Influence of Direct Energy Deposition Parameters on Ti–6Al–4V Component’s Structure-Property Homogeneity

Abstract

:1. Introduction

2. Materials and Methods

3. Artificial Neural Network

4. Results and Discussions

4.1. Design of Experiments

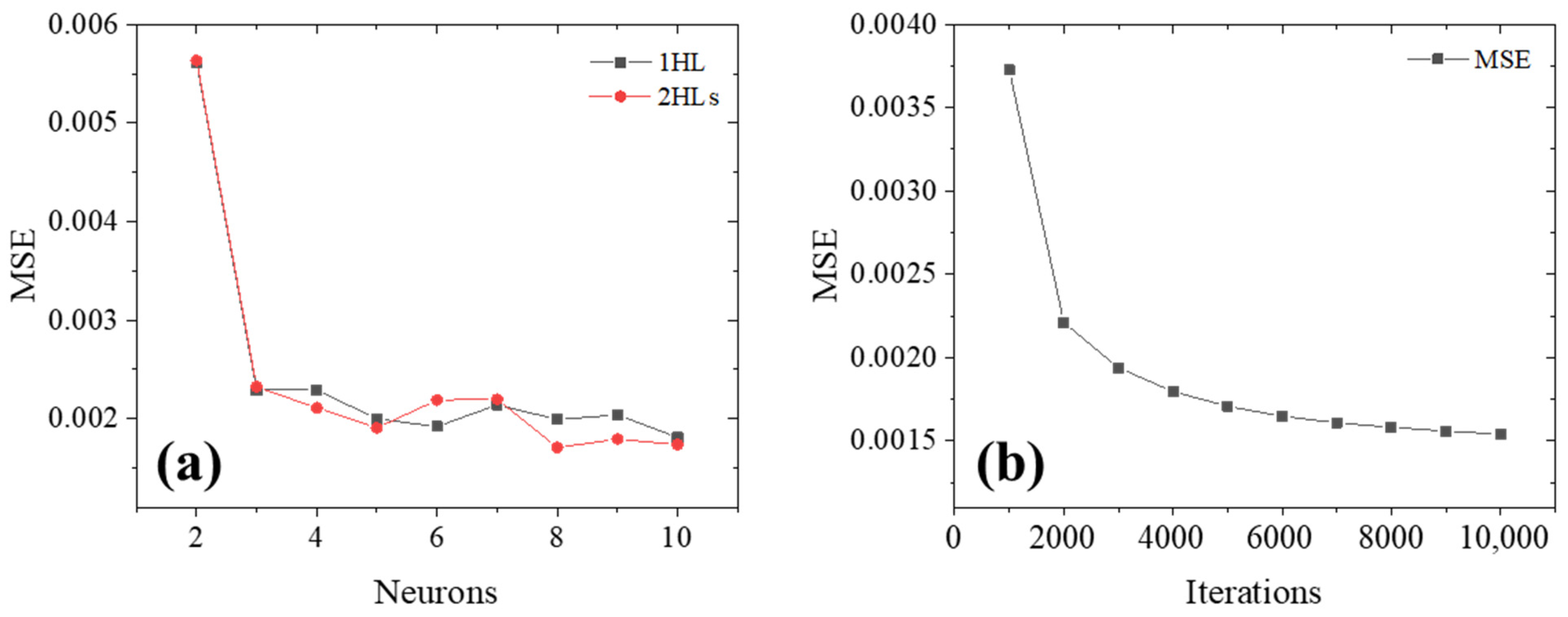

4.2. Model Training and Performance

4.2.1. Model Training

4.2.2. Model Performance

4.3. Effect of Power and Scan Speed: Estimated Using ANN

4.4. Microstructure and Property Variations in the Components

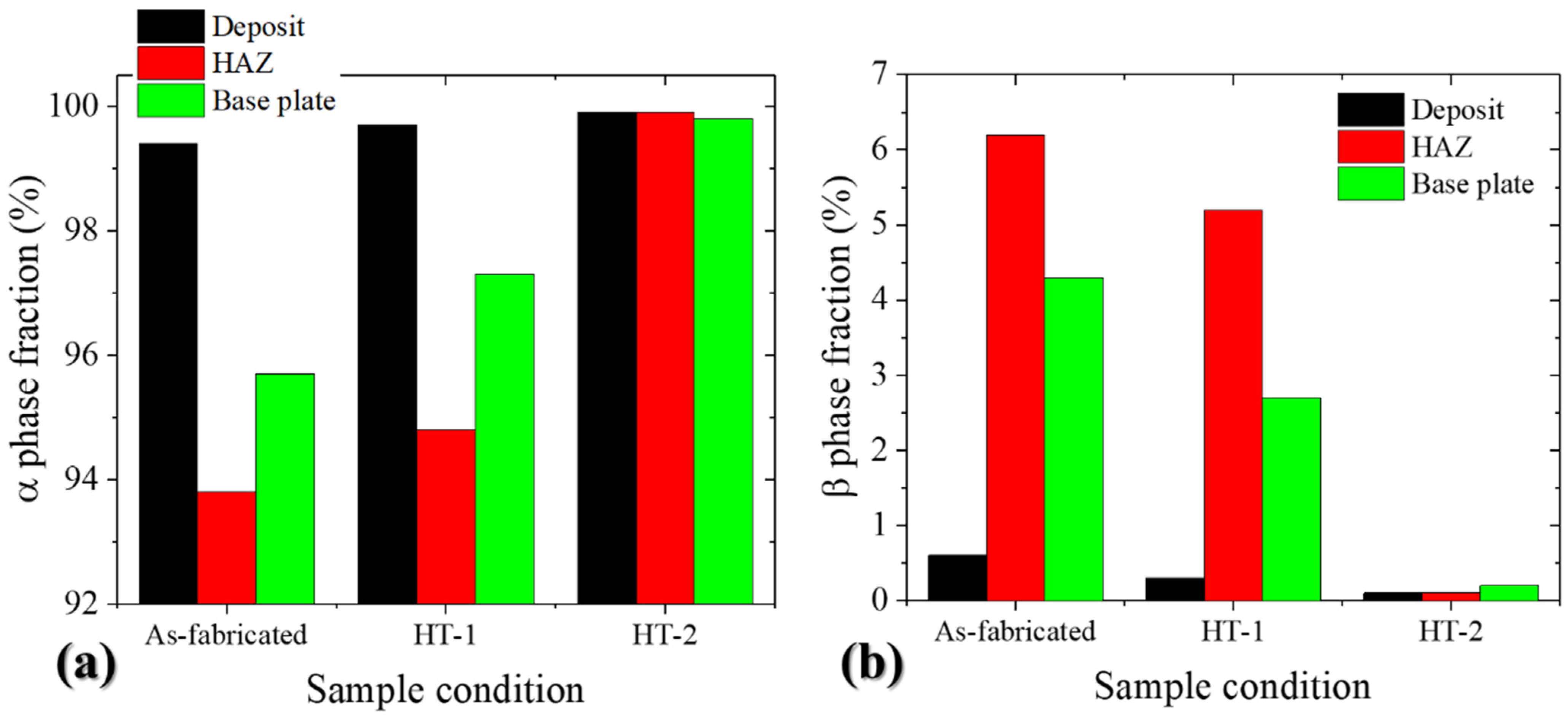

4.5. Effect of Post-Heat Treatment

5. Conclusions

- For the constant scan speed, an increase in the laser power tends to increase the melt pool geometry, grain size, and deposit height of the components. In contrast, for the constant power, an increase in the scan speed tends to decrease these parameters of the components.

- The ANN model successfully correlated the relationship between the process parameters (power and scan speed) and the geometries of the melt pool and deposit as well as the grain size.

- The hardness was measured along the scanning direction. Starting from the base metal, the hardness gradually increased up to the FZ and again decreased when moving away from the FZ.

- The microstructural features of the as-fabricated component varied significantly from the base plate (equiaxed) to the deposition region (martensite); thus, the hardness value was notably varied for each region.

- Post-heat treatment at a lower temperature (HT #1 ~ 550 °C) did not alter the microstructure of the components. However, the heat treatment (HT #2) at 950 °C resulted in a homogeneous microstructure with irregular α plates, which resulted in a uniform hardness value throughout the base plate and deposition regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Hedges, M.; Calder, N. Near net shape rapid manufacture & repair by LENS. In Proceedings of the Cost Effective Manufacturing via Net-Shape Processing, Meeting Proceedings RTO-MP-AVT-139, Paper, Neuilly-sur-Siene, France, 15 May 2006. [Google Scholar]

- Nursyifaulkhair, D.; Park, N.; Baek, E.R.; Lee, J.-B. Effect of Process Parameters on the Formation of Lack of Fusion in Directed Energy Deposition of Ti-6Al-4V Alloy. J. Weld. Join. 2019, 37, 579–584. [Google Scholar] [CrossRef] [Green Version]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. Addit. Manuf. Aerosp. Ind. 2019, 7–31. [Google Scholar] [CrossRef]

- Mudge, R.P.; Wald, N.R. Laser engineered net shaping advances additive manufacturing and repair. Weld. J. N. Y. 2007, 86, 44. [Google Scholar]

- Portolés, L.; Jordá, O.; Jordá, L.; Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. A qualification procedure to manufacture and repair aerospace parts with electron beam melting. J. Manuf. Syst. 2016, 41, 65–75. [Google Scholar] [CrossRef]

- Kim, C.Y.; Kim, J.S.; Lee, H.; Park, M.K.; Kim, S.W.; Shin, S.S.; Hwang, J.H.; Kim, H.D. Effect of Laser Power Feedback Control on Mechanical Properties of Stainless Steel Part Built by Direct Energy Deposition. Korean Weld. Join. Soc. 2020, 38, 197–202. [Google Scholar] [CrossRef] [Green Version]

- Byun, Y.; Lee, S.; Seo, S.M.; Yeom, J.T.; Kim, S.E.; Kang, N.H.; Hong, J.K. Effects of Cr and Fe Addition on Microstructure and Tensile Properties of Ti–6Al–4V Prepared by Direct Energy Deposition. Met. Mater. Int. 2018, 24, 1213–1220. [Google Scholar] [CrossRef]

- Wu, X.; Liang, J.; Mei, J.; Mitchell, C.; Goodwin, P.; Voice, W. Microstructures of laser-deposited Ti–6Al–4V. Mater. Des. 2004, 25, 137–144. [Google Scholar] [CrossRef]

- Qiu, C.; Ravi, G.; Dance, C.; Ranson, A.; Dilworth, S.; Attallah, M.M. Fabrication of large Ti–6Al–4V structures by direct laser deposition. J. Alloys Compd. 2015, 629, 351–361. [Google Scholar] [CrossRef]

- Wolff, S.; Lee, T.; Faierson, E.; Ehmann, K.; Cao, J. Anisotropic properties of directed energy deposition (DED)-processed Ti–6Al–4V. J. Manuf. Process. 2016, 24, 397–405. [Google Scholar] [CrossRef] [Green Version]

- Sterling, A.J.; Torries, B.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Fatigue behavior and failure mechanisms of direct laser deposited Ti–6Al–4V. Mater. Sci. Eng. A 2016, 655, 100–112. [Google Scholar] [CrossRef]

- Carrozza, A.; Mazzucato, F.; Aversa, A.; Lombardi, M.; Bondioli, F.; Biamino, S.; Valente, A.; Fino, P. Single Scans of Ti-6Al-4V by Directed Energy Deposition: A Cost and Time Effective Methodology to Assess the Proper Process Window. Met. Mater. Int. 2021, 1–13. [Google Scholar] [CrossRef]

- Kistler, N.A.; Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Beese, A.M. Effect of processing conditions on the microstructure, porosity, and mechanical properties of Ti-6Al-4V repair fabricated by directed energy deposition. J. Mater. Process. Technol. 2019, 264, 172–181. [Google Scholar] [CrossRef]

- Motyka, M. Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys-An Overview. Metals 2021, 11, 481. [Google Scholar] [CrossRef]

- Shrestha, S.; Panakarajupally, R.P.; Kannan, M.; Morscher, G.; Gyekenyesi, A.L.; Scott-Emuakpor, O.E. Analysis of microstructure and mechanical properties of additive repaired Ti–6Al–4V by Direct Energy Deposition. Mater. Sci. Eng. A 2021, 806, 140604. [Google Scholar] [CrossRef]

- Scherillo, F.; Astarita, A.; Carrino, L.; Pirozzi, C.; Prisco, U.; Squillace, A. Linear friction welding of Ti-6Al-4V parts produced by electron beam melting. Mater. Manuf. Processes 2019, 34, 201–207. [Google Scholar] [CrossRef]

- Anderson, D.; McNeill, G. Artificial neural networks technology. Kaman Sci. Corp. 1992, 258, 1–83. [Google Scholar]

- Reddy, N.; Krishnaiah, J.; Hong, S.-G.; Lee, J.S. Modeling medium carbon steels by using artificial neural networks. Mater. Sci. Eng. A 2009, 508, 93–105. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Akinlabi, S.A. Advanced coating: Laser metal deposition of aluminium powder on titanium substrate. In Proceedings of the World Congress on Engineering, London, UK, 29 June–1 July 2016. [Google Scholar]

- Sobiyi, K.; Akinlabi, E.; Akinlabi, S. The Influence of scanning speed on the laser metal deposition of Ti/Tic powders. Mater. Technol. 2017, 2, 345–351. [Google Scholar] [CrossRef]

- Kobryn, P.; Moore, E.; Semiatin, S. The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4V. Scr. Mater. 2000, 43, 299–305. [Google Scholar] [CrossRef]

- Narayana, P.; Lee, S.; Choi, S.-W.; Li, C.-L.; Park, C.H.; Yeom, J.-T.; Reddy, N.; Hong, J.-K. Microstructural response of β-stabilized Ti–6Al–4V manufactured by direct energy deposition. J. Alloys Compd. 2019, 811, 152021. [Google Scholar] [CrossRef]

- Reichardt, A.; Dillon, R.P.; Borgonia, J.P.; Shapiro, A.A.; McEnerney, B.W.; Momose, T.; Hosemann, P. Development and characterization of Ti-6Al-4V to 304L stainless steel gradient components fabricated with laser deposition additive manufacturing. Mater. Des. 2016, 104, 404–413. [Google Scholar] [CrossRef]

- Suprobo, G.; Ammar, A.A.; Park, N.; Baek, E.R.; Kim, S. Thermal Decomposition of Massive Phase to Fine Lamellar α/β in Ti–6Al–4V Additively Manufactured Alloy by Directed Energy Deposition. Met. Mater. Int. 2019, 25, 1428–1435. [Google Scholar] [CrossRef]

| Power (W) | Scan Speed (m/min) | Length of FZ (mm) | Width of FZ (mm) | Length of HAZ (mm) | Width of HAZ (mm) | Columnar Width (mm) | Deposited Height (mm) |

|---|---|---|---|---|---|---|---|

| 200 | 0.3 | 0.125 | 0.968 | 0.336 | 1.351 | 0.2095 | 1.0857 |

| 300 | 0.3 | 0.213 | 1.305 | 0.382 | 1.712 | 0.2108 | 1.3429 |

| 400 | 0.3 | 0.267 | 1.538 | 0.468 | 2.115 | 0.2693 | 1.5914 |

| 500 | 0.3 | 0.368 | 1.877 | 0.497 | 2.528 | 0.2686 | 1.84 |

| 600 | 0.3 | 0.422 | 2.415 | 0.676 | 2.943 | 0.306 | 2.1 |

| 200 | 0.6 | 0.099 | 0.916 | 0.321 | 1.247 | 0.0855 | 0.6314 |

| 300 | 0.6 | 0.168 | 1.132 | 0.354 | 1.529 | 0.0933 | 0.7843 |

| 400 | 0.6 | 0.233 | 1.345 | 0.38 | 1.743 | 0.0979 | 0.8986 |

| 500 | 0.6 | 0.311 | 1.539 | 0.404 | 2.104 | 0.1297 | 1.06 |

| 600 | 0.6 | 0.33 | 1.821 | 0.463 | 2.401 | 0.2683 | 1.1229 |

| 200 | 0.9 | 0.079 | 0.762 | 0.265 | 1.14 | 0.0889 | 0.3972 |

| 300 | 0.9 | 0.164 | 1.032 | 0.292 | 1.358 | 0.0717 | 0.41 |

| 400 | 0.9 | 0.215 | 1.228 | 0.335 | 1.675 | 0.0902 | 0.6371 |

| 500 | 0.9 | 0.274 | 1.411 | 0.354 | 1.891 | 0.0974 | 0.7486 |

| 600 | 0.9 | 0.292 | 1.581 | 0.419 | 2.027 | 0.0867 | 0.7614 |

| 200 | 1.2 | 0.096 | 0.739 | 0.228 | 1.042 | 0.0592 | 0.2614 |

| 300 | 1.2 | 0.14 | 0.929 | 0.261 | 1.246 | 0.0637 | 0.3429 |

| 400 | 1.2 | 0.19 | 1.131 | 0.29 | 1.412 | 0.0896 | 0.45 |

| 500 | 1.2 | 0.225 | 1.268 | 0.31 | 1.637 | 0.0774 | 0.5029 |

| 600 | 1.2 | 0.264 | 1.418 | 0.347 | 1.852 | 0.0793 | 0.5495 |

| 200 | 1.5 | 0.046 | 0.642 | 0.213 | 0.99 | 0.035 | 0.1543 |

| 300 | 1.5 | 0.105 | 0.89 | 0.237 | 1.154 | 0.0506 | 0.2314 |

| 400 | 1.5 | 0.183 | 1.044 | 0.251 | 1.341 | 0.0733 | 0.3714 |

| 500 | 1.5 | 0.203 | 1.215 | 0.293 | 1.515 | 0.0733 | 0.4 |

| 600 | 1.5 | 0.256 | 1.362 | 0.325 | 1.734 | 0.0783 | 0.4143 |

| Build Feature | Average Error | Adj. R2 |

|---|---|---|

| Length of FZ, µm | 0.009 | 0.99 |

| Width of FZ, µm | 0.015 | 0.96 |

| Length of HAZ, µm | 0.007 | 0.99 |

| Width of HAZ, µm | 0.019 | 0.97 |

| Build height, mm | 0.005 | 0.99 |

| Grain size, µm | 0.020 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.H.; Narayana, P.L.; Choi, S.-W.; Reddy, N.S.; Kim, J.H.; Kang, N.; Hong, J.-K. Influence of Direct Energy Deposition Parameters on Ti–6Al–4V Component’s Structure-Property Homogeneity. Metals 2021, 11, 887. https://doi.org/10.3390/met11060887

Lee CH, Narayana PL, Choi S-W, Reddy NS, Kim JH, Kang N, Hong J-K. Influence of Direct Energy Deposition Parameters on Ti–6Al–4V Component’s Structure-Property Homogeneity. Metals. 2021; 11(6):887. https://doi.org/10.3390/met11060887

Chicago/Turabian StyleLee, Chan Hyeok, P. L. Narayana, Seong-Woo Choi, N. S. Reddy, Jae H. Kim, Namhyun Kang, and Jae-Keun Hong. 2021. "Influence of Direct Energy Deposition Parameters on Ti–6Al–4V Component’s Structure-Property Homogeneity" Metals 11, no. 6: 887. https://doi.org/10.3390/met11060887