A Physical-Based Plane Stress Constitutive Model for High Strength AA7075 under Hot Forming Conditions

Abstract

:1. Introduction

2. Experimentation

2.1. Material

2.2. Test Programme

2.2.1. Uniaxial Hot Tensile Test

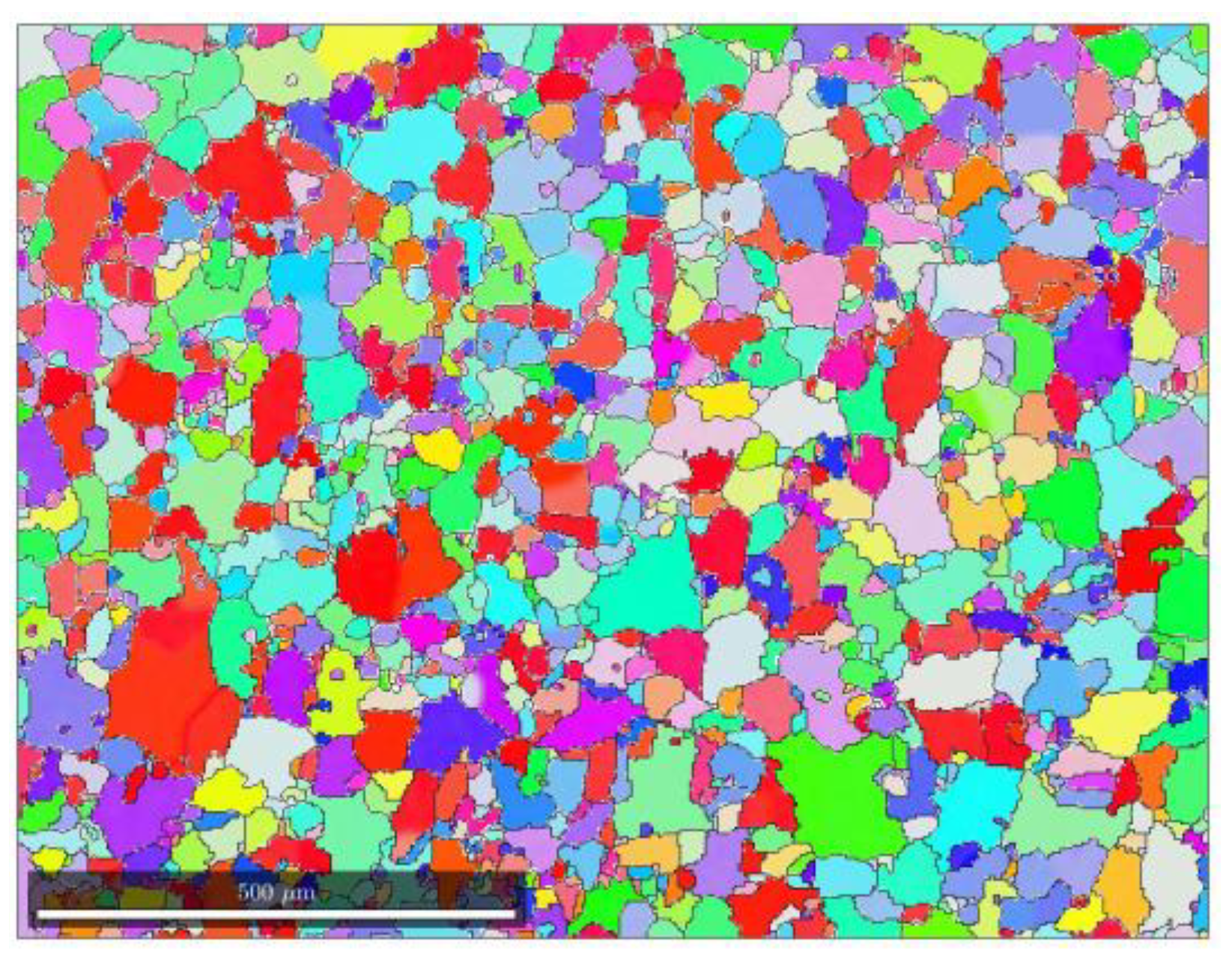

2.2.2. Microstructure Observation

3. Material Modelling

3.1. A Unified Dislocation Mechanics-Based Material Model

3.1.1. Viscoplasticity Law

3.1.2. Modelling of Dislocation Density and Material Hardening

3.1.3. Modelling of Recrystallization Volume Fraction and Grain Size

3.1.4. Modelling of Damage

3.2. Extension to Plane Stress State

3.3. Plane Stress Dislocation Mechanics-Dominant Constitutive Model

4. Microstructure Examination Results

5. Results of Material Model Prediction

5.1. Determination of Material Model Constants

5.2. Hot Flow Behavior

5.3. Comparisons with Phenomeonlogical Models

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex—shaped aluminium panel components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Wang, A.; Zhong, K.; El Fakir, O.; Liu, J.; Sun, C.; Wang, L.-L.; Lin, J.; Dean, T.A. Springback analysis of AA5754 after hot stamping: Experiments and FE modelling. Int. J. Adv. Manuf. Technol. 2017, 89, 1339–1352. [Google Scholar] [CrossRef] [Green Version]

- Yuan, S. Fundamentals and Processes of Fluid Pressure Forming Technology for Complex Thin-Walled Components. Engineering 2020. [Google Scholar] [CrossRef]

- Zheng, K.; Dong, Y.; Zheng, D.; Lin, J.; Dean, T.A. An experimental investigation on the deformation and post-formed strength of heat-treatable aluminium alloys using different elevated temperature forming processes. J. Mater. Process. Technol. 2019, 268, 87–96. [Google Scholar] [CrossRef]

- Toros, S.; Ozturk, F.; Kacar, I. Review of warm forming of aluminum-magnesium alloys. J. Mater. Process. Technol. 2008, 207, 1–12. [Google Scholar] [CrossRef]

- Bariani, P.F.; Bruschi, S.; Ghiotti, A.; Michieletto, F. Hot stamping of AA5083 aluminium alloy sheets. CIRP Ann.Manuf. Technol. 2013, 62, 251–254. [Google Scholar] [CrossRef]

- Smolej, A.; Gnamuš, M.; Slaček, E. The influence of the thermomechanical processing and forming parameters on superplastic behaviour of the 7475 aluminium alloy. J. Mater. Process. Technol. 2001, 118, 397–402. [Google Scholar] [CrossRef]

- Sellars, C.; Zhu, Q. Microstructural modelling of aluminium alloys during thermomechanical processing. Mater. Sci. Eng. A 2000, 280, 1–7. [Google Scholar] [CrossRef]

- Salvado, F.C.; Teixeira-Dias, F.; Walley, S.M.; Lea, L.J.; Cardoso, J.B. A review on the strain rate dependency of the dynamic viscoplastic response of FCC metals. Prog. Mater. Sci. 2017, 88, 186–231. [Google Scholar] [CrossRef] [Green Version]

- Zheng, K.; Politis, D.J.; Lin, J.; Dean, T.A. An experimental and numerical investigation of the effect of macro-textured tool surfaces in hot stamping. Int. J. Mater. Form. 2017, 10, 241–254. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.C.; Chen, X.-M.; Liu, G. A modified Johnson–Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6986. [Google Scholar] [CrossRef]

- He, A.; Xie, G.; Zhang, H.; Wang, X. A comparative study on Johnson–Cook, modified Johnson–Cook and Arrhenius-type constitutive models to predict the high temperature flow stress in 20CrMo alloy steel. Mater. Des. 2013, 52, 677–685. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.-M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, J.; McDowell, D.L. Microstructure-based crystal plasticity modeling of cyclic deformation of Ti–6Al–4V. Int. J. Plast. 2007, 23, 1328–1348. [Google Scholar] [CrossRef]

- Sun, Z.C.; Wu, H.L.; Cao, J.; Yin, Z.K. Modeling of continuous dynamic recrystallization of Al-Zn-Cu-Mg alloy during hot deformation based on the internal-state-variable (ISV) method. Int. J. Plast. 2018, 106, 73–87. [Google Scholar] [CrossRef]

- El Fakir, O.; Wang, L.; Balint, D.; Dear, J.P.; Lin, J.; Dean, T.A. Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754. Int. J. Mach. Tools Manuf. 2014, 87, 39–48. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, M.S.; Foster, A.D.; Lin, J.; Balint, D.S.; Dean, T.A. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling. Int. J. Mach. Tools Manuf. 2011, 53, 27–38. [Google Scholar] [CrossRef]

- Xiao, W.; Wang, B.; Wu, Y.; Yang, X. Constitutive modeling of flow behavior and microstructure evolution of AA7075 in hot tensile deformation. Mater. Sci. Eng. A 2018, 712, 704–713. [Google Scholar] [CrossRef]

- Zheng, K.; Zhu, L.; Lin, J.; Dean, T.A.; Li, N. An experimental investigation of the drawability of AA6082 sheet under different elevated temperature forming processes. J. Mater. Process. Technol. 2019, 273, 116225. [Google Scholar] [CrossRef]

- Zheng, K.; Li, Y.; Yang, S.; Fu, K.; Zheng, J.; He, Z.; Yuan, S. Investigation and Modeling of the Preheating Effects on Precipitation and Hot Flow Behavior for Forming High Strength AA7075 at Elevated Temperatures. J. Manuf. Mater. Process. 2020, 4, 76. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- Lin, J.; Liu, Y.; Dean, T.A. A Review on Damage Mechanisms, Models and Calibration Methods under Various Deformation Conditions. Int. J. Damage Mech. 2005, 14, 299–319. [Google Scholar] [CrossRef]

- Kocks, U.F. A statistical theory of flow stress and work-hardening. Philos. Mag. 1966, 13, 541–566. [Google Scholar] [CrossRef]

- Sakai, T.; Jonas, J.J. Overview no. 35 Dynamic recrystallization: Mechanical and microstructural considerations. Acta Metall. 1984, 32, 189–209. [Google Scholar] [CrossRef]

- Sandström, R.; Lagneborg, R. A model for hot working occurring by recrystallization. Acta Metall. 1975, 23, 387–398. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Prangnell, P.B.; Bowen, J.R.; Gholinia, A.; Harris, C. Developing stable fine–grain microstructures by large strain deformation. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1999, 357, 1663–1681. [Google Scholar] [CrossRef]

- Roucoules, C.; Pietrzyk, M.; Hodgson, P. Analysis of work hardening and recrystallization during the hot working of steel using a statistically based internal variable model. Mater. Sci. Eng. A 2003, 339, 1–9. [Google Scholar] [CrossRef]

- Alabort, E.; Putman, D.; Reed, R.C. Superplasticity in Ti-6Al-4V: Characterisation, modelling and applications. Acta Mater. 2015, 95, 428–442. [Google Scholar] [CrossRef] [Green Version]

- Roberts, W.; Ahlblom, B. A nucleation criterion for dynamic recrystallization during hot working. Acta Metall. 1978, 26, 801–813. [Google Scholar] [CrossRef]

- Li, N.; Sun, C.; Guo, N.; Mohamed, M.; Lin, J.; Matsumoto, T.; Liu, C. Experimental investigation of boron steel at hot stamping conditions. J. Mater. Process. Technol. 2016, 228, 2–10. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Mohamed, M.; Balint, D.; Dean, T.A. The development of continuum damage mechanics-based theories for predicting forming limit diagrams for hot stamping applications. Int. J. Damage Mech. 2014, 23, 684–701. [Google Scholar] [CrossRef]

- Hayhurst, D.R. Creep rupture under multi-axial states of stress. J. Mech. Phys. Solids 1972, 20, 381–382. [Google Scholar] [CrossRef]

- Jiang, J.; Britton, T.B.; Wilkinson, A.J. Evolution of dislocation density distributions in copper during tensile deformation. Acta Mater. 2013, 61, 7227–7239. [Google Scholar] [CrossRef]

- Fan, X.; He, Z.; Lin, P.; Yuan, S. Microstructure, texture and hardness of Al–Cu–Li alloy sheet during hot gas forming with integrated heat treatment. Mater. Des. 2016, 94, 449–456. [Google Scholar] [CrossRef]

- Jiang, J.; Britton, T.B.; Wilkinson, A.J. Measurement of geometrically necessary dislocation density with high resolution electron backscatter diffraction: Effects of detector binning and step size. Ultramicroscopy 2013, 125, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Ben Britton, T.; Wilkinson, A.J. The orientation and strain dependence of dislocation structure evolution in monotonically deformed polycrystalline copper. Int. J. Plast. 2015, 69, 102–117. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Ilinich, A.; Chen, M.; Luckey, G.; D’Amours, G. A comparison study on forming limit prediction methods for hot stamping of 7075 aluminum sheet. Int. J. Mech. Sci. 2019, 151, 444–460. [Google Scholar] [CrossRef]

- Shao, Z.; Li, N.; Lin, J.; Dean, T. Formability evaluation for sheet metals under hot stamping conditions by a novel biaxial testing system and a new materials model. Int. J. Mech. Sci. 2017, 120, 149–158. [Google Scholar] [CrossRef]

- Cheng, Y.Q.; Zhang, H.; Chen, Z.H.; Xian, K.F. Flow stress equation of AZ31 magnesium alloy sheet during warm tensile deformation. J. Mater. Process. Technol. 2008, 208, 29–34. [Google Scholar] [CrossRef]

| Zn | Mg | Cu | Si | Fe | Mn | Cr | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 5.1–6.1 | 2.1–2.9 | 1.2–2.0 | 0.4 | 0.5 | 0.3 | 0.18–0.28 | 0.2 | Remain |

| Uniaxial Equations |

| Plane Stress Extension |

| - |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | 0.2501 | ||

| (J/mol) | 2.347 × 104 | (J/mol) | 2.98 × 104 | (J/mol) | 2.2 × 104 |

| (-) | 0.02059 | (-) | (MPa) | ||

| (J/mol) | 2.336 × 104 | (J/mol) | 4.38 × 104 | (J/mol) | 1.25 × 104 |

| (-) | (-) | () | 1.31 × 10−4 | ||

| (J/mol) | 2.046 × 104 | (J/mol) | 3243 | (J/mol) | 3490 |

| (-) | () | (J/mol) | 1.38 × 104 | ||

| 6795 | (-) | 0.08028 | (-) | 0.04528 | |

| (J/mol) | 1.51 × 104 | (J/mol) | 3.493 × 104 | (J/mol) | |

| () | 1.14 × 104 | (-) | 0.0497 | (s) | 5.72 × 10−9 |

| (J/mol) | 7.5 × 104 | (-) | (-) | ||

| (-) | 20 | (-) | 2.088153 | () | 35 |

| (-) | (-) | 6 | (-) | 10 | |

| () | 800.49 | (J/mol) | 5.0 × 104 | (-) | |

| (J/mol) | 1.003 × 105 | (J/mol) | 2.18 × 104 | (-) | 7.5 |

| (-) | (-) | 0.03086 | w20 (-) | ||

| (J/mol) | 4.241 × 104 | (J/mol) | 7.915 × 104 | (-) | 2.08 × 10−7 |

| Value | |||

| Conditions | 0.1/s | 1/s | 5/s |

| 350 °C | 0.01326 | 0.02382 | 0.5837 |

| 400 °C | 0.0682 | 0.01455 | 0.06062 |

| mValue | |||

| Conditions | 0.1 | 0.2 | 0.3 |

| 350 °C | 0.09412 | 0.10417 | 0.11041 |

| 400 °C | 0.20178 | 0.19181 | 0.18821 |

| 1015.67 | −0.00325 | −0.44101 |

| 1.60276 | 0.00478 | −980.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Qu, H.; Wu, W.; Zheng, J.-H.; Qu, S.; Han, Y.; Zheng, K. A Physical-Based Plane Stress Constitutive Model for High Strength AA7075 under Hot Forming Conditions. Metals 2021, 11, 314. https://doi.org/10.3390/met11020314

Chen F, Qu H, Wu W, Zheng J-H, Qu S, Han Y, Zheng K. A Physical-Based Plane Stress Constitutive Model for High Strength AA7075 under Hot Forming Conditions. Metals. 2021; 11(2):314. https://doi.org/10.3390/met11020314

Chicago/Turabian StyleChen, Fulong, Haitao Qu, Wei Wu, Jing-Hua Zheng, Shuguang Qu, Yujie Han, and Kailun Zheng. 2021. "A Physical-Based Plane Stress Constitutive Model for High Strength AA7075 under Hot Forming Conditions" Metals 11, no. 2: 314. https://doi.org/10.3390/met11020314