Flow Stress of 6061 Aluminum Alloy at Typical Temperatures during Friction Stir Welding Based on Hot Compression Tests

Abstract

:1. Introduction

2. Materials and Methods

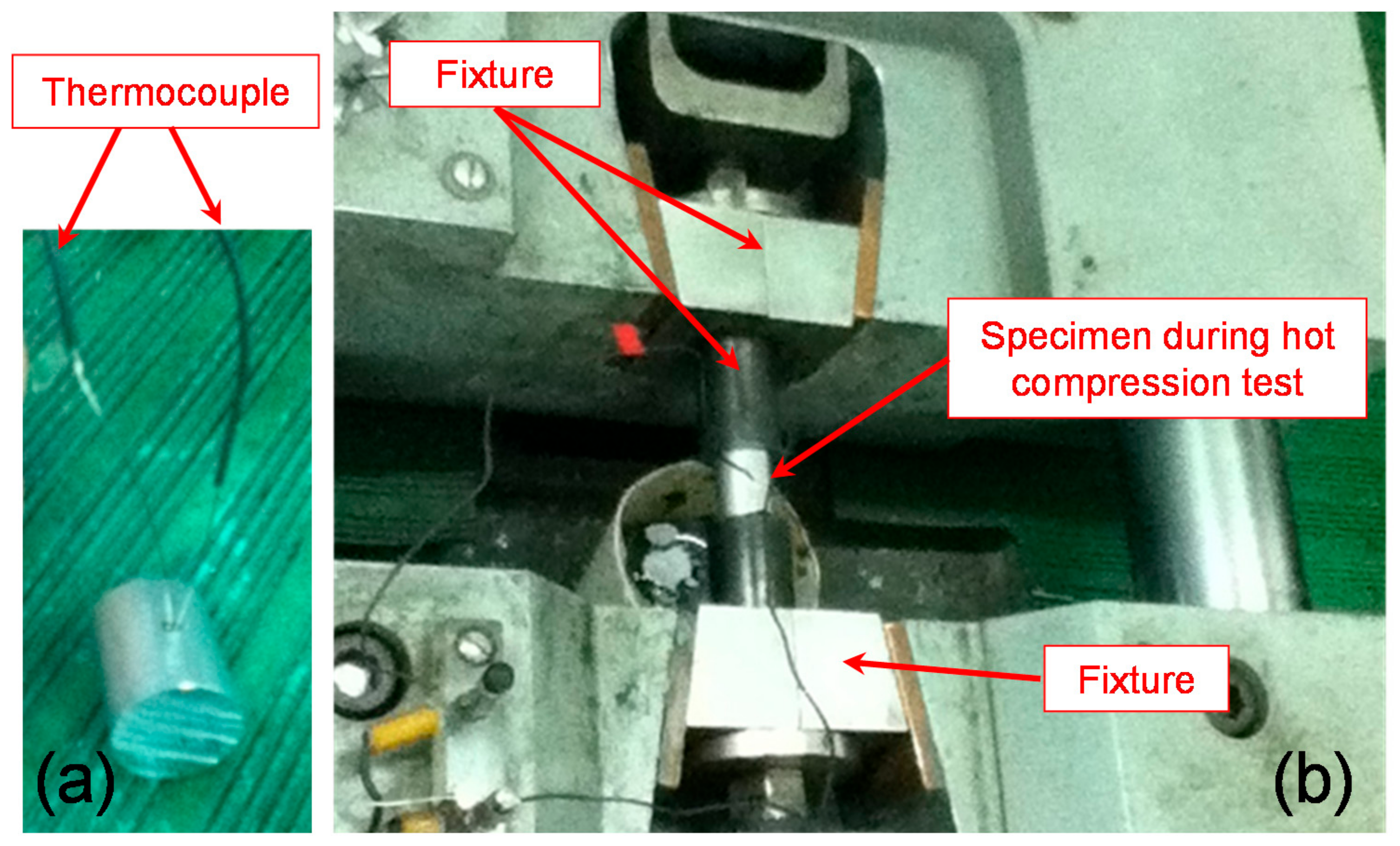

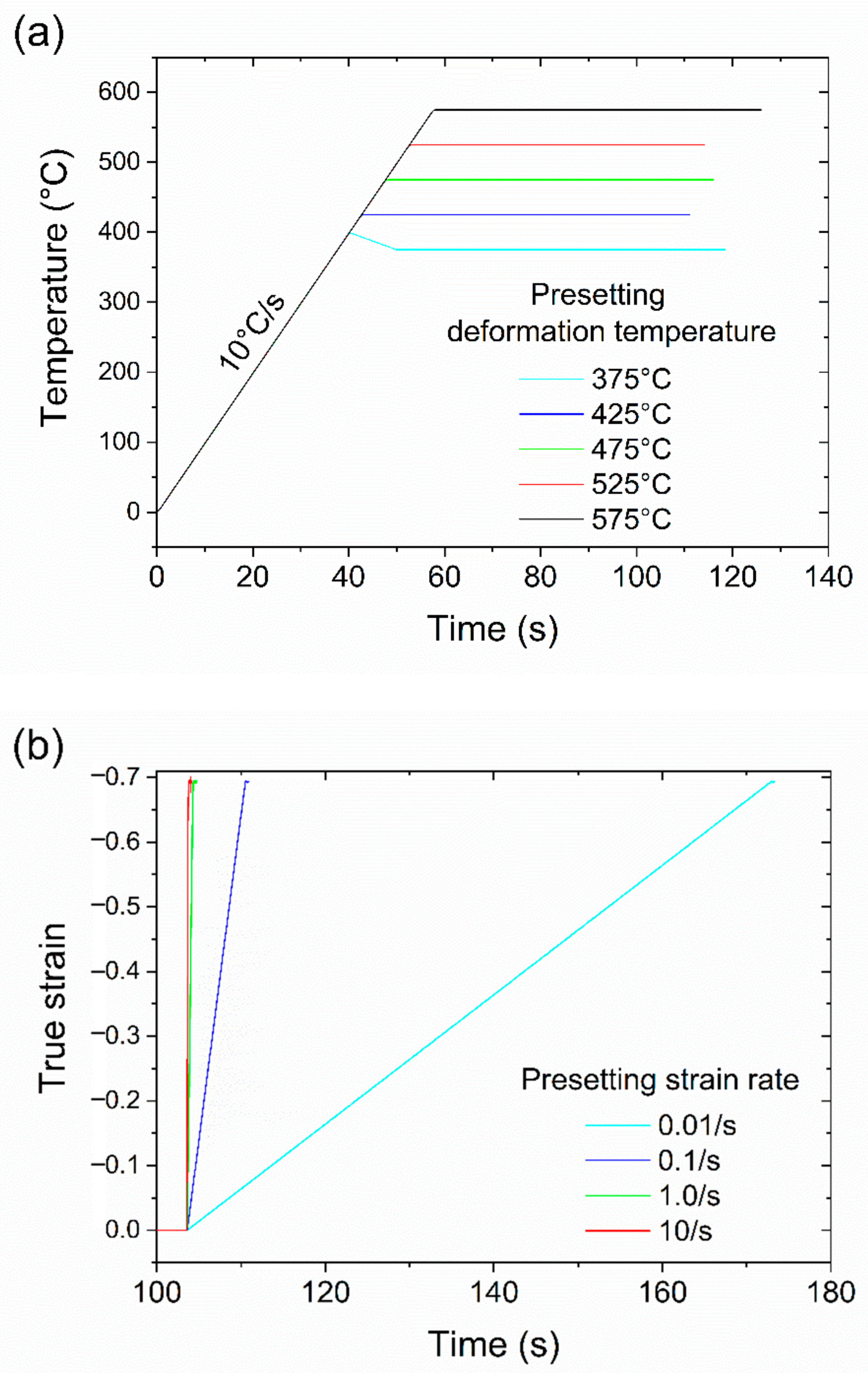

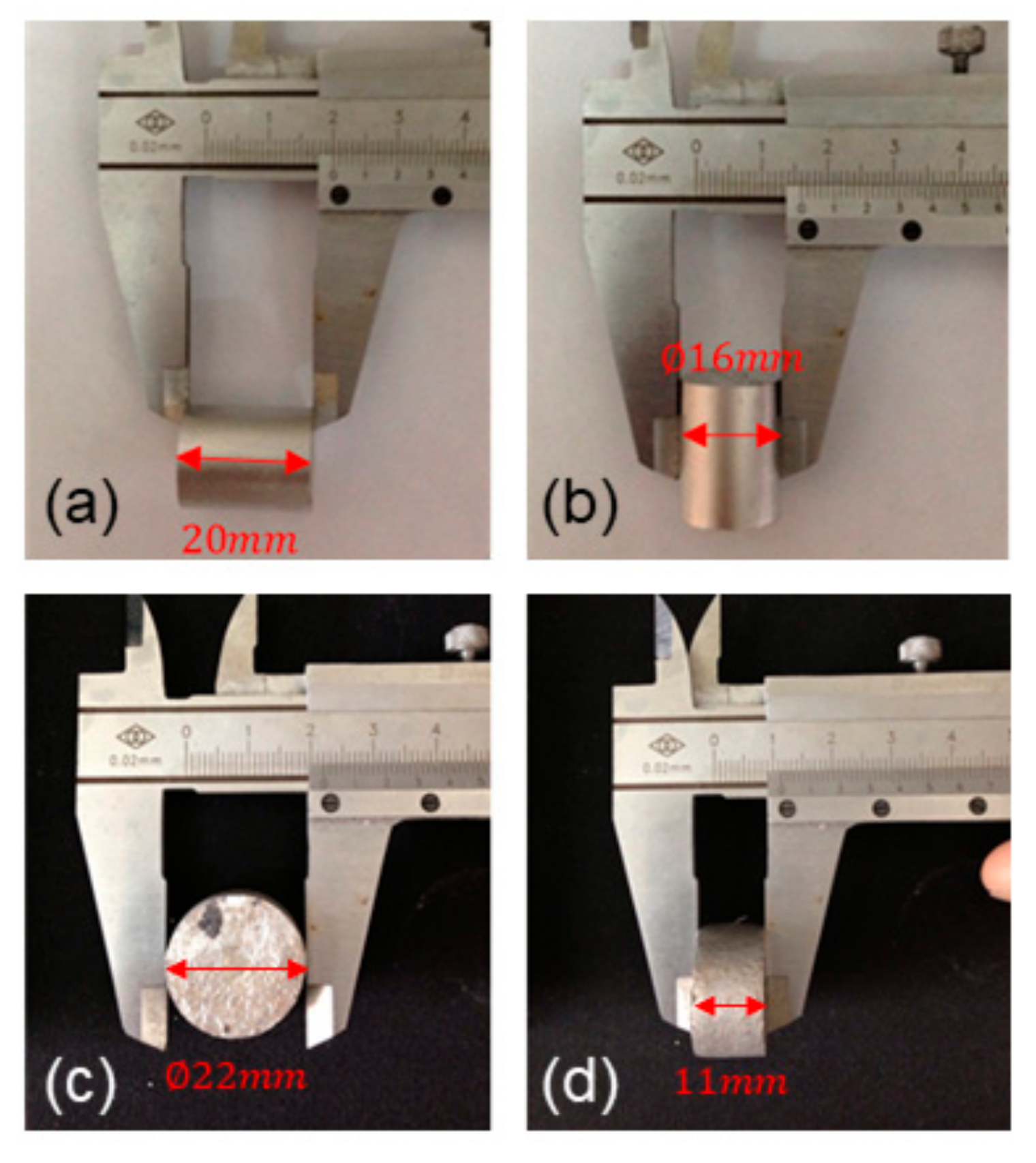

2.1. Hot Compression Tests

2.2. Preparation of Dataset for Building the Flow Stress Models

2.3. Approaches for Determining the Constants in the Sellars–Tegart Equation

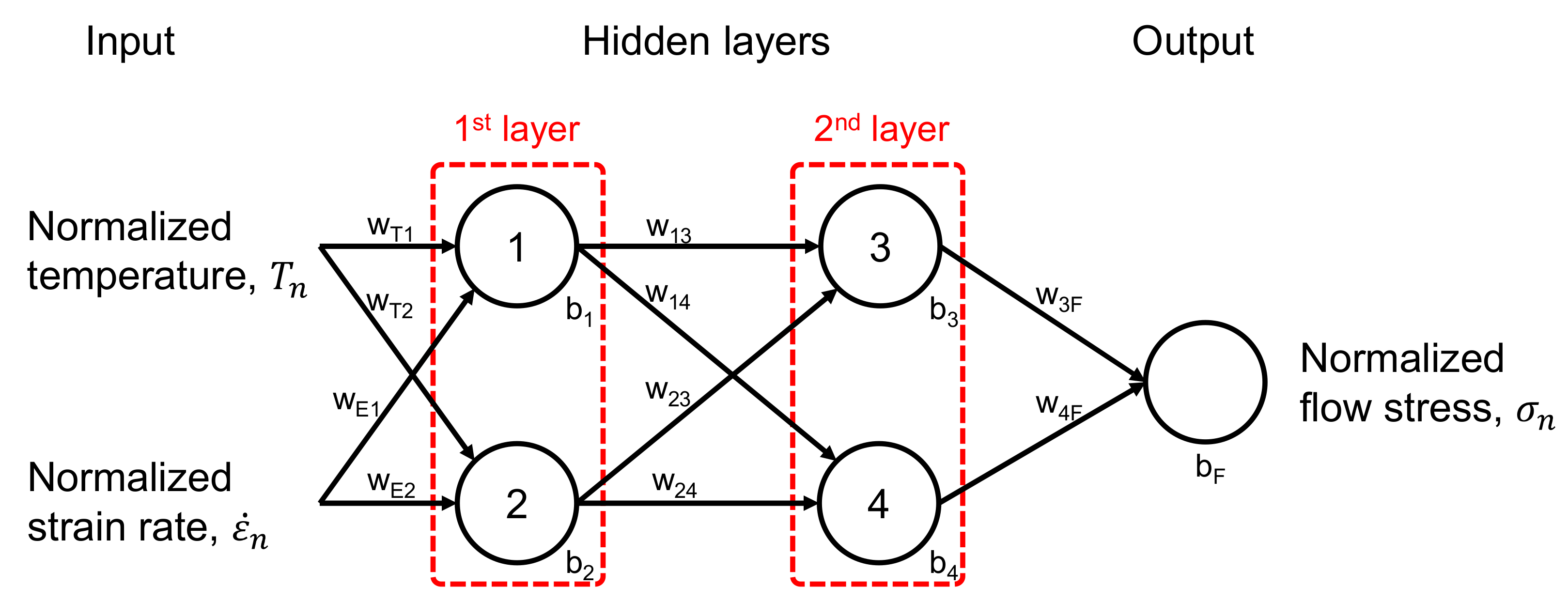

2.4. Structure and Training Method of the Artificial Neural Network

3. Results and Discussion

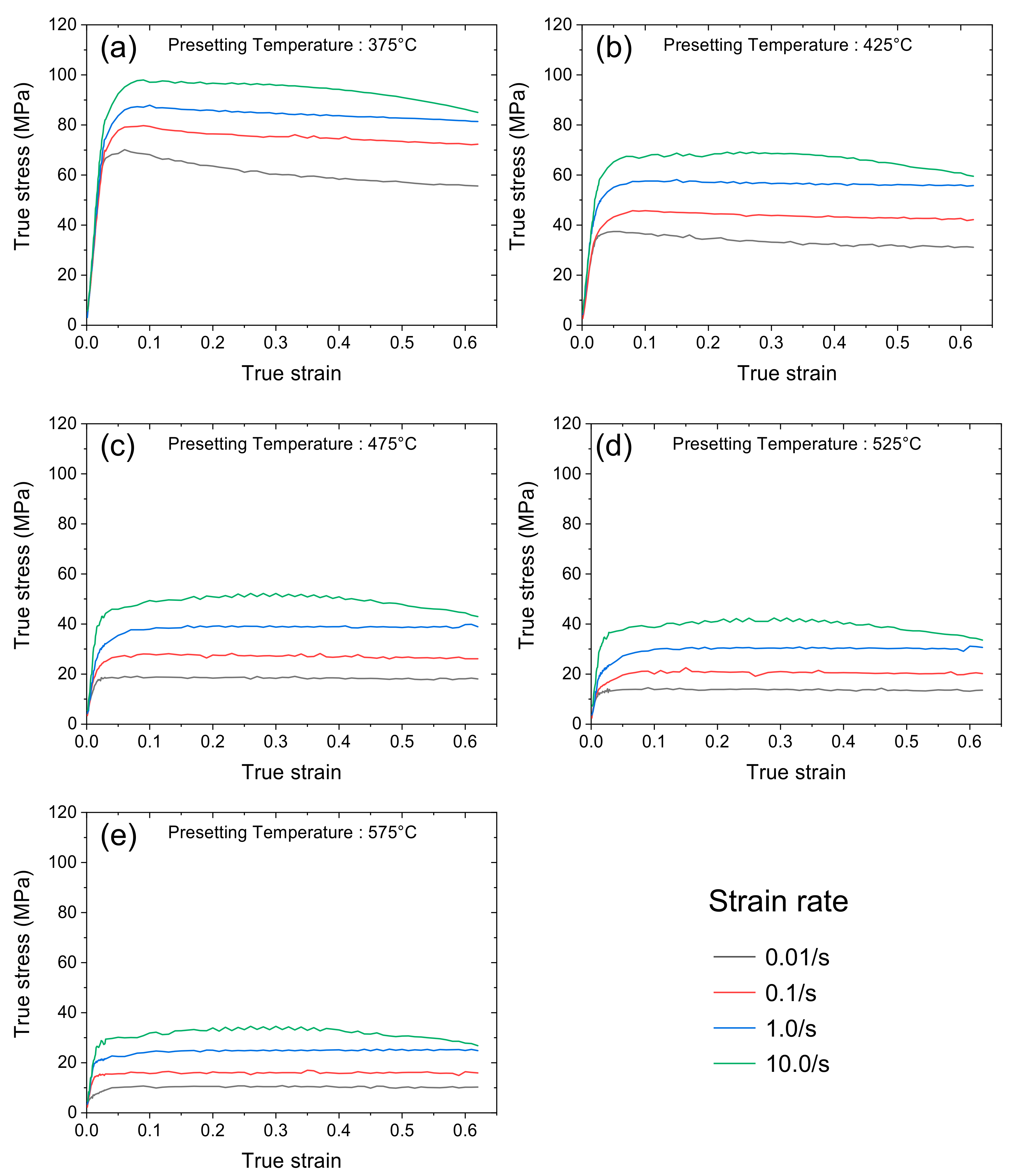

3.1. Measured Stress–Strain Curve

3.2. Measured Temperature–Strain Curve

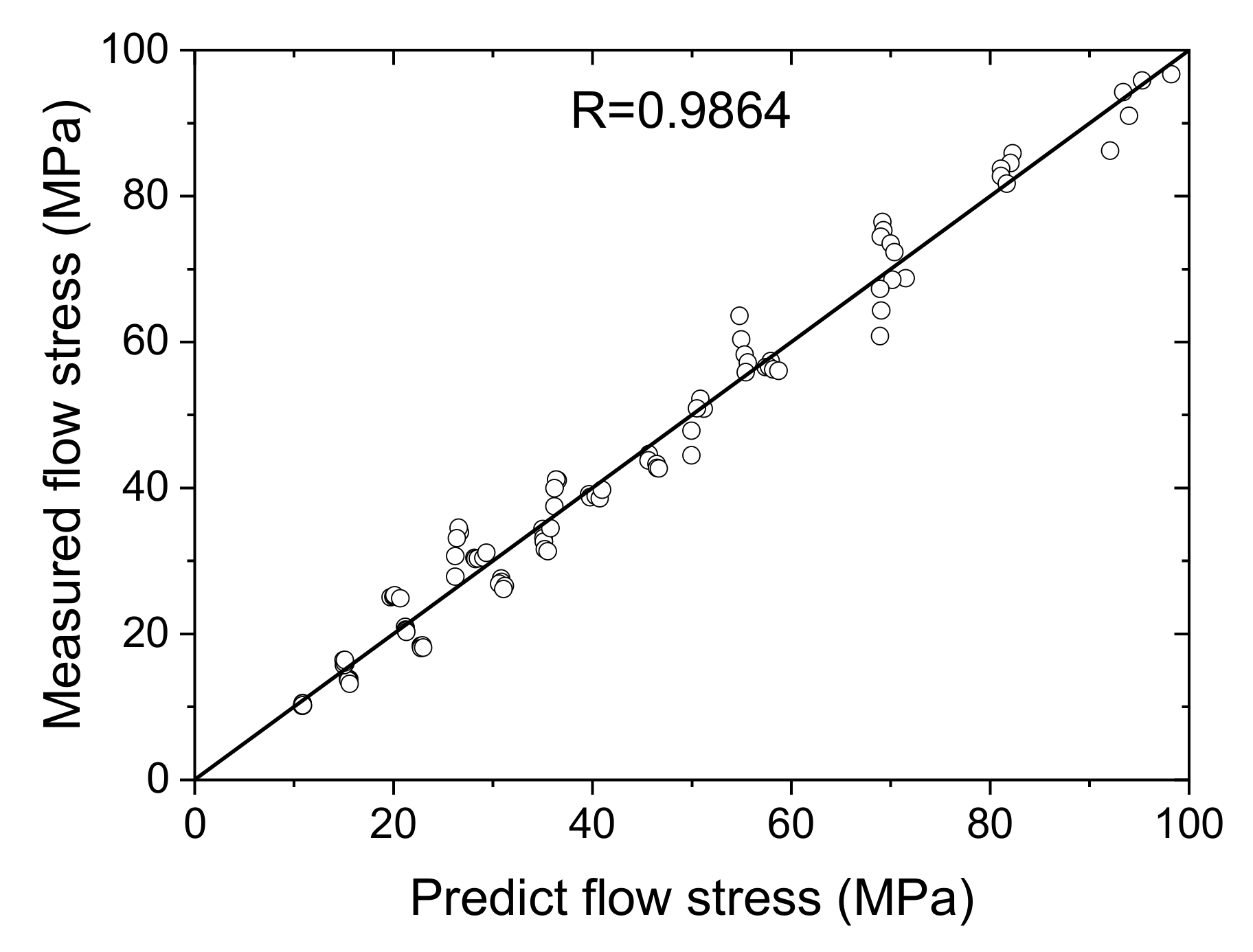

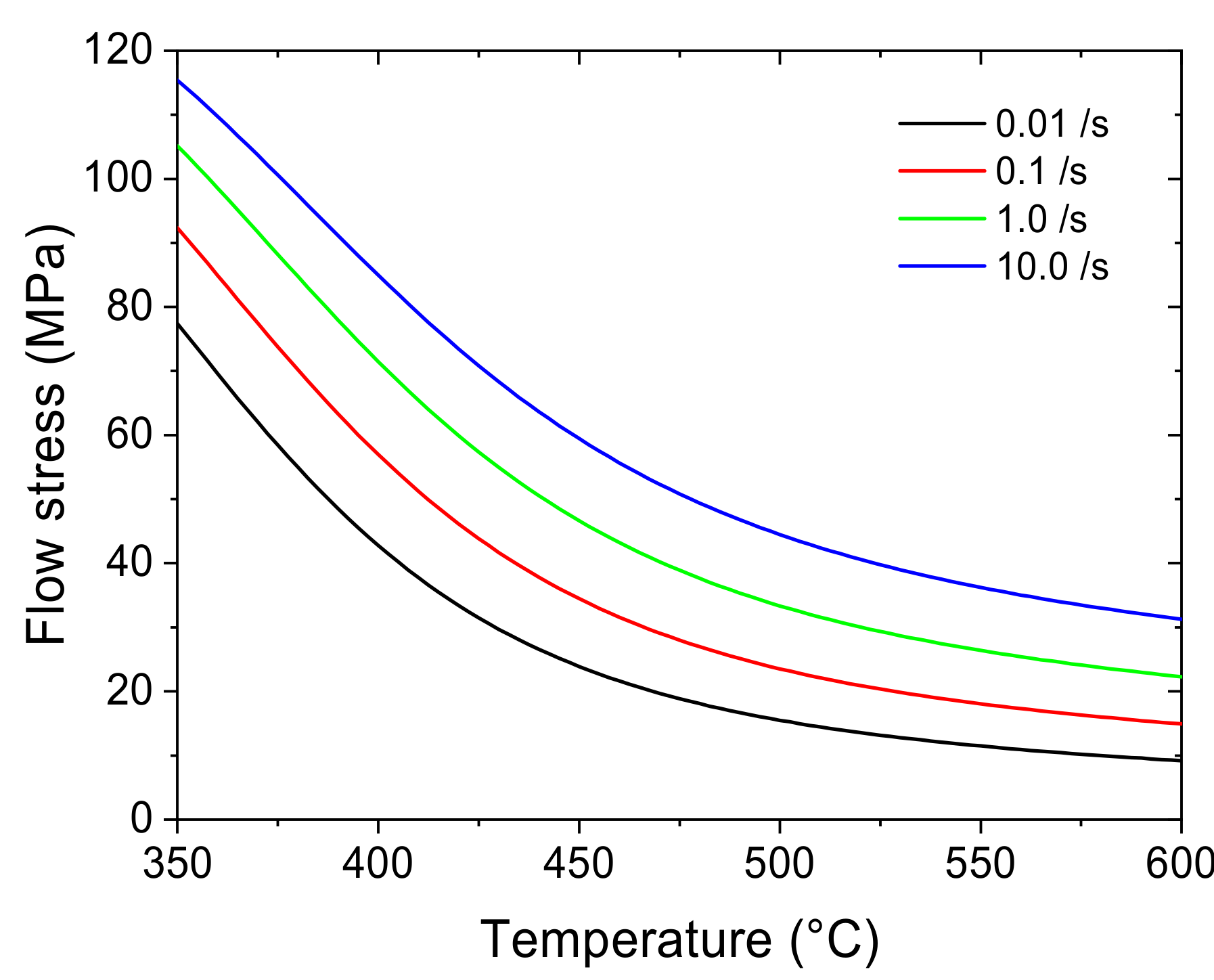

3.3. Predicting the Flow Stress by the Sellars–Tegart Equation

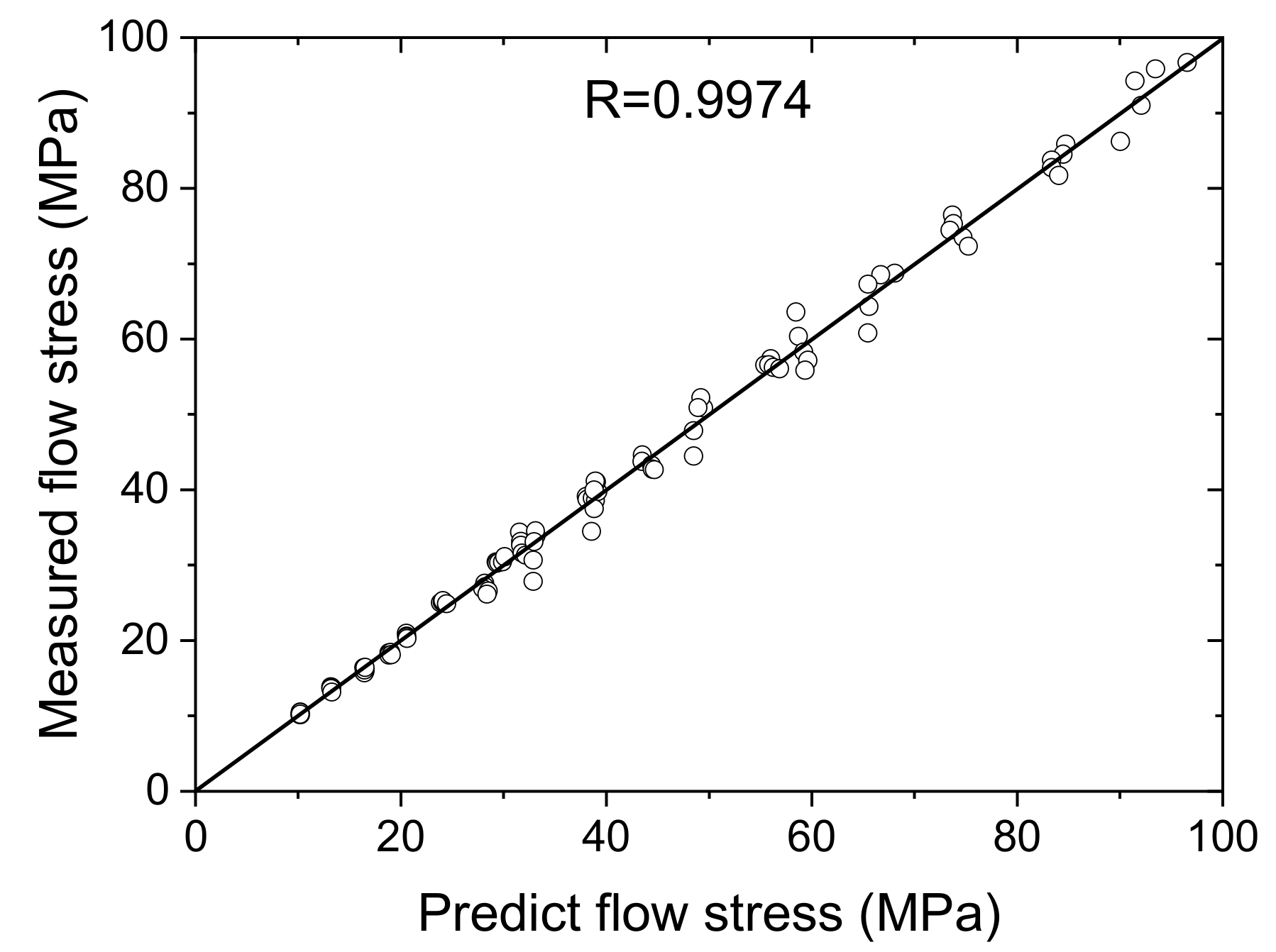

3.4. Predicting the Flow Stress by Artificial Neural Network

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Strain rate | |

| Flow stress | |

| Deformation activation energy | |

| Temperature | |

| , , and | Material constants in the Sellars–Tegart equation |

| Normalized temperature | |

| Normalized strain rate | |

| Normalized flow stress | |

| Input signal of the artificial neural network | |

| Output of neuron 1 | |

| Output of neuron 2 | |

| Output of neuron 3 | |

| Output of neuron 4 | |

| , , , , , , , , and | Weight coefficients |

| Bias of neuron 1 | |

| Bias of neuron 2 | |

| Bias of neuron 3 | |

| Bias of neuron 4 | |

| Bias in the output layer | |

| Number of data point in the dataset | |

| The ith predicted flow stress in the dataset | |

| The ith measured flow stress in the dataset |

References

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R-Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H. Recent advances in friction-stir welding–process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.; Ding, Y.; Gerlich, A.P. Advances in friction stir spot welding. Crit. Rev. Solid State Mater. Sci. 2019, 1–78. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Saboori, A.; Hong, S.I.; Pavese, M. Comparative Insight into the Interfacial Phase Evolutions during Solution Treatment of Dissimilar Friction Stir Welded AA2198-AA7475 and AA2198-AA6013 Aluminum Sheets. Materials 2021, 14, 1290. [Google Scholar] [CrossRef]

- El Rayes, M.M.; Soliman, M.S.; Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Abdel-mawla, M.M. Effect of Feed Rate in FSW on the Mechanical and Microstructural Properties of AA5754 Joints. Adv. Mater. Sci. Eng. 2019, 2019, 4156176. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.F.; Luo, Y.X.; Fu, M.W. Microstructure evolution in the conventional single side and bobbin tool friction stir welding of thick rolled 7085-T7452 aluminum alloy. Mater. Charact. 2018, 138, 48–55. [Google Scholar] [CrossRef]

- Chen, J.; Ueji, R.; Fujii, H. Double-sided friction-stir welding of magnesium alloy with concave-convex tools for texture control. Mater. Des. 2015, 76, 181–189. [Google Scholar] [CrossRef]

- Mori, K.-I.; Bay, N.; Fratini, L.; Micari, F.; Tekkaya, A.E. Joining by plastic deformation. CIRP Ann. 2013, 62, 673–694. [Google Scholar] [CrossRef]

- Chen, G.Q.; Shi, Q.Y.; Li, Y.J.; Sun, Y.J.; Dai, Q.L.; Jia, J.Y.; Zhu, Y.C.; Wu, J.J. Computational fluid dynamics studies on heat generation during friction stir welding of aluminum alloy. Comput. Mater. Sci. 2013, 79, 540–546. [Google Scholar] [CrossRef]

- Nandan, R.; Roy, G.G.; Lienert, T.J.; Debroy, T. Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater. 2007, 55, 883–895. [Google Scholar] [CrossRef]

- Yu, P.; Wu, C.; Shi, L. Analysis and characterization of dynamic recrystallization and grain structure evolution in friction stir welding of aluminum plates. Acta Mater. 2021, 207, 116692. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, C.S.; Su, H. Ultrasonic effect on thickness variations of intermetallic compound layers in friction stir welding of aluminium/magnesium alloys. J. Manuf. Process. 2021, 62, 388–402. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Chen, G.Q.; Chen, Q.L.; Zhang, G.; Shi, Q.Y. Simulation of material plastic flow driven by non-uniform friction force during friction stir welding and related defect prediction. Mater. Des. 2016, 108, 400–410. [Google Scholar] [CrossRef]

- Long, L.; Chen, G.Q.; Zhang, S.; Liu, T.; Shi, Q.Y. Finite-element analysis of the tool tilt angle effect on the formation of friction stir welds. J. Manuf. Process. 2017, 30, 562–569. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, S.; Zhu, Y.; Yang, C.; Shi, Q. Thermo-mechanical Analysis of Friction Stir Welding: A Review on Recent Advances. Acta Metall. Sin. 2020, 33, 3–12. [Google Scholar] [CrossRef] [Green Version]

- He, X.C.; Gu, F.S.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef] [Green Version]

- Sellars, C.; McTegart, W. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R. 3-Dimensional CFD modelling of flow round a threaded friction stir welding tool profile. J. Mater. Process. Technol. 2005, 169, 320–327. [Google Scholar] [CrossRef]

- Pan, W.X.; Li, D.S.; Tartakovsky, A.M.; Ahzi, S.; Khraisheh, M.; Khaleel, M. A new smoothed particle hydrodynamics non-Newtonian model for friction stir welding: Process modeling and simulation of microstructure evolution in a magnesium alloy. Int. J. Plast. 2013, 48, 189–204. [Google Scholar] [CrossRef]

- Woo, W.; Feng, Z.; Wang, X.L.; Brown, D.W.; Clausen, B.; An, K.; Choo, H.; Hubbard, C.R.; David, S.A. In situ neutron diffraction measurements of temperature and stresses during friction stir welding of 6061-T6 aluminium alloy. Sci. Technol. Weld. Join. 2007, 12, 298–303. [Google Scholar] [CrossRef]

- Liu, Z.L.; Ji, S.D.; Meng, X.C. Joining of magnesium and aluminum alloys via ultrasonic assisted friction stir welding at low temperature. Int. J. Adv. Manuf. Technol. 2018, 97, 4127–4136. [Google Scholar] [CrossRef]

- Liu, F.J.; Fu, L.; Chen, H.Y. Effect of high rotational speed on temperature distribution, microstructure evolution, and mechanical properties of friction stir welded 6061-T6 thin plate joints. Int. J. Adv. Manuf. Technol. 2018, 96, 1823–1833. [Google Scholar] [CrossRef]

- Gerlich, A.; Su, P.; North, T.H. Peak temperatures and microstructures in aluminium and magnesium alloy friction stir spot welds. Sci. Technol. Weld. Join. 2005, 10, 647–652. [Google Scholar] [CrossRef]

- Alharthi, N.H.; Sherif, E.M.; Taha, M.A.; Abbas, A.T.; Abdo, H.S.; Alharbi, H.F. Influence of Extrusion Temperature on the Corrosion Behavior in Sodium Chloride Solution of Solid State Recycled Aluminum Alloy 6061 Chips. Crystals 2020, 10, 353. [Google Scholar] [CrossRef]

- Berndt, N.; Frint, P.; Wagner, M.F.X. Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy. Metals 2018, 8, 51. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Q.-L.; Shan, T.-T.; Geng, R.; Zhang, Y.-Y.; He, H.-Y.; Qiu, F.; Jiang, Q.-C. Effect of Preheating Temperature on the Microstructure and Tensile Properties of 6061 Aluminum Alloy Processed by Hot Rolling-Quenching. Metals 2019, 9, 182. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wang, X.; Zhang, D. Investigation into Constitutive Equation and Hot Compression Deformation Behavior of 6061 Al Alloy. Teh. Vjesn. 2019, 26, 1376–1382. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R. CFD modelling of friction stir welding of thick plate 7449 aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 429–441. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R.; Zettler, R. Model for predicting heat generation and temperature in friction stir welding from the material properties. Sci. Technol. Weld. Join. 2007, 12, 284–297. [Google Scholar] [CrossRef] [Green Version]

- Su, H.; Wu, C.S.; Pittner, A.; Rethmeier, M. Thermal energy generation and distribution in friction stir welding of aluminum alloys. Energy 2014, 77, 720–731. [Google Scholar] [CrossRef]

- Shi, L.; Wu, C.S.; Gao, S.; Padhy, G.K. Modified constitutive equation for use in modeling the ultrasonic vibration enhanced friction stir welding process. Scr. Mater. 2016, 119, 21–26. [Google Scholar] [CrossRef]

- Zhao, W.; Wu, C. Constitutive equation including acoustic stress work and plastic strain for modeling ultrasonic vibration assisted friction stir welding process. Int. J. Mach. Tools Manuf. 2019, 145, 103434. [Google Scholar] [CrossRef]

- Chen, G.Q.; Li, H.; Wang, G.Q.; Guo, Z.Q.; Zhang, S.; Dai, Q.L.; Wang, X.B.; Zhang, G.; Shi, Q.Y. Effects of pin thread on the in-process material flow behavior during friction stir welding: A computational fluid dynamics study. Int. J. Mach. Tools Manuf. 2018, 124, 12–21. [Google Scholar] [CrossRef]

- Chen, G.; Wang, G.; Shi, Q.; Zhao, Y.; Hao, Y.; Zhang, S. Three-dimensional thermal-mechanical analysis of retractable pin tool friction stir welding process. J. Manuf. Process. 2019, 41, 1–9. [Google Scholar] [CrossRef]

- Ding, F.J.; Jia, X.D.; Hong, T.J.; Xu, Y.L. Flow Stress Prediction Model of 6061 Aluminum Alloy Sheet Based on GA-BP and PSO-BP Neural Networks. Rare Metal Mater. Eng. 2020, 49, 1840–1853. [Google Scholar]

- Merayo, D.; Rodriguez-Prieto, A.; Camacho, A.M. Prediction of the Bilinear Stress-Strain Curve of Aluminum Alloys Using Artificial Intelligence and Big Data. Metals 2020, 10, 904. [Google Scholar] [CrossRef]

- Huang, C.; Jia, X.; Zhang, Z. A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy. Materials 2018, 11, 855. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khalaj, G.; Azimzadegan, T.; Khoeini, M.; Etaat, M. Artificial neural networks application to predict the ultimate tensile strength of X70 pipeline steels. Neural Comput. Appl. 2013, 23, 2301–2308. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Hosseini Monazzah, A.; Bagheri, R.; Seyed Reihani, S.M.; Khalaj, G.; Nazari, A.; Jandaghi, M.R. Toughness prediction in functionally graded Al6061/SiCp composites produced by roll-bonding. Ceram. Int. 2014, 40, 8809–8825. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Janaszek-Mańkowska, M. Optimisation of ANN topology for predicting the rehydrated apple cubes colour change using RSM and GA. Neural Comput. Appl. 2018, 30, 1795–1809. [Google Scholar] [CrossRef] [Green Version]

- Hwang, Y.-M.; Kang, Z.-W.; Chiou, Y.-C.; Hsu, H.-H. Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys. Int. J. Mach. Tools Manuf. 2008, 48, 778–787. [Google Scholar] [CrossRef]

- Assidi, M.; Fourment, L.; Guerdoux, S.; Nelson, T. Friction model for friction stir welding process simulation: Calibrations from welding experiments. Int. J. Mach. Tools Manuf. 2010, 50, 143–155. [Google Scholar] [CrossRef]

- Feng, Z.; Wang, X.L.; David, S.A.; Sklad, P.S. Modelling of residual stresses and property distributions in friction stir welds of aluminium alloy 6061-T6. Sci. Technol. Weld. Join. 2007, 12, 348–356. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Shen, Y.F.; Li, B.; Xu, H.S.; Yao, X.; Kuang, B.B.; Gao, J.C. Numerical simulation and experimental investigation on friction stir welding of 6061-T6 aluminum alloy. Mater. Des. 2014, 60, 94–101. [Google Scholar] [CrossRef]

- Sun, Z.; Wu, C.S. A numerical model of pin thread effect on material flow and heat generation in shear layer during friction stir welding. J. Manuf. Process. 2018, 36, 10–21. [Google Scholar] [CrossRef]

- Zhai, M.; Wu, C.; Su, H. Influence of tool tilt angle on heat transfer and material flow in friction stir welding. J. Manuf. Process. 2020, 59, 98–112. [Google Scholar] [CrossRef]

- Gerlich, A.; Yamamoto, M.; North, T.H. Strain rates and grain growth in Al 5754 and Al 6061 friction stir spot welds. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2007, 38A, 1291–1302. [Google Scholar] [CrossRef]

- Liu, X.C.; Wu, C.S.; Padhy, G.K. Characterization of plastic deformation and material flow in ultrasonic vibration enhanced friction stir welding. Scr. Mater. 2015, 102, 95–98. [Google Scholar] [CrossRef]

- Lei, B.W.; Chen, G.Q.; Liu, K.H.; Wang, X.; Jiang, X.M.; Pan, J.L.; Shi, Q.Y. Constitutive Analysis on High-Temperature Flow Behavior of 3Cr-1Si-1Ni Ultra-High Strength Steel for Modeling of Flow Stress. Metals 2019, 9, 42. [Google Scholar] [CrossRef] [Green Version]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Prasad, Y.; Sasidhara, S. Hot Working guide: A Compendium of Processing Maps; ASM International: Almere, The Netherlands, 1997. [Google Scholar]

| Element | Mg | Si | Cu | Cr | Fe | Mn | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Mass fraction, % | 0.8~1.2 | 0.4~0.8 | 0.15~0.40 | 0.04–0.35 | ≤0.7 | ≤0.15 | ≤0.25 | ≤0.15 | bal |

| No. | Typical Temperature in FSW | Reference |

|---|---|---|

| 1 | 383 °C~408 °C | [42] |

| 2 | 487 °C~547 °C | [43] |

| 3 | 477 °C~571 °C | [44] |

| 4 | 413 °C~456 °C | [45] |

| 5 | 427 °C~477 °C | [46] |

| 6 | 518 °C~536 °C | [47] |

| 7 | 541 °C | [48] |

| Parameters | Value |

|---|---|

| α | 0.0173 MPa−1 |

| n | 7.25 |

| Q | 292 |

| A |

| Parameters | Value |

|---|---|

| wT1 | −0.15598581 |

| wT2 | 1.81017239 |

| wE1 | 0.63329026 |

| wE2 | 0.04463549 |

| w13 | 0.27981264 |

| w14 | −1.63153269 |

| w23 | 0.24637079 |

| w24 | 1.41631146 |

| w3F | 0.59353861 |

| w4F | −0.76671464 |

| b1 | −0.01082548 |

| b2 | 0.16777425 |

| b3 | 0.83656406 |

| b4 | −0.14121194 |

| bF | 0.28329775 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, S.; Shi, Q.; Chen, G. Flow Stress of 6061 Aluminum Alloy at Typical Temperatures during Friction Stir Welding Based on Hot Compression Tests. Metals 2021, 11, 804. https://doi.org/10.3390/met11050804

Ding S, Shi Q, Chen G. Flow Stress of 6061 Aluminum Alloy at Typical Temperatures during Friction Stir Welding Based on Hot Compression Tests. Metals. 2021; 11(5):804. https://doi.org/10.3390/met11050804

Chicago/Turabian StyleDing, Sansan, Qingyu Shi, and Gaoqiang Chen. 2021. "Flow Stress of 6061 Aluminum Alloy at Typical Temperatures during Friction Stir Welding Based on Hot Compression Tests" Metals 11, no. 5: 804. https://doi.org/10.3390/met11050804