Abstract

Carbon-doped TiZrN nanocomposite coatings were investigated for phase formation and wear behavior. They were prepared by laser carburization using carbon paste, and the thermal energy of the pulsed laser was limited to the range of 20 to 50%. X-ray photoelectron spectroscopy analysis revealed that the ratio of carbide (TiC, ZrC) increased as the thermal energy of the laser increased. The sp2/sp3 ratio increased by approximately 16% when the laser thermal energy was raised from 30 to 40%, and the formation of amorphous carbon was confirmed in the carbon-doped TiZrN coatings. As a result of microstructural analysis, the carbon-doped TiZrN nanocomposite was formed by an increase of hybrid bonds in expanded localized carbon clusters. Wear resistance was evaluated using a ball-on-disc tester, which showed that the friction coefficient decreased from 0.74 to 0.11 and the wear rate decreased from 7.63 × 10−6 mm3 (Nm)−1 to 1.26 × 10−6 mm3 (Nm)−1. In particular, the friction coefficient and wear rate improved by 71 and 66%, respectively, owing to the formation of carbon-doped TiZrN nanocomposite with amorphous carbon while the thermal energy was increased from 30 to 40%.

1. Introduction

Owing to their excellent wear resistance and hardness, transition-metal nitride and carbide coatings have been investigated to improve the tribological properties of tools. However, binary coatings such as TiN and TiC cannot be used under harsh conditions; hence, ternary or multi-phase coatings are being applied in various industries [1,2]. Research into ternary or multi-phase coatings has two main objectives: improve wear resistance and modify the friction coefficient, while simultaneously, increasing or maintaining the strength and hardness of the coatings [3,4,5]. Therefore, multi-phase and nanocomposite coatings have been actively researched because these coatings have excellent properties because of their structural interactions and various microstructures [6].

Light elements such as carbon and nitrogen are added to induce solid solution strengthening. Carbon is a widely adopted element for improving the surface properties of coatings and is used to improve tribological properties and corrosion resistance. It can replace the anion site, and research has been conducted to investigate the effect of carbon composition on the surface properties [7]. Amorphous carbon is thermodynamically metastable, and the ratio of the sp2 and sp3 bonds is variable because the characteristics of amorphous carbon vary depending on the formation method and conditions [8,9,10]. It is chemically inert as a solid lubricant, and improves wear resistance in the carbon nanocomposite lattice. It also improves hardness by preventing crack propagation caused by the hybrid bonds. Therefore, nanocomposite coatings are actively studied to improve the tribological properties by adding soft matrices such as amorphous carbon and Cu [11,12].

In the case of carbon doping by laser carburization, the thermal energy of the laser becomes an energy source for carbon diffusion. The interstitial and substitutional behavior of carbon undergoes change as the thermal energy of the laser is increased, and amorphous carbon accumulates after the limit of the solid solution of carbon [13,14]. Jinlong Li et al. adjusted the C2H2 flow rate for the formation of gradient Ti (C, N) films and reported the variation in wear resistance. J. M. Lackner et al. deposited and characterized (Ti, Al) (C, N) coatings with different carbon content and reported that an increase in carbon content induces carbon precipitation and leads to low friction. A.D. Korotaev et al. analyzed the microstructure and phase state of magnetron-sputtered nanocomposite Ti–C–Ni–Cr coatings based on Ni- and Cr-doped amorphous carbon [15,16,17].

Herein, we doped the coatings with different amounts of carbon by converting the laser thermal energy in the TiZrN coatings, and investigated the wear resistance of carbon-doped TiZrN nanocomposite coatings in the bonding state. The carbon bonding state and crystal structure of the carbon-doped TiZrN coatings were analyzed by X-ray photoelectron spectroscopy (XPS) and high-resolution X-ray diffraction (HR-XRD). Transmission electron microscopy (TEM) analysis was performed to observe the changes in the microstructure of the coating layer with variations in laser thermal energy. After ball-on-disc testing, the wear properties of the corresponding coatings were evaluated by the friction coefficient, wear rate, and microstructure results.

2. Materials and Methods

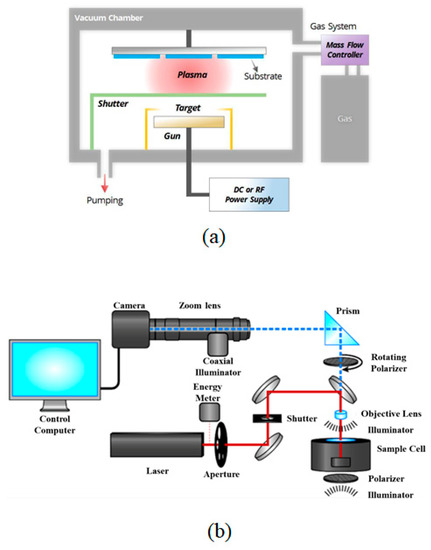

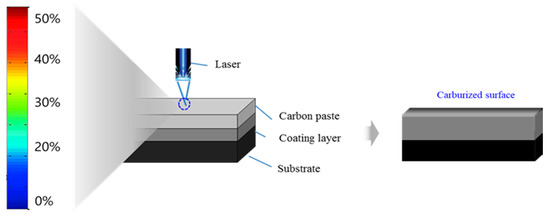

The surface of SUS304 was cleaned using ultrasonication and ethanol to improve the adhesion of the coating layer by removing contamination before deposition. TiZrN coatings (Ti:Zr = 50:50 wt%) were deposited on SUS304 using RF/DC (radio frequency/direct current) magnetron sputtering as shown in Figure 1a. The deposition conditions were 1.0 × 10−5 torr for base pressure and 1.0 × 10−2 torr for working pressure, performed at 723 K for 6 h. Carbon paste was mixed with graphite powder (20 μm) and polyvinylidene fluoride (PVDF) at 9:1, and 1-Methyl-2-pyrrolidinone was used as a solvent to adjust the viscosity of the paste. The carbon paste was covered on the TiZrN coatings and dried at 80 °C. Carburization on the coating surface was performed using a Nd:YAG pulsed-laser ablation system (LSX-213, Teledyne CETAC Technologies, Ames, IA, USA) as shown in Figure 1b, and the laser output was varied by 10% intervals from 20 to 50% as shown in Figure 2 [18,19]. After laser carburization, the carbon paste remaining on the coating surface was cleaned using ultrasonication, acetone, and ethanol.

Figure 1.

(a) Schematic Diagram of RF/DC magnetron sputtering system, (b) Schematic Diagram of the LSX-213 Laser Ablation System.

Figure 2.

Schematic diagram of laser carburization of TiZrN coating.

The phase analysis was performed using an X-ray diffractometer (Ultima-IV, Rigaku, Tokyo, Japan) with a Cu target at 0.02°/2θ step from 20 to 80° at 1°/min. XPS analysis (ESCALAB250, VG scientific, Waltham, MA, USA) was carried out with the MXR1 gun–400 μm 15 kV spectrometer with an Al Kɑ source. Coating specimens for microstructure analysis were prepared using Focused Ion Beam (FIB, Helios G4 UC, ThermoFisher Scientific, Waltham, MA, USA), and the cross-section of the coatings was observed with TEM (Cs-TEM, Titan Themis Z, ThermoFisher Scientific, Waltham, MA, USA). The friction coefficient and wear rate were analyzed according to the ISO 20808 standard test method using a ball-on-disc system (NEO-Tribo Multi-Purpose Wear Test System, Neoplus Inc., Daejeon, Korea) [20].

3. Results and Discussion

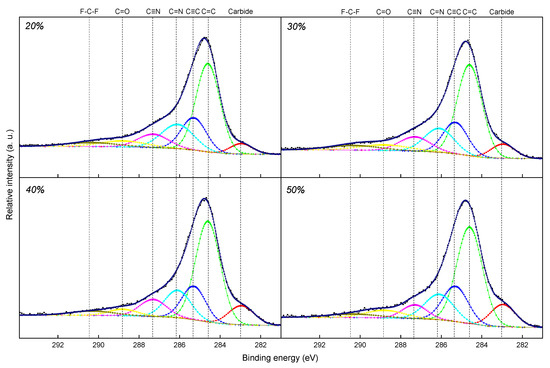

Figure 3 shows the XPS C1s diffraction pattern for investigating the bonding state of the (Ti, Zr)(C, N) coatings with different carbon contents. The lowest binding energy peaks (283.0 eV) correspond to carbide (TiC or ZrC) peaks, and 284.5 eV and 285.2 eV represent sp2 and sp3 bonds, respectively. The two peaks at 286.2 eV and 287.4 eV indicate a CN bond, 288.7 eV shows a CO bond, and 290.4 eV reveals a CF bond with fluorine in the carbon paste. Table 1 displays the changes in the chemical bonding state with variation in thermal energy. The amount of carbide increased as the thermal energy increased, and the diffusion flow was seen to increase as the amount of thermal energy input into the carbon paste increased. Considering the sp2/sp3 ratio, it increased from 2.57 to 3.25 in addition to a significant increase at 40% thermal energy [21]. At low laser thermal energy, carbide formation continued to increase as further carbon doping occurred. However, after reaching 40% thermal energy, amorphous carbon began to form in the nitrogen vacancies or grains of TiZrN because the carbon solid solution limit had been exceeded. It was considered to be the result of the combination of thermal energy and incremental residual stress in the carbon-doped TiZrN coatings by the formation of carbides [22,23].

Figure 3.

XPS C 1s spectra of carbon-doped TiZrN.

Table 1.

Carbon bonding ratio of carbon-doped TiZrN.

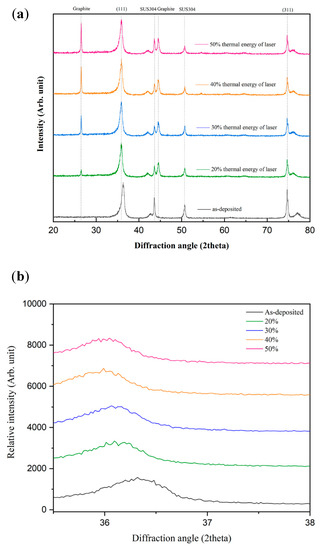

Using HR-XRD, Figure 4 shows the effect of doped carbon on TiZrN coatings according to the laser thermal energy applied. The diffraction peak in Figure 4a showed that the preferred orientation plane of the TiZrN coatings is the (111) plane, which implied columnar grain structures, and the carbon peaks appeared after laser carburization. The diffraction peaks of TiZrN in Figure 4b were proportionally shifted slightly to the left, depending on the carbon doping. This was confirmed to be a result of lattice distortion that occurs when carbon, because of its relatively large atomic radius, is substituted for a nitrogen site or occupies nitrogen-vacancy sites. In addition, the diffraction peak was broadened overall after carbon doping compared to the diffraction peak of TiZrN before laser carburization [24,25]. It was also revealed that the grain size of carbon-doped TiZrN coatings decreased as the amount of doped carbon increased, resulting in a nanocomposite [26,27].

Figure 4.

(a) HR-XRD patterns of as-deposited TiZrN and carbon-doped TiZrN peaks with increasing laser output, (b) HR-XRD patterns of TiZrN (111) peaks with increasing laser output.

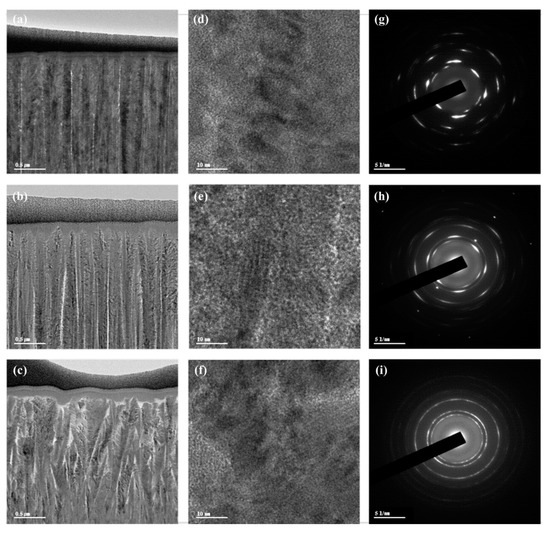

Figure 5 shows cross-section images, IFFT images, and SAED patterns through TEM to understand the microstructure variation of carbon-doped TiZrN coatings with carbon doping. As shown in Figure 5a, it was confirmed that TiZrN formed columnar grains before carburization, and as the thermal energy of the laser increased the columnar shape of the grains gradually disappeared as shown in Figure 5b,c [13]. In the case of Figure 5e,f, it was determined that the carbon-doped TiZrN nanocomposite was formed through the development of localized carbon clusters during carburization [28]. In Figure 5g, the spotty pattern was shown at the 20% laser output, but at the 40% laser output, a ring pattern appeared (Figure 5i), indicating that the grain size had become nano-scale. The SAED pattern was widely diffused as the thermal energy of the laser increased from 20 to 40%, and it was thought that amorphous carbon with short-range ordered structure was formed [29,30]. Accordingly, it was determined that carbon-doped TiZrN nanocomposite with amorphous carbon formed on the surface of the coating layer.

Figure 5.

Cross-section TEM images: (a) as-deposited TiZrN, (b) 20% laser output, and (c) 40% laser output. IFFT images: (d) as-deposited TiZrN, (e) 20% laser output, and (f) 40% laser output. SAED patterns: (g) as-deposited TiZrN, (h) 20% laser output, and (i) 40% laser output.

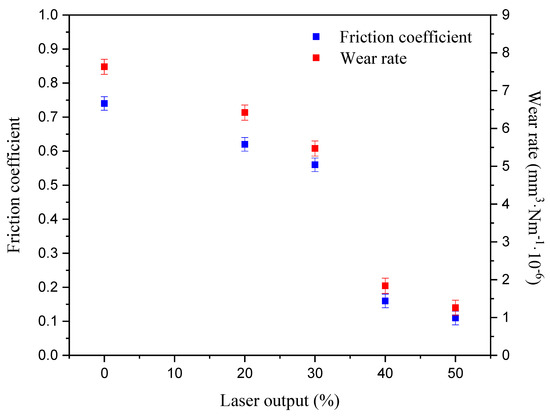

Figure 6 provides the friction coefficient and wear-rate results of ball-on-disc testing to analyze the wear behavior of the carbon-doped TiZrN coatings. The friction coefficient decreased from 0.74 to 0.62 and 0.56 as carbon was doped, and significantly decreased to 0.16 and then 0.11 with the formation of amorphous carbon. After carbon doping, the wear rate decreased from 7.63 × 10−6 mm3 (Nm)−1 to 6.42, 5.47 × 10−6 mm3 (Nm)−1, and decreased even further to 1.84 and 1.26 × 10−6 mm3 (Nm)−1 after the formation of amorphous carbon, which corresponded with the friction coefficient results. Amorphous carbon was chemisorbed with the surrounding gas species, effectively passivating and becoming chemically inert. At this time, the dangling bond was tied up and passivation between sliding surfaces was drastically reduced [31]. Therefore, this was interpreted as the result of the surface becoming lubricated by the amorphous carbon nanocomposite generated by filling the grains of TiZrN or nitrogen vacancies in the lattice with amorphous carbon [32,33].

Figure 6.

Friction coefficient and wear rate of as-deposited TiZrN and carbon-doped TiZrN.

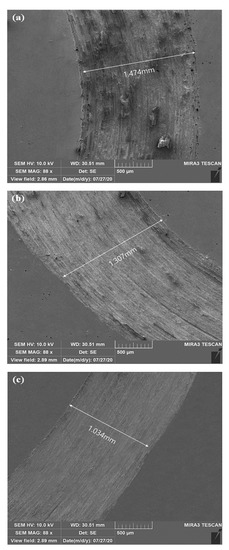

Figure 7 shows the SEM images of the surfaces of the coatings after the wear-track test. In Figure 7a, not only the wear track caused by the ball can be seen, but also the deterioration of the surface because of friction, which caused serious damage to the coating layer. In the case of Figure 7b, it was revealed that deterioration from friction was less than that in Figure 7a, but deterioration in a part of the wear track and damage to the coating layer still occurred. Figure 7c displays a remarkable improvement in deterioration compared to the previous two specimens, and the wear track was also fairly uniform [34,35].

Figure 7.

Wear track images (a) as-deposited TiZrN coating, (b) carbon-doped TiZrN coating (20% laser output), (c) carbon-doped TiZrN coating (40% laser output).

4. Conclusions

The formation of carbon-doped TiZrN nanocomposite coatings by laser carburization and sliding wear were investigated in the phase formation and carbon bonding state. Carbon-doped TiZrN coatings with different carbon contents were prepared by laser carburization, and the thermal energy of the pulsed laser was limited to the range of 20 to 50%. Using XPS analysis, the formation of carbide (TiC, ZrC) was confirmed to have increased, and the sp2/sp3 ratio increased from 2.57 to 3.25 with the increase in the thermal energy of the laser. At 40% thermal energy, the sp2/sp3 ratio increased by 20% compared to the 30% thermal energy of the laser, which was attributed to the formation of amorphous carbon. Phase analysis revealed that the diffraction peak shifted to the left and broadened as the thermal energy of laser increased, which was a result of lattice distortion caused by carbon doping and the formation of carbon-doped TiZrN nanocomposite coatings. TEM results indicated that localized carbon clusters were formed within the grain boundaries of the coating layer. After reaching 40% thermal energy of the laser, it was observed that a carbon-doped TiZrN nanocomposite formed as a result of the increase in hybrid bonds. Wear properties were evaluated by the ball-on-disc tester, which showed that the friction coefficient decreased by 85% and the wear rate by 83% as the thermal energy of the laser continuously increased. Going from 30 to 40% laser thermal energy, the friction coefficient and wear rate greatly improved from 0.56 to 0.16 and 5.47 × 10−6 mm3 (Nm)−1 to 1.84 × 10−6 mm3 (Nm)−1, respectively, demonstrating the initial formation of carbon-doped TiZrN nanocomposite with amorphous carbon.

Author Contributions

Conceptualization, H.L., S.K., E.H., and T.K.; investigation, S.K., E.H., and T.K.; methodology and analysis, H.L., S.K., E.H., T.K., I.J.; writing, H.L., S.K., and J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0008335, The Competency Development Program for Industry specialist).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

In this section, please provide details regarding where data supporting reported results can be found, including links to publicly archived datasets analyzed or generated during the study. Please refer to suggested Data Availability Statements in section “MDPI Research Data Policies” at https://www.mdpi.com/ethics (accessed on 1 April 2021). You might choose to exclude this statement if the study did not report any data.

Acknowledgments

This work was supported by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0008335, The Competency Development Program for Industry specialist).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Djafer, A.Z.A.; Saoula, N.; Madaoui, N.; Zerizer, A. Deposition and characterization of titanium carbide thin films by magnetron sputtering using Ti and TiC targets. Appl. Surf. Sci. 2014, 312, 57–62. [Google Scholar] [CrossRef]

- Yate, L.; Coy, L.E.; Wang, G.; Beltrán, M.; Díaz-Barriga, E.; Załęski, K.; Llarena, I.; Möller, M.; Saucedo, E.M.; Ceniceros, M.A.; et al. Tailoring mechanical properties and electrical conductivity of flexible niobium carbide nanocomposite thin films. RSC Adv. 2014, 4, 61355–61362. [Google Scholar] [CrossRef]

- Bressan, J.; Hesse, R.; Silva, E. Abrasive wear behavior of high speed steel and hard metal coated with TiAlN and TiCN. Wear 2001, 250, 561–568. [Google Scholar] [CrossRef]

- Chuan, S.P.; Ghani, J.A.; Tomadi, S.H.; Hassan, C.H.C. Analysis of Ti-base Hard Coating Performance in Machining Process: A Review. J. Appl. Sci. 2012, 12, 1882–1890. [Google Scholar] [CrossRef]

- Liu, S.; Wheeler, J.M.; Howie, P.R.; Zeng, X.T.; Michler, J.; Clegg, W.J. Measuring the fracture resistance of hard coatings. Appl. Phys. Lett. 2013, 102, 171907. [Google Scholar] [CrossRef]

- Ghareshabani, E.; Rawat, R.S.; Sobhanian, S.; Verma, R.; Karamat, S.; Pan, Z. Synthesis of nanostructured multiphase Ti(C,N)/a-C films by a plasma focus device. Nucl. Instruments Methods Phys. Res. Sect. B: Beam Interactions Mater. Atoms 2010, 268, 2777–2784. [Google Scholar] [CrossRef]

- Cheng, K.-Y.; Pagan, N.; Bijukumar, D.; Mathew, M.T.; McNallan, M. Carburized titanium as a solid lubricant on hip implants: Corrosion, tribocorrosion and biocompatibility aspects. Thin Solid Films 2018, 665, 148–158. [Google Scholar] [CrossRef]

- Robertson, J. Amorphous carbon. Adv. Phys. 1986, 35, 317–374. [Google Scholar] [CrossRef]

- Bhushan, B. Modern Tribology Handbook, Two Volume Set; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Ye, Y.; Wang, Y.; Chen, H.; Li, J.; Yao, Y.; Wang, C. Doping carbon to improve the tribological performance of CrN coatings in seawater. Tribol. Int. 2015, 90, 362–371. [Google Scholar] [CrossRef]

- Stueber, M.; Barna, P.; Simmonds, M.; Albers, U.; Leiste, H.; Ziebert, C.; Holleck, H.; Kovács, A.; Hovsepian, P.; Gee, I. Constitution and microstructure of magnetron sputtered nanocomposite coatings in the system Ti–Al–N–C. Thin Solid Films 2005, 493, 104–112. [Google Scholar] [CrossRef]

- Stueber, M.; Albers, U.; Leiste, H.; Ulrich, S.; Holleck, H.; Barna, P.; Kovacs, A.; Hovsepian, P.; Gee, I. Multifunctional nanolaminated PVD coatings in the system Ti–Al–N–C by combination of metastable fcc phases and nanocomposite microstructures. Surf. Coatings Technol. 2006, 200, 6162–6171. [Google Scholar] [CrossRef]

- Hong, E.; Kim, T.; Kim, S.; Lee, S.; Lee, H. Carbon depth profile and internal stress by thermal energy variation in carbon-doped TiZrN coating. J. Am. Ceram. Soc. 2021, 104, 564–571. [Google Scholar] [CrossRef]

- Kim, T.; Jo, S.-H.; Lee, J.W.; Cho, H.; Lee, H. Surface graphitization of carbon-doped TiZrN coatings. Ceram. Int. 2019, 45, 1790–1793. [Google Scholar] [CrossRef]

- Li, J.; Zhang, S.; Li, M. Influence of the C2H2 flow rate on gradient TiCN films deposited by multi-arc ion plating. Appl. Surf. Sci. 2013, 283, 134–144. [Google Scholar] [CrossRef]

- Lackner, J.; Waldhauser, W.; Ebner, R.; Keckés, J.; Schöberl, T. Room temperature deposition of (Ti,Al)N and (Ti,Al)(C,N) coatings by pulsed laser deposition for tribological applications. Surf. Coatings Technol. 2004, 177–178, 447–452. [Google Scholar] [CrossRef]

- Korotaev, A.D.; Litovchenko, I.Y.; Ovchinnikov, S.V. Structural-Phase State, Elastic Stress, and Functional Properties of Nanocomposite Coatings Based on Amorphous Carbon. Phys. Mesomech. 2019, 22, 488–495. [Google Scholar] [CrossRef]

- Park, S.-I.; Quan, Y.-J.; Kim, S.-H.; Kim, H.; Kim, S.; Chun, D.-M.; Lee, C.S.; Taya, M.; Chu, W.-S.; Ahn, S.-H. A review on fabrication processes for electrochromic devices. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 397–421. [Google Scholar] [CrossRef]

- CETAC LSX-213 G2+/LSX-266 Operator’s Manual. Available online: http://minerva.union.edu/hollochk/laser_ablation/other_documents/480141_LSX213_Operators_Manual_rev2f.pdf (accessed on 2 April 2021).

- Iso 20808, (ISO standard, Fine ceramics (Advanced ceramics, advanced technical ceramics) – Determination of friction and wear characteristics of monolithic ceramics by ball-on-disc method, 2016).

- Lesiak, B.; Kövér, L.; Tóth, J.; Zemek, J.; Jiricek, P.; Kromka, A.; Rangam, N. C sp2/sp3 hybridisations in carbon nanomaterials – XPS and (X)AES study. Appl. Surf. Sci. 2018, 452, 223–231. [Google Scholar] [CrossRef]

- Li, X.; Zhang, N.; Lee, K.-R.; Wang, A. Effect of metal doping on structural characteristics of amorphous carbon system: A first-principles study. Thin Solid Films 2016, 607, 67–72. [Google Scholar] [CrossRef]

- Liu, D.; Zheng, L.; Liu, J.; Luo, L.; Wu, Y. Residual stress relief of hard a-C films though buckling. Ceram. Int. 2018, 44, 3644–3648. [Google Scholar] [CrossRef]

- Rai, S.K.; Kumar, A.; Shankar, V.; Jayakumar, T.; Rao, K.B.S.; Raj, B. Characterization of microstructures in Inconel 625 using X-ray diffraction peak broadening and lattice parameter measurements. Scr. Mater. 2004, 51, 59–63. [Google Scholar] [CrossRef]

- Ungár, T. Microstructural parameters from X-ray diffraction peak broadening. Scr. Mater. 2004, 51, 777–781. [Google Scholar] [CrossRef]

- Zehnder, T.; Patscheider, J. Nanocomposite TiC/a–C:H hard coatings deposited by reactive PVD. Surf. Coatings Technol. 2000, 133–134, 138–144. [Google Scholar] [CrossRef]

- Park, I.-W.; Choi, S.R.; Suh, J.H.; Park, C.-G.; Kim, K.H. Deposition and mechanical evaluation of superhard Ti–Al–Si–N nanocomposite films by a hybrid coating system. Thin Solid Films 2004, 447–448, 443–448. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Xue, Z.; Ma, F.; Zhang, K.; Chen, X.; Feng, R.; Liaw, P.K. Microstructures, mechanical behavior and strengthening mechanism of TiSiCN nanocomposite films. Sci. Rep. 2017, 7, 2140. [Google Scholar] [CrossRef]

- Wu, Y.; Hong, S.; Zhang, J.; He, Z.; Guo, W.; Wang, Q.; Li, G. Microstructure and cavitation erosion behavior of WC–Co–Cr coating on 1Cr18Ni9Ti stainless steel by HVOF thermal spraying. Int. J. Refract. Met. Hard Mater. 2012, 32, 21–26. [Google Scholar] [CrossRef]

- Forsh, E.; Abakumov, A.; Zaytsev, V.; Konstantinova, E.; Forsh, P.; Rumyantseva, M.; Gaskov, A.; Kashkarov, P. Optical and photoelectrical properties of nanocrystalline indium oxide with small grains. Thin Solid Films 2015, 595, 25–31. [Google Scholar] [CrossRef]

- Okubo, H.; Tadokoro, C.; Sasaki, S. Tribological properties of a tetrahedral amorphous carbon (ta-C) film under boundary lubrication in the presence of organic friction modifiers and zinc dialkyldithiophosphate (ZDDP). Wear 2015, 332–333, 1293–1302. [Google Scholar] [CrossRef]

- Gulbinski, W.; Mathur, S.; Shen, H.; Suszko, T.; Gilewicz, A.; Warcholinski, B. Evaluation of phase, composition, microstructure and properties in TiC/a-C:H thin films deposited by magnetron sputtering. Appl. Surf. Sci. 2005, 239, 302–310. [Google Scholar] [CrossRef]

- Van de Sanden, M.C.M.; Severens, R.J.; Bastiaanssen, J.; Schram, D.C. High-quality a-Si:H growth at high rate using an expanding thermal plasma. Surf. Coatings Technol. 1997, 97, 719–722. [Google Scholar] [CrossRef]

- Li, X.; Deng, X.; Kousaka, H.; Umehara, N. Comparative study on effects of load and sliding distance on amorphous hydrogenated carbon (a-C:H) coating and tetrahedral amorphous carbon (ta-C) coating under base-oil lubrication condition. Wear 2017, 392–393, 84–92. [Google Scholar] [CrossRef]

- Martini, C.; Ceschini, L.; Casadei, B.; Boromei, I.; Guion, J. Dry sliding behaviour of hydrogenated amorphous carbon (a-C:H) coatings on Ti-6Al-4V. Wear 2011, 271, 2025–2036. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).