Recent Progress of Low and Medium-Carbon Advanced Martensitic Steels

Abstract

:1. Introduction

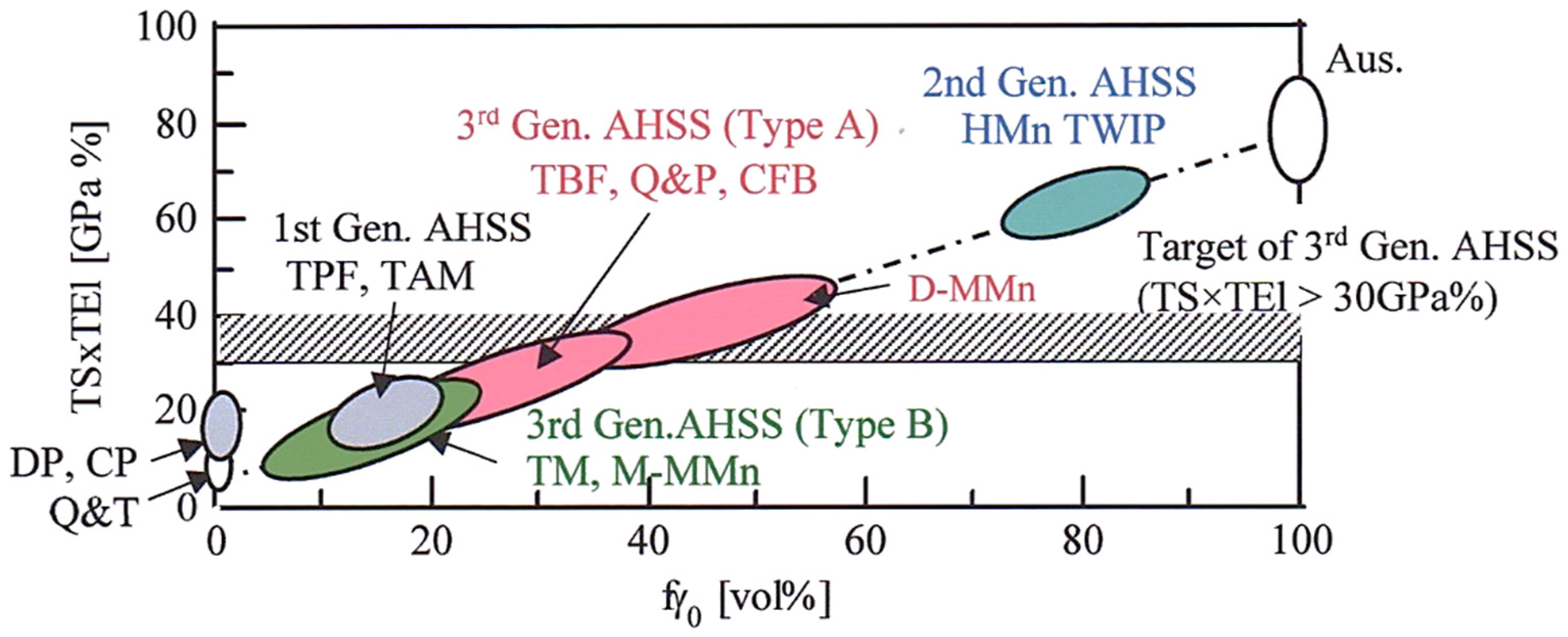

- (I).

- (II).

- (III).

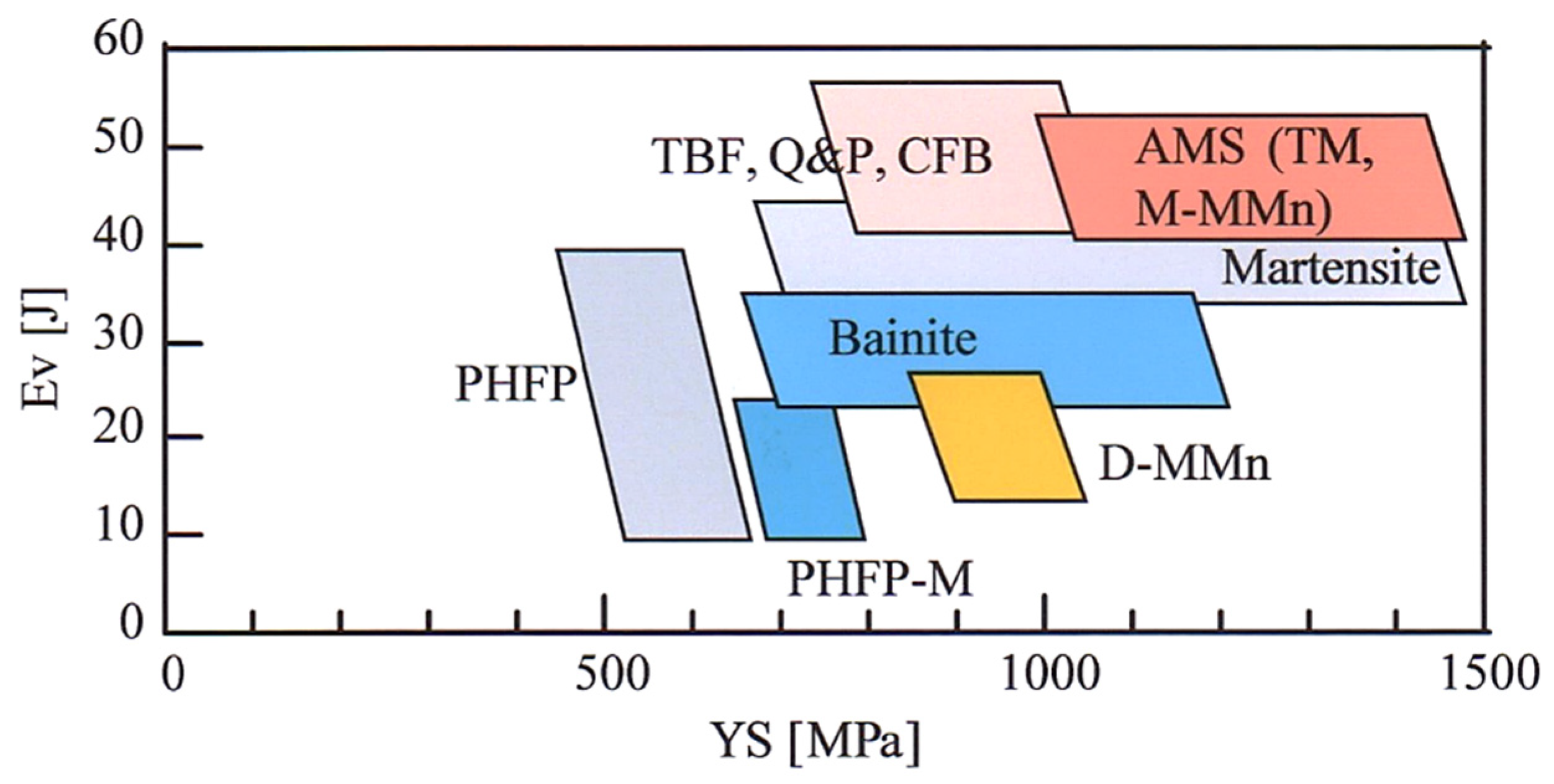

- Third-generation AHSS (Type A): TRIP-aided bainitic ferrite (TBF) steel [9,10,29,30,31,32,33], one-step and two-step quenched and partitioned (Q&P) steels [7,8,9,25,34,35,36,37,38,39,40,41], carbide-free bainitic (CFB) steel [42,43,44,45,46,47,48,49], and duplex type medium manganese (D-MMn) steel [9,25,50,51,52,53,54,55,56,57].

- (IV).

2. Two Kinds of Heat-Treatment Process for AMSs

3. Microstructure and Retained Austenite Characteristics of AMSs

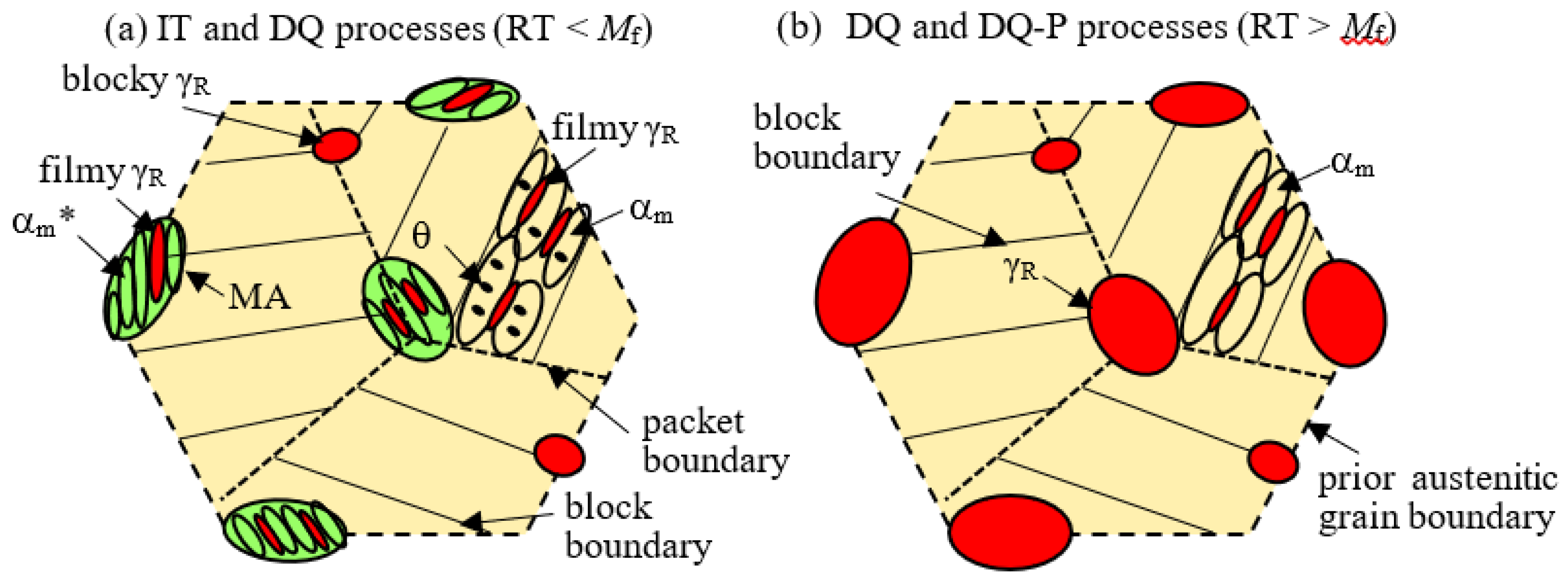

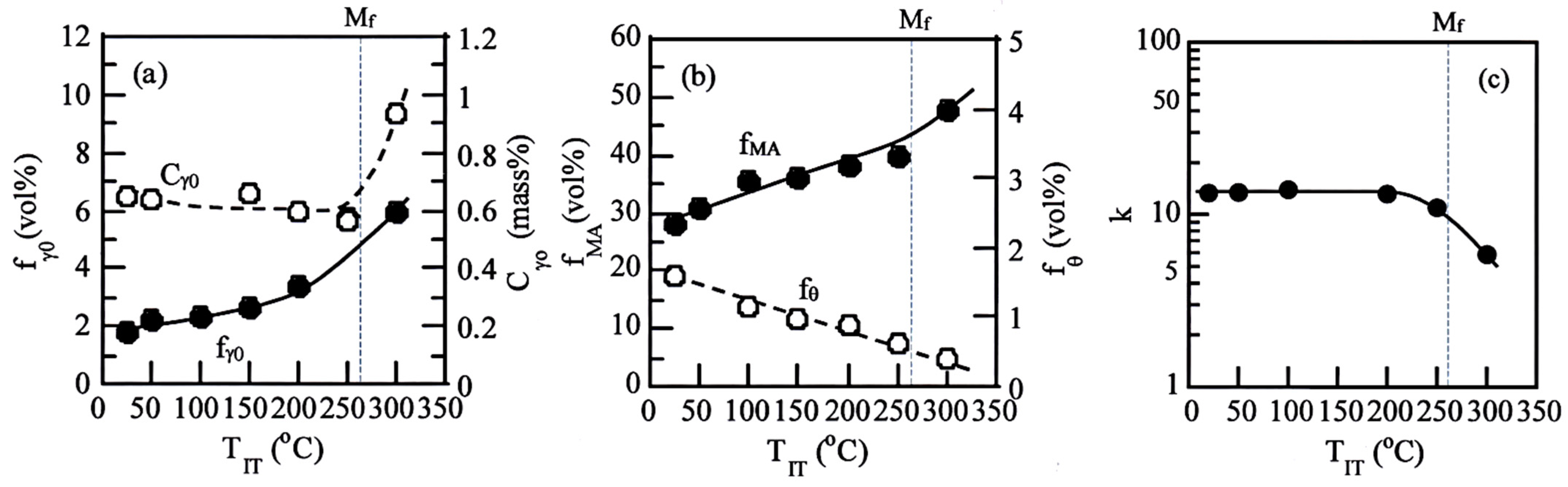

3.1. IT and DQ-P Processes (RT < Mf)

3.2. DQ and DQ-P Processes (RT > Mf)

3.3. Ausforming

4. Tensile Properties and Cold Formability of AMS Sheets

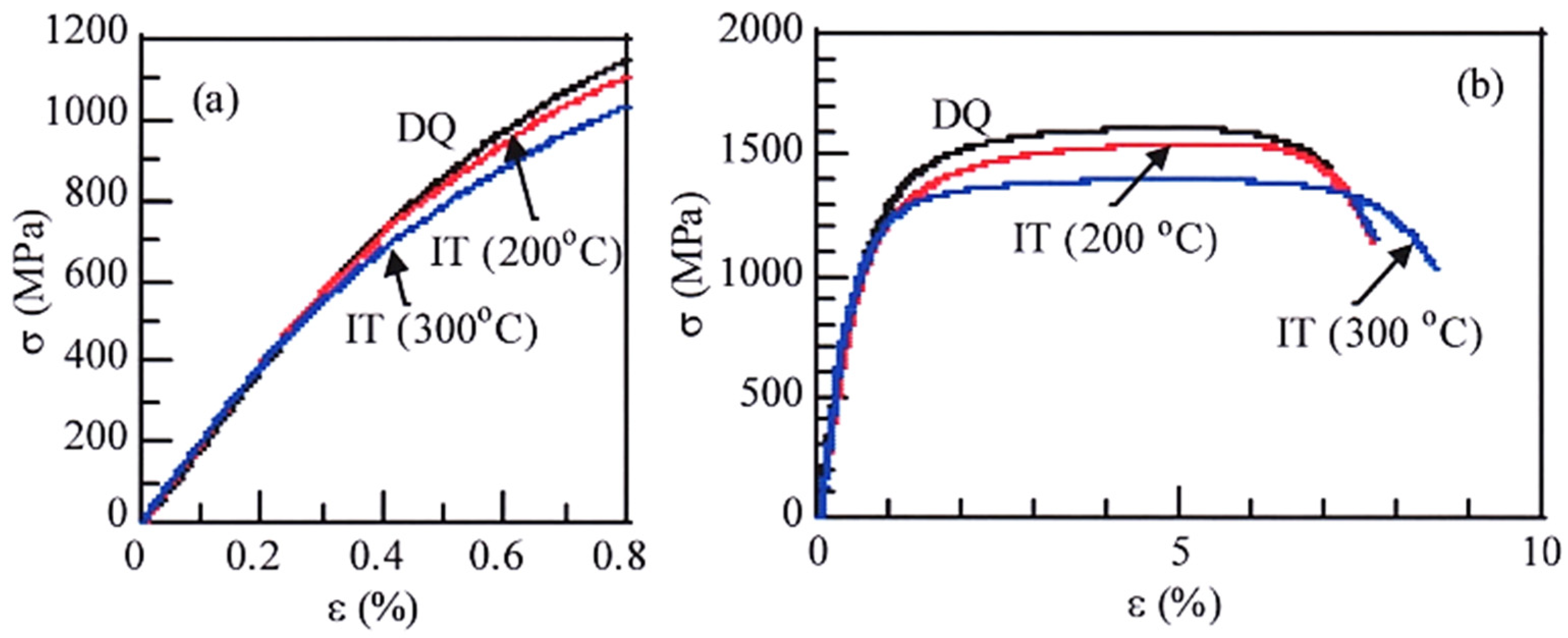

4.1. Tensile Properties

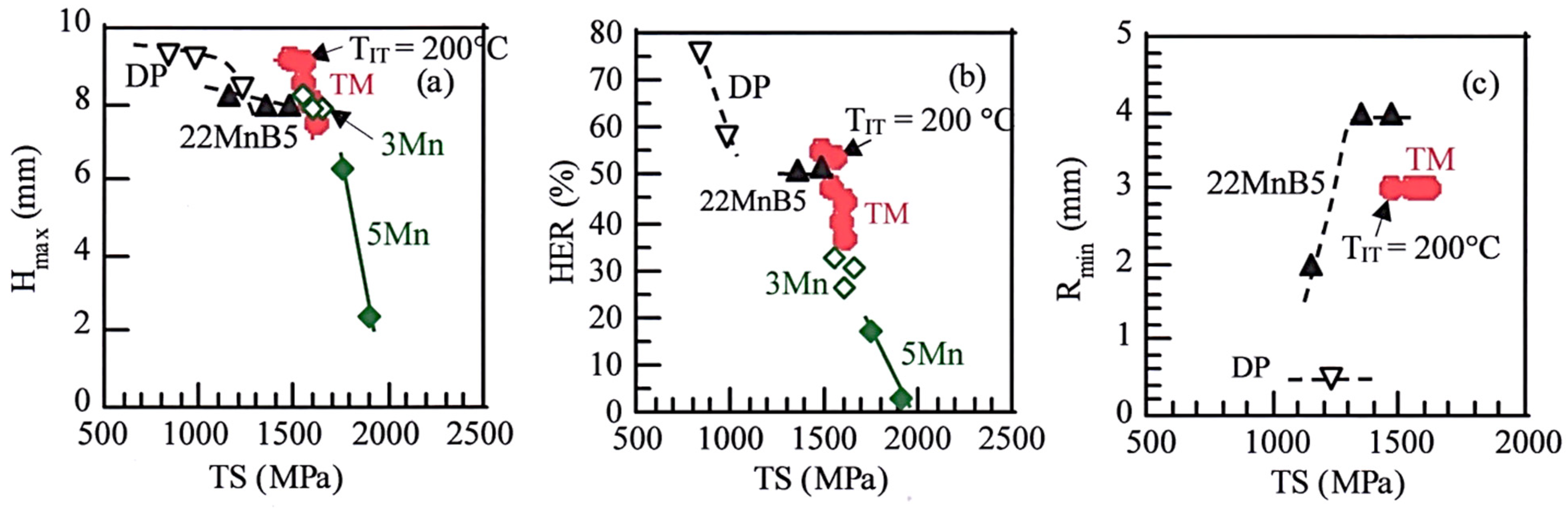

4.2. Formabilities

5. Mechanical Properties of Heat-Treated AMS Plates and Bars

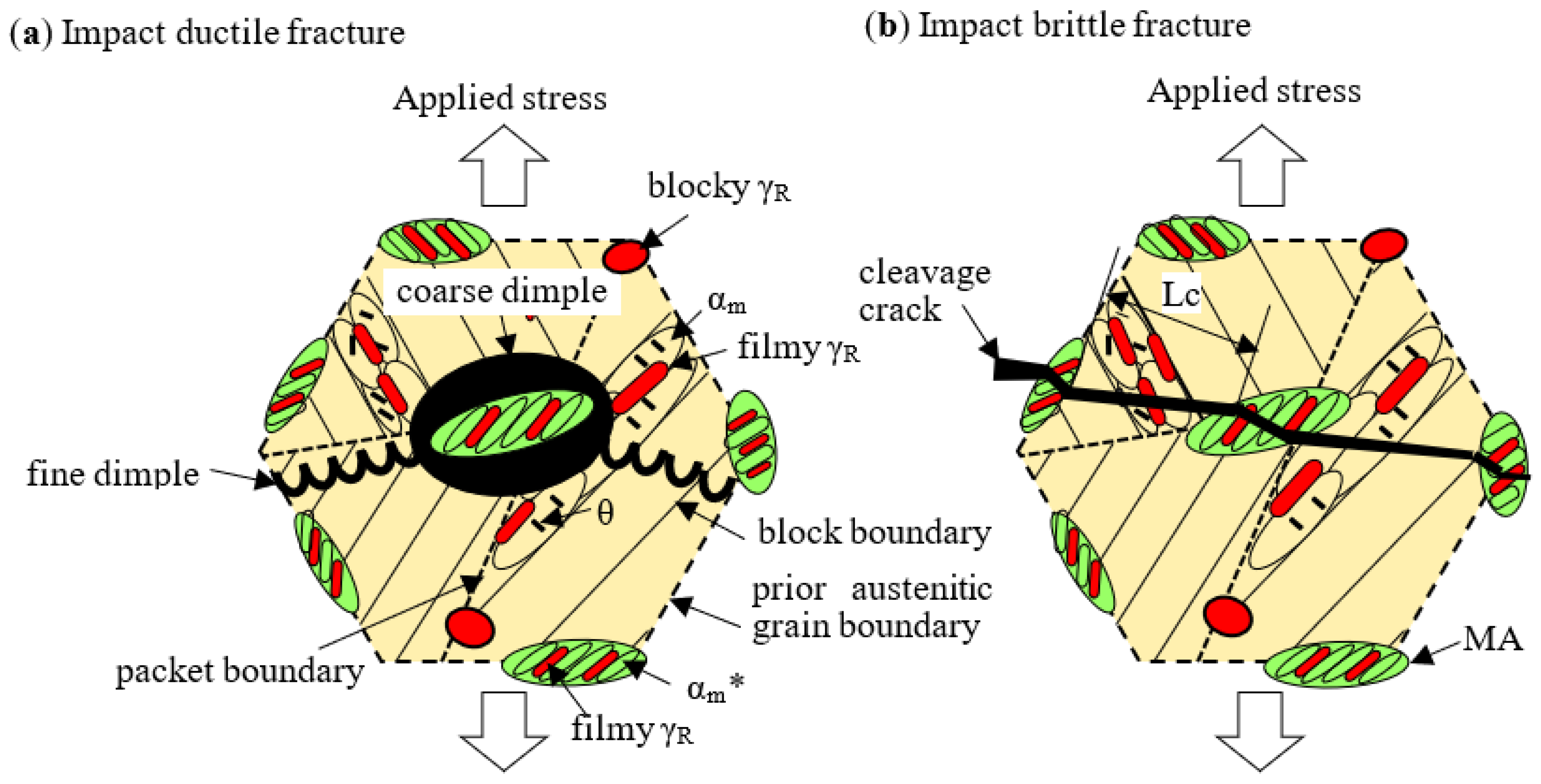

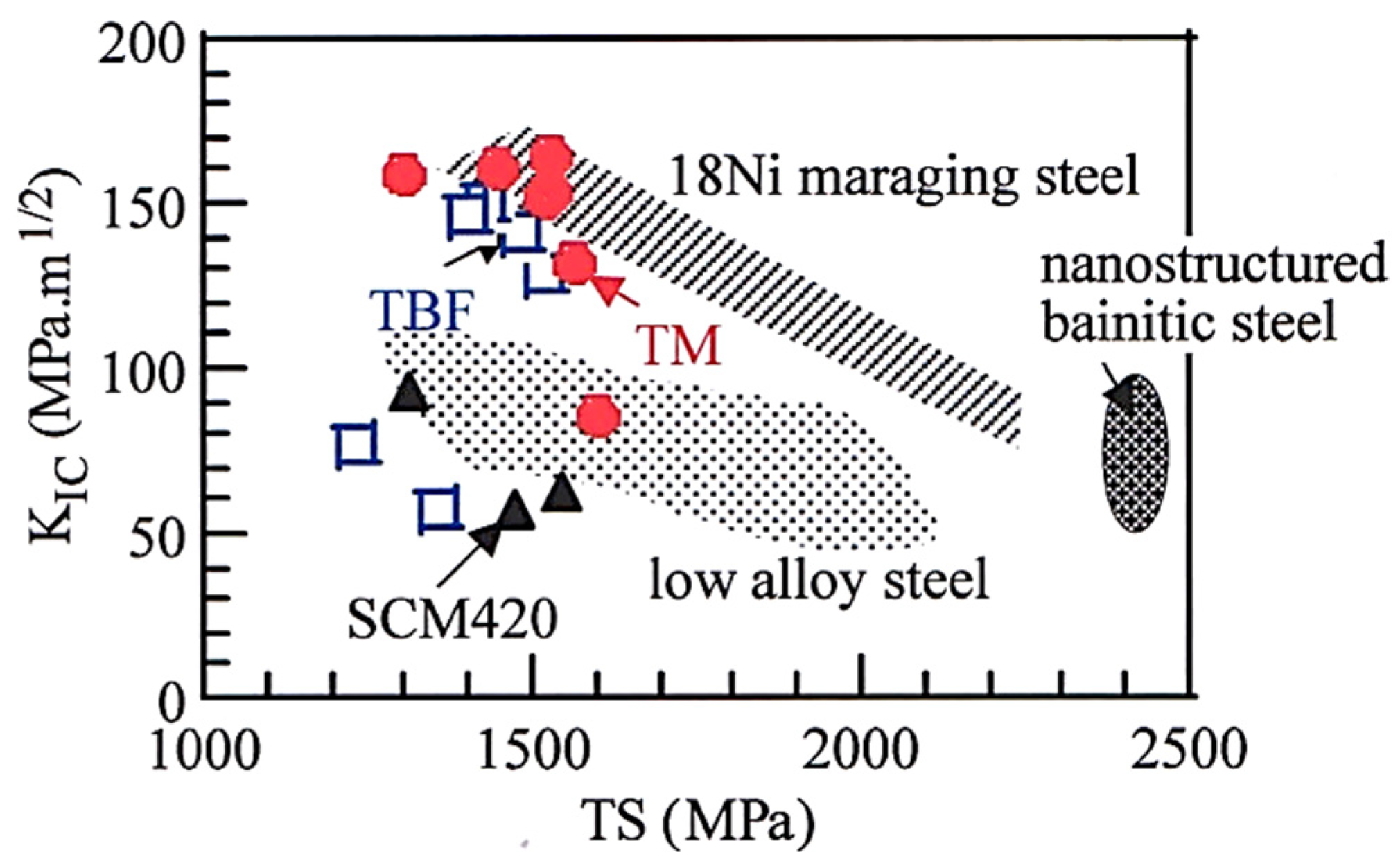

5.1. Impact Toughness and Fracture Toughness

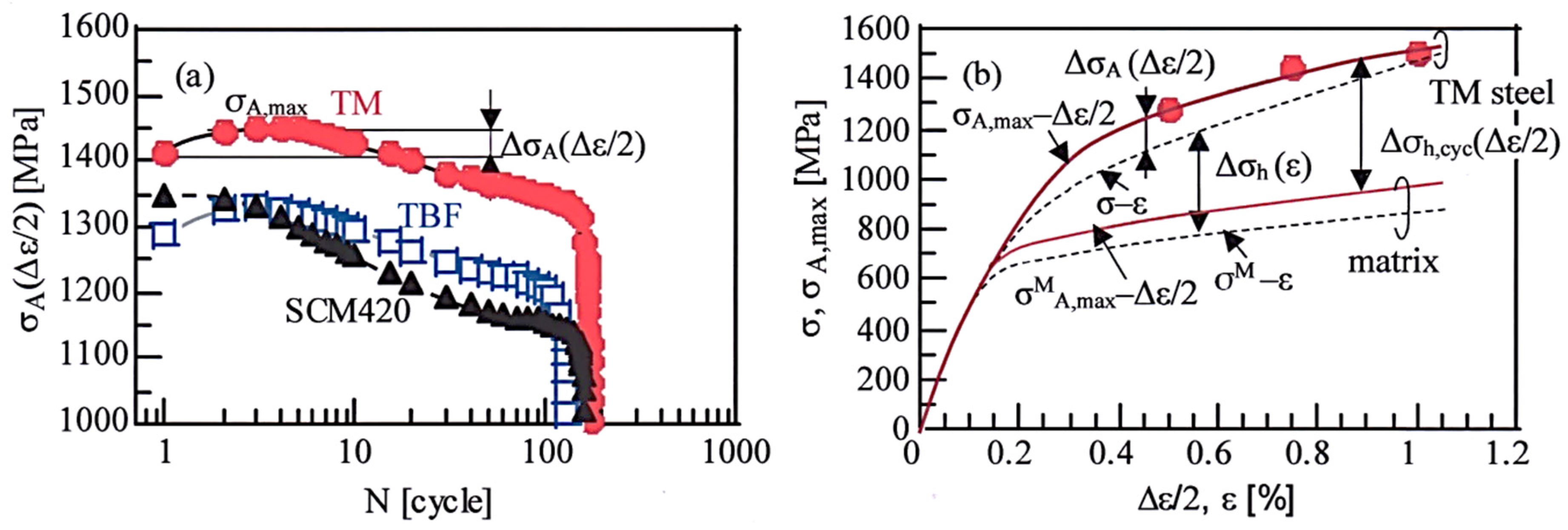

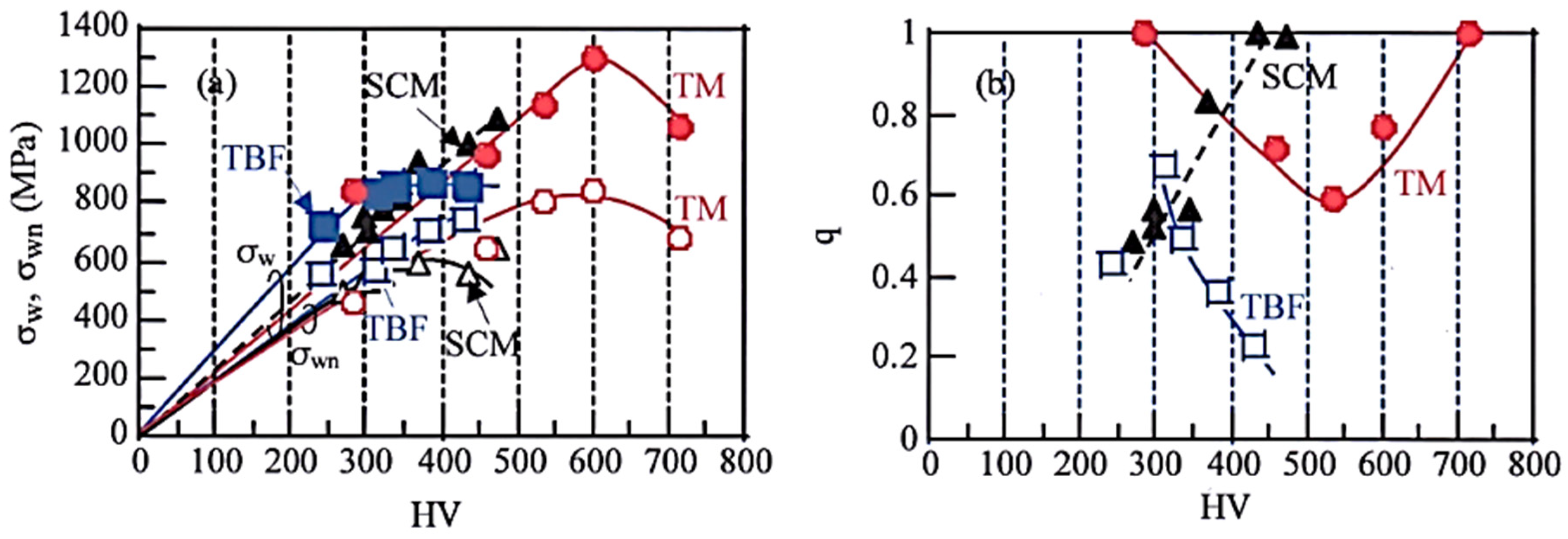

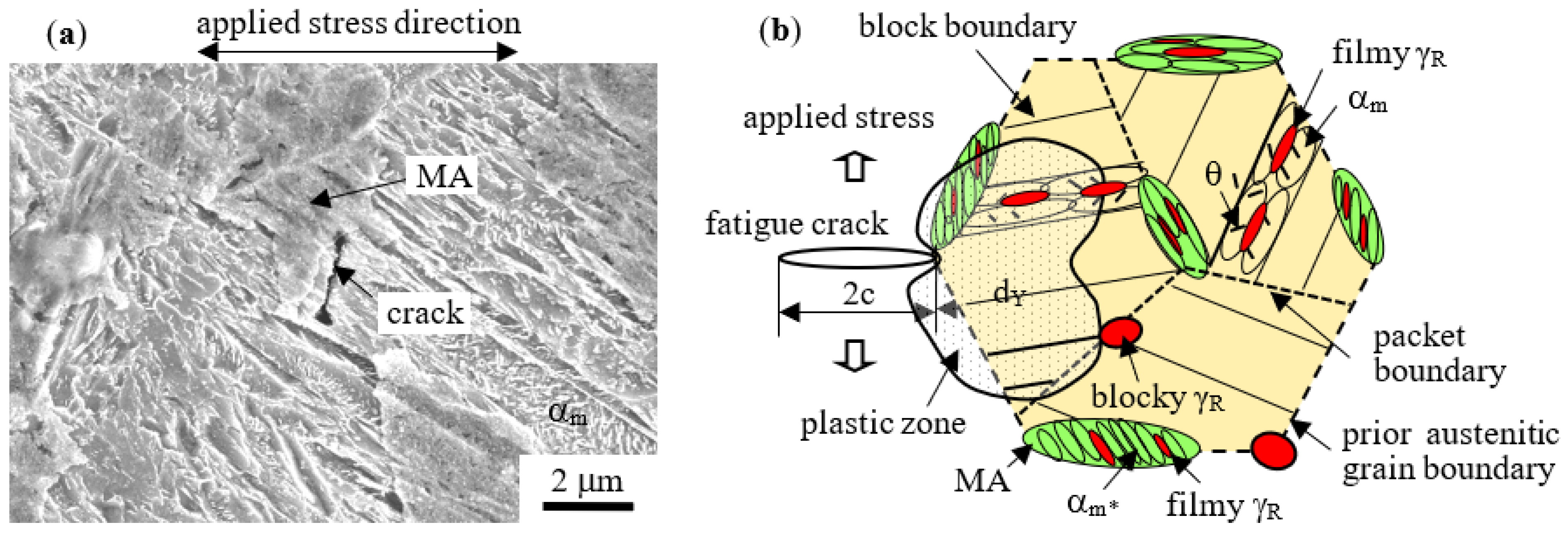

5.2. Fatigue Property

5.3. Delayed Fracture Strength

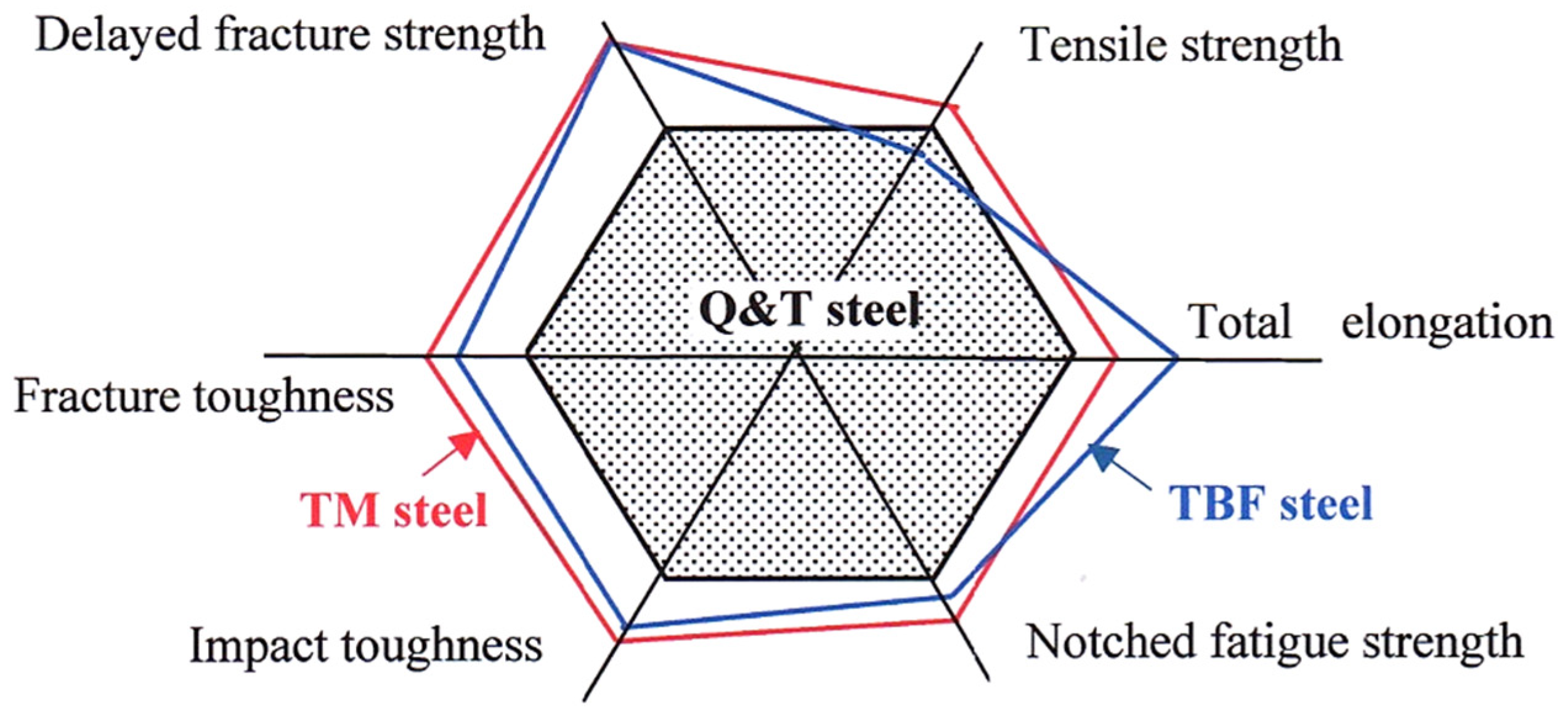

5.4. Wear Property and Overall Performance of Mechanical Properties

6. Hot- and Warm-Workings to Produce Automotive AMS Parts

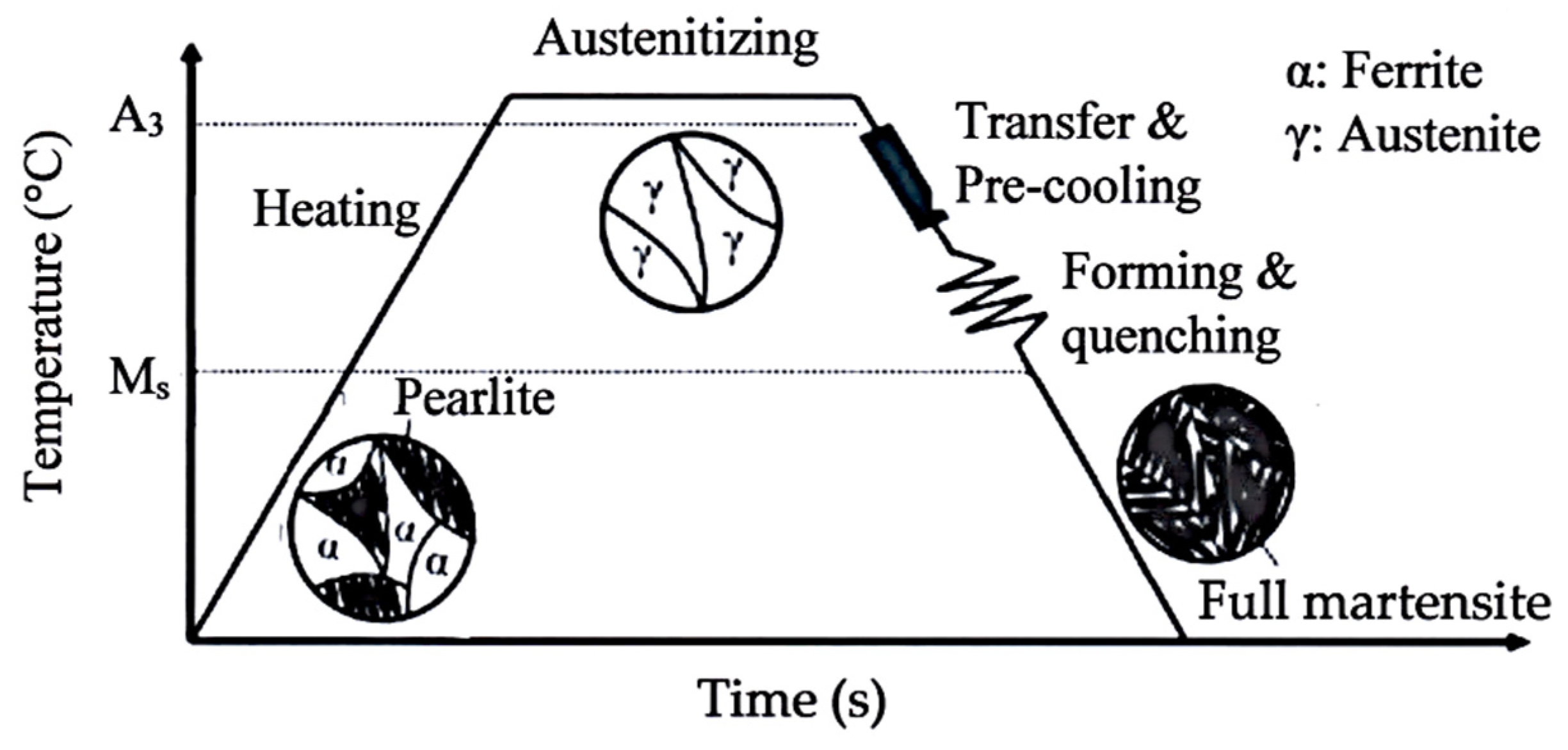

6.1. Hot- and Warm-Stamping

6.2. Hot- and Warm-Forging

7. Case Hardening of AMSs

8. Summary

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zackay, V.F.; Parker, E.R.; Fahr, D.; Bush, R. The enhancement of ductility in high-strength steels. Trans. Am. Soc. Met. 1967, 60, 252–259. [Google Scholar]

- Tamura, I.; Maki, T.; Hato, H. On the morphology of strain-induced martensite and the transformation-induced plasticity in Fe-Ni and Fe-Cr-Ni alloys. Trans. Iron Steel Inst. Jpn. 1970, 10, 163–172. [Google Scholar] [CrossRef] [Green Version]

- Matsumura, O.; Sakuma, Y.; Takechi, H. TRIP in its kinetic aspects in austempered 0.4C–1.5Si–0.8Mn steel. Scr. Met. 1987, 21, 1301–1306. [Google Scholar] [CrossRef]

- Itami, A.; Takahashi, M.; Ushioda, K. Plastic stability of retained austenite in the cold-rolled 0.14%C-1.9%Si-1.7%Mn sheet steel. ISIJ Int. 1995, 35, 1121–1127. [Google Scholar] [CrossRef]

- Hiwatashi, S.; Takahashi, M.; Katayama, T.; Usuda, M. Effect of deformation-induced transformation on deep drawability—Forming mechanism of TRIP type high-strength steel sheet. J. Jpn. Soc. Technol. Plast. 1994, 35, 1109–1114. [Google Scholar]

- Sugimoto, K.; Kobayashi, M.; Nagasaka, A.; Hashimoto, S. Warm stretch-formability of TRIP-aided dual-phase sheet steels. ISIJ Int. 1995, 35, 1407–1414. [Google Scholar] [CrossRef] [Green Version]

- Fonstein, N. Advanced High Strength Sheet Steels—Physical Metallurgy, Design, Processing and Properties; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Speer, J.G.; Edmonds, D.V.; Rizzo, F.C.; Matlock, D.K. Partitioning of carbon from supersaturated plates of ferrite with application to steel processing and fundamentals of the bainitic transformation. Curr. Opin. Solid State Mat. Sci. 2004, 8, 219–237. [Google Scholar] [CrossRef]

- Rana, R.; Singh, S.B. Automotive Steels—Design, Metallurgy, Processing and Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Hausmann, K.; Krizan, D.; Spiradek-Hahn, K.; Pichler, A.; Werner, E. The influence of Nb on transformation behavior and mechanical properties of TRIP-assisted bainitic–ferritic sheet steels. Mater. Sci. Eng. A 2013, 588, 142–150. [Google Scholar] [CrossRef]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L.W. High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development—Properties—Application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- Furukawa, T. Structure and mechanical properties of dual phase steel. J. Jpn. Inst. Met. Mater. 1980, 19, 439–446. [Google Scholar]

- Speich, G.R.; Demarest, V.A.; Miller, R.L. Formation of austenite during intercritical annealing of dual-phase steel. Metall. Trans. A 1981, 12A, 1419–1428. [Google Scholar] [CrossRef]

- Shirasawa, H.; Tanaka, Y.; Miyahara, M. Development of TS980 MPa-grade cold-rolled, high-strength steel sheet with high ductility. Kobelco Technol. Rev. 1987, 1, 13–17. [Google Scholar]

- Spenger, F.; Hebesberger, T.; Pichler, A.; Krempaszky, C.; Werner, E.A. AHSS steel grades: Strain hardening and damage as material design criteria. In Proceedings of the International Conference on New Developments in Advanced High Strength Sheet Steels, Orlando, FL, USA, 15–18 June 2008; pp. 39–49. [Google Scholar]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schmmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; et al. An overview of dual-phase steels: Advanced in microstructure-oriented micromechanically guided design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- De Cooman, B.C. Structure-properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 285–303. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Bhattacharjee, D.; Jha, G.; Gope, N.; Singh, S.S. Microstructural and mechanical characterization of C-Mn-Al-Si cold-rolled TRIP-aided steel. Mater. Sci. Eng. A 2007, 445–446, 549–557. [Google Scholar] [CrossRef]

- Tsuchida, N.; Okura, S.; Tanaka, T.; Toji, Y. High-speed tensile deformation behavior of 1 GPa-grade TRIP-aided multi-phase steels. ISIJ Int. 2018, 58, 978–986. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Kanda, A.; Kikuchi, R.; Hashimoto, S.; Kashima, T.; Ikeda, S. Ductility and formability of newly developed high strength low alloy TRIP-aided sheet steels with annealed martensite matrix. ISIJ Int. 2002, 42, 910–915. [Google Scholar] [CrossRef] [Green Version]

- Ding, R.; Tang, D.; Zhao, A. A novel design to enhance the amount of retained austenite and mechanical properties in low-alloyed steel. Scr. Mater. 2014, 88, 21–24. [Google Scholar] [CrossRef]

- Xie, Z.; Ren, Y.; Zhou, W.; Yang, J.; Shang, C.; Misra, R.D.K. Stability of retained austenite in multi-phase microstructure during austempering and its effect on the ductility of a low carbon steel. Mater. Sci. Eng. A 2014, 603, 69–75. [Google Scholar] [CrossRef]

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Jin, J.; Lee, Y. Effects of Al on microstructure and tensile properties of C-bearing high Mn TWIP steel. Acta Mater. 2012, 60, 1680–1688. [Google Scholar] [CrossRef]

- Bleck, W.; Guo, X.; Ma, Y. The TRIP effect and its application in cold formable sheet steels. Steel Res. Int. 2017, 88, 1700218. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Hamada, A.S.; Kisko, A.; Khosravifard, A.; Hassan, M.A.; Karjalainen, L.P.; Porter, D. Ductility and formability of three high-Mn TWIP steels in quasi-static and high-speed tensile and Erichsen tests. Mater. Sci. Eng. A 2018, 712, 255–265. [Google Scholar] [CrossRef]

- Hwang, J. Deformation behaviors of various Fe-Mn-C twinning-induced plasticity steels: Effect of stacking fault energy and chemical composition. J. Mater. Sci. 2020, 50, 1779–1795. [Google Scholar] [CrossRef]

- Sugimoto, K.; Sakaguchi, J.; Iida, T.; Kashima, T. Stretch-flangeability of a high-strength TRIP type bainitic steel. ISIJ Int. 2000, 40, 920–926. [Google Scholar] [CrossRef]

- Sugimoto, K.; Tsunezawa, M.; Hojo, T.; Ikeda, S. Ductility of 0.1-0.6C-1.5Si-1.5Mn ultra high-strength TRIP-aided sheet steels with bainitic ferrite matrix. ISIJ Int. 2004, 44, 1608–1614. [Google Scholar] [CrossRef]

- Sugimoto, K.; Murata, M.; Song, S. Formability of Al-Nb bearing ultrahigh-strength TRIP-aided sheet steels with bainitic ferrite and/or martensite matrix. ISIJ Int. 2010, 50, 162–168. [Google Scholar] [CrossRef]

- Kobayashi, J.; Song, S.; Sugimoto, K. Ultrahigh-strength TRIP-aided martensitic steels. ISIJ Int. 2012, 52, 1124–1129. [Google Scholar] [CrossRef] [Green Version]

- Weiβensteiner, I.; Suppan, C.; Hebesberger, T.; Winkelhofer, F.; Clemens, H.; Maier-Kiener, V. Effect of morphological differences on the cold formability of an isothermally heat-treated advanced high-strength steel. JOM 2018, 70, 1567–1575. [Google Scholar] [CrossRef] [Green Version]

- Speer, J.G.; De Moor, E.; Findley, K.O.; Matlock, B.C.; De Cooman, B.C.; Edmonds, D.V. Analysis of microstructure evolution in quenching and partitioning automotive sheet steel. Metall. Mater. Trans. A 2011, 42A, 3591–3601. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Cao, W.; Shi, J.; Wang, M.; Dong, H. Austenite/martensite structure and corresponding ultrahigh strength and high ductility of steels processed by Q&P techniques. Technol. Sci. 2012, 55, 1844–1851. [Google Scholar]

- Ghosh, S.; Miettunen, I.; Somani, M.C.; Komi, J.; Porter, D. Nanolath martensite-austenite structures engineered through DQ & P processing for developing tough, ultrahigh strength steels. Mater. Today Proc. 2021, 38. in press. [Google Scholar]

- Tan, X.; Xu, Y.; Yang, X.; Wu, D. Microstructure–properties relationship in a one-step quenched and partitioned steel. Mater. Sci. Eng. A 2014, 589, 101–111. [Google Scholar] [CrossRef]

- Kähkönen, J.; Pierce, D.T.; Speer, J.G.; De Moor, E.; Thomas, G.A.; Coughlin, D.; Clarke, K.; Clarke, A. Quenched and partitioned CMnSi steels containing 0.3 wt.% and 0.4 wt.% carbon. JOM 2016, 68, 210–214. [Google Scholar] [CrossRef]

- Fan, D.; Fonstein, N.; Jun, H. Effect of microstructure on tensile properties and cut-edge formability of DP, TRIP, Q & T and Q & P steels. AIST Trans. 2016, 13, 180–185. [Google Scholar]

- Seo, E.; Cho, L.; Estrin, Y.; De Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning (Q & P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar]

- Huyghe, P.; Dépinoy, S.; Caruso, M.; Mercier, D.; Georges, C.; Malet, L.; Godet, S. On the effect of Q & P processing on the stretch-flange-formability of 0.2C ultra-high strength steel sheets. ISIJ Int. 2018, 58, 1341–1350. [Google Scholar]

- Caballero, F.G.; Santofimia, M.J.; Garcia-Mateo, C.; Chao, J.; Garcia de Andrés, C. Theoretical design and advanced microstructure in super high strength steels. Mater. Des. 2009, 30, 2077–2083. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Xu, G.; Wang, X.; Embury, D.; Bouaziz, O.; Purdy, G.P.; Zurob, H.S. Mechanical behavior of carbide-free medium carbon bainitic steels. Metall. Mater. Trans. A 2014, 45A, 1352–1361. [Google Scholar] [CrossRef]

- Rana, R.; Chen, S.; Halder, A.; Das, S. Mechanical properties of a bainitic steel producible by hot rolling. Arch. Metall. Mater. 2017, 62, 2331–2338. [Google Scholar] [CrossRef] [Green Version]

- Das, S.; Sinha, S.; Lodh, A.; Chintha, A.R.; Krugla, M.; Haldar, A. Hot-rolled and continuously cooled bainitic steel with good strength-elongation combination. Mater. Sci. Technol. 2017, 33, 1026–1037. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Paul, G.; Somani, M.C.; Porter, D.A.; Bracke, L.; Latz, A.; De Andres, C.G.; Caballero, F.G. Transferring nanoscale bainite concept to lower contents: A prospective. Metals 2017, 7, 159. [Google Scholar] [CrossRef] [Green Version]

- Tian, J.; Xu, G.; Zhou, M.; Hu, H. Refined bainite microstructure and mechanical properties of a high-strength low-carbon bainitic steel. Steel Res. Int. 2018, 89, 1700469. [Google Scholar] [CrossRef]

- Navarro-López, A.; Hidalgo, J.; Sietsma, J.; Santofimia, M.J. Influence of the prior athermal martensite on the mechanical response of advanced bainitic steel. Mater. Sci. Eng. A 2018, 735, 343–353. [Google Scholar] [CrossRef]

- Chen, G.; Hu, H.; Xu, G.; Tian, J.; Wan, X.; Wang, X. Optimizing microstructure and property by ausforming in a medium-carbon bainitic steel. ISIJ Int. 2020, 60, 2007–2014. [Google Scholar] [CrossRef]

- Miller, R.I. Ultrafine-grained microstructures and mechanical properties of alloy steels. Metall. Trans. 1972, 3, 905–912. [Google Scholar] [CrossRef]

- Furukawa, T. Dependence of strength-ductility characteristics on thermal history in low carbon, 5 wt-%Mn steels. Mater. Sci. Technol. 1989, 5, 465–470. [Google Scholar] [CrossRef]

- Cao, W.; Wang, C.; Shi, J.; Wang, M.; Hui, W.; Dong, D. Microstructure and mechanical properties of Fe–0.2C–5Mn steel processed by ART-annealing. Mater. Sci. Eng. A 2011, 528, 6661–6666. [Google Scholar] [CrossRef]

- Torizuka, S.; Hanamura, T. Ultra fine heterogeneous microstructure obtained by 5% Mn steel which makes it possible to achieve 10000 GPa%J in the product of strength-ductility-toughness balance. Bull. Iron Steel Inst. Jpn. 2012, 17, 852–857. [Google Scholar]

- Hu, B.; He, B.; Cheng, G.; Yen, H.; Huang, M.; Luo, H. Super-high-strength and formable medium Mn steel manufactured by warm rolling process. Acta Mater. 2019, 174, 131–141. [Google Scholar] [CrossRef]

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Warm stretch-formability of 0.2%C-1.5%Si-(1.5–5.0)%Mn TRIP-aided steels. Arch. Mater. Sci. Eng. 2016, 80, 5–15. [Google Scholar] [CrossRef]

- Ma, Y. Medium-manganese steels processed by austenite-reverted-transformation annealing for automotive applications. Mater. Sci. Technol. 2017, 33, 1713–1727. [Google Scholar] [CrossRef]

- Cho, L.; Kong, Y.; Speer, J.G.; Findley, K.O. Hydrogen embrittlement of medium Mn steels. Metals 2021, 11, 358. [Google Scholar] [CrossRef]

- Wang, X.; Zhong, N.; Rong, Y.; Hsu, T. Novel ultrahigh strength nanolath martensitic steel by quenching-partitioning-tempering process. J. Mater. Res. 2009, 24, 260–267. [Google Scholar] [CrossRef]

- Sugimoto, K.; Kobayashi, J. Newly developed TRIP-aided martensitic steels. In Proceedings of the Materials Science and Technology and Exhibition 2010 (MS & T 10), Houston, TX, USA, 17–21 October 2010; pp. 1639–1649. [Google Scholar]

- Kobayashi, J.; Pham, D.V.; Sugimoto, K. Stretch-flangeability of 1.5GPa grade TRIP-aided martensitic cold rolled sheet steels. Steel Res. Int. Spec. Ed. ICTP 2011 2011, 598–603. [Google Scholar]

- Sugimoto, K.; Kobayashi, J.; Pham, D.V. Advanced ultrahigh-strength TRIP-aided martensitic sheet steels for automotive applications. In Proceedings of the New Developments in Advanced High Strength Sheet Steels (AIST 2013), Vail, CO, USA, 23–27 June 2013; pp. 175–184. [Google Scholar]

- Pham, D.V.; Kobayashi, J.; Sugimoto, K. Effects of microalloying on stretch-flangeability of TRIP-aided martensitic sheet steel. ISIJ Int. 2014, 54, 1943–1951. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Srivastava, A.K. Microstructure and mechanical properties of a TRIP-aided martensitic steel. Metallogr. Microstruct. Anal. 2015, 4, 344–354. [Google Scholar] [CrossRef] [Green Version]

- Hanamura, T.; Torizuka, S.; Tamura, S.; Enokida, S.; Takechi, H. Effect of austenite grain size on transformation behavior, microstructure and mechanical properties of 0.1C-5Mn martensitic steel. ISIJ Int. 2013, 53, 2218–2225. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Impact toughness of medium-Mn transformation-induced plasticity-aided steels. Steel Res. Int. 2015, 86, 1151–1160. [Google Scholar] [CrossRef]

- Sugimoto, K.; Tanino, H. Cold formability of martensite type medium Mn steels. Unpublished work.

- He, B.; Liu, L.; Huang, M.X. Room-temperature quenching and partitioning steel. Metall. Mater. Trans. A 2018, 49, 3167–3172. [Google Scholar] [CrossRef]

- He, B.; Wang, M.; Huang, M.X. Improving tensile properties of room-temperature quenching and partitioning steel by dislocation engineering. Metall. Mater. Trans. A 2019, 50A, 4021–4026. [Google Scholar] [CrossRef]

- Du, P.; Chen, P.; Misra, D.K.; Wu, D.; Yi, H. Transformation-induced ductility of reverse austenite evolved by low-temperature tempering of martensite. Metals 2020, 10, 1343. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, H.; Tan, Z.; Liu, W.; Bai, B. A carbide-free bainite/martensite/austenite triplex steel with enhanced mechanical properties treated by a novel quenching–partitioning–tempering process. Mater. Sci. Eng. A 2013, 559, 165–169. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, H.; Gui, X.; Luo, P.; Tan, Z.; Bai, B. Enhanced ductility and toughness in an ultrahigh-strength Mn-Si-Cr-C steel: The great potential of ultrafine filmy retained austenite. Acta Mater. 2014, 76, 425–433. [Google Scholar] [CrossRef]

- Gao, G.; An, B.; Zhang, H.; Guo, H.; Gui, X.; Bai, B. Concurrent enhancement of ductility and toughness in an ultrahigh strength lean alloy steel treated by bainite-based quenching-partitioning-tempering process. Mater. Sci. Eng. A 2017, 702, 104–122. [Google Scholar] [CrossRef]

- Somani, M.C.; Porter, D.A.; Karjalainen, L.P.; Suikkanen, P.P.; Misra, R.D.K. Process design for tough ductile martensitic steels through direct quenching and partitioning. Mater. Today Proc. 2015, 2S, S631–S634. [Google Scholar] [CrossRef]

- Kobayashi, J.; Ina, D.; Nakajima, Y.; Sugimoto, K. Effects of microalloying on the impact toughness of ultrahigh-strength TRIP-aided martensitic steel. Metall. Mater. Trans. A 2013, 44A, 5006–5017. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, J.; Yoshikawa, N.; Sugimoto, K. Notch-fatigue strength of advanced TRIP-aided martensitic steels. ISIJ Int. 2013, 53, 1479–1486. [Google Scholar] [CrossRef] [Green Version]

- Hojo, T.; Kobayashi, J.; Sugimoto, K.; Nagasaka, A.; Akiyama, E. Effects of alloying elements addition on delayed fracture properties of ultra high-strength TRIP-aided martensitic steels. Metals 2020, 10, 6. [Google Scholar] [CrossRef] [Green Version]

- Gramlich, A.; Emmrich, R.; Bleck, W. Annealing of 4 wt.-% manganese steels for automotive forging application. In Proceedings of the 4th International Conference on Medium and High Mn Steels, Aachen, Germany, 31 March–3 April 2019; pp. 283–286. [Google Scholar]

- Gramlich, A.; Emmrich, R.; Bleck, W. Austenite reversion tempering-annealing of 4 wt.% manganese steels for automotive forging application. Metals 2019, 9, 575. [Google Scholar] [CrossRef] [Green Version]

- Gramlich, A.; Schäfers, H.; Krupp, U. Influence of alloying elements on the dynamic recrystallization of 4 wt.–% medium manganese steels. Materials 2020, 13, 5178. [Google Scholar] [CrossRef] [PubMed]

- Gramlich, A.; Middleton, A.; Schmidt, R.; Krupp, U. On the influence of vanadium on air-hardening medium manganese steels for sustainable forging products. Steel Res. Int. 2021, 2000592. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Zheng, C.; Zhang, F.; Wang, T. Austenite deformation behavior and the effect of ausforming process on martensite starting temperature and ausformed martensite microstructure in medium-carbon Si-Al-rich alloy steel. Mater. Sci. Eng. A 2014, 596, 9–14. [Google Scholar] [CrossRef]

- Hojo, T.; Kobayashi, J.; Kochi, T.; Sugimoto, K. Effects of thermomechanical processing on microstructure and shear properties of 22SiMnCrMoB TRIP-aided martensitic steel. Iron Steel Technol. 2015, 12, 102–110. [Google Scholar]

- Hojo, T.; Kochi, T.; Sugimoto, K. Effects of warm working on microstructural and shear deformation properties of TRIP-aided martensitic steel. Mater. Sci. Forum 2016, 879, 2312–2317. [Google Scholar] [CrossRef]

- Sugimoto, K.; Itoh, M.; Hojo, T.; Hashimoto, S.; Ikeda, S.; Arai, G. Microstructure and mechanical properties of ausformed ultrahigh-strength TRIP-aided steels. Mater. Sci. Forum 2007, 539–543, 4309–4314. [Google Scholar] [CrossRef]

- Zhao, L.; Qian, L.; Zhou, Q.; Li, D.; Wang, T.; Jia, Z.; Zhang, F.; Meng, J. The combining effects of ausforming and below-Ms or above-Ms austempering on the transformation kinetics, microstructure and mechanical properties of low-carbon bainitic steel. Mater. Des. 2019, 183, 108123. [Google Scholar] [CrossRef]

- Koistinen, D.P.; Marburger, R.E. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Deng, B.; Yang, D.; Wang, G.; Hou, Z.; Yi, H. Effects of austenitizing temperature on tensile and impact properties of a martensitic stainless steel containing metastable retained austenite. Materials 2021, 14, 1000. [Google Scholar] [CrossRef] [PubMed]

- Sakaki, T.; Sugimoto, K.; Fukuzato, T. Role of internal stress for continuous yielding of dual-phase steels. Acta Metall. 1983, 31, 1737–1746. [Google Scholar] [CrossRef]

- Kobayashi, J.; Tonegawa, H.; Sugimoto, K. Cold formability of 22SiMnCrB TRIP-aided martensitic sheet steel. Proc. Eng. 2014, 81, 1336–1341. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Hojo, T.; Srivastava, A.K. An overview of fatigue strength of case-hardening TRIP-aided martensitic steels. Metals 2018, 8, 355. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, J.; Ina, D.; Sugimoto, K. Fracture toughness of a 1.5 GPa grade C-Si-Mn-Cr-Nb TRIP-aided martensitic steel. In Proceedings of the MS & T 2012, TMS, Pittsburgh, PA, USA, 7–11 October 2012; pp. 937–944. [Google Scholar]

- Kobayashi, J.; Ina, D.; Futamura, A.; Sugimoto, K. Fracture toughness of an Advanced ultrahigh-strength TRIP-aided steel. ISIJ Int. 2014, 54, 955–962. [Google Scholar] [CrossRef] [Green Version]

- Wu, R.; Li, W.; Zhou, S.; Zhoung, Y.; Wang, L.; Jin, X. Effect of retained austenite on the fracture toughness of quenching and partitioning (Q & P)-treated sheet steels. Metall. Mater. Trans. A 2014, 45A, 1892–1902. [Google Scholar]

- Bhadeshia, H.K.D.H. Some phase transformations in steels. Mater. Sci. Technol. 1999, 15, 22–29. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T. Fatigue hardening behavior of 1.5 GPa grade transformation-induced plasticity-aided martensitic steel. Metall. Mater. Trans. A 2016, 47A, 5272–5278. [Google Scholar] [CrossRef]

- Sugimoto, K.; Kobayashi, M.; Inoue, K.; Masuda, Y. Fatigue-hardening Behavior of TRIP-aided Bainitic Steels. Tetsu Hagane 1999, 85, 856–862. [Google Scholar] [CrossRef] [Green Version]

- Feng, X.; Zhang, F.; Kang, J.; Yang, Z.; Long, X. Sliding wear and low cycle fatigue properties of new carbide free bainitic rail steel. Mater. Sci. Technol. 2014, 30, 1410–1418. [Google Scholar] [CrossRef]

- Glage, A.; Weidner, A.; Biermann, H. Effect of austenite stability on the low cycle fatigue behavior and microstructure of high alloyed metastable austenitic cast TRIP-steels. Proc. Eng. 2010, 2, 2085–2094. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Kobayashi, M.; Yasuki, S. Cyclic deformation behavior of a transformation-induced plasticity–aided dual-phase steel. Metall. Mater. Tran. A 1997, 28A, 2637–2643. [Google Scholar] [CrossRef]

- Yoshikawa, N.; Kobayashi, J.; Sugimoto, K. Notch-fatigue properties of advanced TRIP-aided bainitic ferrite steels. Metall. Mater. Trans. A 2012, 43A, 4129–4136. [Google Scholar] [CrossRef] [Green Version]

- Dieter, G.E. Mechanical Metallurgy; SI Metric Edition; McGraw-Hill Book Company: London, UK, 1988; p. 403. [Google Scholar]

- Knott, J.F. Fundamentals of Fracture Mechanics; Butterworth Group: Baifukan, Tokyo, 1977; p. 127. [Google Scholar]

- Tomita, Y.; Kijima, F.; Morioka, K. Modified austempering effect on bending fatigue properties of Fe-0.6C-1.5Si-0.8Mn steel. Zeitschrift Metallkunde 2000, 91, 43–46. [Google Scholar]

- Huo, C.; Gao, H. Strain-induced martensitic transformation in fatigue crack tip zone for a high strength steel. Mater. Charact. 2005, 55, 12–18. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; Gao, G.; Hui, W.; Misra, R.D.K.; Bai, B.; Weng, Y. The potential significance of microalloying with niobium in governing very high cycle fatigue behavior of bainite/martensite multiphase steels. Mater. Sci. Eng. A 2016, 650, 438–444. [Google Scholar] [CrossRef]

- Hojo, T.; Sugimoto, K.; Mukai, Y.; Akamizu, H.; Ikeda, S. Hydrogen embrittlement properties of ultra high-strength low alloy TRIP-aided steels with bainitic ferrite matrix. Tetsu Hagane 2006, 92, 83–89. [Google Scholar] [CrossRef] [Green Version]

- Hojo, T.; Sugimoto, K.; Mukai, Y.; Ikeda, S. Delayed fracture properties of aluminum bearing ultrahigh strength low alloy TRIP-aided steels. ISIJ Int. 2008, 48, 824–829. [Google Scholar] [CrossRef] [Green Version]

- Hojo, T.; Kobayashi, J.; Sugimoto, K. Hydrogen embrittlement resistances of alloying elements adding ultra high strength low alloy TRIP-aided steels. In Proceedings of the MS & T 2012, TMS, Pittsburgh, PA, USA, 7–11 October 2012; pp. 1186–1193. [Google Scholar]

- Zhu, X.; Li, W.; Zhao, H.; Wang, L.; Jin, X. Hydrogen trapping sites and hydrogen-induced cracking in high strength quenching & partitioning (Q & P) treated steel. Int. J. Hydrog. Energy 2014, 39, 3031–3040. [Google Scholar]

- Hojo, T.; Kumai, B.; Koyama, M.; Akiyama, E.; Waki, H.; Saito, H.; Shiro, H.; Yasuda, R.; Shobu, T.; Nagasaka, A. Hydrogen embrittlement resistance of pre-strained ultra-high-strength low alloy TRIP-aided steel. Int. J. Fract. 2020, 224, 253–260. [Google Scholar] [CrossRef]

- Han, J.; Nam, J.; Lee, Y. The mechanism of hydrogen embrittlement in intercritically annealed medium Mn TRIP steel. Acta Mater. 2016, 113, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.; Hui, W.; Zhao, X.; Wang, C.; Cao, W.; Dong, H. Effect of reverted austenite fraction on hydrogen embrittlement of TRIP-aided medium Mn steel. Eng. Fail. Anal. 2019, 97, 605–616. [Google Scholar] [CrossRef]

- De Oliveira, P.G.B.; Aureliano, R.T.J.; Casteletti, L.C.; Filho, A.I.; Neto, A.L.; Totten, G.E. Adhesive wear resistance of low temperature austempered and quenched and partitioned niobium alloyed steels. In Proceedings of the 30th ASM Heat Treating Society Conference, Detroit, MI, USA, 15–17 October 2019; pp. 193–199. [Google Scholar]

- Wang, K.; Tan, Z.; Gu, K.; Gao, B.; Gao, G.; Misra, R.D.K.; Bai, B. Effect of deep cryogenic treatment on structure-property relationship in an ultrahigh strength Mn-Si-Cr bainite/martensite multiphase rail steel. Mater. Sci. Eng. A 2017, 684, 559–566. [Google Scholar] [CrossRef]

- Haiko, O.; Miettunen, I.; Porter, D.; Ojala, N.; Ratia, V.; Heino, V.; Kemppainen, A. Effect of finish rolling and quench stop temperatures on impact-abrasive wear resistance of 0.35 % carbon direct-quenched steel. Tribol. Fin. J. Tribol. 2017, 35, 5–21. [Google Scholar]

- Sugimoto, K. Fracture strength and toughness of ultrahigh strength TRIP aided steels. Mater. Sci. Technol. 2009, 25, 1108–1117. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Hojo, T.; Srivastava, A.K. Low and medium carbon advanced high-strength forging steels for automotive applications. Metals 2019, 9, 1263. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, J.; Sugimoto, K.; Arai, G. Effects of hot forging process on combination of strength and toughness in ultrahigh-strength TRIP-aided martensitic steels. Adv. Mater. Res. 2012, 409, 696–701. [Google Scholar] [CrossRef]

- Kobayashi, J.; Nakajima, Y.; Sugimoto, K. Effects of cooling rate on impact toughness of an ultrahigh-strength TRIP-aided martensitic steel. Adv. Mater. Res. 2014, 922, 366–371. [Google Scholar] [CrossRef]

- Senuma, T.; Takemoto, Y. Formability and productivity improving technology of hot stamping. Tetsu Hagane 2014, 100, 1481–1489. [Google Scholar] [CrossRef] [Green Version]

- Maeno, T.; Mori, K.; Fujimoto, M. Improvements in productivity and formability by water and die quenching in hot stamping of ultra-high strength steel parts. CIRP Ann. 2015, 64, 281–284. [Google Scholar] [CrossRef]

- Tong, C.; Rong, Q.; Yarley, V.; Li, X.; Luo, J.; Zhu, G.; Shi, Z. New developments and future trends in low-temperature hot stamping technologies: A review. Metals 2020, 10, 1652. [Google Scholar] [CrossRef]

- Mori, K.; Maki, S.; Tanaka, Y. Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating. CIRP Ann. 2005, 54, 209–212. [Google Scholar] [CrossRef]

- Pan, H.; Cai, M.; Ding, H.; Huang, H.; Zhu, B.; Wang, Y.; Zhang, Y. Microstructure evolution and enhanced performance of a novel Nb-Mo microalloyed medium Mn alloy fabricated by low-temperature rolling and warm stamping. Mater. Des. 2017, 134, 352–360. [Google Scholar] [CrossRef]

- Chang, Y.; Wang, C.; Zhao, K.; Dong, H.; Yan, J. An introduction to medium-Mn steel: Metallurgy, mechanical properties and warm stamping process. Mater. Des. 2016, 94, 424–432. [Google Scholar] [CrossRef]

- Zhu, B.; Zhu, J.; Wang, Y.; Rolfe, B.; Wang, Z.; Zhang, Y. Combined hot stamping and Q & P processing with a hot air partitioning device. J. Mater. Process. Technol. 2018, 262, 392–402. [Google Scholar]

- Mohrbacher, H. Martensitic automotive steel sheet—Fundamentals and Metallurgical optimization strategies. Adv. Mater. Res. 2015, 1063, 130–142. [Google Scholar] [CrossRef]

- Yoshida, H.; Isogawa, S.; Ishikawa, T. Basic properties of ferrite-pearlitic microalloyed steel—Development of microalloyed steel for controlled forging. J. Jpn. Soc. Technol. Plast. 2001, 41, 569–573. [Google Scholar]

- Clarke, P.; Green, M.; Dolman, R. Development of high strength microalloyed steel for powertrain applications. In Proceedings of the 4th International Conference on Steels for Cars and Trucks (SCT2014), Braunschweig, Germany, 15–19 June 2014; pp. 442–449. [Google Scholar]

- Bleck, W.; Prahl, U.; Hirt, G.; Bambach, M. Designing new forging steels by ICMPE. In Advances in Production Technology; Chapter 7; Brecher, C., Ed.; Springer: Cham, Switzerland; Heidelberg, Germany, 2015; pp. 85–98. [Google Scholar]

- Maminska, K.; Roth, A.; d’Eramo, E.; Marchal, F.; Galtier, A.; Sourmail, T. A new bainitic forging steel for surface induction hardened components. In Proceedings of the 5th International Conference on Steels for Cars and Trucks (SCT2017), Amsterdam, The Netherland, 18–22 June 2017; p. 228. [Google Scholar]

- Yoshida, H.; Isogawa, S.; Ishikawa, T. Basic property of martensitic microalloyed steel—Development of microalloyed steel for forging using ausforming. J. Jpn. Soc. Technol. Plast. 2000, 41, 379–383. [Google Scholar]

- Riedner, S.; Van Soest, F.; Kunow, S. B-alloyed quench and temper steels—An option to classic CrMo and CrNiMo quench and temper steels. In Proceedings of the 3rd International Conference on Steels for Cars and Trucks (SCT 2011), Salzburg, Austria, 5–9 June 2011; pp. 219–225. [Google Scholar]

- Sugimoto, K.; Sato, S.; Arai, G. Hot forging of ultrahigh-strength TRIP-aided steel. Mater. Sci. Forum 2010, 638–642, 3074–3079. [Google Scholar] [CrossRef]

- Sugimoto, K.; Sato, S.; Kobayashi, J.; Srivastava, A.K. Effects of Cr and Mo on mechanical properties of hot-forged medium carbon TRIP-aided bainitic ferrite steels. Metals 2019, 9, 1066. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Sato, S.; Arai, G. The effects of hot-forging on mechanical properties of ultrahigh-strength TRIP-aided steels. In Proceedings of the International Steel Technologies Symposium (Taiwan 2008), Kaohsiung, Taiwan, 2–5 November 2008; p. D12. [Google Scholar]

- Mašek, B.; Jirková, H. New material concept for forging. In Proceedings of the International Conference on Advances in Civil Structural Mechanical Engineering (ACSME 2014), Bangkok, Thailand, 26–27 August 2014; pp. 92–96. [Google Scholar]

- Garcia-Mateo, C.; Morales-Rivas, L.; Caballero, F.G.; Milbourn, D.; Sourmail, T. Vanadium effect of medium carbon forging steel. Metals 2016, 6, 130. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Yang, Y.; Shan, Q.; Li, Z.; Bi, Z.; Zhou, R. Microstructure evolution and mechanical properties of 0.4C-Si-Mn-Cr steel during high temperature deformation. Materials 2020, 13, 172. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Kobayashi, J.; Nakajima, Y.; Kochi, T. The effects of cooling rate on retained austenite characteristics of a 0.2C-1.5Si-1.5Mn-1.0Cr-0.05Nb TRIP-aided martensitic steel. Mater. Sci. Forum 2014, 783–786, 1015–1020. [Google Scholar] [CrossRef]

- Langeborg, R.; Sandberg, O.; Roberts, W. Fundamentals of Microalloying Forging Steels; Krauss, G., Banerji, S.K., Eds.; TMS: Warrendale, PA, USA, 1987; pp. 39–54. [Google Scholar]

- Keul, C.; Wirths, V.; Bleck, W. New bainitic steel for forgings. Arch. Civ. Mech. Eng. 2012, 12, 119–125. [Google Scholar] [CrossRef]

- Raedt, H.W.; Spekenheuer, U.; Vollrath, K. New forged steels—Energy-efficient solutions for stronger parts. ATZ Worldw. 2012, 114, 5–9. [Google Scholar] [CrossRef]

- Buchmayr, B. Critical assessment 22: Bainitic forging steels. Mater. Sci. Technol. 2016, 32, 517–522. [Google Scholar] [CrossRef] [Green Version]

- Bleck, W.; Bambach, M.; Wirths, V.; Stieben, A. Microalloyed engineering steels with improved performance—An Overview. Heat Treat. Mater. J. 2017, 72, 355–364. [Google Scholar] [CrossRef]

- Sugimoto, K.; Kobayashi, J.; Arai, G. Development of low alloy TRIP-aided steel for hot-forging parts with excellent toughness. Steel Res. Int. Spec. Ed. Met. Form. 2010, 81, 254–257. [Google Scholar]

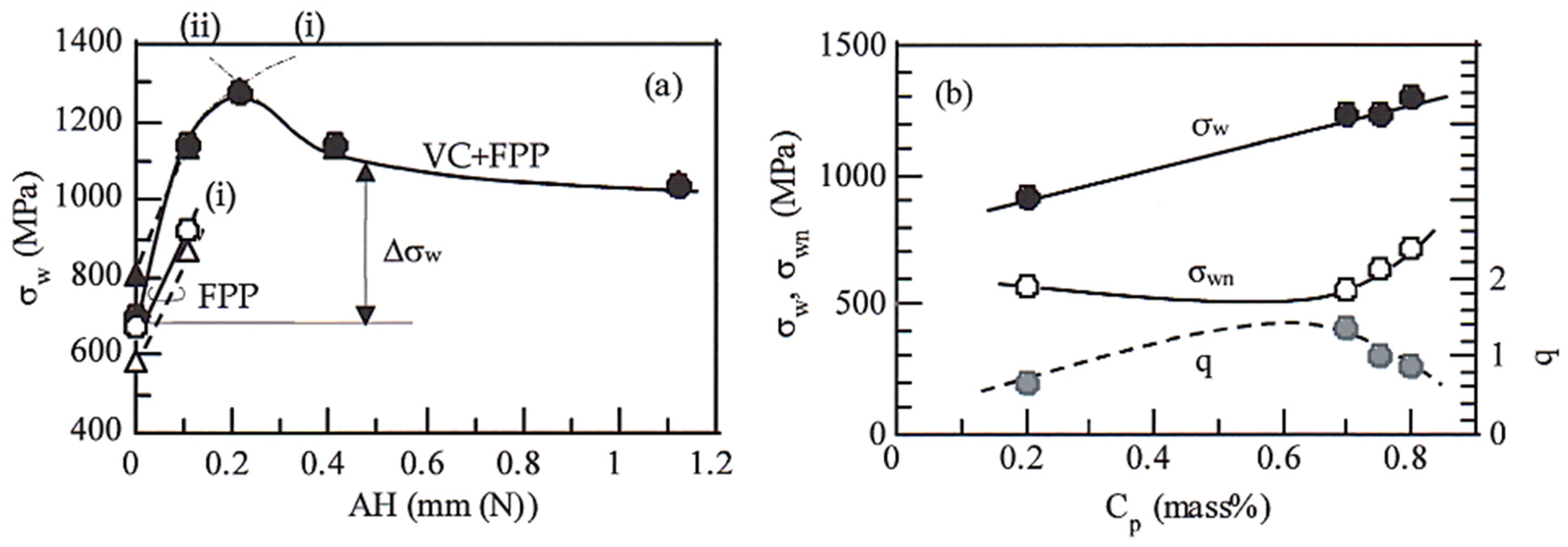

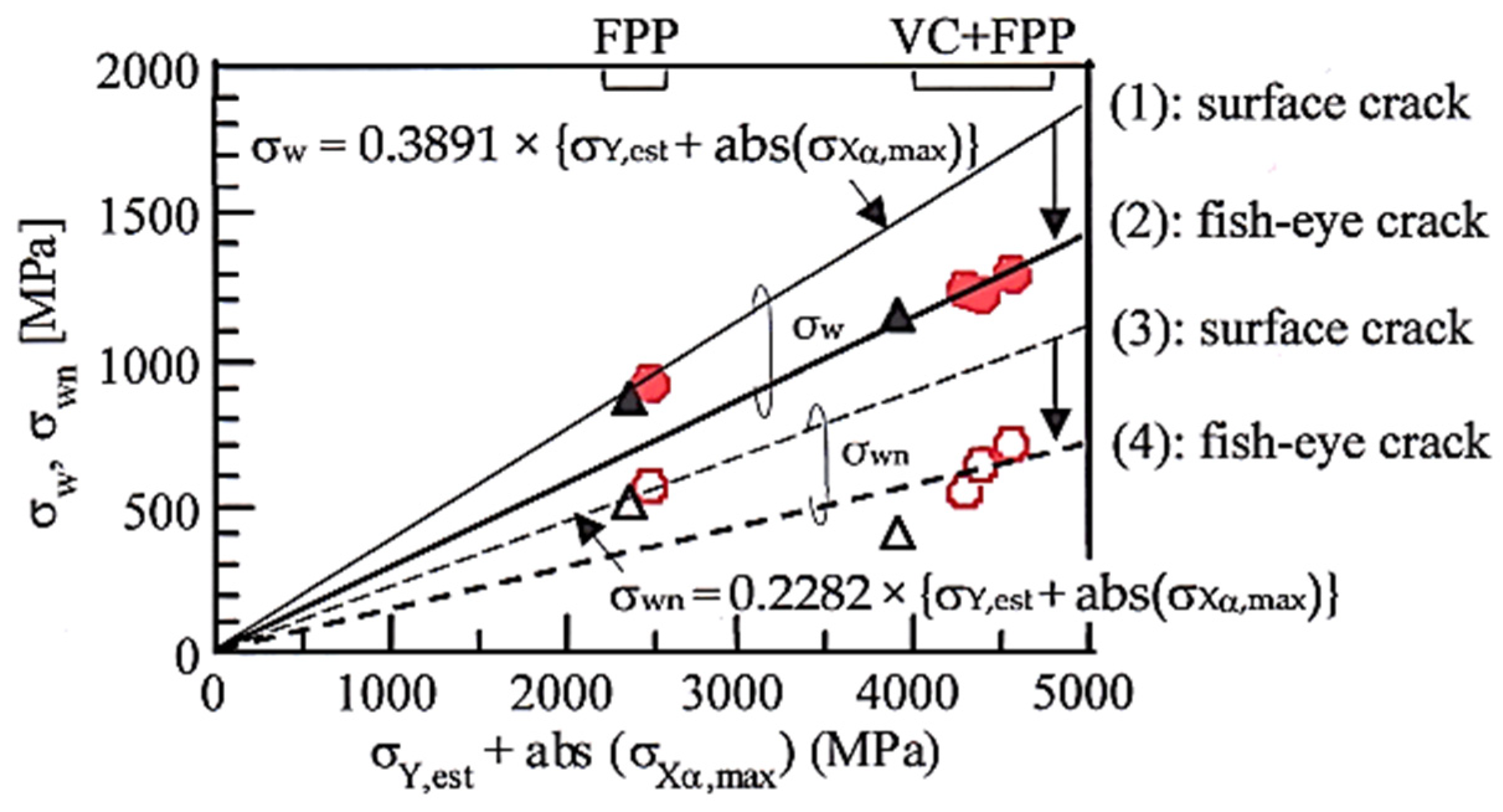

- Sugimoto, K.; Hojo, T.; Mizuno, Y. Effects of fine particle peening conditions on the rotational bending fatigue strength of a vacuum-carburized transformation-induced plasticity-aided martensitic Steel. Metall. Mater. Trans. A 2018, 49A, 1552–1560. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Mizuno, Y. Fatigue strength of a vacuum-carburized TRIP-aided martensitic steel. Mater. Sci. Technol. 2018, 34, 743–750. [Google Scholar] [CrossRef]

- Matsui, K.; Koshimune, M.; Takahashi, K.; Ando, K. Influence of shot peening method on rotating bending fatigue limit for high strength steel. Trans. Jpn. Soc. Spring Eng. 2010, 55, 7–12. [Google Scholar] [CrossRef] [Green Version]

- Koshimune, M.; Matsui, K.; Takahashi, K.; Nakano, W.; Ando, K. Influence of hardness and residual stress on fatigue limit for high strength steel. Trans. Jpn. Soc. Spring Eng. 2009, 54, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Skołek, E.; Wasiak, K.; Świątnicki, W.A. Structure and properties of the carburized surface layer on 35CrSiMn5-5-4 steel after nanostructurization treatment. Mater. Technol. 2015, 49, 933–939. [Google Scholar]

- Kanetani, K.; Moronaga, T.; Hara, T.; Ushioda, K. Deformation-induced martensitic transformation behavior of retained austenite during rolling contact in carburized SAE4320 steel. Tetsu-to-Hagane 2020, 106, 953–960. [Google Scholar] [CrossRef]

- Billur, E.; Altan, T. Three generations of advanced high-strength steels for automotive applications, Part III. Stamp. J. 2014, March/April. 12–13. [Google Scholar]

- Keeler, S.; Kimchi, M.; Mconey, P.J. Advanced High-Strength Steels Application Guidelines Version 6.0.; WorldAutoSteel: Brussels, Belgium, 2017. [Google Scholar]

- Krizan, D.; Steinedei, K.; Kaar, S.; Hebesberger, T. Development of third generation advanced high strength steels for automotive applications. In Proceedings of the 19th International Scientific Conference Transfer 2018, Bansko, Bulgaria, 14–16 December 2018; pp. 1–15. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sugimoto, K.-i. Recent Progress of Low and Medium-Carbon Advanced Martensitic Steels. Metals 2021, 11, 652. https://doi.org/10.3390/met11040652

Sugimoto K-i. Recent Progress of Low and Medium-Carbon Advanced Martensitic Steels. Metals. 2021; 11(4):652. https://doi.org/10.3390/met11040652

Chicago/Turabian StyleSugimoto, Koh-ichi. 2021. "Recent Progress of Low and Medium-Carbon Advanced Martensitic Steels" Metals 11, no. 4: 652. https://doi.org/10.3390/met11040652

APA StyleSugimoto, K.-i. (2021). Recent Progress of Low and Medium-Carbon Advanced Martensitic Steels. Metals, 11(4), 652. https://doi.org/10.3390/met11040652