Analysis of the Advantages of Laser Processing of Aerospace Materials Using Diffractive Optics

Abstract

:1. Introduction

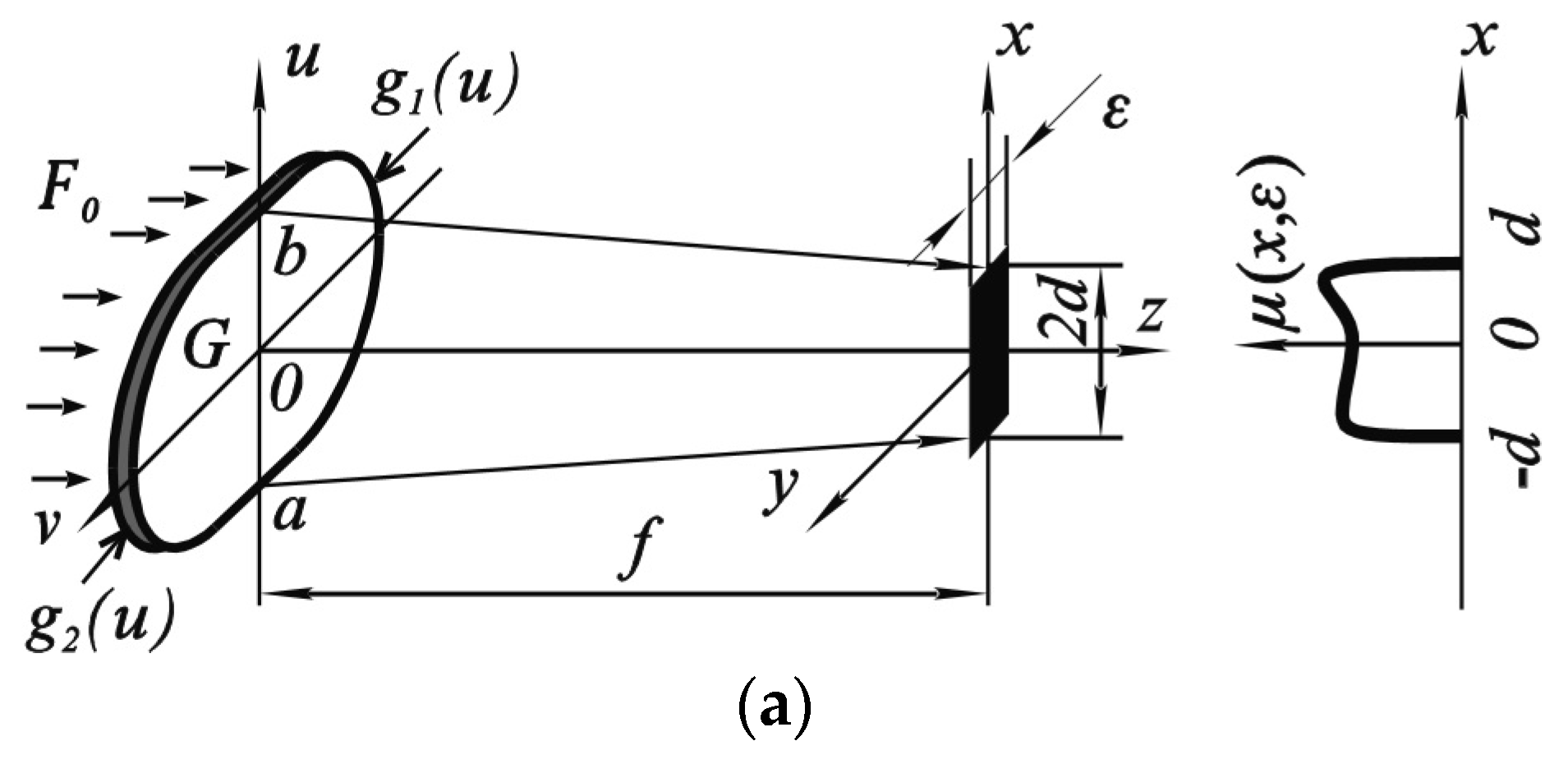

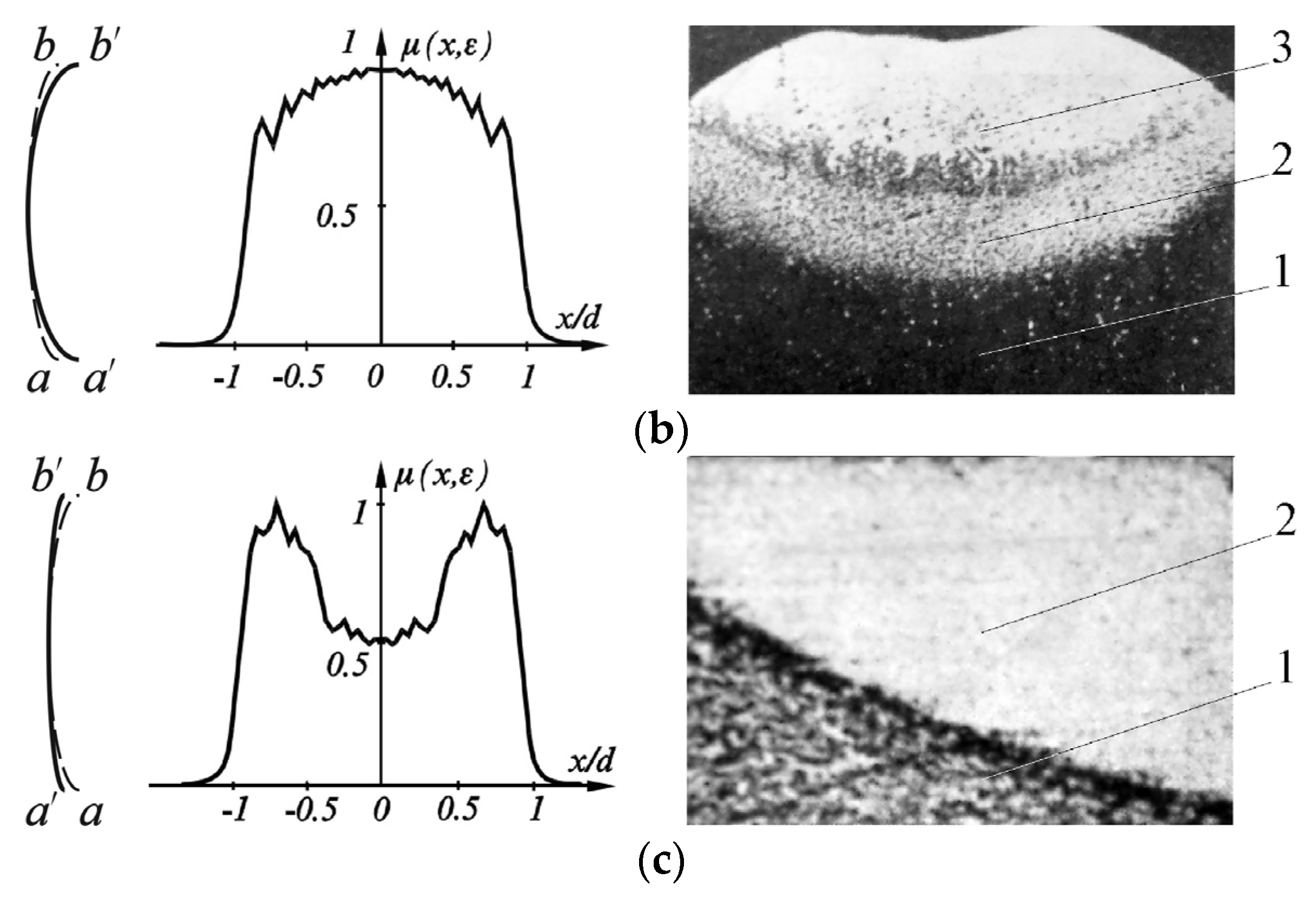

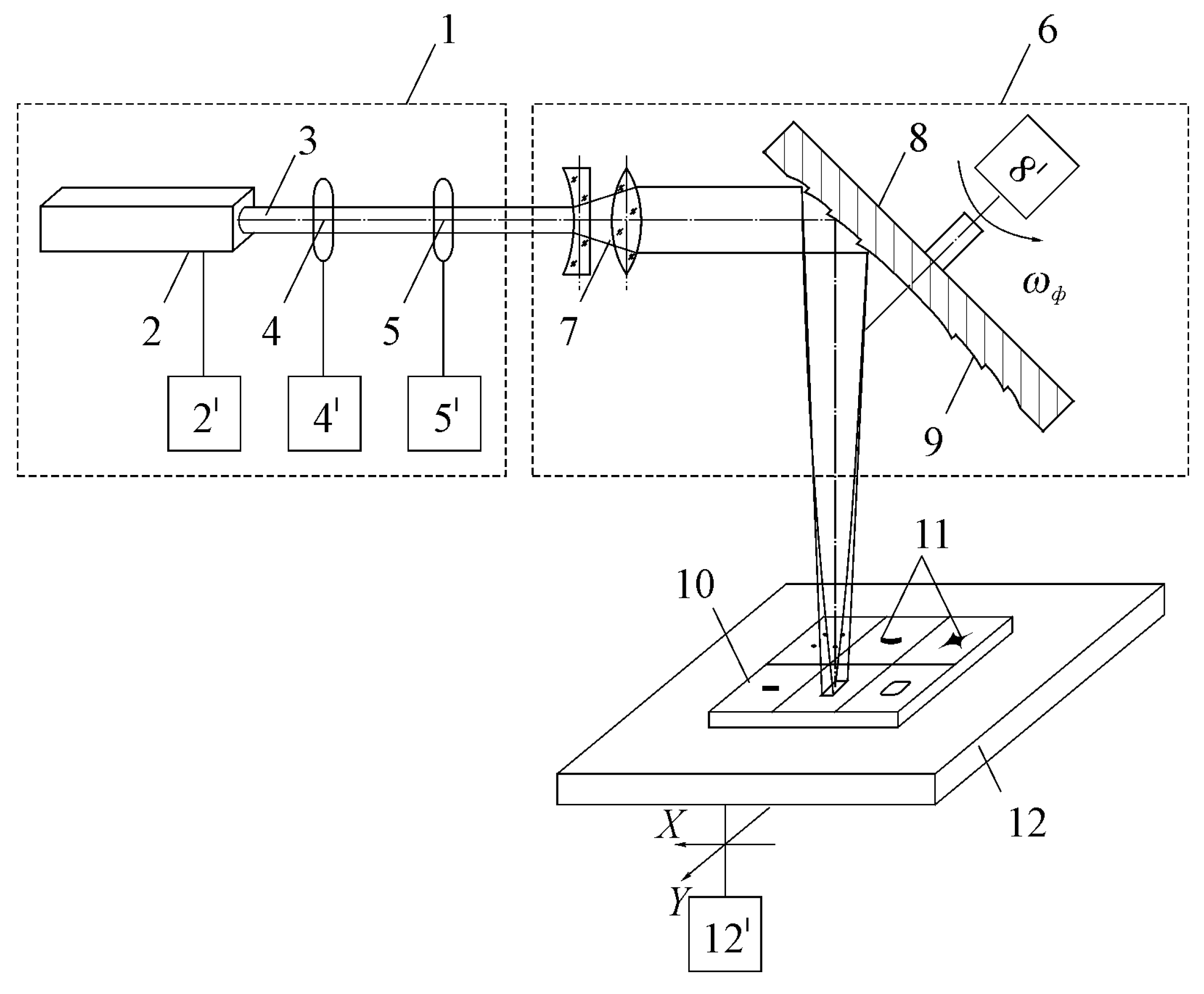

2. Optical Systems for the Shaping of Laser Beams

3. Calculation of the Power Density Distribution of the Laser Beam to Create a Desired Thermal Effect in Materials

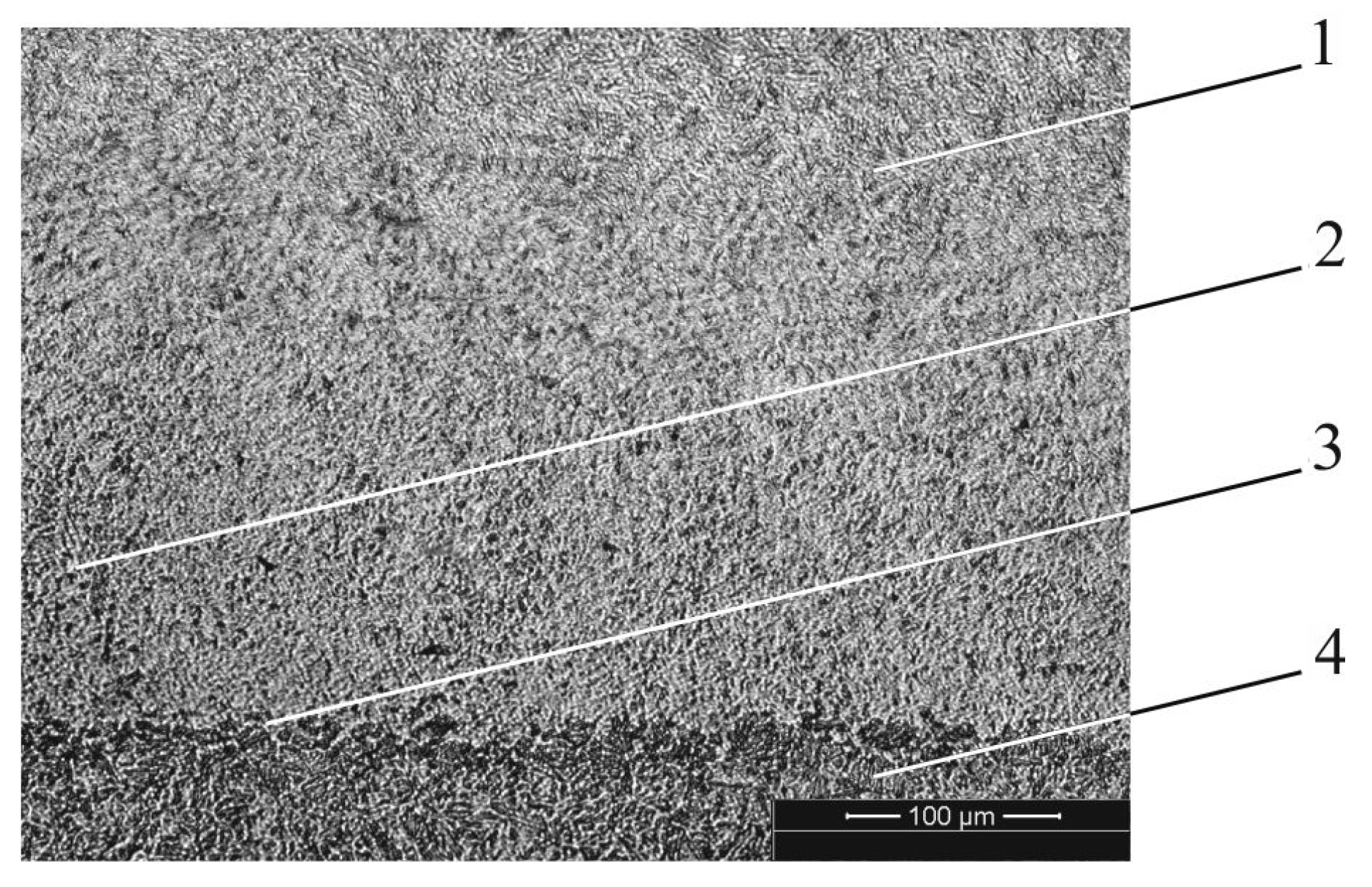

4. Local Laser Annealing of Metallic Sheet Materials

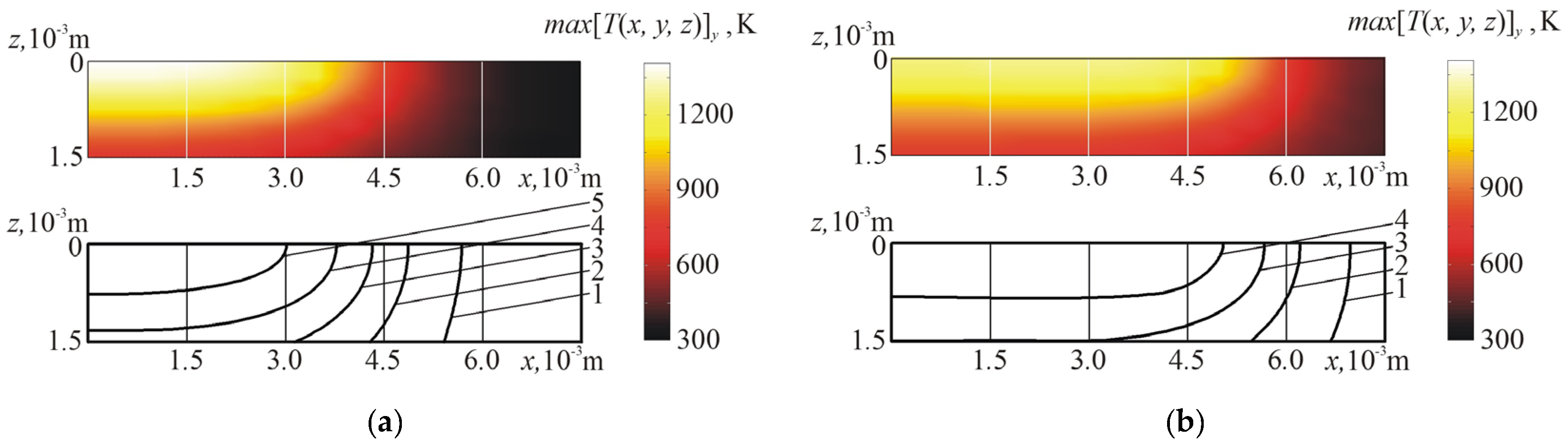

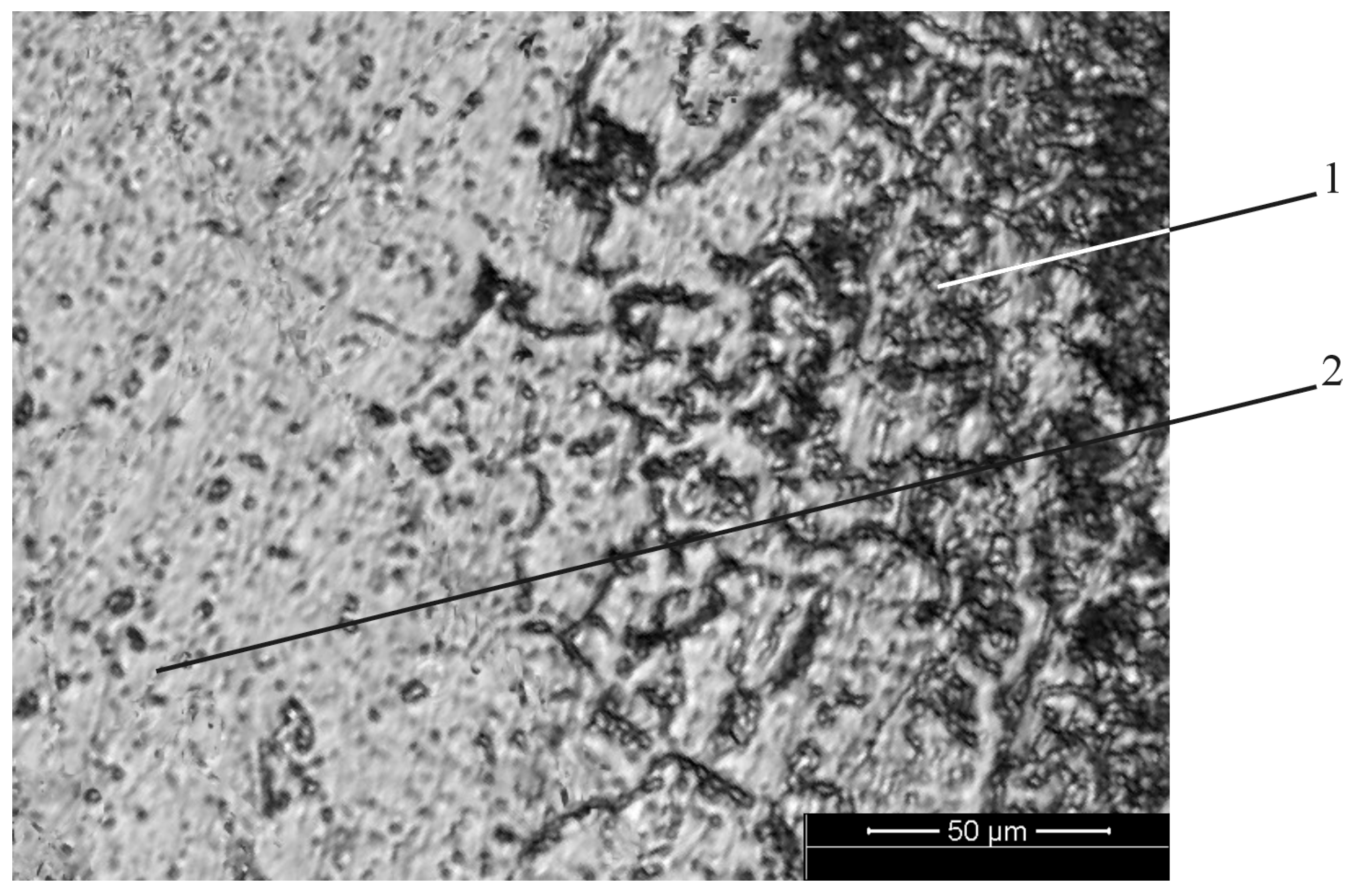

5. Softening of Low-Alloyed Titanium Blanks

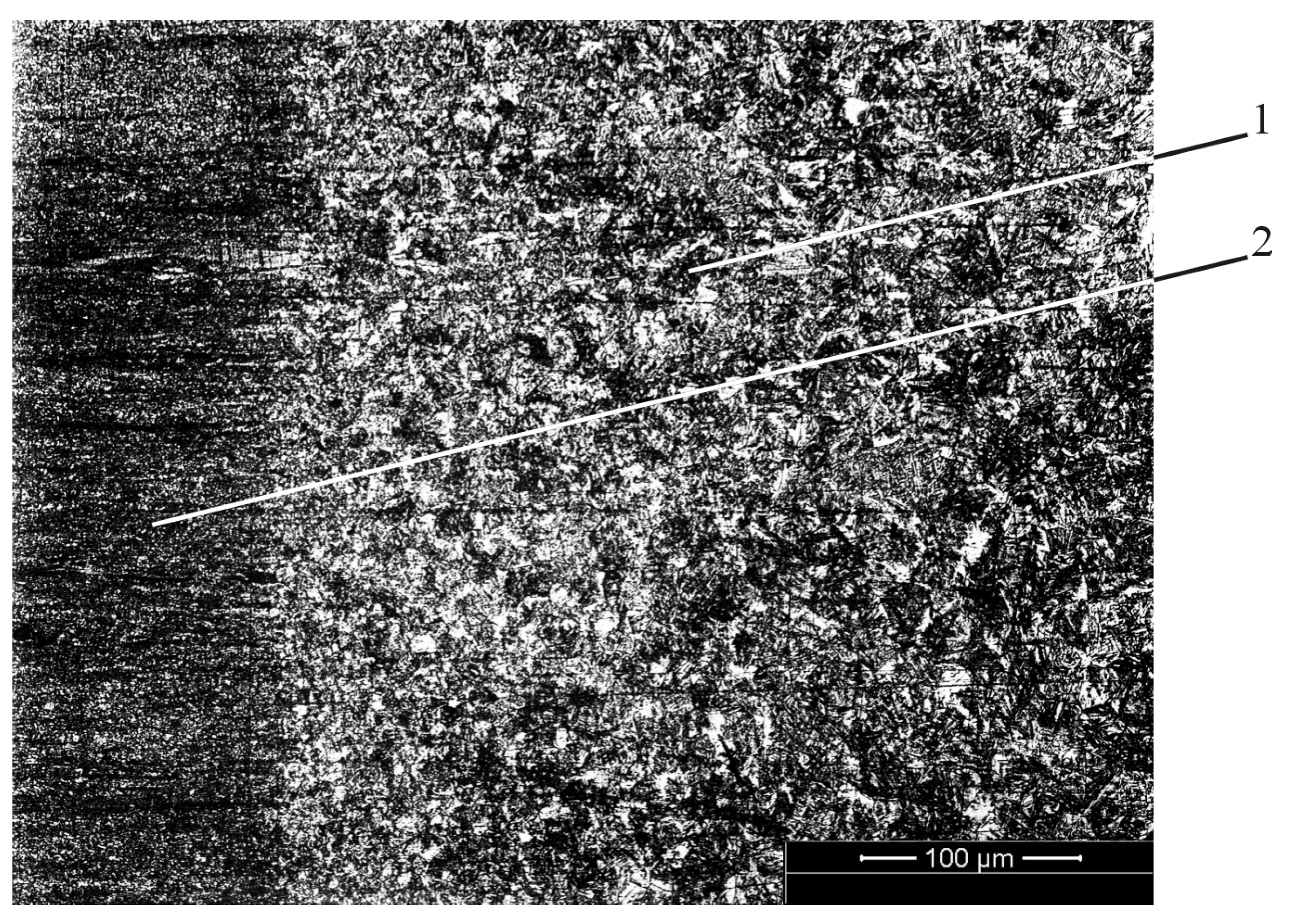

6. Creating Defect-Free Welded Joints of Nickel-Based Alloys

7. Formation of Materials Structures of Coatings for Parts of Gas Turbine Engines and Power Plants

8. Discussion of the Presented Results

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mouritz, A.P. Introduction to Aerospace Materials; Woodhead Publishing Limited: Philadelphia, PA, USA, 2012; 640p. [Google Scholar]

- Eswara Prasad, N.; Wanhill, R.J.H. (Eds.) Aerospace Materials and Material Technologies; Volume 1: Aerospace Materials; Springer: Singapore, 2017; 594p. [Google Scholar]

- Zhang, S.; Zhao, D. (Eds.) Aerospace Materials Handbook; CRC Press Taylor & Francis: Boca Raton, FL, USA, 2013; 743p. [Google Scholar]

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials; Elsevier Ltd.: Kidlington, Oxford, UK, 2006; 600p. [Google Scholar]

- Eswara Prasad, N.; Wanhill, R.J.H. (Eds.) Aerospace Materials and Material Technologies; Volume 2: Aerospace Material Technologies; Springer: Singapore, 2017; 567p. [Google Scholar]

- Alderliesten, R.C. Introduction to Aerospace Structures and Materials; Delft University of Technology: Delft, The Netherlands, 2018; 258p. [Google Scholar]

- Kannatey-Asibu, E., Jr. Principles of Laser Materials Processing; John Wiley & Sons: Hoboken, NJ, USA, 2009; 819p. [Google Scholar]

- Steen, W.M.; Mazumder, J. Laser Material Processing, 4th ed.; Springer: London, UK, 2010; 558p. [Google Scholar]

- Schaaf, P. Laser Processing of Materials: Fundamentals, Applications and Developments; Springer: Berlin/Heidelberg, Germany, 2010; 231p. [Google Scholar]

- Lawrence, J.R. (Ed.) Advances in Laser Materials Processing: Technology, Research and Applications, 2nd ed.; Woodhead Publishing: Oxford, UK, 2017; 802p. [Google Scholar]

- Dowden, J.; Schulz, W. (Eds.) The Theory of Laser Materials Processing: Heat and Mass Transfer in Modern Technology, 2nd ed.; Springer-Verlag: Berlin/Heidelberg, Germany, 2017; 442p. [Google Scholar]

- Duerr, F.; Thienpont, H. Optical design of static and dynamic laser beam shaping systems. Proc. SPIE 2015, 9629, 962902. [Google Scholar]

- Möhl, A.; Kaldun, S.; Kunz, C.; Müller, F.A.; Fuchs, U.; Gräf, S. Tailored focal beam shaping and its application in laser material processing. J. Laser Appl. 2019, 31, 042019. [Google Scholar] [CrossRef] [Green Version]

- Hafner, T.; Strauss, J.; Roider, C.; Heberle, J.; Schmidt, M. Tailored laser beam shaping for efficient and accurate microstructuring. Appl. Phys. A 2018, 124, 111. [Google Scholar] [CrossRef] [Green Version]

- Heath, D.J.; Mackay, B.S.; Grant-Jacob, J.A.; Xie, Y.; Oreffo, R.O.C.; Eason, R.W.; Mills, B. Closed-loop corrective beam shaping for laser processing of curved surfaces. J. Micromech. Microeng. 2018, 28, 127001. [Google Scholar] [CrossRef]

- Hilton, P.A.; Lloyd, D.; Tyrer, J.R. Use of a diffractive optic for high power laser cutting. J. Laser Appl. 2016, 28, 012014. [Google Scholar] [CrossRef] [Green Version]

- Soifer, V.A. (Ed.) Computer Design of Diffractive Optics, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012; 896p. [Google Scholar]

- Kovalenko, V.; Anyakin, M.; Zhuk, R.; Meijer, J.; Uno, Y. The increase in productivity and quality of laser machining. In Proceedings of the 15th International Symposium on Electromachining, Pittsburgh, PA, USA, 23–27 April 2007; pp. 439–444. [Google Scholar]

- Golub, M.A.; Sisakyan, I.N.; Soifer, V.A. Infra-red radiation focusators. Opt. Lasers Eng. 1991, 15, 297–309. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Kotlyar, V.V.; Soifer, V.A. Computer-aided design of diffractive optical elements. Opt. Eng. 1994, 33, 3156–3166. [Google Scholar]

- Danilov, V.A.; Popov, V.V.; Prokhorov, A.M.; Sisakian, I.N.; Sagatelian, D.M.; Soifer, V.A.; Sisakian, E.V.; Naumidi, L.P.; Danileiko, J.K.; Terekhin, J.D.; et al. Device for Laser Treatment of an Object. U.S. Patent 5,103,073, 7 April 1992. [Google Scholar]

- Doskolovich, L.L.; Kazanskiy, N.L.; Kharitonov, S.I.; Uspleniev, G.V. Focusators for laser-branding. Opt. Lasers Eng. 1991, 15, 311–322. [Google Scholar] [CrossRef]

- Babu, P.D.; Balasubramanian, K.R.; Buvanashekaran, G. Laser surface hardening: A review. Int. J. Surf. Sci. Eng. 2011, 5, 131–151. [Google Scholar] [CrossRef]

- Leung, M.K.H.; Man, H.C.; Yu, J.K. Theoretical and experimental studies on laser transformation hardening of steel by customized beam. Int. J. Heat Mass Transf. 2007, 50, 4600–4606. [Google Scholar] [CrossRef]

- Tarasova, T.V.; Gusarov, A.V.; Protasov, K.E.; Filatova, A.A. Effect of thermal fields on the structure of corrosion-resistant steels under different modes of laser treatment. Met. Sci. Heat Treat. 2017, 59, 433–440. [Google Scholar] [CrossRef]

- Vasiliev, M.A.; Nishchenko, M.M.; Gurin, P.A. Laser modification of the surface of titanium implants. Usp. Fiz. Met. 2010, 11, 209–247. [Google Scholar] [CrossRef] [Green Version]

- Soriano, C.; Alberdi, G.; Lambarri, J.; Aranzabe, A.; Yáñez, A. Laser surface tempering of hardened chromium-molybdenum alloyed steel. Procedia CIRP 2018, 74, 353–356. [Google Scholar] [CrossRef]

- Kung, C.-L.; Shih, H.-E.; Hsu, C.-M.; Chen, C.-Y. Tempering effects of multitrack laser surface heat treatment of AISI 1045 steel. Sens. Mater. 2019, 31, 1091–1103. [Google Scholar] [CrossRef]

- Van Elsen, M.; Baelmans, M.; Mercelis, P.; Kruth, J.-P. Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. Int. J. Heat Mass Transf. 2007, 50, 4872–4882. [Google Scholar] [CrossRef]

- Gladush, G.G.; Smurov, I. Physics of Laser Materials Processing: Theory and Experiment; Springer: Berlin, Germany, 2011; 534p. [Google Scholar]

- Akhtar, S.S.; Yilbas, B.S. Laser treatment of steel surfaces: Numerical and experimental investigations of temperature and stress fields. In Comprehensive Materials Processing; Hashmi, S., Ed.; Elsevier: Oxford, UK; Waltham, MA, USA, 2014; pp. 25–46. [Google Scholar]

- Hung, T.-P.; Hsu, C.-M.; Tsai, H.-A.; Chen, S.-C.; Liu, Z.-R. Temperature field numerical analysis mode and verification of quenching heat treatment using carbon steel in rotating laser scanning. Materials 2019, 12, 534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Talesh Alikhani, S.; Kazemi Zahabi, M.; Javad Torkamany, M.; Hasan Nabavi, S. Time-dependent 3D modeling of the thermal analysis of the high-power diode laser hardening process. Opt. Laser Technol. 2020, 128, 106216. [Google Scholar] [CrossRef]

- Casalino, G.; Moradi, M.; Moghadam, M.K.; Khorram, A.; Perulli, P. Experimental and numerical study of AISI 4130 steel surface hardening by pulsed Nd:YAG laser. Materials 2019, 12, 3136. [Google Scholar] [CrossRef] [Green Version]

- Hung, T.-P.; Shi, H.-E.; Kuang, J.-H. Temperature modeling of AISI 1045 steel during surface hardening processes. Materials 2018, 11, 1815. [Google Scholar] [CrossRef] [Green Version]

- Fakir, R.; Barka, N.; Brousseau, J. Case study of laser hardening process applied to 4340 steel cylindrical specimens using simulation and experimental validation. Case Stud. Therm. Eng. 2018, 11, 15–25. [Google Scholar] [CrossRef]

- Lakhkar, R.S.; Shin, Y.C.; Krane, M.J.M. Predictive modeling of multi-track laser hardening of AISI 4140 steel. Mater. Sci. Eng. A 2008, 480, 209–217. [Google Scholar] [CrossRef]

- Nath, A.K.; Gupta, A.; Benny, F. Theoretical and experimental study on laser surface hardening by repetitive laser pulses. Surf. Coat. Technol. 2012, 206, 2602–2615. [Google Scholar] [CrossRef]

- Zammit, A.; Abela, S.; Betts, J.C.; Grech, M. Discrete laser spot hardening of austempered ductile iron. Surf. Coat. Technol. 2017, 331, 143–152. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, C.; Yan, K.; Zou, J.; Liu, C. Effects of overlapping distances on steel microstructure and properties after multi-track laser quenching. J. Mater. Eng. Perform. 2017, 26, 5973–5982. [Google Scholar] [CrossRef]

- Giorleo, L.; Previtali, B.; Semeraro, Q. Modelling of back tempering in laser hardening. International. J. Adv. Manuf. Technol. 2011, 54, 969–977. [Google Scholar] [CrossRef]

- Tani, G.; Orazi, L.; Fortunato, A. Prediction of hypo eutectoid steel softening due to tempering phenomena in laser surface hardening. CIRP Ann. Manuf. Technol. 2008, 57, 209–212. [Google Scholar] [CrossRef]

- Dickey, F.M.; Lizotte, T.E. (Eds.) Laser Beam Shaping Applications, 2nd ed.; CRC Press Taylor & Francis: Boca Raton, FL, USA, 2017; 442p. [Google Scholar]

- Träger, F. (Ed.) Springer Handbook of Lasers and Optics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2012; 1694p. [Google Scholar]

- Doskolovich, L.L.; Mingazov, A.A.; Bykov, D.A.; Bezus, E.A. Formulation of the inverse problem of calculating the optical surface for an illuminating beam with a plane wavefront as the Monge-Kantorovich problem. Comput. Opt. 2019, 43, 705–713. [Google Scholar] [CrossRef]

- Klocke, F.; Schulz, M.; Gräfe, S. Optimization of the laser hardening process by adapting the intensity distribution to generate a top-hat temperature distribution using freeform optics. Coatings 2017, 7, 77. [Google Scholar] [CrossRef]

- Völl, A.; Wester, R.; Berens, M.; Buske, P.; Stollenwerk, J.; Loosen, P. Accounting for laser beam characteristics in the design of freeform optics for laser material processing. Adv. Opt. Technol. 2019, 8, 279–287. [Google Scholar] [CrossRef] [Green Version]

- Ma, D.; Feng, Z.; Liang, R. Freeform illumination lens design using composite ray mapping. Appl. Opt. 2015, 54, 498–503. [Google Scholar] [CrossRef]

- Andreeva, K.V.; Moiseev, M.A.; Kravchenko, S.V.; Doskolovich, L.L. Design of optical elements with TIR freeform surface. Comput. Opt. 2016, 40, 467–474. [Google Scholar] [CrossRef]

- Doskolovich, L.L.; Bykov, D.A.; Andreev, E.S.; Byzov, E.V.; Moiseev, M.A.; Bezus, E.A.; Kazanskiy, N.L. Design and fabrication of freeform mirrors generating prescribed far-field irradiance distributions. Appl. Opt. 2020, 59, 5006–5012. [Google Scholar] [CrossRef]

- Innolite. Tailored Molds & Optics: Turning Complexity into Simplicity. Available online: https://innolite.de/tailored-molds-optics (accessed on 12 June 2021).

- Golub, M.A.; Rybakov, O.E.; Usplenjev, G.V.; Volkov, A.V.; Volotovsky, S.G. The technology of fabricating focusators of infrared laser radiation. Opt. Laser Technol. 1995, 27, 215–218. [Google Scholar] [CrossRef]

- Kononenko, V.V.; Konov, V.I.; Pimenov, S.M.; Prokhorov, A.M.; Pavel’ev, V.S.; Soifer, V.A. Diamond diffraction optics for CO2 lasers. Quantum Electron. 1999, 29, 9–10. [Google Scholar] [CrossRef]

- Pavelyev, V.S.; Borodin, S.A.; Kazanskiy, N.L.; Kostyuk, G.F.; Volkov, A.V. Formation of diffractive microrelief on diamond film surface. Opt. Laser Technol. 2007, 39, 1234–1238. [Google Scholar] [CrossRef]

- Otto, A.; Schmidt, M. Towards a universal numerical simulation model for laser material processing. Phys. Procedia 2010, 5, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Sun, S.; Brandt, M.; Yan, W. 3D transient thermal modelling and experimental validation of the temperature distribution during laser heating of Ti6Al4V alloy. Mater. Sci. Forum 2010, 654–656, 894–897. [Google Scholar] [CrossRef] [Green Version]

- Yilbas, B.S. Laser Heating Applications: Analytical Modelling; Elsevier: Waltham, MA, USA, 2012; 280p. [Google Scholar]

- Kashani, M.M.; Movahhedy, M.R.; Ahmadian, M.T.; Razavi, R.S. Analytical solution of transient three-dimensional temperature field in a rotating cylinder subject to a localized laser beam. J. Heat Transf. 2017, 139, 062701. [Google Scholar] [CrossRef]

- Dutta, J.; Kundu, B.; Soni, H.; Mashinini, P.M. Analytical Modelling for Laser Heating for Materials Processing and Surface Engineering. In Surface Engineering of Modern Materials: Engineering Materials; Gupta, K., Ed.; Springer: Cham, Switzerland, 2020; pp. 103–123. [Google Scholar]

- Isakov, V. Inverse Problems for Partial Differential Equations; Springer: New York, NY, USA, 2006; 344p. [Google Scholar]

- Alifanov, O.M.; Nenarokomov, A.V. Boundary inverse heat conduction problem: Algorithm and error analysis. Inverse Probl. Eng. 2001, 9, 619–644. [Google Scholar] [CrossRef]

- Tikhonov, A.N.; Goncharsky, A.V.; Stepanov, V.V.; Yagola, A.G. Numerical Methods for the Solution of Ill-Posed Problems; Springer: Dordrecht, The Netherlands, 1995; 253p. [Google Scholar]

- Alifanov, O.M. Inverse problems in identification and modeling of thermal processes: Russian contributions. Int. J. Numer. Method H 2017, 27, 711–728. [Google Scholar] [CrossRef]

- Shang, Z.; Liao, Z.; Sarasua, J.A.; Billingham, J.; Axinte, D. On modelling of laser assisted machining: Forward and inverse problems for heat placement control. Int. J. Mach. Tools Manuf. 2019, 138, 36–50. [Google Scholar] [CrossRef] [Green Version]

- Murzin, S.P.; Bielak, R.; Liedl, G. Algorithm for calculating of the power density distribution of the laser beam to create a desired thermal effect on technological objects. Comput. Opt. 2016, 40, 679–684. [Google Scholar] [CrossRef]

- Bergmann, H.W. Short Term Annealing by Laser Treatment. Proc. SPIE 1987, 0801, 296–301. [Google Scholar]

- Minamida, K.; Kido, M.; Ishibashi, A.; Mogami, S.; Sasaki, S. Surface annealing of steel wires for automotive tires by CO2 laser with cone shaped focusing mirror. Laser Inst. Am. 1991, 71, 460–468. [Google Scholar]

- Nolan, S.R. Method for Laser Annealing. U.S. Patent 7,063,755, 20 June 2006. [Google Scholar]

- Łȩcka, K.M.; Antończak, A.J.; Kowalewski, P.; Trzcinski, M. Wear resistance of laser-induced annealing of AISI 316 (EN 1.4401) stainless steel. Laser Phys. 2018, 28, 096005. [Google Scholar] [CrossRef]

- Hallberg, H.; Adamski, F.; Baïz, S.; Castelnau, O. Microstructure and property modifications of cold rolled IF steel by local laser annealing. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2017, 48, 4786–4802. [Google Scholar] [CrossRef]

- Ovchinnikov, V.V. Aircraft Parts Manufacturing; ID FORUM: Infra-M Publishing House: Moscow, Russia, 2020; 368p. (In Russian) [Google Scholar]

- Hosford, W.F.; Caddell, R.M. Metal Forming: Mechanics and Metallurgy, 4th ed.; Cambridge University Press: New York, NY, USA, 2011; 331p. [Google Scholar]

- Vogt, S.; Bechheim, L.; Banik, J.; Flaischerowitz, M.; Weisheit, A.; Schleifenbaum, J.H. Local laser softening of press-hardened steel at high feed rates. J. Laser Appl. 2018, 30, 031201. [Google Scholar] [CrossRef]

- Neugebauer, R.; Scheffler, S.; Poprawe, R.; Weisheit, A. Local laser heat treatment of ultra high strength steels to improve formability. Prod. Eng. 2009, 3, 347–351. [Google Scholar] [CrossRef]

- Lapouge, P.; Dirrenberger, J.; Coste, F.; Schneider, M. Laser heat treatment of martensitic steel and dual-phase steel with high martensite content. Mater. Sci. Eng. A 2019, 752, 128–135. [Google Scholar] [CrossRef] [Green Version]

- Niehuesbernd, J.; Monnerjahn, V.; Bruder, E.; Groche, P.; Müller, C. Improving the formability of linear flow split profiles by laser annealing: Verbesserung der Umformbarkeit von Spaltprofilen mittels Laser-Wärmebehandlung. Materwiss Werksttech 2016, 47, 1174–1181. [Google Scholar] [CrossRef]

- Hofmann, A. Deep drawing of process optimized blanks. J. Mater. Process. Technol. 2001, 119, 127–132. [Google Scholar] [CrossRef]

- Merklein, M.; Herrmann, J. Effect of a local laser heat treatment on the formability of multi-layered 6000 series aluminum alloys. Phys. Procedia 2016, 83, 560–567. [Google Scholar] [CrossRef] [Green Version]

- Merklein, M.; Böhm, W.; Lechner, M. Tailoring material properties of aluminum by local laser heat Treatment. Phys. Procedia 2012, 39, 232–239. [Google Scholar] [CrossRef] [Green Version]

- Zarini, S.; Mostaed, E.; Vedani, M.; Previtali, B. Formability enhancement of Al 6060 sheets through fiber laser heat treatment. Int. J. Mater. Form. 2017, 10, 741–751. [Google Scholar] [CrossRef] [Green Version]

- Piccininni, A.; Palumbo, G. Design and optimization of the local laser treatment to improve the formability of age hardenable aluminium alloys. Materials 2020, 13, 1576. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Gao, Y.; Song, H.; Wang, L.; Wang, J. Research and application of laser local heat treatment to improve the formability of aluminum alloy blanks. Cailiao Daobao Mater. Rep. 2018, 32, 137–144. [Google Scholar]

- Altan, T.; Tekkaya, A.E. Sheet Metal Forming: Processes and Applications; ASM International: Materials Park, OH, USA, 2012; 450p. [Google Scholar]

- Boljanovic, V. Metal Shaping Processes: Casting and Molding; Particulate Processing; Deformation Processes; and Metal Removal; Industrial press: New York, NY, USA, 2009; 453p. [Google Scholar]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Krajewski, P.E.; Hector, L.G., Jr.; Du, N.; Bower, A.F. Microstructure-based model for elevated temperature deformation in aluminum alloys. Acta Mater. 2010, 58, 1074–1086. [Google Scholar] [CrossRef]

- Golovin, I.S.; Mikhaylovskaya, A.V.; Sinning, H.-R. Role of the β-phase in grain boundary and dislocation anelasticity in binary Al-Mg alloys. J. Alloys Compd. 2013, 577, 622–632. [Google Scholar] [CrossRef]

- Li, J.; Carsley, J.E.; Stoughton, T.B.; Hector, L.G., Jr.; Hu, S.J. Forming limit analysis for two-stage forming of 5182-O aluminum sheet with intermediate annealing. Int. J. Plast. 2013, 45, 21–43. [Google Scholar] [CrossRef]

- Steen, W.M. ‘Light’ Industry: An Introduction to Laser Processing and Its Industrial Applications. In Advances in Laser Materials Processing Technology: Technology, Research and Application; Lawrence, J., Pou, J., Low, D.K.Y., Toyserkani, E., Eds.; Woodhead Publishing; CRC Press: Cambridge, UK, 2010; pp. 3–19. [Google Scholar]

- Capello, E.; Previtali, B. Enhancing dual phase steel formability by diode laser heat treatment. J. Laser Appl. 2009, 21, 1–9. [Google Scholar] [CrossRef]

- Vogt, S.; Völl, A.; Wollgarten, S.; Freese, T. Local laser softening of high-strength steel with an adapted intensity. J. Laser Appl. 2019, 31, 012007. [Google Scholar] [CrossRef]

- Murzin, S.P. Local laser annealing for aluminium alloy parts. Lasers Eng. 2016, 33, 67–76. [Google Scholar]

- Jin, H.; Lloyd, D.J. The grain structures in some 5000 series aluminum alloys after asymmetric rolling and annealing. Mater. Sci. Forum 2006, 519–521, 161–168. [Google Scholar] [CrossRef]

- Gundlach, C.; Pantleon, W.; Lauridsen, E.M.; Margulies, L.; Doherty, R.D.; Poulsen, H.F. Direct observation of subgrain evolution during recovery of cold-rolled aluminium. Scr. Mater. 2004, 50, 477–481. [Google Scholar] [CrossRef]

- Moiseyev, V.N. Titanium Alloys: Russian Aircraft and Aerospace Applications; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2006; 196p. [Google Scholar]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Maeno, T.; Tomobe, M.; Mori, K.-I.; Ikeda, Y. Hot stamping of titanium alloy sheets using partial contact heating. Procedia Manuf. 2018, 15, 1149–1155. [Google Scholar] [CrossRef]

- Ozturk, F.; Ece, R.E.; Polat, N.; Koksal, A.; Evis, Z.; Sheikh-Ahmad, J.Y. Application of electric resistance heating method on titanium hot forming at industrial scale. Arab. J. Sci. Eng. 2016, 41, 4441–4448. [Google Scholar] [CrossRef]

- Wang, K.; Wang, L.; Zheng, K.; He, Z.; Politis, D.J.; Liu, G.; Yuan, S. High-efficiency forming processes for complex thin-walled titanium alloys components: State-of-the-art and perspectives. Int. J. Extrem. Manuf. 2020, 2, 032001. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kazanskiy, N.L. Softening of low-alloyed titanium billets with laser annealing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 302, 012070. [Google Scholar] [CrossRef] [Green Version]

- Murzin, S.P. Creating dense defect-free welded joints of nickel-based alloys by pulse laser irradiation. Bull. Samara Sci. Cent. Russ. Acad. Sci. 2013, 15, 181–185. (In Russian) [Google Scholar]

- Murzin, S.P. Formation of structures in materials by laser treatment to enhance the performance characteristics of aircraft engine parts. Comput. Opt. 2016, 40, 353–359. [Google Scholar] [CrossRef] [Green Version]

- Barvinok, V.A.; Bogdanovich, V.I. Physical and mathematical simulation of the formation of mesostructure-ordered plasma coatings. Tech. Phys. 2012, 57, 262–269. [Google Scholar] [CrossRef]

- Bogdanovich, V.I.; Giorbelidze, M.G. Numerical investigation of the thermal transformation of composition powder particles in the technology of selective laser melting. IOP Conf. Ser. Mater. Sci. Eng. 2019, 510, 012005. [Google Scholar] [CrossRef]

- Vollertsen, F.; Partes, K.; Meijer, J. State of the art of laser hardening and cladding. In Proceedings of the Third International WLT-Conference on Lasers in Manufacturing, Munich, Germany, 14–17 June 2005; AT-Fachverlag GmbH: Fellbach, Germany, 2005; pp. 281–305. [Google Scholar]

- Soundarapandian, S.; Dahotre, N.B. Laser Surface Hardenin. In ASM Handbook, Volume 4A: Steel Heat Treating Fundamentals and Processes; Dossett, J., Totten, G.E., Eds.; ASM International: Materials Park, OH, USA, 2013; pp. 476–502. [Google Scholar]

- Lu, Y.; Meyer, H.; Radel, T. Multi-cycle phase transformation during laser hardening of AISI 4140. Procedia CIRP 2020, 94, 919–923. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepouhor, A.; Gerlich, A. Real-time monitoring and prediction of martensite formation and hardening depth during laser heat treatment. Surf. Coat. Technol. 2017, 315, 326–334. [Google Scholar] [CrossRef]

- Santhanakrishnan, S.; Kovacevic, R. Hardness prediction in multi-pass direct diode laser heat treatment by on-line surface temperature monitoring. J. Mater. Process. Technol. 2012, 212, 2261–2271. [Google Scholar] [CrossRef]

- Chakrabarty, J. Applied Plasticity, 2nd ed.; Springer: New York, NY, USA, 2010; 774p. [Google Scholar]

| Optical Systems |

|---|

| Individual lenses or mirrors |

| Lens and mirror systems from several elements |

| Faceted lenses or mirror segments |

| Movable mirrors, including oscillating, rotating, or polygonal mirrors |

| Scanning galvo systems |

| Beam integrators and homogenizers |

| Micro-optics |

| Diffractive optics |

| Thickness | 1.5 mm |

|---|---|

| Beam power | 600 W |

| Laser spot size | 12 × 1.5 mm2 |

| Processing speed | up to 6 mm/s |

| Thickness | 2 mm |

|---|---|

| Beam power | 450 W |

| Laser spot size | 10 × 1.5 mm2 |

| Processing speed | up to 4 mm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murzin, S.P.; Kazanskiy, N.L.; Stiglbrunner, C. Analysis of the Advantages of Laser Processing of Aerospace Materials Using Diffractive Optics. Metals 2021, 11, 963. https://doi.org/10.3390/met11060963

Murzin SP, Kazanskiy NL, Stiglbrunner C. Analysis of the Advantages of Laser Processing of Aerospace Materials Using Diffractive Optics. Metals. 2021; 11(6):963. https://doi.org/10.3390/met11060963

Chicago/Turabian StyleMurzin, Serguei P., Nikolay L. Kazanskiy, and Christian Stiglbrunner. 2021. "Analysis of the Advantages of Laser Processing of Aerospace Materials Using Diffractive Optics" Metals 11, no. 6: 963. https://doi.org/10.3390/met11060963