Future Trends on Displacive Stress and Strain Induced Transformations in Steels

Abstract

:1. Introduction

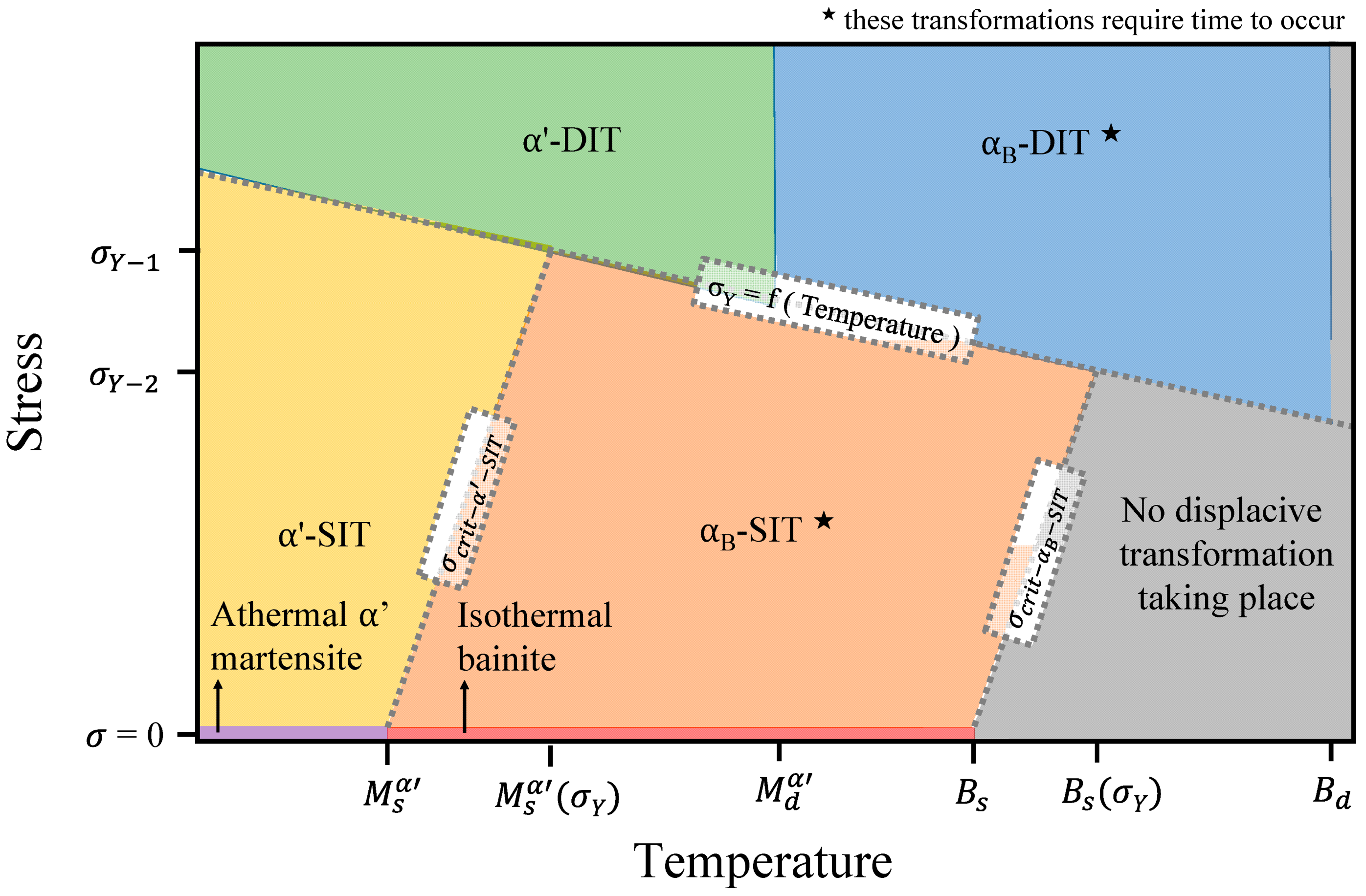

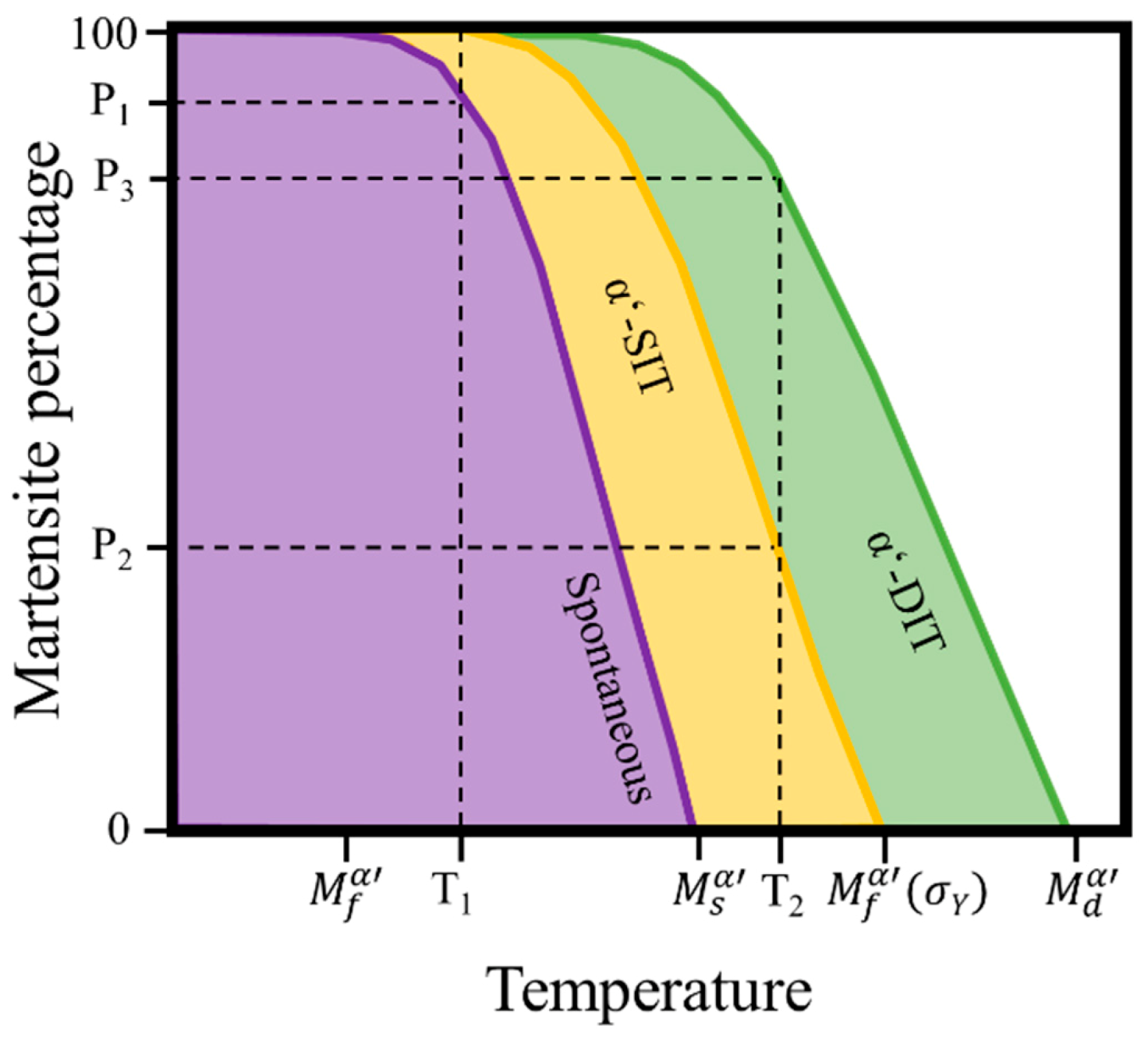

2. Metastable Phases Formed by Stress and Strain Induced Transformations

3. Conditions of Stress/Strain Induced Transformations

3.1. Stacking Fault Energy

3.2. Critical Temperatures and Thermodynamics

3.2.1. Spontaneous Martensite and Bainite Transformations

3.2.2. Stress-Induced Martensite and Bainite Transformations

3.2.3. Strain Induced Martensite and Bainite Transformations

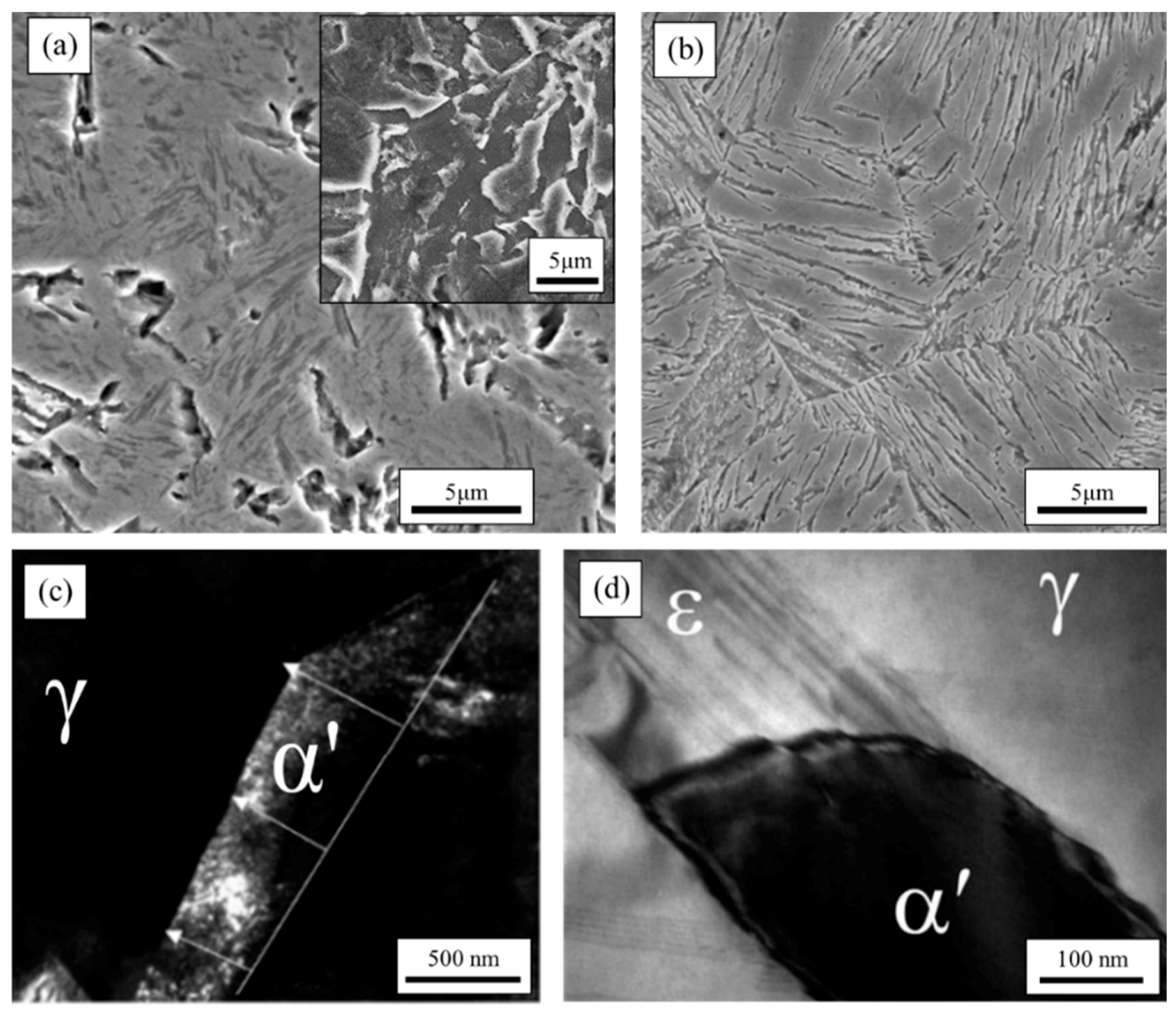

4. Resultant Microstructures of Stress and Strain Induced Transformations and Their Strain Hardening Capacity

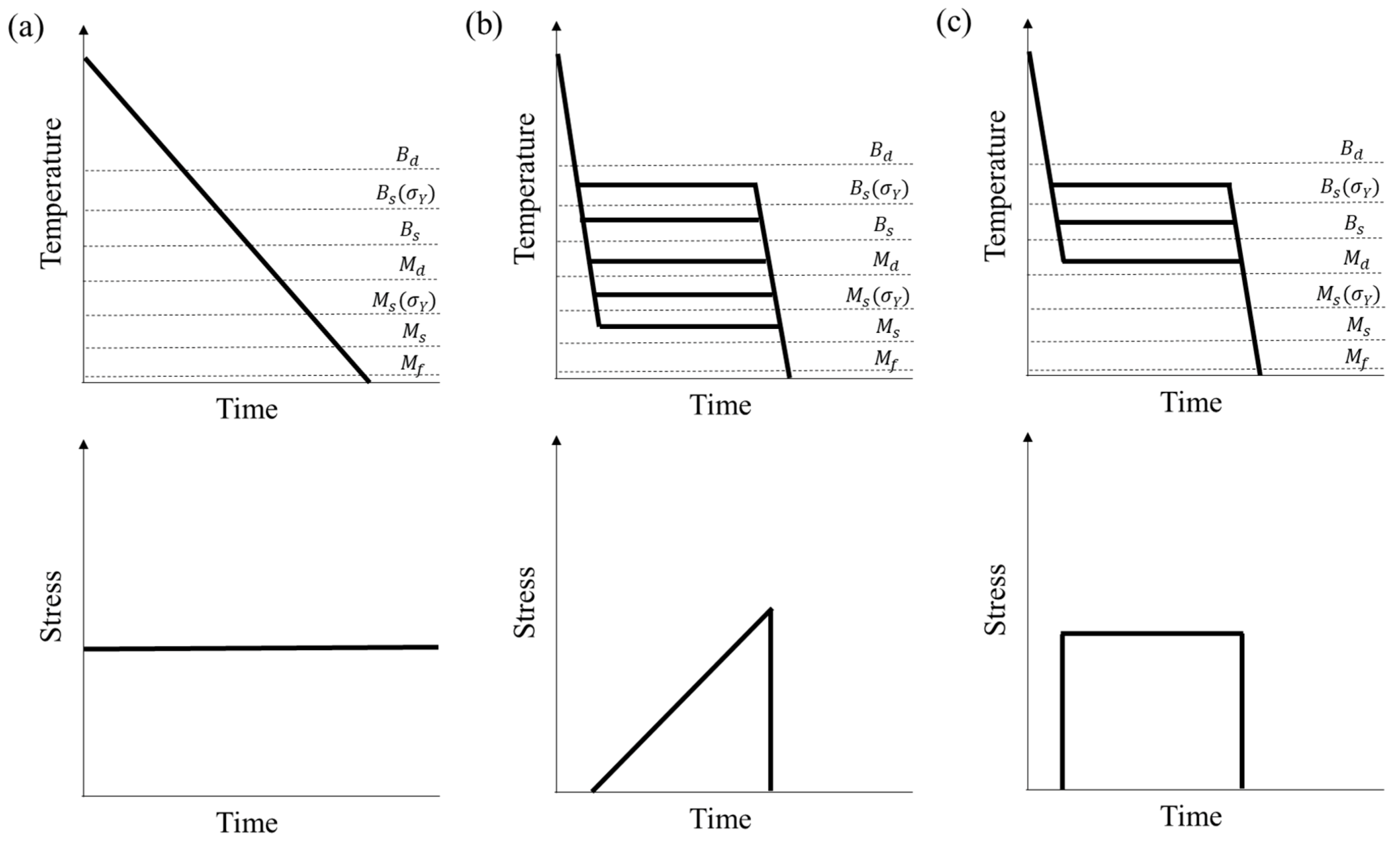

4.1. Stress or Strain Induced Martensite Transformations

4.1.1. Continuous Cooling Treatments under Constant Stress

4.1.2. Deformation at a Constant Temperature

4.2. Stress or Strain Induced Bainite Transformations

5. Issues That Require Further Research

- -

- there is no agreement about the thermodynamic conditions that govern the formation of ε, neither athermally nor induced by stress or strain

- -

- it has been assumed that the nucleation of bainite is not affected by elastic stress, although it has not been experimentally proven

- -

- although it is known that the application of plastic deformation promotes the nucleation of αB, this fact has not been modeled thermodynamically yet

- -

- the scale of the α′ and αB stress/strain-induced laths/plates formed during continuous cooling or during isothermal treatments, respectively, has not been previously reported

- -

- the effect of a constant stress on continuous cooling bainitic microstructures has not been assessed in the literature so far

- -

- the effect on the volume fraction of strain induced αB formed during isothermal treatments under constant stresses needs to be clarified

- -

- the effect of the matrix on the selection of variants of metastable phases formed by TRIP effect in multiphase microstructures is still unclear

- -

- the αB SIT/DIT during tensile/compression deformation from a fully austenitic microstructure has not been studied in the literature and, therefore, it would be necessary to study these transformations, as there are several reasons that suggest that their mechanisms could be different to the ones governing the formation of martensite in the same conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sugimoto, K.; Tsunezawa, M.; Hojo, T.; Ikeda, S. Ductility of 0.1-0.6C-1.5Si-1.5Mn ultra high-strength TRIP-aided sheet steels with bainitic ferrite matrix. ISIJ Int. 2004, 44, 1608–1614. [Google Scholar] [CrossRef]

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Warm ductility of 0.2% C–1.5% Si–5% Mn TRIP-aided steel. Mater. Sci. Eng. A 2017, 688, 237–243. [Google Scholar] [CrossRef]

- Sugimoto, K.-I.; Kobayashi, M.; Hashimoto, S.-I. Ductility and strain-induced transformation in a high-strength transformation-induced plasticity-aided dual-phase steel. Metall. Trans. A 1992, 23, 3085–3091. [Google Scholar] [CrossRef]

- Nagasaka, A.; Sugimoto, K.; Kobayashi, M.; Hashimoto, S. Effects of warm forming on deep drawability of a TRIP-aided dual-phase sheet steel. Tetsu-to-hagane 1999, 85, 552–557. [Google Scholar] [CrossRef]

- Scheil, E. Über die Umwandlung des Austenits in Martensit in Eisen-Nickellegierungen unter Belastung. Zeitschrift für Anorg. und Allg. Chemie 1932, 207, 21–40. [Google Scholar] [CrossRef]

- Huang, G.L.; Matlock, D.K.; Krauss, G. Martensite formation, strain rate sensitivity, and deformation behavior of type 304 stainless steel sheet. Metall. Trans. A 1989, 20, 1239–1246. [Google Scholar] [CrossRef]

- Fang, X.F.; Dahl, W. Strain hardening and transformation mechanism of deformation-induced martensite transformation in metastable austenitic stainless steels. Mater. Sci. Eng. A 1991, 141, 189–198. [Google Scholar] [CrossRef]

- Fang, X.F.; Gusek, C.O.; Dahl, W. Strain hardening of steels at large strain deformation. Part II: Strain hardening of pearlitic and austenitic steels and the estimation of mechanical properties. Mater. Sci. Eng. A 1995, 203, 26–35. [Google Scholar] [CrossRef]

- Choi, J.-Y.; Jin, W. Strain induced martensite formation and its effect on strain hardening behavior in the cold drawn 304 austenitic stainless steels. Scr. Mater. 1997, 36, 99–104. [Google Scholar] [CrossRef]

- Soares, G.C.; Rodrigues, M.C.M.; Santos, L.d.A. Influence of Temperature on Mechanical Properties, Fracture Morphology and Strain Hardening Behavior of a 304 Stainless Steel. Mater. Res. 2017, 20, 141–151. [Google Scholar] [CrossRef]

- Lee, B.-S.; Koizumi, Y.; Matsumoto, H.; Chiba, A. Collective behavior of strain-induced martensitic transformation (SIMT) in biomedical Co–Cr–Mo–N alloy polycrystal: An ex-situ electron backscattering diffraction study. Mater. Sci. Eng. A 2014, 611, 263–273. [Google Scholar] [CrossRef]

- Zackay, V.F.; Parker, E.R.; Fahr, D.; Busch, R. Enhancement Of Ductility In High-Strength Steels. ASM Trans. 1967, 60, 252–259. [Google Scholar]

- Fonstein, N. Advanced High Strength Sheet Steels: Physical Metallurgy, Design, Processing, and Properties; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; ISBN1 9783319191652. ISBN2 9783319191645. [Google Scholar]

- Speich, G.R.; Miller, R.L.; Kot, R.A.; Morris, J.W. Structure and properties of dual-phase steels. Ed. RA Kot JW Morris AIME N. Y. 1979, 146–181. [Google Scholar]

- Sachdev, A.K. Effect of retained austenite on the yielding and deformation behavior of a dual phase steel. Acta Metall. 1983, 31, 2037–2042. [Google Scholar] [CrossRef]

- Chen, H.C.; Era, H.; Shimizu, M. Effect of phosphorus on the formation of retained austenite and mechanical properties in Si-containing low-carbon steel sheet. Metall. Trans. A 1989, 20, 437–445. [Google Scholar] [CrossRef]

- Sakuma, Y.; Matsumura, O.; Takechi, H. Mechanical properties and retained austenite in intercritically heat-treated bainite-transformed steel and their variation with Si and Mn additions. Metall. Trans. A-PHYSICAL Metall. Mater. Sci. 1991, 22, 489–498. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hashimoto, S.; Ikeda, S. Ultra high-strength low-alloy TRIP-aided sheet steels with bainitic ferrite matrix. In Proceedings of the International Conferance on Advanced High Strength Sheet Steels for Automotive Applications, Winter Park, CO, USA, 6–9 June 2004; Volume 2, pp. 63–70. [Google Scholar]

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Warm stretch-formability of 0.2% C-1.5% Si-(1.5-5.0)% Mn TRIP-aided steels. Arch. Mater. Sci. 2016, 6, 6. [Google Scholar] [CrossRef]

- Matsumura, O.; Sakuma, Y.; Takechi, H. Enhancement of elongation by retained austenite in Intercritical Annealed 0.4C-1.5Si-0.8Mn Steel. Trans. ISIJ 1987, 27, 570–579. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Allain, S.; Cornide, J.; Puerta Velasquez, J.D.; Garcia-Mateo, C.; Miller, M.K. Design of cold rolled and continuous annealed carbide-free bainitic steels for automotive application. Mater. Des. 2013, 49, 667–680. [Google Scholar] [CrossRef] [Green Version]

- Kaar, S.; Schneider, R.; Krizan, D.; Béal, C.; Sommitsch, C. Influence of the quenching and partitioning process on the transformation kinetics and hardness in a lean medium manganese TRIP steel. Metals 2019, 9, 353. [Google Scholar] [CrossRef] [Green Version]

- Tasaki, W.; Sawaguchi, T.; Tsuchiya, K. EBSD analysis of dual γ/ε phase microstructures in tensile-deformed Fe-Mn-Si shape memory alloy. J. Alloys Compd. 2019, 797, 529–536. [Google Scholar] [CrossRef]

- Fahr, D. Stress-and strain-induced formation of martensite and its effects on strength and ductility of metastable austenitic stainless steels. Metall. Trans. 1971, 2, 1883–1892. [Google Scholar]

- Weiß, A.; Gutte, H.; Scheller, P.R. Deformation induced martensite formation and its effect on Transformation Induced Plasticity (TRIP). Steel Res. Int. 2006, 77, 727–732. [Google Scholar] [CrossRef]

- Jacques, P.J.; Girault, E.; Harlet, P.; Delannay, F. The developments of cold-rolled TRIP-assisted multiphase steels. Low silicon TRIP-assisted multiphase steels. ISIJ Int. 2001, 41, 1061–1067. [Google Scholar] [CrossRef]

- Tan, X.; He, H.; Lu, W.; Yang, L.; Tang, B.; Yan, J.; Xu, Y.; Wu, D. Effect of matrix structures on TRIP effect and mechanical properties of low-C low-Si Al-added hot-rolled TRIP steels. Mater. Sci. Eng. A 2020, 771, 138629. [Google Scholar] [CrossRef]

- Nakada, N.; Ishibashi, Y.; Tsuchiyama, T.; Takaki, S. Self-stabilization of untransformed austenite by hydrostatic pressure via martensitic transformation. Acta Mater. 2016, 110, 95–102. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Q.; Wang, X.; Zhao, Y.; Wang, L. A phenomenon of strain induced bainitic transformation and its effect on strength enhancement in a lightweight transformation-induced-plasticity steel. Mater. Sci. Eng. A 2019, 751, 340–350. [Google Scholar] [CrossRef]

- Umemoto, M.; Bando, S.; Tamura, I. Morphology and Transformation Kinetics of Bainite in Fe--Ni--C and Fe--Ni--Cr--C Alloys. In Proceedings of the International Conference on Martensitic Transformations (ICOMAT-86), Nara, Japan, 26–30 August 1986; pp. 595–600. [Google Scholar]

- Bhadeshia, H.K.D.H. Bainite in Steels: Theory and Practice; CRC Press: Boca Raton, FL, USA, 2019; ISBN 1351574817. [Google Scholar]

- Shipway, P.H.; Bhadeshia, H.K.D.H. The effect of small stresses on the kinetics of the bainite transformation. Mater. Sci. Eng. A. 1995, 201, 143–149. [Google Scholar] [CrossRef]

- Matsuzaki, A.; Bhadeshia, H.K.D.H.; Harada, H. Stress affected bainitic transformation in a Fe - C - Si - Mn alloy. Acta Metall. Mater. 1994, 42, 1081–1090. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; David, S.A.; Vitek, J.M.; Reed, R.W. Stress induced transformation to bainite in Fe-Cr-Mo-C pressure vessel steel. Mater. Sci. Technol. 1991, 7, 686–698. [Google Scholar] [CrossRef]

- Eres-Castellanos, A.; Caballero, F.G.; Garcia-Mateo, C. Stress or strain induced martensitic and bainitic transformations during ausforming processes. Acta Mater. 2020, 189, 60–72. [Google Scholar] [CrossRef]

- Min, J.; Lin, J.; Min, Y.; Li, F. On the ferrite and bainite transformation in isothermally deformed 22MnB5 steels. Mater. Sci. Eng. A 2012, 550, 375–387. [Google Scholar] [CrossRef]

- Liu, J.; Kaoumi, D. Use of in-situ TEM to characterize the deformation-induced martensitic transformation in 304 stainless steel at cryogenic temperature. Mater. Charact. 2018, 136, 331–336. [Google Scholar] [CrossRef]

- Spencer, K.; Véron, M.; Yu-Zhang, K.; Embury, J.D. The strain induced martensite transformation in austenitic stainless steels: Part 1–Influence of temperature and strain history. Mater. Sci. Technol. 2009, 25, 7–17. [Google Scholar] [CrossRef]

- Brooks, J.W.; Loretto, M.H.; Smallman, R.E. In situ observations of the formation of martensite in stainless steel. Acta Metall. 1979, 27, 1829–1838. [Google Scholar] [CrossRef]

- Sato, K.; Ichinose, M.; Hirotsu, Y.; Inoue, Y. Effects of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe–Mn–Al alloys. ISIJ Int. 1989, 29, 868–877. [Google Scholar] [CrossRef]

- Souza Filho, I.R.; Sandim, M.J.R.; Cohen, R.; Nagamine, L.; Sandim, H.R.Z.; Raabe, D. Magnetic properties of a 17.6 Mn-TRIP steel: Study of strain-induced martensite formation, austenite reversion, and athermal α′-formation. J. Magn. Magn. Mater. 2019, 473, 109–118. [Google Scholar] [CrossRef]

- Pisarik, S.T.; Van Aken, D.C. Crystallographic orientation of the ε→ α′ martensitic (athermal) transformation in a FeMnAlSi steel. Metall. Mater. Trans. A 2014, 45, 3173–3178. [Google Scholar] [CrossRef]

- Lu, F.; Yang, P.; Meng, L.; Cui, F.; Ding, H. Influences of thermal martensites and grain orientations on strain-induced martensites in high manganese TRIP/TWIP steels. J. Mater. Sci. Technol. 2011, 27, 257–265. [Google Scholar] [CrossRef]

- de Dafé, S.S.F.; Sicupira, F.L.; Matos, F.C.S.; Cruz, N.S.; Moreira, D.R.; Santos, D.B. Effect of cooling rate on (ε, α′) martensite formation in twinning/transformation-induced plasticity Fe-17Mn-0.06 C steel. Mater. Res. 2013, 16, 1229–1236. [Google Scholar] [CrossRef]

- Takaki, S.; Nakatsu, H.; Tokunaga, Y. Effects of austenite grain size on ε martensitic transformation in Fe-15mass% Mn alloy. Mater. Trans. JIM 1993, 34, 489–495. [Google Scholar] [CrossRef] [Green Version]

- Nakatsu, H.; Takaki, S. Effect of austenite grain size in Fe-Mn alloys on ε martensitic transformation and their mechanical properties. Nippon Kinzoku Gakkaishi/J. Jpn. Inst. Met. 1996, 60, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.F.; Dong, X.X.; Song, X.T.; Jia, N. Carbon content-tuned martensite transformation in low-alloy TRIP steels. Sci. Rep. 2019, 9, 1–9. [Google Scholar]

- Li, N.; Wang, Y.D.; Liu, W.J.; An, Z.N.; Liu, J.P.; Su, R.; Li, J.; Liaw, P.K. In situ X-ray microdiffraction study of deformation-induced phase transformation in 304 austenitic stainless steel. Acta Mater. 2014, 64, 12–23. [Google Scholar] [CrossRef]

- Liu, M.; Xu, G.; Chen, G.; Jia, J.; Chen, Z.; Xiong, Z. Effects of Stress on Martensite Transformation During Continuous Cooling and Mechanical Response of a Medium-Carbon High-Strength Steel. Metall. Mater. Trans. A 2020, 51, 597–607. [Google Scholar] [CrossRef]

- Das, A. Crystallographic variant selection of martensite at high stress/strain. Philos. Mag. 2015, 95, 2210–2227. [Google Scholar] [CrossRef]

- de Abreu, H.F.G.; Gomes da Silva, M.J.; Maia do Nascimento, A.; Freitas, F.N.C. Stress induced martensite transformation texture in AISI 304 austenitic stainless steel. Mater. Sci. Technol. 2011, 27, 1627–1631. [Google Scholar] [CrossRef]

- Malet, L.; Sinclair, C.W.; Jacques, P.; Godet, S. Grain scale analysis of variant selection during the gamma-epsilon-alpha’phase transformation in austenitic steels. Solid State Phenom. 2011, 172, 84–89. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Hu, J.C.; Song, H.M.; Jin, X.J. Compatible strain evolution in two phases due to epsilon martensite transformation in duplex TRIP-assisted stainless steels with high hydrogen embrittlement resistance. Int. J. Plast. 2017, 88, 53–69. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Stress-assisted isothermal martensitic transformation: Application to TRIP steels. Metall. Trans. A 1982, 13, 1907–1914. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Hodgson, P.D.; Pereloma, E.V. Effect of microstructure on the stability of retained austenite in transformation-induced-plasticity steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35 A, 2331–2341. [Google Scholar] [CrossRef] [Green Version]

- Mukherjee, M.; Mohanty, O.N.; Hashimoto, S.; Hojo, T.; Sugimoto, K. Strain-induced transformation behaviour of retained austenite and tensile properties of TRIP-aided steels with different matrix microstructure. ISIJ Int. 2006, 46, 316–324. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Usui, N.; Kobayashi, M.; Hashimoto, S. Effects of Volume Fraction and Stability of Retained Austenite on Ductility of TRIP-aided Dual-phase Steels. ISIJ Int. 1992, 32, 1311–1318. [Google Scholar] [CrossRef]

- Van der Wegen, G.J.L.; Bronsveld, P.M.; De Hosson, J.T.M. A comparison between different theories predicting the stacking fault energy from extended nodes. Scr. Metall. 1980, 14, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Molnár, D.; Sun, X.; Lu, S.; Li, W.; Engberg, G.; Vitos, L. Effect of temperature on the stacking fault energy and deformation behaviour in 316L austenitic stainless steel. Mater. Sci. Eng. A 2019, 759, 490–497. [Google Scholar] [CrossRef]

- Mohammadzadeh, M.; Mohammadzadeh, R. Effect of interstitial and substitution alloying elements on the intrinsic stacking fault energy of nanocrystalline fcc-iron by atomistic simulation study. Appl. Phys. A 2017, 123, 720. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC - HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar] [CrossRef]

- Talonen, J. Effect of Strain-Induced α′-Martensite Transformation on Mechanical Properties of Metastable Austenitic Stainless Steels; Aalto University: Espoo, Filand, 2007. [Google Scholar]

- Olson, G.B.; Cohen, M. A mechanism for the strain-induced nucleation of martensitic transformations. J. Less Common Met. 1972, 28, 107–118. [Google Scholar] [CrossRef]

- Bolling, G.F.; Richman, R.H. The influence of stress on martensite-start temperatures in Fe-Ni-C alloys. Scr. Metall. 1970, 4, 539–543. [Google Scholar] [CrossRef]

- Bolling, G.F.; Richman, R.H. The plastic deformation of ferromagnetic face-centred cubic Fe-Ni-C alloys. Philos. Mag. 1969, 19, 247–264. [Google Scholar] [CrossRef]

- Bolling, G.F.; Richman, R.H. The plastic deformation-transformation of paramagnetic fcc Fe-Ni-C alloys. Acta Metall. 1970, 18, 673–681. [Google Scholar] [CrossRef]

- Richman, R.H.; Bolling, G.F. Stress, deformation, and martensitic transformation. Metall. Trans. 1971, 2, 2451–2462. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bhadeshia, H.K.D.H. Transformation induced plasticity assisted steels: Stress or strain affected martensitic transformation? Mater. Sci. Technol. 2007, 23, 1101–1104. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R.W.K. Steels: Microstructure and Properties; Butterworths-Heinemann (Elsevier): Amsterdam, The Netherlands, 2006; ISBN 9780750680844. [Google Scholar]

- Capdevila, C.; Caballero, F.G.; García de Andrés, C. Analysis of effect of alloying elements on martensite start temperature of steels. Mater. Sci. Technol. 2003, 19, 581–586. [Google Scholar] [CrossRef] [Green Version]

- Nikravesh, M.; Naderi, M.; Akbari, G.H. Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Mater. Sci. Eng. A 2012, 540, 24–29. [Google Scholar] [CrossRef]

- Ghosh, G.; Olson, G.B. Kinetics of FCC→ BCC heterogeneous martensitic nucleation—I. The critical driving force for athermal nucleation. Acta Metall. Mater. 1994, 42, 3361–3370. [Google Scholar] [CrossRef]

- Yang, H.S.; Jang, J.H.; Bhadeshia, H.K.D.H.; Suh, D.W. Critical assessment: Martensite-start temperature for the γ → ε transformation. Calphad Comput. Coupling Phase Diagrams Thermochem. 2012, 36, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Forsberg, A.; Ågren, J. Thermodynamic evaluation of the Fe-Mn-Si system and the γ/ε martensitic transformation. J. Phase Equilibria 1993, 14, 354–363. [Google Scholar] [CrossRef]

- Jang, J.H.; Moon, J.; Ha, H.-Y.; Lee, T.-H.; Suh, D.-W. Quantum-mechanical analysis of effect of alloying elements on ε-martensite start temperature of steels. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mosecker, L.; Saeed-Akbari, A. Nitrogen in chromium-manganese stainless steels: A review on the evaluation of stacking fault energy by computational thermodynamics. Sci. Technol. Adv. Mater. 2013, 14. [Google Scholar] [CrossRef]

- Pisarik, S.T.; Van Aken, D.C. Thermodynamic driving force of the γ→ ε transformation and resulting M S temperature in high-Mn steels. Metall. Mater. Trans. A 2016, 47, 1009–1018. [Google Scholar] [CrossRef]

- Dogan, A.; Ozer, T. Determination of martensite transformation temperatures associated with Fe-Mn-Si-Ni-Cr-Ce-Ti-N shape memory alloys. Can. Metall. Q. 2005, 44, 555–562. [Google Scholar] [CrossRef]

- Kang, S.; Yoon, S.; Lee, S.J. Prediction of bainite start temperature in alloy steels with different grain sizes. ISIJ Int. 2014, 54, 997–999. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Bhadeshia, H.K.D.H. Nucleation theory for high-carbon bainite. Mater. Sci. Eng. A-STRUCTURAL Mater. Prop. Microstruct. Process. 2004, 378, 289–292. [Google Scholar] [CrossRef] [Green Version]

- Bhadeshia, H.K.D.H. A rationalisation of shear transformations in steels. Acta Metall. 1981, 29, 1117–1130. [Google Scholar] [CrossRef]

- Christian, J.W. Deformation by moving interfaces. Metall. Trans. A 1982, 13, 509–538. [Google Scholar] [CrossRef]

- Patel, J.R.; Cohen, M. Criterion for the action of applied stress in the martensitic transformation. Acta Metall. 1953, 1, 531–538. [Google Scholar] [CrossRef]

- Sandvik, B.P.J. The Bainite reaction in Fe-Si-C Alloys: The primary stage. Metall. Trans. A 1982, 13, 777–787. [Google Scholar] [CrossRef]

- Yan, P.; Bhadeshia, H.K.D.H. Mechanism and kinetics of solid-state transformation in high-temperature processed linepipe steel. Metall. Mater. Trans. A 2013, 44, 5468–5477. [Google Scholar] [CrossRef] [Green Version]

- Swallow, E.; Bhadeshia, H.K.D.H. High resolution observations of displacements caused by bainitic transformation. Mater. Sci. Technol. 1996, 12, 121–125. [Google Scholar] [CrossRef]

- Peet, M.J.; Bhadeshia, H.K.D.H. Surface Relief Due to Bainite Transformation at 473 K (200 °C). Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3344–3348. [Google Scholar] [CrossRef] [Green Version]

- Dunne, D.P.; Wayman, C.M. The crystallography of ferrous martensites. Metall. Trans. 1971. [Google Scholar] [CrossRef]

- Hsu, T.Y. Martensitic transformation under stress. Mater. Sci. Eng. A 2006, 438, 64–68. [Google Scholar]

- Hsu, T.Y. A unified technology combining plastic forming and heat treatment of steels. Mater. Sci. Forum 2005, 475, 31–36. [Google Scholar] [CrossRef]

- Gautier, E.; Simon, A.; Collette, G.; Beck, G. Effect of stress and strain on martensitic transformation in a Fe-Ni-Mo-C alloy with a high MS temperature. Le J. Phys. Colloq. 1982, 43, C4–C473. [Google Scholar] [CrossRef] [Green Version]

- Creuziger, A.; Foecke, T. Transformation potential predictions for the stress-induced austenite to martensite transformation in steel. Acta Mater. 2010, 58, 85–91. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Waugh, A.R. Bainite: An atom-probe study of the incomplete reaction phenomenon. Acta Metall. 1982, 30, 775–784. [Google Scholar] [CrossRef]

- Kovalev, A.; Wendler, M.; Jahn, A.; Weiß, A.; Biermann, H. Thermodynamic-Mechanical Modeling of Strain-Induced α′-Martensite Formation in Austenitic Cr–Mn–Ni As-Cast Steel. Adv. Eng. Mater. 2013, 15, 609–617. [Google Scholar] [CrossRef]

- Andersson, M.; Stalmans, R.; Ågren, J. Unified thermodynamic analysis of the stress-assisted γ→ ε martensitic transformation in Fe–Mn–Si alloys. Acta Mater. 1998, 46, 3883–3891. [Google Scholar] [CrossRef]

- Maalekian, M.; Kozeschnik, E.; Chatterjee, S.; Bhadeshia, H.K.D.H. Mechanical stabilisation of eutectoid steel. Mater. Sci. Technol. 2007, 23, 610–612. [Google Scholar] [CrossRef]

- Chatterjee, S.; Wang, H.S.; Yang, J.R.; Bhadeshia, H.K.D.H. Mechanical stabilisation of austenite. Mater. Sci. Technol. 2006, 22, 641–644. [Google Scholar] [CrossRef]

- Taylor, K.A.; Thompson, S.W.; Fletcher, F.B. Physical metallurgy of direct-quenched steels. In Proceedings of the Minerals, Metals, and Materials Society/American Society for Metals (TMS/ASM) Materials Week 92, Chicago, IL, USA, 2–4 November 1992; Available online: https://www.osti.gov/biblio/6100643-physical-metallurgy-direct-quenched-steels (accessed on 12 October 2020).

- Tomota, Y.; Piao, M.; Hasunuma, T.; Kimura, Y. Effects of Applied Stress and Plastic Strain on gamma <-> epsilon Martensitic Transformation in High Manganese Alloy Polycrystals. J. Jpn. Inst. Met. 1990, 54, 628–634. [Google Scholar] [CrossRef] [Green Version]

- Videau, J.-C.; Cailletaud, G.; Pineau, A. Experimental study of the transformation-induced plasticity in a Cr-Ni-Mo-Al-Ti steel. Le J. Phys. IV 1996, 6, C1–C465. [Google Scholar] [CrossRef]

- Nagayama, K.; Terasaki, T.; Tanaka, K.; Fischer, F.D.; Antretter, T.; Cailletaud, G.; Azzouz, F. Mechanical properties of a Cr–Ni–Mo–Al–Ti maraging steel in the process of martensitic transformation. Mater. Sci. Eng. A 2001, 308, 25–37. [Google Scholar] [CrossRef]

- Oberste-Brandenburg, C. A unified tensorial driving force for phase transitions–calculation of the onset of the transformation. PAMM Proc. Appl. Math. Mech. 2003, 2, 200–201. [Google Scholar] [CrossRef]

- Kundu, S.; Verma, A.K.; Sharma, V. Quantitative analysis of variant selection for displacive transformations under stress. Metall. Mater. Trans. A 2012, 43, 2552–2565. [Google Scholar] [CrossRef]

- Kundu, S.; Bhadeshia, H.K.D.H. Crystallographic texture and intervening transformations. Scr. Mater. 2007, 57, 869–872. [Google Scholar] [CrossRef] [Green Version]

- Mishiro, Y.; Nambu, S.; Inoue, J.; Koseki, T. Effect of stress on variant selection in lath martensite in low-carbon steel. ISIJ Int. 2013, 53, 1453–1461. [Google Scholar] [CrossRef] [Green Version]

- Tamura, I. Deformation-induced martensitic transformation and transformation-induced plasticity in steels. Met. Sci. 1982, 16, 245–253. [Google Scholar] [CrossRef]

- Ou, X.; Sietsma, J.; Santofimia, M.J. Coalescence of martensite under uniaxial tension of iron crystallites by atomistic simulations. Mater. Sci. Technol. 2020, 36, 1191–1199. [Google Scholar] [CrossRef]

- Tian, Y.; Borgenstam, A.; Hedström, P. Comparing the deformation-induced martensitic transformation with the athermal martensitic transformation in Fe-Cr-Ni alloys. J. Alloys Compd. 2018, 766, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-J.; Han, J.; Lee, S.; Kang, S.-H.; Lee, S.-M.; Lee, Y.-K. Design for Fe-high Mn alloy with an improved combination of strength and ductility. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Celada-Casero, C.; Kooiker, H.; Groen, M.; Post, J.; San-Martin, D. In-situ investigation of strain-induced martensitic transformation kinetics in an austenitic stainless steel by inductive measurements. Metals 2017, 7, 271. [Google Scholar] [CrossRef] [Green Version]

- Yamashita, T.; Koga, N.; Umezawa, O. Martensitic Transformation of Retained Austenite in Ferrite Matrix for Low Alloy Steel. Mater. Trans. 2018, M2017330. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Xie, Z.L.; Hänninen, H.; Van Humbeeck, J.; Pietikäinen, J. Isothermal martensitic transformation as an internal-stress-increasing process. Le J. Phys. IV 1995, 5, C8–C179. [Google Scholar] [CrossRef] [Green Version]

- Sadhukhan, P. Computational Design and Analysis of High Strength Austenitic TRIP Steels for Blast Protection Applications. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 2008. [Google Scholar]

- Tsuchida, N.; Morimoto, Y.; Tonan, T.; Shibata, Y.; Fukaura, K.; Ueji, R. Stress-induced martensitic transformation behaviors at various temperatures and their TRIP effects in SUS304 metastable austenitic stainless steel. ISIJ Int. 2011, 51, 124–129. [Google Scholar] [CrossRef] [Green Version]

- Narutani, T.; Olson, G.B.; Cohen, M. Constitutive flow relations for austenitic steels during straininduced martensitic transformation. Le J. Phys. Colloq. 1982, 43, C4–C429. [Google Scholar] [CrossRef] [Green Version]

- Olson, G.B. Transformation plasticity and toughening. Le J. Phys. IV 1996, 6, C1–C407. [Google Scholar] [CrossRef] [Green Version]

- Datta, K.; Delhez, R.; Bronsveld, P.M.; Beyer, J.; Geijselaers, H.J.M.; Post, J. A low-temperature study to examine the role of ε-martensite during strain-induced transformations in metastable austenitic stainless steels. Acta Mater. 2009, 57, 3321–3326. [Google Scholar] [CrossRef]

- Hedström, P.; Lienert, U.; Almer, J.; Odén, M. Elastic strain evolution and ε-martensite formation in individual austenite grains during in situ loading of a metastable stainless steel. Mater. Lett. 2008, 62, 338–340. [Google Scholar] [CrossRef]

- Lin, S. Deformation-Induced Martensitic Transformation and Mechanical Properties of Duplex and Austenitic Stainless Steels: A Synchrotron X-Ray Diffraction Study. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2017. [Google Scholar]

- Zhou, W.; Hou, T.; Zhang, C.; Zhong, L.; Wu, K. Effect of carbon content in retained austenite on the dynamic tensile behavior of nanostructured bainitic steel. Metals 2018, 8, 907. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G.; Chao, J.; Capdevila, C.; Garcia de Andres, C. Mechanical stability of retained austenite during plastic deformation of super high strength carbide free bainitic steels. J. Mater. Sci. 2009, 44, 4617–4624. [Google Scholar] [CrossRef]

- Babu, S.S.; Vogel, S.; Garcia-Mateo, C.; Clausen, B.; Morales-Rivas, L.; Caballero, F.G. Microstructure evolution during tensile deformation of a nanostructured bainitic steel. Scr. Mater. 2013, 69, 777–780. [Google Scholar] [CrossRef] [Green Version]

- Seetharaman, V. Deformation and martensitic transformation. Bull. Mater. Sci. 1984, 6, 703–716. [Google Scholar] [CrossRef] [Green Version]

- Tamura, I.; Maki, T.; Hato, H.; Aburai, K. Plasticity induced by martensitic transformation in Fe-Ni and Fe-Cr-Ni alloys. J. Jpn. Inst. Met. 1969, 33, 1383–1389. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G. Ultra-high-strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.J.; Ren, Y.Q.; Zhou, W.H.; Yang, J.R.; Shang, C.J.; Misra, R.D.K. Stability of retained austenite in multi-phase microstructure during austempering and its effect on the ductility of a low carbon steel. Mater. Sci. Eng. A 2014, 603, 69–75. [Google Scholar] [CrossRef]

- De Moor, E.; Lacroix, S.; Clarke, A.J.; Penning, J.; Speer, J.G. Effect of retained austenite stabilized via quench and partitioning on the strain hardening of martensitic steels. Metall. Mater. Trans. A 2008, 39, 2586. [Google Scholar] [CrossRef]

- Benzing, J.T.; Poling, W.A.; Pierce, D.T.; Bentley, J.; Findley, K.O.; Raabe, D.; Wittig, J.E. Effects of strain rate on mechanical properties and deformation behavior of an austenitic Fe-25Mn-3Al-3Si TWIP-TRIP steel. Mater. Sci. Eng. A 2018, 711, 78–92. [Google Scholar] [CrossRef]

- Wan, J.; Chen, S.; Xu, Z. The influence of temperature on stacking fault energy in Fe-based alloys. Sci. China Ser. E Technol. Sci. 2001, 44, 345–352. [Google Scholar] [CrossRef]

- Talonen, J.; Nenonen, P.; Pape, G.; Hänninen, H. Effect of strain rate on the strain-induced γ → α′-martensite transformation and mechanical properties of austenitic stainless steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2005, 36 A, 421–432. [Google Scholar] [CrossRef]

- Krüger, L.; Wolf, S.; Martin, U.; Martin, S.; Scheller, P.R.; Jahn, A.; Weiß, A. The influence of martensitic transformation on mechanical properties of cast high alloyed CrMnNi-steel under various strain rates and temperatures. In Proceedings of the Journal of Physics: Conference Series, Dresden, Germany, 16–21 August 2009; IOP Publishing: Dresden, Germany, 2010; Volume 240, p. 12098. [Google Scholar]

- Latourte, F.; Feinberg, Z.; Mori, L.F.; Olson, G.B.; Espinosa, H.D. Shear and tensile plastic behavior of austenitic steel TRIP-120 compared with martensitic steel HSLA-100. Int. J. Fract. 2010, 162, 187–204. [Google Scholar] [CrossRef]

- Wu, C.-C.; Wang, S.-H.; Chen, C.-Y.; Yang, J.-R.; Chiu, P.-K.; Fang, J. Inverse effect of strain rate on mechanical behavior and phase transformation of superaustenitic stainless steel. Scr. Mater. 2007, 56, 717–720. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, C.; He, Z.; He, Y.; Li, L. Response characteristics and adiabatic heating during high strain rate for trip steel and dp steel. J. Iron Steel Res. Int. 2015, 22, 48–54. [Google Scholar] [CrossRef]

- He, Z.; He, Y.; Ling, Y.; Wu, Q.; Gao, Y.; Li, L. Effect of strain rate on deformation behavior of TRIP steels. J. Mater. Process. Technol. 2012, 212, 2141–2147. [Google Scholar] [CrossRef]

- Rana, R.; Matlock, D.K.; Speer, J.G.; De Moor, E. Effects of Strain Rate and Temperature on the Mechanical Properties of Medium Manganese Steels. In Proceedings of the 1st International Conference on Automobile Steel (ICAS2016), Chengdu, China, 16–18 November 2016; United States Automotive Materials Partnership LLC (USAMP LLC): Washington, DC, USA, 2016. [Google Scholar]

- Freiwillig, R.; Kudrman, J.; Chráska, P. Bainite transformation in deformed austenite. Metall. Trans. A 1976, 7, 1091–1097. [Google Scholar] [CrossRef]

- Jepson, M.D.; Thompson, F.C. The acceleration of the rate of isothermal transformation of austenite. J. Iron Steel Inst. 1949, 162, 49. [Google Scholar]

- Drozdov, B.Y.; Kogan, L.I.; Entin, R.I. Influence of stresses and strains on the kinetics of the intermediate austenite transformation. Phys. Met. Met. 1962, 13, 135–138. [Google Scholar]

- Shipway, P.H.; Bhadeshia, H.K.D.H. Mechanical stabilisation of bainite. Mater. Sci. Technol. 1995, 11, 1116–1128. [Google Scholar] [CrossRef]

- Lambers, H.-G.; Tschumak, S.; Maier, H.J.; Canadinc, D. On the bainitic and martensitic phase transformation behavior and the mechanical properties of low alloy 51CrV4 steel. Int. J. Struct. Chang. Solids 2011, 3, 15–27. [Google Scholar]

- Holzweissig, M.J.; Canadinc, D.; Maier, H.J. In-situ characterization of transformation plasticity during an isothermal austenite-to-bainite phase transformation. Mater. Charact. 2012, 65, 100–108. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; KEHL, G.L. Isothermal Transformation of Austenite under Externally Applied Tensile Stress; Henry Krumb School of Mines: New York, NY, USA, 1954. [Google Scholar]

- Hase, K.; Garcia-Mateo, C.; Bhadeshia, H.K.D.H. Bainite formation influenced by large stress. Mater. Sci. Technol. 2004, 20, 1499–1505. [Google Scholar] [CrossRef] [Green Version]

- Cornide, J.; Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G. An assessment of the contributing factors to the nanoscale structural refinement of advanced bainitic steels. J. Alloys Compd. 2013, 577, S43–S47. [Google Scholar] [CrossRef]

- Singh, S.B.; Bhadeshia, H.K.D.H. Estimation of bainite plate-thickness in low-alloy steels. Mater. Sci. Eng. A 1998, 245, 72–79. [Google Scholar] [CrossRef]

- Yang, Z.; Chu, C.; Jiang, F.; Qin, Y.; Long, X.; Wang, S.; Chen, D.; Zhang, F. Accelerating nano-bainite transformation based on a new constructed microstructural predicting model. Mater. Sci. Eng. A 2019, 748, 16–20. [Google Scholar] [CrossRef]

- Eres-Castellanos, A.; Hidalgo, J.; Zorgani, M.; Jahazi, M.; Toda-Caraballo, I.; Caballero, F.G.; Garcia-Mateo, C. Assessing the scale contributing factors of three carbide-free bainitic steels: A complementary theoretical and experimental approach. Mater. Des. 2021, 197, 109217. [Google Scholar] [CrossRef]

- Pak, J.; Suh, D.W.; Bhadeshia, H.K.D.H. Promoting the Coalescence of Bainite Platelets. Scr. Mater. 2012, 66, 951–953. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.-H.; Ha, H.-Y.; Hwang, B.; Kim, S.-J.; Shin, E. Effect of carbon fraction on stacking fault energy of austenitic stainless steels. Metall. Mater. Trans. A 2012, 43, 4455–4459. [Google Scholar] [CrossRef]

- Schramm, R.E.; Reed, R.P. Stacking fault energies of seven commercial austenitic stainless steels. Metall. Trans. A 1975, 6, 1345. [Google Scholar] [CrossRef]

- Hasan, S.M.; Ghosh, A.; Chakrabarti, D.; Singh, S.B. Orientation Dependence of Deformation-Induced Martensite Transformation During Uniaxial Tensile Deformation of Carbide-Free Bainitic Steel. Metall. Mater. Trans. A 2020, 51, 2053–2063. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eres-Castellanos, A.; Garcia-Mateo, C.; Caballero, F.G. Future Trends on Displacive Stress and Strain Induced Transformations in Steels. Metals 2021, 11, 299. https://doi.org/10.3390/met11020299

Eres-Castellanos A, Garcia-Mateo C, Caballero FG. Future Trends on Displacive Stress and Strain Induced Transformations in Steels. Metals. 2021; 11(2):299. https://doi.org/10.3390/met11020299

Chicago/Turabian StyleEres-Castellanos, Adriana, Carlos Garcia-Mateo, and Francisca G. Caballero. 2021. "Future Trends on Displacive Stress and Strain Induced Transformations in Steels" Metals 11, no. 2: 299. https://doi.org/10.3390/met11020299