Metallurgical Modelling of Ti-6Al-4V for Welding Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

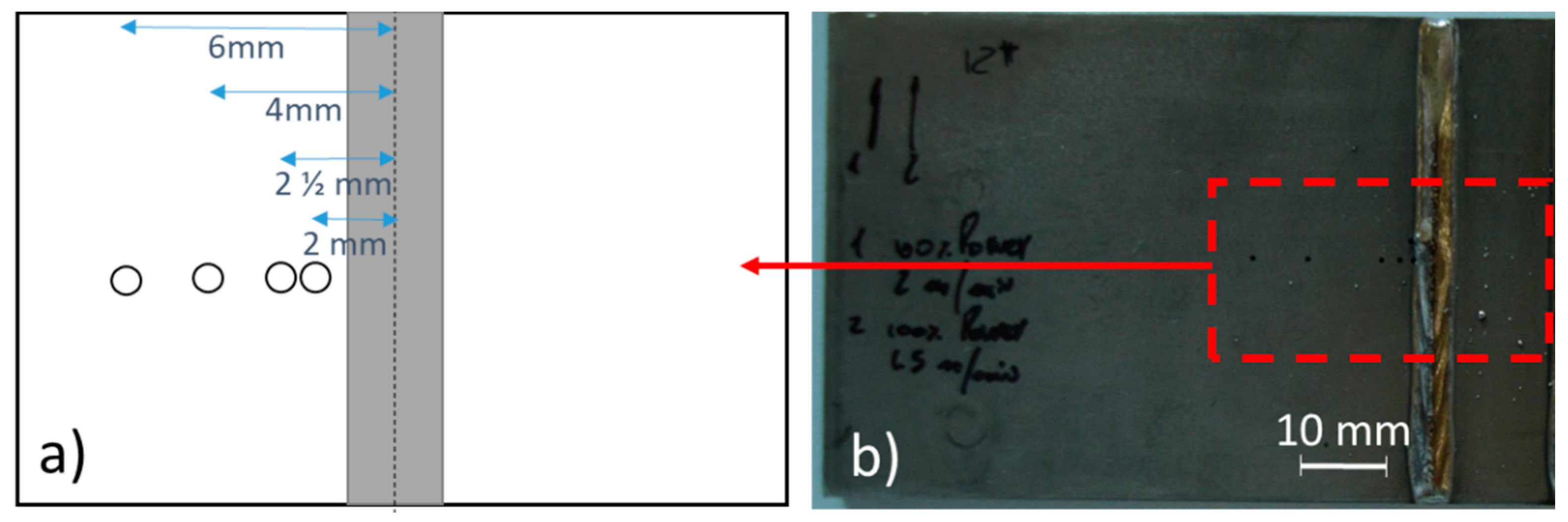

2.2. Welding Experiments

3. Results—Microstructure Characterisation

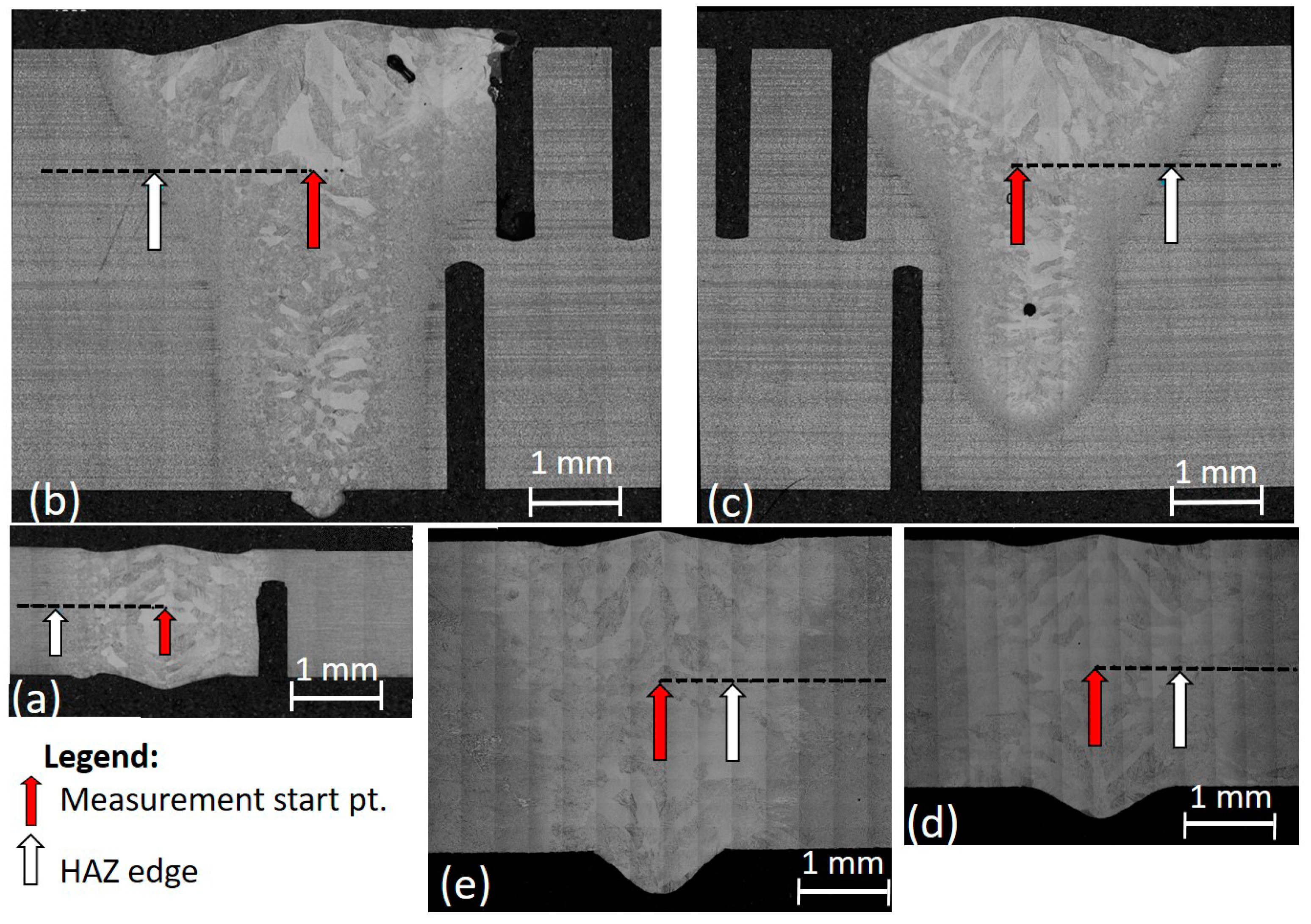

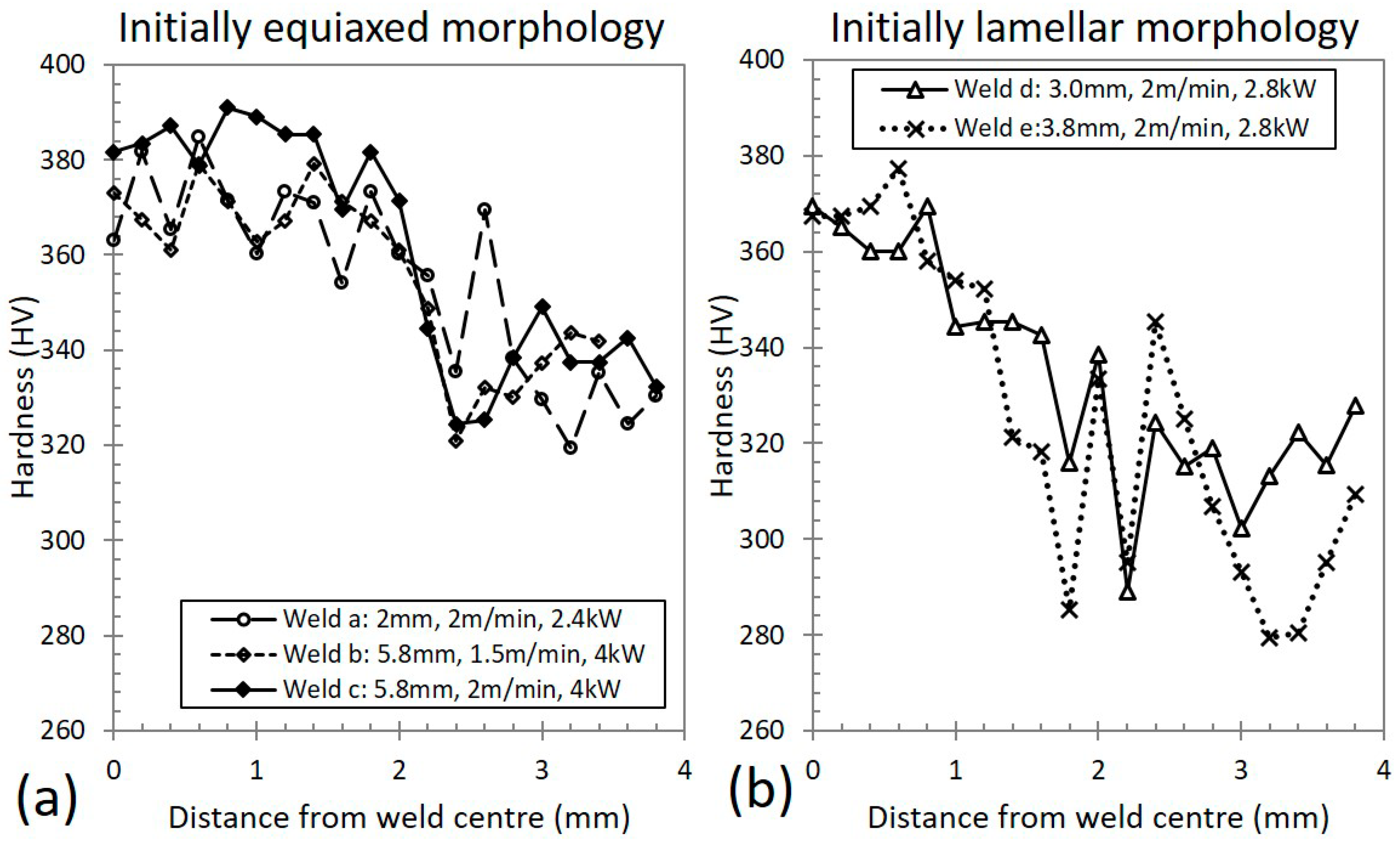

3.1. Weld Pool Imaging and Hardness Measurements

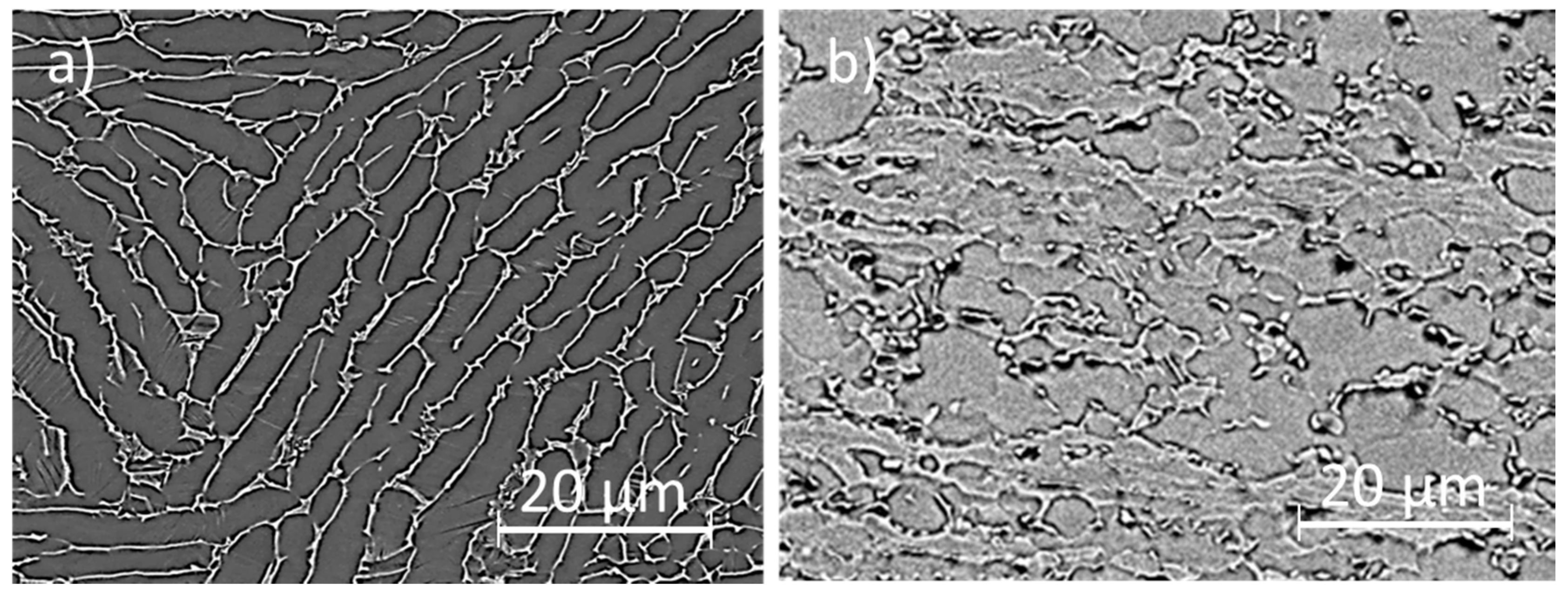

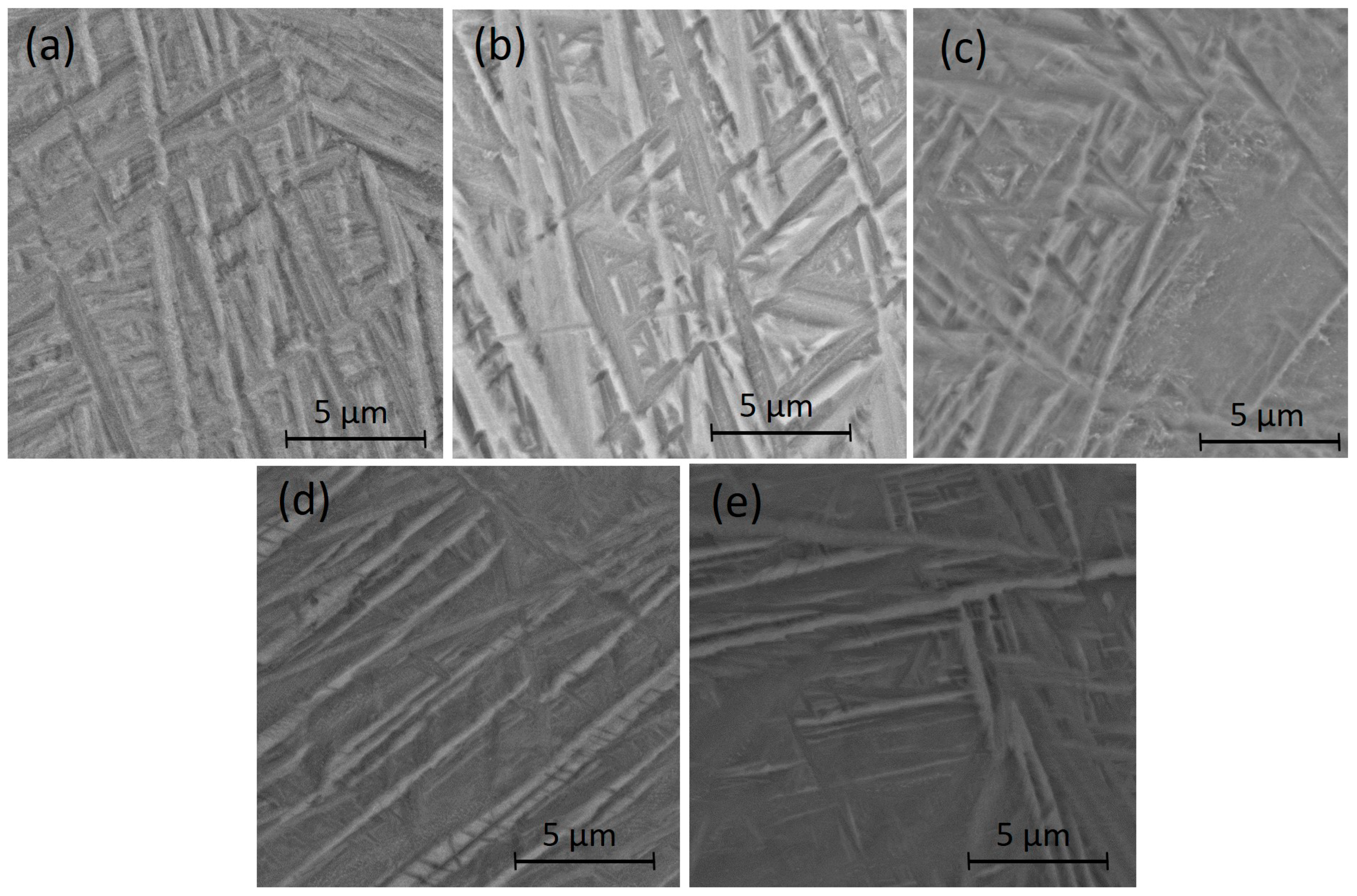

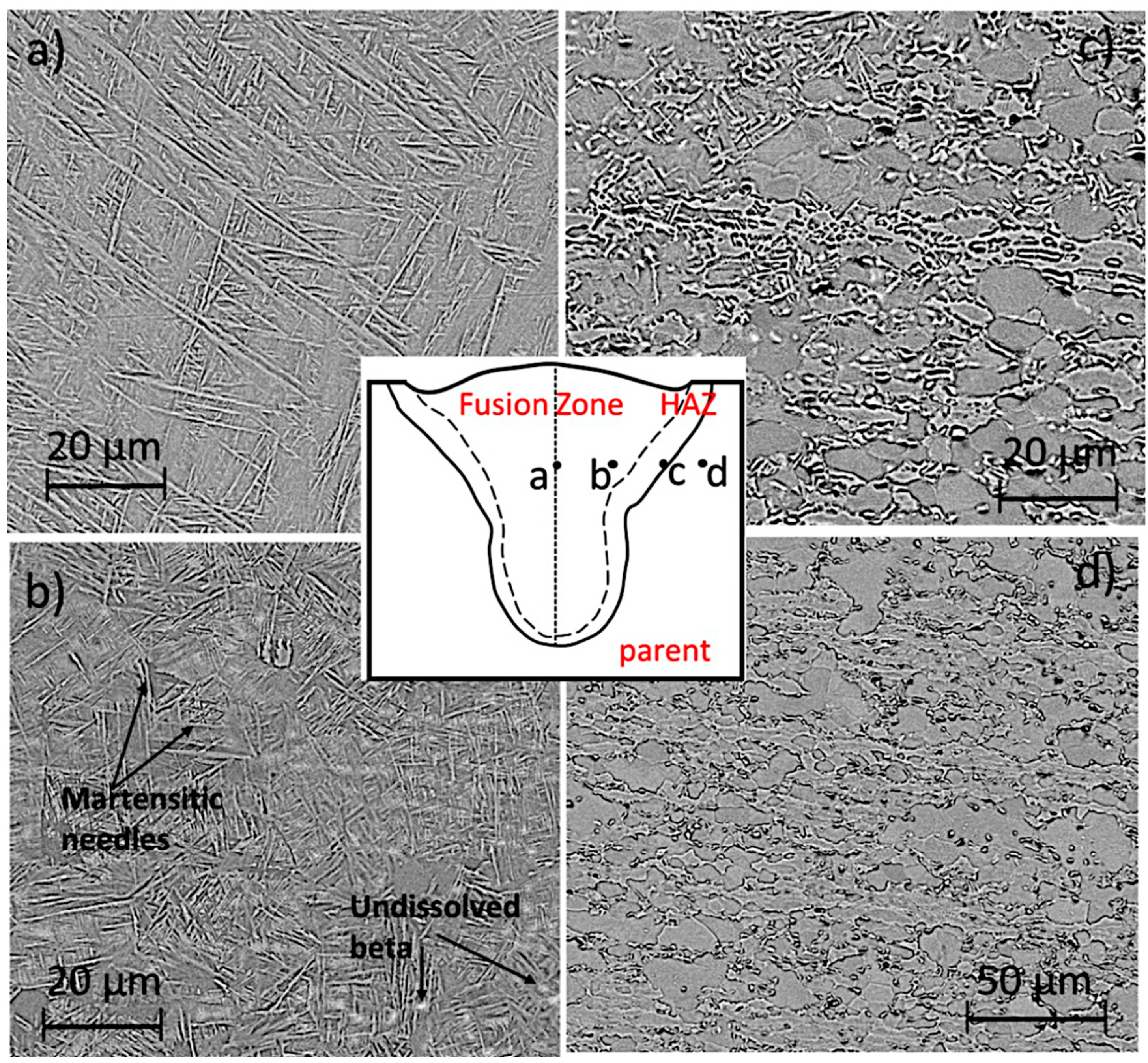

3.2. Microstructure of the Initially Equiaxed Plates

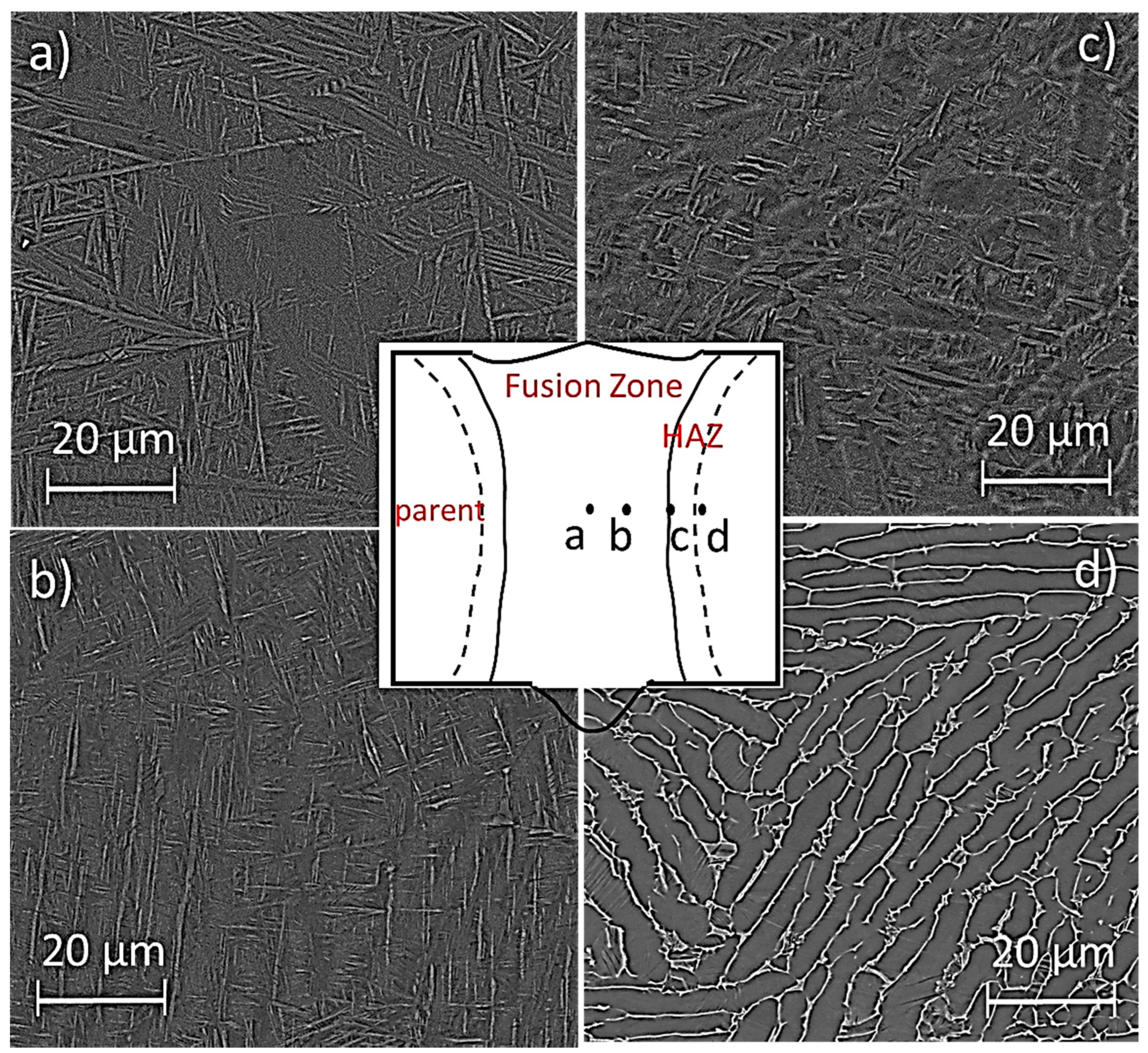

3.3. Microstructure of the Initially Lamellar Plates

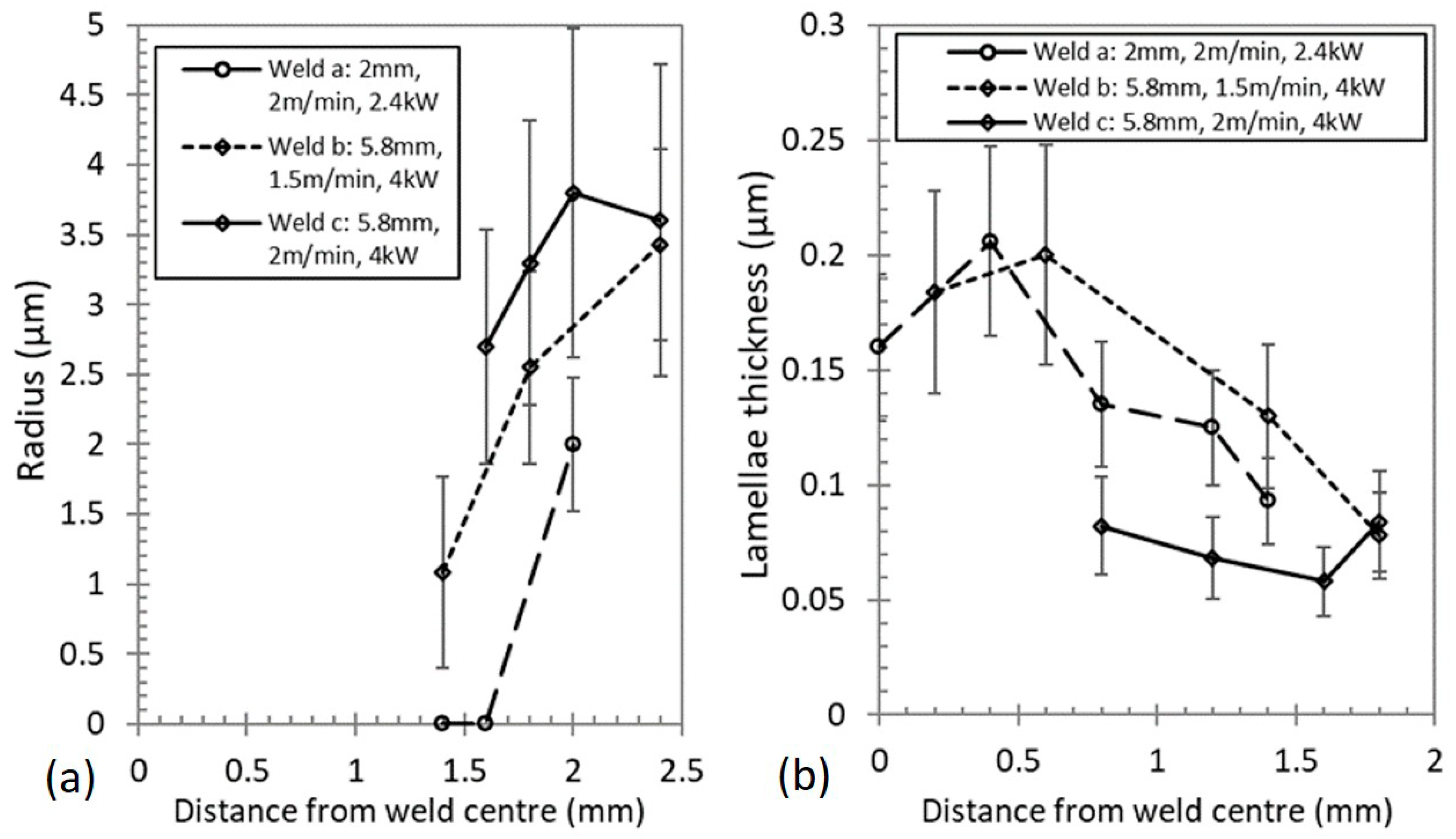

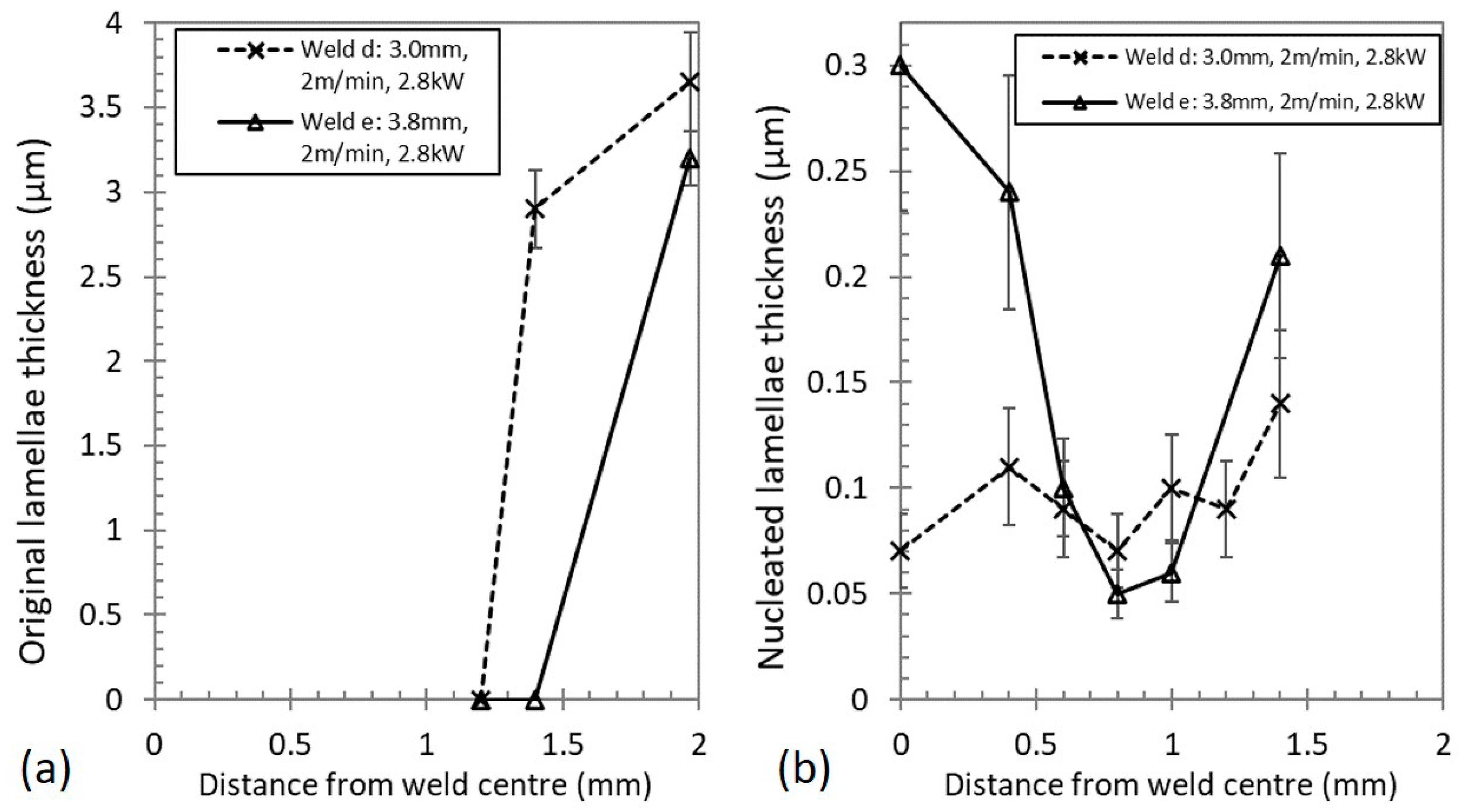

3.4. Lamellar Thickness and Equiaxed Grain Size

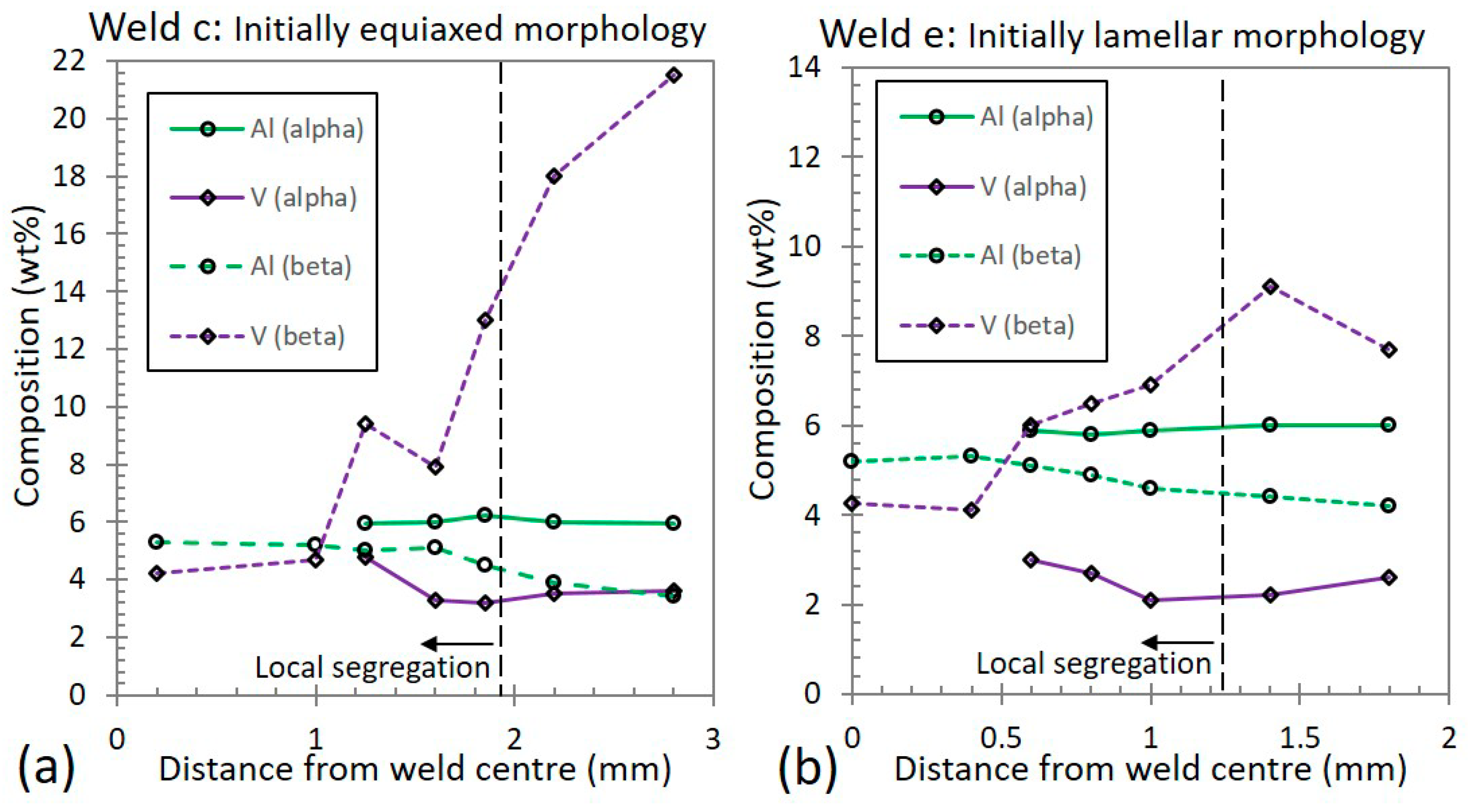

3.5. Chemical Analysis

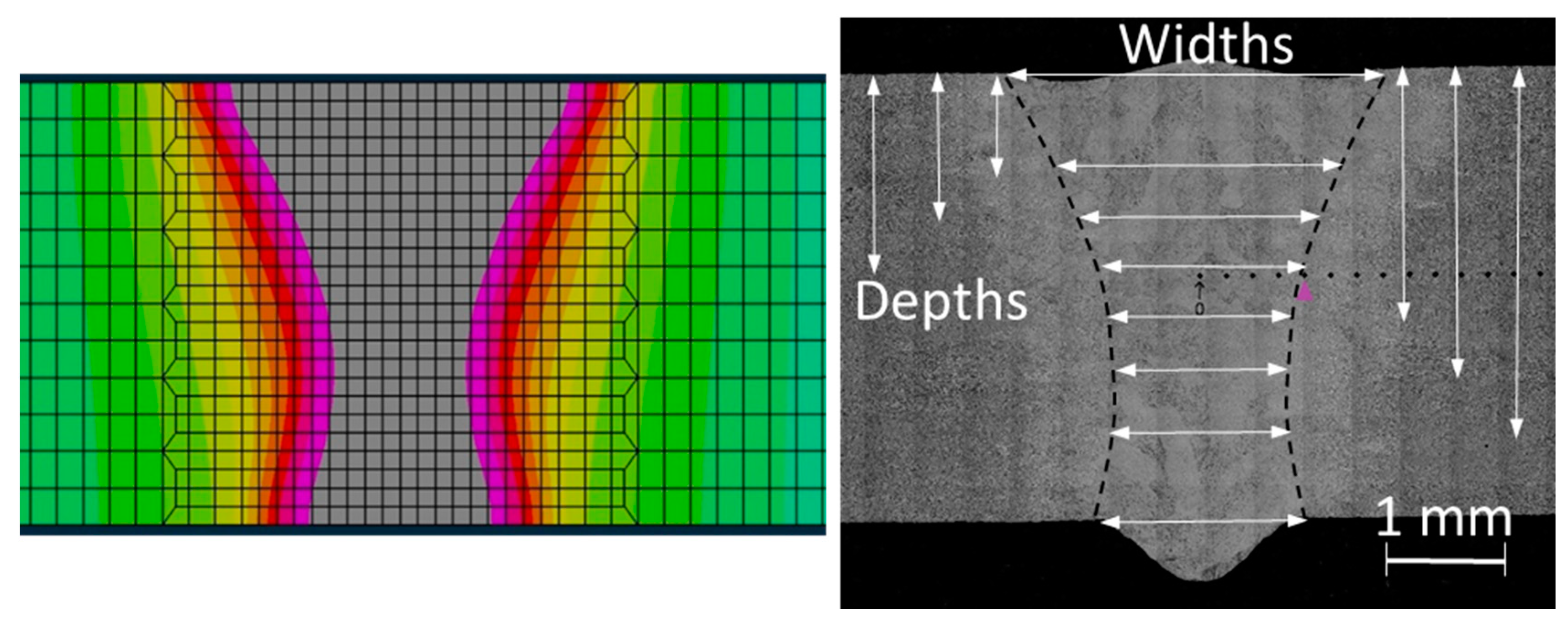

4. Finite Element Modelling

5. Calibration and Validation

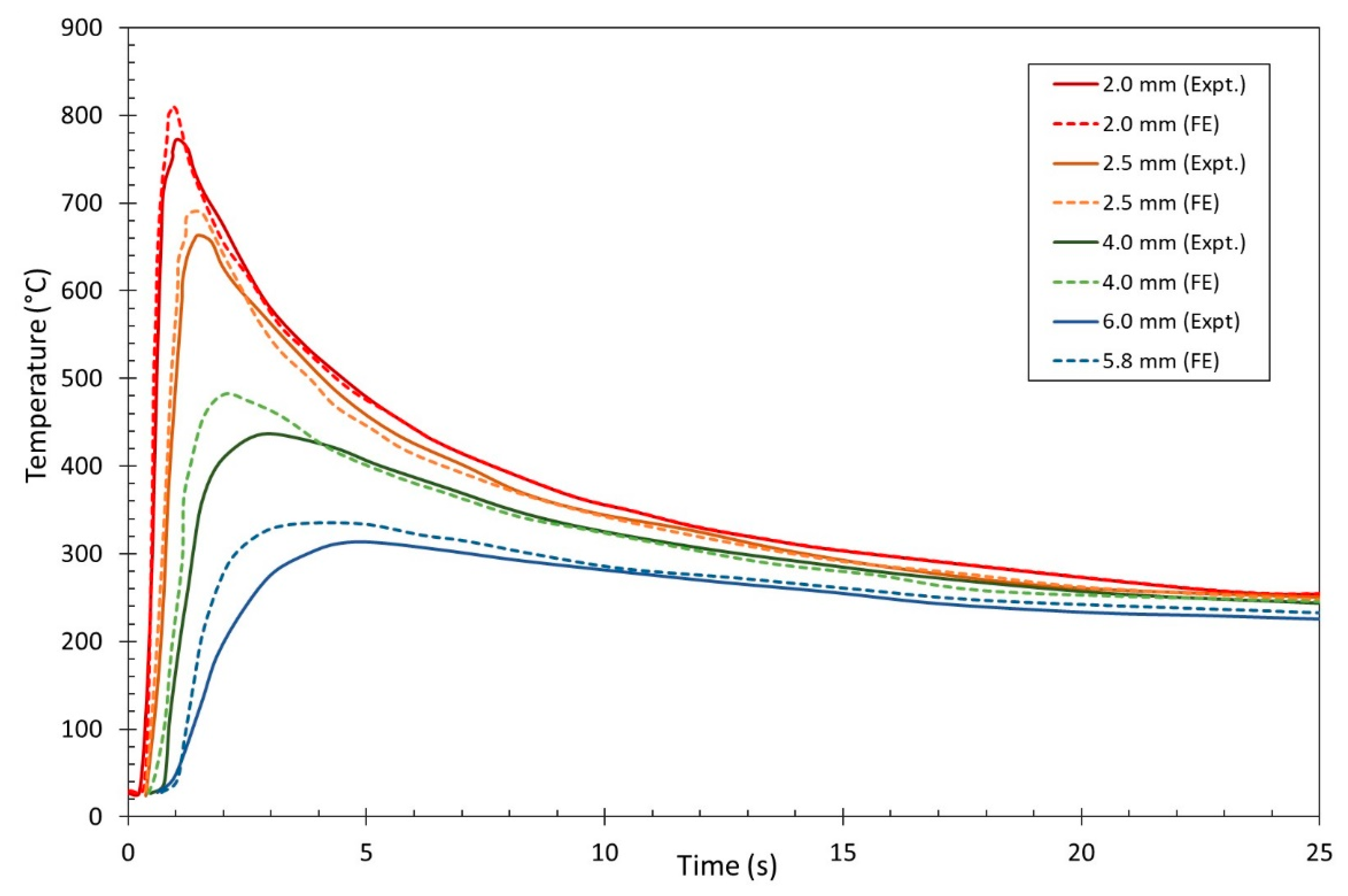

5.1. Calibration of Thermal Data

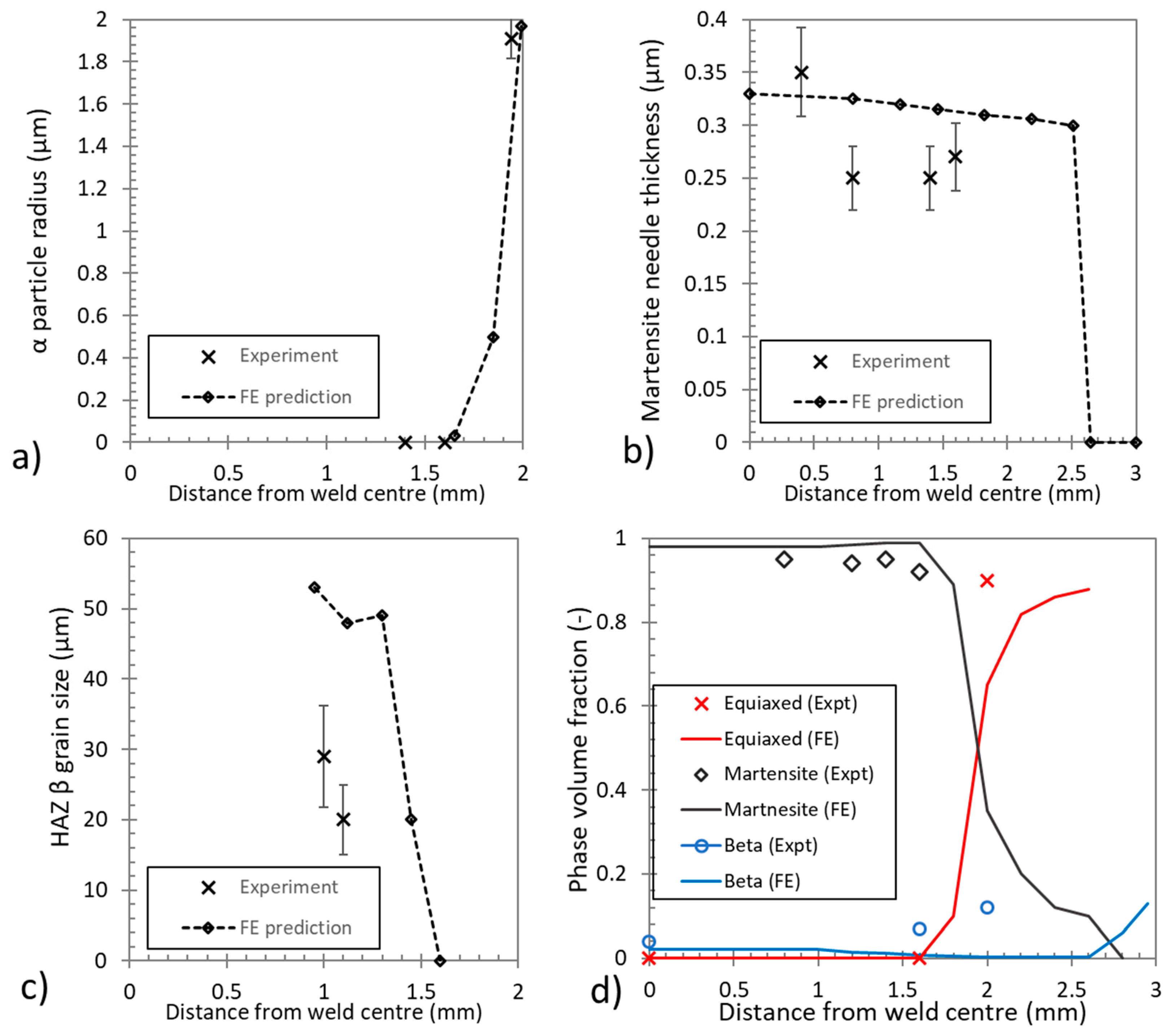

5.2. Plates with an Initially Equiaxed Microstructure

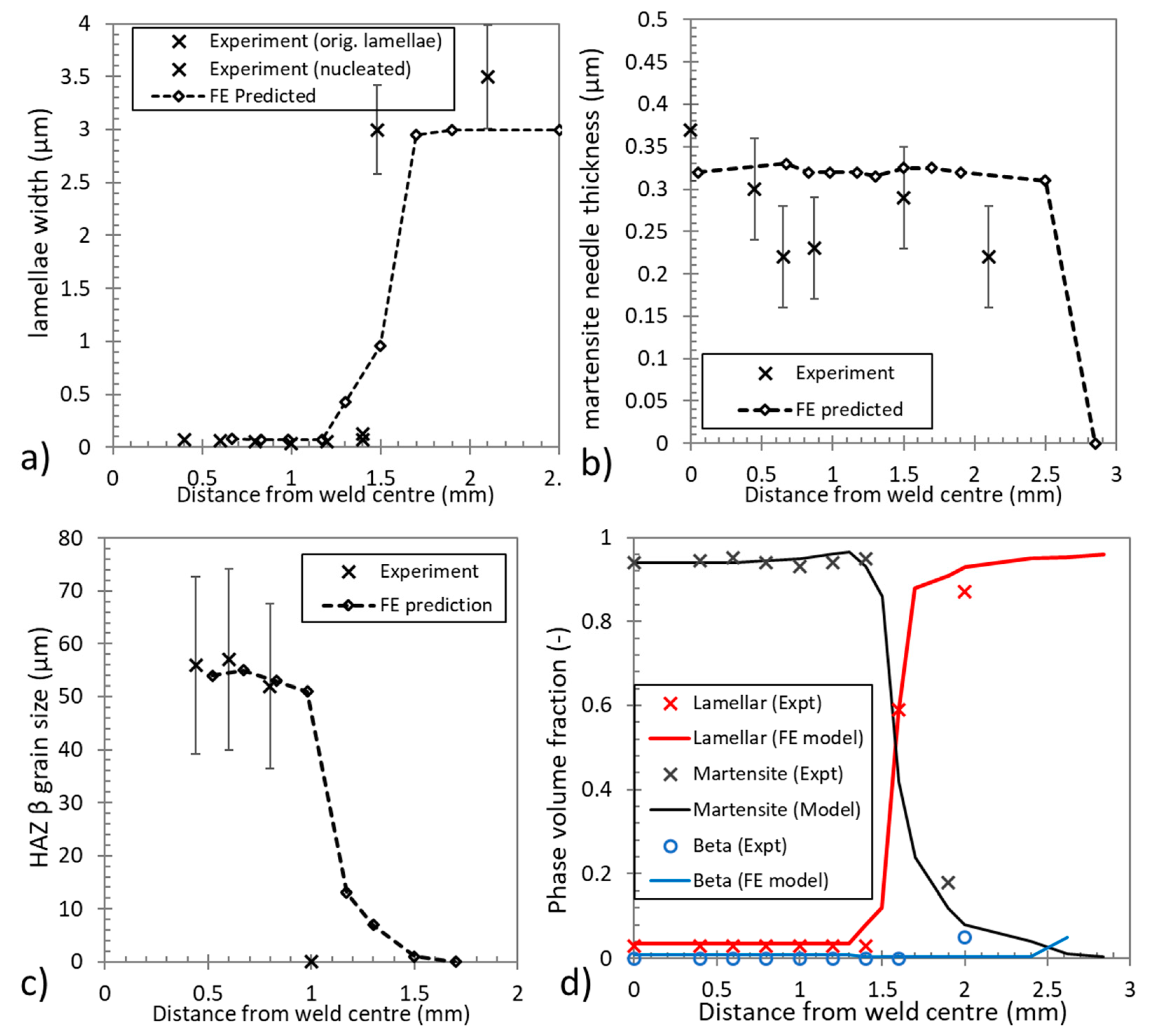

5.3. Plates with an Initially Lamellar Microstructure

6. Conclusions

- The microstructural model predictions are in good agreement with the structural characterisation results obtained from the test welds. The increase in welding simulation run times obtained when adopting the models developed in this work was roughly 100% when compared to those for the conventional approach adopted in the welding FE code;

- The diffusion-based approach, which was previously developed and validated, can be adopted to describe the microstructure evolution within the α+β field in welding processes. The diffusion-based model is accurate and is based only on fundamental material properties; thus, once the initial chemical composition and particle dimensions of the material are known, the model is ready for both equiaxed and lamellar microstructures;

- There is considerable potential for further refinement of this approach for use by welding engineers. Further studies to extend this physics-based approach to the full range of temperatures that occur during welding is desirable. This would cause longer computational times but would require no further calibration experiments;

- The microstructural evolution of the particle dimensions was successfully predicted, which is important for mechanical strength predictions of titanium alloys and for possible future fatigue life modelling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Mendez, P.F.; Eagar, T.W. Welding Processes for Aeronautics. Adv. Mater. Process. 2001, 5, 39–43. [Google Scholar]

- Haque, R. Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: A review. Arch. Civ. Mech. Eng. 2018, 18, 83–93. [Google Scholar] [CrossRef]

- Galinska, A.; Galinski, C. Mechanical Joining of Fibre Reinforced Polymer Composites to Metals—A Review. Part II: Riveting, Clinching, Non-Adhesive Form-Locked Joints, Pin and Loop Joining. Polymers 2020, 12, 1681. [Google Scholar] [CrossRef] [PubMed]

- Pederson, R. Microstructure and Phase Transformation of Ti-6Al-4V. Ph.D. Thesis, Lulea University, Luleå, Sweden, 2002. [Google Scholar]

- Lopez de Lacalle, L.N.; Sanchez, J.A.; Lamkiz, A.; Celaya, A. Plasma Assisted Milling of Heat-Resistant Superalloys. ASME J. Manuf. Sci. Eng. 2004, 126, 274–285. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change, I—General Theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change, II—Transformation—Time relations. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. III—Granulation, Phase Change, and Microstructure. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- ESI-Group. Sysweld 2013 Reference Manual; ESI-Group: Lyon, France, 2012. [Google Scholar]

- Ding, R.; Guo, Z.X.; Wilson, A. Microstructural evolution of Ti–6Al–4V alloy during thermomechanical processing. Mater. Sci. Eng. A 2002, 327, 233–245. [Google Scholar] [CrossRef]

- Gil, F.J.; Manero, J.M.; Ginebra, M.P.; Planell, J.A. The effect of cooling rate on the cyclic deformation of β-annealed Ti–6Al–4V. Mater. Des. 2003, 349, 150–155. [Google Scholar] [CrossRef]

- Tiley, J.; Searles, T.; Lee, E.; Kar, S.; Banerjee, R.; Russ, J.; Fraser, H. Quantification of microstructural features in α/β titanium alloys. Mater. Sci. Eng. A 2004, 372, 191–198. [Google Scholar] [CrossRef]

- Mi, G.; Wei, Y.; Zhan, X.; Gu, C.; Yu, F. A coupled thermal and metallurgical model for welding simulation of Ti–6Al–4V alloy. J. Mat. Proc. Technol. 2014, 214, 2434–2443. [Google Scholar] [CrossRef]

- Fan, Y.; Cheng, P.; Yao, Y.L.; Yang, Z.; Egland, K. Effect of phase transformations on laser forming of Ti–6Al–4V alloy. J. Appl. Phys. 2005, 98, 1–10. [Google Scholar] [CrossRef]

- Malinov, S.; Guo, Z.; Sha, W.; Wilson, A. Differential scanning calorimetry study and computer modeling of β ⇒ α phase transformation in a Ti-6Al-4V alloy. Metall. Mater. Trans. A 2000, 32A, 879–887. [Google Scholar] [CrossRef]

- Katzarov, I.; Malinov, S.; Sha, W. Finite element modeling of the morphology of β to α phase transformation in Ti-6Al-4V alloy. Metall. Mater. Trans. A 2001, 33A, 1027–1040. [Google Scholar] [CrossRef]

- Villa, M.; Brooks, J.; Turner, R.P.; Wang, H.; Boitout, F.; Ward, R.M. Microstructural Modeling of the α + β Phase in Ti-6Al-4V: A Diffusion-Based Approach. Metall. Mater. Trans. B 2019, 50, 2898–2911. [Google Scholar] [CrossRef] [Green Version]

- Villa, M.; Brooks, J.; Turner, R.P.; Boitout, F.; Ward, R.M. Microstructural Modeling of Thermally-Driven β Grain Growth, Lamellae & Martensite in Ti-6Al-4V. Modeling Numer. Simul. Mater. Sci. 2020, 10, 55–73. [Google Scholar]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Metall. Mater. Trans. A 2020, 51A, 2593–2625. [Google Scholar] [CrossRef] [Green Version]

- Gil, F.J.; Ginebra, M.P.; Manero, J.M.; Planell, J.A. Formation of α-Widmanstätten structure: Effects of grain size and cooling rate on the Widmanstätten morphologies and on the mechanical properties in Ti6Al4V alloy. J. Alloys Compd. 2001, 329, 142–152. [Google Scholar] [CrossRef]

- Kempf, J.M.; Gautier, E.; Simon, A.; Uginet, J.F.; Gavart, A. Titanium ’92: Science and Technology; Froes, F.H., Caplan, I.L., Eds.; TMS: Warrendale, PA, USA, 1993; pp. 627–634. [Google Scholar]

- Allan, M.; Thomas, M.; Brooks, J.; Blackwell, P. β Recrystallisation Characteristics of α + β Titanium Alloys for Aerospace Applications. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–30 August 2015; Venkatesh, V., Pilchak, A.L., Allison, J.E., Ankem, S., Boyer, R., Christodoulou, J., Fraser, H.L., Imam, M.A., Kosaka, Y., Rack, H.J., et al., Eds.; TMS: Warrandale, PA, USA, 2016; pp. 203–208. [Google Scholar]

- Ivasishin, O.M.; Shevchenko, S.V.; Semiatin, S.L. Effect of crystallographic texture on the isothermal β grain-growth kinetics of Ti–6Al–4V. Mater. Sci. Eng. A 2002, A332, 343–350. [Google Scholar] [CrossRef]

- Konovalov, S.; Komissarova, I.; Ivanov, Y.; Gromov, V.; Kosinov, D. Structural and phase changes under electropulse treatment of fatigue-loaded titanium alloy VT1-0. J. Mater. Res. Technol. 2019, 8, 1300–1307. [Google Scholar] [CrossRef]

- De Jesus, J.; Ferreira, J.A.M.; Borrego, L.; Costa, J.D.; Capela, C. Fatigue Failure from Inner Surfaces of Additive Manufactured Ti-6Al-4V Components. Materials 2021, 14, 737. [Google Scholar] [CrossRef]

- Xia, J.; Jin, H. Numerical modeling of coupling thermal–metallurgical transformation phenomena of structural steel in the welding process. Adv. Eng. Softw. 2018, 115, 66–74. [Google Scholar] [CrossRef]

- Jones, S.J.; Bhadeshia, H.K.D.H. Kinetics of the simultaneous decomposition of Austenite in to several transformation products. Acta Mater. 1996, 45, 2911–2920. [Google Scholar] [CrossRef]

- Lindgren, L.-E. Computational Welding Mechanics Thermomechanical and Microstructural Simulations; Woodhead Publishing: Cambridge, UK; Maney Publishing: Leeds, UK, 2007. [Google Scholar]

- Anderson, R.L. Thermocouple Error Analysis in the Design of Large Engineered Experiments. Oak Ridge National Labs. Internal Report. 1979. Available online: https://www.osti.gov/servlets/purl/12104847 (accessed on 15 March 2021).

- Squillace, A.; Prisco, U.; Ciliberto, S.; Astarita, A. Influence of Welding Parameters and Post-weld Aging on Tensile Properties and Fracture Location of AA2139-T351 Friction-stir-welded Joints. J. Mater. Process. Technol. 2012, 212, 427–436. [Google Scholar] [CrossRef]

- Pharr, G.M.; Tsui, T.Y.; Bolshakov, A.; Oliver, W.C. Effects of Residual Stress on the Measurement of Hardness and Elastic Modulus using Nanoindentation. MRS Proc. 1994, 338, 127. [Google Scholar] [CrossRef]

- Boivineau, M.; Cagran, C.; Doytier, D.; Eyraud, V.; Nadal, M.H.; Wilthan, B.; Pottlacher, G. Thermophysical Properties of Solid and Liquid Ti-6Al-4V (TA6V) Alloy. Int. J. Thermophys. 2005, 27, 507–528. [Google Scholar] [CrossRef]

- Turner, R.P.; Gebelin, J.-C.; Ward, R.M.; Reed, R.C. Linear Friction Welding of Ti-6Al-4V: Modelling and Validation. Acta Mater. 2011, 59, 3792–3803. [Google Scholar] [CrossRef]

- Mills, K.C. Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing Ltd.: Cambridge, UK, 2002. [Google Scholar]

- Basak, D.; Overfelt, R.A.; Wang, D. Measurement of Specific Heat Capacity and Electrical Resistivity of Industrial Alloys Using Pulse Heating Techniques. Int. J. Thermophys. 2003, 24, 1721–1733. [Google Scholar] [CrossRef]

- Boyer, R.; Welsch, G.; Collings, E.W. Materials Properties Handbook: Titanium Alloys; ASM International: Almere, The Netherlands, 1994. [Google Scholar]

- Villa, M. Metallurgical and Mechanical Modelling of Ti-6Al-4V for Welding Applications. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2016. [Google Scholar]

- Goldak, J.A.; Akhlaghi, M. Computational Welding Mechanics; Springer: Berlin, Germany, 2010. [Google Scholar]

- Turner, R.P.; Villa, M.; Sovani, Y.; Panwisawas, C.; Perumal, B.; Ward, R.M.; Brooks, J.W.; Basoalto, H.C. An Improved Method of Capturing the Surface Boundary of a Ti-6Al-4V Fusion Weld Bead for Finite Element Modeling. Metall. Mater. Trans. B 2015, 47, 485–494. [Google Scholar] [CrossRef]

- Dabrowski, R. The Kinetics of Phase Transformations during Continuous Cooling of Ti6Al4V Alloy from the Diphase α + β Range. Arch. Metall. Mater. 2011, 56, 217–221. [Google Scholar] [CrossRef]

| Plate Thickness (mm) | Microstructure | Al | V | Fe | H | N | O | Ti |

|---|---|---|---|---|---|---|---|---|

| 2.0 | Equiaxed | 5.82 | 4.00 | 0.06 | 0.0096 | 0.010 | 0.07 | Bal. |

| 5.8 | Equiaxed | 6.05 | 3.99 | 0.19 | 0.0031 | 0.005 | 0.18 | Bal. |

| 3.0 | Lamellar | 5.75 | 3.96 | 0.07 | 0.0045 | 0.013 | 0.11 | Bal. |

| 3.8 | Lamellar | 5.75 | 3.96 | 0.07 | 0.0045 | 0.013 | 0.11 | Bal. |

| Weld Experiment | Plate Thickness (mm) | Microstructure | Weld Speed (m.min−1) | Laser Power (kW) | Nozzle Distance (mm) |

|---|---|---|---|---|---|

| a | 2.0 | Equiaxed | 2.0 | 2.4 | 6.8 |

| b | 5.8 | Equiaxed | 1.5 | 4.0 | 6.8 |

| c | 5.8 | Equiaxed | 2.0 | 4.0 | 6.8 |

| d | 3.0 | Lamellar | 2.0 | 2.8 | 6.8 |

| e | 3.8 | Lamellar | 2.0 | 2.8 | 6.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villa, M.; Brooks, J.W.; Turner, R.; Boitout, F.; Ward, R.M. Metallurgical Modelling of Ti-6Al-4V for Welding Applications. Metals 2021, 11, 960. https://doi.org/10.3390/met11060960

Villa M, Brooks JW, Turner R, Boitout F, Ward RM. Metallurgical Modelling of Ti-6Al-4V for Welding Applications. Metals. 2021; 11(6):960. https://doi.org/10.3390/met11060960

Chicago/Turabian StyleVilla, Matteo, Jeffery W. Brooks, Richard Turner, Frédéric Boitout, and Robin Mark Ward. 2021. "Metallurgical Modelling of Ti-6Al-4V for Welding Applications" Metals 11, no. 6: 960. https://doi.org/10.3390/met11060960

APA StyleVilla, M., Brooks, J. W., Turner, R., Boitout, F., & Ward, R. M. (2021). Metallurgical Modelling of Ti-6Al-4V for Welding Applications. Metals, 11(6), 960. https://doi.org/10.3390/met11060960