Microstructure and Mechanical Properties of Novel Quasibinary Al-Cu-Yb and Al-Cu-Gd Alloys

Abstract

1. Introduction

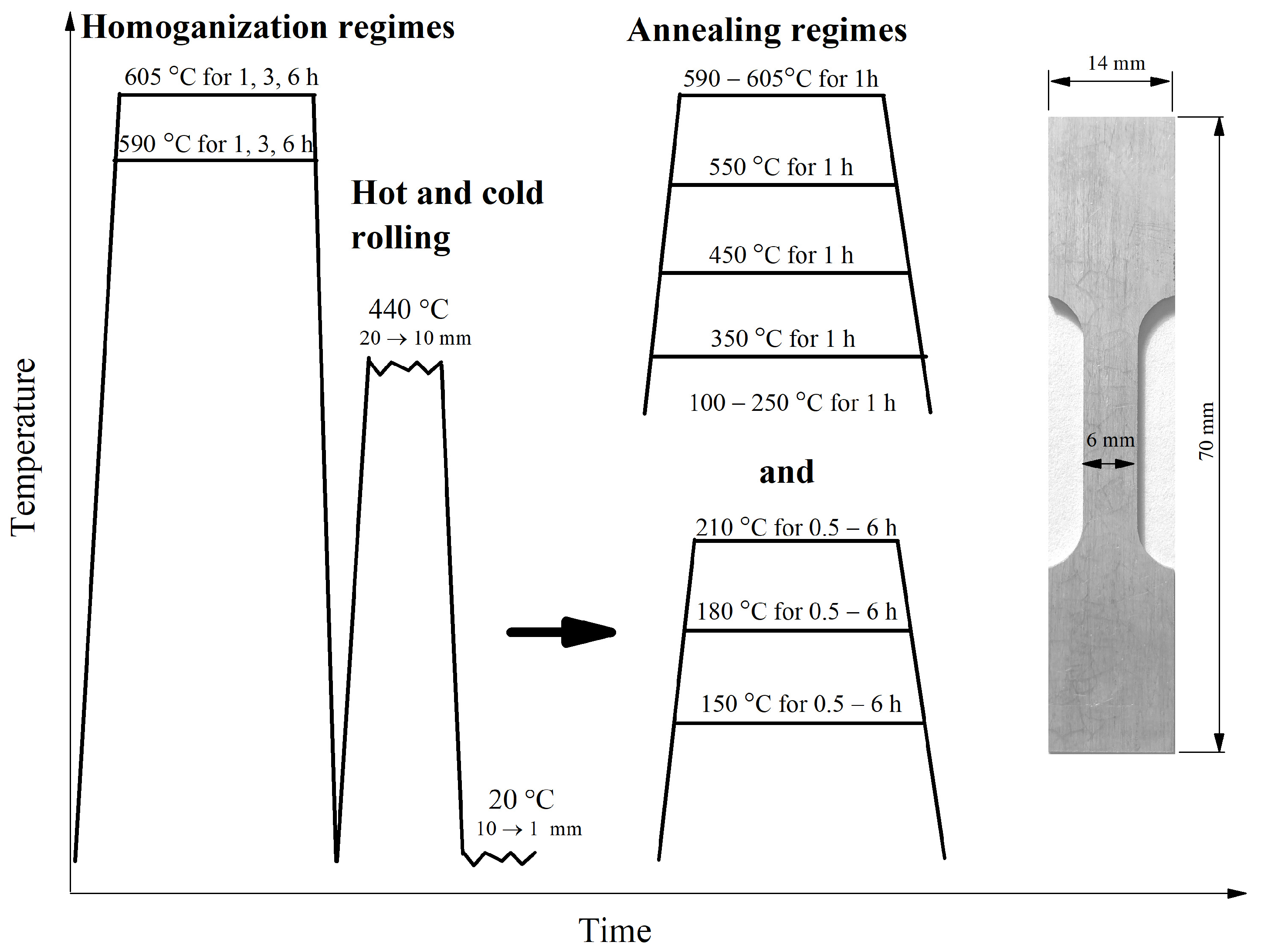

2. Materials and Methods

3. Results and Discussion

4. Conclusions

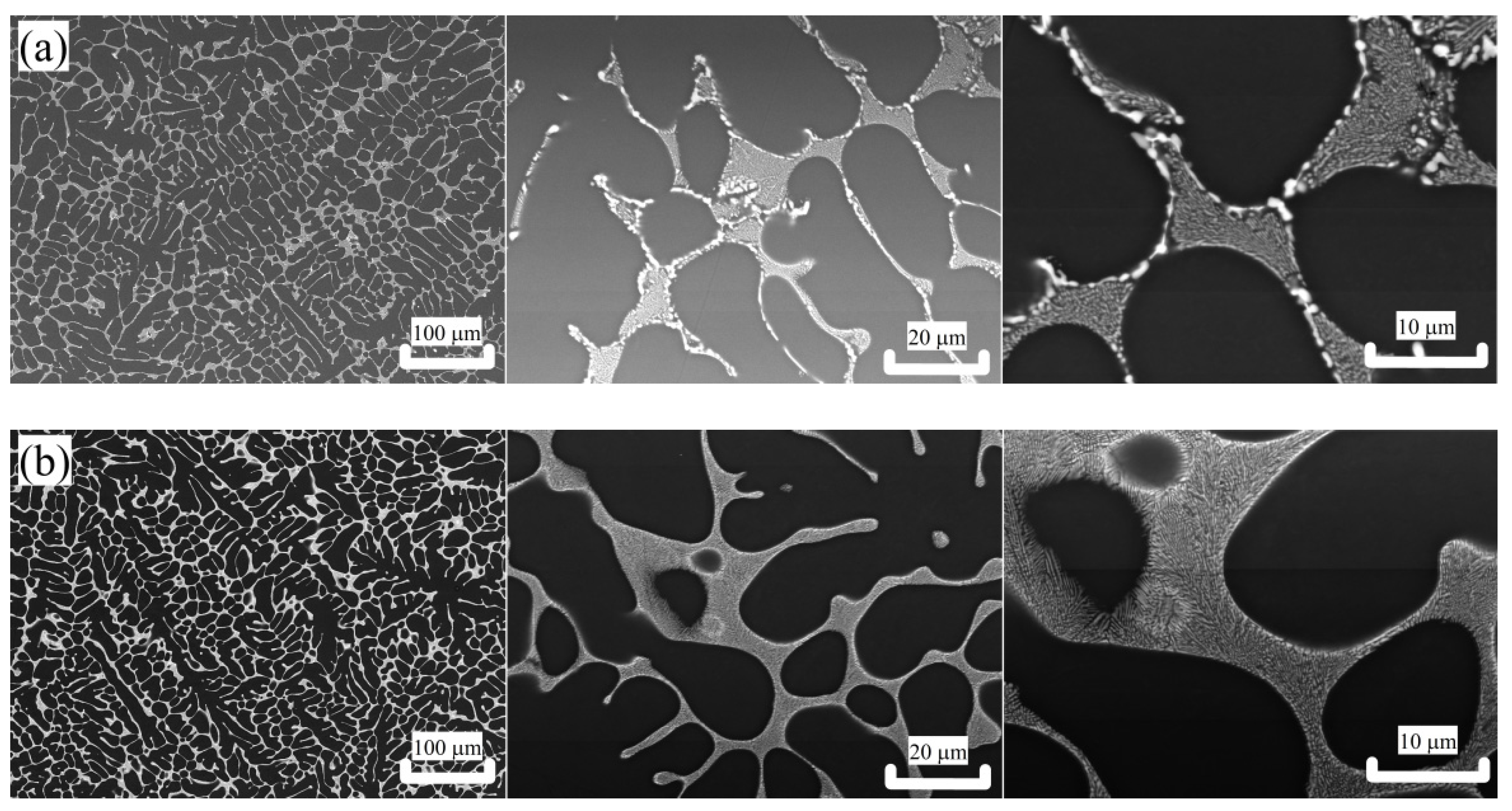

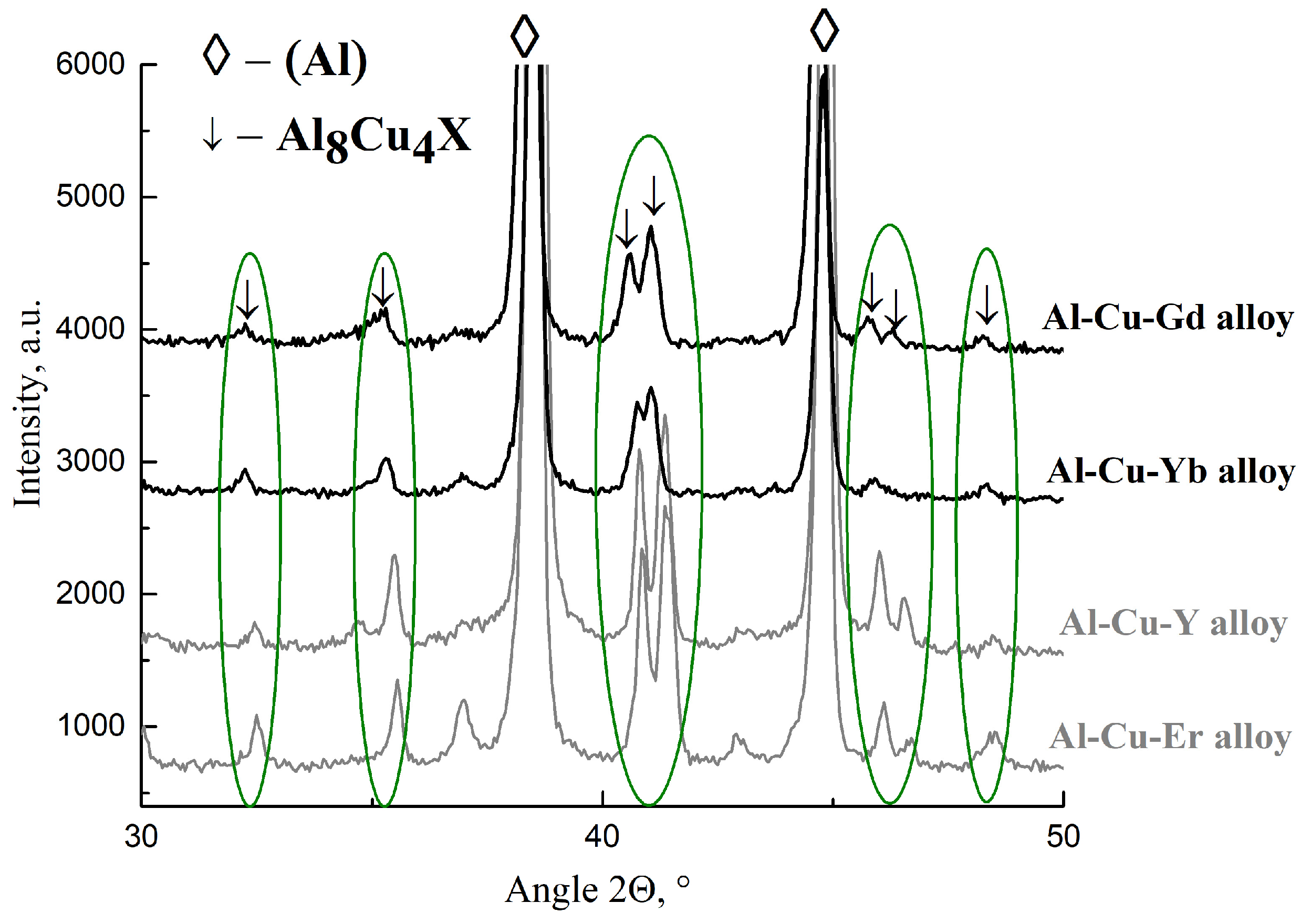

- The microstructure and mechanical properties of Al-4.4Cu-2.5Yb and Al-4.5Cu-2.5Gd alloys were investigated. The microstructure revealed the presence of the aluminum solid solution and Al8Cu4Yb and Al8Cu4Gd phases, which play an important role as recrystallization inhibitor. These also phases improved the mechanical properties of Al-Cu alloys. Al3Yb or (Al,Cu)17Y2 phase was found in addition in the Al-Cu-Yb alloy at the boundary between the eutectic and aluminum dendrites.

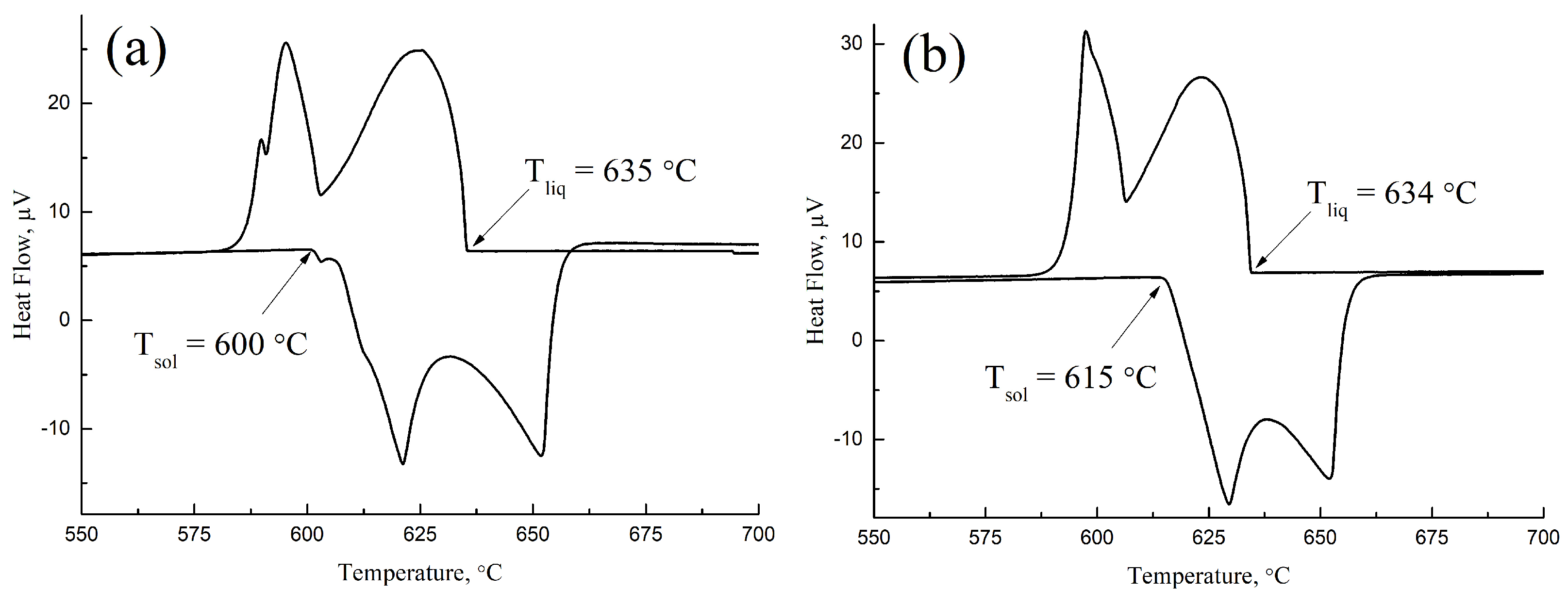

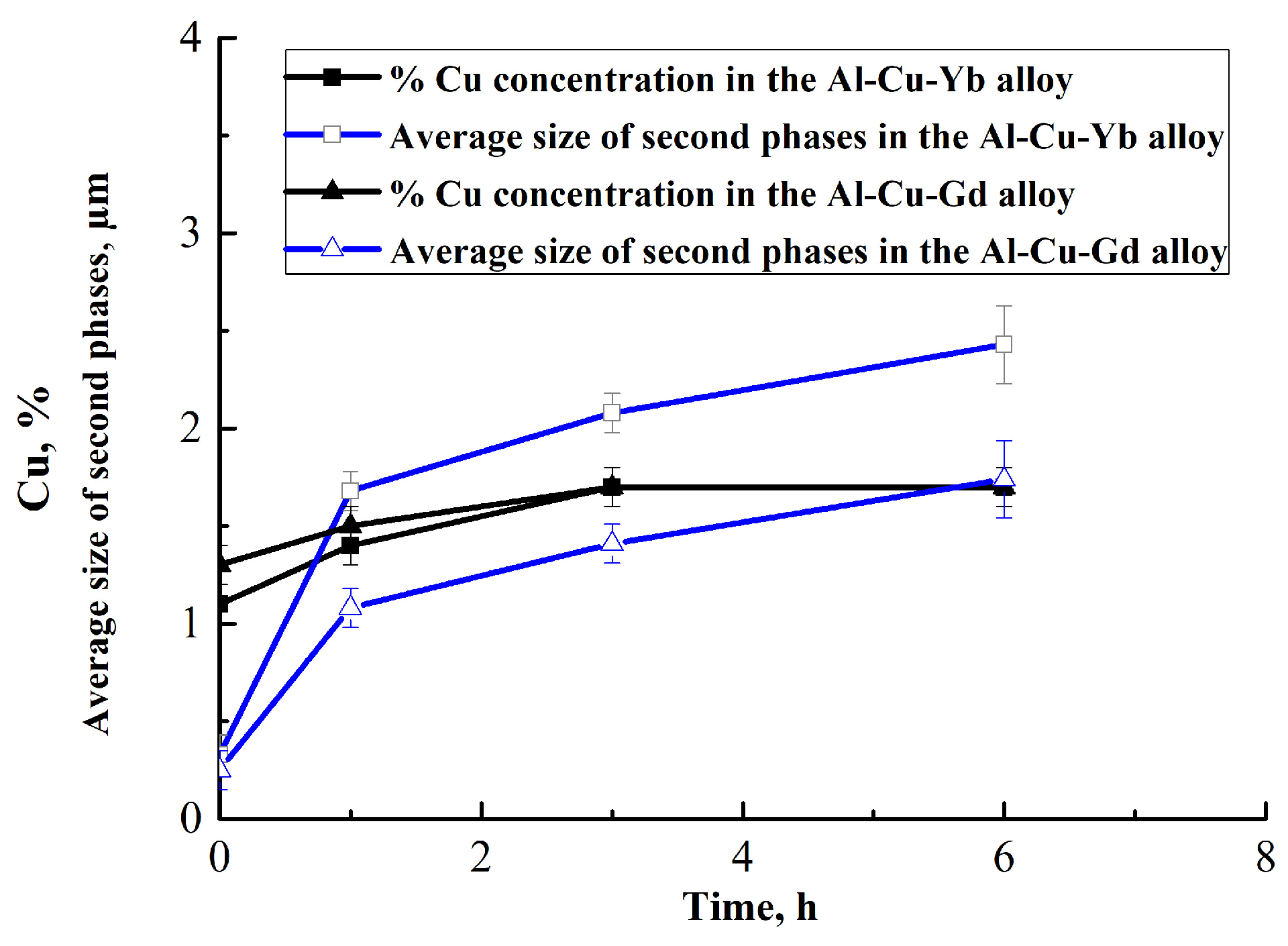

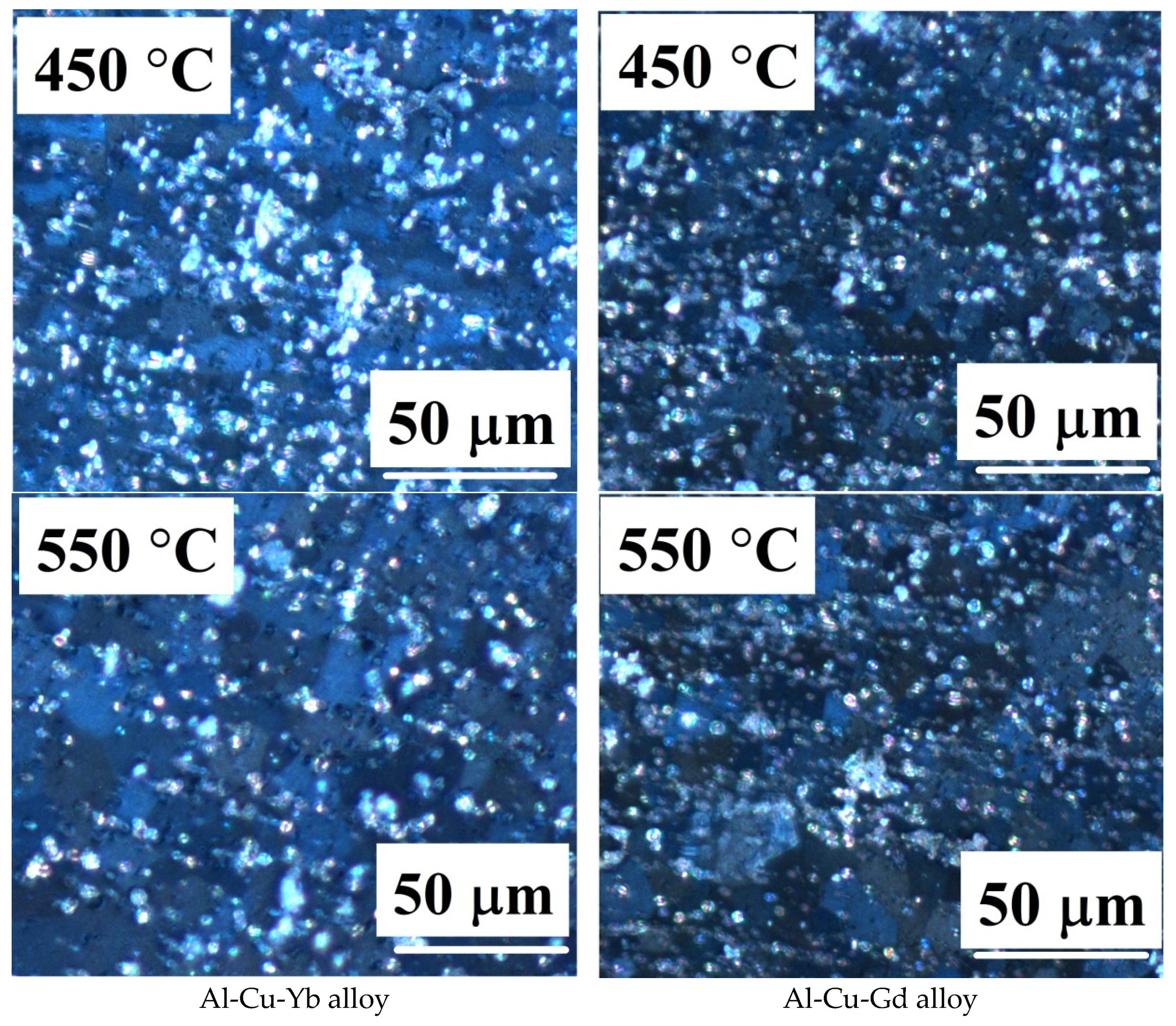

- The size of Al8Cu4Yb and Al8Cu4Gd phases increased from 0.25–0.3 to 1.8–2.4 µm after homogenization at 590 and 605 °C for 6 h. The Al8Cu4Yb and Al8Cu4Gd phases demonstrate a good thermal stability at high temperature homogenization treatment.

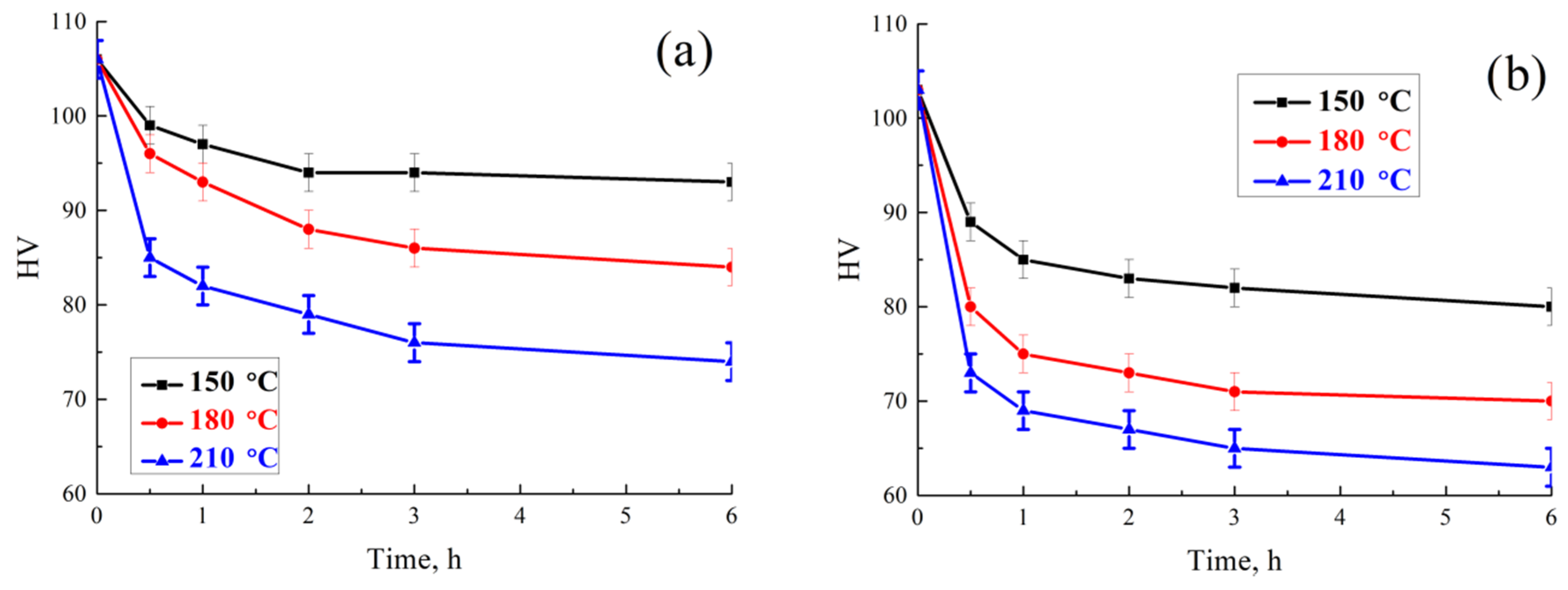

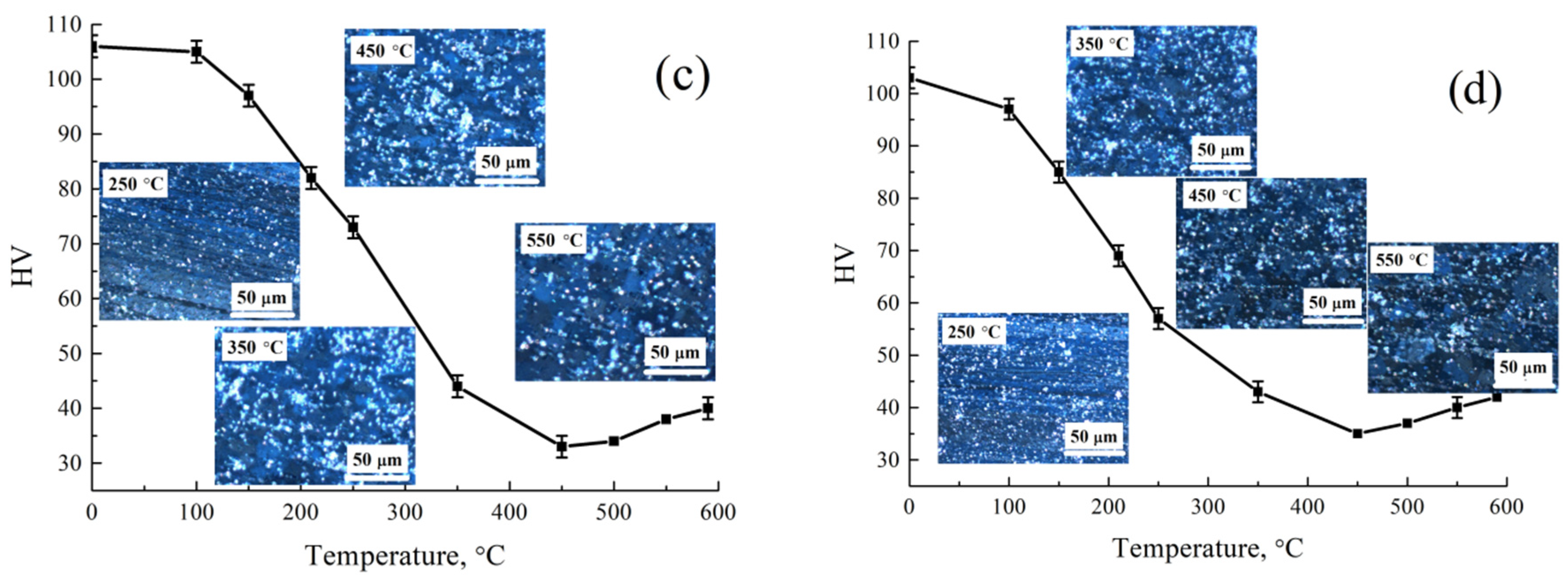

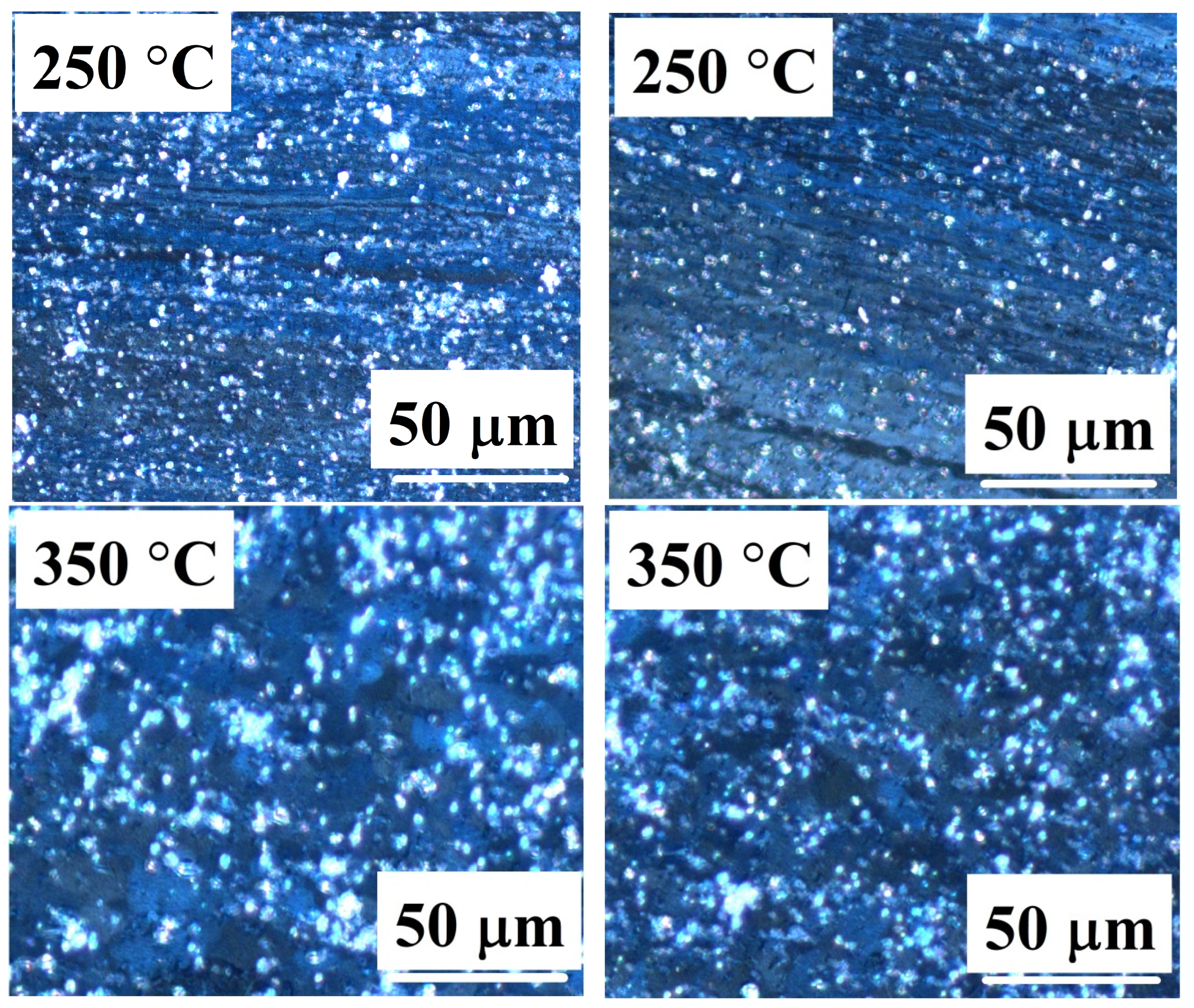

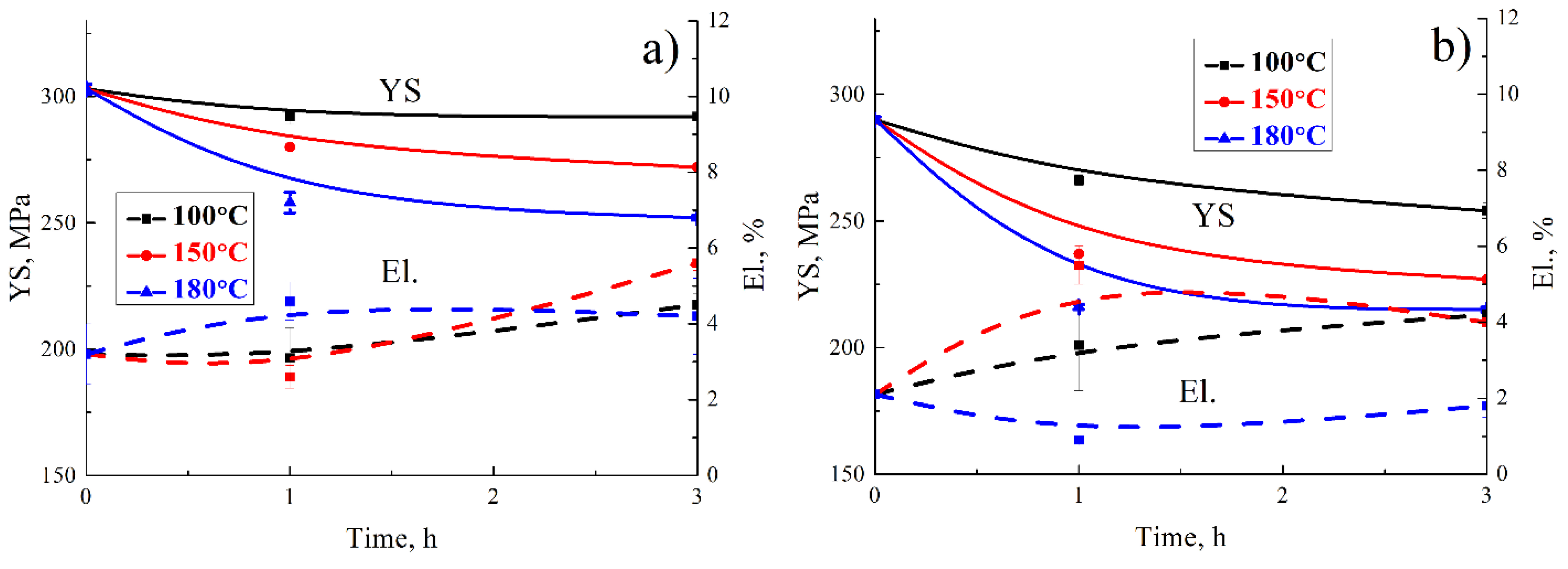

- By increasing the annealing temperature and time after rolling, the hardness and tensile properties of rolled alloys Al-4.4Cu-2.5Yb and Al-4.5Cu-2.5Gd are reduced. The mechanical properties of the Al-Cu-Yb rolled alloy were higher than that of Al-Cu-Gd, Al-Cu-Y and Al-Cu-Er in the same case of annealing temperatures and time. This may be attributed to the presence of either Al3Yb or (Al,Cu)17Y2 phase, which increased the alloy’s mechanical properties.

- The as-rolled and annealed at 150 °C for 3 h alloys mechanical tensile properties: YS = 272 MPa, UTS= 294 MPa and El.= 5.6% for Al-Cu-Yb alloy, while YS = 227 MPa, UTS = 244 MPa and El. = 2.2% for Al-Cu-Gd alloy.

- The alloys may be a prospective for the development of novel heat-resistant materials for the aerospace industry due to the high thermal stability of the eutectic phases and may be used as a cast and wrought base alloy due to a wide solidification range and tensile strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Zhan, L.; Ma, Z.; Xu, Y.; Zheng, Q.; Cai, Y. Study on tensile/compressive asymmetry in creep ageing behavior of Al–Cu alloy under different stress levels. J. Alloys Compd. 2020, 843, 156157. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Liu, C.; Wang, X.; Wang, Q.; Tang, Z.; Li, G.; Huang, M.; Hu, Z. Stress-relaxation ageing behavior and microstructural evolution under varying initial stresses in an Al-Cu alloy: Experiments and modeling. Int. J. Plast. 2020, 127, 102646. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of cold predeformation on dissolution of second-phase Al2Cu particles during solution treatment of 2219 Al-Cu alloy forgings. Mater. Charact. 2018, 135, 18–24. [Google Scholar] [CrossRef]

- Inforzato, D.J.; Costa, P.R.; Fernandez, F.F.; Travessa, D.N. Creep-age forming of AA7475 aluminum panels for aircraft lower wing skin application. Mater. Res. 2012, 15, 596–602. [Google Scholar] [CrossRef]

- Wang, H.; Yi, Y.; Huang, S. Microstructure Evolution and Mechanical Properties of 2219 Al Alloy During Aging Treatment. J. Mater. Eng. Perform. 2017, 26, 1475–1482. [Google Scholar] [CrossRef]

- Meng, F.; Wang, Z.; Zhao, Y.; Zhang, D.; Zhang, W. Microstructures and properties evolution of Al-Cu-Mn alloy with addition of vanadium. Metals 2017, 7, 10. [Google Scholar] [CrossRef]

- Belov, N.A.; Avksent’eva, N.N. Quantitative analysis of the Al-Cu-Mg-Mn-Si phase diagram as applied to commercial aluminum alloys of series 2xxx. Met. Sci. Heat Treat. 2013, 55, 358–363. [Google Scholar] [CrossRef]

- Matvienko, Y.I.; Polishchuk, S.S.; Rud, A.D.; Popov, O.Y.; Demchenkov, S.A.; Fesenko, O.M. Effect of graphite additives on microstructure and mechanical properties of Al–Cu composites prepared by mechanical alloying and sintering. Mater. Chem. Phys. 2020, 254, 123437. [Google Scholar] [CrossRef]

- Immarigeon, J.P.; Holt, R.T.; Koul, A.K.; Zhao, L.; Wallace, W.; Beddoes, J.C. Lightweight materials for aircraft applications. Mater. Charact. 1995, 35, 41–67. [Google Scholar] [CrossRef]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- Zhang, L.; Masset, P.J.; Cao, F.; Meng, F.; Liu, L.; Jin, Z. Phase relationships in the Al-rich region of the Al-Cu-Er system. J. Alloys Compd. 2011, 509, 3822–3831. [Google Scholar] [CrossRef]

- Zhang, L.G.; Liu, L.B.; Huang, G.X.; Qi, H.Y.; Jia, B.R.; Jin, Z.P. Thermodynamic assessment of the Al-Cu-Er system. Calphad Comput. Coupling Phase Diagr. Thermochem. 2008, 32, 527–534. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Lan, Y.; Zhang, Y.; Xia, T. The effect of Sc addition on the novel nano-AlCu phase in as-cast Al-5%Cu alloy. J. Alloys Compd. 2020, 831, 154739. [Google Scholar] [CrossRef]

- Gao, Y.H.; Kuang, J.; Zhang, J.Y.; Liu, G.; Sun, J. Tailoring precipitation strategy to optimize microstructural evolution, aging hardening and creep resistance in an Al–Cu–Sc alloy by isochronal aging. Mater. Sci. Eng. A 2020, 795, 139943. [Google Scholar] [CrossRef]

- Huang, G.; Liu, L.; Zhang, L.; Jin, Z. Thermodynamic description of the al-cu-yb ternary system supported by first-principles calculations. J. Min. Metall. Sect. B Metall. 2016, 52, 177–183. [Google Scholar] [CrossRef]

- Karnesky, R.A.; van Dalen, M.E.; Dunand, D.C.; Seidman, D.N. Effects of substituting rare-earth elements for scandium in a precipitation-strengthened Al-0.08 at. %Sc alloy. Scr. Mater. 2006, 55, 437–440. [Google Scholar] [CrossRef]

- Zhang, L.G.; Dong, H.Q.; Huang, G.X.; Shan, J.; Liu, L.B.; Jin, Z.P. Thermodynamic assessment of the Al-Cu-Gd system. Calphad Comput. Coupling Phase Diagr. Thermochem. 2009, 33, 664–672. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Wei, Z.; Zhu, Z. The effect of Y on the hot-tearing resistance of Al-5 wt.% Cu based alloy. Mater. Des. 2010, 31, 2483–2487. [Google Scholar] [CrossRef]

- Amer, S.M.; Yu Barkov, R.; Yakovtseva, O.A.; Loginova, I.S.; Pozdniakov, A.V. Effect of Zr on microstructure and mechanical properties of the Al–Cu–Er alloy. Mater. Sci. Technol. 2020, 36, 453–459. [Google Scholar] [CrossRef]

- Rouxel, B.; Ramajayam, M.; Langan, T.J.; Lamb, J.; Sanders, P.G.; Dorin, T. Effect of dislocations, Al3(Sc,Zr) distribution and ageing temperature on θ′ precipitation in Al-Cu-(Sc)-(Zr) alloys. Materialia 2020, 9, 100610. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Barkov, R.Y.; Amer, S.M.; Levchenko, V.S.; Kotov, A.D.; Mikhaylovskaya, A.V. Microstructure, mechanical properties and superplasticity of the Al–Cu–Y–Zr alloy. Mater. Sci. Eng. A 2019, 758, 28–35. [Google Scholar] [CrossRef]

- Amer, S.M.; Barkov, R.Y.; Pozdniakov, A.V. Effect of Mn on the Phase Composition and Properties of Al-Cu-Y-Zr Alloy. Phys. Met. Metallogr. 2020, 121, 1227–1232. [Google Scholar] [CrossRef]

- Amer, S.; Yakovtseva, O.; Loginova, I.; Medvedeva, S.; Prosviryakov, A.; Bazlov, A.; Barkov, R.; Pozdniakov, A. The Phase Composition and Mechanical Properties of the Novel Precipitation-Strengthening Al-Cu-Er-Mn-Zr Alloy. Appl. Sci. 2020, 10, 5345. [Google Scholar] [CrossRef]

- Belov, N.A.; Khvan, A.V. The ternary Al-Ce-Cu phase diagram in the aluminum-rich corner. Acta Mater. 2007, 55, 5473–5482. [Google Scholar] [CrossRef]

- Belov, N.A.; Khvan, A.V.; Alabin, A.N. Microstructure and Phase Composition of Al-Ce-Cu Alloys in the Al-Rich Corner. Mater. Sci. Forum 2006, 519–521, 395–400. [Google Scholar] [CrossRef]

- Amer, S.M.; Barkov, R.Y.; Yakovtseva, O.A.; Pozdniakov, A.V. Comparative Analysis of Structure and Properties of Quasibinary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er Alloys. Phys. Met. Metallogr. 2020, 121, 476–482. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Barkov, R.Y. Microstructure and materials characterisation of the novel Al–Cu–Y alloy. Mater. Sci. Technol. 2018, 34, 1489–1496. [Google Scholar] [CrossRef]

- Amer, S.M.; Barkov, R.Y.; Pozdniakov, A.V. Effect of Iron and Silicon Impurities on Phase Composition and Mechanical Properties of Al–6.3Cu–3.2Y Alloy. Phys. Met. Metallogr. 2020, 121, 1002–1007. [Google Scholar] [CrossRef]

- Pozdnyakov, A.V.; Barkov, R.Y.; Sarsenbaev, Z.; Amer, S.M.; Prosviryakov, A.S. Evolution of Microstructure and Mechanical Properties of a New Al–Cu–Er Wrought Alloy. Phys. Met. Metallogr. 2019, 120, 614–619. [Google Scholar] [CrossRef]

- Amer, S.M.; Barkov, R.Y.; Pozdniakov, A.V. Effect of Impurities on the Phase Composition and Properties of a Wrought Al–6% Cu–4.05% Er Alloy. Phys. Met. Metallogr. 2020, 121, 495–499. [Google Scholar] [CrossRef]

- Ilyasov, R.R.; Avtokratova, E.V.; Krymskiy, S.V.; Sitdikov, O.S.; Markushev, M.V. Effect of preliminary heterogenization on the structure and hardness of cryorolled aluminum alloy D16. IOP Conf. Ser. Mater. Sci. Eng. 2018, 447, 012047. [Google Scholar] [CrossRef]

| Alloys | Cu | Yb | Gd | Al |

|---|---|---|---|---|

| Al-Cu-Yb | 4.4 | 2.5 | - | bal. |

| Al-Cu-Gd | 4.5 | - | 2.5 | bal. |

| State | YS, MPa | UTS, MPa | El., % |

|---|---|---|---|

| Al-Cu-Yb | |||

| As rolled | 303 ± 2 | 327 ± 2 | 3.2 ± 0.8 |

| Annealed at 100 °C for 1 h | 292 ± 3 | 319 ± 3 | 3.1 ± 0.8 |

| Annealed at 100 °C for 3 h | 292 ± 4 | 318 ± 4 | 4.5 ± 0.3 |

| Annealed at 150 °C for 1 h | 280 ± 1 | 303 ± 1 | 2.6 ± 0.3 |

| Annealed at 150 °C for 3 h | 272 ± 2 | 294 ± 3 | 5.6 ± 0.2 |

| Annealed at 180 °C for 1 h | 258 ± 4 | 276 ± 2 | 4.6 ± 0.5 |

| Annealed at 180 °C for 3 h | 252 ± 1 | 268 ± 1 | 4.2 ± 1.0 |

| Annealed at 210 °C for 1 h | 238 ± 2 | 253 ± 1 | 5.9 ± 0.1 |

| Annealed at 250 °C for 0.5 h | 216 ± 2 | 229 ± 1 | 6 ± 2 |

| Al-Cu-Gd | |||

| As rolled | 290 ± 1 | 315 ± 2 | 2.1 ± 0.1 |

| Annealed at 100 °C for 1 h | 266 ± 2 | 285 ± 3 | 3.4 ± 1.2 |

| Annealed at 100 °C for 3 h | 254 ± 3 | 278 ± 4 | 4.2 ± 0.6 |

| Annealed at 150 °C for 1 h | 237 ± 2 | 253 ± 1 | 5.5 ± 0.5 |

| Annealed at 150 °C for 3 h | 227 ± 2 | 244 ± 2 | 4.0 ± 1.0 |

| Annealed at 180 °C for 1 h | 216 ± 1 | 226 ± 1 | 0.9 ± 0.1 |

| Annealed at 180 °C for 3 h | 215 ± 1 | 225 ± 2 | 1.8 ± 0.3 |

| Annealed at 210 °C for 1 h | 202 ± 1 | 210 ± 1 | 6.7 ± 0.7 |

| Annealed at 250 °C for 0.5 h | 175 ± 4 | 182 ± 3 | 16.0 ± 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amer, S.; Barkov, R.; Pozdniakov, A. Microstructure and Mechanical Properties of Novel Quasibinary Al-Cu-Yb and Al-Cu-Gd Alloys. Metals 2021, 11, 476. https://doi.org/10.3390/met11030476

Amer S, Barkov R, Pozdniakov A. Microstructure and Mechanical Properties of Novel Quasibinary Al-Cu-Yb and Al-Cu-Gd Alloys. Metals. 2021; 11(3):476. https://doi.org/10.3390/met11030476

Chicago/Turabian StyleAmer, Sayed, Ruslan Barkov, and Andrey Pozdniakov. 2021. "Microstructure and Mechanical Properties of Novel Quasibinary Al-Cu-Yb and Al-Cu-Gd Alloys" Metals 11, no. 3: 476. https://doi.org/10.3390/met11030476

APA StyleAmer, S., Barkov, R., & Pozdniakov, A. (2021). Microstructure and Mechanical Properties of Novel Quasibinary Al-Cu-Yb and Al-Cu-Gd Alloys. Metals, 11(3), 476. https://doi.org/10.3390/met11030476