Towards Understanding Relationships between Tension Property and Twinning Boundaries in Magnesium Alloy

Abstract

1. Introduction

2. Experiments

2.1. Initial Material and Deformation

2.2. EBSD and TEM Examinations

3. Results

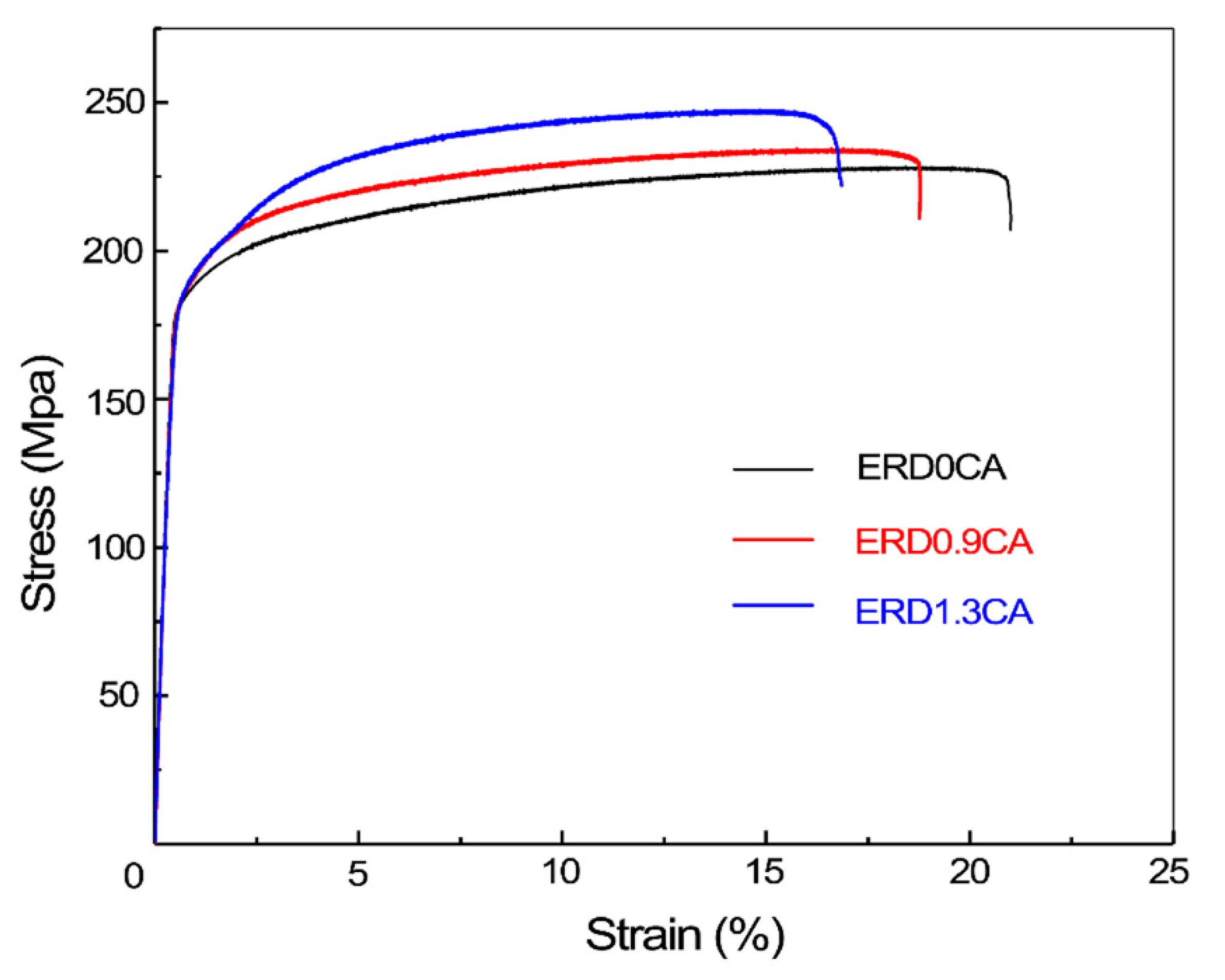

3.1. Mechanical Properties

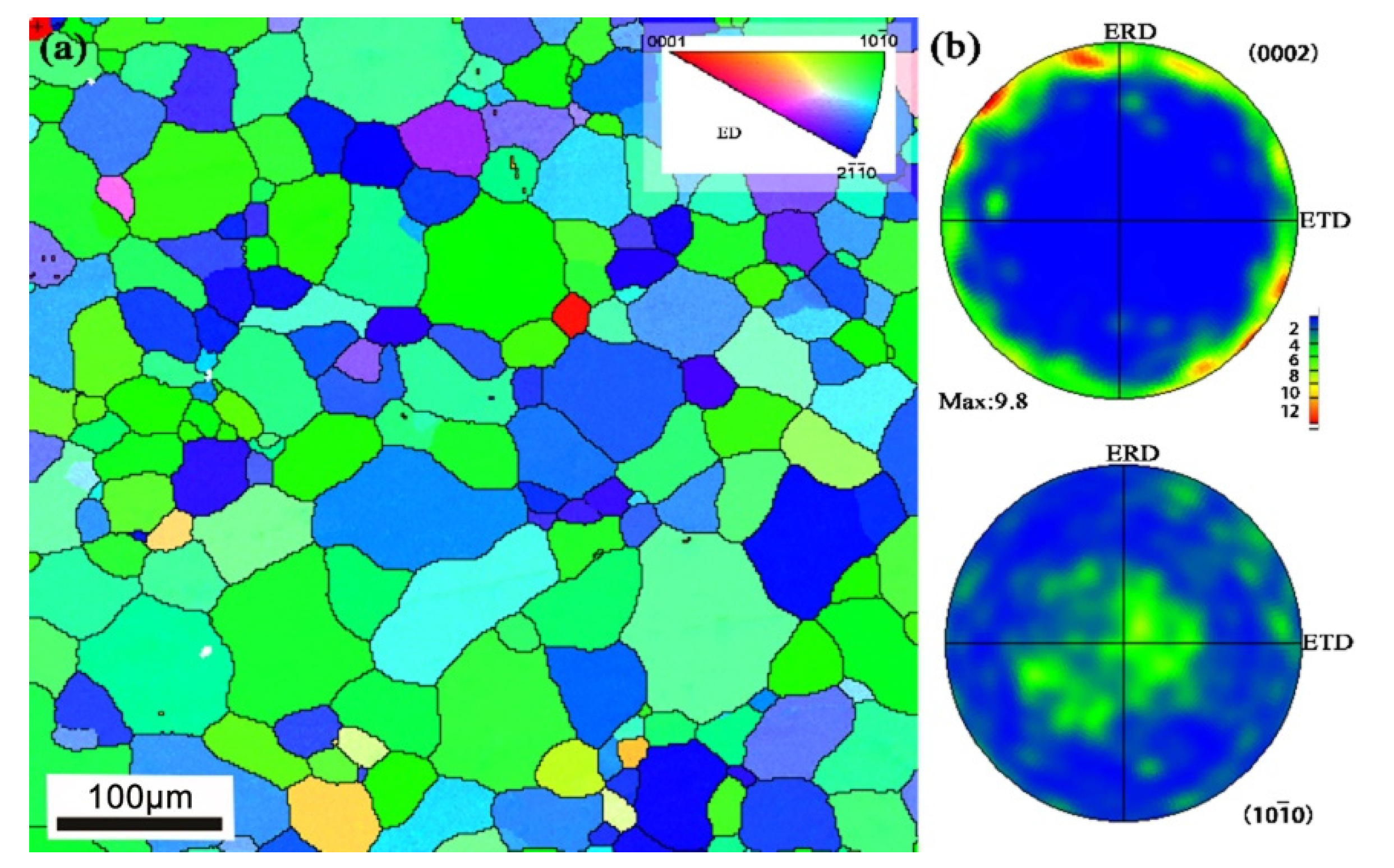

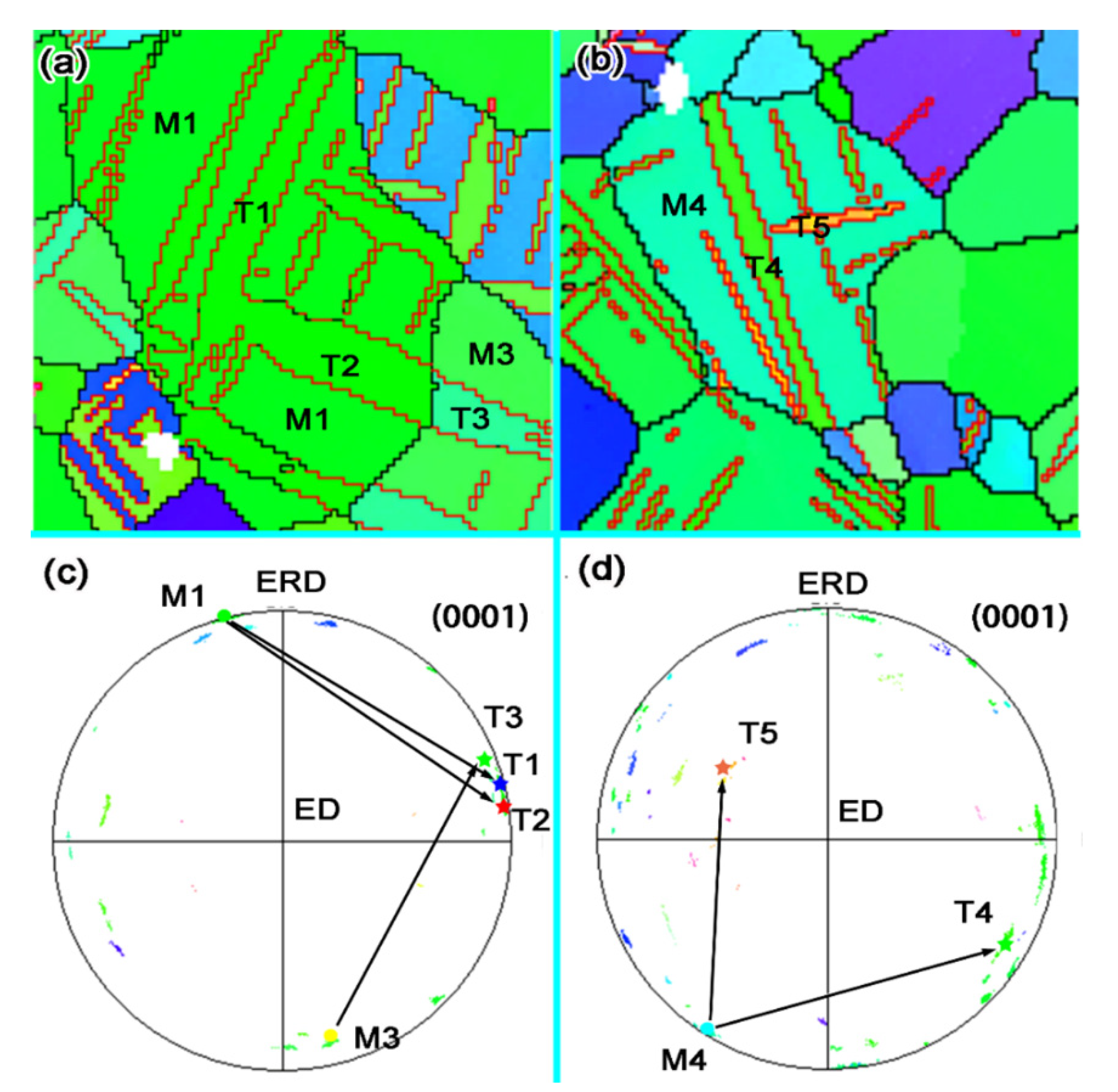

3.2. Microstructure Features Caused by Pre-Strain

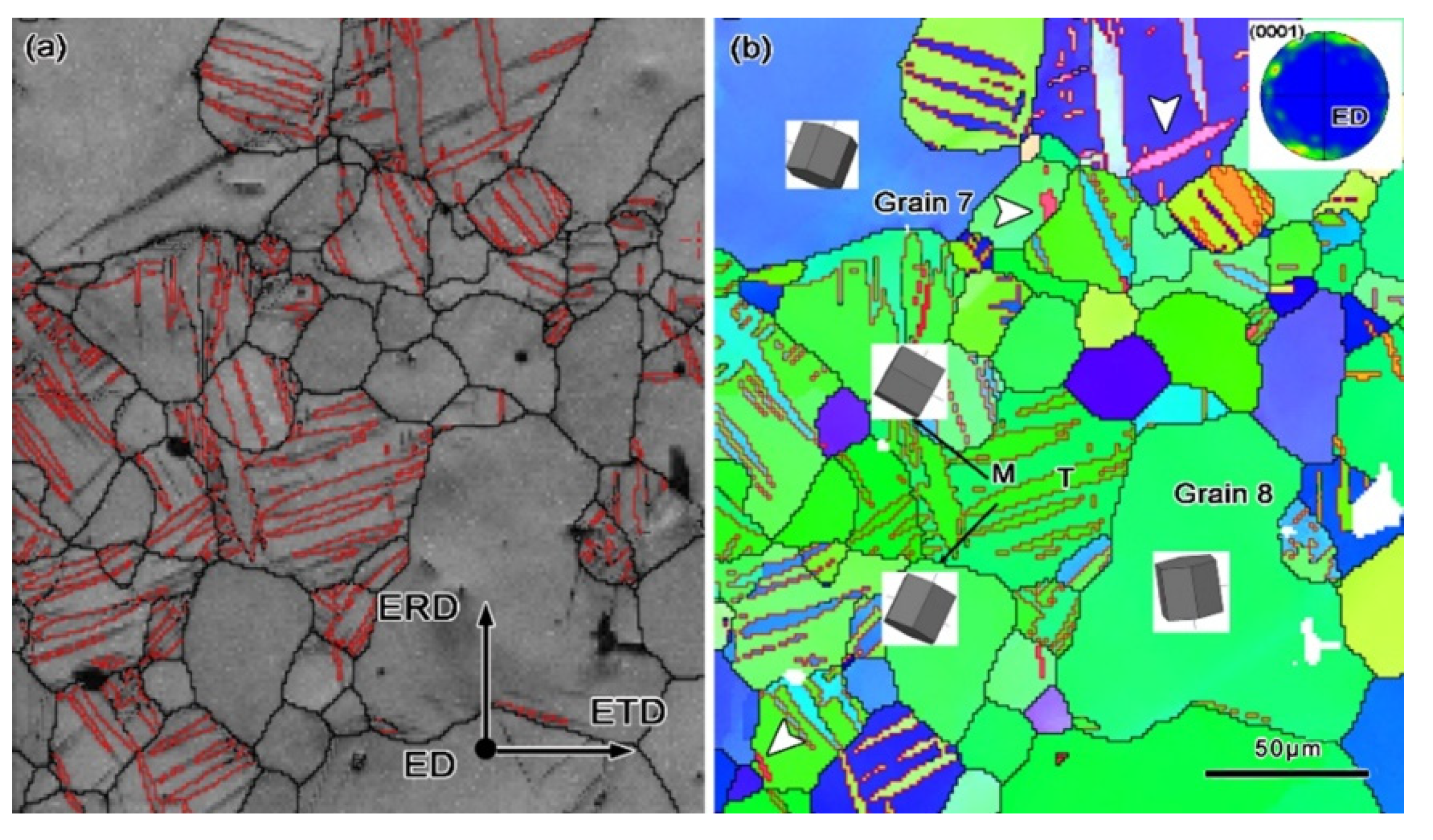

3.3. Microstructures Investigated by TEM

4. Discussions

4.1. The Influence of Pre-Strain on the Tension Property

4.2. Strengthening Related to Twinning Boundaries

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Magnesium: Properties-applications-potential. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Zhang, K.; Shao, Z.; Daniel, C.S.; Turski, M.; Pruncu, C.; Lang, L.; Robson, J.; Jiang, J. A comparative study of plastic deformation mechanisms in room-temperature and cryogenically deformed magnesium alloy AZ31. Mater. Sci. Eng. A 2021, 807, 140821. [Google Scholar] [CrossRef]

- Zhang, K.; Zheng, J.-H.; Huang, Y.; Pruncu, C.; Jiang, J. Evolution of twinning and shear bands in magnesium alloys during rolling at room and cryogenic temperature. Mater. Des. 2020, 193, 108793. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Zhu, Y.M.; Xu, S.W.; Bian, M.Z.; Davies, C.H.J.; Birbilis, N.; Nie, J.F. Texture evolution during static recrystallization of cold-rolled magnesium alloys. Acta Mater. 2016, 105, 479–494. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.-G.; Lee, J.H.; Huh, Y.-H. Texture evolution of rolled Mg-3Al-1Zn alloy undergoing a {10–12} twinning dominant strain path change. J. Alloy. Compd. 2015, 646, 573–579. [Google Scholar] [CrossRef]

- Sun, Q.; Fang, X.Y.; Wang, Y.C.; Tan, L.; Zhang, X.Y. Changes in misorientations of twin boundaries in deformed magnesium alloy. J. Mater. Sci. 2018, 53, 7834–7844. [Google Scholar] [CrossRef]

- Yu, H.H.; Li, C.Z.; Xin, Y.C.; Chapuis, A.; Huang, X.X.; Liu, Q. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Mater. 2017, 128, 313–326. [Google Scholar] [CrossRef]

- Ghaderi, A.; Barnett, M.R. Sensitivity of deformation twinning to grain size in titanium and magnesium. Acta Mater. 2011, 59, 7824–7839. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, J.K.; Kim, B.J.; Park, Y.B. The effect of grain size distribution on the shape of flow stress curves of Mg-3Al-1Zn under uniaxial compression. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 488, 458–467. [Google Scholar] [CrossRef]

- Li, B.; Joshi, S.; Azevedo, K.; Ma, E.; Ramesh, K.T.; Figueiredo, R.B.; Langdon, T.G. Dynamic testing at high strain rates of an ultrafine-grained magnesium alloy processed by ECAP. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2009, 517, 24–29. [Google Scholar] [CrossRef]

- Zheng, R.X.; Bhattacharjee, T.; Shibata, A.; Sasaki, T.; Hono, K.; Joshi, M.; Tsuji, N. Simultaneously enhanced strength and ductility of Mg-Zn-Zr-Ca alloy with fully recrystallized ultrafine grained structures. Scr. Mater. 2017, 131, 1–5. [Google Scholar] [CrossRef]

- Guo, X.; Ma, C.; Zhao, L.; Chapuis, A.; Liu, Q.; Wu, P. Effect of pre-deformation on the activation stress of {10–12} twinning in Mg–3Al–1Zn alloy. Mater. Sci. Eng. A 2021, 800, 140384. [Google Scholar] [CrossRef]

- Xin, Y.C.; Wang, M.Y.; Zeng, Z.; Nie, M.G.; Liu, Q. Strengthening and toughening of magnesium alloy by {10–12} extension twins. Scr. Mater. 2012, 66, 25–28. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.L.; Sun, L.Y.; Chen, G.; Liu, Q. Enhancing the strength of rolled ZK60 alloys via the combined use of twinning deformation and aging treatment. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 582, 68–75. [Google Scholar] [CrossRef]

- Song, B.; Guo, N.; Liu, T.T.; Yang, Q.S. Improvement of formability and mechanical properties of magnesium alloys via pre-twinning: A review. Mater. Des. 2014, 62, 352–360. [Google Scholar] [CrossRef]

- Xin, Y.C.; Wang, M.Y.; Zeng, Z.; Huang, G.J.; Liu, Q. Tailoring the texture of magnesium alloy by twinning deformation to improve the rolling capability. Scr. Mater. 2011, 64, 986–989. [Google Scholar] [CrossRef]

- Barnett, M.R. Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31. J. Light Met. 2001, 1, 167–177. [Google Scholar] [CrossRef]

- Knezevic, M.; Levinson, A.; Harris, R.; Mishra, R.K.; Doherty, R.D.; Kalidindi, S.R. Deformation twinning in AZ31: Influence on strain hardening and texture evolution. Acta Mater. 2010, 58, 6230–6242. [Google Scholar] [CrossRef]

- Wang, B.S.; Xin, R.L.; Huang, G.J.; Liu, Q. Strain rate and texture effects on microstructural characteristics of Mg-3Al-1Zn alloy during compression. Scr. Mater. 2012, 66, 239–242. [Google Scholar] [CrossRef]

- Chen, P.; Wang, F.X.; Li, B. Dislocation absorption and transmutation at {10–12} twin boundaries in deformation of magnesium. Acta Mater. 2019, 164, 440–453. [Google Scholar] [CrossRef]

- Chen, P.; Li, B.; Culbertson, D.; Jiang, Y. Negligible effect of twin-slip interaction on hardening in deformation of a Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2018, 729, 285–293. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Lee, C.S. Role of {10–12} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy. Acta Mater. 2010, 58, 5873–5885. [Google Scholar] [CrossRef]

- Sun, Q.; Xia, T.; Tan, L.; Tu, J.; Zhang, M.; Zhu, M.; Zhang, X. Influence of {10–12} twin characteristics on detwinning in Mg-3Al-1Zn alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 735, 243–249. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, J.H.; Huh, Y.-H.; Hong, S.-G. Enhancing the effect of texture control using {10–12} twins by retarding detwinning activity in rolled Mg–3Al–1Zn alloy. Scr. Mater. 2013, 69, 797–800. [Google Scholar] [CrossRef]

- Li, Y.P.; Cui, Y.J.; Bian, H.K.; Sun, S.H.; Tang, N.; Chen, Y.; Liu, B.; Koizumi, Y.; Chiba, A. Detwining in Mg alloy with a high density of twin boundaries. Sci. Technol. Adv. Mater. 2014, 15, 8. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Jonas, J.J.; Luo, A.A.; Sachdev, A.K.; Godet, S. Influence of {10–12} extension twinning on the flow behavior of AZ31 Mg alloy. Mater. Sci. Eng. A 2007, 445–446, 302–309. [Google Scholar] [CrossRef]

- Yu, H.; Xin, Y.; Wang, M.; Liu, Q. Hall-Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar] [CrossRef]

- Yu, H.H.; Xin, Y.C.; Chapuis, A.; Huang, X.X.; Xin, R.L.; Liu, Q. The different effects of twin boundary and grain boundary on reducing tension-compression yield asymmetry of Mg alloys. Sci. Rep. 2016, 6, 8. [Google Scholar] [CrossRef]

- Wang, L.H.; Teng, J.; Wu, Y.; Sha, X.C.; Xiang, S.S.; Mao, S.C.; Yu, G.H.; Zhang, Z.; Zou, J.; Han, X.D. In situ atomic scale mechanisms of strain-induced twin boundary shear to high angle grain boundary in nanocrystalline Pt. Ultramicroscopy 2018, 195, 69–73. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, X.Y.; Ren, Y.; Tu, J.; Liu, Q. Interfacial structure of {10–12} twin tip in deformed magnesium alloy. Scr. Mater. 2014, 90–91, 41–44. [Google Scholar] [CrossRef]

| Yield Stress (MPa) | Stresses Corresponding to Different Strains (MPa) | Elongation (%) | ||||

|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | |||

| ERD0CA | 178 | 184 | 205 | 211 | 221 | 21 |

| ERD0.9CA | 182 | 192 | 213 | 221 | 229 | 19 |

| ERD1.3CA | 186 | 193 | 220 | 232 | 244 | 17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Yang, P.; Yang, Z.; Sun, Q.; Tan, L. Towards Understanding Relationships between Tension Property and Twinning Boundaries in Magnesium Alloy. Metals 2021, 11, 745. https://doi.org/10.3390/met11050745

Bai J, Yang P, Yang Z, Sun Q, Tan L. Towards Understanding Relationships between Tension Property and Twinning Boundaries in Magnesium Alloy. Metals. 2021; 11(5):745. https://doi.org/10.3390/met11050745

Chicago/Turabian StyleBai, Jianhui, Pengfei Yang, Zhiyuan Yang, Qi Sun, and Li Tan. 2021. "Towards Understanding Relationships between Tension Property and Twinning Boundaries in Magnesium Alloy" Metals 11, no. 5: 745. https://doi.org/10.3390/met11050745

APA StyleBai, J., Yang, P., Yang, Z., Sun, Q., & Tan, L. (2021). Towards Understanding Relationships between Tension Property and Twinning Boundaries in Magnesium Alloy. Metals, 11(5), 745. https://doi.org/10.3390/met11050745