Kinetic Analysis of the Transformation from 14M Martensite to L21 Austenite in Ni-Fe-Ga Melt Spun Ribbons

Abstract

1. Introduction

2. Materials and Methods

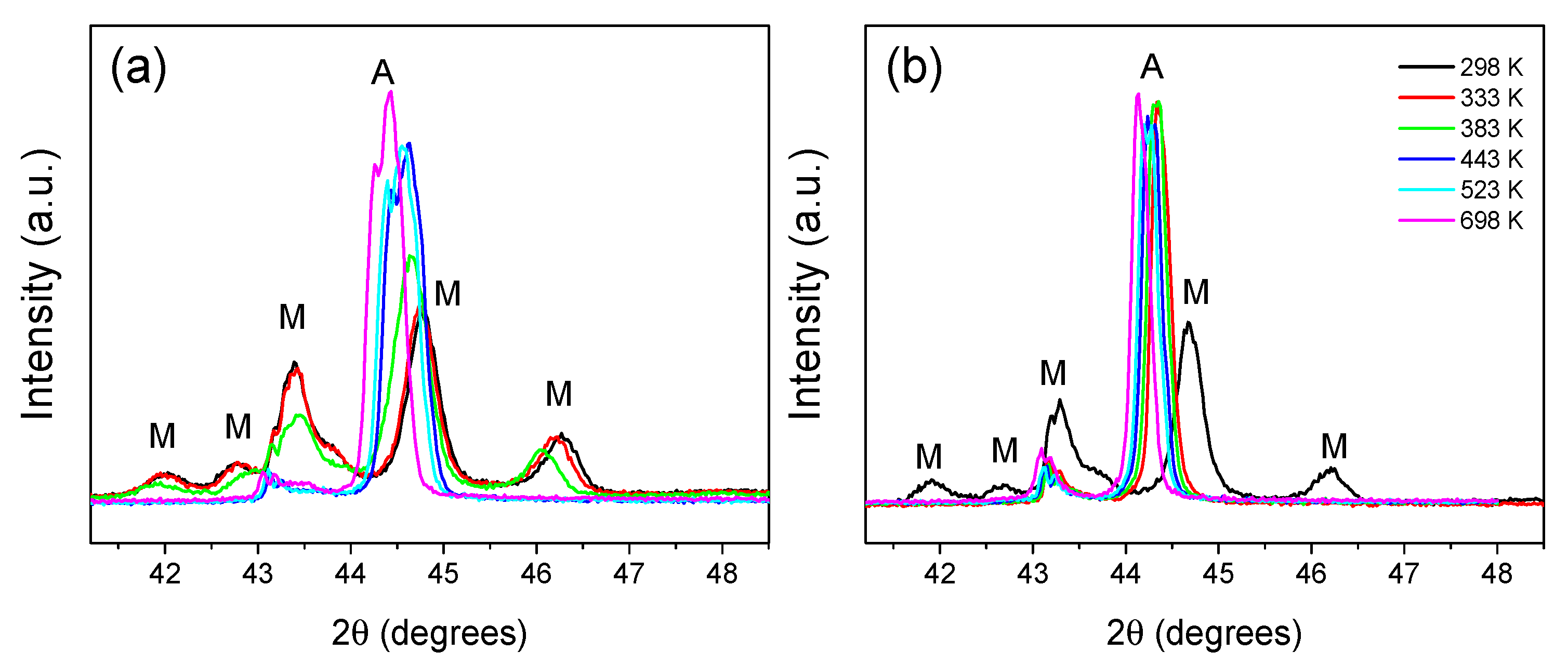

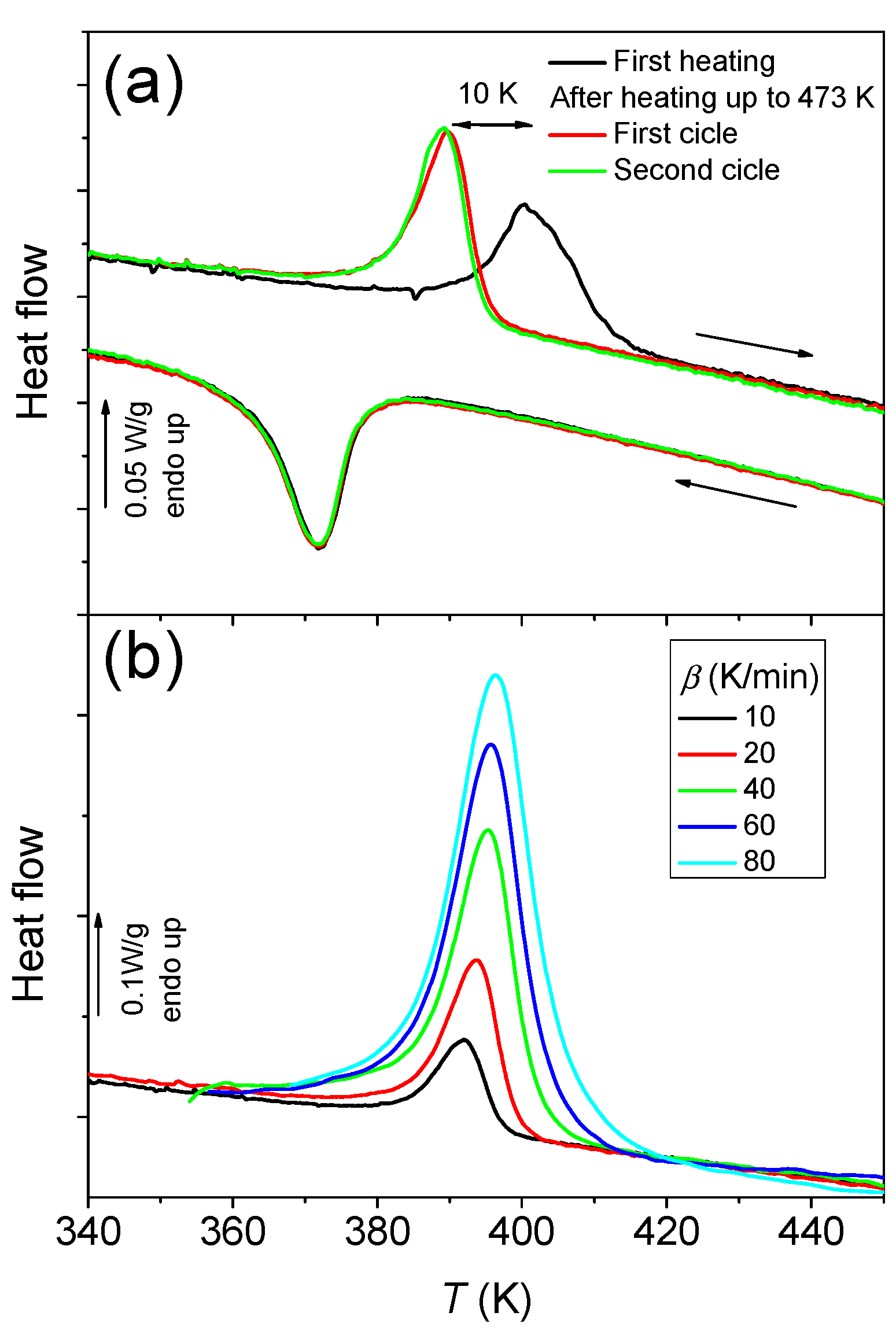

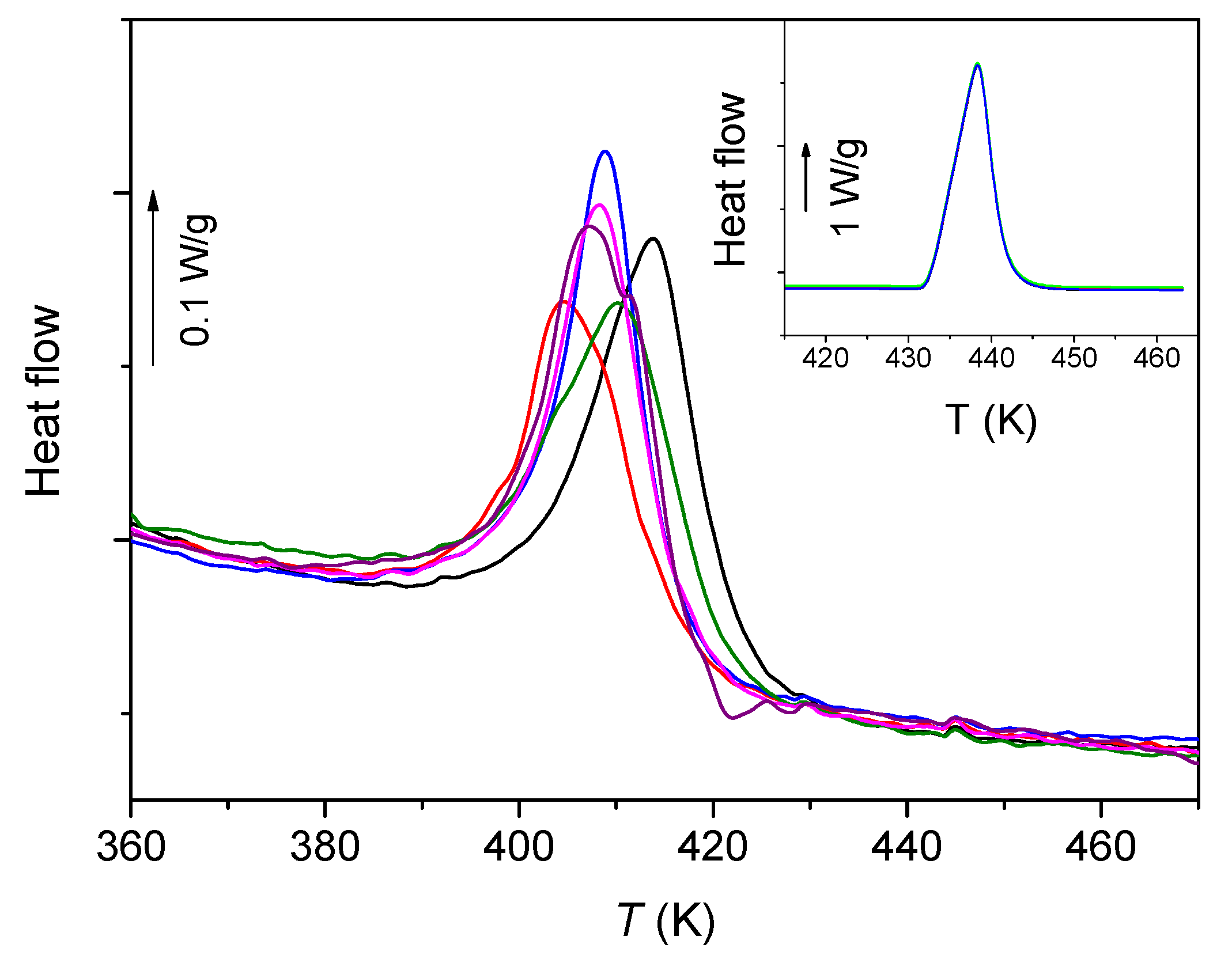

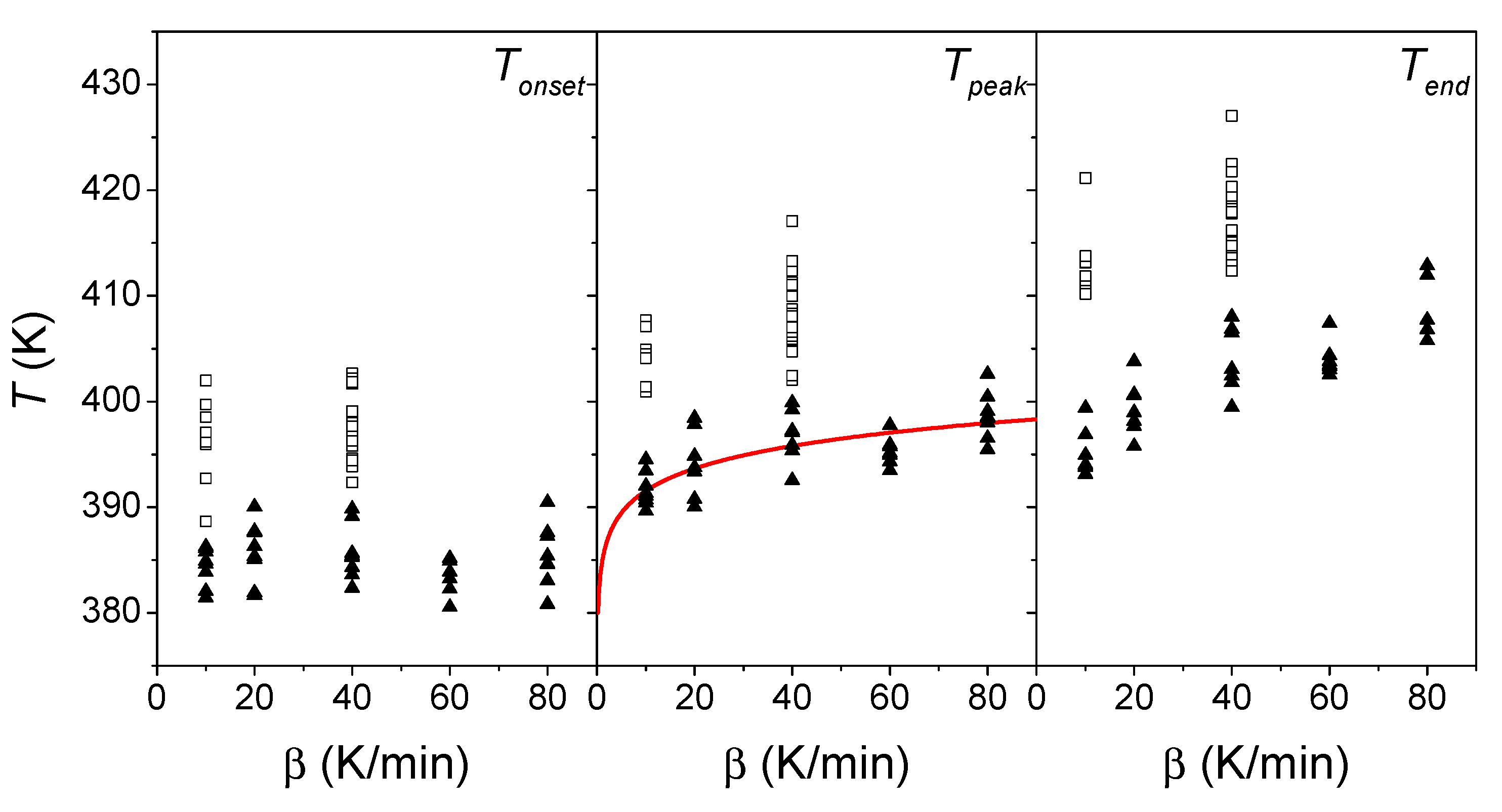

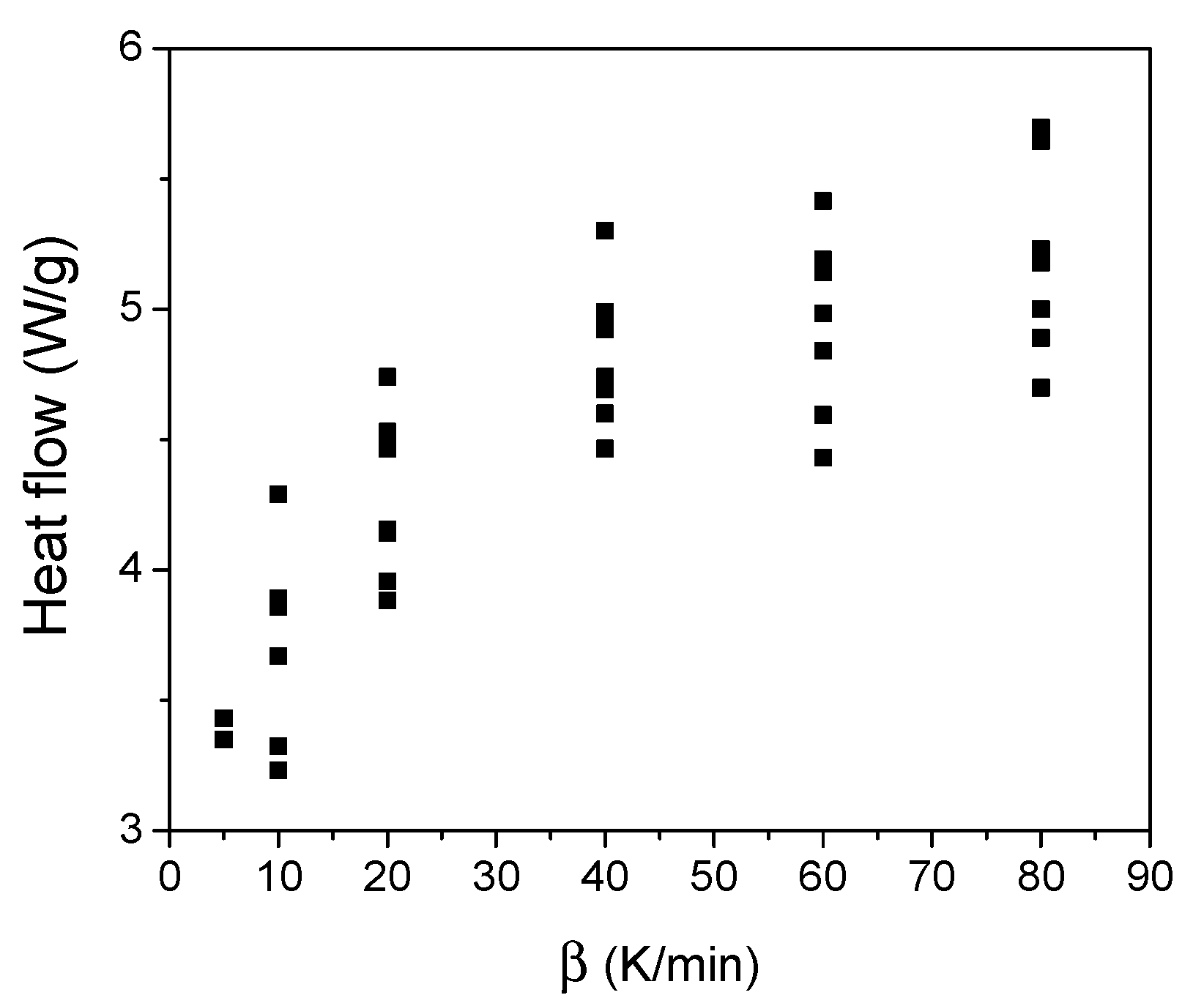

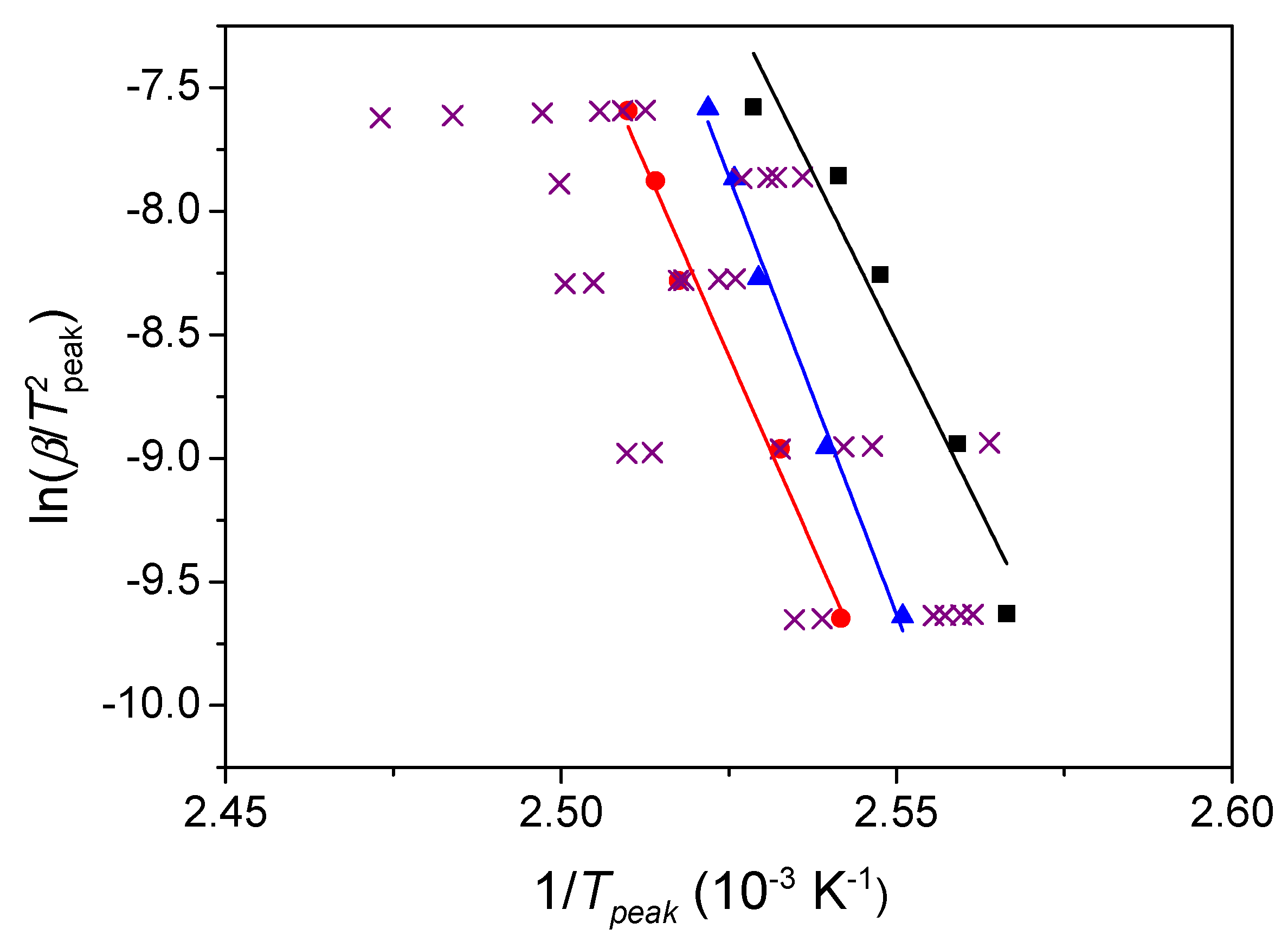

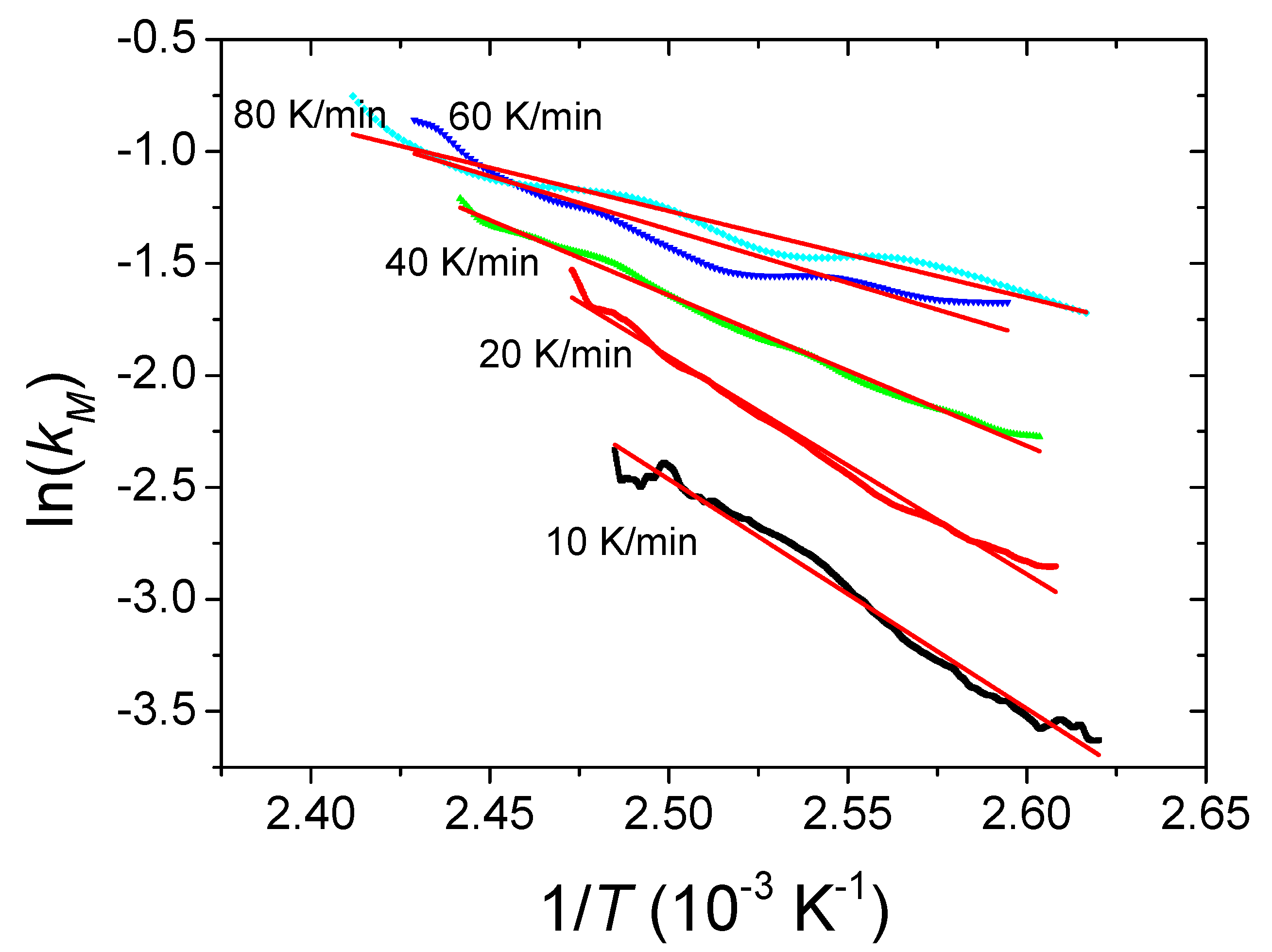

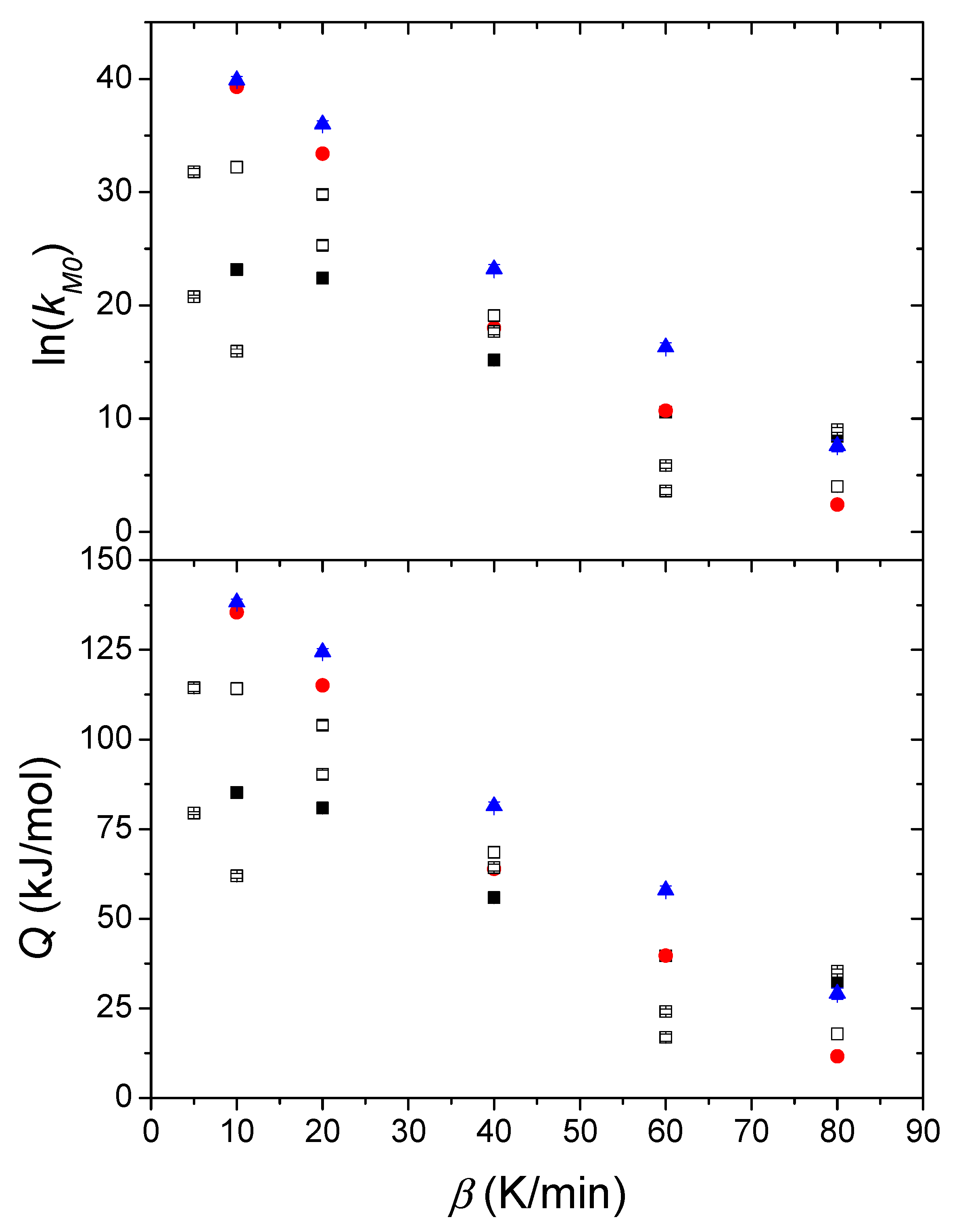

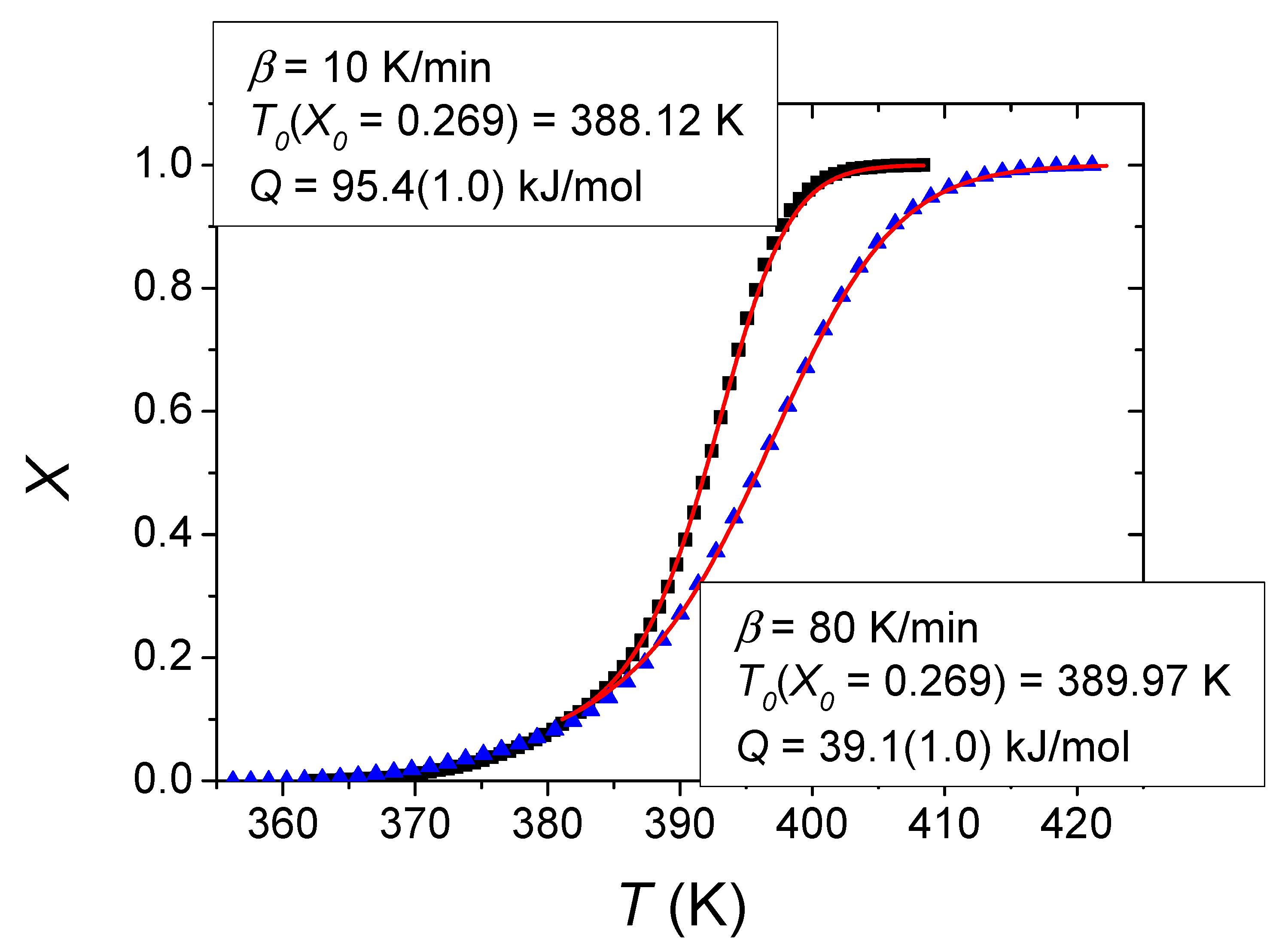

3. Results

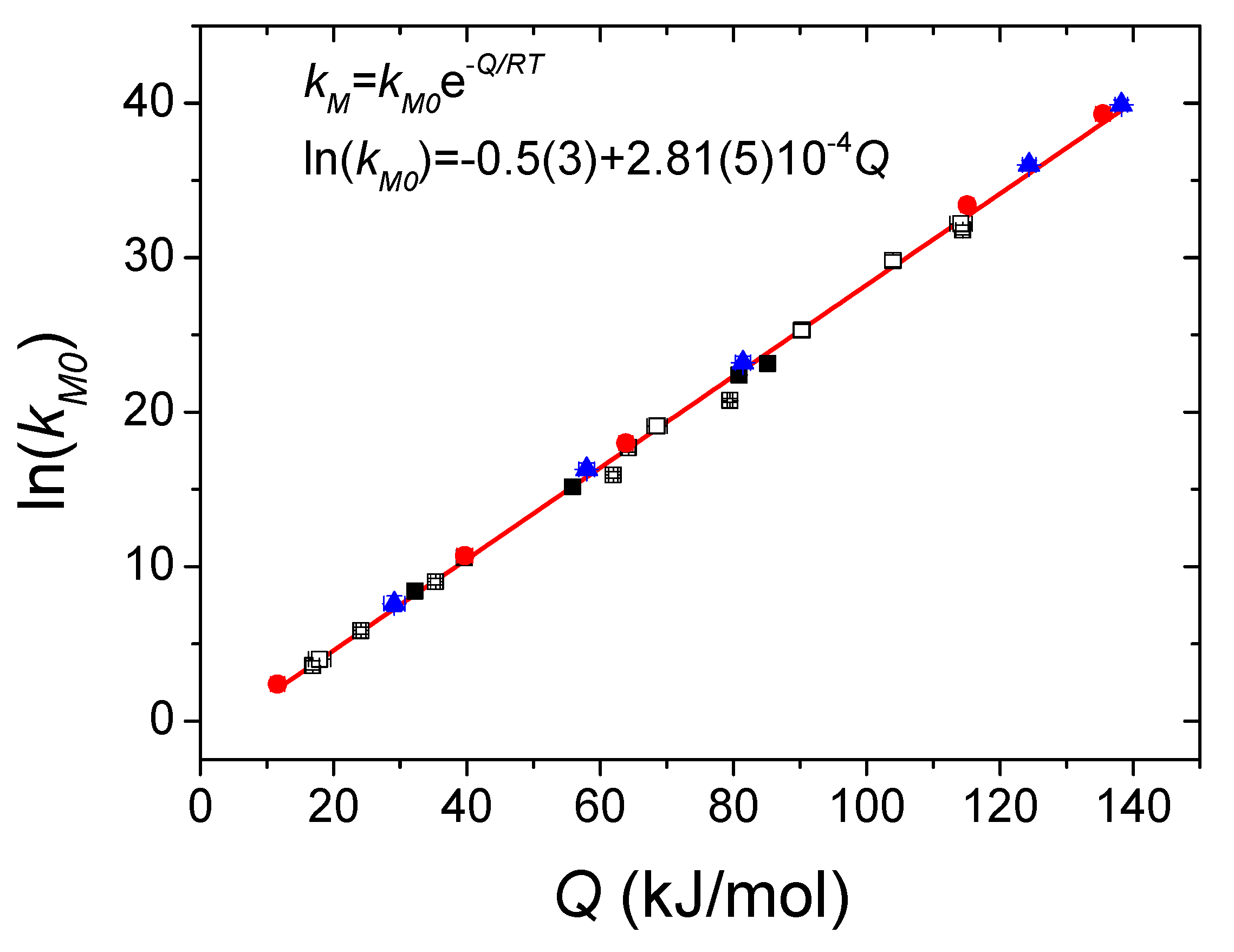

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ullakko, K.; Huang, J.K.; Kantner, C.L.S.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Gràcia-Condal, A.; Gottschall, T.; Pfeuffer, L.; Gutfleisch, O.; Planes, A.; Mañosa, L. Multicaloric effects in metamagnetic Heusler Ni-Mn-In under uniaxial stress and magnetic field. Appl. Phys. Rev. 2020, 7, 41406. [Google Scholar] [CrossRef]

- Krenke, T.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A. Ferromagnetism in the austenitic and martensitic states ofNi−Mn−Inalloys. Phys. Rev. B 2006, 73, 174413. [Google Scholar] [CrossRef]

- Yu, S.Y.; Liu, Z.H.; Liu, G.D.; Chen, J.L.; Cao, Z.X.; Wu, G.H.; Zhang, B.; Zhang, X.X. Large magnetoresistance in single-crystalline Ni50Mn50−xInx alloys (x = 14–16) upon martensitic transformation. Appl. Phys. Lett. 2006, 89, 162503. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Pons, J.; Cesari, E.; Segui, C.; Masdeu, F.; Santamarta, R. Ferromagnetic shape memory alloys: Alternatives to Ni–Mn–Ga. Mater. Sci. Eng. A 2008, 481–482, 57–65. [Google Scholar] [CrossRef]

- Álvarez-Alonso, P.; Aguilar-Ortiz, C.; Villa, E.; Nespoli, A.; Flores-Zúñiga, H.; Chernenko, V. Conventional and inverse elastocaloric effect in Ni-Fe-Ga and Ni-Mn-Sn ribbons. Scr. Mater. 2017, 128, 36–40. [Google Scholar] [CrossRef]

- Pal, D.; Mandal, K. Magnetocaloric effect and magnetoresistance of Ni–Fe–Ga alloys. J. Phys. D Appl. Phys. 2010, 43, 455002. [Google Scholar] [CrossRef]

- Morito, H.; Fujita, A.; Oikawa, K.; Ishida, K.; Fukamichi, K.; Kainuma, R. Stress-assisted magnetic-field-induced strain in Ni–Fe–Ga–Co ferromagnetic shape memory alloys. Appl. Phys. Lett. 2007, 90, 62505. [Google Scholar] [CrossRef]

- Zhang, H.-R.; Wu, G.-H. Atomic-size effect on the microstructural properties of Ni2FeGa. Acta Mater. 2011, 59, 1249–1258. [Google Scholar] [CrossRef]

- Barandiarán, J.M.; Chernenko, V.A.; Lázpita, P.; Gutiérrez, J.; Feuchtwanger, J. Effect of martensitic transformation and magnetic field on transport properties of Ni-Mn-Ga and Ni-Fe-Ga Heusler alloys. Phys. Rev. B 2009, 80, 104404. [Google Scholar] [CrossRef]

- Hamilton, R.; Sehitoglu, H.; Efstathiou, C.; Maier, H. Inter-martensitic transitions in Ni–Fe–Ga single crystals. Acta Mater. 2007, 55, 4867–4876. [Google Scholar] [CrossRef]

- Pérez-Reche, F.-J.; Stipcich, M.; Vives, E.; Mañosa, L.; Planes, A.; Morin, M. Kinetics of martensitic transitions in Cu-Al-Mn under thermal cycling: Analysis at multiple length scales. Phys. Rev. B 2004, 69, 64101. [Google Scholar] [CrossRef]

- Christian, J. The Theory of Transformations in Metals and Alloys; Pergamon Elsevier Science: Oxford, UK, 2002. [Google Scholar]

- Johnson, W.A.; Mehl, R.F. Reaction kinetics in processes of nucleation and growth. Am. Inst. Min. Met. Eng. 1939, 135, 416. [Google Scholar]

- Avrami, M. Kinetics of Phase Change. I General Theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. II Transformation-Time Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Kolmogorov, A.N. A statistical theory for the recrystallisation of metals. Bull. Acad. Sci. USSR Phys. Ser. 1937, 1, 355. [Google Scholar]

- Zhou, Z.; Yang, L.; Li, R.; Li, J.; Hu, Q. Martensitic transformations and kinetics in Ni-Mn-In-Mg shape memory alloys. Intermetallics 2018, 92, 49–54. [Google Scholar] [CrossRef]

- Blazquez, J.S.; Millán, M.; Conde, C.F.; Conde, A.; Amiano, C.F.C. Nanocrystallization kinetics under instantaneous growth approximation: Experiments and cellular automata simulations. Phys. Status Solidi 2010, 207, 1148–1153. [Google Scholar] [CrossRef]

- Koistinen, D.; Marburger, R. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Met. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Burke, J. The Kinetics of Phase Transformations in Metals; Pergamon: Oxford, UK, 1965. [Google Scholar]

- Manchón-Gordón, A.; Ipus, J.; Kowalczyk, M.; Wójcik, A.; Blázquez, J.; Conde, C.; Maziarz, W.; Švec, P.; Kulik, T.; Conde, A. Effect of pressure on the phase stability and magnetostructural transitions in nickel-rich NiFeGa ribbons. J. Alloys Compd. 2020, 844, 156092. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Landazábal, J.; Gomez-Polo, C.; Sánchez-Alarcos, V.; Cesari, E.; Pons, J. Vibrational and magnetic contributions to the entropy change associated with the martensitic transformation of Ni–Fe–Ga ferromagnetic shape memory alloys. J. Phys. Condens. Matter 2010, 22, 416001. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zu, X.; Huo, Y. Effect of heating/cooling rate on the transformation temperatures in TiNiCu shape memory alloys. Thermochim. Acta 2005, 436, 153–155. [Google Scholar] [CrossRef]

- Kalbfleisch, A.-S.; Matthews, G.; Jacques, P.J. On the influence of the cooling rate on the martensitic transformation of Ni–Mn–Sn Heusler alloys. Scr. Mater. 2016, 114, 121–124. [Google Scholar] [CrossRef]

- Yu, H.; Zu, X.; Fu, H.; Zhang, X.; Wang, Z. Effect of annealing and heating/cooling rate on the transformation temperatures of NiFeGa alloy. J. Alloys Compd. 2009, 470, 237–240. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Xu, K.; Kang, Y.; Cao, Y.; Qin, N.; He, X.; Wei, S.; Zeng, H.; Jing, C. Effect of hydrostatic pressure on martensitic transformation and low-temperature magnetic properties in Ni45Cu5Mn35In15 Heusler alloy. J. Magn. Magn. Mater. 2021, 528, 167835. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, R.; Xu, L.; Yang, F.; Yang, C. Pressure effect of magnetic and electronic properties of Mn 2 PtGa Heusler alloy. Phys. Lett. A 2018, 382, 224–230. [Google Scholar] [CrossRef]

- Huo, Y.; Zu, X.; Li, A.; Wang, Z.; Wang, L. Modeling and simulation of irradiation effects on martensitic transformations in shape memory alloys. Acta Mater. 2004, 52, 2683–2690. [Google Scholar] [CrossRef]

- Ben Fraj, B.; Zghal, S.; Tourki, Z. DSC Investigation on Entropy and Enthalpy Changes in Ni-Rich NiTi Shape Memory Alloy at Various Cooling/Heating Rates. In Proceedings of the 2nd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2020); Springer Science and Business Media LLC: Cham, Switzerland, 2018; pp. 631–639. [Google Scholar]

- Nurveren, K.; Akdogan, A.; Huang, W. Evolution of transformation characteristics with heating/cooling rate in NiTi shape memory alloys. J. Mater. Process. Technol. 2008, 196, 129–134. [Google Scholar] [CrossRef]

- Kissinger, H.E. Reaction Kinetics in Differential Thermal Analysis. Anal. Chem. 1957, 29, 1702–1706. [Google Scholar] [CrossRef]

- Sánchez-Alarcos, V.; Pérez-Landazabal, J.; Gomez-Polo, C.; Recarte, V. Influence of the atomic order on the magnetic characteristics of a Ni–Mn–Ga ferromagnetic shape memory alloy. J. Magn. Magn. Mater. 2008, 320, e160–e163. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, D.; Xue, S.; Frenzel, J.; Eggeler, G.; Zhai, Q. Martensitic transformation in rapidly solidified Heusler Ni49Mn39Sn12 ribbons. Acta Mater. 2011, 59, 5692–5699. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Landazábal, J.; Ibarra, A.; Nó, M.; Juan, J.S. High temperature β phase decomposition process in a Cu–Al–Ni shape memory alloy. Mater. Sci. Eng. A 2004, 378, 238–242. [Google Scholar] [CrossRef]

- Brown, M.E.; Galwey, A.K. The significance of “compensation effects” appearing in data published in “computational aspects of kinetic analysis”: ICTAC project, 2000. Thermochim. Acta 2002, 387, 173–183. [Google Scholar] [CrossRef]

- Mianowski, A.; Radko, T.; Siudyga, T. Kinetic compensation effect of isoconversional methods. React. Kinet. Mech. Catal. 2021, 132, 37–58. [Google Scholar] [CrossRef]

- Planes, A.; Pérez-Reche, F.-J.; Vives, E.; Mañosa, L. Kinetics of martensitic transitions in shape-memory alloys. Scr. Mater. 2004, 50, 181–186. [Google Scholar] [CrossRef]

- Kustov, S.; Salas, D.; Cesari, E.; Santamarta, R.; Van Humbeeck, J. Isothermal and athermal martensitic transformations in Ni–Ti shape memory alloys. Acta Mater. 2012, 60, 2578–2592. [Google Scholar] [CrossRef]

- Hürrich, C.; Roth, S.; Pötschke, M.; Rellinghaus, B.; Schultz, L. Isothermal martensitic transformation in polycrystalline Ni50Mn29Ga21. J. Alloys Compd. 2010, 494, 40–43. [Google Scholar] [CrossRef]

- Kakeshita, T.; Saburi, T.; Shimizu, K. Effects of hydrostatic pressure and magnetic field on martensitic transformations. Mater. Sci. Eng. A 1999, 273–275, 21–39. [Google Scholar] [CrossRef]

- Kakeshita, T.; Kuroiwa, K.; Shimizu, K.; Ikeda, T.; Yamagishi, A.; Date, M. A New Model Explainable for Both the Athermal and Isothermal Natures of Martensitic Transformations in Fe–Ni–Mn Alloys. Mater. Trans. JIM 1993, 34, 423–428. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manchón-Gordón, A.F.; López-Martín, R.; Ipus, J.J.; Blázquez, J.S.; Svec, P., Sr.; Conde, C.F.; Conde, A. Kinetic Analysis of the Transformation from 14M Martensite to L21 Austenite in Ni-Fe-Ga Melt Spun Ribbons. Metals 2021, 11, 849. https://doi.org/10.3390/met11060849

Manchón-Gordón AF, López-Martín R, Ipus JJ, Blázquez JS, Svec P Sr., Conde CF, Conde A. Kinetic Analysis of the Transformation from 14M Martensite to L21 Austenite in Ni-Fe-Ga Melt Spun Ribbons. Metals. 2021; 11(6):849. https://doi.org/10.3390/met11060849

Chicago/Turabian StyleManchón-Gordón, Alejandro F., Raúl López-Martín, Jhon J. Ipus, Javier S. Blázquez, Peter Svec, Sr., Clara F. Conde, and Alejandro Conde. 2021. "Kinetic Analysis of the Transformation from 14M Martensite to L21 Austenite in Ni-Fe-Ga Melt Spun Ribbons" Metals 11, no. 6: 849. https://doi.org/10.3390/met11060849

APA StyleManchón-Gordón, A. F., López-Martín, R., Ipus, J. J., Blázquez, J. S., Svec, P., Sr., Conde, C. F., & Conde, A. (2021). Kinetic Analysis of the Transformation from 14M Martensite to L21 Austenite in Ni-Fe-Ga Melt Spun Ribbons. Metals, 11(6), 849. https://doi.org/10.3390/met11060849