Influences of Residual Stress, Surface Roughness and Peak-Load on Micro-Cracking: Sensitivity Analysis

Abstract

:1. Introduction

2. Materials and Methods

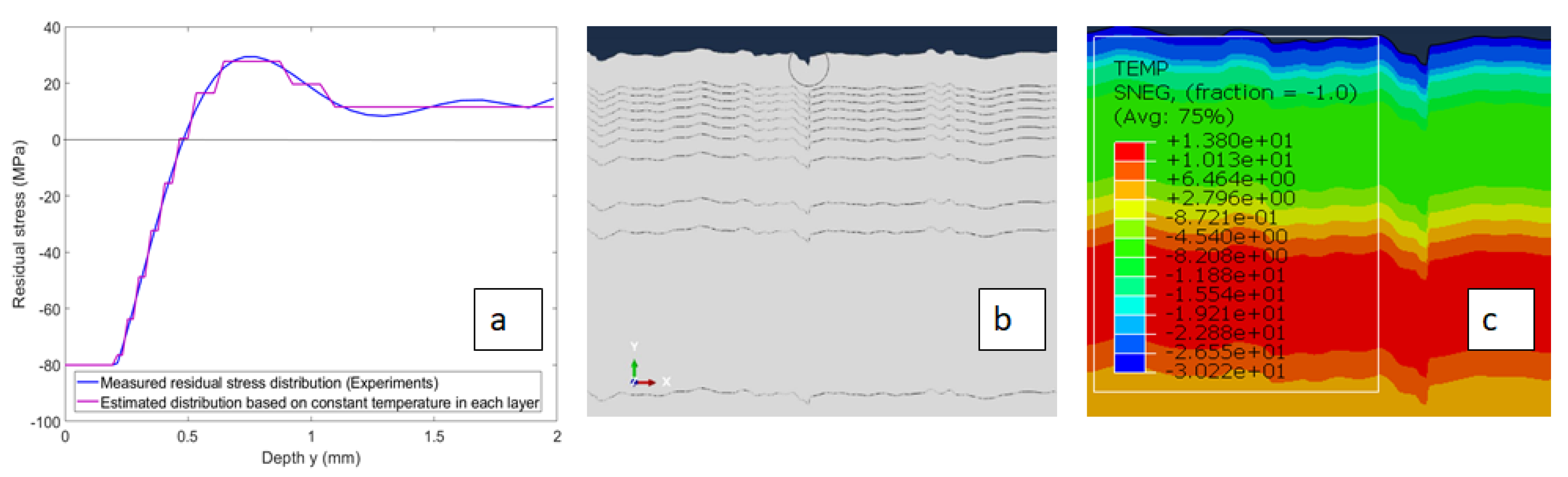

2.1. Characteristics of Sandblasted High-Strength Steel Surface

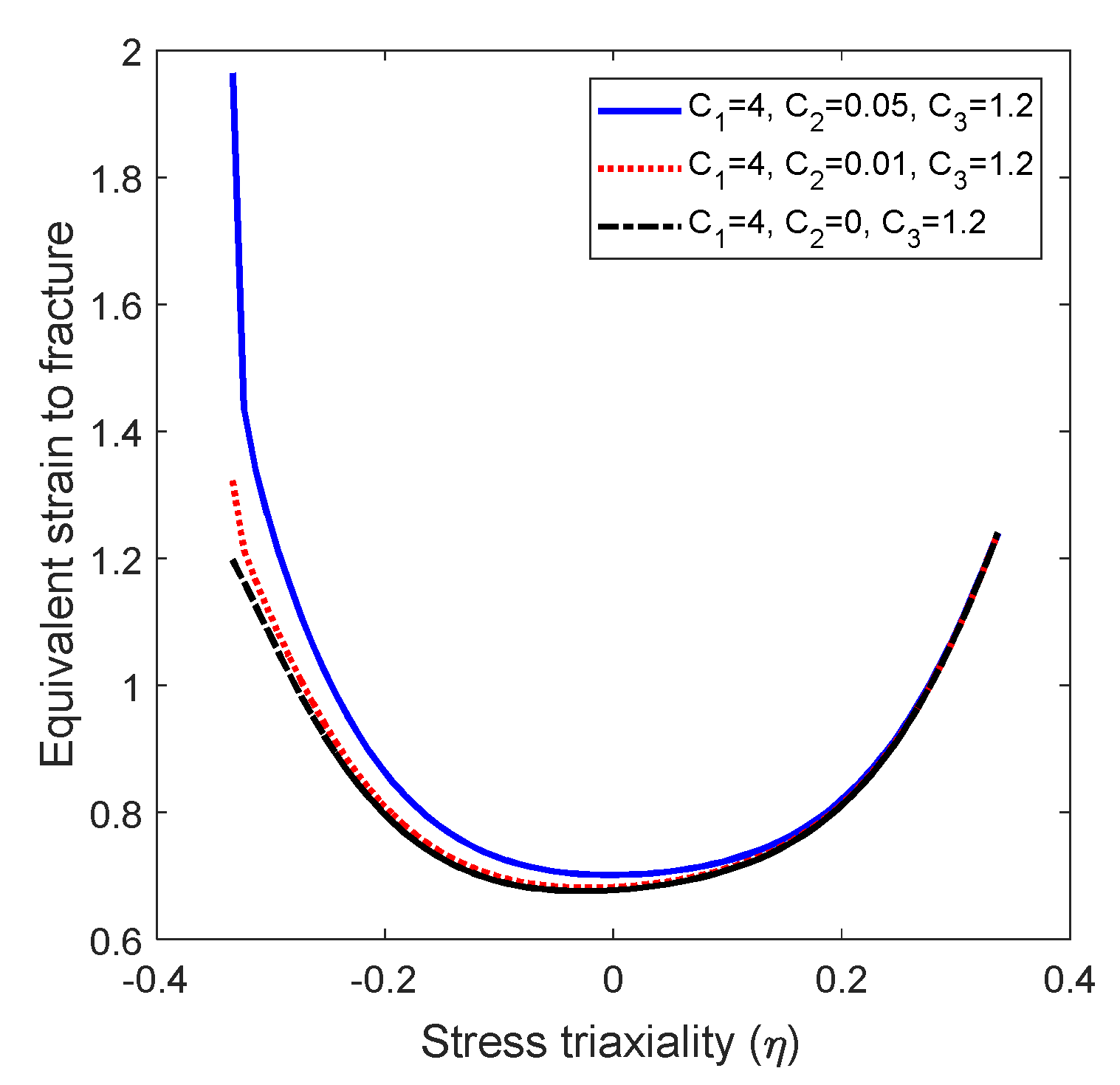

2.2. Ductile Fracture Criterion

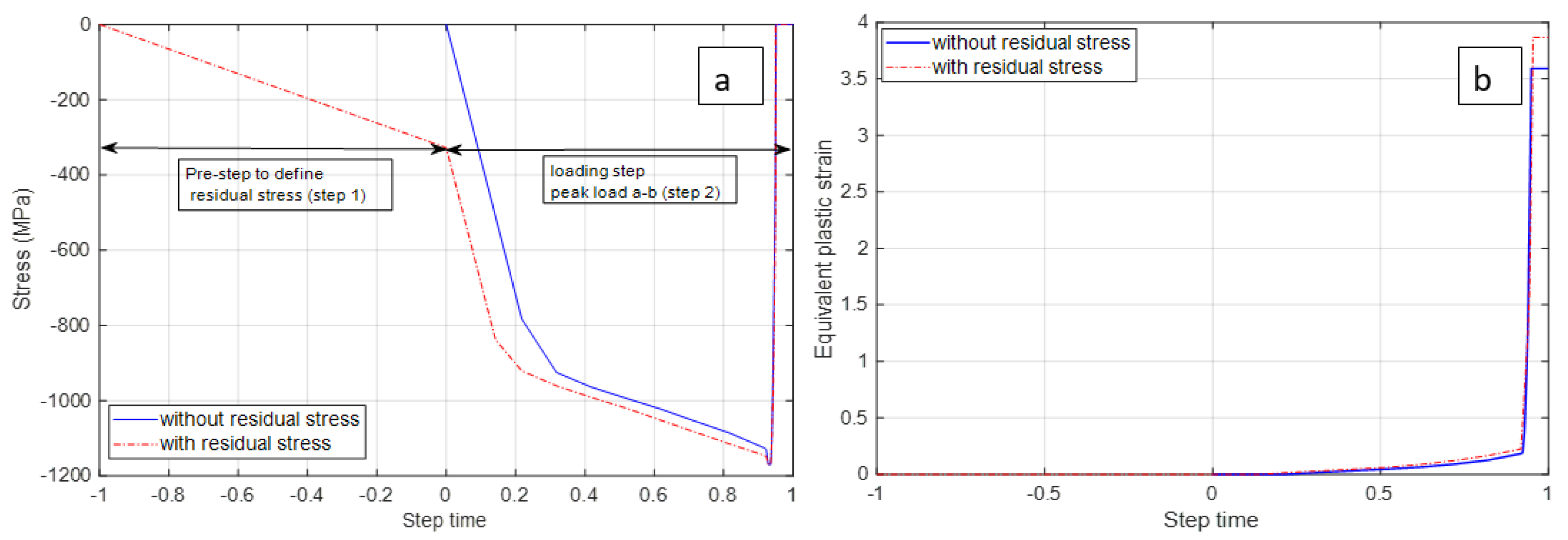

2.3. Numerical Simulation

3. Results and Discussion

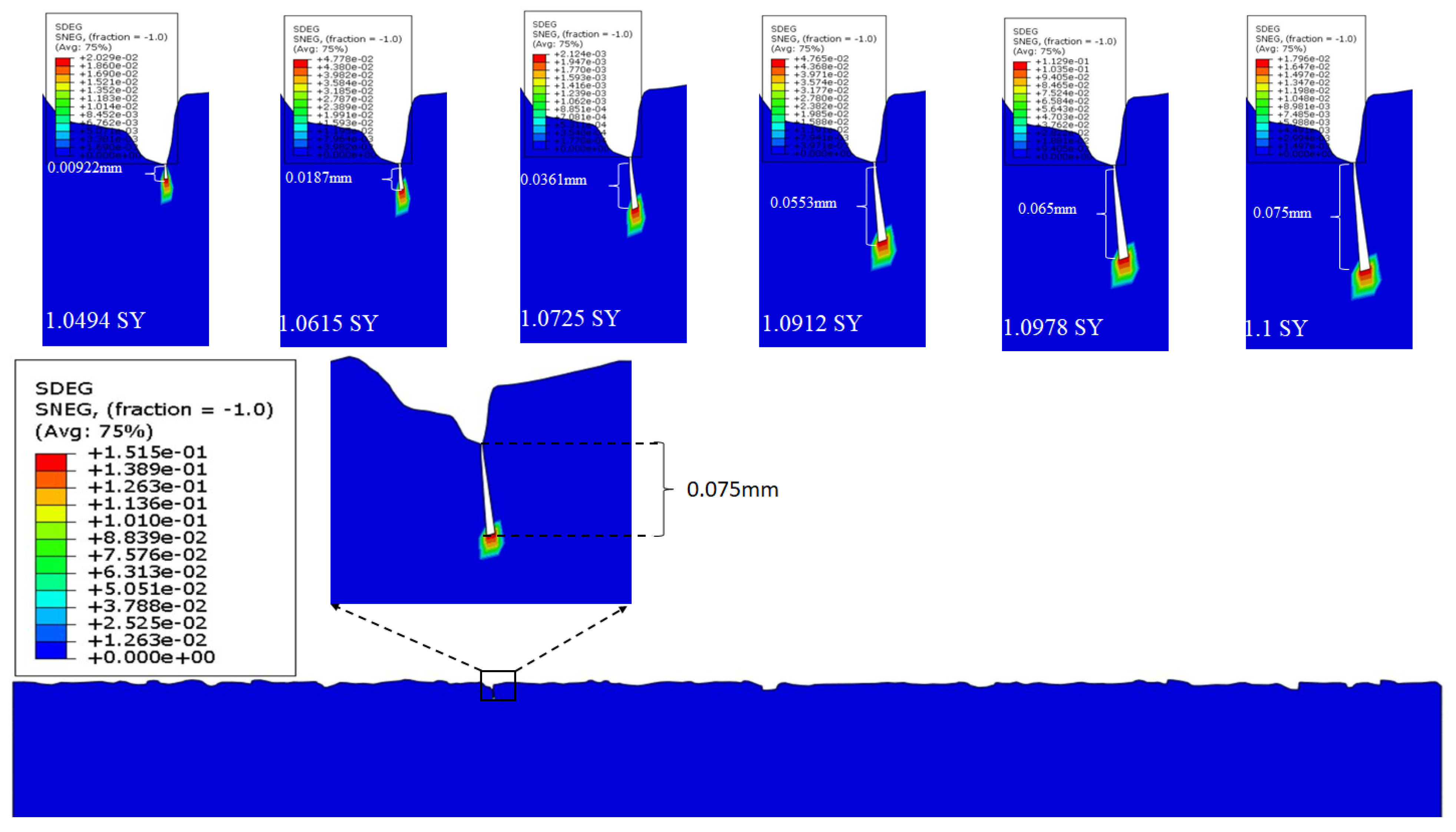

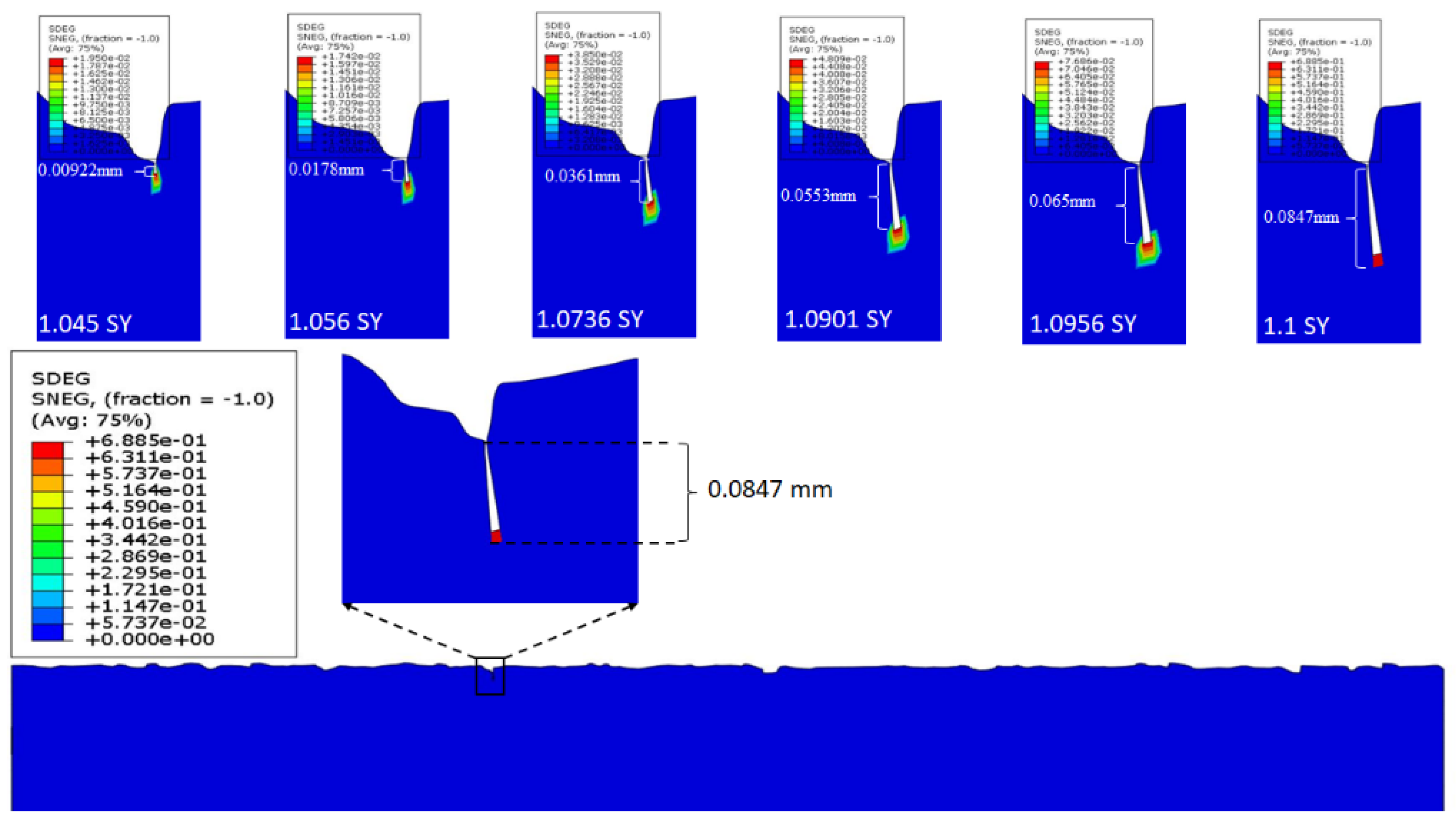

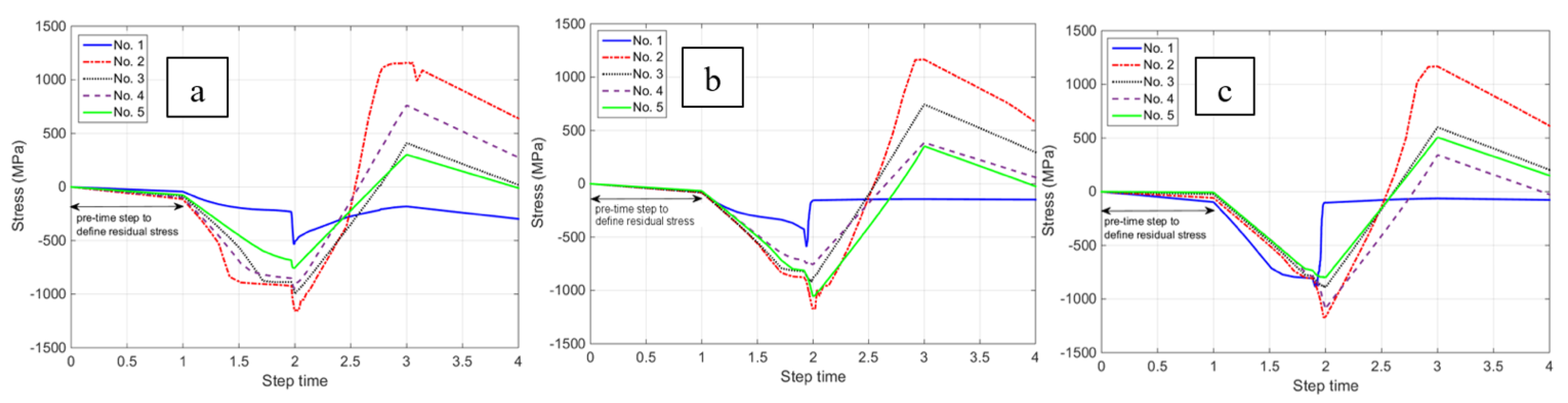

3.1. Influence of Residual Stress on Micro-Crack Formation

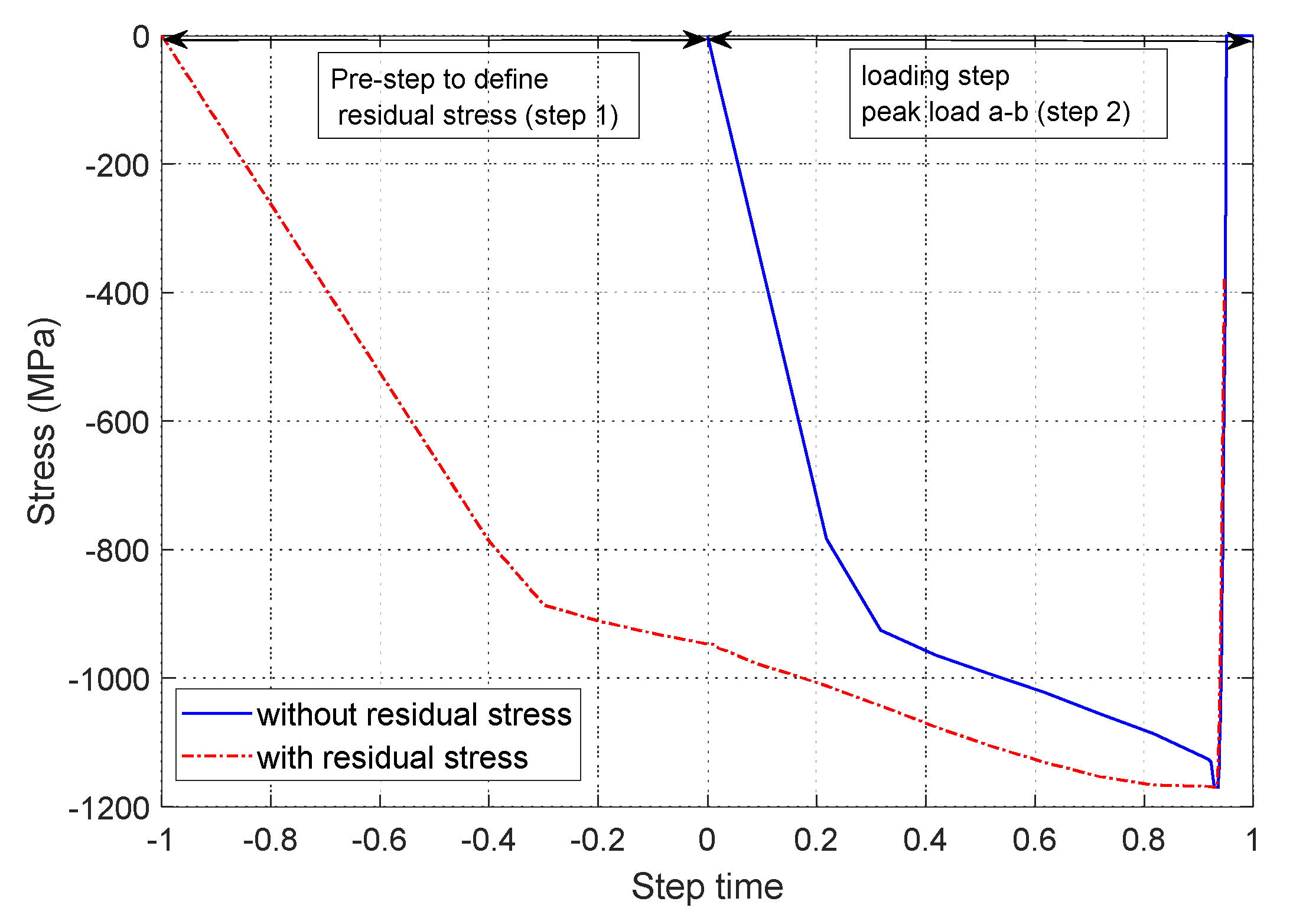

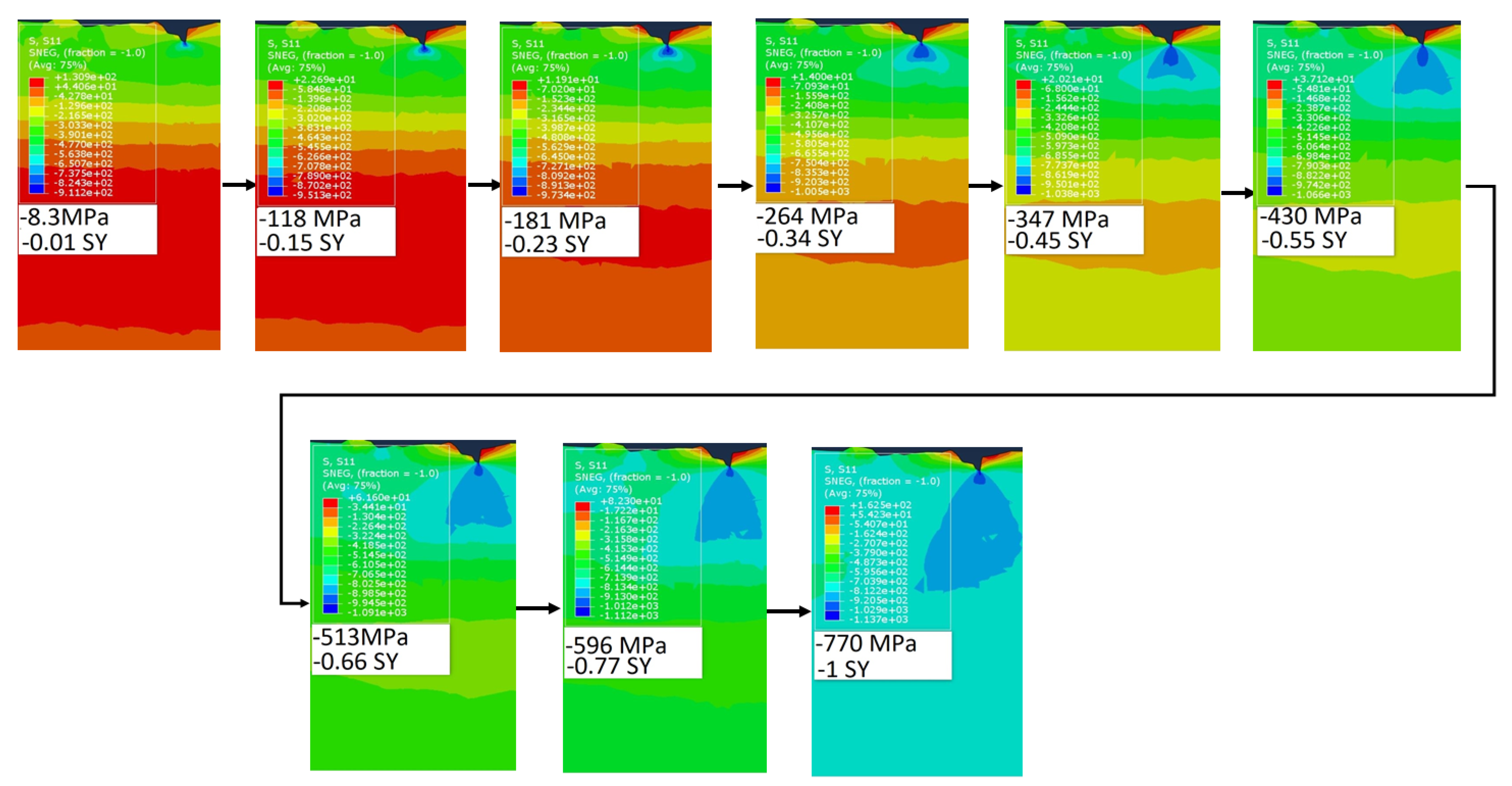

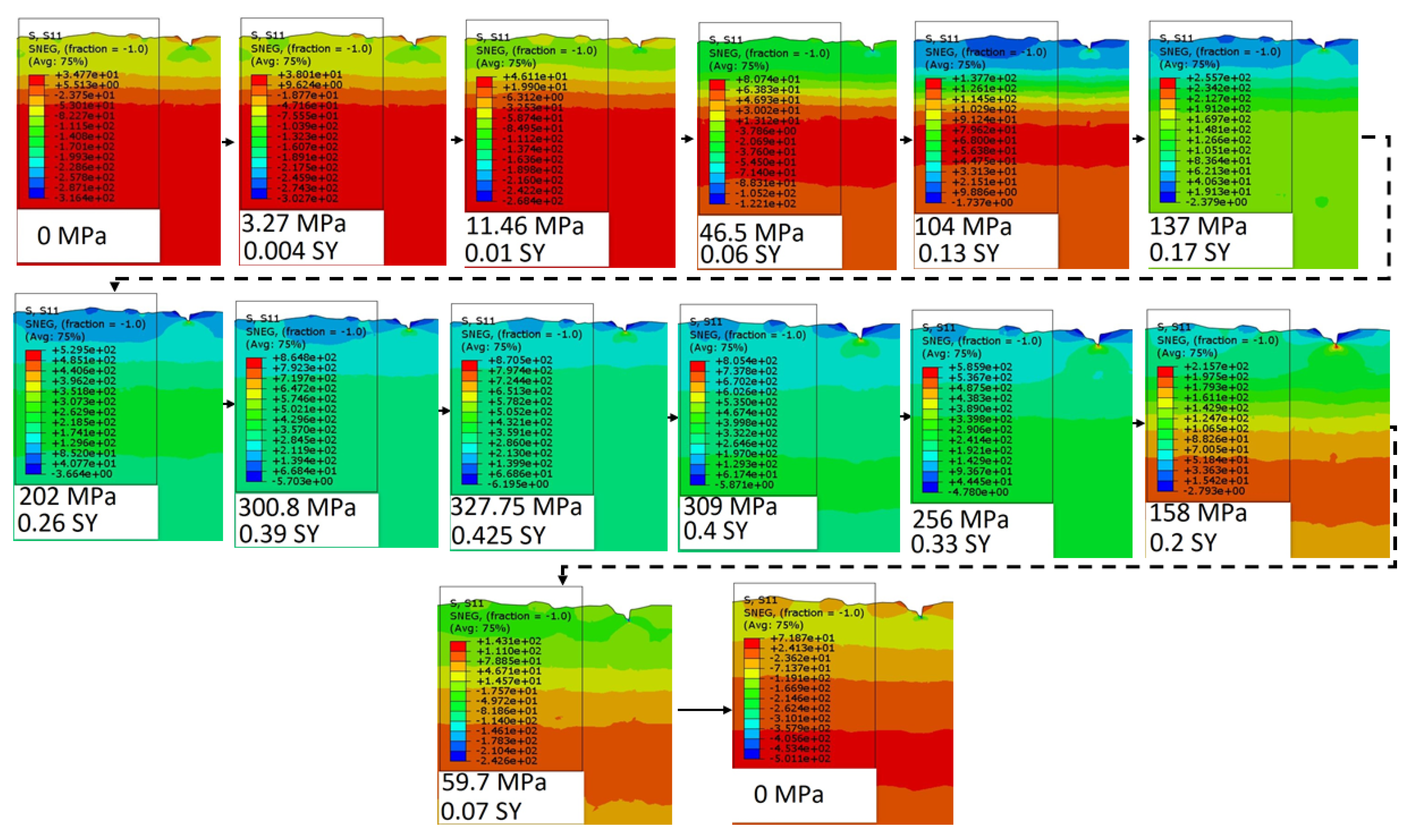

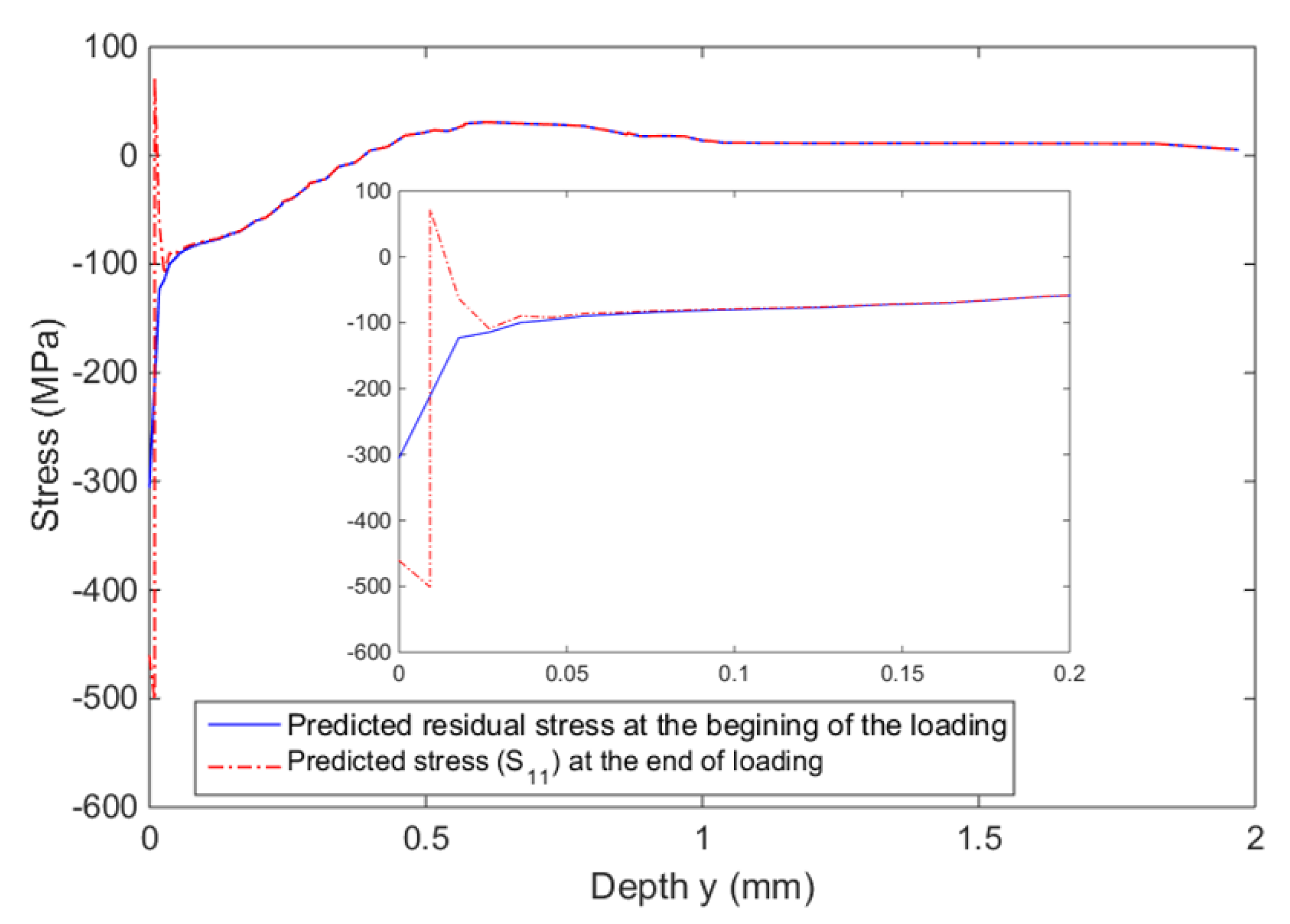

3.2. Influence of Peak Load on Relaxation of Residual Stress

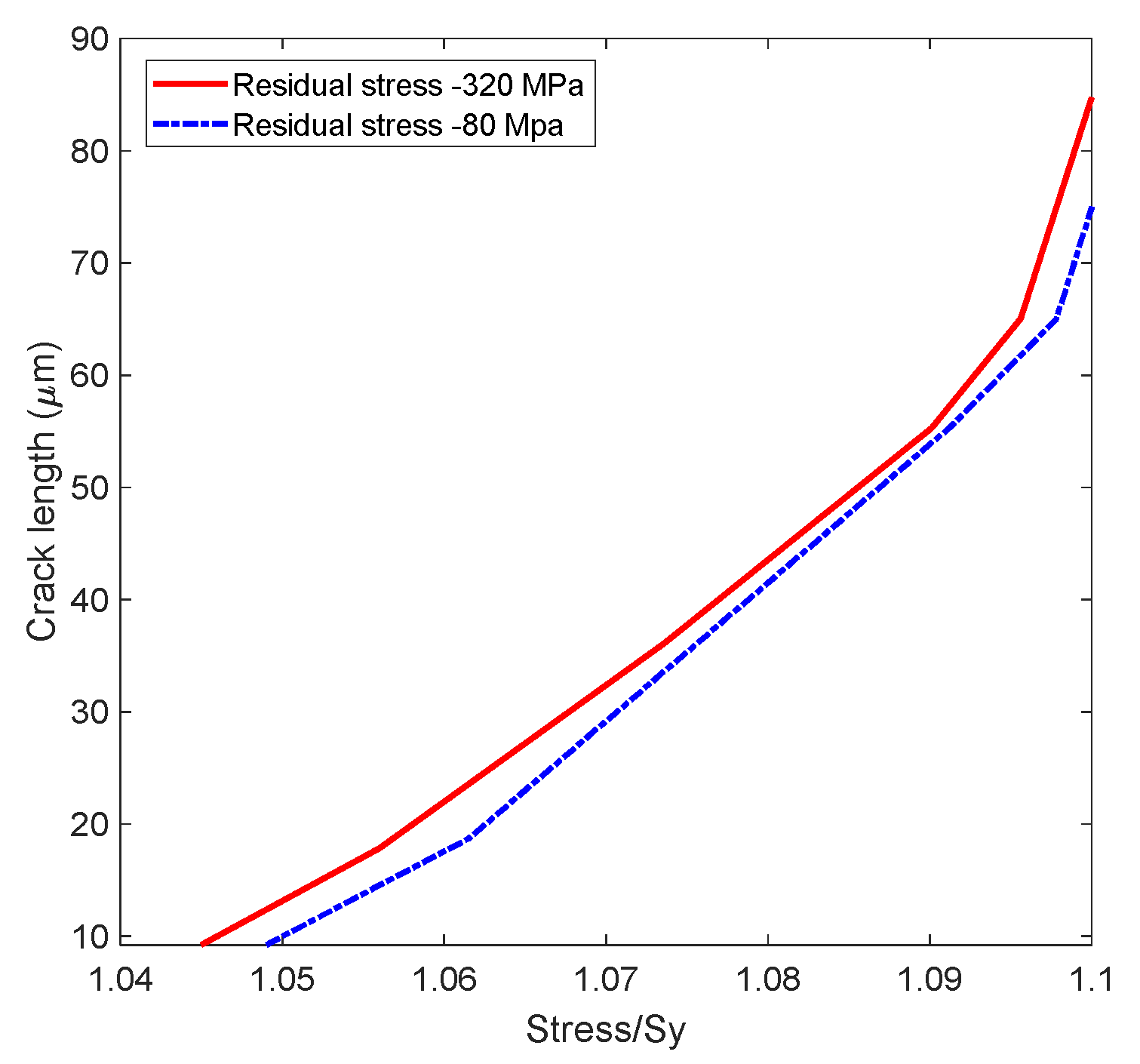

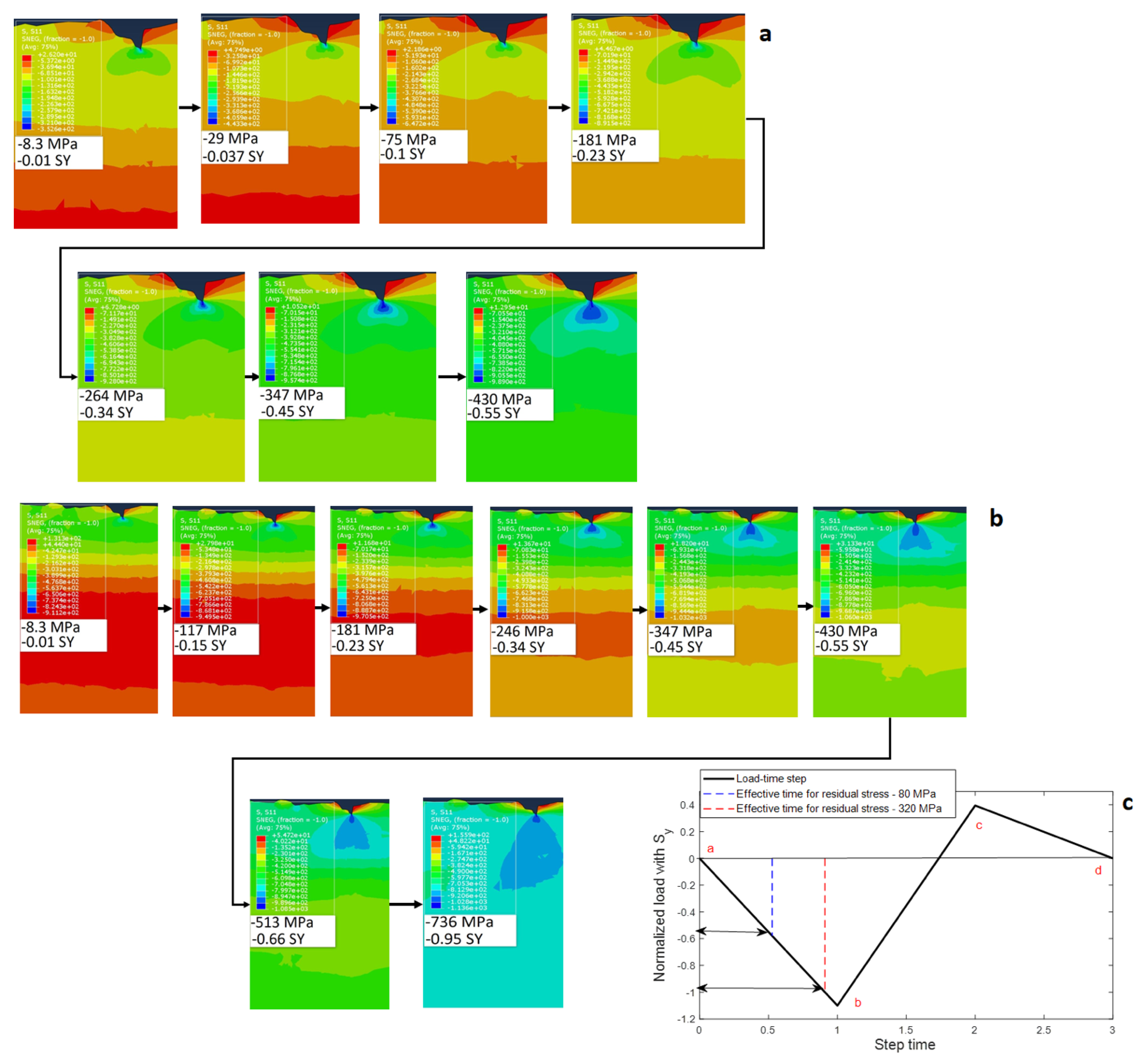

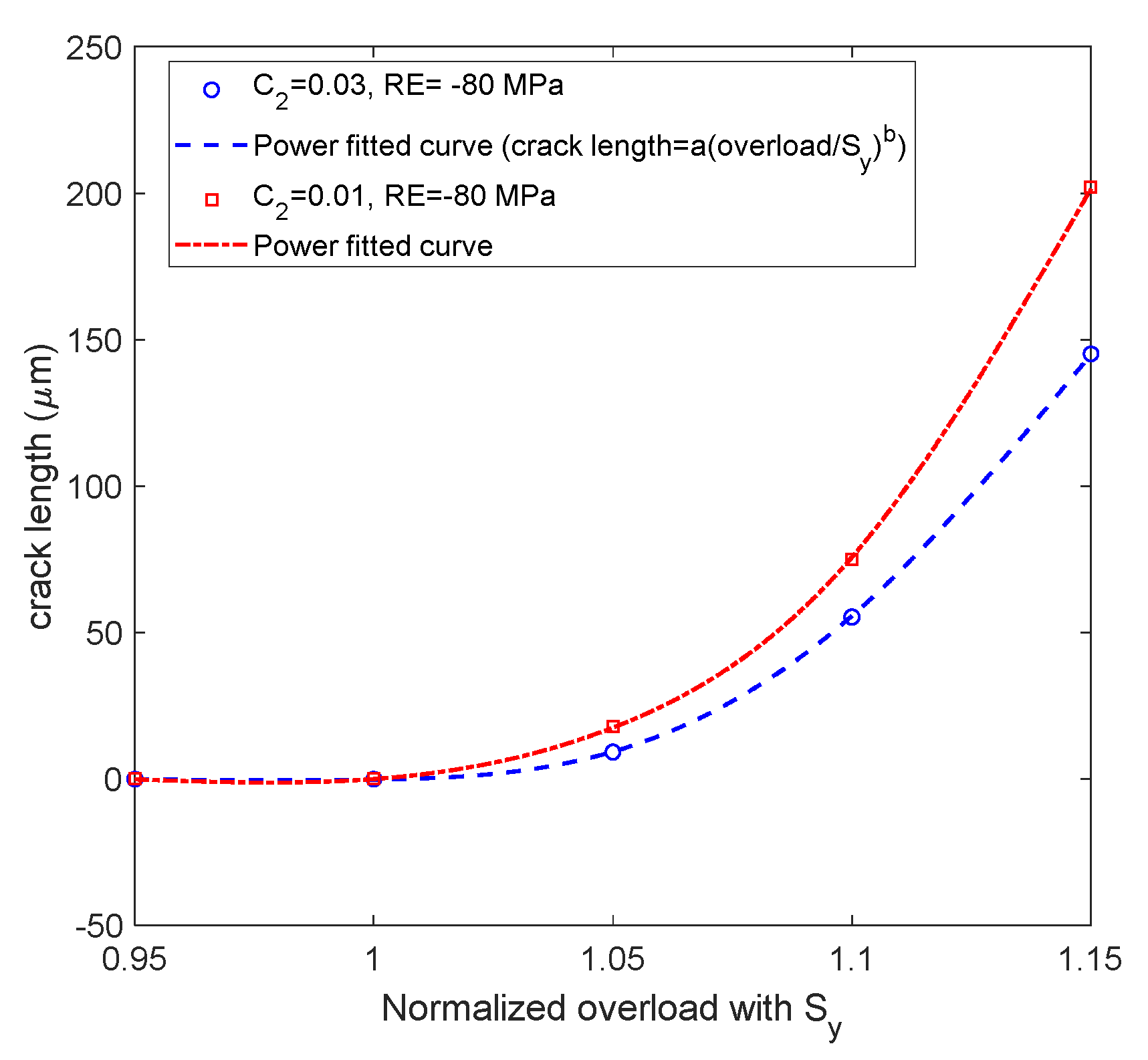

3.3. Influence of Fracture Locus and Load Level on Micro Crack Formation

4. Conclusions

- With increasing values of residual stress, the residual stress relaxation rate decreases in comparison to the other studied case with lower magnitudes of residual stress. The residual stress relaxation rate is an affecting parameter with respect to the damage mechanism, and crack size increased with lower residual relaxation rates; however, this effect was not very significant.

- Under peak load conditions, surface roughness has a far more important influence on microcrack formation than residual stresses.

- The influence of compressive overload on damage formation and crack size is greater than the residual stress effect, and there are significant differences in the crack size between various overload values with constant residual stress magnitude. There was no significant variance in crack size between different residual stress magnitudes with a constant overload value. Meanwhile it was found that crack size increases exponentially with increasing magnitudes of peak load in cases with a constant magnitude of residual stress.

- Material areas located in regions close to the crack tip are prone to damage even with low loading magnitudes in other load scenarios after subjecting the material to peak load. The size of the affected region close to the crack tip is more extensive with higher magnitudes of peak stress, especially in cases where the fracture locus has a lower equivalent plastic strain on the compression side.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diekhoff, P.; Hensel, J.; Nitschke, T.; Dilger, K. Investigation on fatigue strength of cut edges produced by various cutting methods for high-strength steels. Weld. World 2020, 64, 545–561. [Google Scholar] [CrossRef] [Green Version]

- Sperle, J.O. Influence of Parent Metal Strength on the Fatigue Strength of Parent Material with Machined and Thermally Cut Edges. IIW Document XIII-2174-07; International Institute of Welding: Paris, France, 2007. [Google Scholar]

- Alhussein, A.; Capelle, J.; Gilgert, J.; Tidu, A.; Hariri, S.; Azari, Z. Static, dynamic and fatigue characteristics of the pipeline API 5L X52 steel after sandblasting. Eng. Fail. Anal. 2013, 27, 1–15. [Google Scholar] [CrossRef]

- McKelvey, S.A.; Fatemi, A. Surface finish effect on fatigue behavior of forged steel. Int. J. Fatigue 2012, 36, 130–145. [Google Scholar] [CrossRef]

- Hussain, K.; Wilkinson, D.; Embury, J. Effect of surface finish on high temperature fatigue of a nickel based super alloy. Int. J. Fatigue 2009, 31, 743–750. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effect of defects, inclusions and inhomogenities on fatigue strength. Int. J. Fatigue 1994, 16, 163–182. [Google Scholar] [CrossRef]

- Sasahara, H. The effect on fatigue life of residual stress and surface hardness resulting from different cutting conditions of 0.45%C steel. Int. J. Mach. Tools Manuf. 2005, 25, 131–136. [Google Scholar] [CrossRef]

- Małecka, J.; Rozumek, D. Metallographic and mechanical research of the O-Ti2AlNb alloy. Meterials 2020, 13, 3006. [Google Scholar] [CrossRef] [PubMed]

- Ryu, H.R.; Kim, W.S.; Ha, H.I.; Kang, S.W.; Kim, M.H. Effect of toe grinding on fatigue strength of ship structure. J. Ship Prod. 2008, 24, 152–160. [Google Scholar] [CrossRef]

- Xun, L.I.; Guan, C.; Zhao, P. Influences of milling and grinding on machined surface roughness and fatigue behavior of GH4169 superalloy workpieces. Chin. J. Aeronaut. 2018, 31, 1399–1405. [Google Scholar]

- Zhang, M.; Wang, W.Q.; Wang, P.F.; Liu, Y.; Li, J. The fatigue behavior and mechanism of FV520B-I with large surface roughness in a very high cycle regime. Eng. Fail. Anal. 2016, 66, 432–444. [Google Scholar] [CrossRef]

- Lopes, H.P.; Elias, C.N.; Vieira, M.V.; Vieira, V.T.; de Souza, L.C.; Dos Santos, A.L. Influence of surface roughness on the fatigue life of nickel-titanium rotary endodontic instruments. J. Endod. 2016, 42, 965–968. [Google Scholar] [CrossRef]

- Pegues, J.; Roach, M.; Scott Williamson, R.; Shamsaei, N. Surface roughness effects on the fatigue strength of additively manufactured Ti-6Al-4V. Int. J. Fatigue 2018, 116, 543–552. [Google Scholar] [CrossRef]

- Novovic, D.; Dewes, R.C.; Aspinwall, D.K.; Voice, W.; Bowen, P. The effect of machined topography and integrity on fatigue life. Int. J. Mach. Tools Manuf. 2004, 44, 125–134. [Google Scholar] [CrossRef]

- Haghshenas, A.; Khonsari, M.M. Damage accumulation and crack initiation detection based on the evolution of surface roughness parameters. Int. J. Fatigue 2018, 107, 130–144. [Google Scholar] [CrossRef]

- Gao, Y.; Li, X.; Yang, Q.; Yao, M. Influence of surface integrity on fatigue strength of 40CrNi2Si2MoVA steel. Mater. Lett. 2007, 61, 466–469. [Google Scholar] [CrossRef]

- Remes, H.; Korhonen, E.; Lehto, P.; Romanoff, J.; Ehlers, S.; Niemela, A.; Hiltunen, P.; Kotakanen, T. Influence of surface integrity on fatigue strength of high-strengh steel. J. Constr. Steel Res. 2013, 89, 21–29. [Google Scholar] [CrossRef]

- Lillemae-Avi, I.; Liinalampis Lehtimalil, E.; Remes, H.; Lehto, P.; Romanoff, J.; Ehlers, S.; Niemela, A. Fatigue strength of high strength steel after shipyard production process of plasma cutting, grinding and sandblasting. Weld. World 2018, 62, 1273–1287. [Google Scholar] [CrossRef] [Green Version]

- Rozumek, D.; Lewandowski, J.; Lesiuk, G.; Correia, J. The influence of heat treatment on the behavior of fatigue crack growth in welded joints made of S355 under bending loading. Int. J. Fatigue 2020, 131, 105328. [Google Scholar] [CrossRef]

- Bao, Y.B.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Papasidero, J.; Doquet, V.; Mohr, D. Ductile fracture of aluminum 2024-T351 under proportional and non-proportional multi-axial loading: Bao–Wierzbicki results revisited. Int. J. Solids Struct. 2015, 69–70, 459–474. [Google Scholar] [CrossRef]

- Lou, Y.; Huh, H. Prediction of ductile fracture for advanced high strength steel with a new criterion: Experiments and simulation. J. Mater. Process. Tech. 2013, 213, 1284–1302. [Google Scholar] [CrossRef]

- Kõrgesaar, M.; Romanoff, J.; Remes, H.; Palokangas, P. Experimental and numerical penetration response of laser-welded stiffened panels. Int. J. Impact. Eng. 2018, 114, 78–92. [Google Scholar] [CrossRef]

- Hu, Q.; Li, X.; Han, X.; Chen, J. A new shear and tension based ductile fracture criterion: Modeling and validation. Eur. J. Mech. A-Solids 2017, 66, 370–386. [Google Scholar] [CrossRef]

- Mohr, D.; Marcadet, S.J. Micromechanically-motivated phenomenological Hosford–Coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int. J. Solids Struct. 2015, 67–68, 55. [Google Scholar] [CrossRef]

- Brünig, M.; Albrecht, D.; Gerke, S. Modeling of ductile damage and fracture behavior based on different micromechanisms. Int. J. Damage Mech. 2011, 20, 558–577. [Google Scholar] [CrossRef]

- Nafar Dastgerdi, J.; Sheibanian, F.; Remes, H.; Lehto, P.; Hosseini Toudeshky, H. Numerical modeling approach for considering effects of surface integrity on micro-crack formation. J. Constr. Steel Res. 2020, 175, 106387. [Google Scholar] [CrossRef]

- Lou, Y.; Huh, H.; Lim, S.; Pack, K. New ductile fracture criterion for prediction of fracture forming limit diagrams of sheet metals. Int. J. Solids Struct. 2012, 49, 3605–3615. [Google Scholar] [CrossRef] [Green Version]

- McClung, R.C. A literature survey on the stability and significance of residual stresses during fatigue. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 173–205. [Google Scholar] [CrossRef]

- Dalaei, K.; Karlsson, B.; Svensson, L.E. Stability of shot peening induced residual stresses and their influence on fatigue lifetime. Mater. Sci. Eng. 2011, A528, 1008–1015. [Google Scholar] [CrossRef]

- Farajian-Sohi, M.; Nitschke-Pagel, T.; Dilger, K. Residual stress relaxation of quasi-statically and cyclically-loaded steel welds. Weld. World 2010, 54, 49–60. [Google Scholar] [CrossRef]

- Laamouri, A.; Sidhom, H.; Braham, C. Evaluation of residual stress relaxation and its effect on fatigue strength of AISI 316L stainless steel ground surfaces: Experimental and numerical approaches. Int. J. Fatigue 2013, 48, 109–121. [Google Scholar] [CrossRef] [Green Version]

- SFS-EN ISO 4288. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture; ISO: Genève, Switzerland, 1996. [Google Scholar]

- Hoa, H.C.; Chunga, K.F.; Liua, X.; Xiaoa, M.; Nethercot, D.A. Modelling tensile tests on high strength S690 steel materials undergoing large deformations. Eng. Struct. 2019, 192, 305–322. [Google Scholar] [CrossRef]

- Radaj, D.; Sonsino, C.M.; Fricke, W. Recent developments in local concepts of fatigue 26 assessment of welded joints. Int. J. Fatigue 2009, 31, 2–11. [Google Scholar] [CrossRef]

- Arola, D.; Ramulu, M. An examination of the effects from surface texture on the strength of fiber reinforced plastics. J. Compos. Mater. 1999, 33, 102–123. [Google Scholar] [CrossRef]

- Arola, D.; Williams, C.L. Estimating the fatigue stress concentration factor of machined surfaces. Int. J. Fatigue 2002, 24, 923–930. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P | S | Al | Nb | V | Ti | Cu | Cr | Ni | Mo | B | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S690 | 0.16 | 0.21 | 1.39 | 0.011 | 0.001 | 0.047 | 0.015 | 0.018 | 0.007 | 0.01 | 0.25 | 0.06 | 0.502 | 0.001 | 0.002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nafar Dastgerdi, J.; Sheibanian, F.; Remes, H.; Hosseini Toudeshky, H. Influences of Residual Stress, Surface Roughness and Peak-Load on Micro-Cracking: Sensitivity Analysis. Metals 2021, 11, 320. https://doi.org/10.3390/met11020320

Nafar Dastgerdi J, Sheibanian F, Remes H, Hosseini Toudeshky H. Influences of Residual Stress, Surface Roughness and Peak-Load on Micro-Cracking: Sensitivity Analysis. Metals. 2021; 11(2):320. https://doi.org/10.3390/met11020320

Chicago/Turabian StyleNafar Dastgerdi, Jairan, Fariborz Sheibanian, Heikki Remes, and Hossein Hosseini Toudeshky. 2021. "Influences of Residual Stress, Surface Roughness and Peak-Load on Micro-Cracking: Sensitivity Analysis" Metals 11, no. 2: 320. https://doi.org/10.3390/met11020320