Aging Behavior of Intercritically Quenched Ductile Iron

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials and Preparation of Samples

2.2. Microstructure Characterization

2.3. Defining the Intercritical Region

2.3.1. Dilatometry

2.3.2. Thermodynamic Software

2.3.3. Intercritical Austenitizing Heat Treatment

2.4. Aging Treatment

2.5. Tensile Test

2.6. Hardness Test

3. Results and Discussion

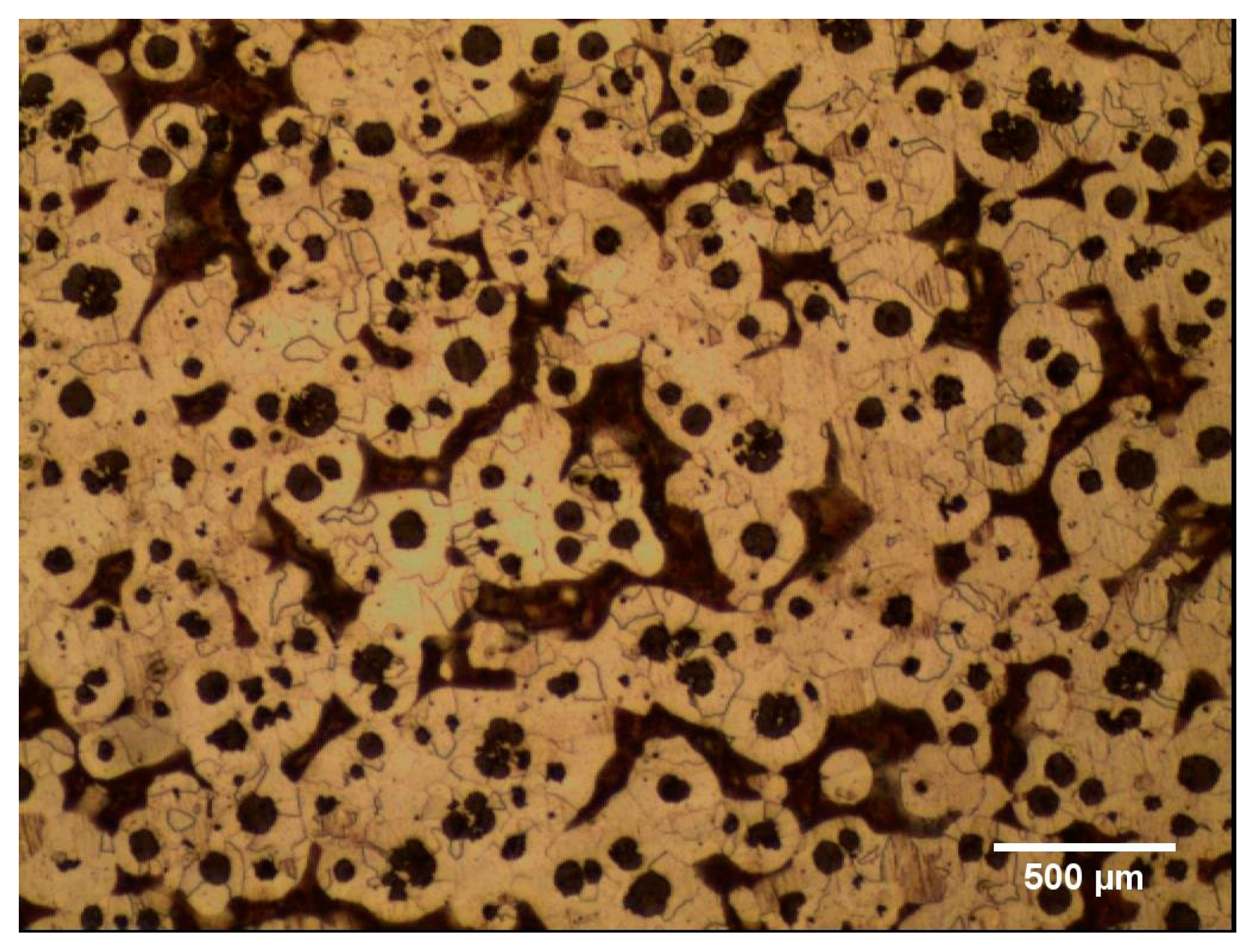

3.1. Characteristics of the As-Cast

3.2. The Intercritical Region

3.3. Microstructural Analysis

3.4. Mechanical Properties of the Aged DMS-DI

- Stress-induced arrangement of solute atoms in interstitial sites (Snoek effect).

- Segregation of solute atoms into dislocations to form and stabilize a Cottrell atmosphere.

- Precipitation of carbides.

3.5. Microhardness

4. Conclusions

- The estimating range of the intercritical region by dilatometric method applying continuous heating transformation is more accurate than that estimated by ThermoCalc software and empirical equations. The latter two methods overestimate the lower and underestimate the upper critical transformation temperatures by about +45 °C and −43 °C, respectively.

- For all investigated aged samples, the aging conditions have no major effect on the ultimate tensile strength UTS and macro hardness.

- The increase in yield strength BH0 value (~11% increase) associated with the aging process is observed to go through two strengthening stages followed by a decrease in BH0 value (over-aging).

- The maximum BH0 is found to be achieved after aging for 100, 500, and 5000 min when aging at 220 °C, 170 °C, and 140 °C, respectively.

- The over-aging in DMS-DI is found to be closely related to the martensite tempering, which was revealed by microhardness measurements. The decrease in the martensite hardness starts to be more significant after aging times corresponding to the over-aging start-times.

- The aging process has no significant effect on the microhardness of the ferrite phase in DMS-DI, which recorded a HV0.01 value of about 235 kgf/mm2.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murcia, S.C.; Paniagua, M.A.; Ossa, E.A. Materials science & engineering a development of As-cast dual matrix structure (DMS) ductile iron. Mater. Sci. Eng. A 2013, 566, 8–15. [Google Scholar] [CrossRef]

- Lacaze, J.; Sertucha, J.; Åberg, L.M. Microstructure of As-cast ferritic-pearlitic nodular cast irons. ISIJ Int. 2016, 56, 1606–1615. [Google Scholar] [CrossRef] [Green Version]

- Soliman, M.; Nofal, A.; Palkowski, H. Alloy and process design of thermo-mechanically processed multiphase ductile iron. Mater. Des. 2015, 87, 450–465. [Google Scholar] [CrossRef]

- Gonzaga, R.A. Influence of ferrite and pearlite content on mechanical properties of ductile cast irons. Mater. Sci. Eng. A 2013, 567, 1–8. [Google Scholar] [CrossRef]

- Rashidi, A.M.; Rashidi, A.M. Dual matrix structure (DMS) ductile cast iron: The effect of heat treating variables on the mechanical properties. Int. J. Cast Met. Res. 2016, 13, 293–297. [Google Scholar] [CrossRef]

- Soliman, M.; Ibrahim, H.; Nofal, A.; Palkowski, H. Thermo-mechanically processed dual matrix ductile iron produced by continuous cooling transformation. J. Mater. Process. Technol. 2016, 227, 1–10. [Google Scholar] [CrossRef]

- Sikora, J.; Basso, A. Review on production processes and mechanical properties of dual phase austempered ductile iron. Int. J. Met. 2012, 6, 7–14. [Google Scholar]

- Soliman, M.; Palkowski, H.; Nofal, A. Thermo-mechanically processed multi-phase ductile iron: Microstructure development. Key Eng. Mater. 2011, 457, 199–204. [Google Scholar] [CrossRef]

- Kocatepe, K.; Cerah, M.; Erdogan, M. Effect of martensite volume fraction and its morphology on the tensile properties of ferritic ductile iron with dual matrix structures. J. Mater. Process. Technol. 2006, 178, 44–51. [Google Scholar] [CrossRef]

- Erdogan, M.; Kilicli, V.; Demir, B. Transformation characteristics of ductile iron austempered from intercritical austenitizing temperature ranges. J. Mater. Sci. 2009, 44, 1394–1403. [Google Scholar] [CrossRef]

- Mozumder, Y.H. Influence of Intercritical Austenitizing Temperature, Quenching Media and Tempering Temperature on Mechanical Properties and Wear Behavior of Ductile Iron with Dual Matrix Structure Metallurgical and Materials Engineering National Institute of Technology. Ph.D. Thesis, National Institute of Technology Rourkela, Odisha, India, 2015. [Google Scholar]

- Basso, A.; Martínez, R.; Sikora, J.; Sikora, J. Influence of section size on dual phase ADI microstructure and properties: Comparison with fully ferritic and fully ausferritic matrices Influence of section size on dual phase ADI microstructure and properties: Comparison with fully ferritic and fully. Mater. Sci. Technol. 2013, 25, 1271–1278. [Google Scholar] [CrossRef]

- Sikora, J.A.; Basso, A.D.; Martı, R.A. Influence of austenitising and austempering temperatures on microstructure and properties of dual phase ADI. Mater. Sci. Technol. 2007, 23, 1321–1327. [Google Scholar] [CrossRef]

- Basso, A.; Caldera, M.; Rivera, G.; Sikora, J. High silicon ductile iron: Possible uses in the production of parts with “dual phase ADI”. Microstructure 2012, 52, 1130–1134. [Google Scholar]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys. Int. Mater. Rev. 2005, 50, 193–215. [Google Scholar] [CrossRef] [Green Version]

- Age Hardening—Metallurgical Processes. Available online: https://www.azom.com/article.aspx?ArticleID=9623 (accessed on 13 August 2013).

- Avner, S.H. Introduction to Physical Metallurgy, 2nd ed.; New York City Community College, City University of New York: New York, NY, USA, 1974; ISBN 0070024995. [Google Scholar]

- Askeland, D.R.; Fulay, P.P. Essentials of Materials Science and Engineering, 2nd ed.; Cengage Learning: Belmont, CA, USA, 2009; ISBN 9780495438502. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 18th ed.; Wiley: New York, NY, USA, 2013; Volume 53, ISBN 9788578110796. [Google Scholar]

- Pereloma, E.; Timokhina, I. Bake Hardening of Automotive Steels; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; ISBN 9780081006535. [Google Scholar]

- Elsen, P.; Hougardy, H.P. On the mechanism of bake-hardening. Steel Res. 1993, 64, 431–436. [Google Scholar] [CrossRef]

- Teague, J.; Richards, V. Age strengthening of cast irons: Review of research and literature. Int. J. Met. 2010, 4, 45–57. [Google Scholar] [CrossRef]

- Catalina, A.V.; Buhrig-Polaczek, A.; Monroe, C.; Sabau, A.S.; Richards, V.L. Age-Strengthening of Cast Iron and Its Effects on Machinability: Review of the Literature. In Advances in the Science and Engineering of Casting Solidification: An MPMD Symposium Honoring Doru Michael Stefanescu; John Wiley and Sons: New York, NY, USA, 2015; pp. 269–276. [Google Scholar]

- Gokhale, S.P. Aging of Austempered Ductile Irons; University of New Brunswick: Fredericton, NB, Canada, 1995. [Google Scholar]

- Rezvani, M. Precipitation Hardening for Ferritic Ductile Iron; University of Birmingham: Birmingham, UK, 1996. [Google Scholar]

- Nicola, W.M.; Richards, V. Age strengthening of gray cast iron, phase I: Statistical verification. AFS Trans. 1999, 107, 233–237. [Google Scholar]

- Nicola, W.M.; Richards, V.L. Age strengthening of gray cast iron, phase II: Nitrogen and melting method effects. AFS Trans. Am. Foundry Soc. 2000, 108, 233–237. [Google Scholar]

- Lekakh, S.N.; Richards, V.L. Aging and machinability interactions in cast iron. Trans. Am. Foundry Soc. 2012, 120, 307–318. [Google Scholar]

- Richards, V.L.; Lekakh, S.N.; Teague, J.; Peaslee, K.D. Aging and machinability of irons with compact and spheroidal graphite. Trans. Am. Foundry Soc. 2010, 118, 10–36. [Google Scholar]

- Richards, V.L.; Van Aken, D.C.; Nicola, W. Age strengthening of gray cast iron. Int. J. Cast Metals Res. 2016, 16, 275–280. [Google Scholar] [CrossRef]

- Richards, V.L.; Van Aken, D.C.; Nicola, W. Age strengthening of gray cast iron: Kinetics, mechanical property effects. AFS Trans. 2003, 111, 733–742. [Google Scholar]

- Edington, J.; Nicola, W.; Richards, V.L. Age strengthening of gray cast iron: Nitrogen effects and machinability. AFS Trans. 2002, 110, 983–993. [Google Scholar]

- Nicola, W.M.; Richards, V. Age strengthening of gray cast iron phase III—Effect of aging temperature. AFS Trans. 2001, 81, 1–9. [Google Scholar]

- Richards, L.; Nicola, W. Final Technical Report: Age Strengthening of Gray Cast Iron Phase iii Summary of Activities Discussion of Results List of Papers Produced during This Contract; University of Missouri-Rolla: Rolla, MO, USA, 2003. [Google Scholar]

- Teague, J.A.; Richards, V.L.; Lekakh, S.N.; Peaslee, K.D. Age strengthening and machinability interactions in gray cast iron. AFS Trans. 2009, 117, 475. [Google Scholar]

- Anish, T.; Lekakh, S.N.; Richards, V.L. The effect of Ti and N on iron age strengthening. AFS Trans. 2008, 116, 653. [Google Scholar]

- Richards, V.L.; Van Aken, D.C.; Mereau, O.P.; Nicola, W.M. Effects of room temperature aging on ductile iron. AFS Trans. 2004, 38, 1–12. [Google Scholar]

- Richards, V.L.; Anish, T.V.; Lekakh, S.; Van Aken, D.C.; Nicola, W. Composition effects on age strengthening of gray iron. AFS Trans. 2006, 114, 507. [Google Scholar]

- Teague, J.A.; Richards, V.L.; Lekakh, S.N.; Peaslee, K.D. Aging effect on gray cast iron machinability: Tool force and tool wear. AFS Trans. 2008, 116, 733. [Google Scholar]

- Lekakh, S.N.; Richards, V.L.; Medvedeva, J.; Murphy, J.M. Effect of alloying elements on gray iron natural aging, part 1: Manganese. AFS Trans. 2011, 119, 379. [Google Scholar]

- Bayati, H.; Elliott, R. Aging Process of Alloyed ADI. In Proceedings of the Second International Conference on Processing Materials for Properties, San Francisco, CA, USA, 5–8 November 2000; pp. 77–82. [Google Scholar]

- Radzikowska, J.M. Metallography and microstructures of cast iron. ASM Handb. Metallogr. Microstruct. 2004, 9, 565–587. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count; ASTM: West Conshohocken, PA, USA, 2008; pp. E562–E568. [Google Scholar]

- DIL L75 PT Horizontal. Available online: https://www.linseis.com/en/products/dilatometer/dil-l75-pt-horizontal/ (accessed on 25 May 2021).

- Basso, A.; Martínez, R.; Sikora, J. Influence of chemical composition and holding time on austenite (γ)→ ferrite (α) transformation in ductile iron occurring within the intercritical interval. J. Alloys Compd. 2011, 509, 9884–9889. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Li, Q.; Hong, X. Mechanical properties and rolling-sliding wear performance of dual phase austempered ductile iron as potential metro wheel material. Wear 2018, 406–407, 156–165. [Google Scholar] [CrossRef]

- Soliman, M.; Palkowski, H. Tensile properties and bake hardening response of dual phase steels with varied martensite volume fraction. Mater. Sci. Eng. A 2020, 777, 139044. [Google Scholar] [CrossRef]

- Soliman, M.; Shan, Y.V.; Mendez-Martin, F.; Kozeschnik, E.; Palkowski, H. Strain aging characterization and physical modelling of over-aging in dual phase steel. Mater. Sci. Eng. A 2020, 788, 139595. [Google Scholar] [CrossRef]

- ISO. 6892-1. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Chakrabarty, I. Heat Treatment of Cast Irons; Elsevier: Amsterdam, The Netherlands, 2017; Volume 2, ISBN 9780128035818. [Google Scholar]

- ASTM. ASTM E2567—11 Standard Test Method for Determining Nodularity and Nodule Count in Ductile Iron Using Image Analysis; ASTM: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Ghergu, R.M.; Sertucha, J.; Thebault, Y.; Lacaze, J. Critical temperature range in standard and Ni-bearing spheroidal graphite cast irons. ISIJ Int. 2012, 52, 2036–2041. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Chen, Y.; Han, J.; Ping, D.; Zhao, X. Microstructure of ultrahigh carbon martensite. Prog. Nat. Sci. Mater. Int. 2018, 28, 749–753. [Google Scholar] [CrossRef]

- Shan, Y.V.; Soliman, M.; Palkowski, H.; Kozeschnik, E. Modeling of bake hardening kinetics and carbon redistribution in dual-phase steels. Steel Res. Int. 2021, 92. [Google Scholar] [CrossRef]

- Jalava, K.; Laine, J.; Vaara, J.; Frondelius, T.; Orkas, J.; Jalava, K. Investigation on dynamic strain aging behaviour of ferritic-pearlitic ductile cast irons. Mater. Sci. Technol. 2019, 36, 1–8. [Google Scholar] [CrossRef]

| C | Si | Mn | Mg | S | P | Fe | CE1 |

|---|---|---|---|---|---|---|---|

| 3.39 | 2.63 | 0.33 | 0.03 | 0.01 | 0.05 | Bal. | 4.27 |

| Technique | Empirical Equations | ThermoCalc Software | Dilatometry | Partial Austenitizing Heat Treatment | ||

|---|---|---|---|---|---|---|

| Temperature | Heating | Cooling | ||||

| Lower critical transformation temperature [°C] | 782.7 | 787.8 | 755 | 714 | 740 | |

| Upper critical transformation temperature [°C] | 813.3 | 821.3 | 890 | 843 | 860 | |

| UTS [MPa] | YS [MPa] | TEL [%] | HRB | FMH [kgf/mm2] | MMH [kgf/mm2] | E [GPa] |

|---|---|---|---|---|---|---|

| 14.14 | 3.97 | 2.11 | 1.48 | 2.59 | 15.01 | 154.6 ± 25.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelmonem, A.; Soliman, M.; Palkowski, H.; Elsabbagh, A. Aging Behavior of Intercritically Quenched Ductile Iron. Metals 2021, 11, 897. https://doi.org/10.3390/met11060897

Abdelmonem A, Soliman M, Palkowski H, Elsabbagh A. Aging Behavior of Intercritically Quenched Ductile Iron. Metals. 2021; 11(6):897. https://doi.org/10.3390/met11060897

Chicago/Turabian StyleAbdelmonem, Ali, Mohamed Soliman, Heinz Palkowski, and Ahmed Elsabbagh. 2021. "Aging Behavior of Intercritically Quenched Ductile Iron" Metals 11, no. 6: 897. https://doi.org/10.3390/met11060897

APA StyleAbdelmonem, A., Soliman, M., Palkowski, H., & Elsabbagh, A. (2021). Aging Behavior of Intercritically Quenched Ductile Iron. Metals, 11(6), 897. https://doi.org/10.3390/met11060897