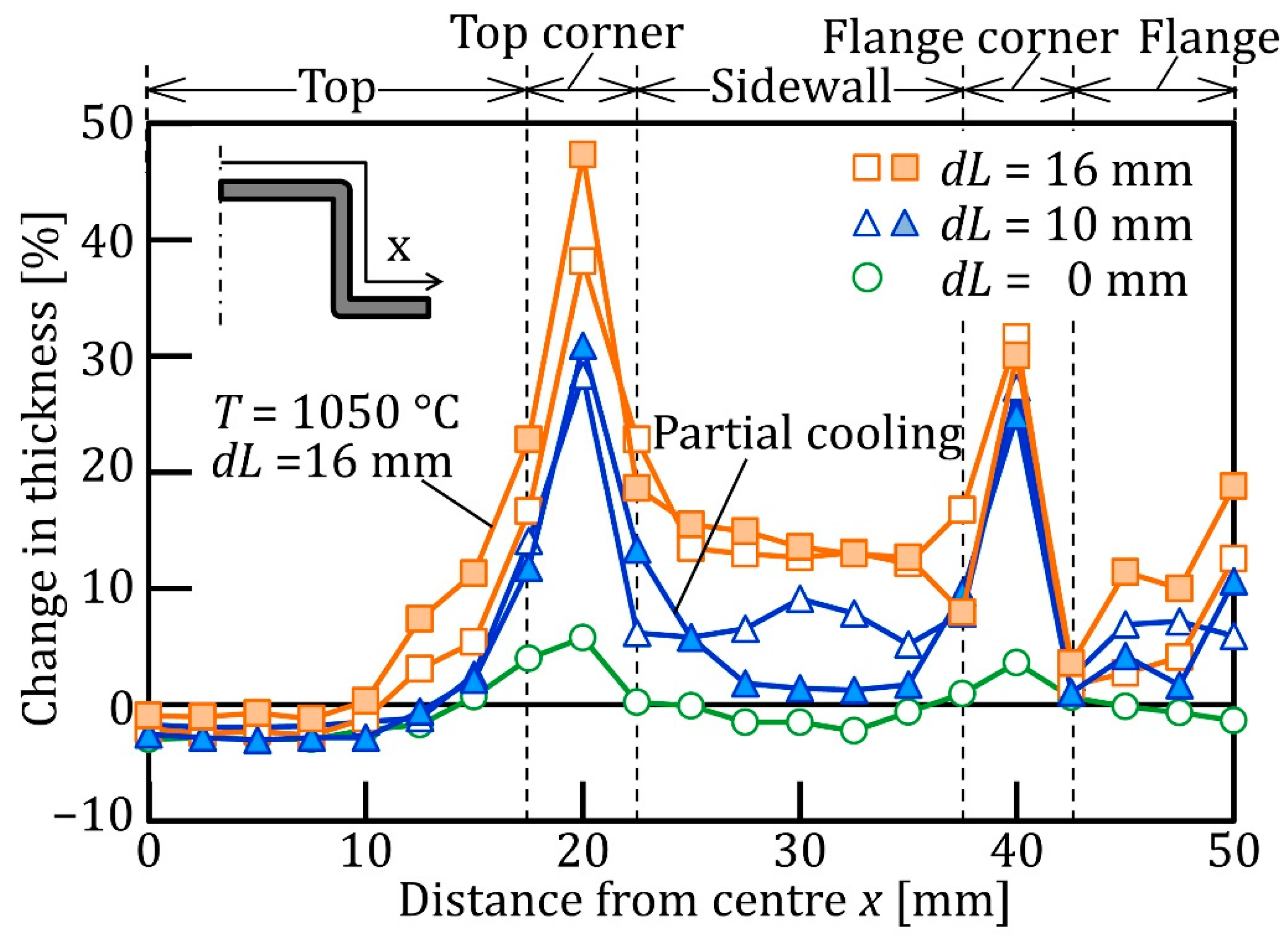

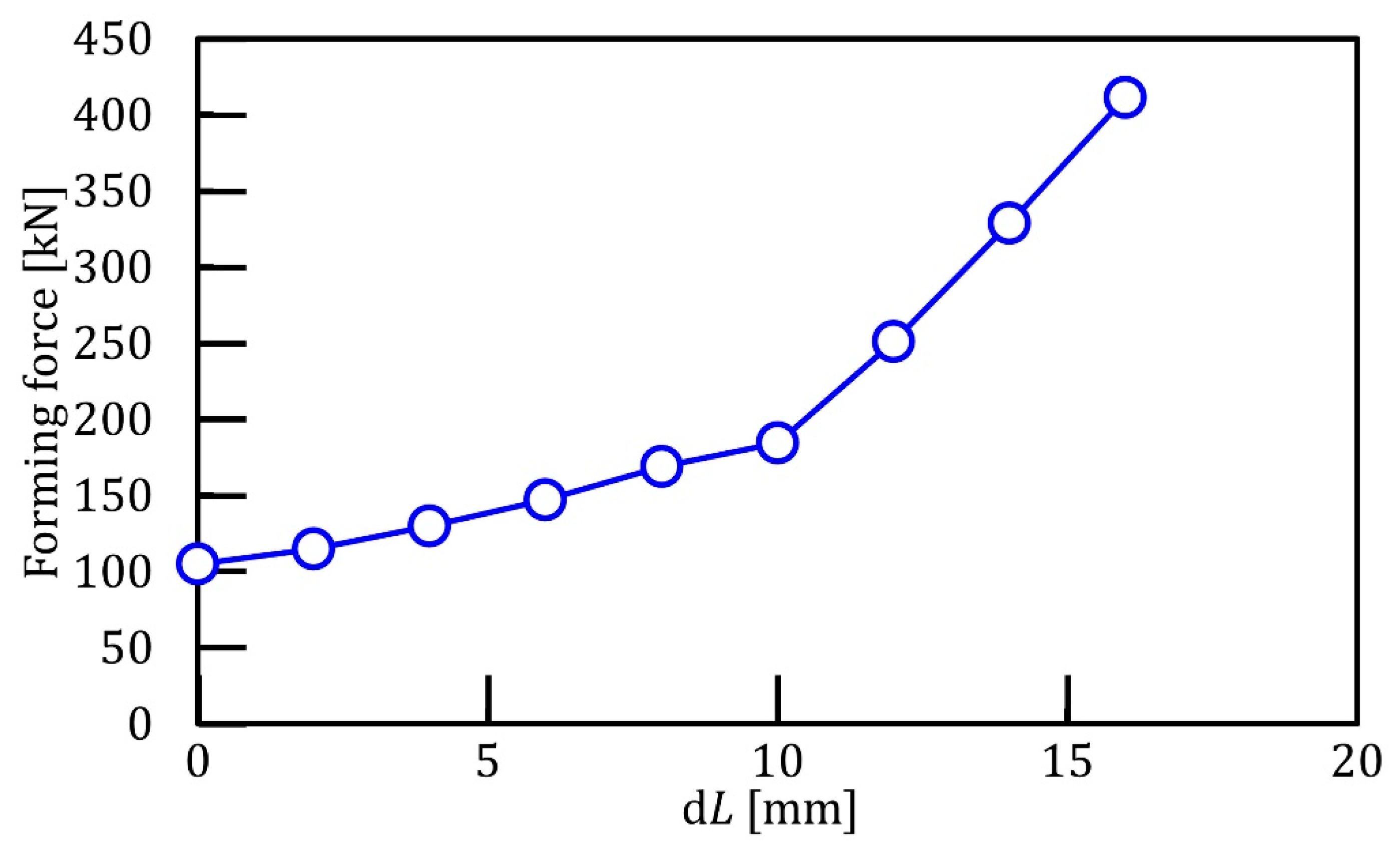

3.1. Local Thickening

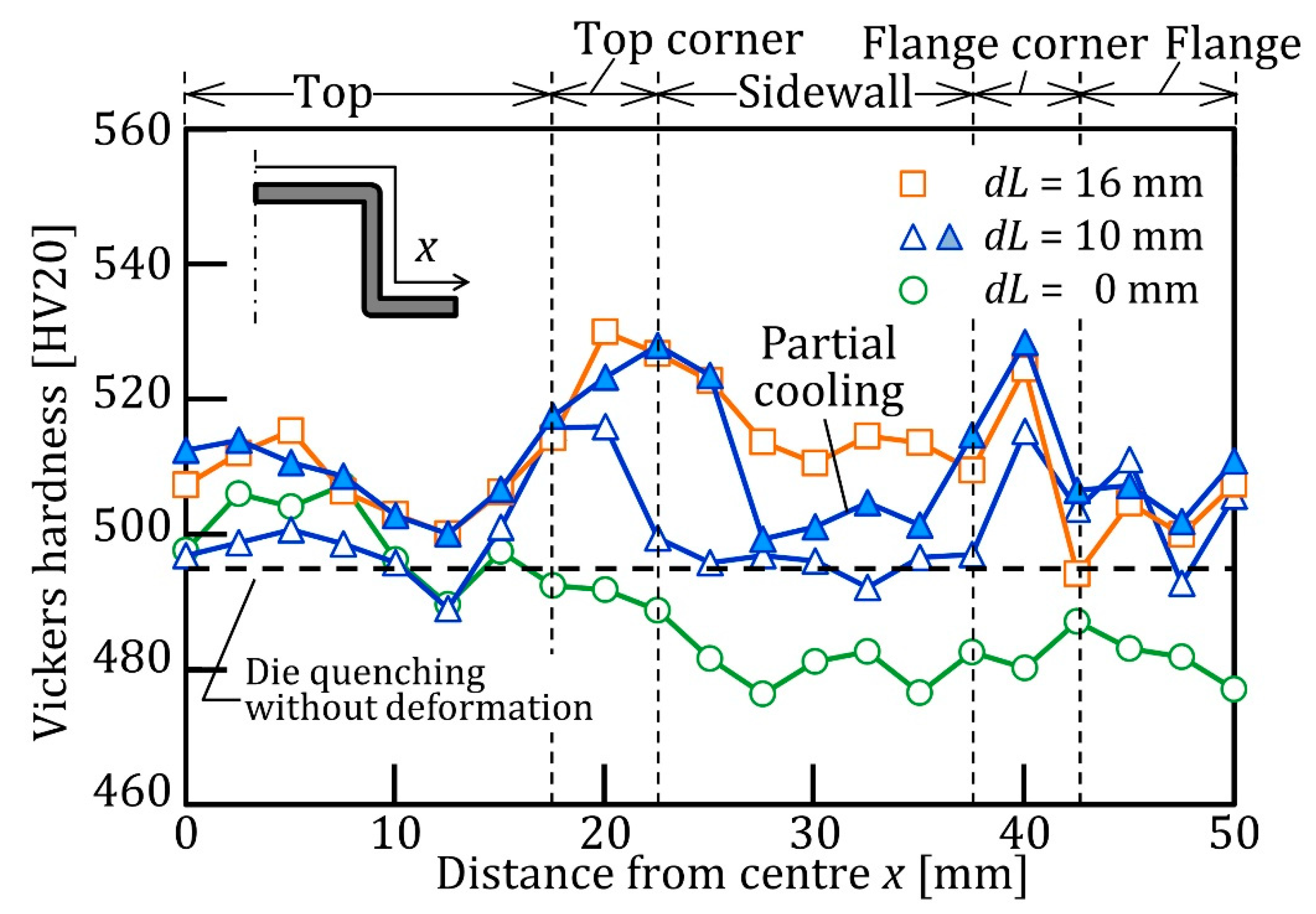

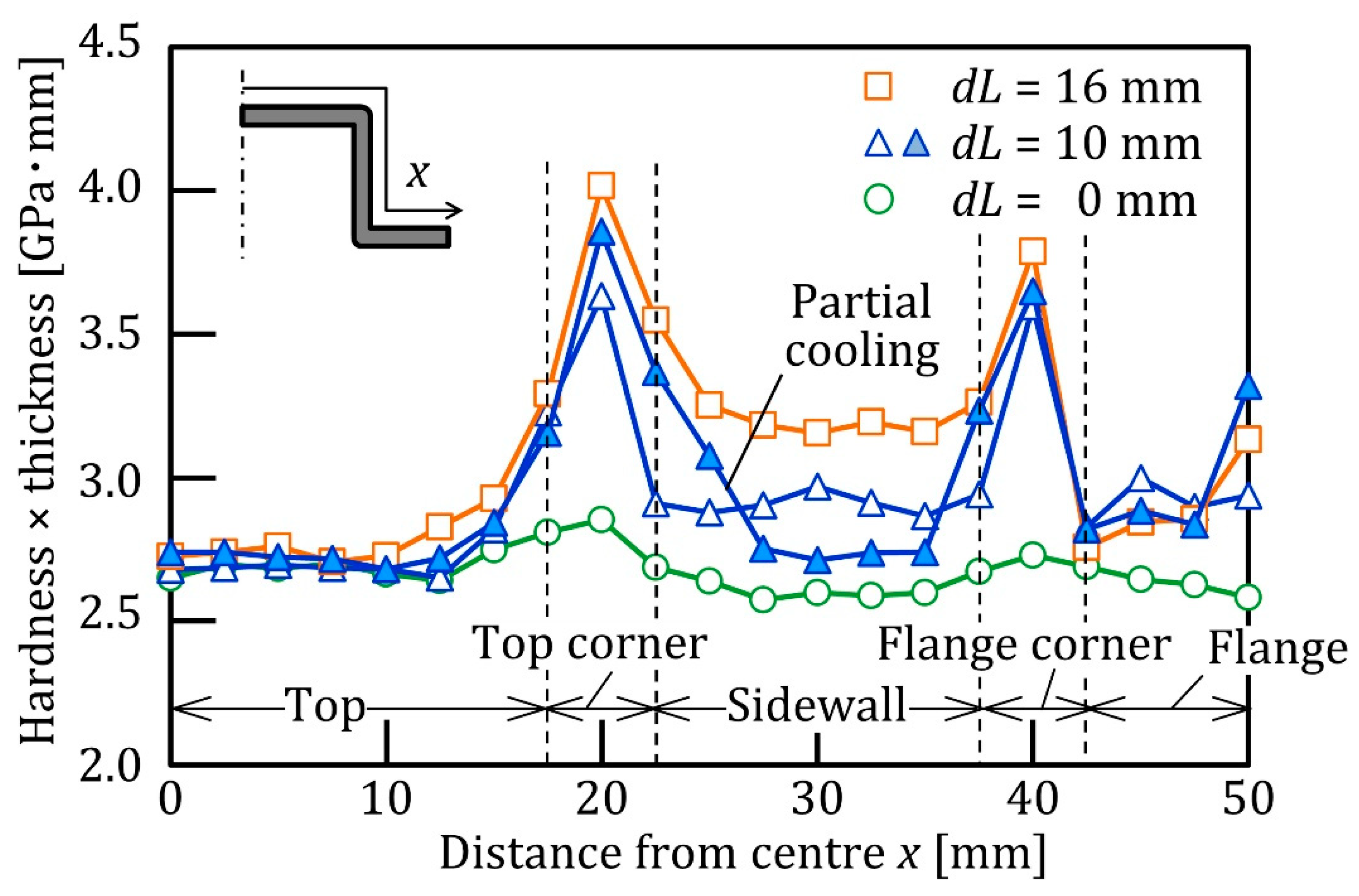

3.2. Increase in Hardness around Corners

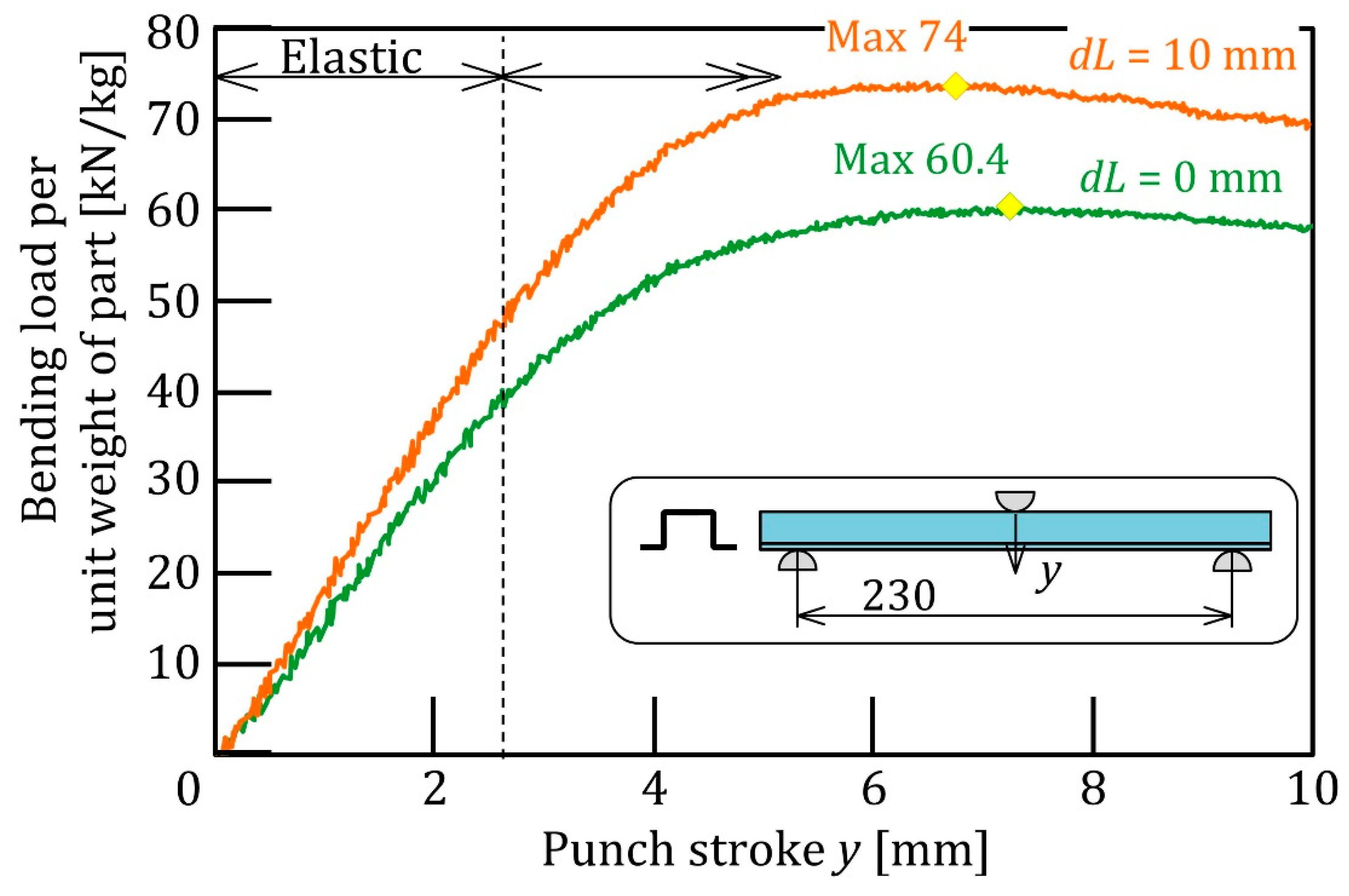

3.3. Strength of Hot-Stamped Part Using Planar Compression

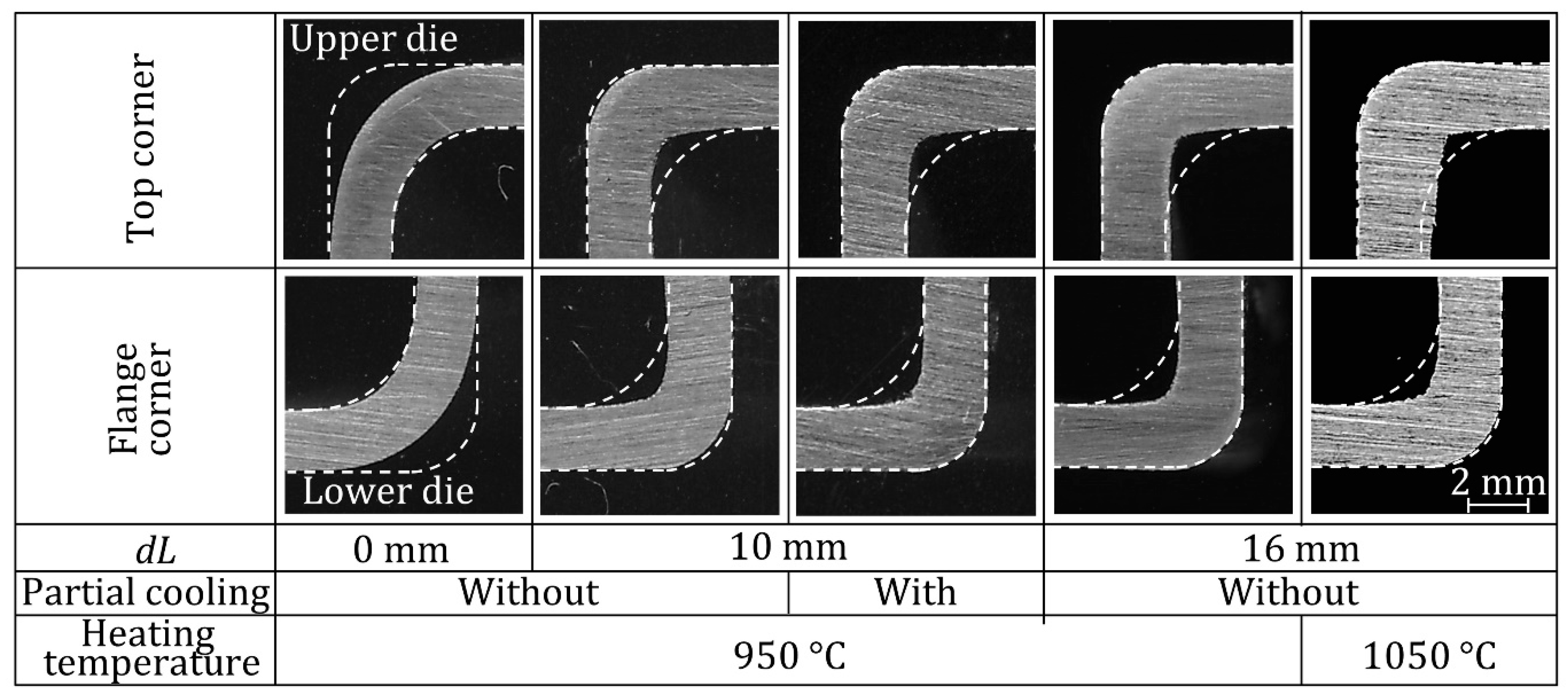

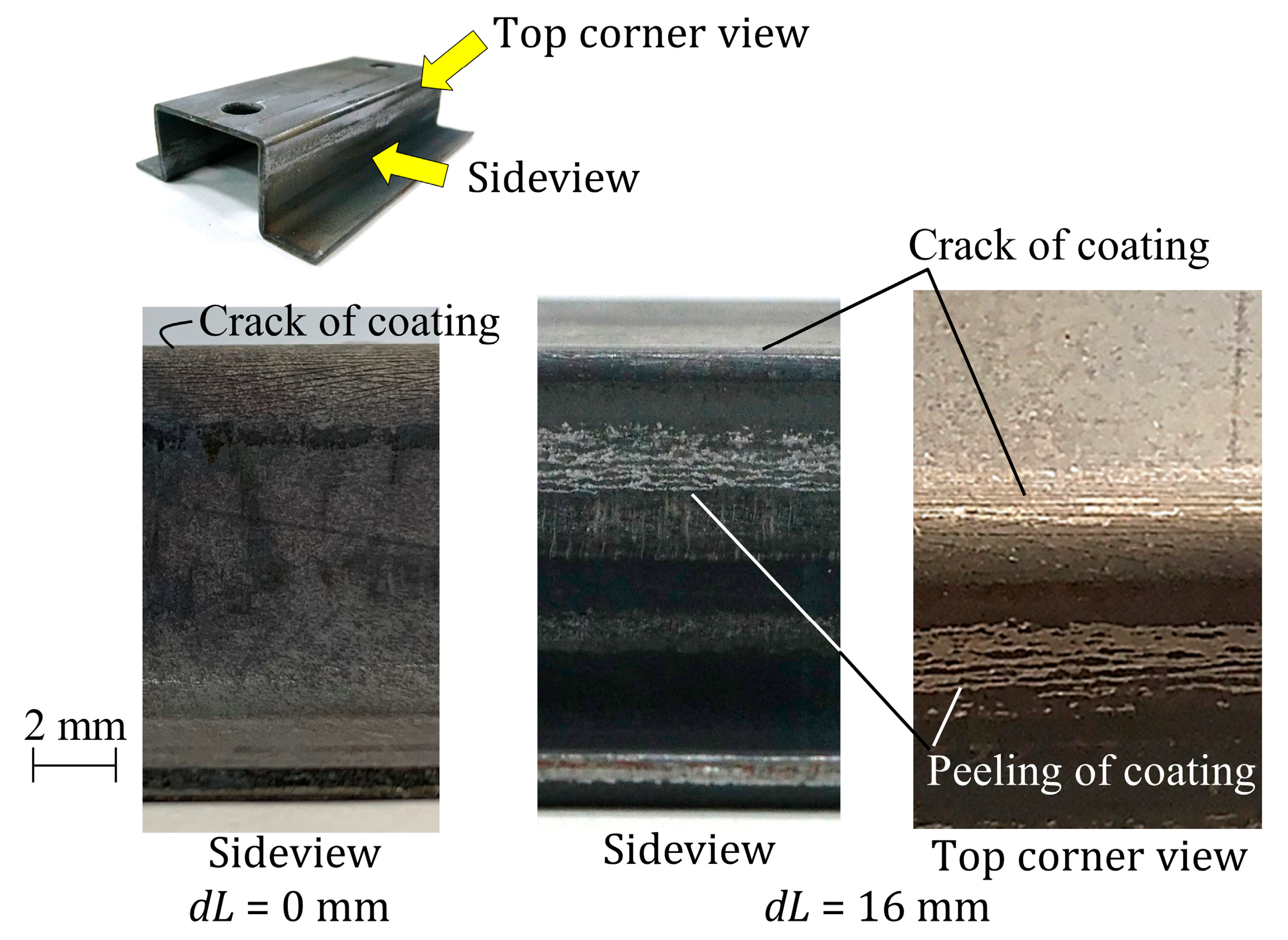

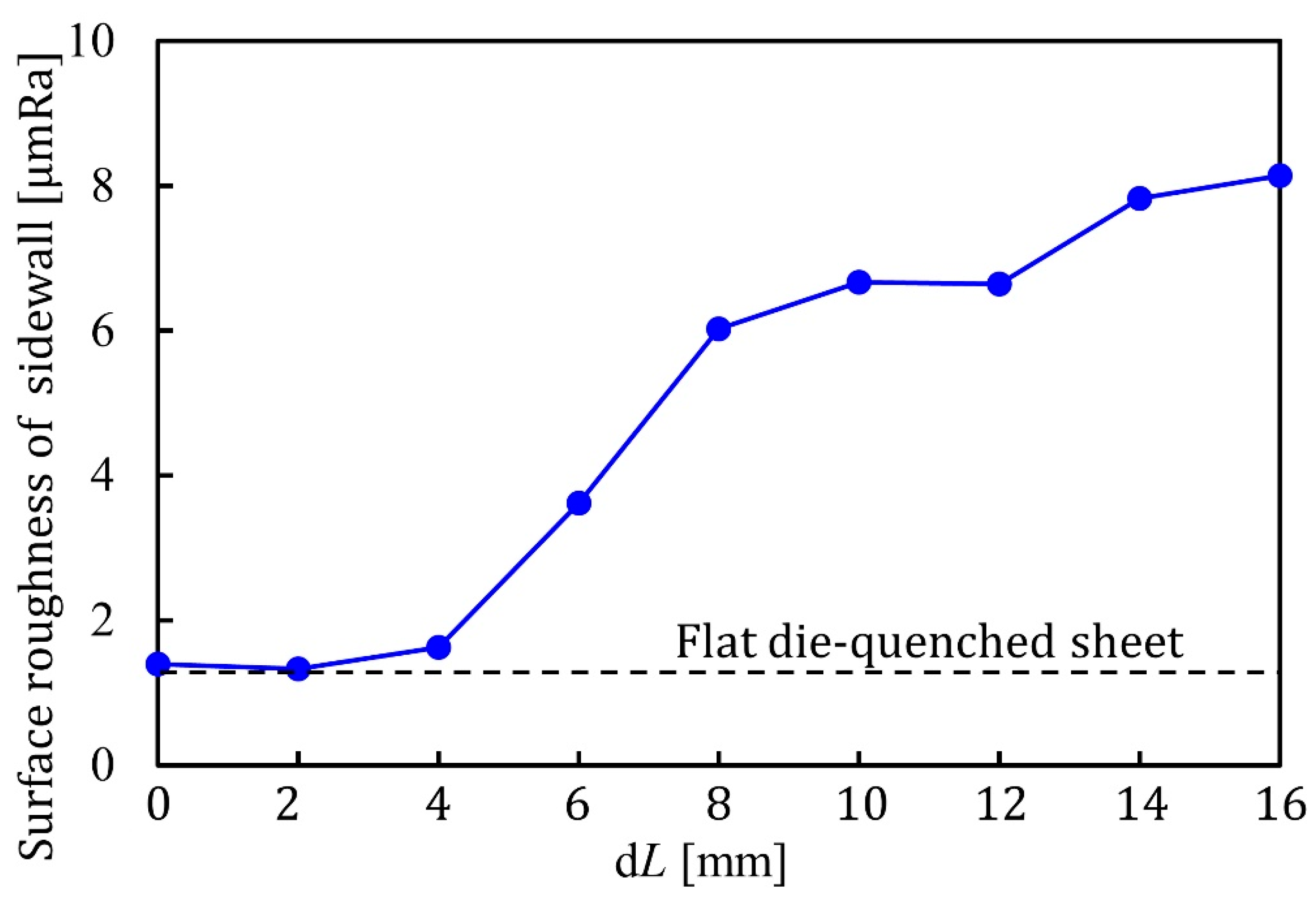

3.4. Surface Quality after Local Thickening

4. Conclusions

- The top and flange corners of a hat-shaped part were thickened by blocking the movement of both edges of the blank with stoppers of the lower dies during the latter stage of hot stamping.

- The strength of the formed components was heightened by the increase in not only thickness but also hardness.

- The increase in hardness was induced by the large plastic deformation of thickening, i.e., the ausforming was utilised for hot stamping.

- The hardness increased linearly below = 0.8, and it reached 600 HV10 by ausforming under die quenching, which is equivalent to 1.8 GPa parts in tensile strength.

- A 20% increase in bending load and high shape accuracy were obtained by the planar compression.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Maeno, T.; Mori, K.; Sakagami, M.; Nakao, Y.; Talebi-Anaraki, A. Minimisation of heating time for full hardening in hot stamping using direct resistance heating. J. Manuf. Mater. Process. 2020, 4, 80. [Google Scholar] [CrossRef]

- Talebi-Anaraki, A.; Maeno, T.; Ikeda, R.; Morishita, K.; Mori, K. Quenchability improvement and control simplification by ice mandrel in hot stamping of ultra-high strength steel hollow parts. J. Manuf. Process. 2021, 64, 916–926. [Google Scholar] [CrossRef]

- Billur, E. (Ed.) Chapter 1 Introduction. In Hot stamping of Ultra High-Strength Steels: From a Technological and Business Perspective; Springer Nature: Cham, Switzerland, 2018; pp. 1–18. [Google Scholar]

- Mori, K.-I.; Abe, Y.; Sedoguchi, K. Delayed fracture in cold blanking of ultra-high strength steel sheets. CIRP Ann. Manuf. Technol. 2019, 68, 297–300. [Google Scholar] [CrossRef]

- Tokizawa, A.; Yamamoto, K.; Takemoto, Y.; Senuma, T. Development of 2000 MPa class hot stamped steel components with good toughness and high resistance against delayed fracture. In Proceedings of the 4th International Conference on Hot Sheet Metal Forming of High-Performance Steel–CHS2, Luleå, Sweden, 9–12 June 2013; pp. 473–479.6. [Google Scholar]

- Gerber, T.; Heckelmann, I.; Diaz, N.V.; Lenze, F.J. Efforts in expanding the portfolio of hot forming steel material concepts. In Proceedings of the 4th International Conference on Hot Sheet Metal Forming of High-Performance Steel—CHS2, Luleå, Sweden, 9–12 June 2013; pp. 145–152. [Google Scholar]

- De Castro, M.R.; Monteiro, W.A.; Politano, R. Enhancements on strength of body structure due to bake hardening effect on hot stamping steel. Int. J. Adv. Manuf. Technol. 2019, 100, 771–782. [Google Scholar] [CrossRef]

- Chang, Z.; Li, Y.; Wu, D. Enhanced ductility and toughness in 2000 MPa grade press hardening steels by auto-tempering. Mater. Sci. Eng. A 2020, 784, 139342. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Huang, Y.H.; Sun, B.T.; Liao, Q.L.; Lu, H.Z.; Jian, B.; Mohrbacher, H.; Zhang, W.; Guo, A.M.; Zhang, Y. Effect of Nb on hydrogen-induced delayed fracture in high strength hot stamping steels. Mater. Sci. Eng. A 2015, 626, 136–143. [Google Scholar] [CrossRef]

- Jo, M.C.; Yoo, J.; Kim, S.; Kim, S.; Oh, J.; Bian, J.; Sohn, S.S.; Lee, S. Effects of Nb and Mo alloying on resistance to hydrogen embrittlement in 1.9 GPa-grade hot-stamping steels. Mater. Sci. Eng. A 2020, 789, 139656. [Google Scholar] [CrossRef]

- Mallick, P.K. (Ed.) Chapter 10—Designing lightweight vehicle body. In Materials, Design and Manufacturing for Lightweight Vehicles, 2nd ed.; Woodhead Publishing in Materials: Sawston, UK, 2021; pp. 405–432. [Google Scholar] [CrossRef]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Mori, K.-I.; Bariani, P.; Behrens, B.-A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. Manuf. Technol. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Wilsius, J.; Tavernier, B.; Abou-Khalil, D. Experimental and numerical investigation of various hot stamped B-pillar concepts based on Usibor® 1500P. In Proceedings of the 3rd International Conference on Hot Sheet Metal Forming of High-Performance Steel—CHS2, Kassel, Germany, 13–17 June 2011; pp. 427–435. [Google Scholar]

- Mu, Y.; Zhou, J.; Wang, B.; Wang, Q.; Ghiotti, A.; Bruschi, S. Numerical simulation of hot stamping by partition heating based on advanced constitutive modelling of 22MnB5 behaviour. Finite Elem. Anal. Des. 2018, 147, 34–44. [Google Scholar] [CrossRef]

- Erturk, S. Simulation of Tailored Tempering with a thermo-mechanical metallurgical model in autoform plus. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2011; Volume 1383, p. 610. [Google Scholar] [CrossRef]

- Wang, Z.J.; Liu, P.X.; Xu, Y.; Wang, Y.L.; Zhang, Y.S. Hot stamping of high strength steel with tailored properties by two methods. In Proceedings of the Procedia Engineering, Nogaya, Japan, 19–24 October 2014; pp. 1725–1730. [Google Scholar]

- Tang, B.T.; Wang, Q.L.; Bruschi, S.; Ghiotti, A.; Bariani, P.F. Influence of temperature and deformation on phase transformation and Vickers hardness in tailored tempering process: Numerical and experimental verifications. ASME J. Manuf. Sci. Eng. 2014, 136, 051018. [Google Scholar] [CrossRef]

- Yun, S.; Lee, S.H.; Song, K.S.; Cho, W.; Kim, Y. Performance improvement of tailored die quenching using material combinations with phase change material in hot stamping. Int. J. Heat Mass Transf. 2020, 161, 120286. [Google Scholar] [CrossRef]

- Kong, L.; Peng, Y.; Liu, C. Research on the re-deformation characteristics of hot stamping of boron steel parts with tailored properties. Metals 2020, 10, 1136. [Google Scholar] [CrossRef]

- Mori, K.-I.; Maeno, T.; Mongkolkaji, K. Tailored die quenching of steel parts having strength distribution using bypass resistance heating in hot stamping. J. Mater. Process. Technol. 2013, 213, 508–514. [Google Scholar] [CrossRef]

- Fernandez, B.; Zarate, J.; Garcia, I.; Varela, S. Tailored strategies in press hardening. In Proceedings of the 3rd International Conference on Hot Sheet Metal Forming of High-Performance Steel—CHS2, Kassel, Germany, 13–17 June 2011; pp. 437–446. [Google Scholar]

- Nakagawa, Y.; Mori, K.-I.; Suzuki, Y.; Shimizu, Y. Tailored tempering without die heating in hot stamping of ultra-high strength steel parts. Mater. Des. 2020, 192, 108712. [Google Scholar] [CrossRef]

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A review on tailored blanks-production, applications and evaluation. J. Mater. Process. Technol. 2014, 214, 151–164. [Google Scholar] [CrossRef]

- Kang, M.; Kim, Y.-M.; Kim, C. Effect of heating parameters on laser welded tailored blanks of hot press forming steel. J. Mater. Process. Technol. 2016, 228, 137–144. [Google Scholar] [CrossRef]

- Mori, K.-I.; Suzuki, Y.; Yokoo, D.; Nishikata, M.; Abe, Y. Steel sheets partnered with quenchable sheet in hot stamping of tailor-welded blanks and its application to separation prevention of fractured components. Int. J. Adv. Manuf. Technol. 2020, 111, 725–734. [Google Scholar] [CrossRef]

- Ouyang, X.; Zhang, Z.; Jia, H.; Ren, M.; Sun, Y. Study on the Effect of Heat Treatment on Microstructures and High Temperature Mechanical Properties of Welding Spots of Hot Stamped Ultra-High Strength Steel Patchwork Blanks. Metals 2021, 11, 1033. [Google Scholar] [CrossRef]

- Yogo, Y.; Kurato, N.; Iwata, N. Investigation of hardness change for spot welded tailored blank in hot stamping using CCT and deformation-CCT diagrams. Met. Mater. Trans. A 2018, 49, 2293–2301. [Google Scholar] [CrossRef]

- Yun, S.; Kwon, J.; Cho, W.; Lee, D.; Kim, Y. Performance improvement of hot stamping die for patchwork blank using mixed cooling channel designs with straight and conformal channels. Appl. Them. Eng. 2020, 165, 114562. [Google Scholar] [CrossRef]

- Mori, K.-I.; Kaido, T.; Suzuki, Y.; Nakagawa, Y.; Abe, Y. Combined process of hot stamping and mechanical joining for producing ultra-high strength steel patchwork components. J. Manuf. Process. 2020, 59, 444–455. [Google Scholar] [CrossRef]

- Grüber, M.; Kopp, R.; Hirt, G. Flexible rolling. In 60 Excellent Inventions in Metal Forming; Tekkaya, A.E., Homberg, W., Brosius, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 213–218. [Google Scholar]

- Tajul, L.; Maeno, T.; Kinoshita, T.; Mori, K.-I. Successive forging of tailored blank having thickness distribution for hot stamping. Int. J. Adv. Manuf. Technol. 2017, 89, 3731–3739. [Google Scholar] [CrossRef]

- Vogel, M.; Merklein, M. Manufacturing of tailored blanks by orbital forming with a two-sided material thickening. J. Mater. Process. Technol. 2019, 287, 116491. [Google Scholar] [CrossRef]

- Han, S.; Hwang, T.; Oh, I.; Choi, M.; Moon, Y.H. Manufacturing of tailor-rolled blanks with thickness variations in both the longitudinal and latitudinal directions. J. Mater. Process. Technol. 2018, 256, 172–182. [Google Scholar] [CrossRef]

- Mori, K.I.; Nakano, T. State-of-the-art of plate forging in Japan. Prod. Eng. 2016, 10, 81–91. [Google Scholar] [CrossRef]

- Mori, K.-I.; Maeno, T.; Yamada, H.; Matsumoto, H. 1-shot hot stamping of ultra-high strength steel parts consisting of resistance heating, forming, shearing and die quenching. Int. J. Mach. Tools Manufact. 2015, 89, 124–131. [Google Scholar] [CrossRef]

- Tekkaya, A.; Allwood, J.; Bariani, P.; Bruschi, S.; Cao, J.; Gramlich, S.; Groche, P.; Hirt, G.; Ishikawa, T.; Löbbe, C.; et al. Metal forming beyond shaping: Predicting and setting product properties. CIRP Ann. Manuf. Technol. 2015, 64, 629–653. [Google Scholar] [CrossRef]

- Vaughan, M.; Samimi, P.; Gibbons, S.; Abrahams, R.; Harris, R.; Barber, R.; Karaman, I. Exploring performance limits of a new martensitic high strength steel by ausforming via equal channel angular pressing. Scr. Mater. 2020, 184, 63–69. [Google Scholar] [CrossRef]

- Naderi, M.; Durrenberger, L.; Molinari, A.; Black, W. Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperatures. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2008, 478, 130–139. [Google Scholar] [CrossRef]

- Sugimoto, A.; Tanaka, T.; Oki, T.; Wakimon, K. Impact of improved ausforming on the structure of spring steel. Trans. Jpn. Soc. Spring Eng. 1989, 34, 38–43. [Google Scholar] [CrossRef][Green Version]

- Fan, D.W.; De Cooman, B.C. State-of-the-Knowledge on Coating Systems for Hot Stamped Parts. Steel Res. Int. 2012, 83, 412–433. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maeno, T.; Mori, K.-i.; Homma, H.; Talebi-Anaraki, A.; Ikeda, R. Corner Strengthening by Local Thickening and Ausforming Using Planar Compression in Hot Stamping of Ultra-High Strength Steel Parts. Metals 2021, 11, 1977. https://doi.org/10.3390/met11121977

Maeno T, Mori K-i, Homma H, Talebi-Anaraki A, Ikeda R. Corner Strengthening by Local Thickening and Ausforming Using Planar Compression in Hot Stamping of Ultra-High Strength Steel Parts. Metals. 2021; 11(12):1977. https://doi.org/10.3390/met11121977

Chicago/Turabian StyleMaeno, Tomoyoshi, Ken-ichiro Mori, Hiroki Homma, Ali Talebi-Anaraki, and Ryohei Ikeda. 2021. "Corner Strengthening by Local Thickening and Ausforming Using Planar Compression in Hot Stamping of Ultra-High Strength Steel Parts" Metals 11, no. 12: 1977. https://doi.org/10.3390/met11121977

APA StyleMaeno, T., Mori, K.-i., Homma, H., Talebi-Anaraki, A., & Ikeda, R. (2021). Corner Strengthening by Local Thickening and Ausforming Using Planar Compression in Hot Stamping of Ultra-High Strength Steel Parts. Metals, 11(12), 1977. https://doi.org/10.3390/met11121977