Statistical Soil Characterization of an Underground Corroded Pipeline Using In-Line Inspections

Abstract

:1. Introduction

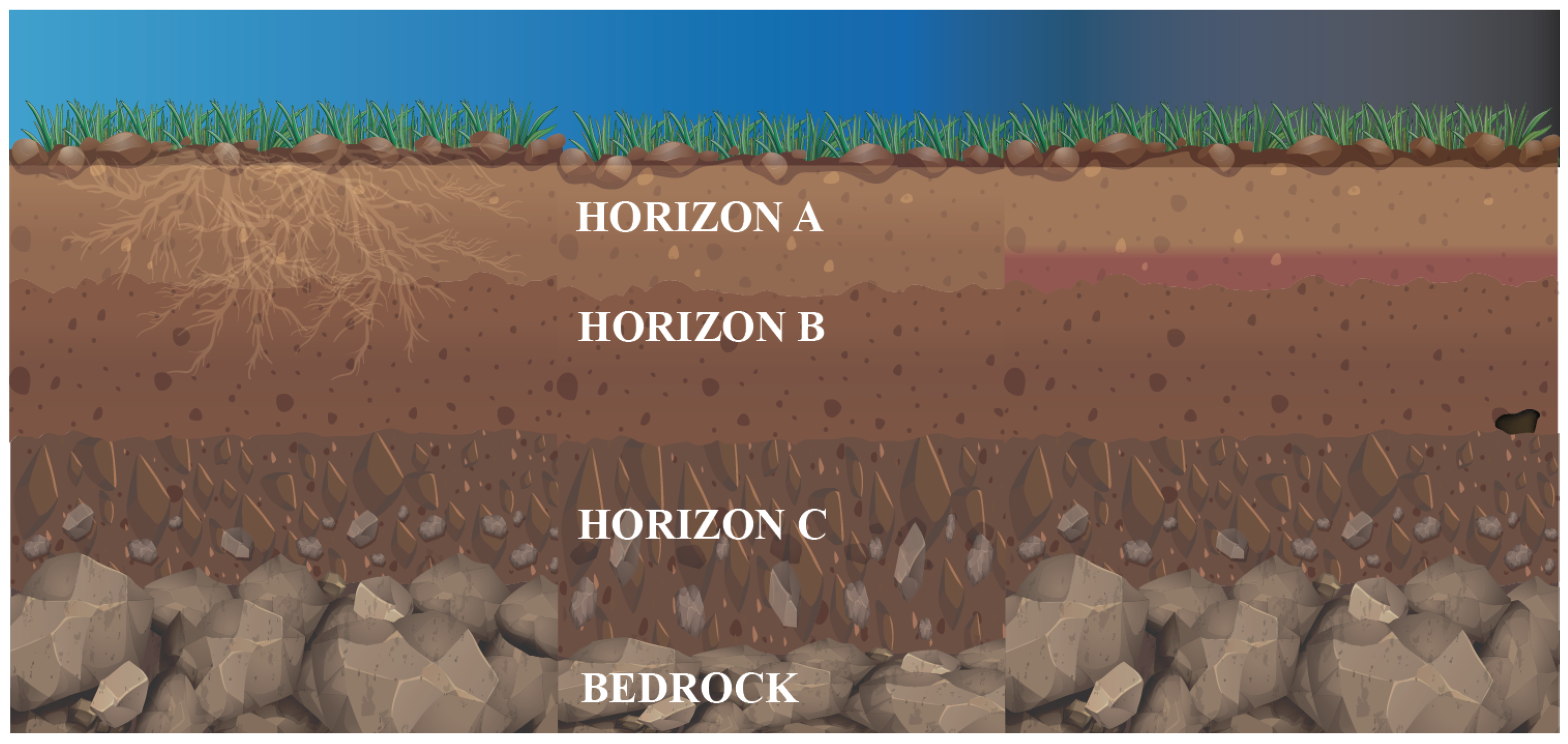

2. Brief Description of the Soil Surrounding the Pipeline

- Horizon A (Eluvial zone): This zone is at the top of the soil profile; it directly contacts the atmosphere, receiving the rainfall and nutrients from the environment. In this zone, the biological activity is related to humus formation, and the leaching process of gravitational water produces more stable minerals (extracts of soluble minerals).

- Horizon B (Illuvial zone): This zone is rich in soluble minerals thanks to the leaching and weathering process in the overlying layer; however, this zone has low organic content.

- Horizon C: Weathering processes commonly leave this zone unaltered, and it tends to host little biological activity.

3. Soil Factors Influencing External Corrosion

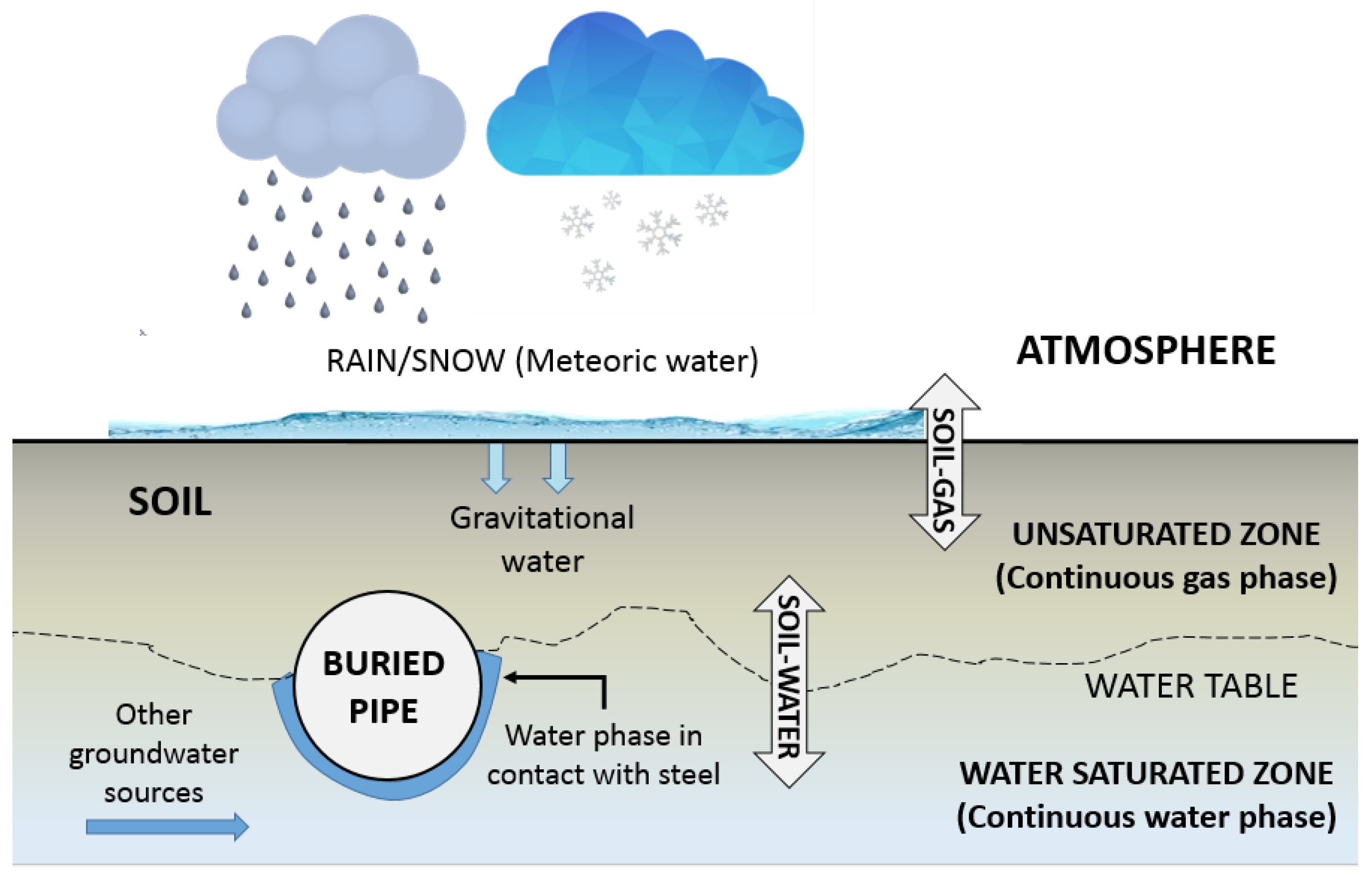

3.1. Moisture Content

3.2. Resistivity

3.3. Acidity of Soils, pH

3.4. Aeration

- Consider a change of aeration between the top and bottom of the pipeline, which could be obtained by installing a pipeline in undisturbed soil and a permeable backfill such as sand.

- Contemplate a difference in aeration because the water table is close to the bottom of the pipeline, where again the bottom of the pipeline would represent an anodic area that favors pits’ appearance.

- The final scenario corresponds to mixed of soils with different permeabilities; for instance, pipelines with a significant portion of clay adhered to metal or coating in a pipeline surrounded mostly by sand. This case would induce an anodic area in the section in contact with the less permeable soil [28].

3.5. Bacteria Activity

3.6. Main Links between Factors

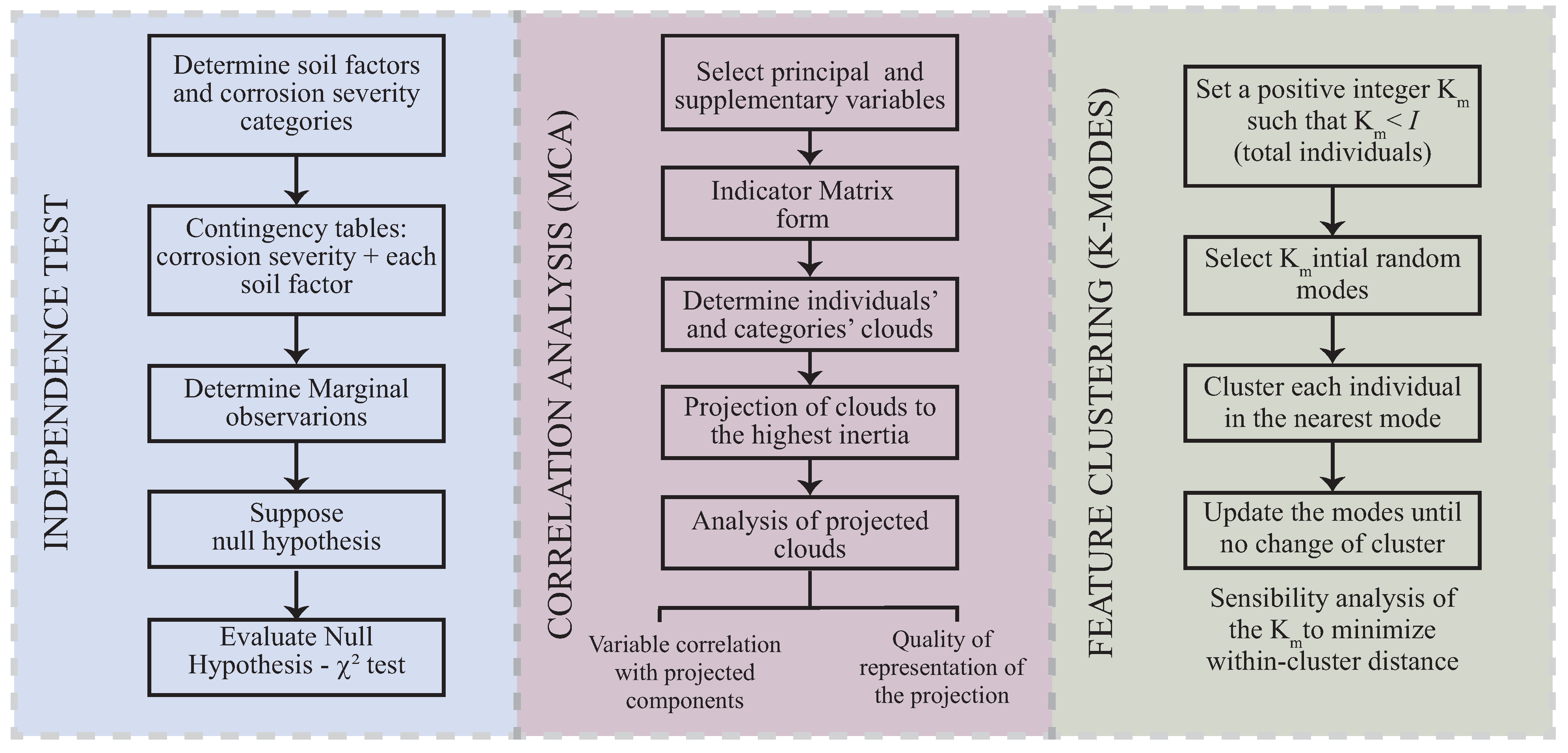

4. Correspondence between Corrosion Depth and Soil Properties: Proposed Methodology

4.1. Soil Features and Corrosion Depth Independence

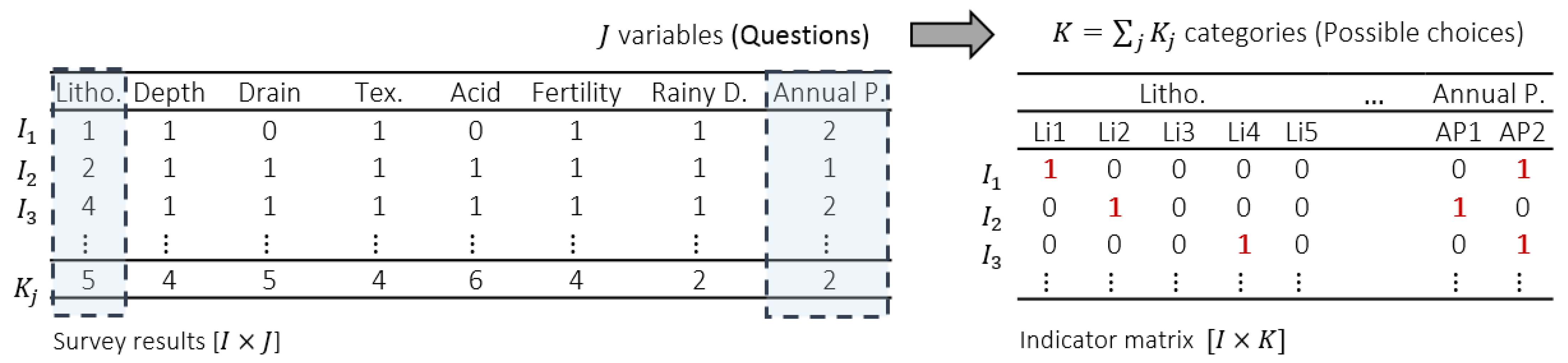

4.2. Multiple Correspondence Analysis of the Soil Features

4.3. Soil Aggressiveness Clusters: K-Modes Approach

5. Case Study: Description and Spatial Dependencies

6. Results and Discussion

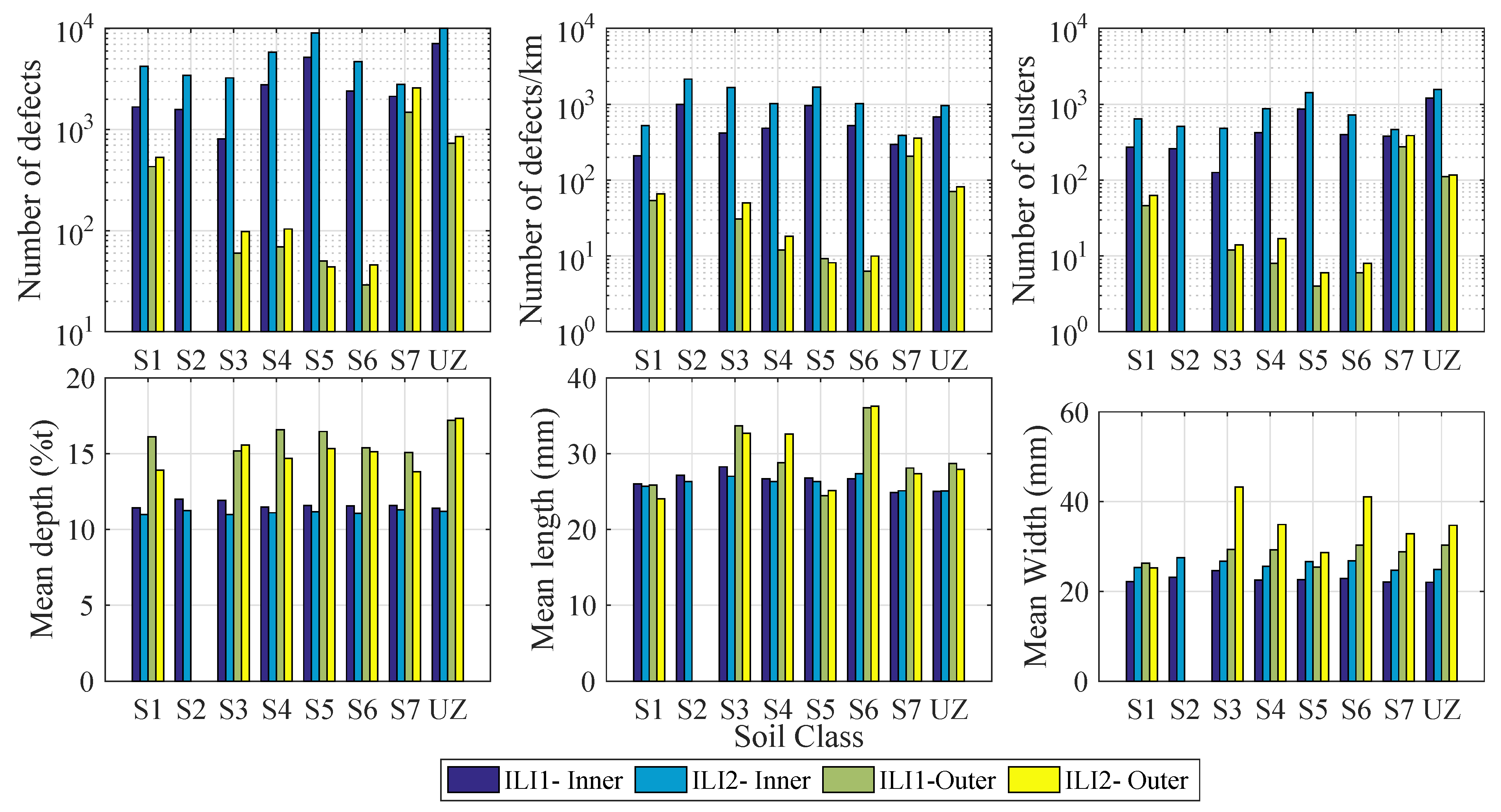

6.1. Correspondence Results with the Soil Categories

- ILI1-Inner: Lithology, texture, acidity, and fertility.

- ILI2-Inner: Fertility.

- ILI1-Outer: Lithology, soil depth, texture, fertility, rainy days, and annual precipitation.

- ILI2-Outer: Lithology, soil depth, drainage, texture, fertility, rainy days, and annual precipitation.

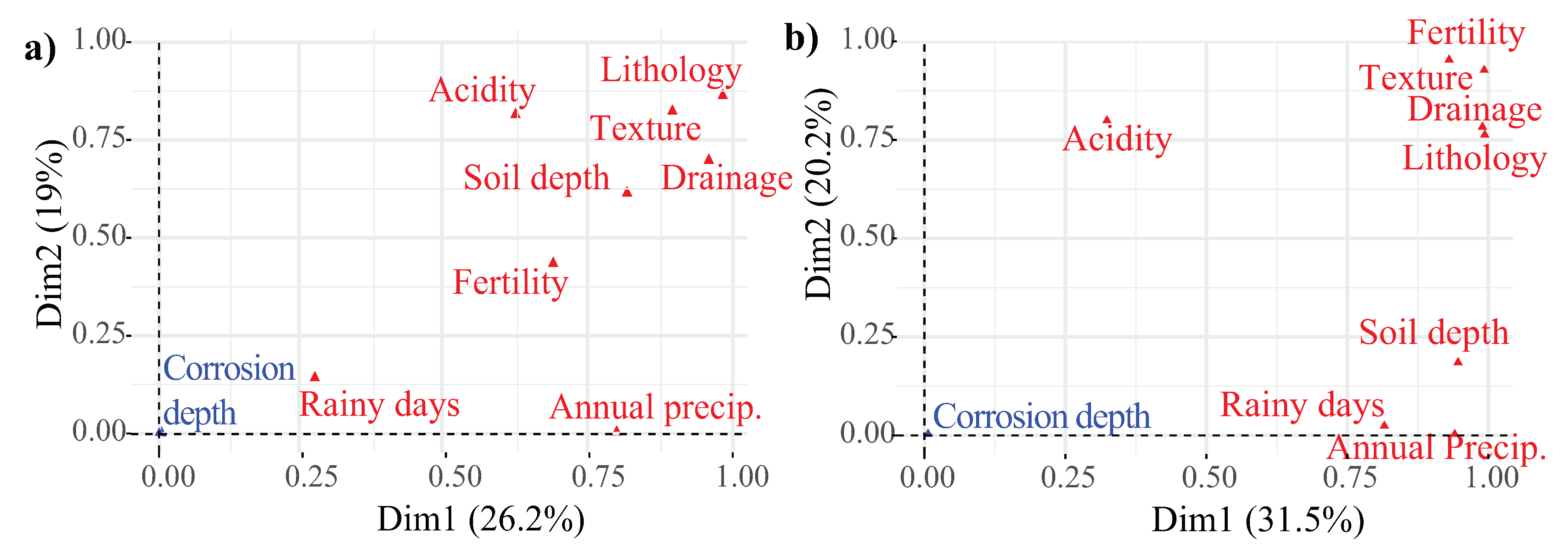

6.2. Multiple Correspondence Analysis (MCA) Results of the Soil Features Categories

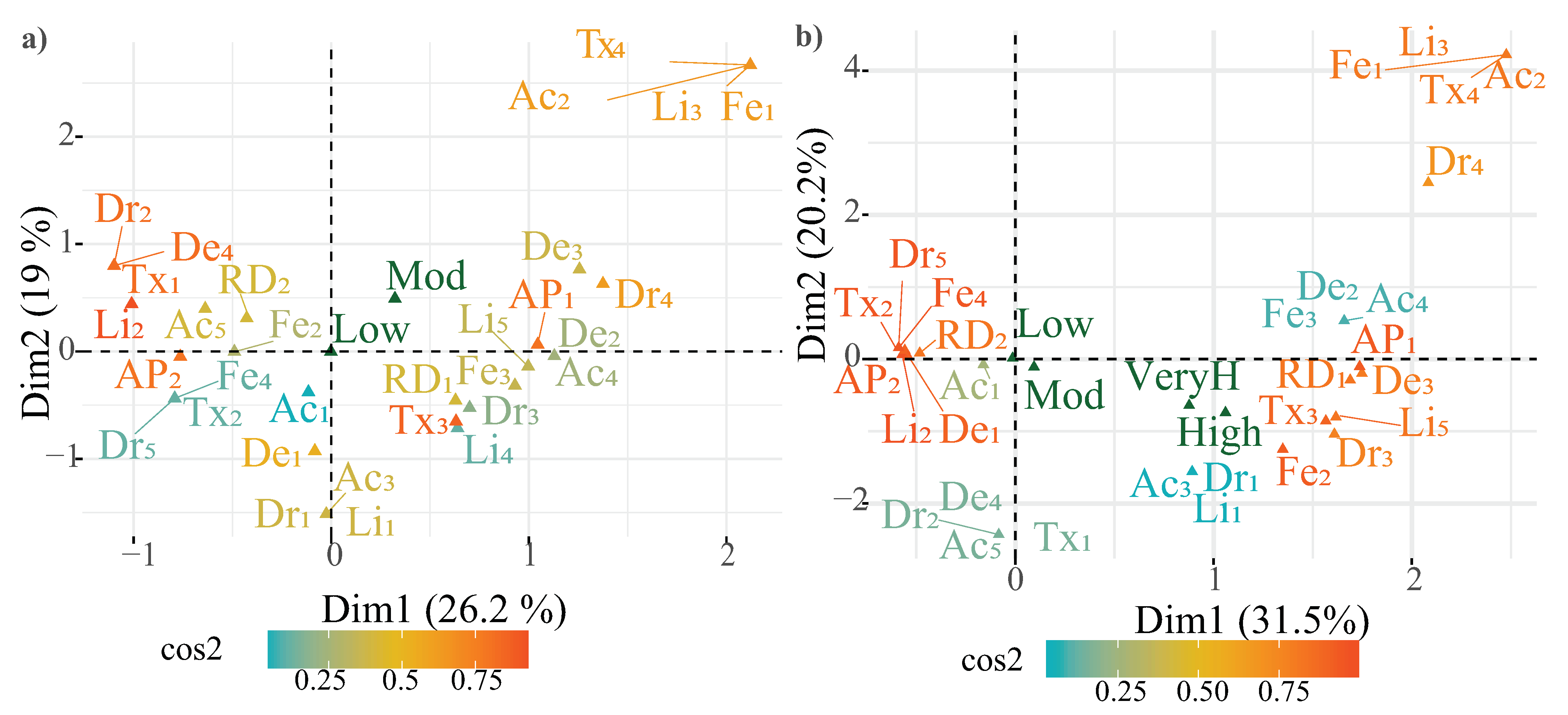

6.3. Corrosion and Soil Characteristics: Result of K-Mode Analysis

7. Conclusions

- The -test results suggested that the fertility and texture categories are related in a higher proportion with the corrosion depth. Other related features include the soil depth, lithology, the number of rainy days, and the annual precipitation. Surprisingly, the results for acidity meant that we failed to reject the null hypothesis, although this is one of the main factors affecting the corrosion rate.

- The MCA results and the K-modes revealed that moderate to high corrosion depths are preferred for poorly drained soils with high annual precipitation and high acidity. This result confirms the reports by different authors about soil moisture and aeration. According to the corrosion literature, poorly drained soils usually trigger poor aeration and favor the corrosion process.

- Some categories that were more correlated included moderate to deep soil (), a fine-to-moderately coarse texture () and moderate soil fertility (). The results of the K-modes method for the outer wall indicated that the acidity was almost entirely clustered in extremely to moderately acid (e.g., pH within 3.5 to 6), in moderate to deep soils and in well to poorly drained soils.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

Abbreviations

| GIS | Geographic Information System |

| ICCP | Impressed current cathodic protection system |

| ILI | In-line inspections |

| LOC | Loss of containment |

| PIG | Pipeline inspection gauge |

| MFL | Magnetic flux leakage |

| MIC | Microbiologically influenced corrosion |

| MCA | Multiple correspondence analysis |

| PCA | Principal component analysis |

| SRB | Sulfate-reducing bacteria |

| ROW | Right-of-way |

| USDA | United States Department of Agriculture |

References

- Castaneda, H.; Rosas, O. External Corrosion of Pipelines in Soil. In Oil and Gas Pipelines; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; Chapter 20; pp. 265–274. [Google Scholar] [CrossRef]

- Romanoff, M. Underground Corrosion; Technical Report; National Bureau of Standards Circular 579; United States Department of Commerce: Washington, DC, USA, 1957.

- Kucera, V.; Mattsson, E. Chapter Atmospheric Corrosion. In Corrosion Mechanisms; Chemical Industries, Marcel Dekker: New York, NY, USA, 1987. [Google Scholar]

- Southwell, C.; Bultman, J.; Alexander, A. Corrosion of Metal in Tropical Environments. Final Report of 16-Year Exposures; Technical Report; US Naval Research Laboratory: Washington, DC, USA, 1976. [Google Scholar]

- Velázquez, J.; Caleyo, F.; Valor, A.; Hallen, J. Predictive Model for Pitting Corrosion in Buried Oil and Gas Pipelines. Corrosion 2009, 65, 332–342. [Google Scholar] [CrossRef]

- Caleyo, F.; Velázquez, J.; Valor, A.; Hallen, J. Probability distribution of pitting corrosion depth and rate in underground pipelines: A Monte Carlo study. Corros. Sci. 2009, 51, 1925–1934. [Google Scholar] [CrossRef]

- Wang, H.; Yajima, A.; Liang, R.Y.; Castaneda, H. Bayesian Modeling of External Corrosion in Underground Pipelines Based on the Integration of Markov Chain Monte Carlo Techniques and Clustered Inspection Data. Comput. Aided Civ. Infrastruct. Eng. 2015, 30, 300–316. [Google Scholar] [CrossRef]

- Winkelmann, R. Seemingly Unrelated Negative Binomial Regression. Oxf. Bull. Econ. Stat. 2000, 62, 553–560. [Google Scholar] [CrossRef]

- Chib, S.; Winkelmann, R. Markov Chain Monte Carlo Analysis of Correlated Count Data. J. Bus. Econ. Stat. 2001, 19, 428–435. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, H.; Tang, F.; Castaneda, H.; Liang, R. Statistical analysis of spatial distribution of external corrosion defects in buried pipelines using a multivariate Poisson-lognormal model. Struct. Infrastruct. Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Rhodes, C. Feeding and healing the world: Through regenerative agriculture and permaculture. Sci. Prog. 2012, 95, 345–446. [Google Scholar] [CrossRef] [PubMed]

- Multiquip Inc. Soil Compaction Handbook; Technical Report; Multiquip Inc.: Carson, CA, USA, 2011. [Google Scholar]

- Jack, T.R.; Wilmott, M.J. Corrosion by Soils. In Uhlig’s Corrosion Handbook; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011; Chapter 25; pp. 333–349. [Google Scholar] [CrossRef]

- Soil Survey. Illustrated Guide to Soil Taxonomy; Technical Report; U.S. Department of Agriculture, Natural Resources Conservation Service: Lincoln, NE, USA, 2015.

- Murray, J.; Moran, P. Influence of Moisture on Corrosion of Pipeline Steel in Soils Using In Situ Impedance Spectroscopy. Corrosion 1989, 45, 34–43. [Google Scholar] [CrossRef]

- King, R. A Review of Soil Corrosiveness with Particular Reference to Reinforced Earth; Technical Report; Transport and Road Research Laboratory: Berkshire, UK, 1977; ISSN 0305-1315. [Google Scholar]

- Gupta, S.; Gupta, B. The critical soil moisture content in the underground corrosion of mild steel. Corros. Sci. 1979, 19, 171–178. [Google Scholar] [CrossRef]

- Noor, E.; Al-Moubaraki, A. Influence of Soil Moisture Content on the Corrosion Behavior of X60 Steel in Different Soils. Arab. J. Sci. Eng. 2014, 39, 5421–5435. [Google Scholar] [CrossRef]

- Schaschl, E.; Marsh, G.A. Some New Views on Soil Corrosion. Mater. Prot. 1963, 2, 8–17. [Google Scholar]

- Benmoussa, A.; Hadjel, M.; Traisnel, M. Corrosion behavior of API 5L X-60 pipeline steel exposed to near-neutral pH soil simulating solution. Mater. Corros. 2006, 57, 771–777. [Google Scholar] [CrossRef]

- Pereira, R.; Oliveira, E.; Lima, M.; Brasil, S. Corrosion of Galvanized Steel Under Different Soil Moisture Contents. Mater. Res. 2015, 18, 563–568. [Google Scholar] [CrossRef] [Green Version]

- Kulman, F. Microbiological Corrosion of Buried Steel Pipe. Corrosion 1953, 9, 11–18. [Google Scholar] [CrossRef]

- Miller, F.; Foss, J.; Wolf, D. Soil Surveys: Their Synthesis, Confidence Limits, and Utilization for Corrosion Assessment of Soil. In Underground Corrosion; Escalante, E., Ed.; ASTM International: West Conshohocken, PA, USA, 1981; pp. 3–23. [Google Scholar] [CrossRef]

- Wasim, M.; Shoaib, S.; Mubarak, N.; Inamuddin; Asiri, A. Factors influencing corrosion of metal pipes in soils. Environ. Chem. Lett. 2018, 16, 861–879. [Google Scholar] [CrossRef]

- Cole, I.; Marney, D. The science of pipe corrosion: A review of the literature on the corrosion of ferrous metals in soils. Corros. Sci. 2012, 56, 5–16. [Google Scholar] [CrossRef]

- Xanthakos, P. Ground Anchors and Anchored Structures; John Wiley & Sons: Washington, DC, USA, 1991. [Google Scholar]

- Arriba-Rodriguez, L.; Villanueva-Balsera, J.; Ortega-Fernandez, F.; Rodriguez-Perez, F. Methods to Evaluate Corrosion in Buried Steel Structures: A Review. Metals 2018, 8, 334. [Google Scholar] [CrossRef] [Green Version]

- Petersen, R.; Melchers, R. Long-Term Corrosion of Cast Iron Cement Lined Pipes. Corrosion & Prevention 2012: Corrosion Management for a Sustainable World: Transport, Energy, Mining, Life Extension and Modelling. 2012. Available online: http://hdl.handle.net/1959.13/1327302 (accessed on 15 November 2019).

- Hamilton, W.A. Sulphate-reducing Bacteria and Anaerobic Corrosion. Annu. Rev. Microbiol. 1985, 39, 195–217. [Google Scholar] [CrossRef]

- Husson, F.; Lê, S.; Pagès, J. Exploratory Multivariate Analysis by Example Using R; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Everit, B. The Analysis of Contingency Tables; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Husson, F. Multiple Correspondence Analysis, Agrocampus Ouest, Applied Mathematics Department. 2017. Available online: https://francoishusson.files.wordpress.com/2017/07/mca_course_slides.pdf (accessed on 15 January 2020).

- Lê, S.; Josse, J.; Husson, F. FactoMineR: A Package for Multivariate Analysis. J. Stat. Softw. 2008, 25, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z. A fast clustering algorithm to cluster very large categorical data sets in data mining. In Proceedings of the SIGMOD Workshop on Research Issues on Data Mining and Knowledge Discovery; Technical Report; University of British Columbia: Tucson, AZ, USA, 1997. [Google Scholar]

- Weihs, C.; Ligges, U.; Luebke, K.; Raabe, N. klaR Analyzing German Business Cycles. In Data Analysis and Decision Support; Baier, D., Decker, R., Schmidt-Thieme, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 335–343. [Google Scholar] [CrossRef]

- Amaya-Gómez, R.; Bastidas-Arteaga, E.; Schoefs, F.; Muñoz, F.; Sánchez-Silva, M. A condition-based dynamic segmentation of large systems using a Changepoints algorithm: A corroding pipeline case. Struct. Saf. 2020, 84, 101912. [Google Scholar] [CrossRef]

- Amaya-Gómez, R.; Sánchez-Silva, M.; Muñoz, F. Pattern recognition techniques implementation on data from In-Line Inspection (ILI). J. Loss Prev. Process Ind. 2016, 44, 735–747. [Google Scholar] [CrossRef]

- Pandey, M.; Lu, D. Estimation of parameters of degradation growth rate distribution from noisy measurement data. Struct. Saf. 2013, 43, 60–69. [Google Scholar] [CrossRef]

- Weldon, D. Failure Analysis of Paints and Coatings; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; ISBN 978-0-470-69753-5. [Google Scholar]

- Lee, S.; Oh, W.; Kim, J. Acceleration and quantitative evaluation of degradation for corrosion protective coatings on buried pipeline: Part II. Application to the evaluation of polyethylene and coal-tar enamel coatings. Prog. Org. Coatings 2013, 76, 784–789. [Google Scholar] [CrossRef]

- Wang, H.; Yajima, A.; Liang, R.; Castaneda, H. A clustering approach for assessing external corrosion in a buried pipeline based on hidden Markov random field model. Struct. Saf. 2015, 56, 18–29. [Google Scholar] [CrossRef]

- Zabowski, D.; Whitney, N.; Gurung, J.; Hatten, J. Total Soil Carbon in the Coarse Fraction and at Depth. For. Sci. 2011, 57, 11–18. [Google Scholar] [CrossRef]

| Aggressiveness | Resistivity (Ω ·cm) | Redox Potential mV |

|---|---|---|

| Mild-to-non corrosive | >5000 | >400 * |

| Moderate corrosion | 2000–5000 | 200–400 |

| Corrosive | 700–2000 | 100–200 |

| Very corrosive | <700 | <100 |

| Category | Corrosion Depth (%t) |

|---|---|

| Low | 0–24 |

| Moderate | 25–49 |

| High | 50–74 |

| Very High | 75–100 |

| Segment * | Category | Classification | ID |

|---|---|---|---|

| 0.00–6.66 km | Complex | Pachic Melanudands (50%), Andic Dystrudepts (20%), Aeric Endoaquepts (15%), Aquic Hapludands (15%) | S1 |

| 6.66–8.2 km | Association | Humic Lithic Eutrudepts (35%), Typic Placudands (25%), Dystric Eutrudepts (25%) | S2 |

| 8.2–9.66 km | Complex | Pachic Melanudands (50%), Andic Dystrudepts (20%), Aeric Endoaquepts (15%), Aquic Hapludands (15%) | S1 |

| 9.66–11.61 km | Association | Humic Dystrudepts (60%), Typic Hapludalfs (40%) | S3 |

| 11.61–13.48 km | Complex | Pachic Haplustands (35%), Humic Haplustands (35%), Fluventic Dystrustepts (30%) | S4 |

| 13.48–14.86 km | Association | Aeric Epiaquents (60%), Fluvaquentic Endoaquepts (40%) | S5 |

| 14.86–15.89 km | Complex | Humic Dystrustepts (40%), Typic Haplustalfs (35%), Fluvaquentic Endoaquepts (25%) | S6 |

| 15.89–17.62 km | Association | Aeric Epiaquents (60%), Fluvaquentic Endoaquepts (40%) | S5 |

| 17.62–18.65 km | Complex | Humic Dystrustepts (40%), Typic Haplustalfs (35%), Fluvaquentic Endoaquepts (25%) | S6 |

| 18.65–18.84 km | Association | Typic Endoaquepts (40%), Aeric Endoaquepts (30%), Thaptic Hapludands (20%) | S7 |

| 18.84–21.40 km | Complex | Humic Dystrustepts (40%), Typic Haplustalfs (35%), Fluvaquentic Endoaquepts (25%) | S6 |

| 21.40–22.63 km | Association | Typic Endoaquepts (40%), Aeric Endoaquepts (30%), Thaptic Hapludands (20%) | S7 |

| 26.07–27.35 km | Complex | Pachic Haplustands (35%), Humic Haplustands (35%), Fluventic Dystrustepts (30%) | S4 |

| 27.35–28.22 km | Urban zone | - | UZ |

| 28.22–30.52 km | Association | Aeric Epiaquents (60%), Fluvaquentic Endoaquepts (40%) | S5 |

| 30.52–33.10 km | Complex | Pachic Haplustands (35%), Humic Haplustands (35%), Fluventic Dystrustepts (30%) | S4 |

| 33.10–35.45 km | Association | Typic Endoaquepts (40%), Aeric Endoaquepts (30%), Thaptic Hapludands (20%) | S7 |

| 35.45–45.00 km | Urban zone | - | UZ |

| Parameter | Mean (Coefficient of Variation) | |||

|---|---|---|---|---|

| ILI-1 Inner Wall | ILI-2 Inner Wall | ILI-1 Outer Wall | ILI-2 Outer Wall | |

| Average depth (%t) | 5.49 (0.26) | 5.29 (0.27) | 7.28 (0.49) | 6.77 (0.46) |

| Maximum depth (%t) | 11.54 (0.21) | 11.14 (0.19) | 15.84 (0.46) | 14.62 (0.43) |

| Length (mm) | 26.07 (0.49) | 26.07 (0.43) | 28.07 (0.48) | 27.37 (0.44) |

| Width (mm) | 22.5 (0.40) | 25.92 (0.53) | 28.81 (0.67) | 32.60 (0.75) |

| Number of defects | 23,708 | 43,399 | 2862 | 4264 |

| Soil Feature | Category | Description |

|---|---|---|

| Lithology | Hydrogenic clastic deposits | |

| Hydrogenic clastic deposits. Volcanic ashes in some sectors | ||

| Sandy clastic rock and clay silt | ||

| Sandy clastic rocks, carbonated clay silt with some deposits of volcanic ash | ||

| Volcaniclastic hydrogenic ash deposits | ||

| Depth * | Deep to shallow (25 to 150 cm) | |

| Deep to very deep (≥100 cm) | ||

| Moderate to deep (50 to 100 cm) | ||

| Very shallow (<25 cm) | ||

| Drainage | Poor to moderately drained | |

| Poor to very poor drained | ||

| Well to imperfectly drained | ||

| Well to moderately well drained | ||

| Well to poor drained | ||

| Texture ** | Fine texture | |

| Fine to medium | ||

| Fine to moderately coarse | ||

| Medium to fine | ||

| Acidity | Extremely to moderately acid (pH 3.5 to 6) | |

| Extremely to strongly acid (pH 3.5 to 5.5) | ||

| Extremely acid to neutral (pH 3.5 to 7.3) | ||

| Moderately to slightly acid (pH 5.6 to 6.5) | ||

| Strongly to moderately acid (pH 5.1 to 6) | ||

| Fertility | Low | |

| Moderate | ||

| Moderate to high | ||

| Moderate to low | ||

| Rainy days per year | 100 to 150 | |

| 100 to 200 | ||

| Annual Precipitation | 1000 to 1500 mm | |

| 500 to 1000 mm |

| Soil Feature | Parameter | ILI1-Inner | ILI1-Outer | ILI2-Inner | ILI2-Outer |

|---|---|---|---|---|---|

| Lithology | test | 15.56 | 23.34 | 5.52 | 33.36 |

| p-value | 4.50 | 4.30 | 2.30 | 2.00 | |

| Depth | test | 1.30 | 26.80 | 4.41 | 23.89 |

| p-value | 7.25 | 2.45 | 2.18 | 1.20 | |

| Drainage | test | 6.19 | 25.49 | 6.53 | 30.52 |

| p-value | 1.65 | 5.85 | 1.63 | 6.50 | |

| Texture | test | 15.93 | 22.64 | 4.64 | 30.79 |

| p-value | 3.00 | 3.10 | 2.05 | 3.00 | |

| Acidity | test | 17.57 | 9.92 | 2.02 | 19.44 |

| p-value | 3.40 | 4.93 | 7.41 | 4.30 * | |

| Fertility | test | 15.04 | 26.31 | 7.86 | 32.09 |

| p-value | 3.50 | 2.45 | 4.65 | 1.00 | |

| Rainy days | test | 0.001 | 14.45 | 0.33 | 28.53 |

| p-value | 1.00 | 2.50 | 6.17 | 5.00 | |

| Annual precipitation | test | 0.25 | 19.39 | 3.40 | 19.65 |

| p-value | 6.28 | 5.00 | 8.10 | 5.00 |

| Dataset | Corrosion | Cluster | Points | Within Cluster | Litho. | Depth | Drain. | Tex. | Aci. | Fer. | R.Days | Precipi. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ILI1-Inner | Low | 1 | 4512 | 16,142 | ||||||||

| 2 | 3489 | 4925 | ||||||||||

| Mod. | 1 | 21 | 77 | |||||||||

| 2 | 16 | 15 | ||||||||||

| ILI2-Inner | Low | 1 | 9104 | 33,241 | ||||||||

| 2 | 5357 | 6570 | ||||||||||

| Mod. | 1 | 43 | 148 | |||||||||

| 2 | 18 | 40 | ||||||||||

| ILI1-Outer | Low | 1 | 409 | 595 | ||||||||

| 2 | 1210 | 190 | ||||||||||

| Mod. | 1 | 47 | 60 | |||||||||

| 2 | 90 | 25 | ||||||||||

| High * | 1 | 2 | 1 | |||||||||

| 2 | 7 | 8 | ||||||||||

| ILI2-Outer | Low | 1 | 403 | 510 | ||||||||

| 2 | 75 | 0 | ||||||||||

| 3 | 1861 | 185 | ||||||||||

| Mod. | 1 | 121 | 20 | |||||||||

| 2 | 56 | 100 | ||||||||||

| High | 1 | 7 | 15 | |||||||||

| 2 | 3 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaya-Gómez, R.; Bastidas-Arteaga, E.; Muñoz, F.; Sánchez-Silva, M. Statistical Soil Characterization of an Underground Corroded Pipeline Using In-Line Inspections. Metals 2021, 11, 292. https://doi.org/10.3390/met11020292

Amaya-Gómez R, Bastidas-Arteaga E, Muñoz F, Sánchez-Silva M. Statistical Soil Characterization of an Underground Corroded Pipeline Using In-Line Inspections. Metals. 2021; 11(2):292. https://doi.org/10.3390/met11020292

Chicago/Turabian StyleAmaya-Gómez, Rafael, Emilio Bastidas-Arteaga, Felipe Muñoz, and Mauricio Sánchez-Silva. 2021. "Statistical Soil Characterization of an Underground Corroded Pipeline Using In-Line Inspections" Metals 11, no. 2: 292. https://doi.org/10.3390/met11020292