Numerical Analysis of Particle Trajectories in a Gas–Powder Jet during the Laser-Based Directed Energy Deposition Process

Abstract

:1. Introduction

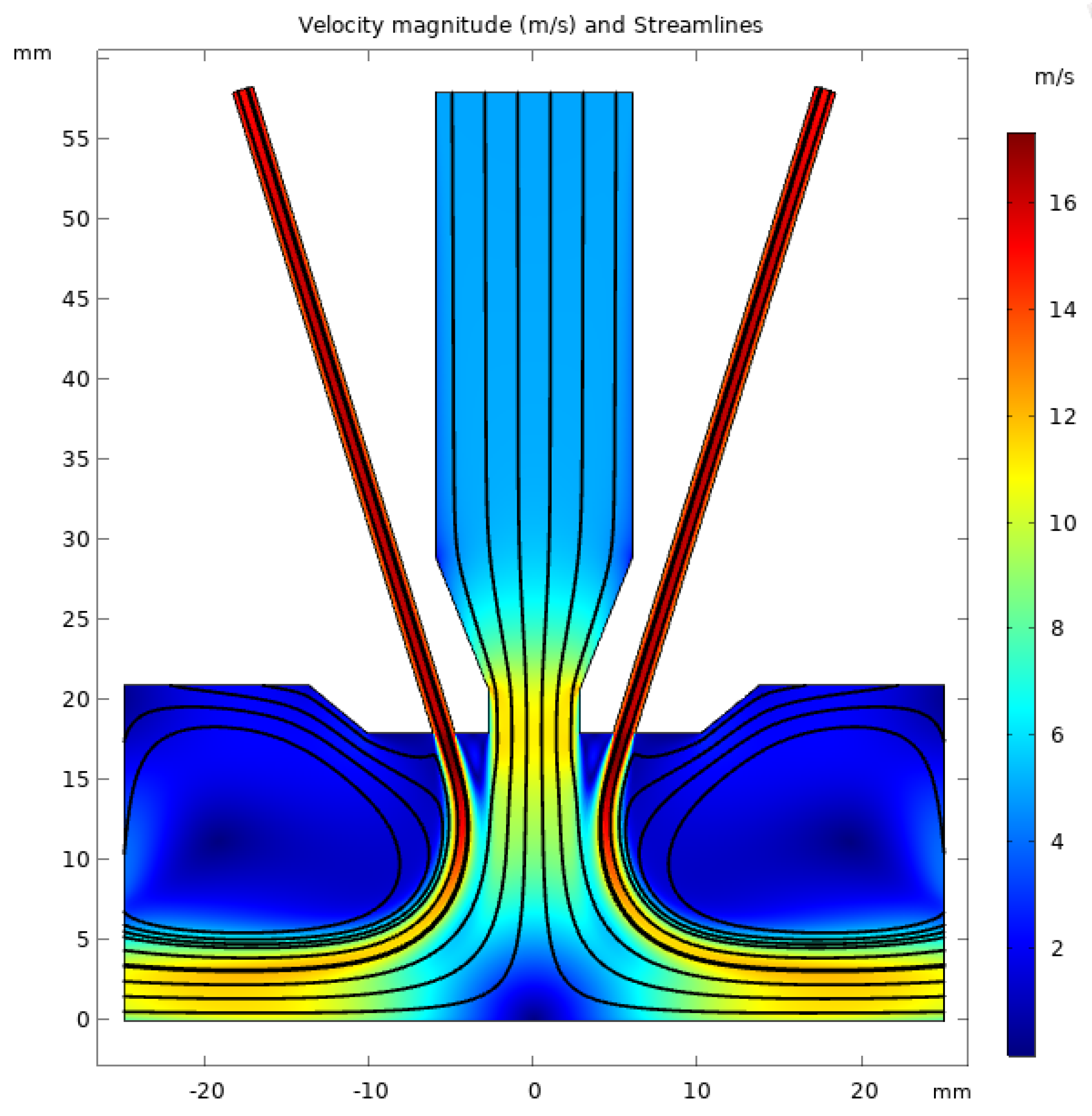

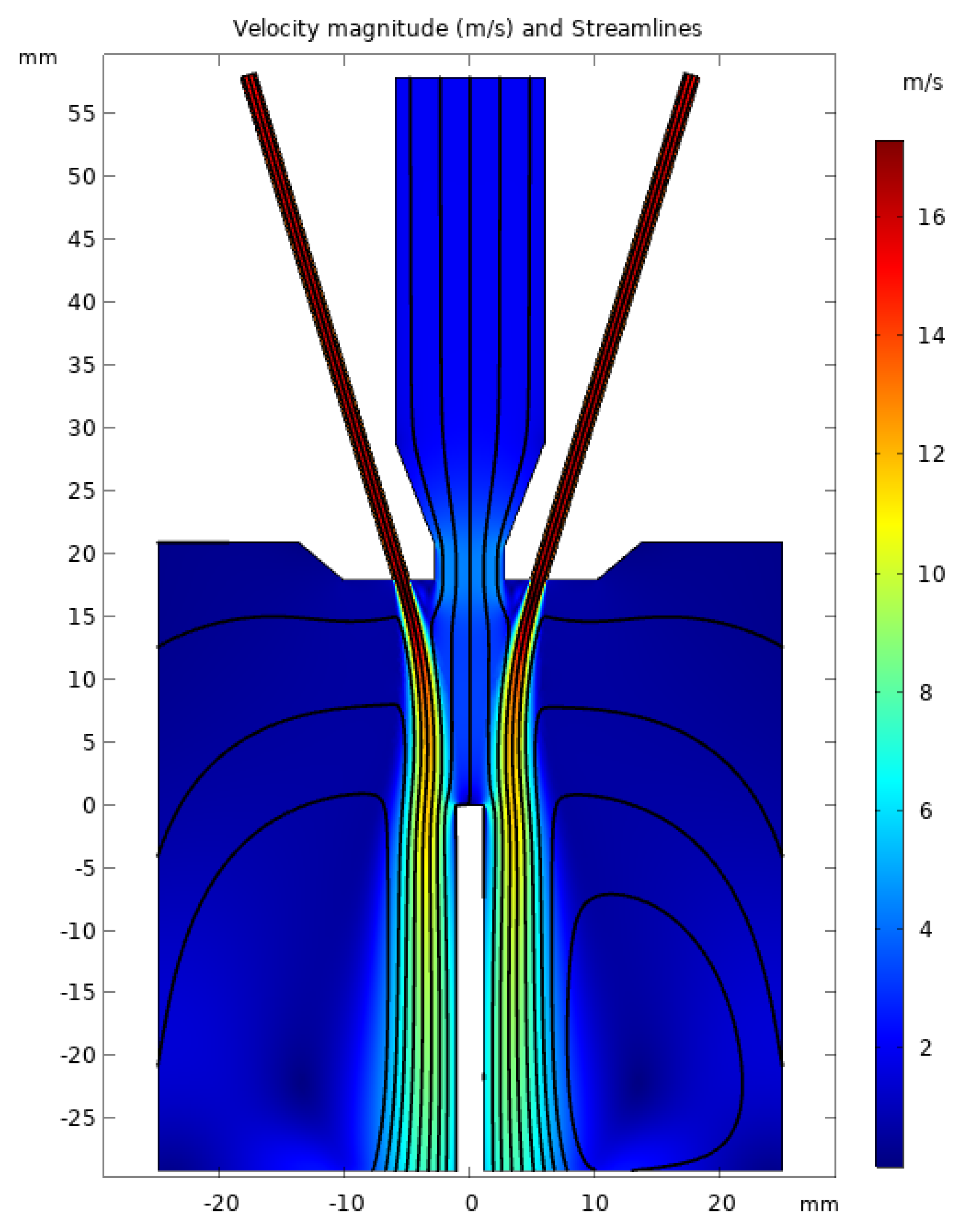

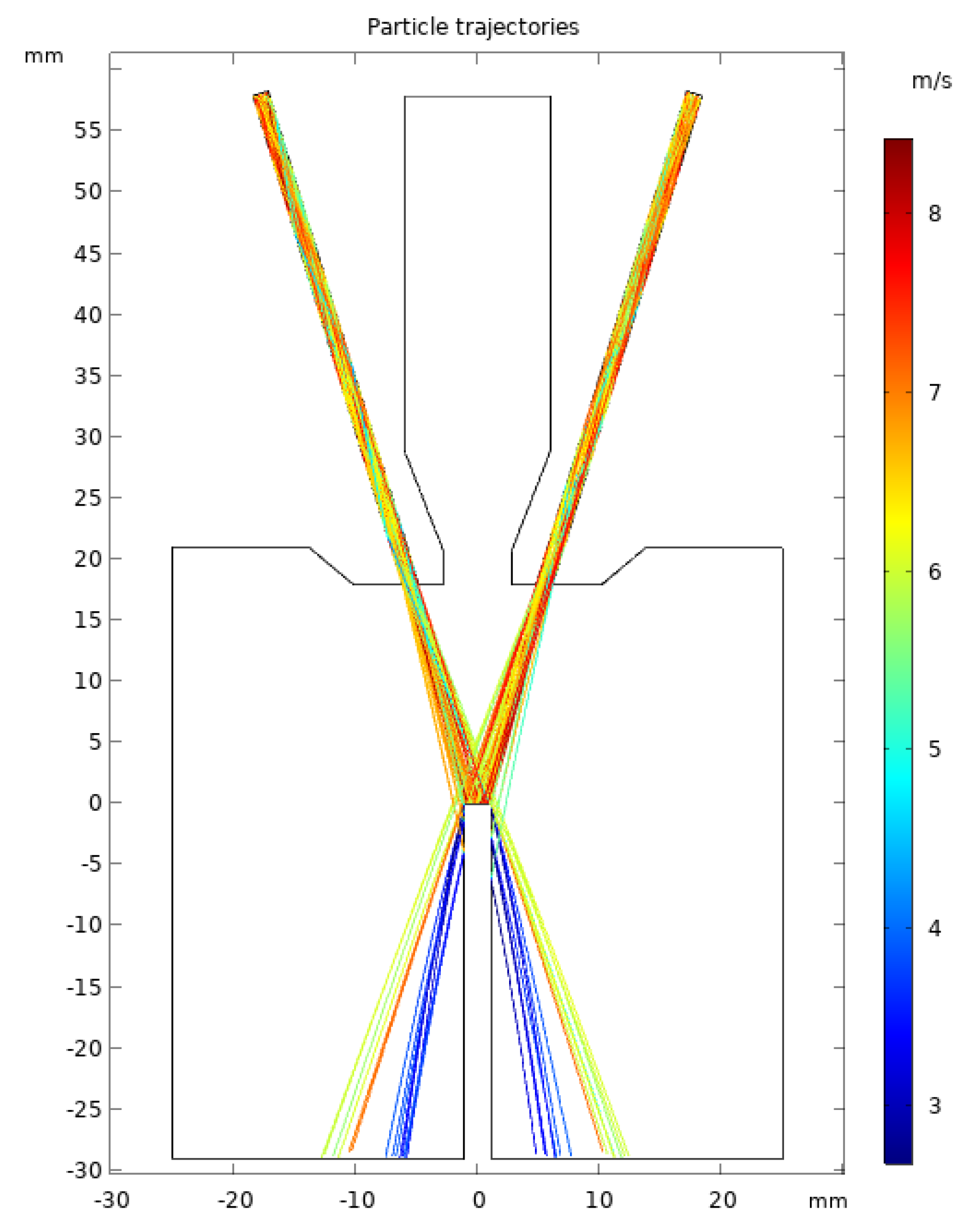

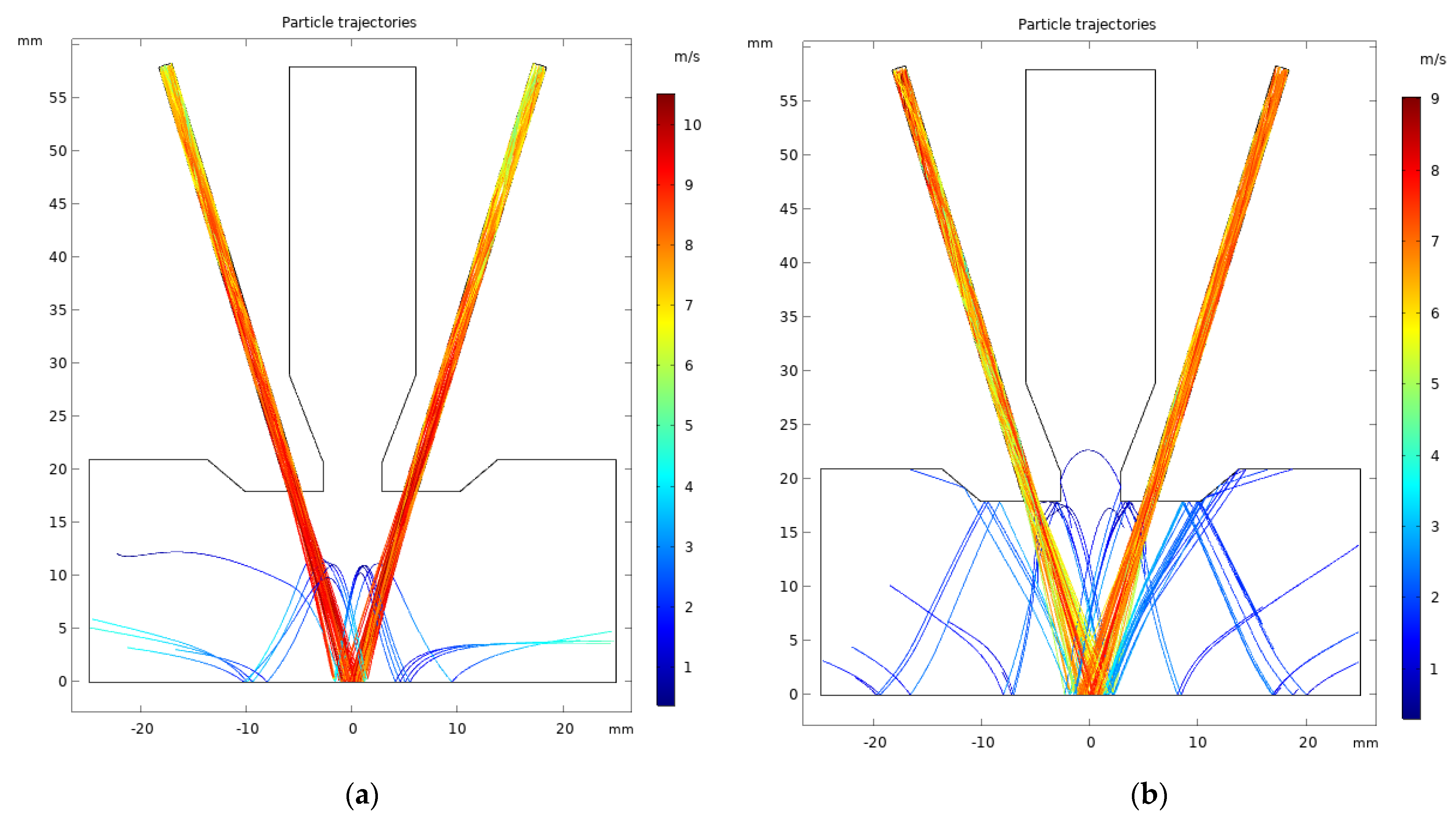

2. The Geometry of the L-DED Experiment, Approximations, and the Mathematical Model

2.1. The Geometry of the L-DED Experiment

2.2. Approximations Used

- Gas flows inside and outside the nozzle are in the approximation of a viscous compressible gas with a Mach number M < 0.3 and modeled by the Navier–Stokes equations averaged by Reynolds together with the turbulence model k-ε.

- The substrate and the powder material are in the solid state.

- The powder particles do not interact with each other and have a shape close to spherical.

- Heating of the gas–powder jet by laser radiation is not considered, and the gas temperature is constant.

- The effect of laser radiation is taken into account indirectly through the melt pool, into which the powder particles “freeze”.

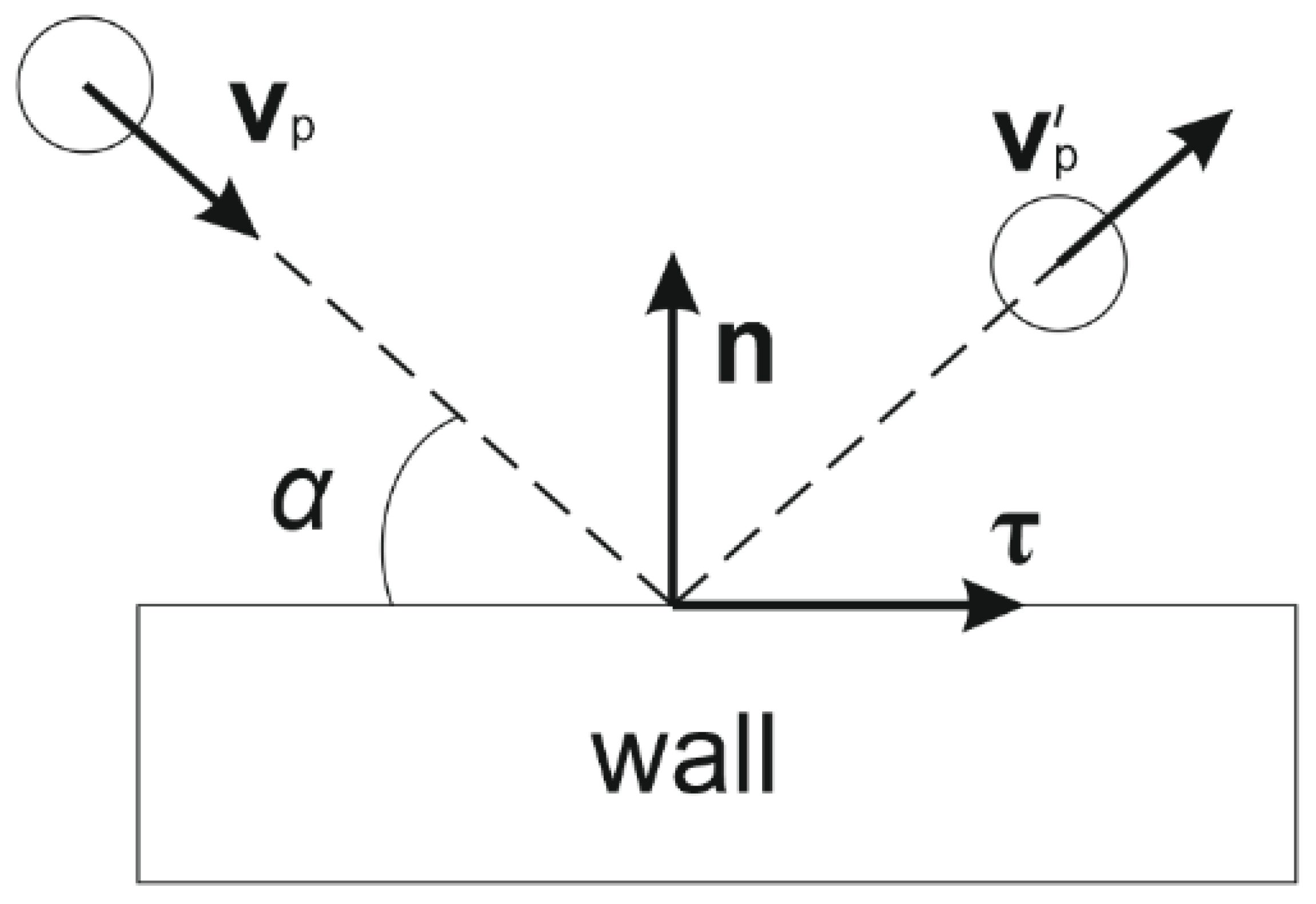

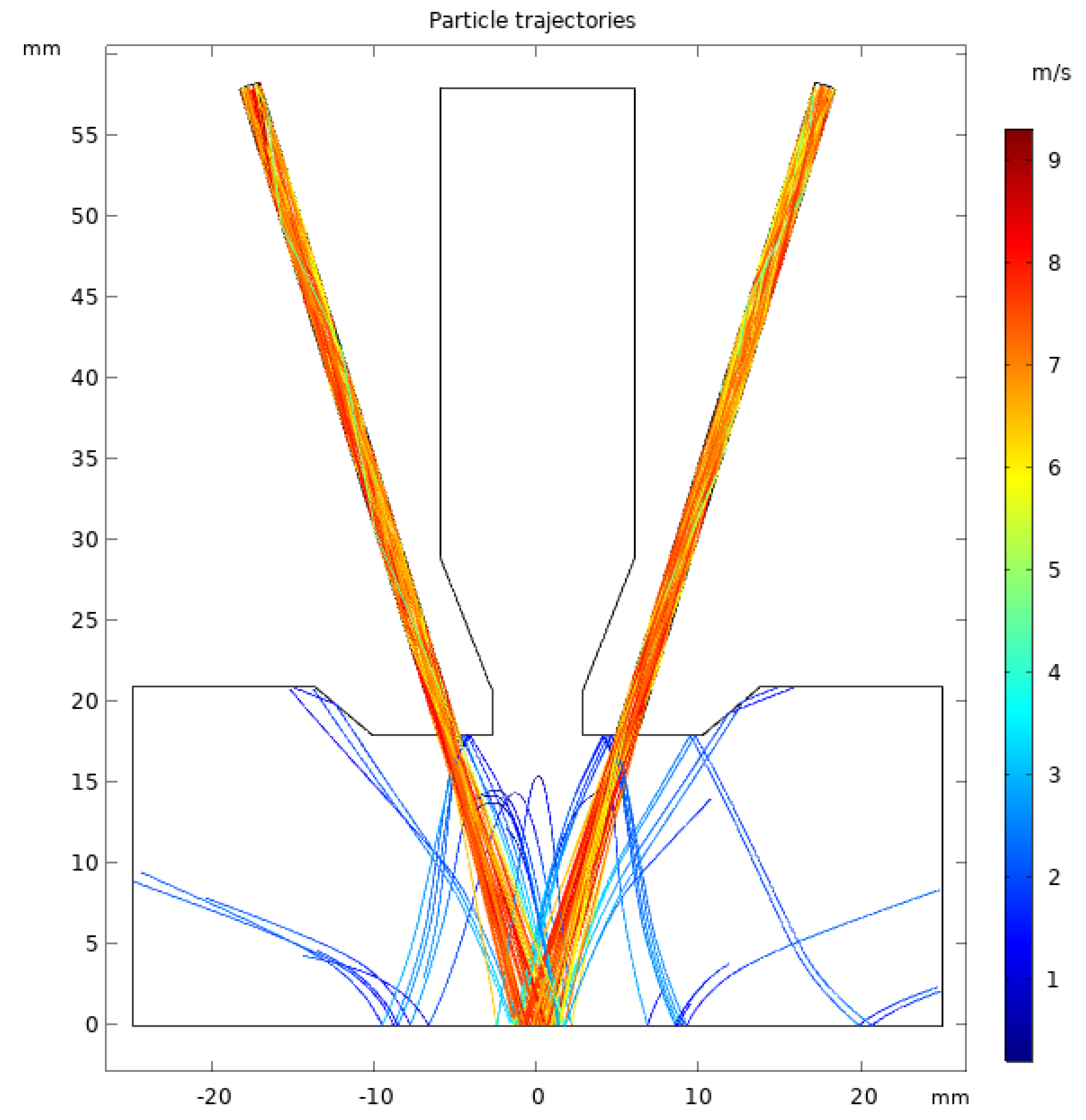

- The trajectories of powder particles are caused by the presence of only three forces: the Stokes force, adjusted for the case of gas movement; the force of interaction when particles collide with obstacles; and gravity.

2.3. Mathematical Model: Description of the Mixture Flow

2.4. Initial and Boundary Conditions for the Mixture Flow

2.5. Mathematical Model: Equation of Motion of Powder Particles in a Given Gas Flow

2.6. Initial and Boundary Conditions for Particles

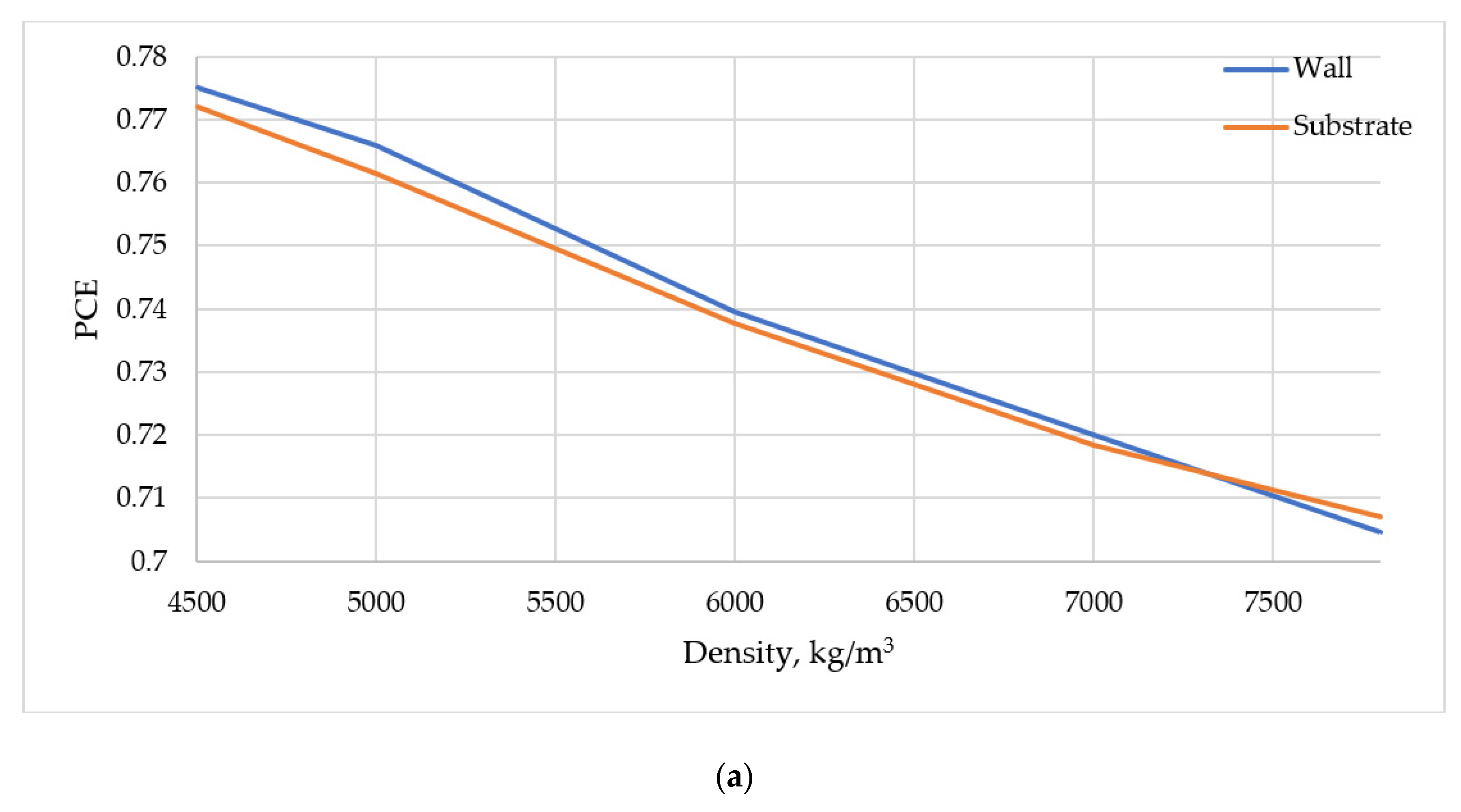

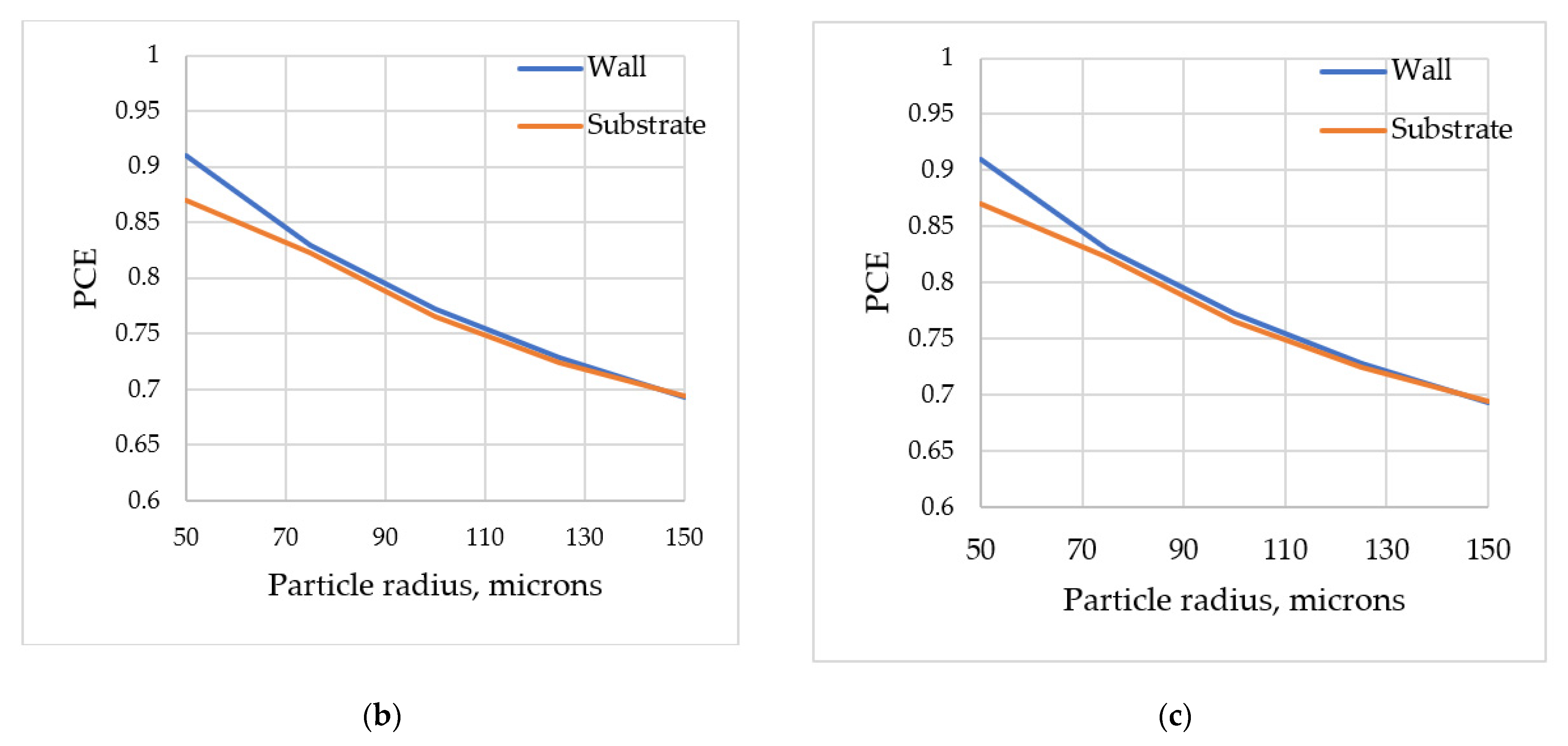

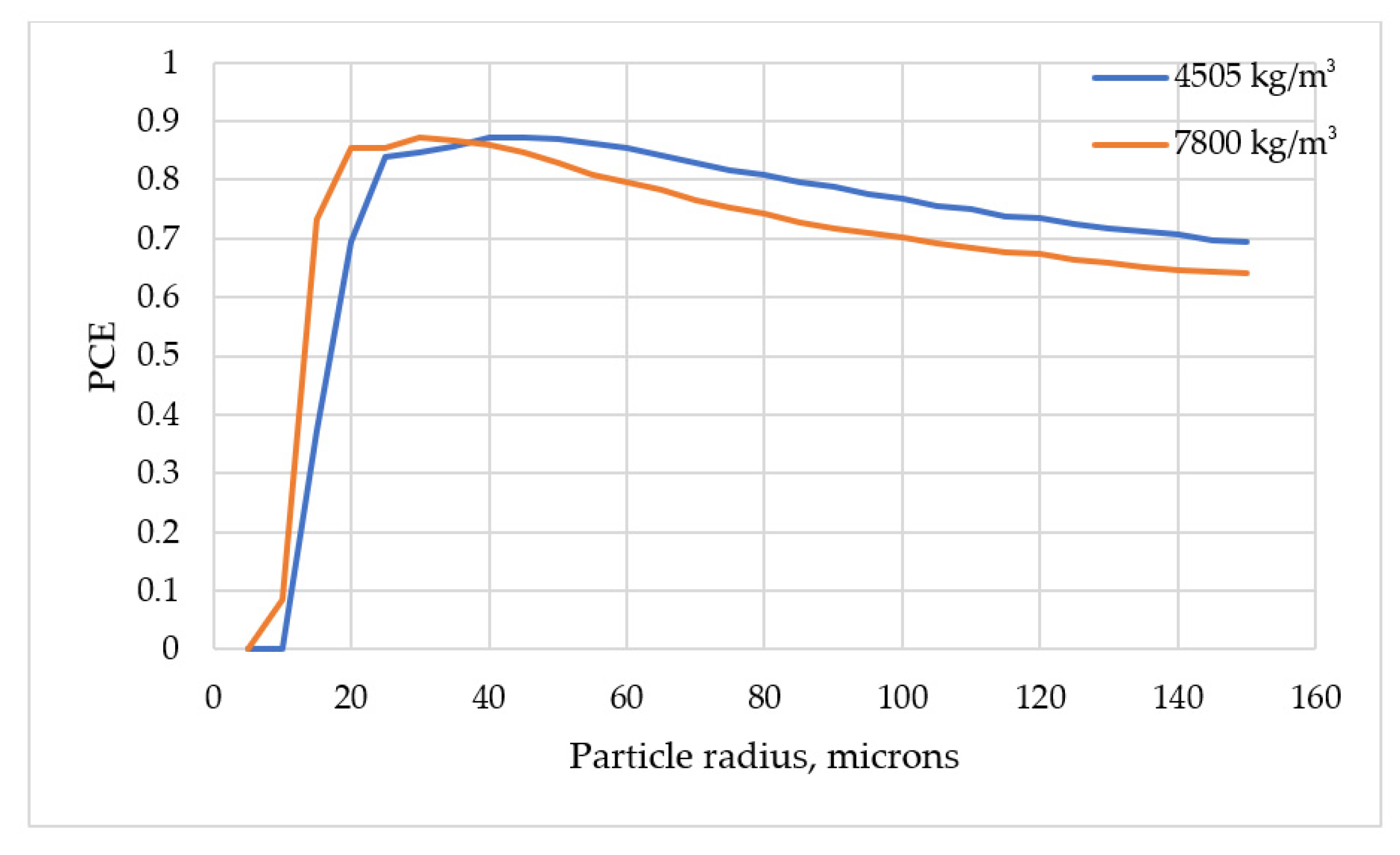

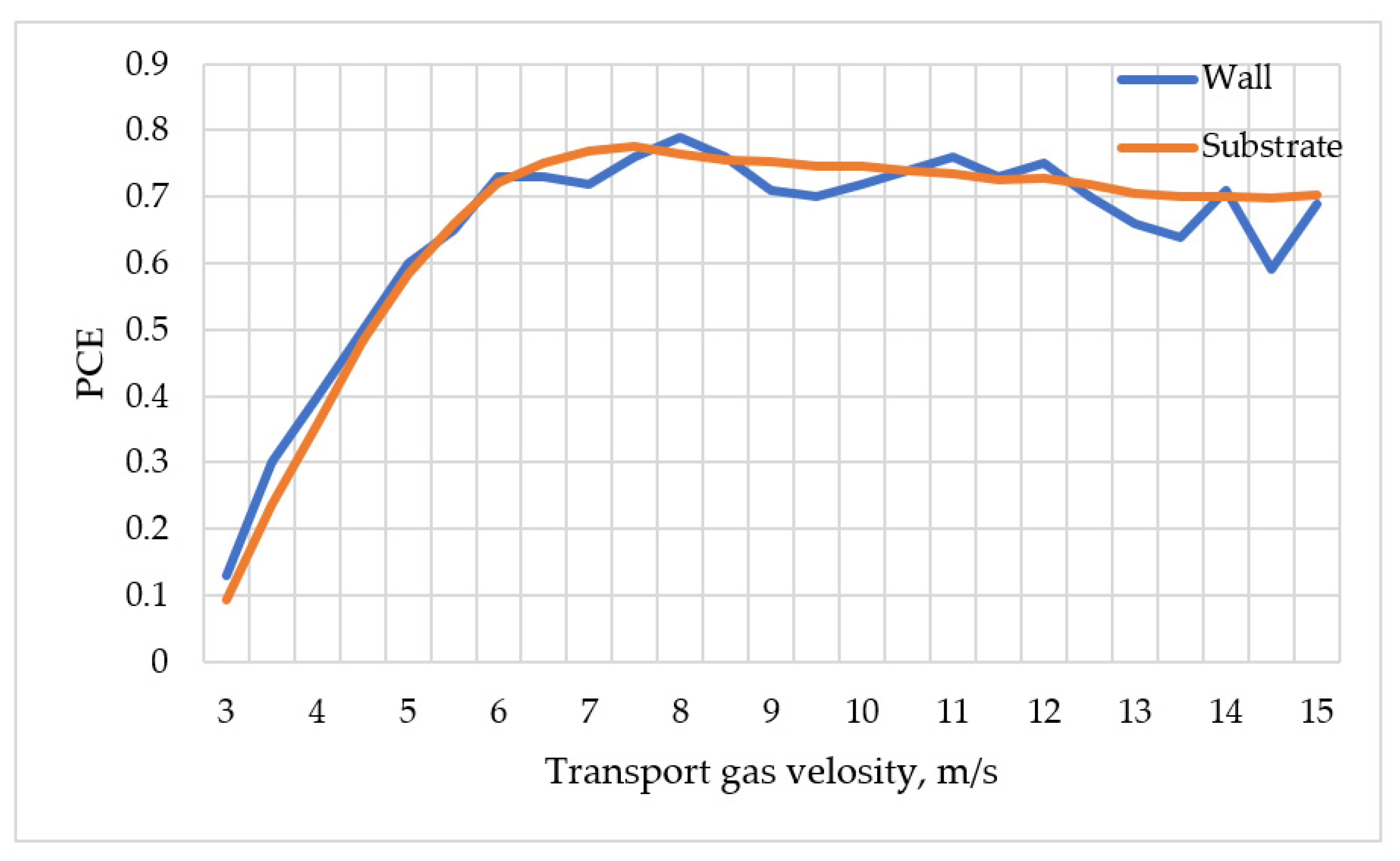

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Turichin, G.A.; Zemlyakov, E.V.; Klimova, O.G.; Babkin, K.D.; Shamraj, F.A.; Kolodyazhnyj, D.Y. Pryamoe lazernoe vyrashchivanie-perspektivnaya additivnaya tekhnologiya dlya aviadvigatelestroeniya. Svarka i Diagnostika (Weld. Diagn. Russ.) 2015, 3, 54–57. [Google Scholar]

- Shedrin, E.Y.U.; Yakushin, N.I.; Popov, A.S.; Turichin, G.A.; Shamraj, F.A.; Kolodyazhnyj, D.Y. Vnedrenie industrial’noj tekhnologii geterofaznoj poroshkovoj lazernoj metallurgii v pao "kuznecov" dlya proizvodstva detalej dvigatelya nk-36st. Additivnye Tekhnol. Nastoyashchee I Budus. (Addit. Technol. Now Future Russ.) 2016, 14. [Google Scholar]

- Turichin; Zemlyakov; Babkin; Vil’danov; Golovin; Topalov; Rodionov. 2020 Method for production of topologically optimized water-jet propellers impeller by direct laser growth method. RU Patent 2718823 C1, 14 April 2020. [Google Scholar]

- Turichin, G.A.; Zemlyakov, E.V.; Klimova-Korsmik, O.G.; Babkin, K.D. Pryamoe lazernoe vyrashchivanie krupnogabar-itnyh metallicheskih komponentov morskoj i aviacionnoj tekhniki. In Proceedings of the Vysokoenergeticheskie i Special’nye Materialy: Demilitarizaciya, Antiterrorizm i Grazhdanskoe Primenenie (Collection of Conference HEMS-2018 Reports In Russian), Tomsk, Russia, 3–5 September 2018. [Google Scholar]

- Magerramova; Babkin; Klimova-Korsmik; Turichin. Method of manufacturing hollow disk of gas turbine engine. RU Patent 2672989 C1, 22 November 2018. [Google Scholar]

- Turichin, G.A.; Kotov, V.S.; Barskov, V.V.; Reznikova, R.K. Additivnye tekhnologii v kachestve osnovy vnedreniya op-erativnogo remonta energeticheskogo oborudovaniya korablei i sudov VMF. Transp. Delo Ross. (Transp. Bus. Russ. Russ.) 2021, 1, 144–147. [Google Scholar]

- Turichin, G.A.; Korsmik, R.S.; Klimova-Korsmik, O.G.; Zemlyakov, E.V.; Babkin, K.D. Lazernaya poroshkovaya voss-tanovitel’naya naplavka lopatok gazoturbinnogo dvigatelya. In Proceedings of the Problemy i Perspektivy Razvitiya Dvigatelestroeniya (Problems and Prospects of Engine Building Development in Russian), Samara, Russia, 22–24 June 2016. [Google Scholar]

- Gol’dfarb, V.I.; Trubachev, E.S.; Haranzhevskij, E.V.; Ipatov, A.G.; Bogdanov, K.V.; Matveeva, Y.U. Novaya tekhnologiya lazernoj modifikacii poverhnostej nizkoskorostnyh tyazhelonagruzhennyh opor skol’zheniya. Vestn. IzhGTU Im. MT Kalashnikova (J. Kalashnikov ISTU Russ.) 2017, 20, 112–117. [Google Scholar]

- Chen, B.; Mazumder, J. Role of process parameters during additive manufacturing by direct metal deposition of Inconel 718. Rapid Prototyp. J. 2017, 23, 919–929. [Google Scholar] [CrossRef]

- Izadi, M.; Farzaneh, A.; Mohammed, M.; Gibson, I.; Rolfe, B. A review of laser engineered net shaping (LENS) build and process parameters of metallic parts. Rapid Prototyp. J. 2020, 26, 1059–1078. [Google Scholar] [CrossRef]

- Turichin, G.; Zemlyakov, E.; Klimova, O.; Babkin, K. Hydrodynamic Instability in High-speed Direct Laser Deposition for Additive Manufacturing. Phys. Procedia 2016, 83, 674–683. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; He, X.; Yu, G.; Wang, Z.; Li, S.; Zheng, C.; Ning, W. Numerical simulation of powder transport behavior in laser cladding with coaxial powder feeding. Sci. China Ser. G Physics. Mech. Astron. 2015, 58, 104701. [Google Scholar] [CrossRef] [Green Version]

- Zekovic, S.; Rajeev, D.; Radovan, K. Numerical simulation and experimental investigation of gas–powder flow from radially symmetrical nozzles in laser-based direct metal deposition. Int. J. Mach. Tools Manuf. 2007, 47, 112–123. [Google Scholar] [CrossRef]

- Li, L.; Huang, Y. Numerical and experimental study on powder stream characteristics in coaxial laser cladding process. In Proceedings of the 6th International Conference on Welding Science and Engineering, Beijing, China, 13–15 October 2015. [Google Scholar]

- Liu, Z.; Zhang, H.C.; Peng, S.; Kim, H.; Du, D.; Cong, W. Analytical modeling and experimental validation of powder stream distribution during direct energy deposition. Addit. Manuf. 2019, 30, 100848. [Google Scholar] [CrossRef]

- Varaksin, A.Y. Turbulent Particle-Laden Gas Flows; Springer: Berlin, Germany, 2007. [Google Scholar]

- Volkov, K.; Emel’yanov, V. Techeniya gaza s Chasticami [Gas Flows with Particles]; FIZMATLIT: Moscow, Russia, 2008. (In Russian) [Google Scholar]

- Boothroyd, R.G. Flowing Gas Solids Suspensions; Chapman and Hall: London, UK, 1971. [Google Scholar]

- Gulyaev, I.P.; Kovalev, O.B.; Pinaev, P.A.; Grachev, G.N. Optical diagnostics of radiation interaction with the powder stream laterally transported during laser cladding. Opt. Lasers Eng. 2019, 126, 105877. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Kulish, A.; Sova, A.; Petrovskiy, P.; Smurov, I. Experimental and numerical study of gas-powder flux in coaxial laser cladding nozzles of Precitec. Surf. Coatings Technol. 2020, 406, 126672. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Zaitsev, A.V.; Novichenko, D.; Smurov, I. Theoretical and Experimental Investigation of Gas Flows, Powder Transport and Heating in Coaxial Laser Direct Metal Deposition (DMD) Process. J. Therm. Spray Technol. 2010, 20, 465–478. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Bedenko, D.V.; Zaitsev, A.V. Development and application of laser cladding modeling technique: From coaxial powder feeding to surface deposition and bead formation. Appl. Math. Model. 2018, 57, 339–359. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Kovaleva, I.O.; Smurov, I.Y. Numerical investigation of gas-disperse jet flows created by coaxial nozzles during the laser direct material deposition. J. Mater. Process. Technol. 2017, 249, 118–127. [Google Scholar] [CrossRef]

- Kuzmin, D.; Mierka, O.; Turek, S. On the implementation of the κ-ε turbulence model in incompressible flow solvers based on a finite element discretisation. Int. J. Comput. Sci. Math. 2007, 1, 193–206. [Google Scholar] [CrossRef]

- Wendt, J.F. (Ed.) Omputational Fluid Dynamics: An Introduction; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Jones, W.P.; Launder, B.E. The prediction of laminarization with a two-equation model of turbulence. Int. J. Heat Mass Transf. 1972, 15, 301–314. [Google Scholar] [CrossRef]

- Haider, A.; Levenspiel, O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989, 58, 63–70. [Google Scholar] [CrossRef]

- Gladush, G.G.; Smurov, I. Physics of Laser Materials Processing: Theory and Experiment; Springer: Berlin, Germany, 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stankevich, S.; Larionov, N.; Valdaytseva, E. Numerical Analysis of Particle Trajectories in a Gas–Powder Jet during the Laser-Based Directed Energy Deposition Process. Metals 2021, 11, 2002. https://doi.org/10.3390/met11122002

Stankevich S, Larionov N, Valdaytseva E. Numerical Analysis of Particle Trajectories in a Gas–Powder Jet during the Laser-Based Directed Energy Deposition Process. Metals. 2021; 11(12):2002. https://doi.org/10.3390/met11122002

Chicago/Turabian StyleStankevich, Stanislav, Nikolay Larionov, and Ekaterina Valdaytseva. 2021. "Numerical Analysis of Particle Trajectories in a Gas–Powder Jet during the Laser-Based Directed Energy Deposition Process" Metals 11, no. 12: 2002. https://doi.org/10.3390/met11122002

APA StyleStankevich, S., Larionov, N., & Valdaytseva, E. (2021). Numerical Analysis of Particle Trajectories in a Gas–Powder Jet during the Laser-Based Directed Energy Deposition Process. Metals, 11(12), 2002. https://doi.org/10.3390/met11122002