Influence of Grain Orientation Distribution on the High Temperature Fatigue Behaviour of Notched Specimen Made of Polycrystalline Nickel-Base Superalloy

Abstract

1. Introduction

2. Materials and Methods

3. Modelling Approaches

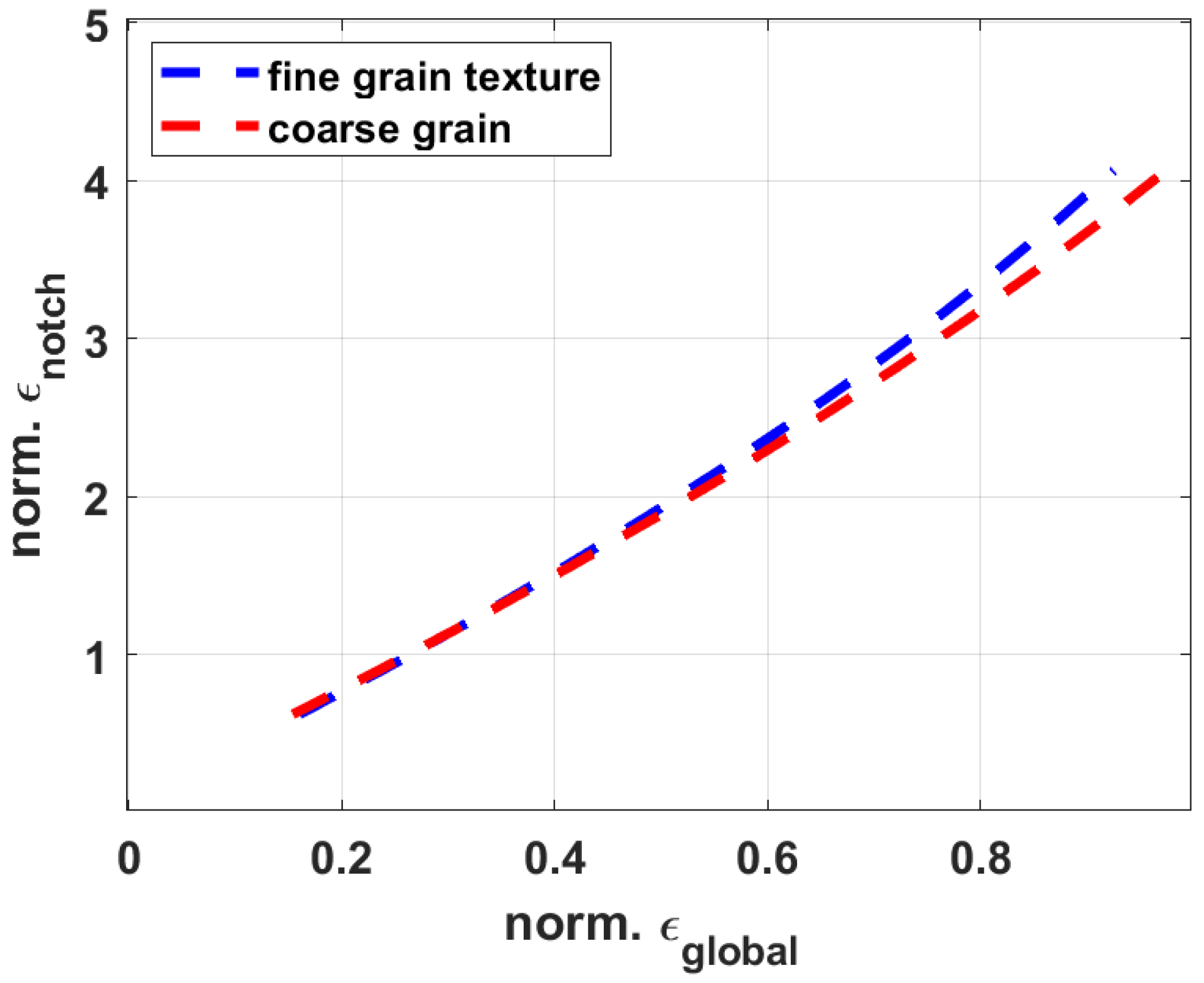

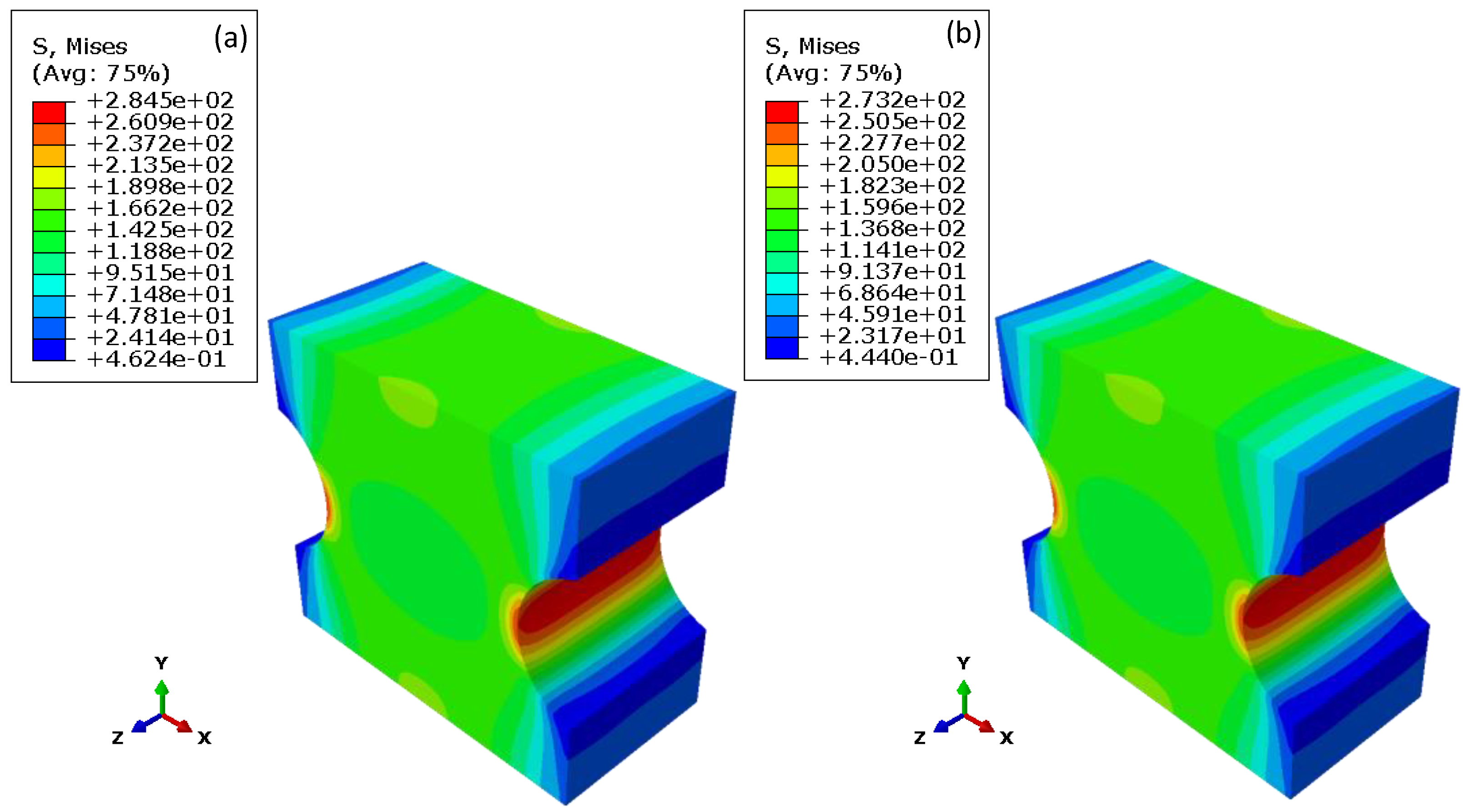

3.1. Modelling the Notch Strain with Finite Element Analysis for an Isotropic Material Assumption

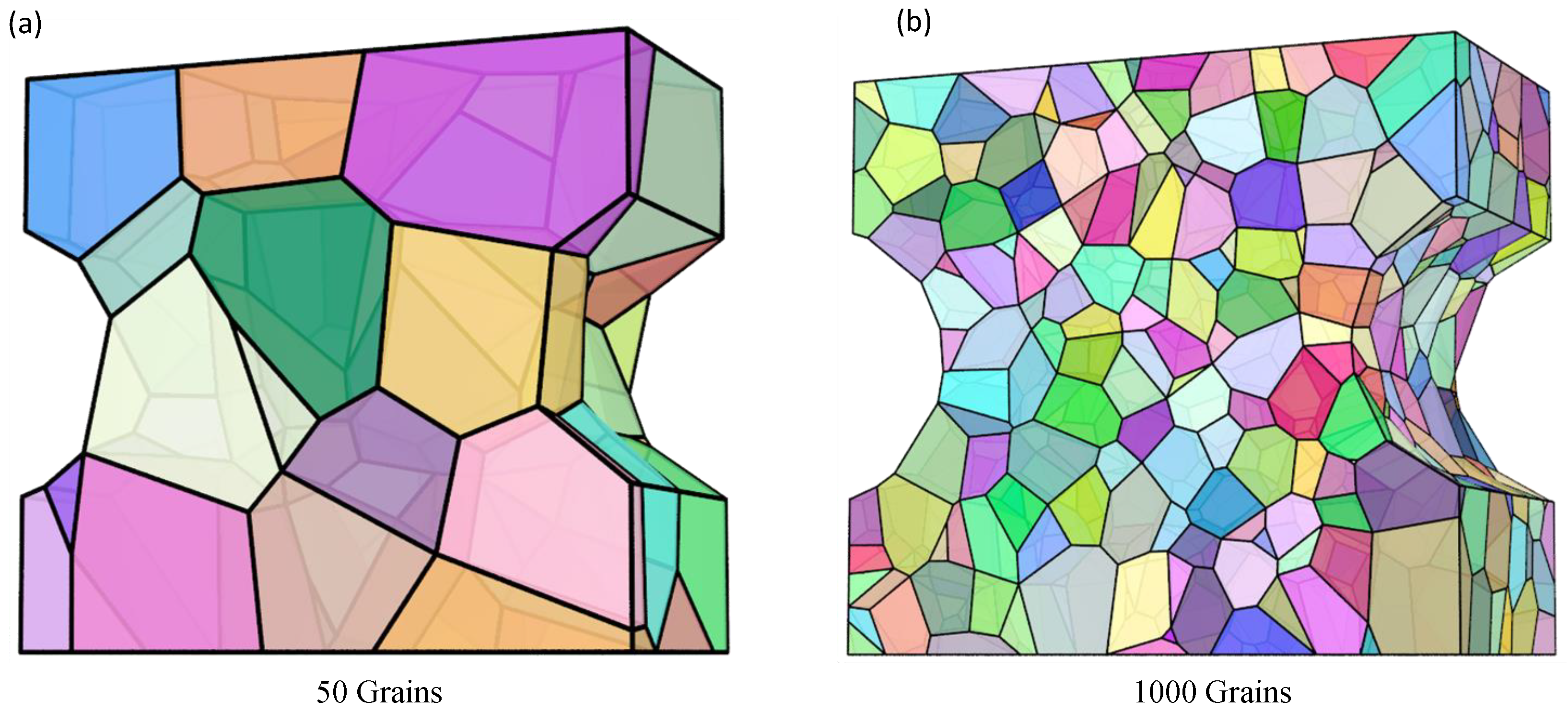

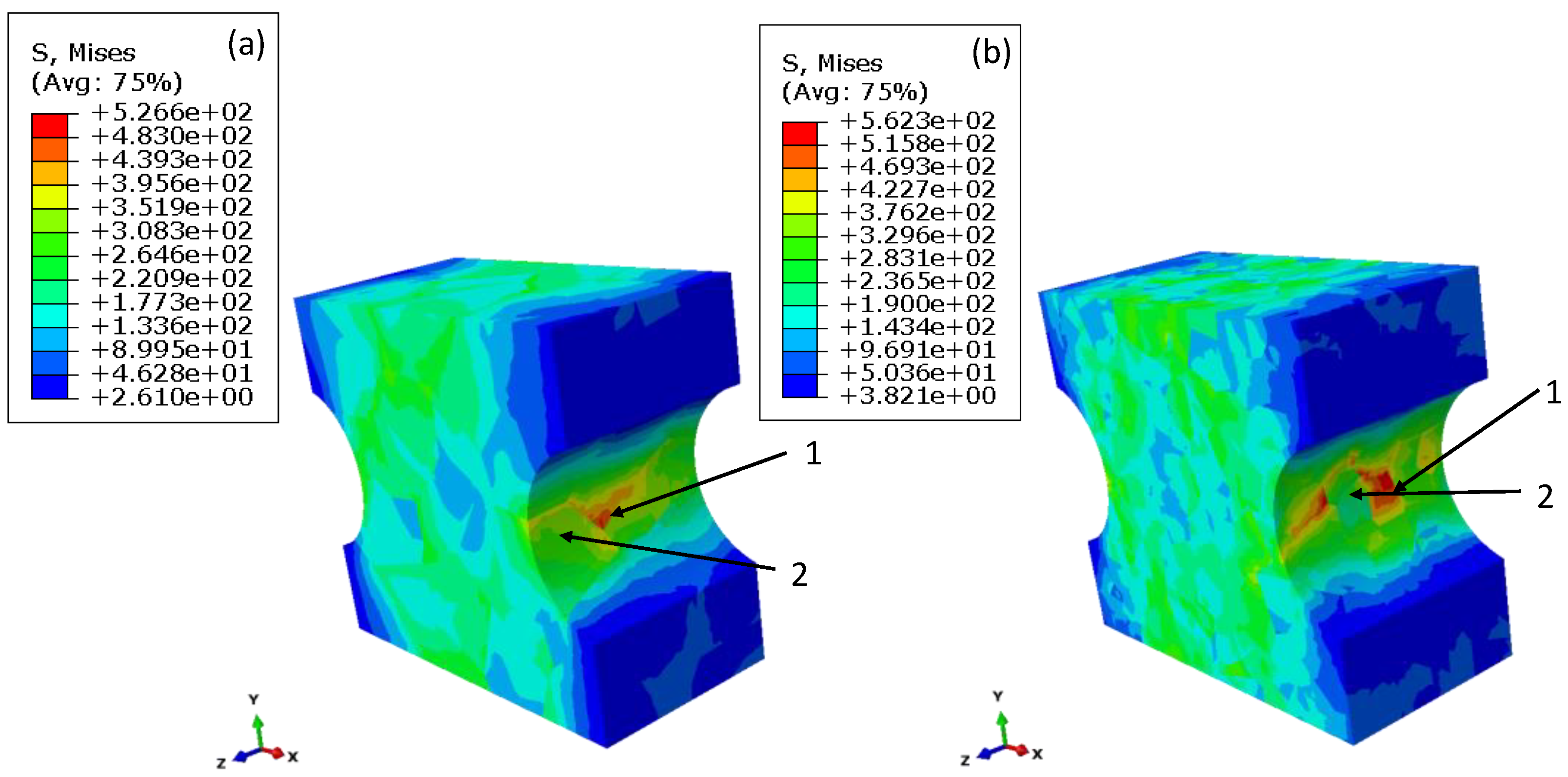

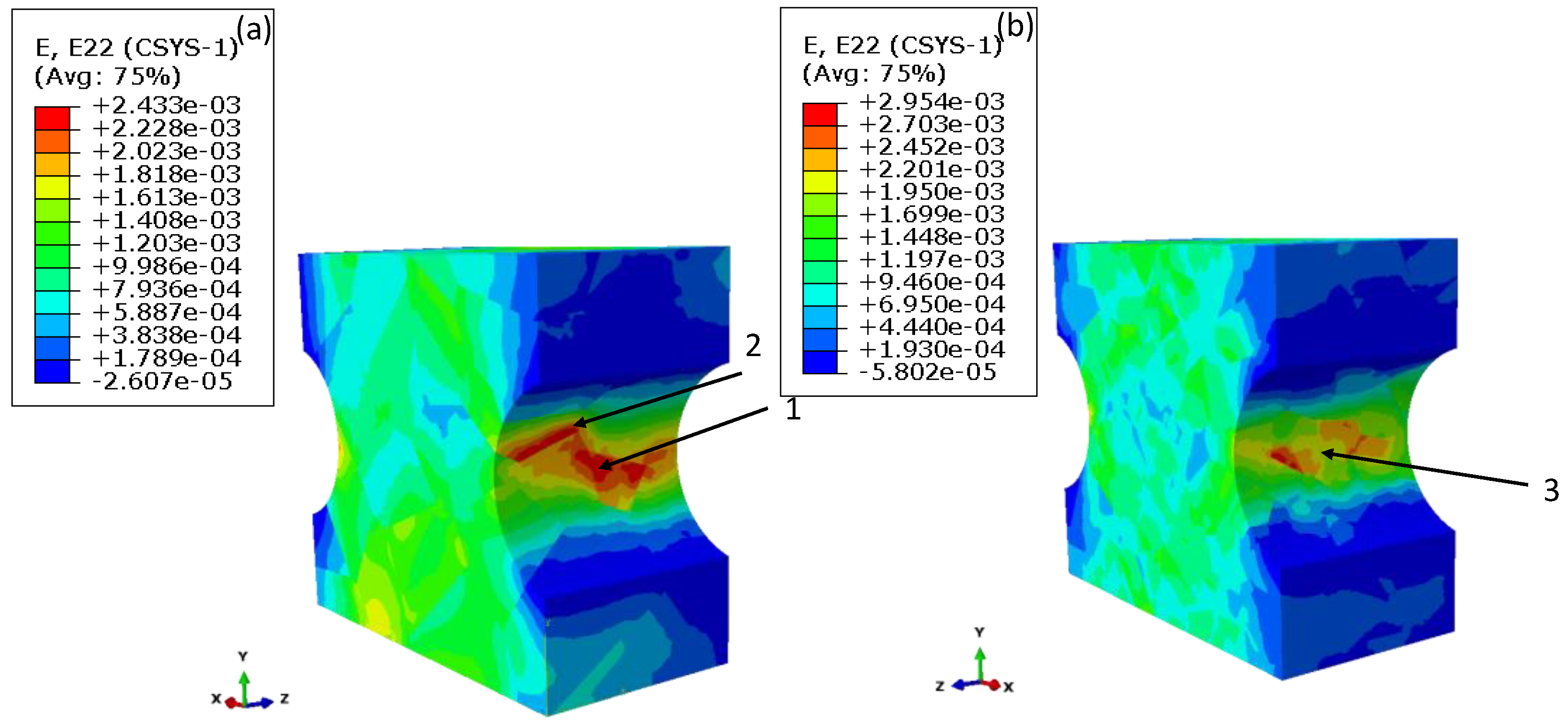

3.2. Modelling the Local Material Behaviour with Finite Element Analysis for Polycrystalline Nickel-Base Superalloys

4. Results

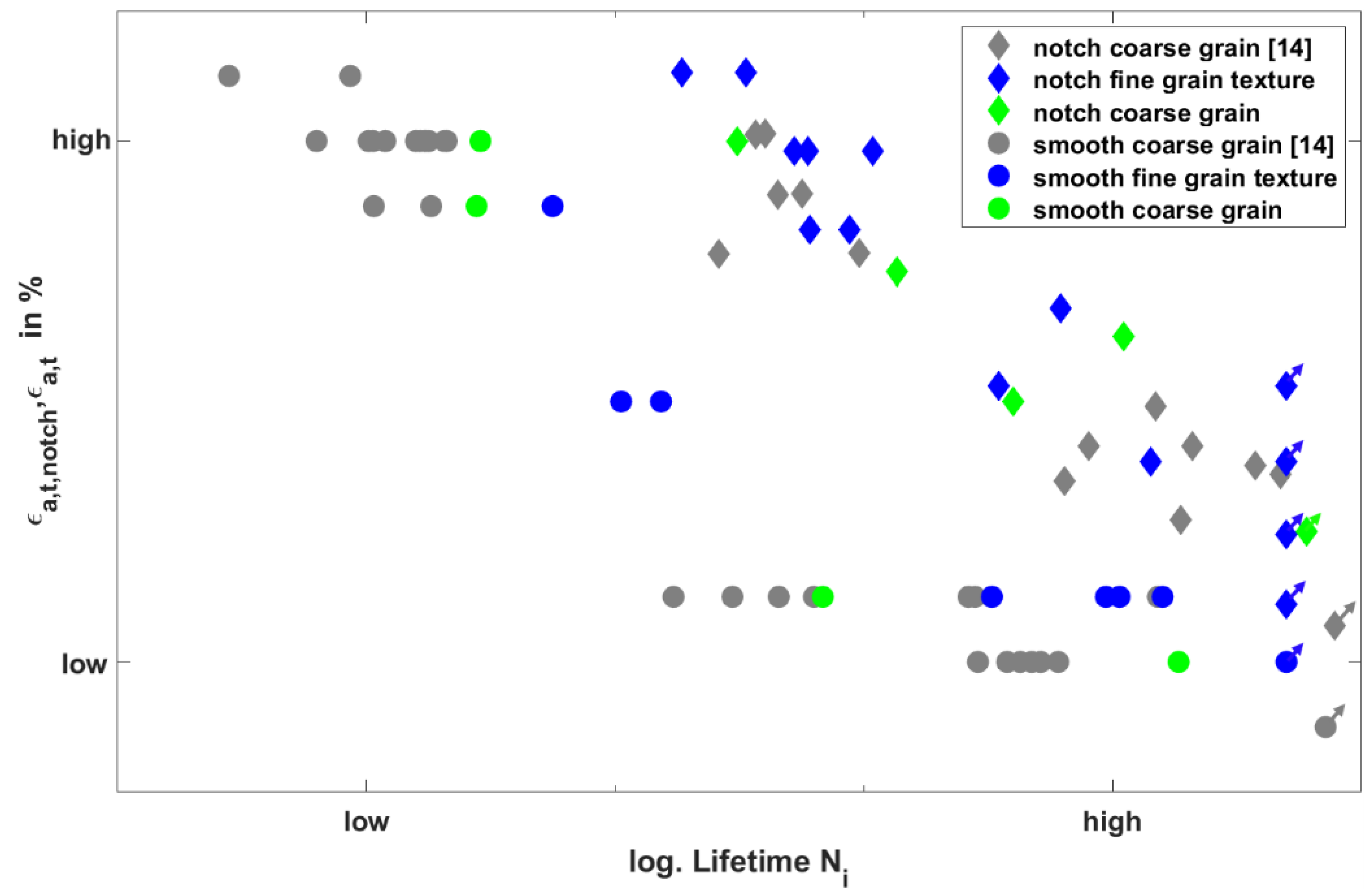

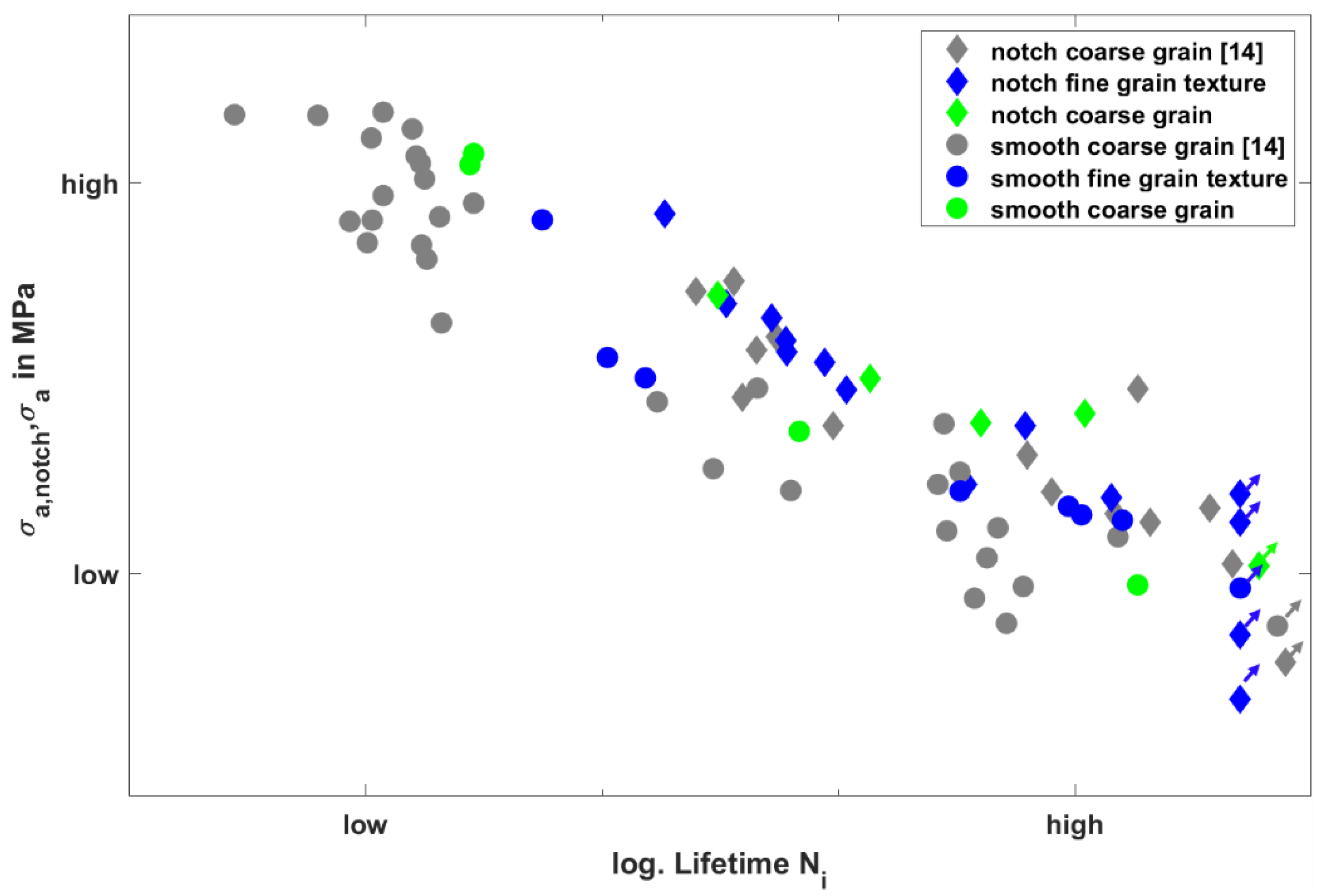

4.1. Experimental Results of Isothermal LCF Tests at 850 °C for Smooth and Notched Specimen

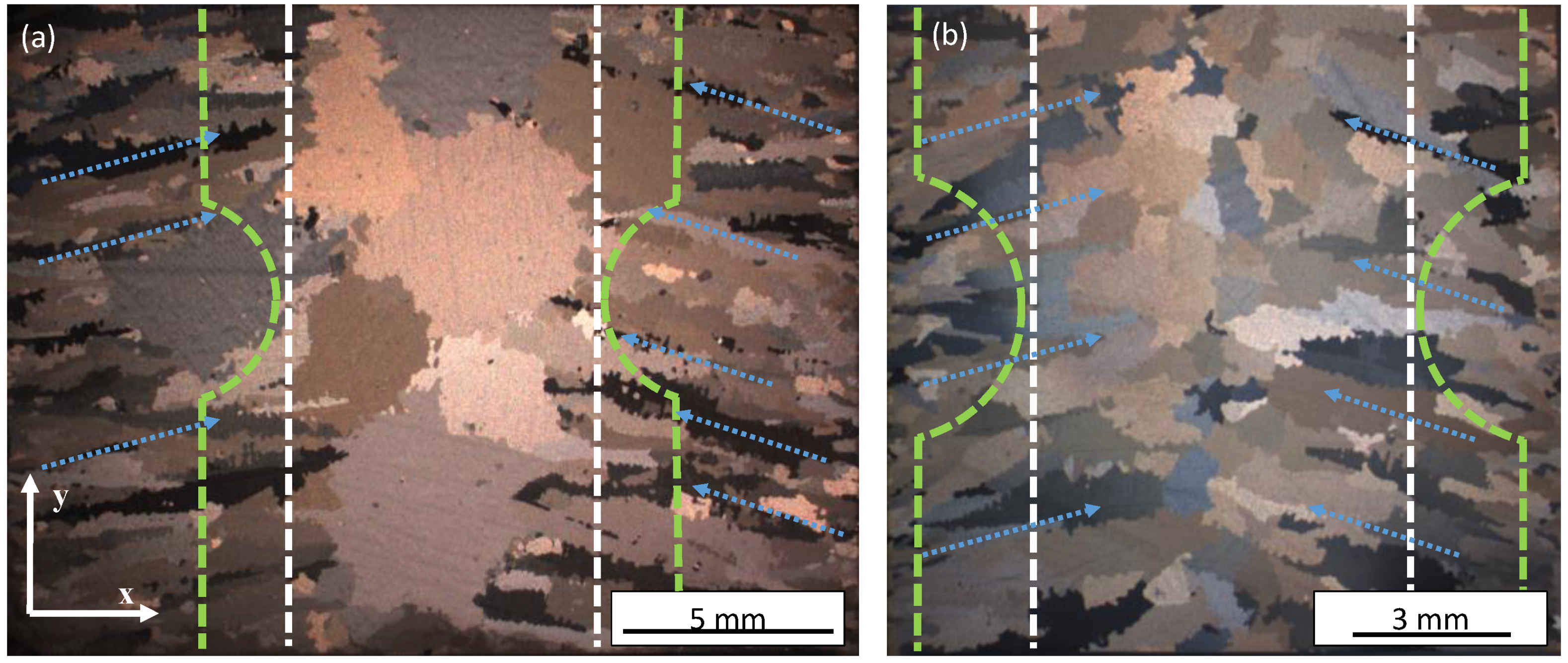

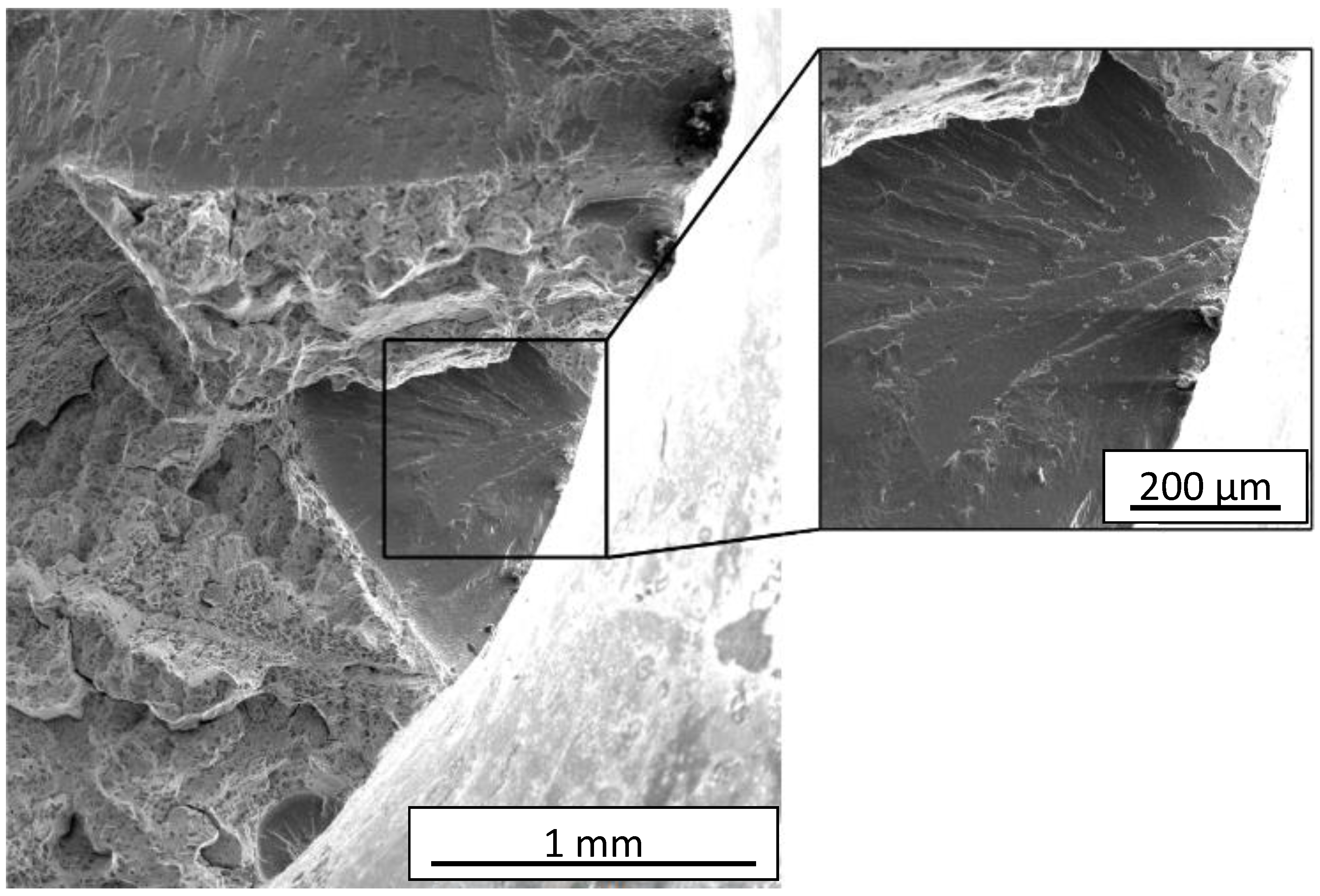

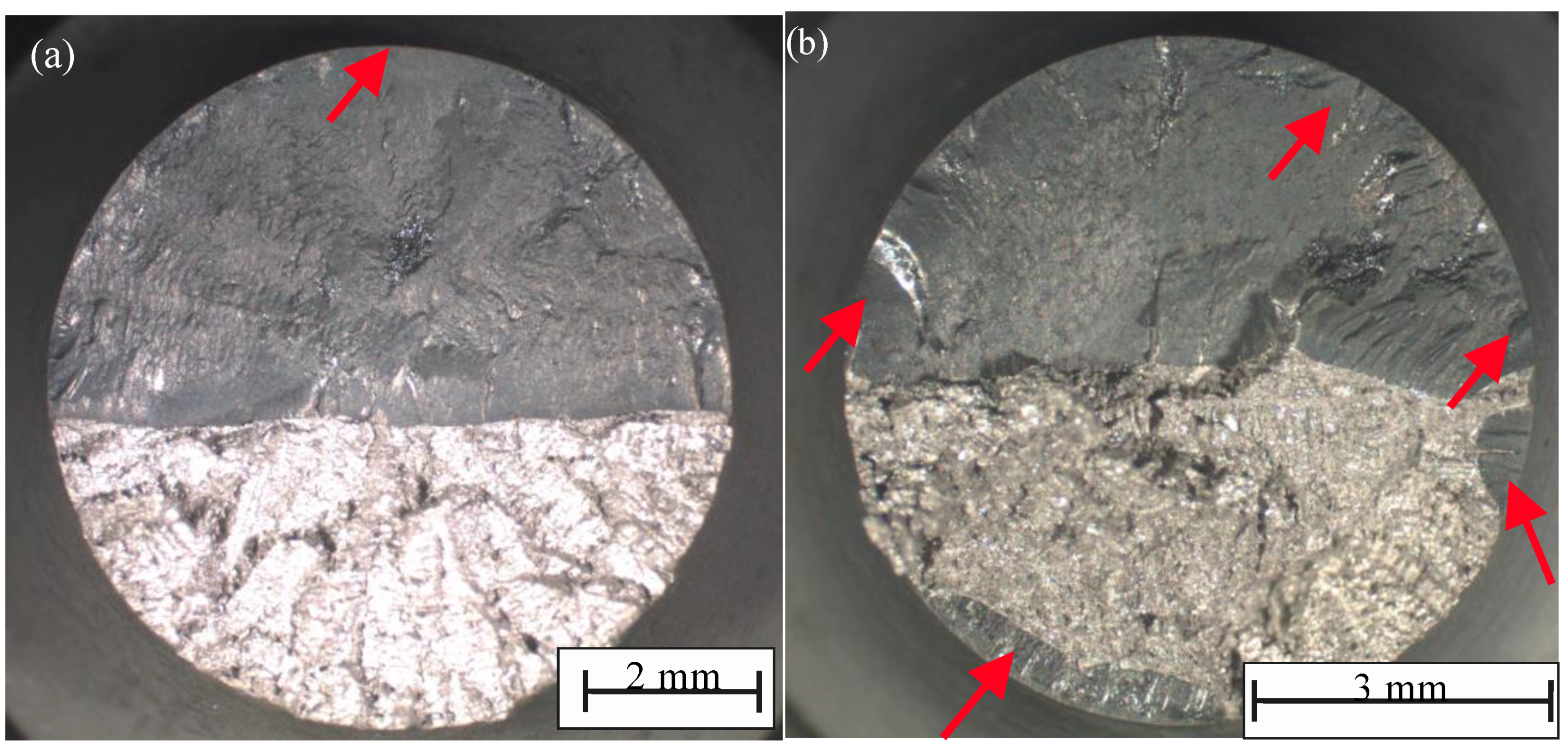

4.2. Microscopic Analysis of the Fracture Aurfaces

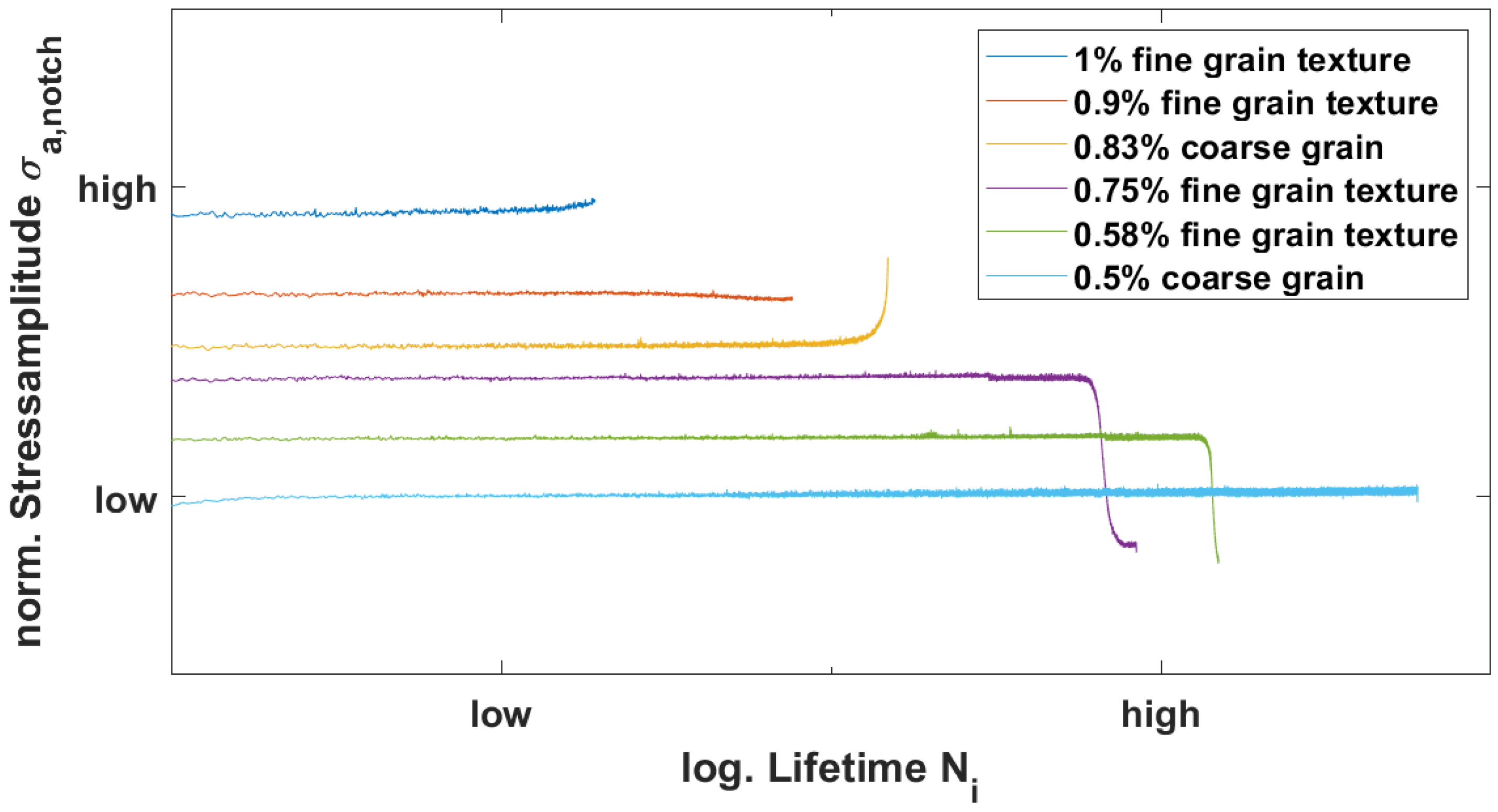

4.3. Cyclic Deformation Behaviour of the Notched Specimen under Total Strain Control

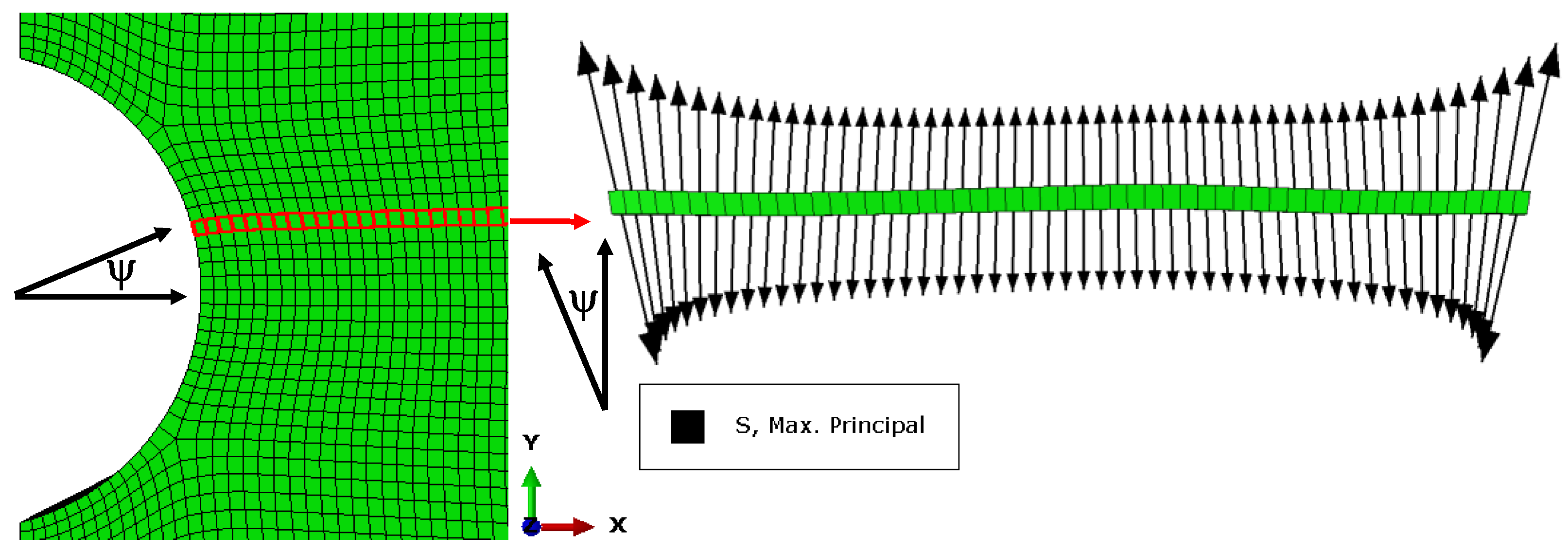

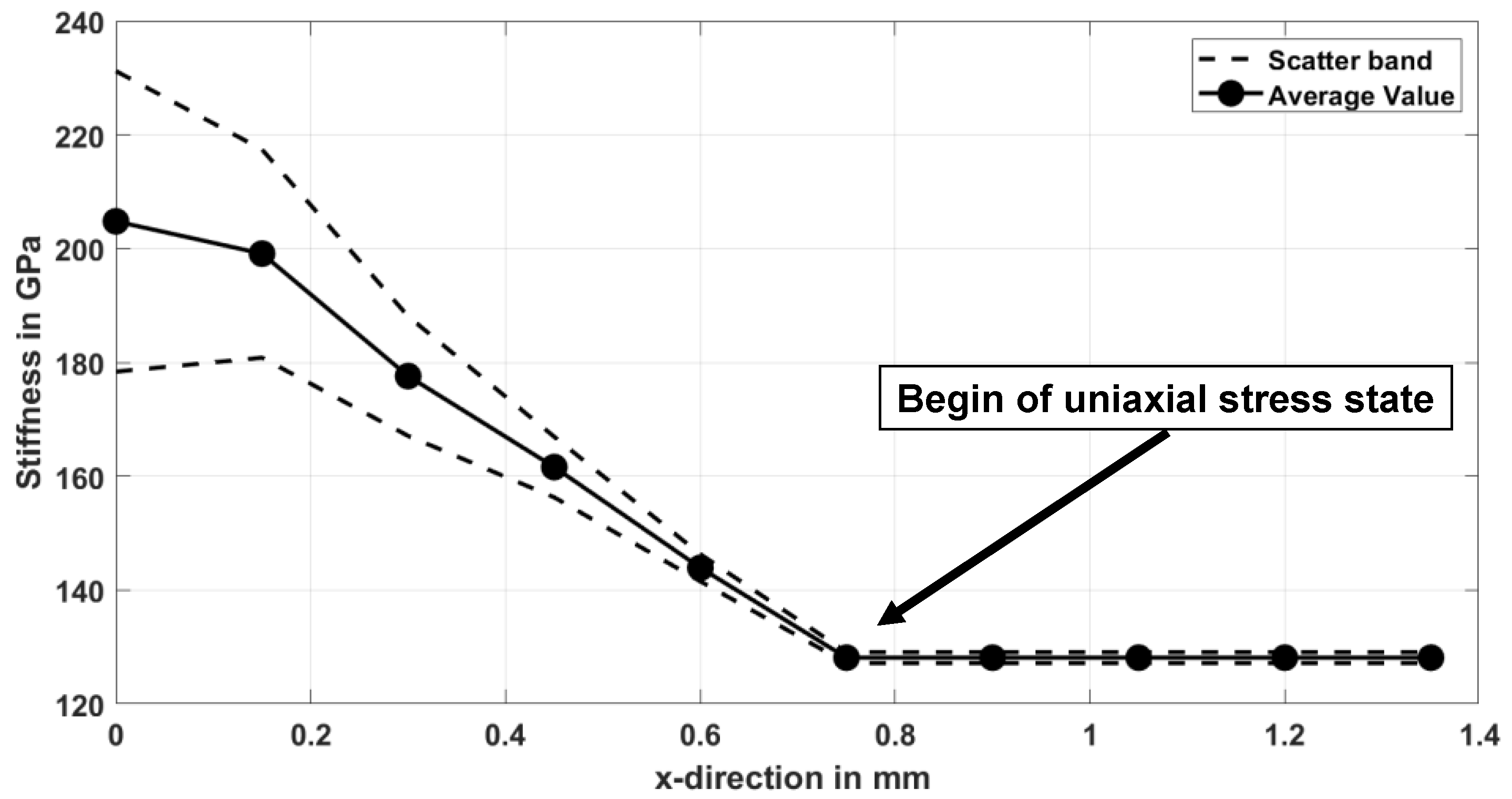

4.4. Results of the Finite Element Simulation

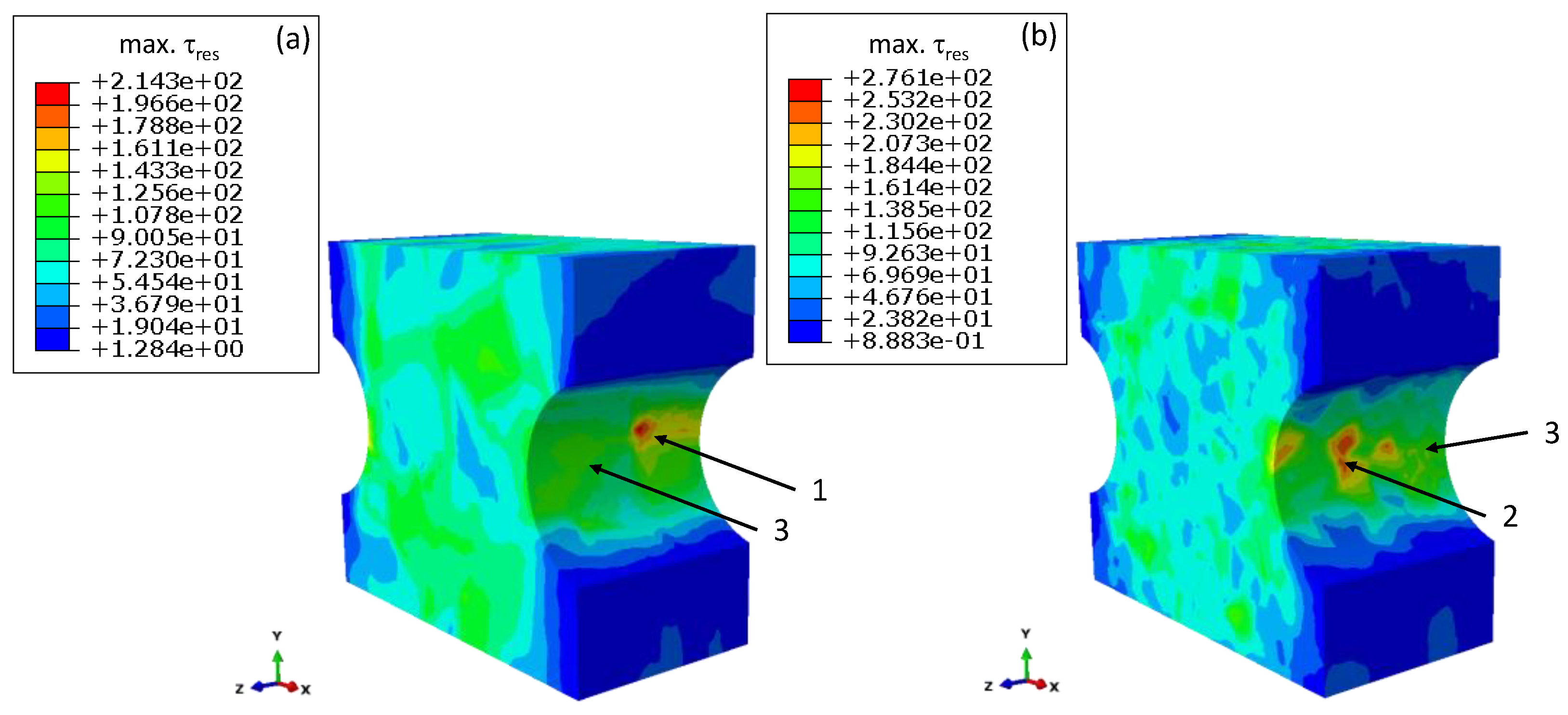

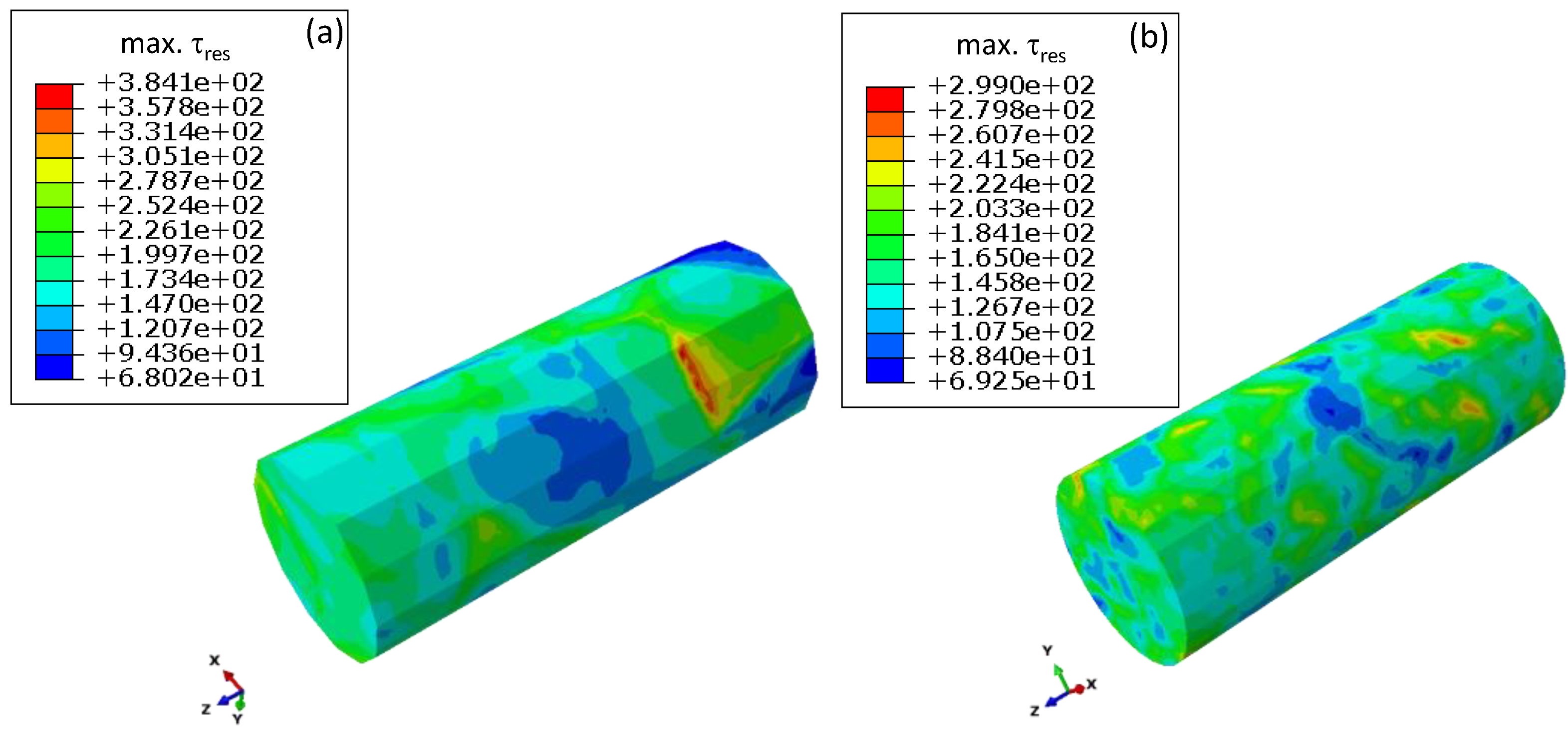

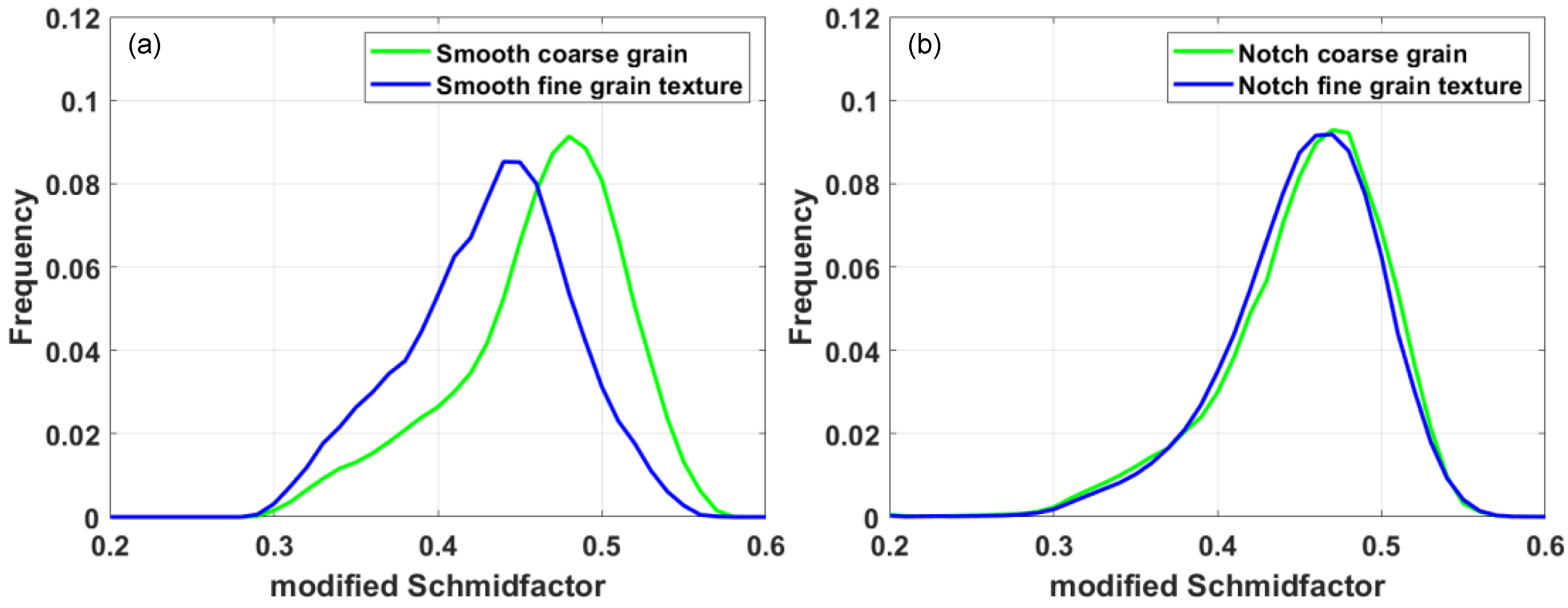

4.5. Shear Stress Distribution of the Smooth Specimen

5. Discussion

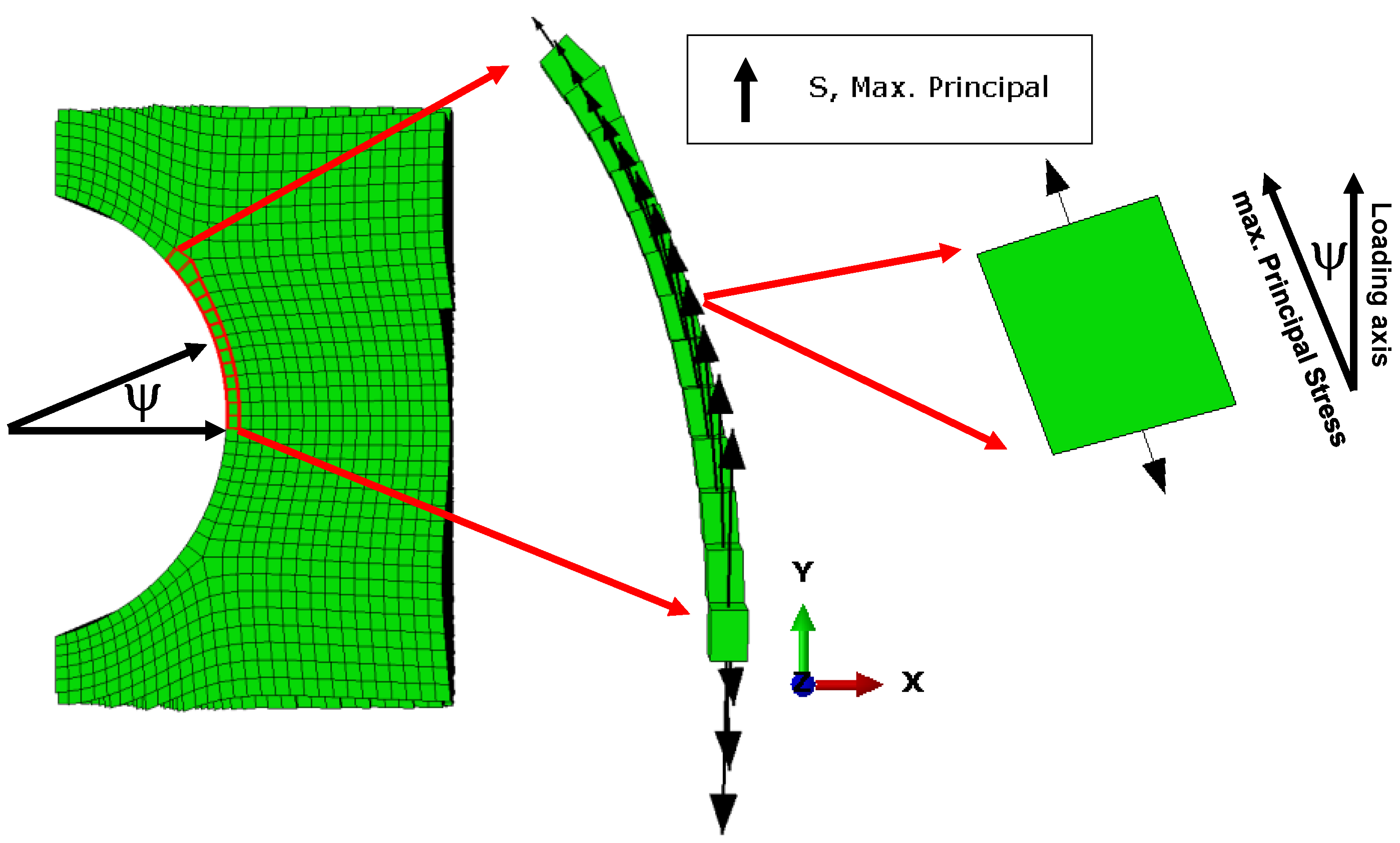

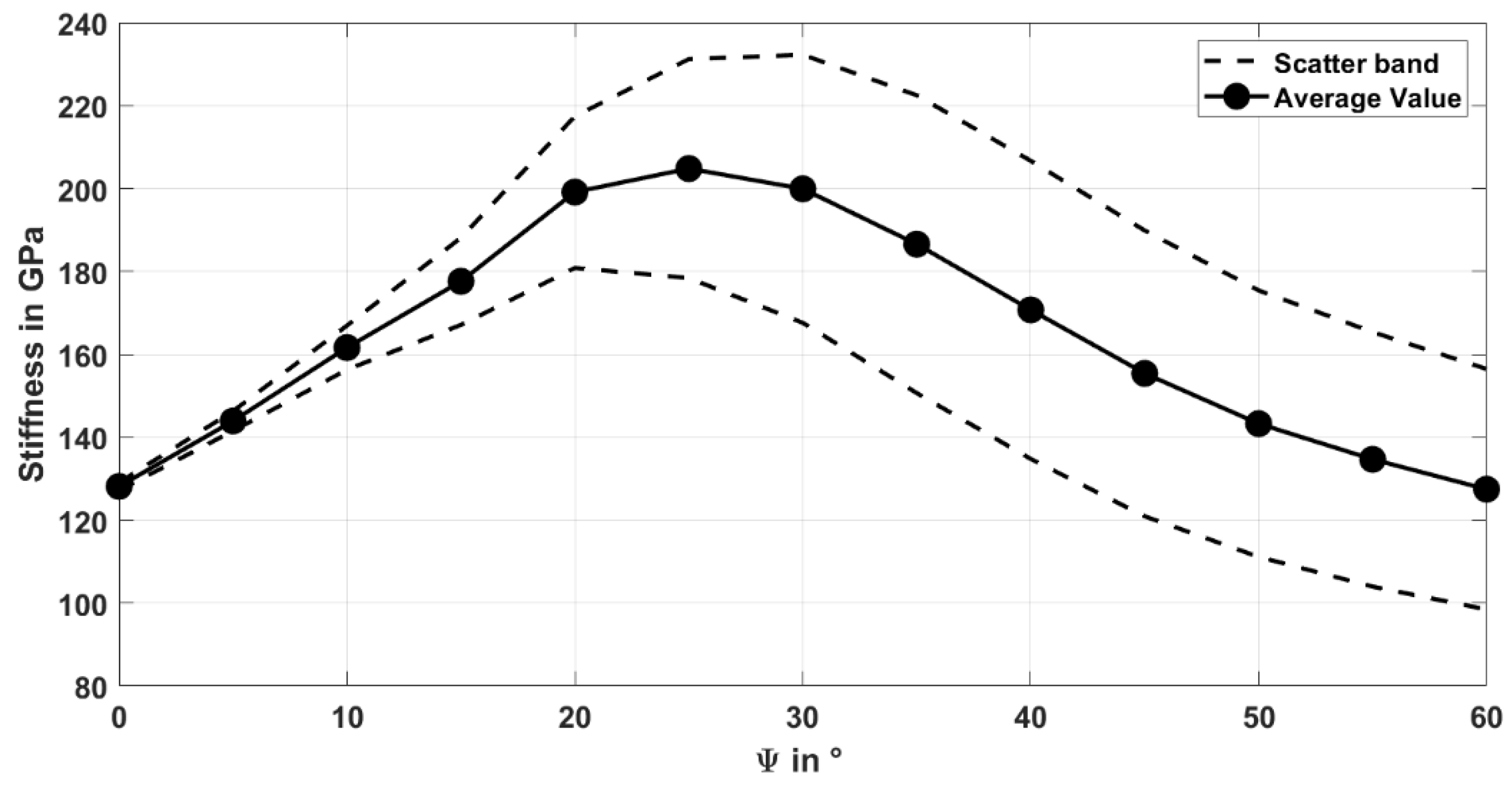

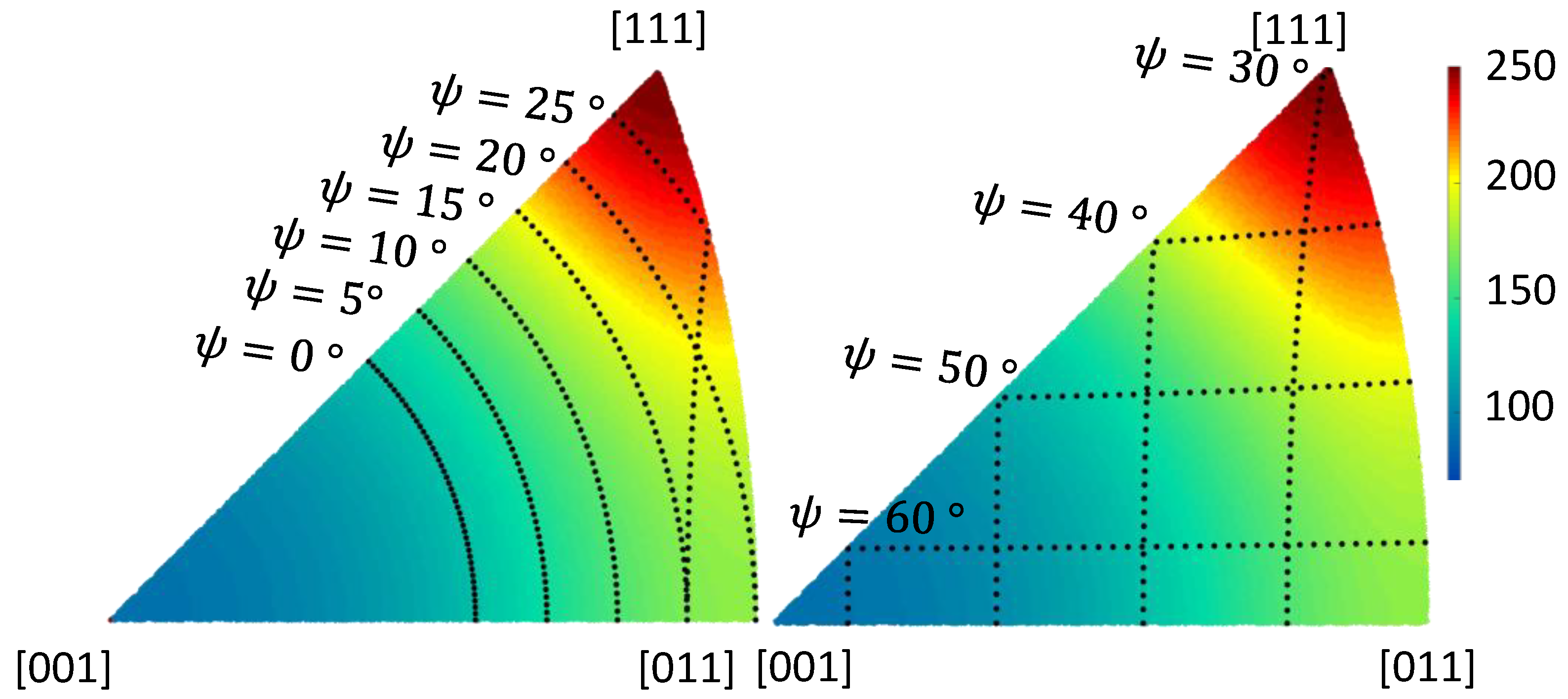

5.1. Development of Stiffness along the Notch

5.2. Influence of Grain Orientation Distribution on the Shear Stress in Slip Systems

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walsh, P.P.; Fletcher, P. Gas Turbine Performance; Blackwell Science Ltd.: Oxford, UK, 2004. [Google Scholar]

- Ramberg, W.; Osgood, W.R. Description of Stress-Strain Curves by Three Parameters; National Advisory Committee for Aeronautics: Edwards, CA, USA, 1943.

- Zhao, L.G.; Tong, J.; Vermeulen, B.; Byrne, J. On the uniaxial mechanical behaviour of an advanced nickel base superalloy at high temperature. Mech. Mater. 2001, 33, 593–600. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, H.; Dong, C. LCF behavior and life prediction method of a single crystal nickel-based superalloy at high temperature. Front. Mech. Eng. 2015, 10, 418–423. [Google Scholar] [CrossRef]

- Neidel, A.; Riesenbeck, S.; Ullrich, T.; Völker, J.; Yao, C. Hot cracking in the HAZ of laser-drilled turbine blades made from René 80. Mater. Test. 2005, 47, 553–559. [Google Scholar] [CrossRef]

- Siavashani, R.S.; Novinrooz, A.J.; Taherkhani, A. The Effect of Different Continuous Cooling Rates on Lattice Constant and Morphology of the Precipitates in Nickel-Base Super Alloy Rene 80. J. Basic. Appl. Sci. 2013, 3, 14–19. [Google Scholar]

- Donachie, M.J.; Donachie, S. Superalloys: A Technical Guide, 2nd ed.; ASM International: Russell Township, OH, USA, 2002. [Google Scholar]

- Kulawinski, D. Biaxial-Planare Isotherme und Thermo-Mechanische Ermüdung an polykristallinen Nickelbasis-Superlegierungen; Logos Verlag: Berlin, Germany, 2015. [Google Scholar]

- Holländer, D. Experimentelles Verfahren zur Charakterisierung des Einachsigen Ermüdungsverhaltens auf Basis Miniaturisierter Prüfkörper und Anwendung auf Hochtemperatur-Legierungen der Energietechnik. Ph.D. Thesis, Logos Verlag, Berlin, Germany, 2017. [Google Scholar]

- Moch, N. From Microscopic Models of Damage Accumulation to the Probability of Failure of Gas Turbines. Ph.D. Thesis, Universitätsbibliothek Wuppertal, Wuppertal, Germany, 2019. [Google Scholar]

- Schmitz, S.; Seibel, T.; Beck, T.; Rollmann, G.; Krause, R.; Gottschalk, H. A probabilistic model for LCF. Comput. Mater. Sci. 2013, 79, 584–590. [Google Scholar] [CrossRef]

- Gottschalk, H.; Schmitz, S.; Seibel, T.; Rollmann, G.; Krause, R.; Beck, T. Probabilistic Schmid factors and scatter of low cycle fatigue (LCF) life. Materialwissenschaft und Werkstofftechnik 2015, 46, 156–164. [Google Scholar] [CrossRef]

- Mäde, L.; Kumar, K.; Schmitz, S.; Gundavarapu, S.; Beck, T. Evaluation of component-similar rotor steel specimens with a local probabilistic approach for LCF. Fatigue Fract. Eng. Mater. Struct. 2019, 91, 319. [Google Scholar] [CrossRef]

- Seibel, T. Einfluss der Probengröße und der Kornorientierung auf die Lebensdauer einer polykristallinen Ni-Basislegierung bei LCF-Beanspruchung. Ph.D. Thesis, Forschungszentrum Jülich, Jülich, Germany, 2014. [Google Scholar]

- Mäde, L.; Schmitz, S.; Gottschalk, H.; Beck, T. Combined notch and size effect modeling in a local probabilistic approach for LCF. Comput. Mater. Sci. 2018, 142, 377–388. [Google Scholar] [CrossRef]

- Engel, B.; Beck, T.; Moch, N.; Gottschalk, H.; Schmitz, S. Effect of local anisotropy on fatigue crack initiation in a coarse grained nickel-base superalloy. In Proceedings of the 12th International Fatigue Congress (FATIGUE 2018), Poitiers, France, 27 May–1 June 2018. [Google Scholar] [CrossRef]

- Engel, B.; Mäde, L.; Lion, P.; Moch, N.; Gottschalk, H.; Beck, T. Probabilistic Modeling of Slip System-Based Shear Stresses and Fatigue Behavior of Coarse-Grained Ni-Base Superalloy Considering Local Grain Anisotropy and Grain Orientation. Metals 2019, 9, 813. [Google Scholar] [CrossRef]

- Engel, B.; Beck, T.; Schmitz, S. High temperatue Low Cylce Fatigue of the Ni-base Superallor René80. In Proceedings of the Eighth International Conference on Low Cycle Fatigue (LCF8), Dresden, Germany, 27–29 June 2018. [Google Scholar]

- Safari, J.; Nategh, S. On the heat treatment of Rene-80 nickel-base superalloy. J. Mater. Process. Technol. 2006, 176, 240–250. [Google Scholar] [CrossRef]

- Takaki, T.; Sakane, S.; Ohno, M.; Shibuta, Y.; Aoki, T.; Gandin, C.-A. Competitive grain growth during directional solidification of a polycrystalline binary alloy: Three-dimensional large-scale phase-field study. Materialia 2018, 1, 104–113. [Google Scholar] [CrossRef]

- Engel, B. Einfluss der Lokalen Kornorientierung und der Korngröße auf das Verformungs- und Ermüdungsverhalten von Nickelbasis Superlegierungen. Ph.D. Thesis, Technische Universität Kaiserslautern, Kaiserslautern, Germany, 2019. [Google Scholar]

- ISO International Organization for Standardization. Metallic Materials—Fatigue Testing—Axial-Strain-Controlled; ISO International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Quey, R.; Dawson, P.R.; Barbe, F. Large-scale 3D random polycrystals for the finite element method: Generation, meshing and remeshing. Comput. Meth. Appl. Mech. Eng. 2011, 200, 1729–1745. [Google Scholar] [CrossRef]

- Ghazvinian, E.; Diederichs, M.S.; Quey, R. 3D random Voronoi grain-based models for simulation of brittle rock damage and fabric-guided micro-fracturing. J. Rock Mech. Geotech. Eng. 2014, 6, 506–521. [Google Scholar] [CrossRef]

- Quey, R.; Renversade, L. Optimal polyhedral description of 3D polycrystals: Method and application to statistical and synchrotron X-ray diffraction data. Comput. Meth. Appl. Mech. Eng. 2018, 330, 308–333. [Google Scholar] [CrossRef]

- Hermann, W.; Sockel, H.G.; Han, J.; Bertram, A. Elastic Properties and Determination of Elastic Constants of Nickel-Base Superalloys by a Free-Free Beam Technique. In Proceedings of the Eighth International Symposium on Superalloys, Champion, PA, USA, 22–26 September 1996; pp. 229–238. [Google Scholar]

- Gollmer, M. Schadensakkumulationsverhalten der Superlegierung René 80 unter Zweistufiger Low Cycle Fatigue Beanspruchung. Ph.D. Thesis, Technische Universität Kaiserslautern, Kaiserslautern, Germany, 2018. [Google Scholar]

- Hyde, T.H.; Sun, W.; Williams, J.A. Requirements for and use of miniature test specimens to provide mechanical and creep properties of materials: A review. Int. Mater. Rev. 2007, 52, 213–255. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Co | Ti | Mo | W | Al | C | B | Zr |

|---|---|---|---|---|---|---|---|---|---|---|

| René80 | Bal. | 14.04 | 9.48 | 5.08 | 4.03 | 4.02 | 2.93 | 0.17 | 0.015 | 0.011 |

| Specimen Type | Number of Grains | Grain Orientation Distribution | Number of Models with Different Grain Morphologies | Number of Simulations per Model |

|---|---|---|---|---|

| Notched, flat | 100 | coarse random | 4 | 3 |

| Notched, flat | 1000 | fine textured | 3 | 3 |

| Smooth, round | 49 | coarse random | 6 | 1 |

| Smooth, round | 500 | fine textured | 6 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Engel, B.; Ohneseit, S.; Mäde, L.; Beck, T. Influence of Grain Orientation Distribution on the High Temperature Fatigue Behaviour of Notched Specimen Made of Polycrystalline Nickel-Base Superalloy. Metals 2021, 11, 731. https://doi.org/10.3390/met11050731

Engel B, Ohneseit S, Mäde L, Beck T. Influence of Grain Orientation Distribution on the High Temperature Fatigue Behaviour of Notched Specimen Made of Polycrystalline Nickel-Base Superalloy. Metals. 2021; 11(5):731. https://doi.org/10.3390/met11050731

Chicago/Turabian StyleEngel, Benedikt, Sebastian Ohneseit, Lucas Mäde, and Tilmann Beck. 2021. "Influence of Grain Orientation Distribution on the High Temperature Fatigue Behaviour of Notched Specimen Made of Polycrystalline Nickel-Base Superalloy" Metals 11, no. 5: 731. https://doi.org/10.3390/met11050731

APA StyleEngel, B., Ohneseit, S., Mäde, L., & Beck, T. (2021). Influence of Grain Orientation Distribution on the High Temperature Fatigue Behaviour of Notched Specimen Made of Polycrystalline Nickel-Base Superalloy. Metals, 11(5), 731. https://doi.org/10.3390/met11050731