Microband-Induced Plasticity in a Nb Content Fe–28Mn–10Al–C Low Density Steel

Abstract

:1. Introduction

2. Experimental Procedure

3. Results

3.1. Microstructure and Precipitate Morphology

3.2. Stacking Fault Energy

3.3. Mechanical Properties

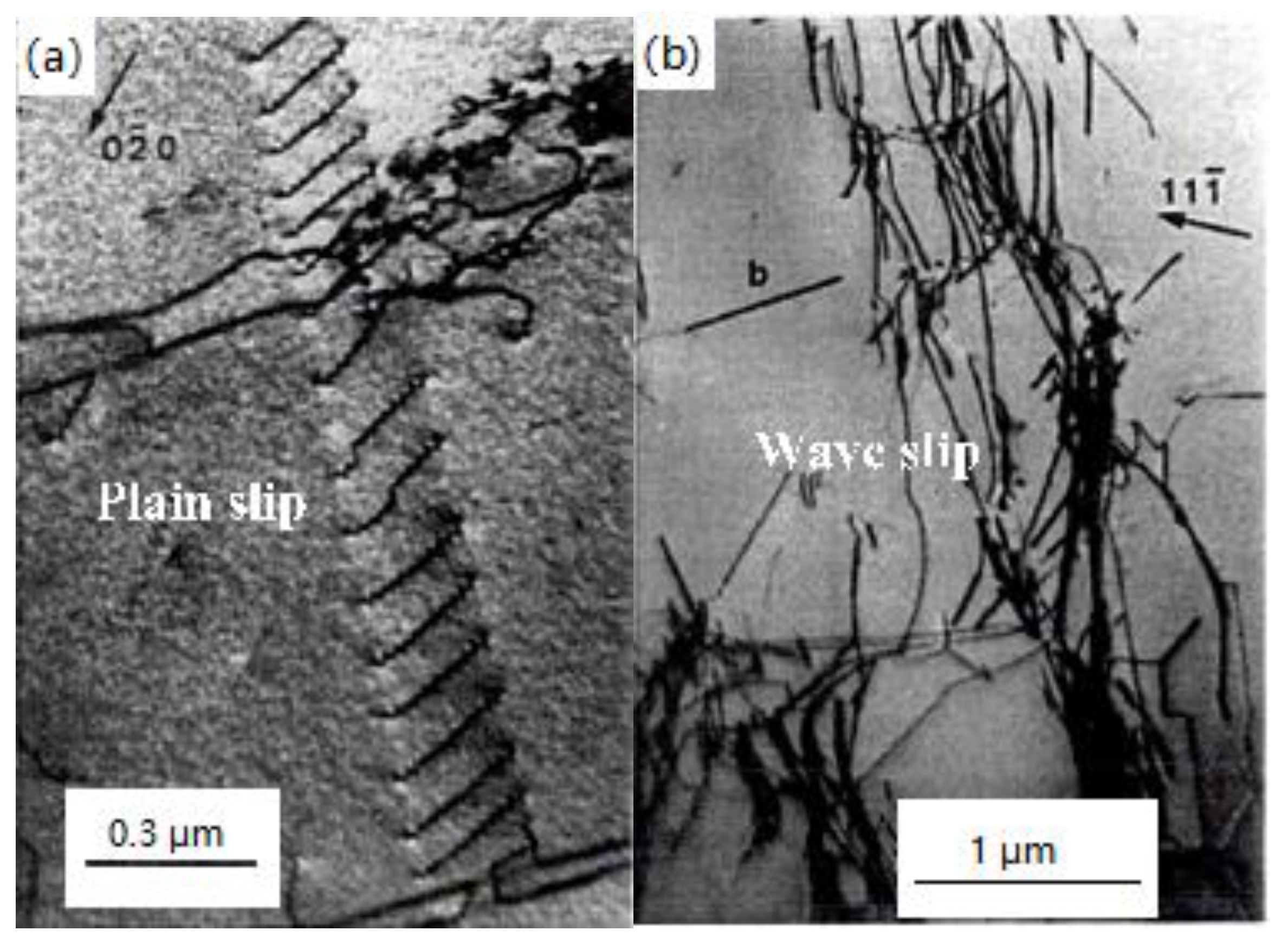

3.4. Deformed Micro-Structures

4. Discussion

4.1. Stacking Fault Energy and Deformation Modes of Austenitic Steel

4.2. Glide Plane Softening and Microband-Induced Plasticity

4.2.1. Glide Plane Softening

4.2.2. Microband-Induced Plasticity

5. Conclusions

- Fe–28Mn–10Al–C–0.5Nb steel had a low density (6.63 g/cm3) after solution treatment, and was fully austenitic with extremely few annealing twins. The and stacking fault energy of the steel at room temperature was estimated to be 1128 J/mol and 84 MJ/m2, respectively.

- The fully austenitic Fe–28Mn–10Al–C–0.5Nb low-density steel showed an excellent ultimate tensile strength (1084 MPa) and elongation (37.5%), and the steel exhibited an excellent combination of strength and ductility with the product of strength and plastic value of 40.65 GPa%.

- The Fe–28Mn–10Al–C–0.5Nb low-density steel exhibited typical planar glide characteristics during deformation. The excellent combination of strength and ductility can be attributed to plasticity induced by microbands and leads to the continuous strain hardening during deformation at room temperature.

- The addition of Nb did not change the deformation mechanism and strengthening mechanism of Fe–Mn–Al–C low-density steel, and in the absence of aging treatment and without the formation of κ-carbide, the present Fe–Mn–Al–C–Nb steel achieved a balance between ultra-high ultimate tensile strength and excellent ductility, which can optimize the mechanical properties of the steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jimenez-Melero, E.; van Dijk, N.H.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; van der Zwaag, S. Characterization of individual retained austenite grains and their stability in low-alloyed TRIP steels. Acta Mater. 2007, 55, 6713–6723. Available online: https://www.sciencedirect.com/science/article/pii/S1359645407005769 (accessed on 10 October 2020). [CrossRef]

- Curtze, S.; Kuokkala, V.T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta. Mater. 2010, 58, 5129–5141. Available online: https://www.sciencedirect.com/science/article/pii/S1359645410003344 (accessed on 10 October 2020). [CrossRef]

- Moon, J.; Park, S.J.; Jang, J.H.; Lee, T.H.; Lee, C.H.; Hong, H.U.; Suh, D.W.; Kim, S.H.; Han, H.N.; Lee, B.H. Atomistic investigations of κ-carbide precipitation in austenitic Fe-Mn-Al-C lightweight steels and the effect of Mo addition, Scripta. Mater 2017, 127, 97–101. Available online: https://www.sciencedirect.com/science/article/pii/S1359646216304146#! (accessed on 12 October 2020). [CrossRef]

- Xing, J.; Wei, Y.H.; Hou, L.F. An Overview of the Effects of Alloying Elements on the Properties of Lightweight Fe-(15–35) Mn-(5–12) Al-(0.3–1.2) C Steel. J. Metal. 2018, 70, 929–937. [Google Scholar] [CrossRef]

- Song, H.; Yoo, J.; Kim, S.H.; Sohn, S.S.; Koo, M.; Kim, N.J.; Lee, S. Novel ultra-high-strength Cu-containing medium-Mn duplex lightweight steels. Acta. Mater. 2017, 135, 215–225. Available online: https://www.sciencedirect.com/science/article/pii/S1359645417305116?via%3Dihub (accessed on 12 October 2020). [CrossRef]

- Yang, M.X.; Yuan, F.P.; Xie, Q.G.; Wang, Y.D.; Ma, E.; Wu, X.L. Strain hardening in Fe–16Mn–10Al–0.86C–5Ni high specific strength steel. Acta. Mater. 2016, 109, 213–222. Available online: https://www.sciencedirect.com/science/article/pii/S1359645416301173 (accessed on 10 October 2020). [CrossRef] [Green Version]

- Li, X.; Ma, T.; Cao, Y.P.; Li, M.X.; Zhang, H.B.; Li, Y.G. Research Progress of Fe-Mn-Al-C Series Light Steel. Hot. Work. Technol. 2018, 47, 15–18. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-SJGY201806005.htm (accessed on 10 October 2020).

- Park, K.T.; Hwang, S.W.; Son, C.Y.; Lee, J.K. Effects of heat treatment on microstructure and tensile properties of a Fe-27Mn-12Al-0.8C low-density steel. JOM 2014, 66, 1828–1836. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Ding, H.; Li, H.Y.; Huang, M.L.; Cao, F.R. Microstructural evolution and strain hardening behavior during plastic deformation of Fe-12Mn-8Al-0.8C steel. Mater. Sci. Eng. A 2013, 584, 150–155. Available online: https://www.sciencedirect.com/science/article/pii/S092150931300782X (accessed on 18 October 2020). [CrossRef]

- Cheng, W.C. Phase transformations of an Fe-0.85C-17.9Mn-7.1Al austenitic steel after quenching and annealing. JOM 2014, 66, 1809–1820. [Google Scholar] [CrossRef]

- Jeong, J.; Lee, C.Y.; Park, I.J.; Lee, Y.K. Isothermal precipitation behavior of κ-carbide in the Fe-9Mn-6Al-0.15C lightweight steel with a multiphase microstructure. J. Alloys Compd. 2013, 574, 299–304. [Google Scholar] [CrossRef]

- Zhao, C.; Song, R.; Zhang, L.; Kang, T. Effect of annealing temperature on the microstructure and tensile properties of Fe-10Mn-10Al-0.7C low-density steel. Mater. Des. 2016, 91, 348–360. Available online: https://www.sciencedirect.com/science/article/pii/S0264127515308558?via%3Dihub (accessed on 18 October 2020). [CrossRef]

- Sutou, Y.; Kamiya, N.; Umino, R.; Ohnuma, I. High-strength Fe–20Mn–Al–C-based Alloys with Low Density. ISIJ. Int. 2010, 50, 893–899. Available online: https://www.researchgate.net/publication/275840288_High-strength_Fe-20Mn-Al-C-based_Alloys_with_Low_Density (accessed on 20 October 2020). [CrossRef] [Green Version]

- Kalashnikov, I.; Shalkevich, A.; Acselrad, O.; Pereira, L.C. Chemical composition optimization for austenitic steels of the Fe-Mn-Al-C system. J. Mater. Eng. Perform. 2000, 9, 597–602. [Google Scholar] [CrossRef]

- Lu, W.J.; Zhang, X.F.; Qin, R.S. κ-carbide hardening in a low-density high-Al high-Mn multiphase steel. Mater. Lett. 2015, 138, 96–99. Available online: https://www.sciencedirect.com/science/article/pii/S0167577X14017510 (accessed on 20 October 2020). [CrossRef]

- Liu, D.G.; Cai, M.H.; Ding, H.; Dong, H. Control of inter/intra-granular κ-carbides and its influence on overall mechanical properties of a Fe-11Mn-10Al-1.25C low density steel. Mater. Sci. Eng. A 2018, 75, 25–32. Available online: https://www.sciencedirect.com/science/article/pii/S0921509317317094?via%3Dihub (accessed on 20 October 2020). [CrossRef]

- Moon, J.; Ha, H.Y.; Park, S.J.; Lee, T.H.; Jang, J.H.; Lee, G.H.; Han, H.N.; Hong, H.U. Effect of Mo and Cr additions on the microstructure, mechanical properties and pitting corrosion resistance of austenitic Fe-30Mn-10.5Al-1.1C lightweight steels. J. Alloys Compd. 2019, 775, 1136–1146. Available online: https://www.sciencedirect.com/science/article/pii/S0925838818339276?via%3Dihub (accessed on 20 October 2020). [CrossRef]

- Jeong, S.; Park, G.; Kim, B.; Moon, J.; Park, S.J.; Lee, C. Precipitation behavior and its effect on mechanical properties in weld heat-affected zone in age hardened FeMnAlC lightweight steels. Mater. Sci. Eng. A 2019, 742, 61–68. Available online: https://www.sciencedirect.com/science/article/pii/S092150931831517X (accessed on 20 October 2020). [CrossRef]

- Ding, H.; Li, H.Y.; Ding, H.; Qiu, C.L.; Tang, Z.Y. Partial Inverse Grain Size Dependence of Strength in High Mn Steels Microalloyed With Nb. J. Iron Steel Res. Int. 2012, 19, 68–72. [Google Scholar] [CrossRef]

- Powell, D.J.; Pilkington, R.; Miller, D.A. The precipitation characteristics of 20% Cr/25% Ni-Nb stabilised stainless steel. Acta. Metall. 1988, 36, 713–724. Available online: https://www.sciencedirect.com/science/article/abs/pii/0001616088901058 (accessed on 20 October 2020). [CrossRef]

- Wang, M.; Sun, H.Y.; Phaniraj, M.P.; Han, H.N.; Jang, J.; Zhou, Z.J. Evolution of microstructure and tensile properties of Fe-18Ni-12Cr based AFA steel during aging at 700°C. Mater. Sci. Eng. A 2016, 672, 23–31. Available online: https://www.sciencedirect.com/science/article/pii/S0921509316307183 (accessed on 20 October 2020). [CrossRef]

- Wu, W. Discussion analysis of tensile test rate in standard GB/T228.1-Heat. Treat. Met. 2019, 44, 571–574. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=145r0480u02502507a0u00q0pm598003&site=xueshu_se (accessed on 2 November 2020).

- Zhu, Y.T.; Wu, L.; Liao, X.Z.; Narayan, J.; Kecskés, L.J.; Mathaudhu, S.N. Dislocation–twin interactions in nanocrystalline fcc metals. Acta. Mater. 2011, 59, 812–821. Available online: https://www.sciencedirect.com/science/article/pii/S1359645410006907 (accessed on 2 November 2020). [CrossRef] [Green Version]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part II. FCC→BCC and other martensitic transformations. Metall. Mater. Trans. A. 1976, 12, 1905–1914. Available online: https://www.researchgate.net/publication/227060026_A_general_mechanism_of_martensitic_nucleation_Part_II_FCC_BCC_and_other_martensitic_transformations (accessed on 2 November 2020).

- Yoo, J.D.; Park, K.T. Microband-induced plasticity in a high Mn–Al–C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. Available online: https://www.sciencedirect.com/science/article/pii/S092150930800662X (accessed on 2 November 2020). [CrossRef]

- Sohn, S.S.; Lee, B.J.; Lee, S.; Kim, N.J.; Kwak, J.H. Effect of annealing temperature on microstructural modification and tensile properties in 0.35C-3.5Mn-5.8Al light-weight steel. Acta Mater. 2013, 61, 5050–5066. Available online: https://www.sciencedirect.com/science/article/pii/S135964541300311X?via%3Dihub (accessed on 2 November 2020). [CrossRef]

- Neeraj, T.; Srinivasan, R.; Li, J. Hydrogen embrittlement of ferritic steels: Observations on deformation microstructure, nanoscale dimples and failure by nanovoiding. Acta. Mater. 2012, 60, 5160–5171. Available online: https://www.sciencedirect.com/science/article/pii/S135964541200376X (accessed on 2 November 2020). [CrossRef]

- Sohn, S.S.; Song, H.; Suh, B.; Kwak, J.H.; Lee, B.J.; Kim, N.J.; Lee, S. Novel ultra-high-strength (ferrite + austenite) duplex lightweight steels achieved by fine dislocation substructures (Taylor lattices), grain refinement, and partial recrystallization. Acta. Mater. 2015, 96, 301–310. Available online: https://www.sciencedirect.com/science/article/pii/S1359645415004073?via%3Dihub (accessed on 2 November 2020). [CrossRef]

- Ding, H.; Han, D.; Zhang, J.; Cai, Z.H.; Wu, Z.Q.; Cai, M.H. Tensile deformation behavior analysis of low density Fe-18Mn-10Al-xC steels. Mater. Sci. Eng. A 2016, 652, 69–76. Available online: https://www.sciencedirect.com/science/article/pii/S0921509315306614?via%3Dihub (accessed on 2 November 2020). [CrossRef]

- Frommeyer, G.; Brüx, U. Microstructures and Mechanical Properties of High-Strength Fe-Mn-Al-C Light-Weight TRIPLEX Steels. Steel Res. Int. 2006, 77, 627–633. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/srin.200606440 (accessed on 2 November 2020). [CrossRef]

- Wu, Z.Q.; Ding, H.; An, X.H.; Liao, X.Z. Influence of Al content on the strain-hardening behavior of aged low density Fe–Mn–Al–C steels with high Al content. Mater. Sci. Eng. A 2015, 639, 187–191. Available online: https://www.sciencedirect.com/science/article/pii/S0921509315005122 (accessed on 2 November 2020). [CrossRef]

- Han, J.; Nam, J.; Lee, Y. The mechanism of hydrogen embrittlement in intercritically annealed medium Mn TRIP steel. Acta Mater. 2016, 113, 1–10. Available online: https://www.sciencedirect.com/science/article/pii/S1359645416303068?via%3Dihub (accessed on 7 November 2020). [CrossRef]

- Janjatovic, P.; Cekic, O.E.; Sidjanin, L.; Balos, S.; Dramicanin, M.; Novakovic, J.G.; Rajnovic, D. Effect of Water Concentration in Ethyl Alcohol on the Environmentally Assisted Embrittlement of Austempered Ductile Irons. Metals 2021, 11, 94. Available online: https://www.mdpi.com/2075-4701/11/1/94 (accessed on 7 November 2020). [CrossRef]

- Meng, Y.; Sugiyama, S.; Yanagimoto, J. Effects of heat treatment on microstructure andmechanical properties of Cr-V-Mo steel processed by recrystallization and partial melting method. J. Mater. Process. Technol. 2014, 214, 87–96. Available online: https://www.sciencedirect.com/science/article/pii/S0924013613002446?via%3Dihub (accessed on 7 November 2020). [CrossRef]

- Raabe, D.; Herbig, M.; Sandlöbes, S.; Li, Y.; Tytko, D.; Kuzmina, M.; Ponge, D.; Choi, P.P. Grain boundary segregation engineering in metallic alloys: A pathway to the design of interfaces. Curr. Opin. Solid. State. Mater. Sci. 2014, 18, 253–261. Available online: https://www.sciencedirect.com/science/article/pii/S1359028614000394?via%3Dihub (accessed on 12 November 2020). [CrossRef]

- Zambrano, O.A.; Valdés, J.; Aguilar, Y.; Coronado, J.J.; Rodríguez, S.A.; Logé, Roland, E. Hot deformation of a Fe-Mn-Al-C steel susceptible of κ-carbide precipitation. Mater. Sci. Eng. A 2017, 698, 269–285. Available online: https://www.sciencedirect.com/science/article/pii/S0921509317302198 (accessed on 12 November 2020). [CrossRef]

- Byun, T.S. On the stress dependence of partial dislocation separation and deformation microstructure in austenitic stainless steels. Acta. Mater. 2003, 51, 3063–3071. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1359645403001174?via%3Dihub (accessed on 12 November 2020). [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O. A physical model of the twinning-induced plasticity effect in a high manganese austenitic steel. Mater. Sci. Eng. A 2004, 387–389, 143–147. Available online: https://www.sciencedirect.com/science/article/pii/S0921509304004368?via%3Dihub (accessed on 12 November 2020). [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. Available online: https://www.sciencedirect.com/science/article/pii/S0921509304004356?via%3Dihub. (accessed on 12 November 2020). [CrossRef]

- Kamthaler, H.P.; Fischer, L. TEM-Investigation of the dislocation structure of plastically deformed nickel single crystals. Z. Metallkd. 1975, 66, 631–638. Available online: https://www.researchgate.net/publication/280017758_TEM-Investigation_of_the_Dislocation_Structure_of_Plastically_De_formed_Nickel_Single_CrystalsTEM-UNTERSUCHUNG_DER_VERSETZUNGSSTRUKTUR_PLASTISCH_VERFORMETER_NICKELEINKRISTALLE (accessed on 16 November 2020).

- Choi, K.; Seo, C.; Lee, H.; Kim, S.K.; Kwak, J.H.; Chin, K.G.; Park, T.; Kim, N.J. Effect of aging on the microstructure and deformation behavior of austenite base lightweight Fe-28Mn-9Al-0.8C steel. Scr. Mater. 2010, 63, 1028–1031. Available online: https://www.sciencedirect.com/science/article/pii/S1359646210005099?via%3Dihub (accessed on 19 November 2020). [CrossRef]

- Park, K.T.; Jin, K.G.; Han, S.H.; Hwang, S.W.; Choi, K.; Lee, C.S. Stacking fault energy and plastic deformation of fully austenitic high manganese steels: Effect of Al addition. Mater. Sci. Eng. A 2010, 527, 3651–3661. Available online: https://www.sciencedirect.com/science/article/pii/S0921509310002248?via%3Dihub (accessed on 10 November 2020). [CrossRef]

- Welsch, E.; Ponge, D.; Hafez Haghighat, S.M.; Sandlöbes, S.; Choi, P.; Herbig, M.; Zaefferer, S.; Raabe, D. Strain hardening by dynamic slip band refinement in a high-Mn lightweight steel. Acta. Mater. 2016, 116, 188–199. [Google Scholar] [CrossRef]

| Composition | Al | Mn | C | Nb | S | P | Fe |

|---|---|---|---|---|---|---|---|

| Wt.% | 10.83 | 29.33 | 1.02 | 0.52 | 0.0028 | 0.0031 | Bal |

| Parameters | Values and Functions |

|---|---|

| 2.94 × 10−5(mol/m2) | |

| σ | 9 (MJ/mol) |

| −2243.38 + 4.309T (J/mol) | |

| −1000 + 1.123T (J/mol) | |

| 2800 + 5T (J/mol) | |

| −22,166 (J/mol) | |

| 4046 (J/mol) | |

| 2180 + 532() (J/mol) | |

| 3339 (J/mol) | |

| 42,500 (J/mol) | |

| 26,910 (J/mol) | |

| 27,403 (J/mol) | |

| 0.7+ 0.62− 0.64− 4 | |

| 0.62− 4 | |

| 580 | |

| 250− 4750− 6.2 | |

When | |

When . Where , |

| Composition | Annealing and Cooling Condition | YS (MPa) | UTS (MPa) | EI (%) | PSE (GPa%) |

|---|---|---|---|---|---|

| Fe–28Mn–10Al–C–0.5Nb | 950 °C/60 min-water-quenched | 963 | 1084 | 37.5 | 40.65 |

| Fe–28Mn–9Al–0.8C [26] | 1000 °C/60 min-water-quenched | 440 | 880 | 100 | 88.00 |

| Fe–8.5Mn–5.6Al–0.3C [27] | 900 °C/30 min-air cooling | 502 | 734 | 77 | 56.52 |

| Fe–3.5Mn–5.8Al–0.35C [28] | 830 °C/15 s-air cooling | 622 | 800 | 42.0 | 33.60 |

| Fe–12Mn–5.5Al–0.7C [29] | 640 °C/10 min-air cooling | 1290 | 1415 | 8.2 | 11.60 |

| Fe–18Mn–10Al–1.2C [30] | 1000 °C/15 min-water-quenched | 702 | 875 | 77.4 | 67.72 |

| Fe–27Mn–12Al–0.9C [31] | 1025 °C/25 min-water-quenched | – | 875 | 58 | 50.75 |

| Fe–28Mn–10Al–C [31] | 1000 °C/60 min-water-quenched | – | 873 | 98.9 | 86.33 |

| Fe–30Mn–8Al–1.2C [31] | 1100 °C/120 min-water-quenched | – | 900 | 68 | 61.20 |

| Fe–26Mn–8Al–C [32] | 1000 °C/15 min-water-quenched | 625 | 915 | 50.9 | 46.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, T.; Gao, J.; Li, H.; Li, C.; Zhang, H.; Li, Y. Microband-Induced Plasticity in a Nb Content Fe–28Mn–10Al–C Low Density Steel. Metals 2021, 11, 345. https://doi.org/10.3390/met11020345

Ma T, Gao J, Li H, Li C, Zhang H, Li Y. Microband-Induced Plasticity in a Nb Content Fe–28Mn–10Al–C Low Density Steel. Metals. 2021; 11(2):345. https://doi.org/10.3390/met11020345

Chicago/Turabian StyleMa, Tao, Jianxin Gao, Huirong Li, Changqing Li, Haichao Zhang, and Yungang Li. 2021. "Microband-Induced Plasticity in a Nb Content Fe–28Mn–10Al–C Low Density Steel" Metals 11, no. 2: 345. https://doi.org/10.3390/met11020345

APA StyleMa, T., Gao, J., Li, H., Li, C., Zhang, H., & Li, Y. (2021). Microband-Induced Plasticity in a Nb Content Fe–28Mn–10Al–C Low Density Steel. Metals, 11(2), 345. https://doi.org/10.3390/met11020345