Martensitic Transformation and Metamagnetic Transition in Co-V-(Si, Al) Heusler Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

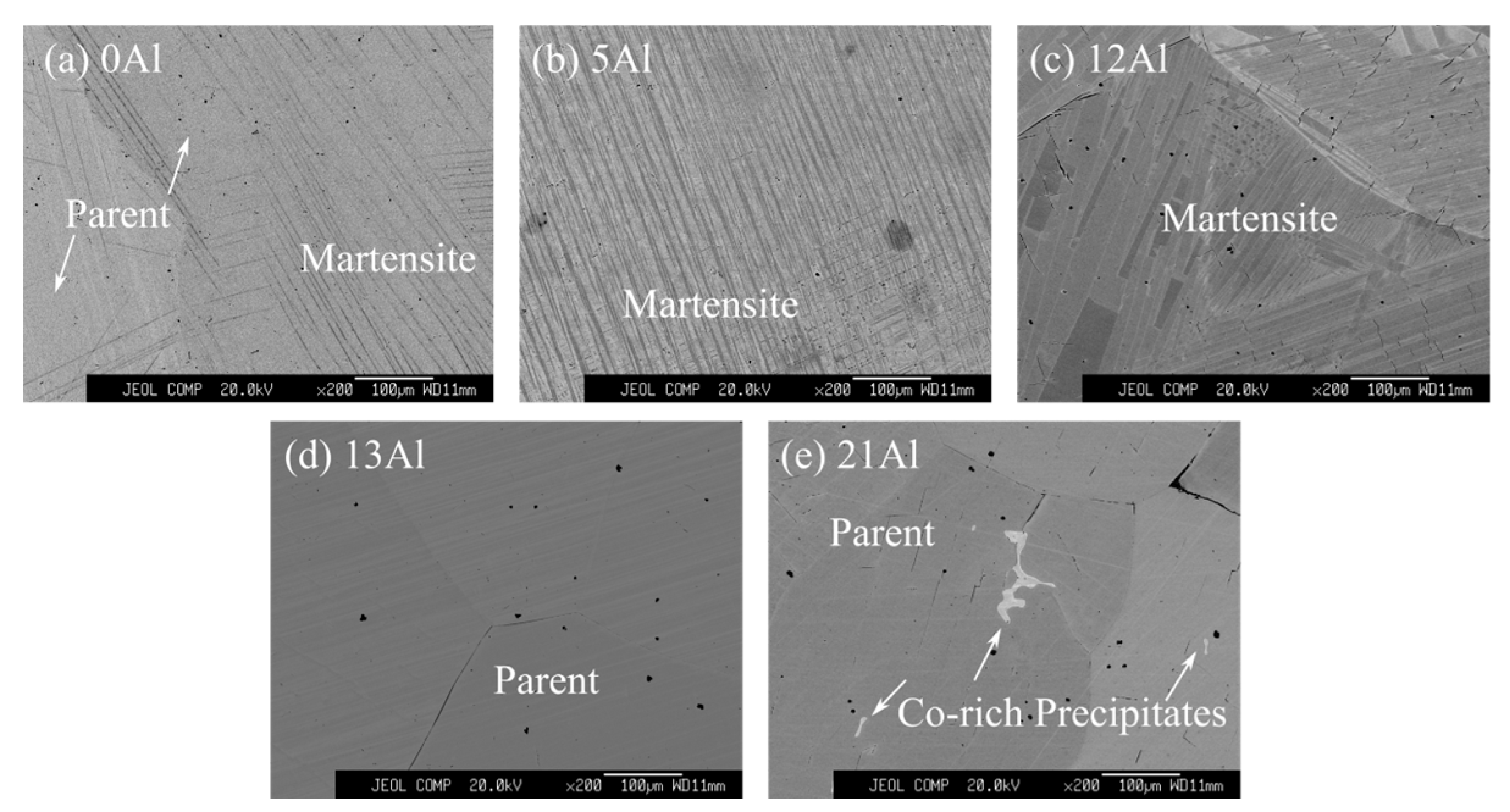

3.1. Microstructure Observation

3.2. Crystal Structures

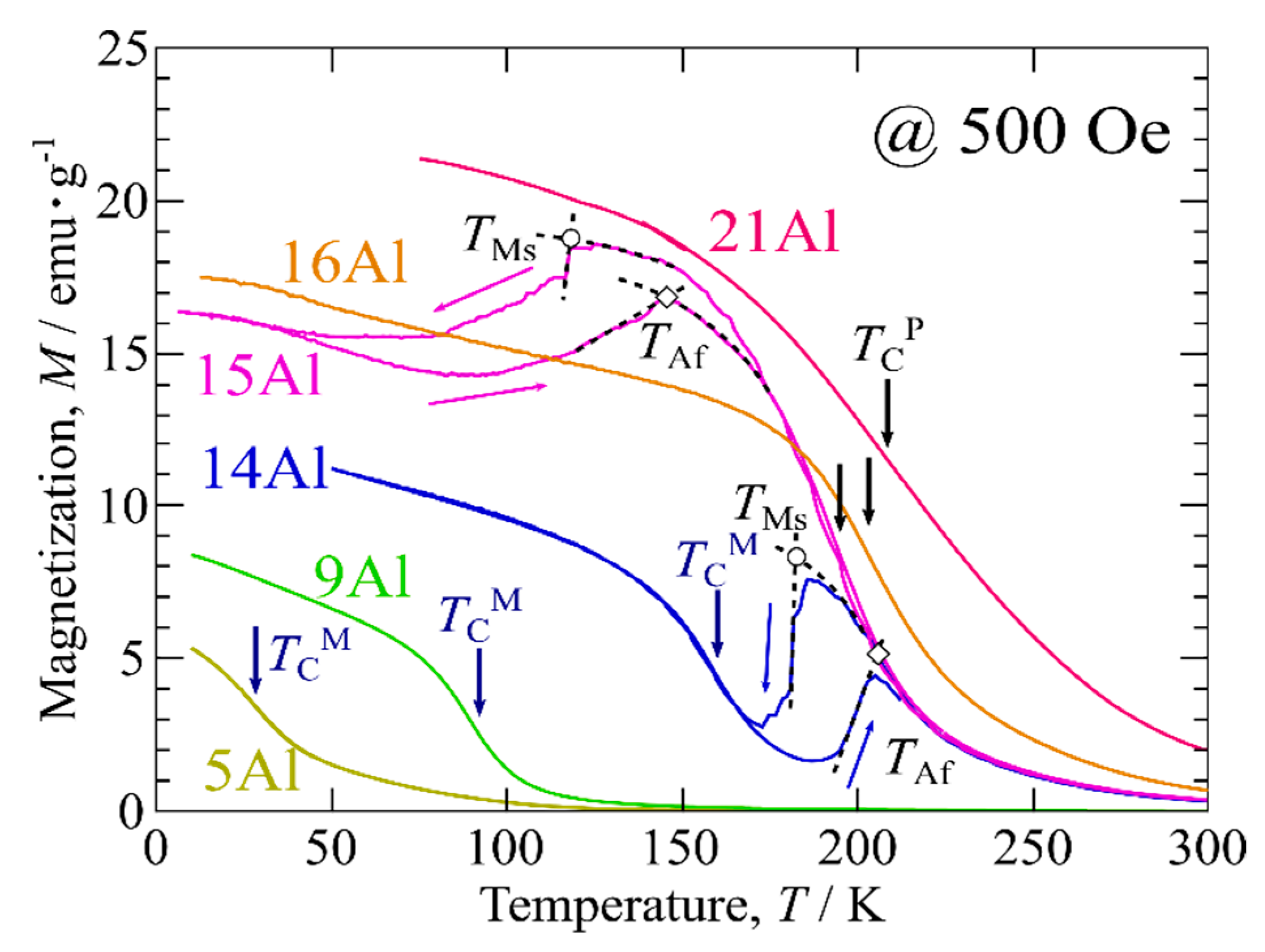

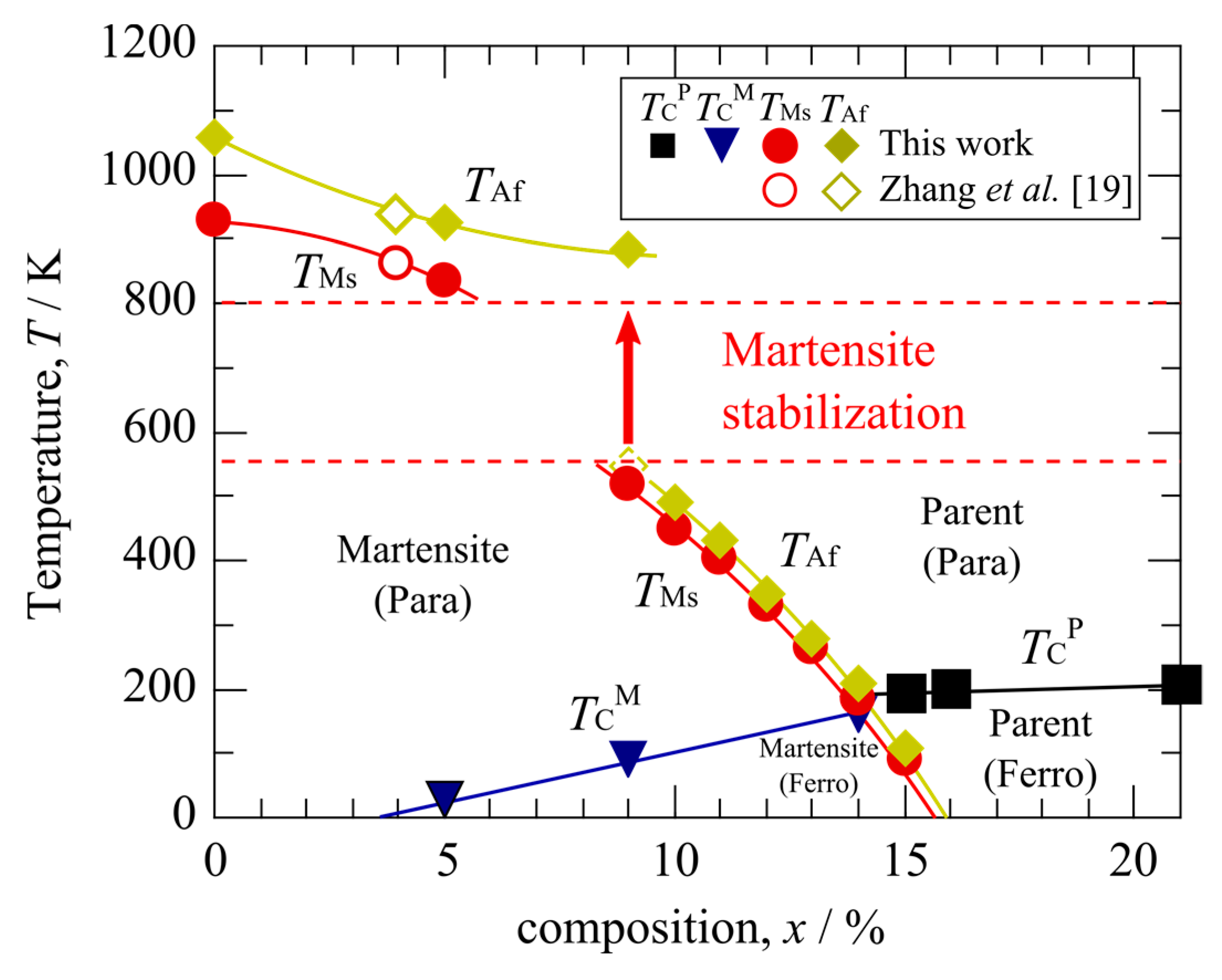

3.3. Determination of Martensitic and Magnetic Transformation Temperatures

3.4. Magnetic Properties

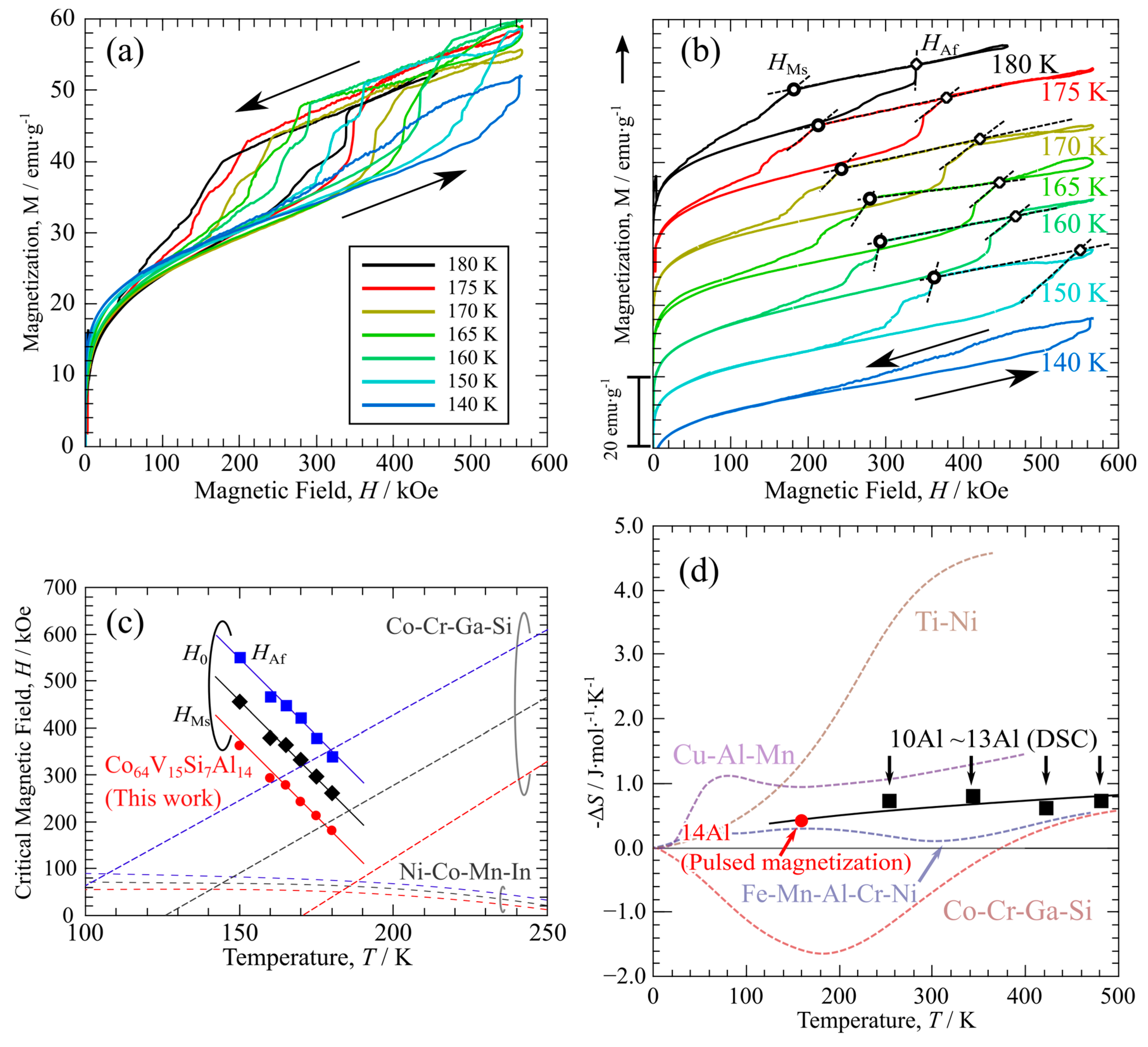

3.5. Magnetic-Field-Induced Reverse Martensitic Transformation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Kainuma, R.; Takahashi, S.; Ishida, K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1996, 27, 2187–2195. [Google Scholar] [CrossRef]

- Omori, T.; Ando, K.; Okano, M.; Xu, X.; Tanaka, Y.; Ohnuma, I.; Kainuma, R.; Ishida, K. Superelastic Effect in Polycrystalline Ferrous Alloys. Science 2011, 333, 68–71. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Koike, J. A lightweight shape-memory magnesium alloy. Science 2016, 353, 368–370. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef]

- Sutou, Y.; Imano, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K.; Oikawa, K. Magnetic and martensitic transformations of NiMnX(X=In, Sn, Sb) ferromagnetic shape memory alloys. Appl. Phys. Lett. 2004, 85, 4358–4360. [Google Scholar] [CrossRef]

- Galanakis, I.; Dederichs, P.H.; Papanikolaou, N. Slater-Pauling behavior and origin of the half-metallicity of the full-Heusler alloys. Phys. Rev. B 2002, 66, 174429. [Google Scholar] [CrossRef] [Green Version]

- Terada, M.; Fujita, Y.; Endo, K. Magnetic properties of the Heusler alloys M2XSn (M=Co or Ni, X=Zr, Nb or Hf). J. Phys. Soc. Jpn. 1974, 36, 620. [Google Scholar] [CrossRef]

- Xu, X.; Omori, T.; Nagasako, M.; Okubo, A.; Umetsu, R.Y.; Kanomata, T.; Ishida, K.; Kainuma, R. Cooling-induced shape memory effect and inverse temperature dependence of superelastic stress in Co2Cr(Ga,Si) ferromagnetic Heusler alloys. Appl. Phys. Lett. 2013, 103, 164104. [Google Scholar] [CrossRef]

- Hirata, K.; Xu, X.; Omori, T.; Nagasako, M.; Kainuma, R. Martensitic transformation and superelasticity in off-stoichiometric Co2Cr(AlSi) Heusler alloys. J. Alloys Compd. 2015, 642, 200–203. [Google Scholar] [CrossRef]

- Xu, X.; Nagashima, A.; Nagasako, M.; Omori, T.; Kanomata, T.; Kainuma, R. Martensitic transformation and phase diagram in ternary Co-V-Ga Heusler alloys. Appl. Phys. Lett. 2017, 110, 121906. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, X.; Omori, T.; Nagasako, M.; Ruan, J.; Yang, S.; Wang, C.; Liu, X.; Kainuma, R. Martensitic transformation and shape memory effect at high temperatures in off-stoichiometric Co2VSi Heusler alloys. Mater. Sci. Eng. A 2016, 676, 191–196. [Google Scholar] [CrossRef]

- Jiang, H.; Yang, S.; Wang, C.; Zhang, Y.; Xu, X.; Chen, Y.; Omori, T.; Kainuma, R.; Liu, X. Martensitic transformation and shape memory effects in Co-V-Al alloys at high temperatures. J. Alloys Compd. 2019, 786, 648–654. [Google Scholar] [CrossRef]

- Xu, X.; Kihara, T.; Miyake, A.; Tokunaga, M.; Kanomata, T.; Kainuma, R. Magnetic-field-induced transition for reentrant martensitic transformation in Co-Cr-Ga-Si shape memory alloys. J. Magn. Magn. Mater. 2018, 466, 273–276. [Google Scholar] [CrossRef]

- Odaira, T.; Xu, X.; Miyake, A.; Omori, T.; Tokunaga, M.; Kainuma, R. Thermal, magnetic field- and stress-induced transformation in Heusler-type Co-Cr-Al-Si shape memory alloys. Scripta Mater. 2018, 153, 35–39. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.; Zhang, Y.; Huang, Y.; Ye, M.; Sun, X.; Zhang, G.; Cao, Y.; Xu, K.; Jing, C. Realization of metamagnetic martensitic transformation with multifunctional properties in Co50V34Ga16 Heusler alloy. Appl. Phys. Lett. 2018, 112, 211903. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, C.; Xu, W.; Xu, X.; Yang, S.; Kainuma, R.; Liu, X. Alloying effects of Ga on the Co-V-Si high-temperature shape memory alloys. Mater. Des. 2017, 116, 300–308. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, H.; Liu, X.; Huang, L.; Yang, S.; Wang, C. Thermal cycle stability of Co64V15Si17Al4 high-temperature shape memory alloy. Mater. Lett. 2020, 260, 126930. [Google Scholar] [CrossRef]

- Odaira, T.; Xu, S.; Xu, X.; Omori, T.; Kainuma, R. Elastocaloric switching effect induced by reentrant martensitic transformation. Appl. Phys. Rev. 2020, 7, 031406. [Google Scholar] [CrossRef]

- Kindo, K. 100T magnet developed in Osaka. Phys. B Condens. Matter 2001, 294–295, 585–590. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Mechanism of martensite aging effect. Scripta Mater. 2004, 50, 207–212. [Google Scholar] [CrossRef]

- Kainuma, R.; Ishida, K.; Nakano, H. Martensitic transformations in NiMnAl β phase alloys. Metall. Mater. Trans. A 1996, 27, 4153–4162. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A.; Suard, E.; Ouladdiaf, B. Magnetic superelasticity and inverse magnetocaloric effect in Ni-Mn-In. Phys. Rev. B 2007, 75, 104414. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Ito, W.; Umetsu, R.Y.; Koyama, K.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in Ni33.0Co13.4Mn39.7Ga13.9 metamagnetic shape memory alloy. Mater. Trans. 2010, 51, 469–471. [Google Scholar] [CrossRef] [Green Version]

- Sozinov, A.; Likhachev, A.A.; Lanska, N.; Ullakko, K. Giant magnetic-field-induced strain in NiMnGa seven-layered martensitic phase. Appl. Phys. Lett. 2002, 80, 1746–1748. [Google Scholar] [CrossRef]

- Xu, X.; Nagasako, M.; Ito, W.; Umetsu, R.Y.; Kanomata, T.; Kainuma, R. Magnetic properties and phase diagram of Ni50Mn 50-xGax ferromagnetic shape memory alloys. Acta Mater. 2013, 61, 6712–6723. [Google Scholar] [CrossRef]

- Arrott, A. Criterion for ferromagnetism from observations of magnetic isotherms. Phys. Rev. 1957, 108, 1394–1396. [Google Scholar] [CrossRef]

- Kanomata, T.; Yasuda, T.; Sasaki, S.; Nishihara, H.; Kainuma, R.; Ito, W.; Oikawa, K.; Ishida, K.; Neumann, K.U.; Ziebeck, K.R.A. Magnetic properties on shape memory alloys Ni2Mn1+xIn1-x. J. Magn. Magn. Mater. 2009, 321, 773–776. [Google Scholar] [CrossRef]

- Ito, W.; Ito, K.; Umetsu, R.Y.; Kainuma, R.; Koyama, K.; Watanabe, K.; Fujita, A.; Oikawa, K.; Ishida, K.; Kanomata, T. Kinetic arrest of martensitic transformation in the NiCoMnIn metamagnetic shape memory alloy. Appl. Phys. Lett. 2008, 92, 021908. [Google Scholar] [CrossRef]

- Niitsu, K.; Kimura, Y.; Omori, T.; Kainuma, R. Cryogenic superelasticity with large elastocaloric effect. NPG Asia Mater. 2018, 10, e457. [Google Scholar] [CrossRef] [Green Version]

- Xia, J.; Noguchi, Y.; Xu, X.; Odaira, T.; Kimura, Y.; Nagasako, M.; Omori, T.; Kainuma, R. Iron-based superelastic alloys with near-constant critical stress temperature dependence. Science 2020, 369, 855–858. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Xu, X.; Miyake, A.; Kimura, Y.; Omori, T.; Tokunaga, M.; Kainuma, R. Stress- and magnetic field-induced martensitic transformation at cryogenic temperatures in Fe–Mn–Al–Ni shape memory alloys. Shape Mem. Superelasticity 2017, 3, 467–475. [Google Scholar] [CrossRef]

| Alloy | Phase at Room Temperature | Composition (Atomic %) | |||

|---|---|---|---|---|---|

| Co | V | Si | Al | ||

| 0Al | P + M | 64.0 | 15.4 | 20.6 | - |

| 5Al | M | 63.6 | 15.4 | 16.5 | 4.5 |

| 9Al | M | 64.2 | 15.5 | 11.3 | 9.0 |

| 10Al | M | 64.1 | 15.5 | 10.1 | 10.2 |

| 11Al | M | 64.3 | 15.7 | 9.1 | 10.9 |

| 12Al | M | 63.8 | 15.6 | 8.3 | 12.3 |

| 13Al | P | 64.2 | 15.7 | 7.1 | 13.0 |

| 14Al | P | 64.2 | 15.7 | 6.1 | 13.9 |

| 15Al | P | 64.2 | 15.5 | 5.3 | 15.0 |

| 16Al | P | 64.8 | 15.7 | 3.7 | 15.8 |

| 21Al | P (Matrix) | 64.5 | 15.5 | - | 20.0 |

| 2nd | 77.2 | 15.4 | - | 7.4 | |

| Alloy | Lattice Constant (Powder) | Lattice Constant (Bulk) | ||||||

|---|---|---|---|---|---|---|---|---|

| a (L21, nm) | a (D022, nm) | c (D022, nm) | c/2a | a (L21, nm) | a (D022, nm) | c (D022, nm) | c/2a | |

| 0Al | 0.5627 | - | - | - | 0.5628 | 0.3693 | 0.6579 | 0.8909 |

| 5Al | - | 0.3739 | 0.6472 | 0.8654 | - | 0.3739 | 0.6472 | 0.8654 |

| 9Al | 0.5684 | 0.3783 | 0.6389 | 0.8444 | - | 0.3781 | 0.6399 | 0.8462 |

| 10Al | - | 0.3808 | 0.6348 | 0.8335 | - | - | - | - |

| 11Al | 0.5688 | 0.3806 | 0.6341 | 0.8330 | - | - | - | - |

| 12Al | 0.5696 | 0.3825 | 0.6275 | 0.8203 | - | - | - | - |

| 13Al | 0.5703 | - | - | - | - | - | - | - |

| 14Al | 0.5709 | - | - | - | - | - | - | - |

| 15Al | 0.5710 | - | - | - | - | - | - | - |

| 21Al | 0.5733 | - | - | - | - | - | - | - |

| Alloy | Transformation Temperatures (K) | Thermal Hysteresis TAf − TMs (K) | |||

|---|---|---|---|---|---|

| TCP | TCM | TMs | TAf | ||

| 0Al | - | 928 | 1056 | 128 | |

| 5Al | - | 27 | 836 | 923 | 88 |

| 9Al | - | 92 | 518 | 882 | 364 |

| 10Al | - | - | 449 | 491 | 24 |

| 11Al | - | - | 405 | 430 | 25 |

| 12Al | - | - | 330 | 348 | 18 |

| 13Al | - | - | 265 | 280 | 15 |

| 14Al | - | 160 | 185 | 209 | 24 |

| 15Al | 195 | - | 90 | 108 | 18 |

| 16Al | 202 | - | - | - | - |

| 21Al | 210 | - | - | - | - |

| Alloy | Spontaneous Magnetization | |

|---|---|---|

| emu g−1 | μB f.u.−1 | |

| 5Al | 10.8 | 0.39 |

| 9Al | 18.6 | 0.68 |

| 14Al | 28.8 | 1.05 |

| 15Al | 30.5 | 1.11 |

| 16Al | 35.0 | 1.28 |

| 21Al | 40.4 | 1.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakamura, K.; Miyake, A.; Xu, X.; Omori, T.; Tokunaga, M.; Kainuma, R. Martensitic Transformation and Metamagnetic Transition in Co-V-(Si, Al) Heusler Alloys. Metals 2021, 11, 226. https://doi.org/10.3390/met11020226

Nakamura K, Miyake A, Xu X, Omori T, Tokunaga M, Kainuma R. Martensitic Transformation and Metamagnetic Transition in Co-V-(Si, Al) Heusler Alloys. Metals. 2021; 11(2):226. https://doi.org/10.3390/met11020226

Chicago/Turabian StyleNakamura, Kousuke, Atsushi Miyake, Xiao Xu, Toshihiro Omori, Masashi Tokunaga, and Ryosuke Kainuma. 2021. "Martensitic Transformation and Metamagnetic Transition in Co-V-(Si, Al) Heusler Alloys" Metals 11, no. 2: 226. https://doi.org/10.3390/met11020226

APA StyleNakamura, K., Miyake, A., Xu, X., Omori, T., Tokunaga, M., & Kainuma, R. (2021). Martensitic Transformation and Metamagnetic Transition in Co-V-(Si, Al) Heusler Alloys. Metals, 11(2), 226. https://doi.org/10.3390/met11020226