Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate

Abstract

1. Introduction

1.1. APS Process Parameters

1.2. Testing of Coatings

1.3. SPT on Coatings

2. Materials and Methods

2.1. Materials

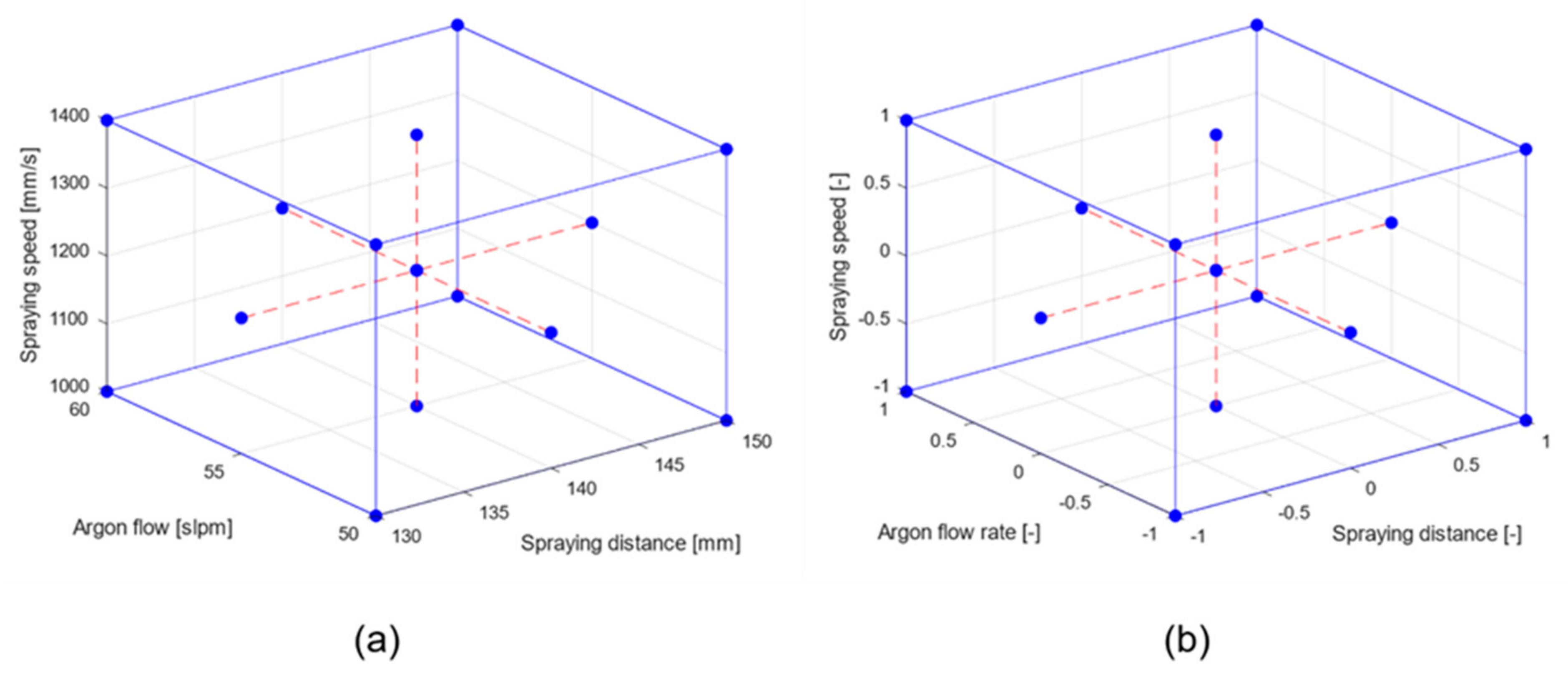

2.2. Methodology

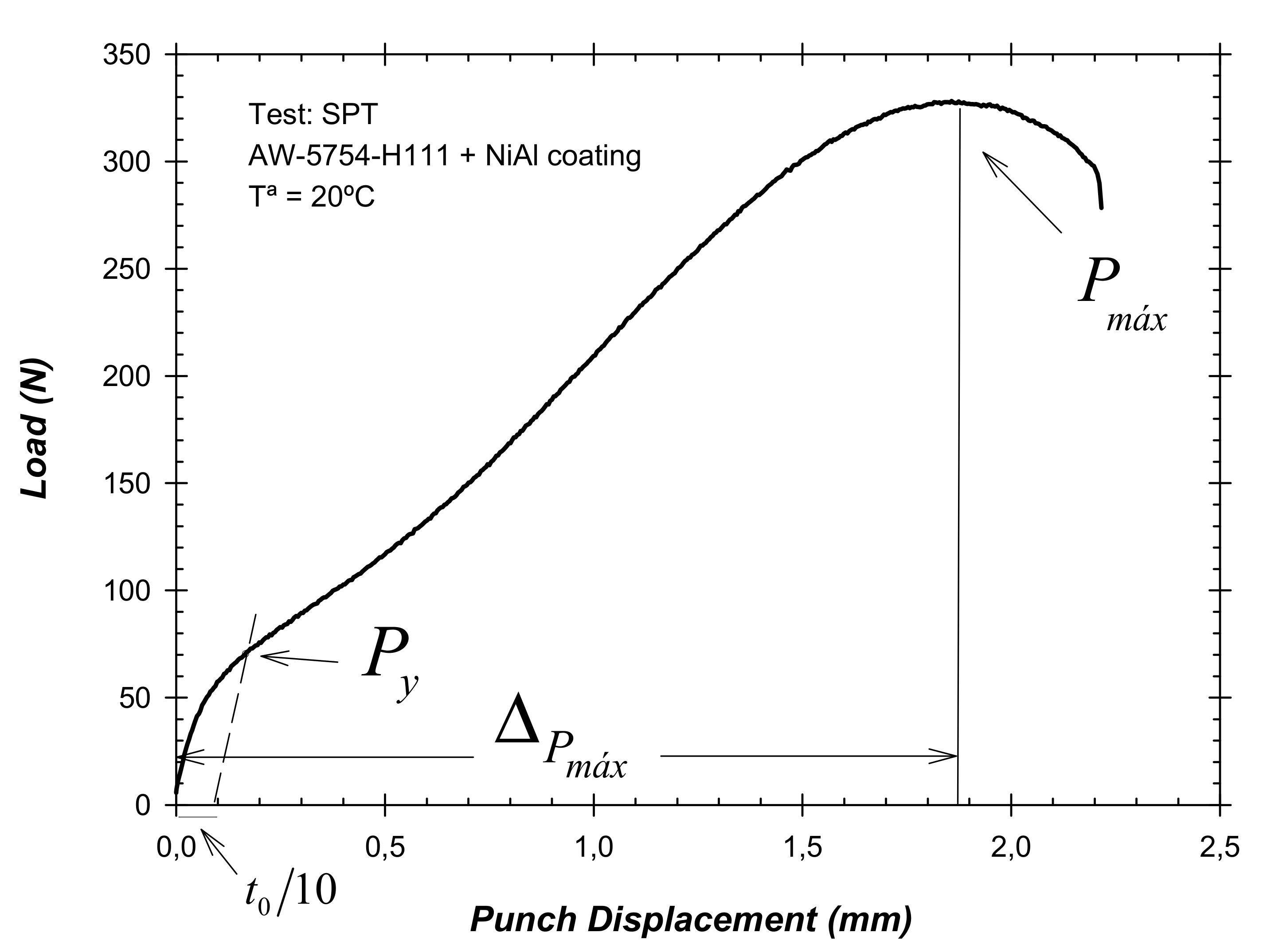

2.2.1. Small Punch Test (SPT)

2.2.2. Surface Roughness

- Amplitude field parameters: , , , and . These parameters are related to the averaged profile ordinates ( and ) or to the peak/valley amplitudes (, , ).

- Peak/valley feature parameter: This parameter represents the mean height of profile elements within the sampling length.

- Spacing feature parameter: . It is determined by averaging the width of profile elements.

3. Results

4. Discussion

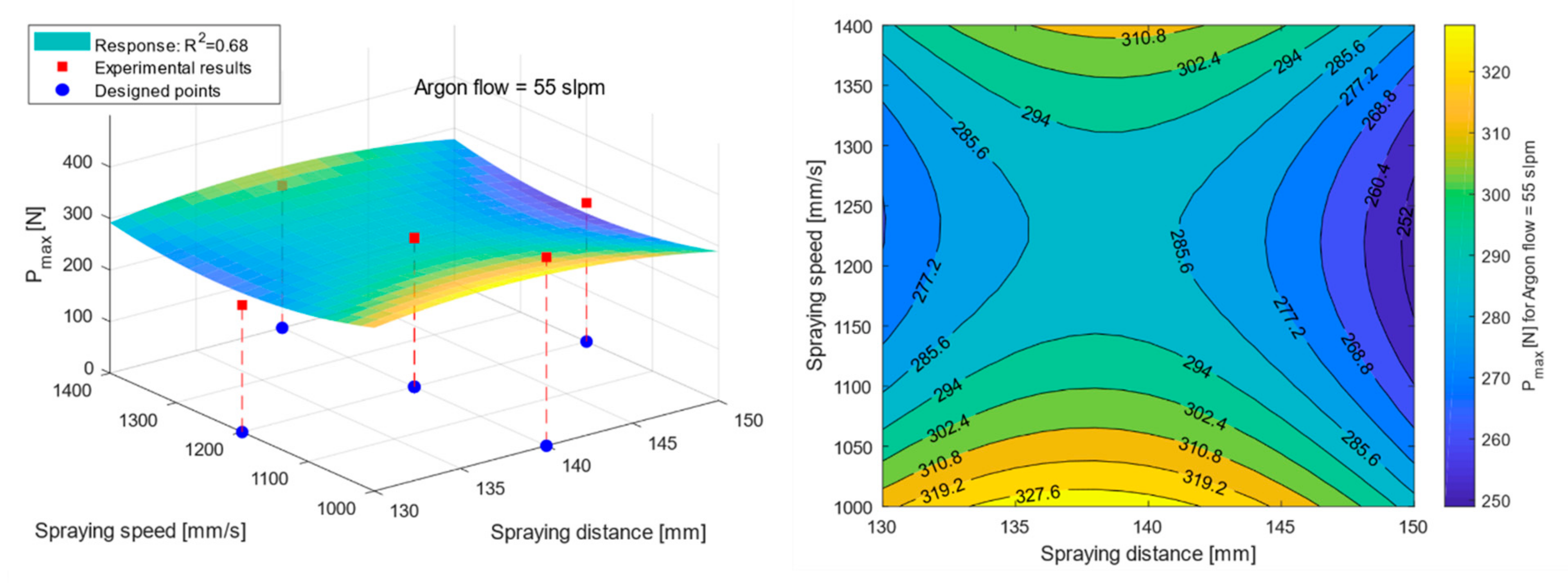

4.1. Maximum Load in SPT

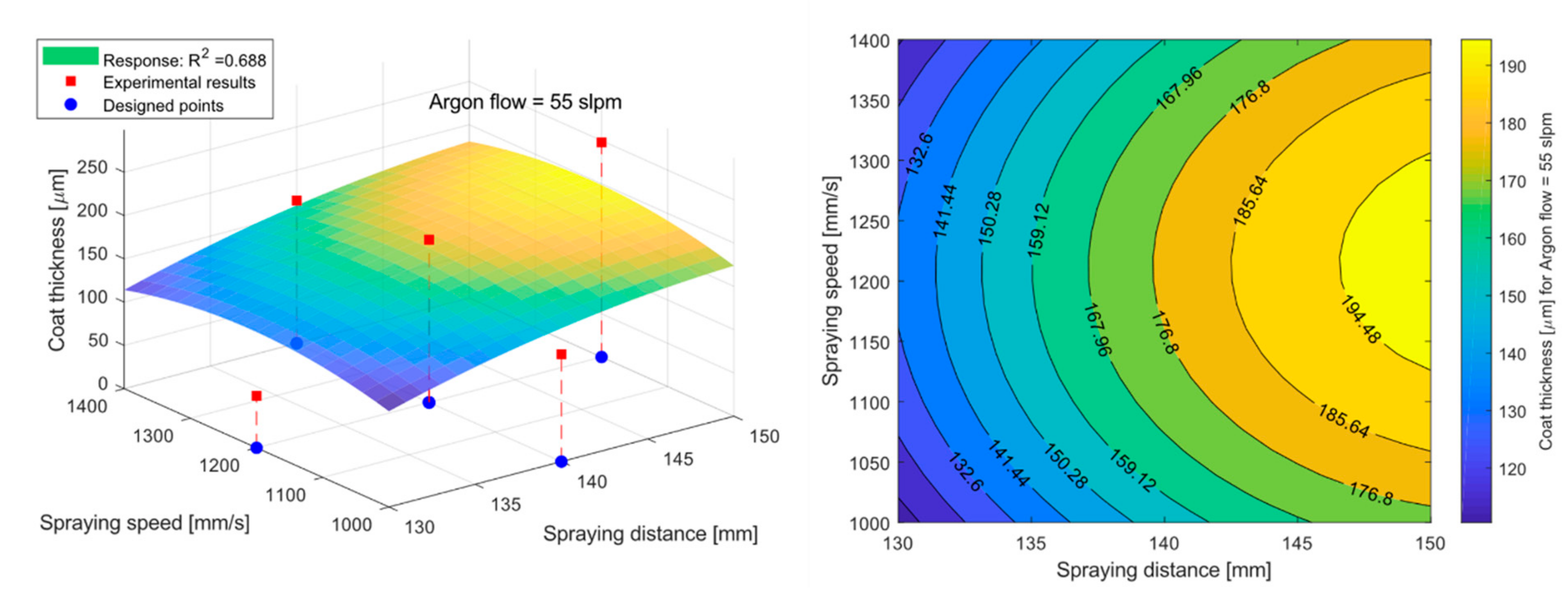

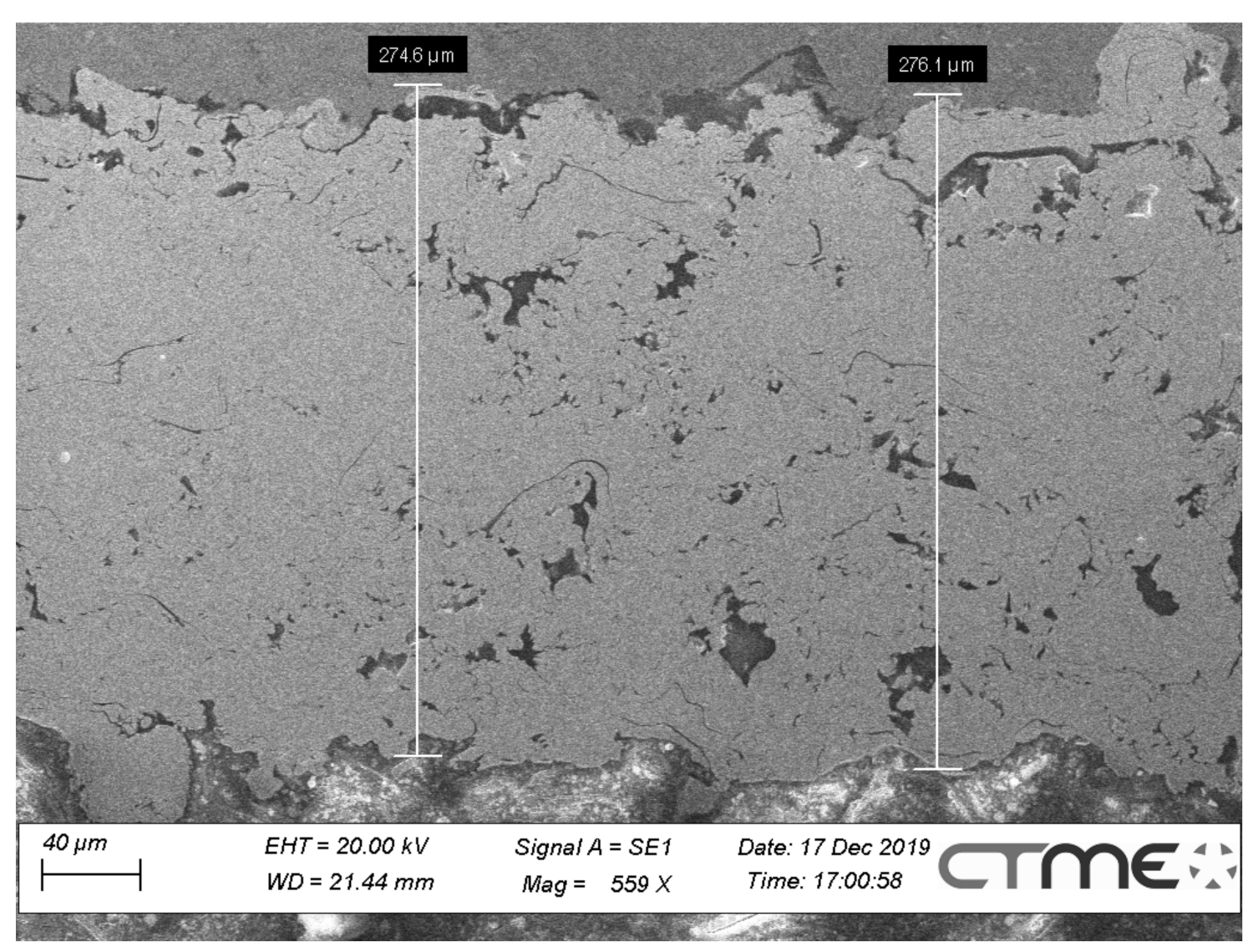

4.2. Coating Thickness

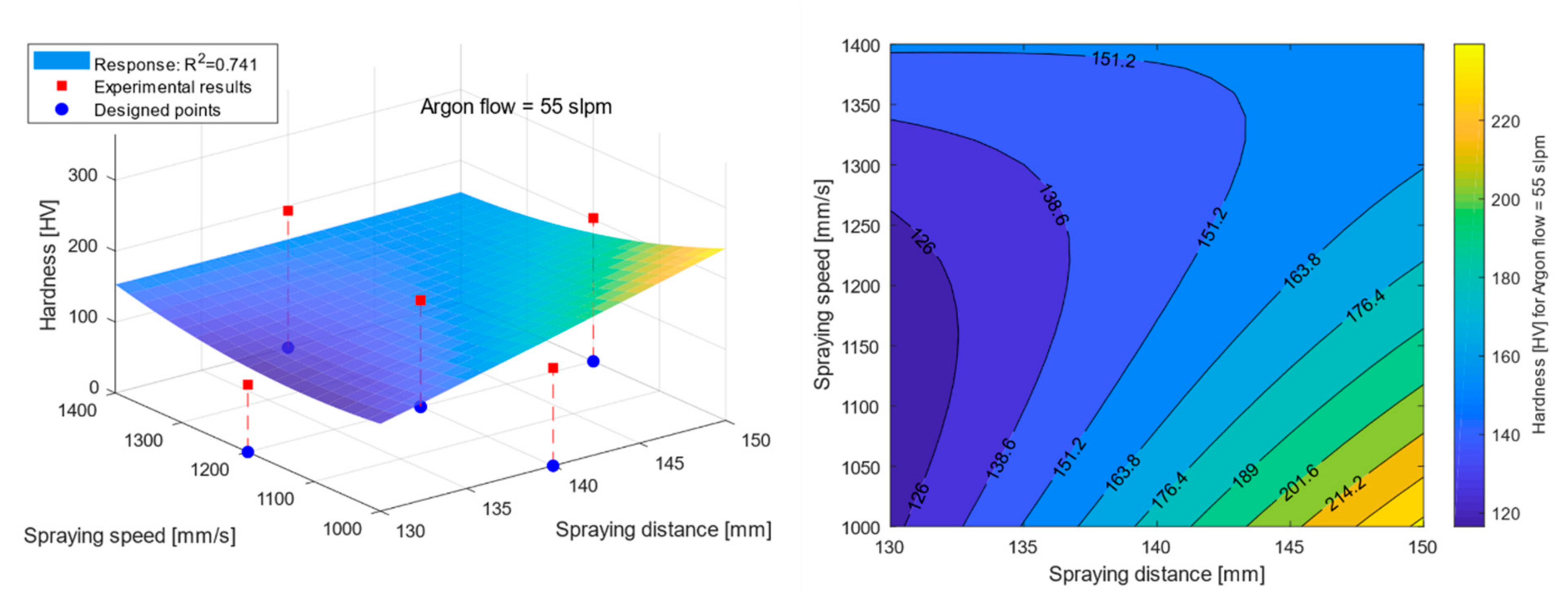

4.3. Microhardness

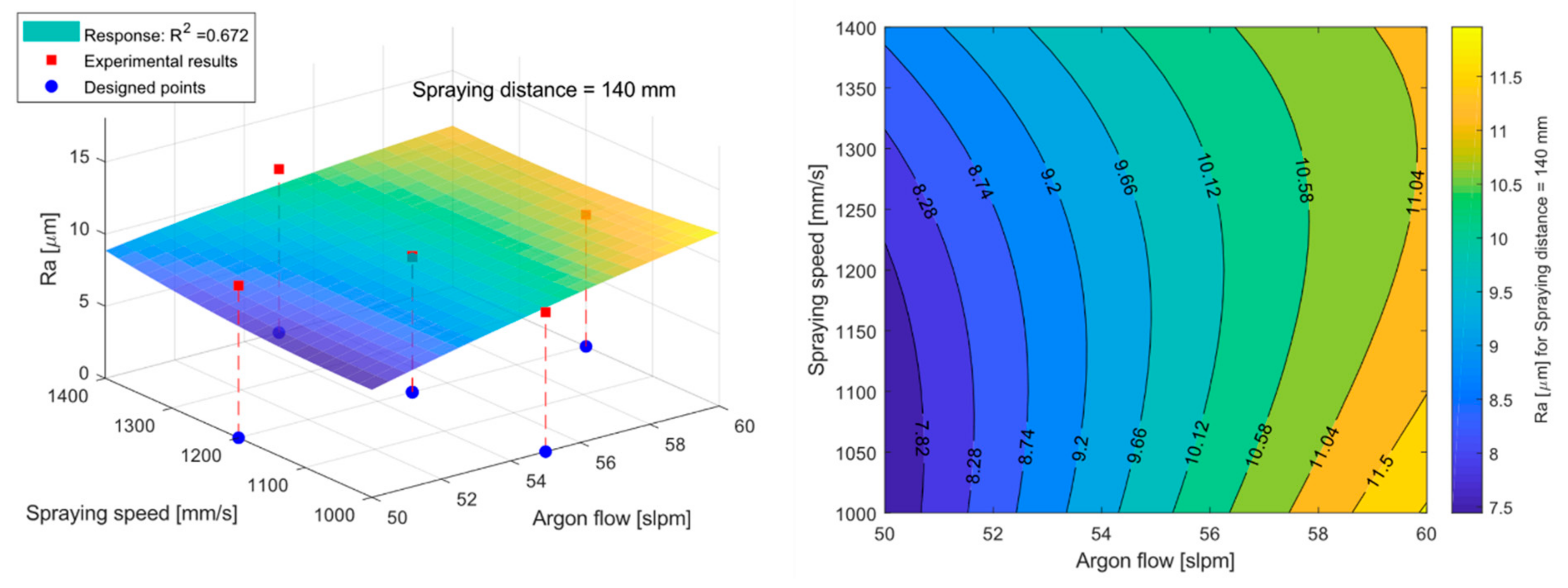

4.4. Surface Roughness Ra

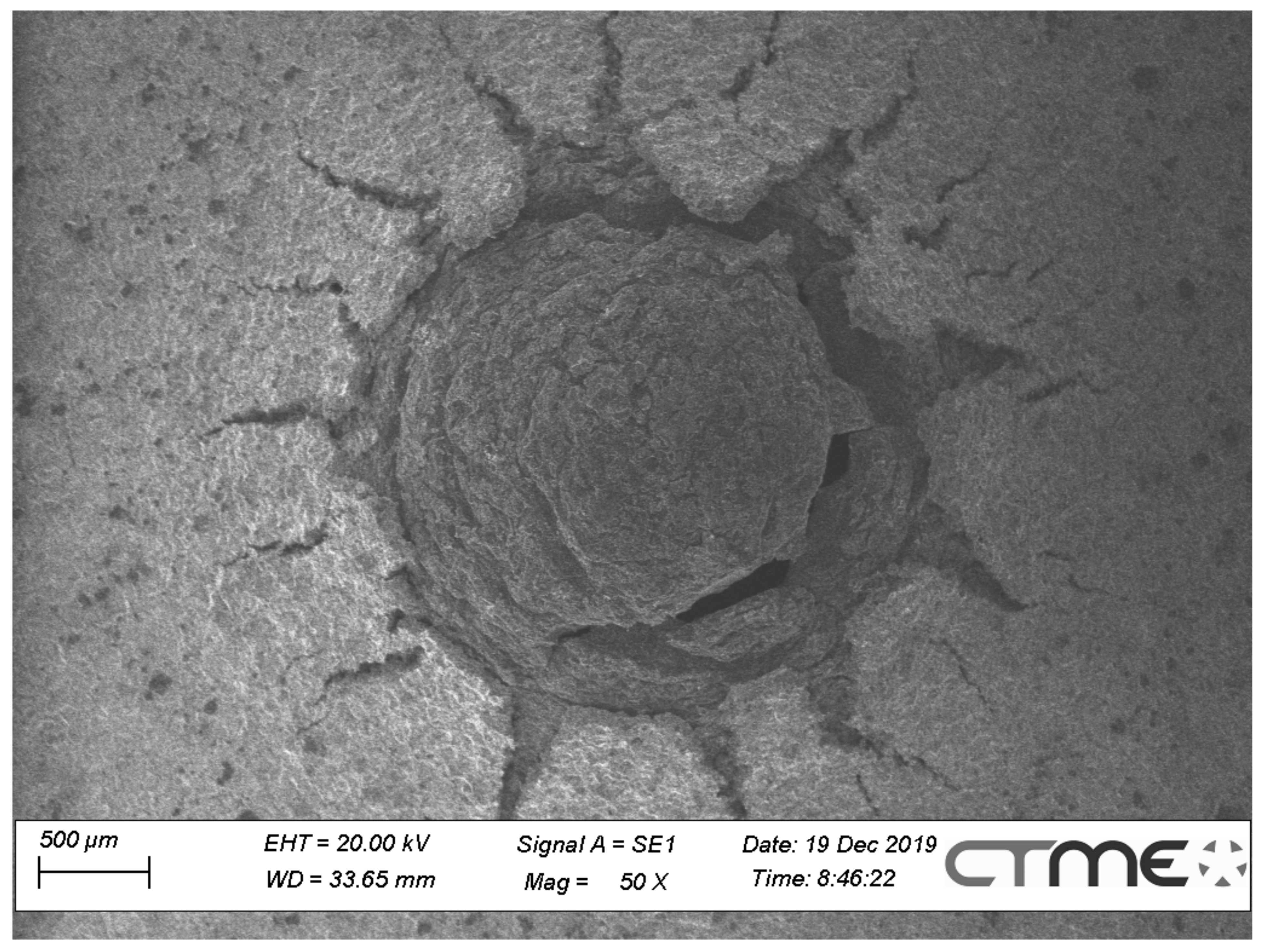

4.5. Fractographic Analysis

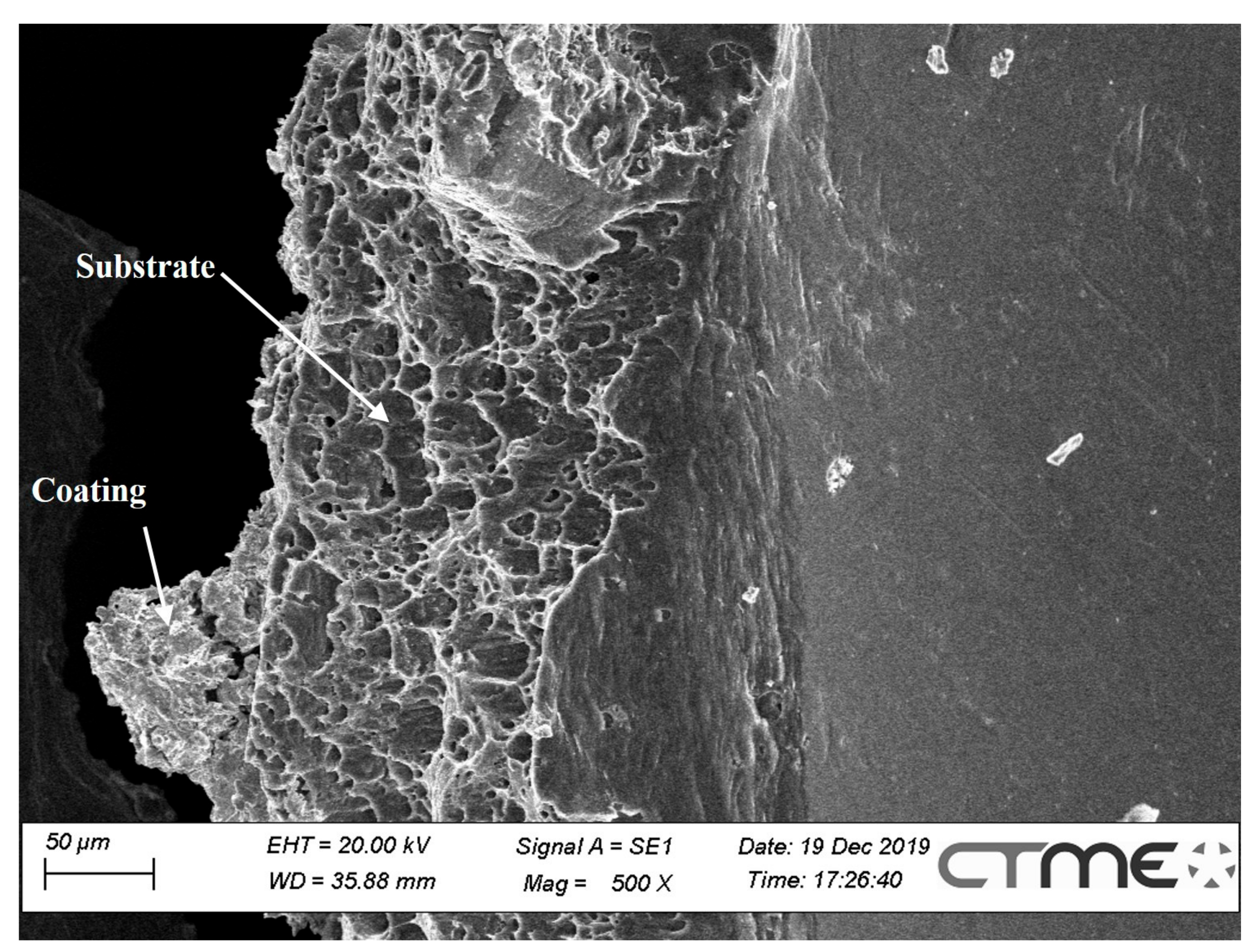

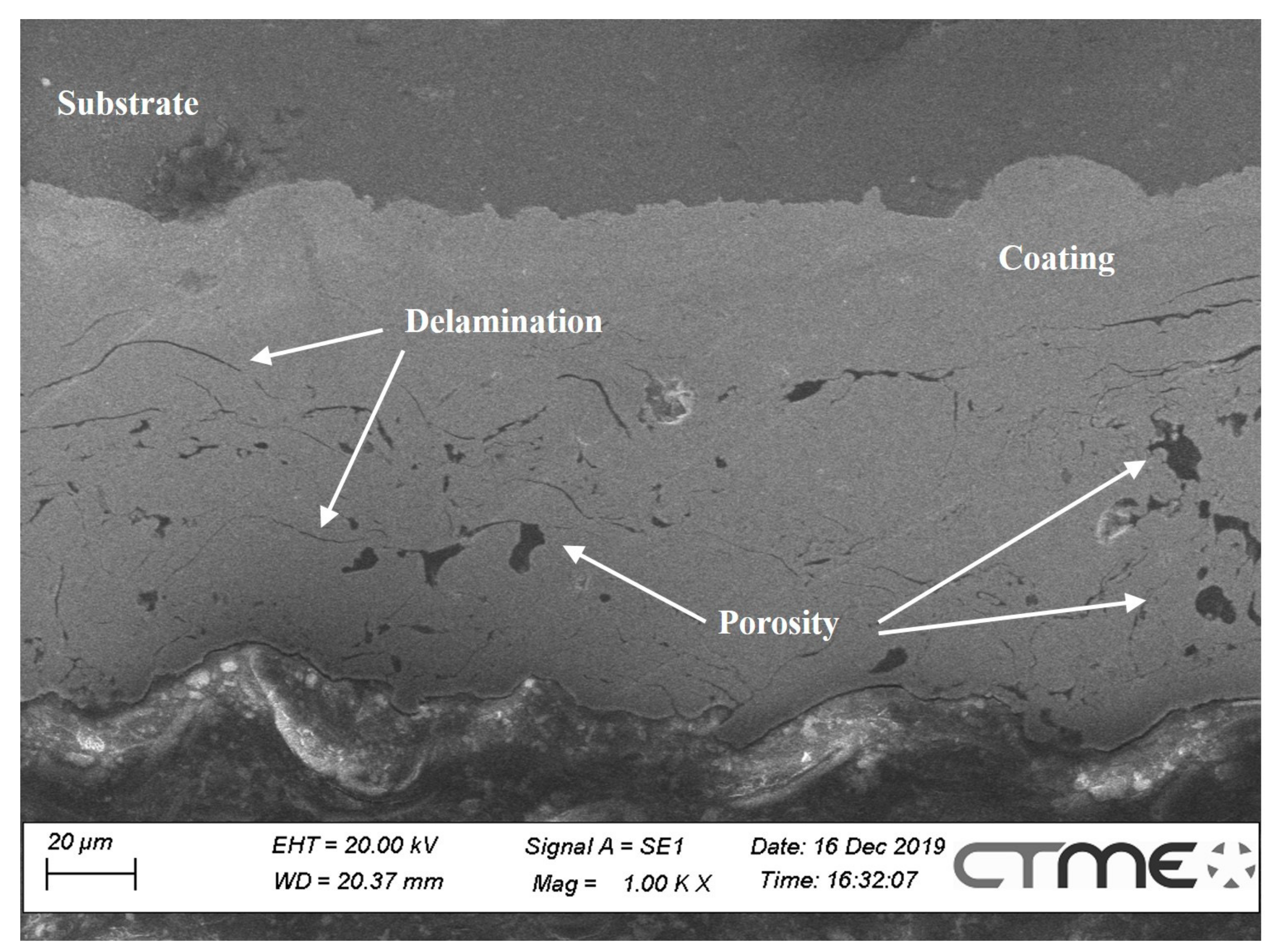

4.6. Coating Metallographic Analysis

5. Conclusions

- Within the assessed range of variables, low spraying speeds and an increase in spraying distance, for intermediate values of argon flow rates, produce coatings with higher strength.

- Alternatively, the thicker coatings were obtained for a greater spraying distance combined with high argon flow rates.

- On the other hand, for a greater spraying distance and a slow spraying process, surface microhardness was maximized.

- Finally, for high argon flow rates together and great spraying distance, the highest surface roughness has been found.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Legg, K.O.; Sartwell, B.D.; Legoux, J.–G.; Nestler, M.; Dambra, C.; Wang, D.; Quets, J.; Natishan, P.; Bretz, P.; Devereaux, J. Investigation of Plasma Spray Coatings as an Alternative to Hard Chrome Plating on Internal Surfaces; Report NRL/MR/6170--06-8987; Naval Research Lab: Washington, DC, USA, 2006. [Google Scholar]

- Legg, K.O. Overview of chromium and cadmium alternative technologies. In Surface Modification Technologies XV; ASM International, Materials Park: Novelty, OH, USA; IOM Communications Ltd.: London, UK, 2002. [Google Scholar]

- Espallargas, N.; Berget, J.; Guilemany, J.; Benedetti, A.; Suegama, P. Cr3C2–NiCr and WC–Ni thermal spray coatings as alternatives to hard chromium for erosion–corrosion resistance. Surf. Coatings Technol. 2008, 202, 1405–1417. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA US). National Emission Standards for Hazardous Air Pollutant Emissions: Hard and Decorative Chromium Electroplating and Chromium Anodizing Tanks; and Steel Pickling—HCl Process Facilities and Hydrochloric Acid Regeneration Plants. Dly. J. United State Gov. 2012, 77, 58219–58253. [Google Scholar]

- Miguel, J.M.; Vizcaino, S.; Lorenzana, C.; Cinca, N.; Guilemany, J.M. Tribological Behavior of Bronze Composite Coatings Obtained by Plasma Thermal Spraying. Tribol. Lett. 2011, 42, 263–273. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Navarro, J.; Lorenzana, C.; Vizcaino, S.; Miguel, J.M. Tribological behaviour of abradable coatings obtained by atmospheric plasma spraying (APS). In Proceedings of the International Thermal Spray Conference, Singapore, 28–30 May 2001; pp. 1115–1118. [Google Scholar]

- Carter, T.J. Common failures in gas turbine blades. Eng. Fail. Anal. 2005, 12, 237–247. [Google Scholar] [CrossRef]

- Mazur, Z.; Luna-Ramírez, A.; Juárez-Islas, J.; Campos-Amezcua, A. Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Eng. Fail. Anal. 2005, 12, 474–486. [Google Scholar] [CrossRef]

- Tawancy, H.; Mohammad, A.; Al-Hadhrami, L.; Dafalla, H.; Alyousf, F. On the performance and failure mechanism of thermal barrier coating systems used in gas turbine blade applications: Influence of bond coat/superalloy combination. Eng. Fail. Anal. 2015, 57, 1–20. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, M.; Handa, A. Comparative study of high temperature oxidation behavior and mechanical properties of wire arc sprayed Ni Cr and Ni Al coatings. Eng. Fail. Anal. 2019, 106, 104173. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Bakan, E.; Vassen, R. Ceramic Top Coats of Plasma-Sprayed Thermal Barrier Coatings: Materials, Processes, and Properties. J. Therm. Spray Technol. 2017, 26, 992–1010. [Google Scholar] [CrossRef]

- Heimann, R.B. Principles of Thermal Spraying. In Plasma-Spray Coating: Principles and Applications; Wiley: Weinheim, Germany, 1996. [Google Scholar] [CrossRef]

- Luo, X.; Smith, G.M.; Sampath, S. On the Interplay Between Adhesion Strength and Tensile Properties of Thermal Spray Coated Laminates—Part I: High Velocity Thermal Spray Coatings. J. Therm. Spray Technol. 2018, 27, 296–307. [Google Scholar] [CrossRef]

- Sun, J.; Chang, E.; Wu, B.; Tsai, C. The properties and performance of (ZrO2-8wt.%Y2O3)/(chemically vapour-deposited Al2O3)/(Ni-22wt.%Cr-10wt.%Al-lwt.%Y) thermal barrier coatings. Surf. Coatings Technol. 1993, 58, 93–99. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, J.S.; Lee, K.H.; Song, Y.S.; Kang, M.C. Effects of the laser treatment and thermal oxidation behavior of CoNiCrAlY/ZrO2–8wt%Y2O3 thermal barrier coating. J. Mater. Process. Technol. 2008, 201, 331–335. [Google Scholar] [CrossRef]

- Gray, A.; Sampson, E.R. Tech spotlight: Coating solutions for military applications. Adv. Mater. Process. 2002, 160, 41–42. [Google Scholar]

- Oksa, M.; Turunen, E.; Suhonen, T.; Varis, T.; Hannula, S.-P. Optimization and Characterization of High Velocity Oxy-fuel Sprayed Coatings: Techniques, Materials, and Applications. Coatings 2011, 1, 17–52. [Google Scholar] [CrossRef]

- Gautam, R.K.S.; Rao, U.; Tyagi, R. High temperature tribological properties of Ni-based self-lubricating coatings deposited by atmospheric plasma spray. Surf. Coatings Technol. 2019, 372, 390–398. [Google Scholar] [CrossRef]

- Anupam, A.; Kottada, R.S.; Kashyap, S.; Meghwal, A.; Murty, B.; Berndt, C.; Ang, A. Understanding the microstructural evolution of high entropy alloy coatings manufactured by atmospheric plasma spray processing. Appl. Surf. Sci. 2020, 505, 144117. [Google Scholar] [CrossRef]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International Materials Park: Novelty, OH, USA, 2004; p. 338. [Google Scholar]

- Ganvir, A.; Curry, N.; Govindarajan, S.; Markocsan, N. Characterization of Thermal Barrier Coatings Produced by Various Thermal Spray Techniques Using Solid Powder, Suspension, and Solution Precursor Feedstock Material. Int. J. Appl. Ceram. Technol. 2015, 13, 324–332. [Google Scholar] [CrossRef]

- Prochazka, Z.; Khor, K.A.; Cizek, J. Influence of Input Parameters on Splat Formation and Coating Thermal Diffusivity in Plasma Spraying. Adv. Eng. Mater. 2006, 8, 645–650. [Google Scholar] [CrossRef]

- Nouri, A.; Sola, A. Powder morphology in thermal spraying. J. Adv. Manuf. Process. 2019, 1, 10020. [Google Scholar] [CrossRef]

- Janisson, S.; Vardelle, A.; Coudert, J.F.; Meillot, E.; Pateyron, B.; Fauchais, P. Plasma Spraying Using Ar-He-H2 Gas Mixtures. J. Therm. Spray Technol. 1999, 8, 545–552. [Google Scholar] [CrossRef]

- Chen, X.; Kuroda, S.; Ohnuki, T.; Araki, H.; Watanabe, M.; Sakka, Y. Effects of Processing Parameters on the Deposition of Yttria Partially Stabilized Zirconia Coating During Suspension Plasma Spray. J. Am. Ceram. Soc. 2016, 99, 3546–3555. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, A.; Dussoubs, B. Quo Vadis Thermal Spraying? J. Therm. Spray Technol. 2001, 10, 44–66. [Google Scholar] [CrossRef]

- Fauchais, P. Understanding plasma spraying. J. Phys. D Appl. Phys. 2004, 37, R86–R108. [Google Scholar] [CrossRef]

- Ng, H.; Gan, Z. A finite element analysis technique for predicting as-sprayed residual stresses generated by the plasma spray coating process. Finite Elements Anal. Des. 2005, 41, 1235–1254. [Google Scholar] [CrossRef]

- Teixeira, V.; Andritschky, M.; Fischer, W.; Buchkremer, H.; Stöver, D. Analysis of residual stresses in thermal barrier coatings. J. Mater. Process. Technol. 1999, 92–93, 209–216. [Google Scholar] [CrossRef]

- Sarikaya, O. Effect of the substrate temperature on properties of plasma sprayed Al2O3 coatings. Mater. Des. 2005, 26, 53–57. [Google Scholar] [CrossRef]

- Fogarassy, P.; Turquier, F.; Lodini, A. Residual stress in plasma sprayed zirconia on cylindrical components. Mech. Mater. 2003, 35, 633–640. [Google Scholar] [CrossRef]

- Mellali, M.; Fauchais, P.; Grimaud, A. Influence of substrate roughness and temperature on the adhesion/cohesion of alumina coatings. Surf. Coatings Technol. 1996, 81, 275–286. [Google Scholar] [CrossRef]

- Guessasma, S.; Bounazef, M. Experimental Design to Study the Effect of APS Process Parameters on Friction Behaviour of Alumina-Titania Coatings. Adv. Eng. Mater. 2004, 6, 907–910. [Google Scholar] [CrossRef]

- Helminiak, M.A.; Yanar, N.M.; Pettit, F.S.; Taylor, T.A.; Meier, G.H. Factors affecting the microstructural stability and durability of thermal barrier coatings fabricated by air plasma spraying. Mater. Corros. 2012, 63, 929–939. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Thakur, L. Performance of different coating materials against slurry erosion failure in hydrodynamic turbines: A review. Eng. Fail. Anal. 2020, 115, 104622. [Google Scholar] [CrossRef]

- Song, Y.; Zhuan, X.; Wang, T.; Chen, X. Evolution of thermal stress in a coating/substrate system during the cooling process of fabrication. Mech. Mater. 2014, 74, 26–40. [Google Scholar] [CrossRef]

- Krella, A.; Sobczyk, A.; Krupa, A.; Jaworek, A. Thermal resistance of Al2O3 coating produced by electrostatic spray deposition method. Mech. Mater. 2016, 98, 120–133. [Google Scholar] [CrossRef]

- Premkumar, K.; Balasubramanian, K. Evaluation of cyclic oxidation behavior and mechanical properties of nanocrystalline composite HVOF coatings on SA 210 grade C material. Eng. Fail. Anal. 2019, 97, 635–644. [Google Scholar] [CrossRef]

- Choi, B.-Y.; Liang, J.; Gao, W. Correlation of microstructure and high temperature oxidation resistance of plasma sprayed NiCrAl, NiCrAlY, and TiAlO composite coatings on Ti−6Al−4V. Met. Mater. Int. 2005, 11, 499–503. [Google Scholar] [CrossRef]

- Ahmed, R.; Hadfield, M. Mechanisms of Fatigue Failure in Thermal Spray Coatings. J. Therm. Spray Technol. 2002, 11, 333–349. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Dikici, H.; Kucuk, Y. Effects of heat treatment on adhesion strength of thermal barrier coating systems. Eng. Fail. Anal. 2013, 32, 16–22. [Google Scholar] [CrossRef]

- Boruah, D.; Robinson, B.; London, T.; Wu, H.; De Villiers-Lovelock, H.; McNutt, P.; Doré, M.; Zhang, X. Experimental evaluation of interfacial adhesion strength of cold sprayed Ti-6Al-4V thick coatings using an adhesive-free test method. Surf. Coatings Technol. 2020, 381, 125130. [Google Scholar] [CrossRef]

- Kang, J.-J.; Xu, B.-S.; Wang, H.-D.; Wang, C.-B.; Zhu, L.-N. Delamination failure monitoring of plasma sprayed composite ceramic coatings in rolling contact by acoustic emission. Eng. Fail. Anal. 2018, 86, 131–141. [Google Scholar] [CrossRef]

- International Organization for Standardization. Thermal Spraying–Determination of Tensile Adhesive Strength (ISO 14916:2017). 2017. Available online: https://www.iso.org/standard/60995.html (accessed on 2 February 2021).

- International Organization for Standardization. Thermal Spraying—Evaluation of Adhesion/Cohesion of Thermal Sprayed Ceramic Coatings by Transverse Scratch Testing (ISO 27307:2015). 2015. Available online: https://www.iso.org/standard/51692.html (accessed on 2 February 2021).

- International Organization for Standardization. Thermal Spraying–Classification Method of Adhesive Strength by Indentation (ISO 19207:2016.). 2016. Available online: https://www.iso.org/standard/63998.html (accessed on 2 February 2021).

- ASTM C633-13 (2017), Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 18 March 2021).

- Hivart, P.; Crampon, J. Interfacial indentation test and adhesive fracture characteristics of plasma sprayed cermet Cr3C2/Ni–Cr coatings. Mech. Mater. 2007, 39, 998–1005. [Google Scholar] [CrossRef]

- Azarmi, F.; Sevostianov, I. Comparative micromechanical analysis of alloy 625 coatings deposited by air plasma spraying, wire arc spraying, and cold spraying technologies. Mech. Mater. 2020, 144, 103345. [Google Scholar] [CrossRef]

- Dwivedi, G.; Viswanathan, V.; Sampath, S.; Shyam, A.; Lara-Curzio, E. Fracture Toughness of Plasma-Sprayed Thermal Barrier Ceramics: Influence of Processing, Microstructure, and Thermal Aging. J. Am. Ceram. Soc. 2014, 97, 2736–2744. [Google Scholar] [CrossRef]

- He, X.; Song, P.; Yu, X.; Li, C.; Huang, T.; Zhou, Y.; Li, Q.; Lü, K.; Lü, J.; Lu, J. Evolution of cracks within an Al2O3–40 wt%TiO2/NiCoCrAl gradient coating. Ceram. Int. 2018, 44, 20798–20807. [Google Scholar] [CrossRef]

- Nordhorn, C.; Mücke, R.; Mack, D.E.; Vaßen, R. Probabilistic lifetime model for atmospherically plasma sprayed thermal barrier coating systems. Mech. Mater. 2016, 93, 199–208. [Google Scholar] [CrossRef]

- Kind, N.; Berthel, B.; Fouvry, S.; Poupon, C.; Jaubert, O. Plasma-sprayed coatings: Identification of plastic properties using macro-indentation and an inverse Levenberg–Marquardt method. Mech. Mater. 2016, 98, 22–35. [Google Scholar] [CrossRef]

- Rezaei, S.; Arghavani, M.; Wulfinghoff, S.; Kruppe, N.C.; Brögelmann, T.; Reese, S.; Bobzin, K. A novel approach for the prediction of deformation and fracture in hard coatings: Comparison of numerical modeling and nanoindentation tests. Mech. Mater. 2018, 117, 192–201. [Google Scholar] [CrossRef]

- Lewis, F.; Mantovani, D. Methods to Investigate the Adhesion of Soft Nano-Coatings on Metal Substrates-Application to Polymer-Coated Stents. Macromol. Mater. Eng. 2008, 294, 11–19. [Google Scholar] [CrossRef]

- Chen, H.; Rushworth, A.; Sun, W.; He, J.; Guo, H. Some considerations in using the small punch testing for thermally sprayed CoNiCrAlY coatings. Surf. Coatings Technol. 2019, 357, 684–690. [Google Scholar] [CrossRef]

- Chen, H.; Hyde, T.; Voisey, K.; McCartney, D.; Mc Cartney, G. Application of small punch creep testing to a thermally sprayed CoNiCrAlY bond coat. Mater. Sci. Eng. A 2013, 585, 205–213. [Google Scholar] [CrossRef]

- Jackson, G.; Sun, W.; McCartney, D.G. The Application of the Small Punch Tensile Test to Evaluate the Ductile to Brittle Transition of a Thermally Sprayed CoNiCrAlY Coating. Key Eng. Mater. 2017, 734, 144–155. [Google Scholar] [CrossRef]

- Saunders, S.R.J.; Banks, J.P.; Wright, M. Measurement of Ductile Brittle Transition Temperature of Coatings Using the Small Punch Test; Report NPL MATC(A)60; National Physical Laboratory: Teddington, Middlesex, UK, 2001. [Google Scholar]

- Nambu, T.; Shimizu, K.; Matsumoto, Y.; Rong, R.; Watanabe, N.; Yukawa, H.; Morinaga, M.; Yasuda, I. Enhanced hydrogen embrittlement of Pd-coated niobium metal membrane detected by in situ small punch test under hydrogen permeation. J. Alloy. Compd. 2007, 446–447, 588–592. [Google Scholar] [CrossRef]

- Kameda, J.; Bloomer, T.; Sugita, Y.; Ito, A.; Sakurai, S. Mechanical properties of aluminized CoCrAlY coatings in advanced gas turbine blades. Mater. Sci. Eng. A 1997, 234–236, 489–492. [Google Scholar] [CrossRef]

- Kameda, J.; Bloomer, T.E.; Sakurai, S. Oxidation/Carbonization/Nitridation and In-Service Mechanical Property Degradation of CoCrAlY Coatings in Land-Based Gas Turbine Blades. J. Therm. Spray Technol. 1999, 8, 440–446. [Google Scholar] [CrossRef]

- Gallino, E.; Massey, S.; Tatoulian, M.; Mantovani, D. Plasma polymerized allylamine films deposited on 316L stainless steel for cardiovascular stent coatings. Surf. Coat. Technol. 2010, 205, 2461–2468. [Google Scholar] [CrossRef]

- Eskner, M. Mechanical Behaviour of Gas Turbine Coatings. Ph.D. Thesis, Department of Materials Science and Engineering Royal Institute of Technology, Stockholm, Sweden, 3 June 2004. Available online: http://kth.diva-portal.org/smash/get/diva2:9627/FULLTEXT01.pdf (accessed on 4 February 2021).

- Latreche, H.; Doublet, S.; Tegeder, G.; Wolf, G.; Masset, P.; Weber, T.; Schütze, M. Behaviour of NiAl APS-coatings in chlorine-containing atmospheres. Mater. Corros. 2008, 59, 573–583. [Google Scholar] [CrossRef]

- Abu-Warda, N.; López, A.; López, M.; Utrilla, M. High temperature corrosion and wear behavior of HVOF-sprayed coating of Al2O3-NiAl on AISI 304 stainless steel. Surf. Coatings Technol. 2019, 359, 35–46. [Google Scholar] [CrossRef]

- Metallic Materials–Small Punch Test Method; prEN 10371; European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Ju, J.-B.; Kwon, D. Assessment of fracture characteristics from revised small punch test using pre-cracked specimen. Met. Mater. 1998, 4, 742–746. [Google Scholar] [CrossRef]

- Arunkumar, S. Overview of Small Punch Test. Met. Mater. Int. 2019, 26, 719–738. [Google Scholar] [CrossRef]

- International Organization for Standardization. (1997)-Geometrical Product Specifications (GPS)—Surface texture: Profile method — Terms, definitions and surface texture parameters (ISO 4287:1997). Available online: https://www.iso.org/standard/10132.html (accessed on 2 February 2021).

- Azarmi, F.; Coyle, T.; Mostaghimi, J. Optimization of Atmospheric Plasma Spray Process Parameters using a Design of Experiment for Alloy 625 coatings. J. Therm. Spray Technol. 2008, 17, 144–155. [Google Scholar] [CrossRef]

- Mawdsley, J.R.; Su, Y.; Faber, K.; Bernecki, T.F. Optimization of small-particle plasma-sprayed alumina coatings using designed experiments. Mater. Sci. Eng. A 2001, 308, 189–199. [Google Scholar] [CrossRef]

- Ramachandran, C.S.; Balasubramanian, V.; Ananthapadmanabhan, P.V. Multiobjective Optimization of Atmospheric Plasma Spray Process Parameters to Deposit Yttria-Stabilized Zirconia Coatings Using Response Surface Methodology. J. Therm. Spray Technol. 2010, 20, 590–607. [Google Scholar] [CrossRef]

- Kanta, A.F.; Montavon, G.; Coddet, C. Predicting Spray Processing Parameters from Required Coating Structural Attributes by Artificial Intelligence. Adv. Eng. Mater. 2006, 8, 628–635. [Google Scholar] [CrossRef]

- Kanta, A.-F.; Montavon, G.; Planche, M.-P.; Coddet, C. Artificial neural networks implementation in plasma spray process: Prediction of power parameters and in-flight particle characteristics vs. desired coating structural attributes. Surf. Coatings Technol. 2009, 203, 3361–3369. [Google Scholar] [CrossRef]

- Turba, K.; Hurst, R.; Hähner, P. Evaluation of the ductile–brittle transition temperature in the NESC-I material using small punch testing. Int. J. Press. Vessel. Pip. 2013, 111–112, 155–161. [Google Scholar] [CrossRef]

| Combination # | Spraying Distance (mm) | Argon Flow Rate (slpm) | H2 Flow Rate (slpm) | Spraying Speed (mm/s) |

|---|---|---|---|---|

| 1 | 130 | 50 | 10 | 1000 |

| 2 | 150 | 50 | 10 | 1000 |

| 3 | 130 | 60 | 9 | 1000 |

| 4 | 150 | 60 | 9 | 1000 |

| 5 | 130 | 50 | 10 | 1400 |

| 6 | 150 | 50 | 10 | 1400 |

| 7 | 130 | 60 | 9 | 1400 |

| 8 | 150 | 60 | 9 | 1400 |

| 9 | 130 | 55 | 9.5 | 1200 |

| 10 | 150 | 55 | 9.5 | 1200 |

| 11 | 140 | 50 | 10 | 1200 |

| 12 | 140 | 60 | 9 | 1200 |

| 13 | 140 | 55 | 9.5 | 1000 |

| 14 | 140 | 55 | 9.5 | 1400 |

| 15 | 140 | 55 | 9.5 | 1200 |

| Run # | (N) | (N) | (mm) | Coating Thickness (µm) | Microhardness (0.3 HV) | (μm) | (μm) | (μm) | (μm) | (μm) | (μm) | (μm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 55.1 | 264.6 | 1.92 | 78 ± 23 | 142 ± 4 | 7.5 | 9.3 | 45.8 | 23.2 | 22.7 | 31.3 | 239.3 |

| 2 | 58.6 | 253.3 | 1.87 | 112 ± 12 | 385 ± 15 | 4.8 | 6.1 | 32.9 | 16.2 | 16.8 | 18.5 | 137.1 |

| 3 | 61.6 | 337.0 | 1.87 | 112 ± 19 | 169 ± 46 | 9.9 | 12.4 | 53.9 | 26.3 | 27.7 | 35.1 | 196.3 |

| 4 | 56.0 | 272.6 | 1.94 | 143 ± 24 | 142 ± 19 | 13.8 | 16.8 | 71.3 | 33.4 | 37.9 | 53.5 | 265.3 |

| 5 | 63.2 | 325.3 | 1.89 | 97 ± 25 | 162 ± 26 | 4.7 | 6.0 | 30.7 | 16.3 | 14.4 | 18.0 | 123.0 |

| 6 | 54.0 | 288.9 | 1.91 | 87 ± 28 | 159 ± 12 | 9.6 | 12.1 | 55.0 | 27.0 | 28.0 | 35.3 | 240.9 |

| 7 | 50.7 | 262.6 | 1.94 | 82 ± 29 | 167 ± 19 | 9.4 | 11.6 | 52.7 | 26.4 | 26.3 | 33.9 | 218.8 |

| 8 | 53.1 | 250.9 | 1.89 | 164 ± 35 | 152 ± 31 | 12.0 | 14.5 | 61.7 | 32.0 | 29.7 | 44.4 | 287.2 |

| 9 | 54.5 | 246.6 | 1.94 | 60 ± 25 | 95 ± 16 | 7.8 | 9.8 | 46.5 | 23.7 | 22.8 | 30.0 | 184.9 |

| 10 | 52.9 | 269.2 | 1.91 | 248 ± 22 | 202 ± 38 | 10.8 | 13.2 | 58.3 | 29.5 | 28.9 | 39.3 | 229.0 |

| 11 | 54.0 | 283.7 | 1.93 | 64 ± 9 | 164 ± 42 | 10.6 | 12.9 | 58.4 | 27.9 | 30.5 | 44.8 | 276.5 |

| 12 | 54.6 | 263.5 | 1.92 | 191 ± 55 | 162 ± 9 | 9.1 | 11.0 | 49.1 | 23.5 | 25.6 | 32.3 | 206.8 |

| 13 | 66.5 | 365.9 | 1.87 | 124 ± 40 | 138 ± 32 | 9.7 | 11.7 | 55.4 | 27.8 | 27.6 | 38.8 | 268.5 |

| 14 | 57.1 | 276.2 | 1.91 | 165 ± 31 | 193 ± 37 | 11.3 | 13.7 | 59.4 | 29.8 | 29.6 | 44.4 | 287.2 |

| 15 | 52.4 | 288.7 | 1.88 | 188 ± 58 | 150 ± 22 | 9.4 | 12.1 | 58.1 | 34.0 | 24.1 | 31.0 | 244.9 |

| (N) | 287.6 | −10.1 | −2.9 | −9.0 | −3.6 | 3.4 | −24.1 | −28.3 | −12.6 | 34.8 |

| (%) | 101.1 | −3.6 | −1.0 | −3.1 | −1.2 | 1.2 | −8.5 | −9.9 | −4.4 | 12.2 |

| β0 | β1 | β2 | β3 | β12 | β13 | β23 | β11 | β22 | β33 | |

|---|---|---|---|---|---|---|---|---|---|---|

| (μm) | 178.2 | 32.5 | 25.4 | 2.6 | 11.1 | 0.9 | −0.4 | −12.0 | −38.5 | −21.5 |

| (%) | 127.0 | 23.2 | 18.1 | 1.9 | 7.9 | 0.6 | −0.3 | −8.5 | −27.4 | −15.3 |

| β0 | β1 | β2 | β3 | β12 | β13 | β23 | β11 | β22 | β33 | |

|---|---|---|---|---|---|---|---|---|---|---|

| (HV) | 148.7 | 30.5 | −22.0 | −14.3 | −35.3 | −29.3 | 26.8 | 1.4 | 15.9 | 18.4 |

| (%) | 88.8 | 18.2 | −13.1 | −8.5 | −21.0 | −17.5 | 16.0 | 0.8 | 9.5 | 11.0 |

| β0 | β1 | β2 | β3 | β12 | β13 | β23 | β11 | β22 | β33 | |

|---|---|---|---|---|---|---|---|---|---|---|

| (µm) | 9.70 | 1.17 | 1.72 | 0.14 | 0.55 | 0.79 | −0.56 | −0.81 | −0.25 | 0.42 |

| (%) | 103.6 | 12.5 | 18.4 | 1.5 | 5.8 | 8.4 | −6.0 | −8.7 | −2.6 | 4.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lorenzo-Bañuelos, M.; Díaz, A.; Rodríguez, D.; Cuesta, I.I.; Fernández, A.; Alegre, J.M. Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate. Metals 2021, 11, 612. https://doi.org/10.3390/met11040612

Lorenzo-Bañuelos M, Díaz A, Rodríguez D, Cuesta II, Fernández A, Alegre JM. Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate. Metals. 2021; 11(4):612. https://doi.org/10.3390/met11040612

Chicago/Turabian StyleLorenzo-Bañuelos, Miriam, Andrés Díaz, David Rodríguez, Isidoro I. Cuesta, Adrian Fernández, and Jesus M. Alegre. 2021. "Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate" Metals 11, no. 4: 612. https://doi.org/10.3390/met11040612

APA StyleLorenzo-Bañuelos, M., Díaz, A., Rodríguez, D., Cuesta, I. I., Fernández, A., & Alegre, J. M. (2021). Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate. Metals, 11(4), 612. https://doi.org/10.3390/met11040612