Influence of Austempering Temperatures on the Microstructure and Mechanical Properties of Austempered Ductile Cast Iron

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Experimental Setup

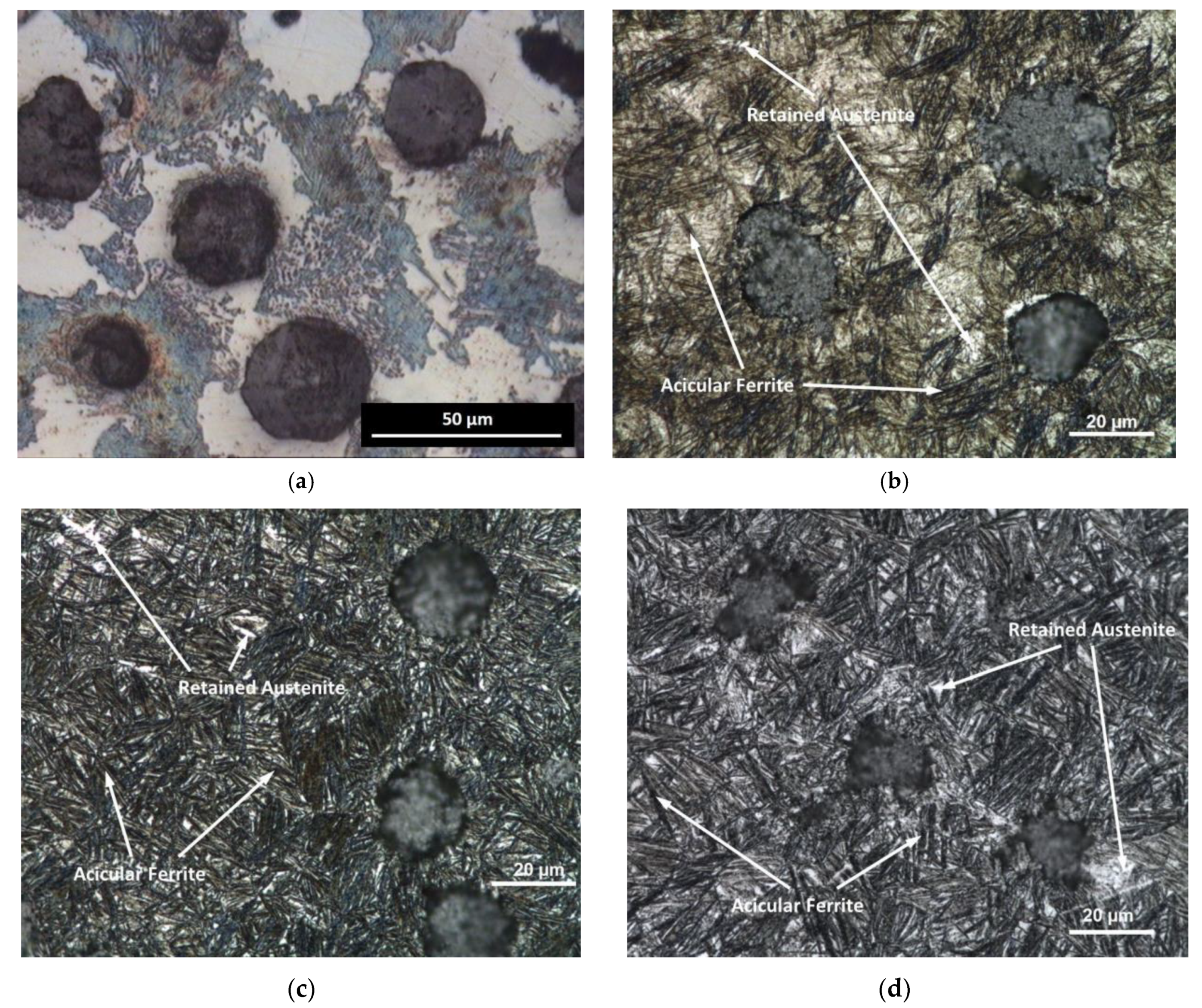

3.2. Microstructure Analysis

3.3. Mechanical Properties

3.4. Fractography

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Echeverría, M.D.; Moncada, O.J.; Sikora, J.A. Influence of the dimensional change, and its dispersion, on the fabrication size tolerances of austempered ductile iron (ADI) parts: Comparison with SAE 4140 steel. ISIJ Int. 2001, 41, 25–30. [Google Scholar] [CrossRef] [Green Version]

- Han, J.M.; Zou, Q.; Barber, G.C.; Nasir, T.; Northwood, D.O.; Sun, X.C.; Seaton, P. Study of the effects of austempering temperature and time on scuffing behavior of austempered Ni–Mo–Cu ductile iron. Wear 2012, 290–291, 99–105. [Google Scholar] [CrossRef]

- Parhad, P.; Dakre, V.; Likhite, A.; Bhatt, J. The impact of cutting speed and depth of cut on cutting force during turning of austempered ductile iron. Mater. Today Proc. 2019, 19, 663–669. [Google Scholar] [CrossRef]

- Pedro, D.I.; Dommarco, R.C. Rolling contact fatigue resistance of Carbidic Austempered Ductile Iron (CADI). Wear 2019, 418–419, 94–101. [Google Scholar] [CrossRef]

- Putatunda, S.K.; Kesani, S.; Tackett, R.; Lawes, G. Development of austenite free ADI (austempered ductile cast iron). Mater. Sci. Eng. A 2006, 435–436, 112–122. [Google Scholar] [CrossRef]

- Radulovic, B.; Bosnjak, B.; Harding, R.; Pop-Tonev, K.; Asanovic, V. The influence of austenitising temperature on the microstructure and mechanical properties of low-alloyed Ni-Mo-Cu austempered ductile iron. Mater. Technol. 2000, 34, 207–212. [Google Scholar]

- Sellamuthu, P.; Samuel, D.G.H.; Dinakaran, D.; Premkumar, V.P.; Li, Z.; Seetharaman, S. Austempered ductile iron (ADI): Influence of austempering temperature on microstructure, mechanical and wear properties and energy consumption. Metals 2018, 8, 53. [Google Scholar] [CrossRef] [Green Version]

- Bedolla-Jacuinde, A.; Mejía, I.; Zuno, J.; Maldonado, C. Effects of boron addition and austempering time on microstructure, hardness and tensile properties of ductile irons. Mater. Sci. Eng. A 2015, 648, 193–201. [Google Scholar] [CrossRef]

- Tanaka, Y.; Kage, H. Development and application of austempered spheroidal graphite cast iron. Mater. Trans. JIM 1992, 33, 543–557. [Google Scholar] [CrossRef] [Green Version]

- Nan, R.; Fu, H.; Yang, P.; Lin, J.; Guo, X. Microstructure Evolution and Wear Resistance of Cu-Bearing Carbidic Austempered Ductile Iron after Austempering. J. Mater. Eng. Perform. 2020, 29, 2440–2459. [Google Scholar] [CrossRef]

- Panneerselvam, S.; Putatunda, S.K.; Gundlach, R.; Boileau, J. Influence of intercritical austempering on the microstructure and mechanical properties of austempered ductile cast iron (ADI). Mater. Sci. Eng. A 2017, 694, 72–80. [Google Scholar] [CrossRef]

- Eric, O.; Sidjanin, L.; Miskovic, Z.; Zec, S.; Jovanovic, M.T. Microstructure and toughness of CuNiMo austempered ductile iron. Mater. Lett. 2004, 58, 2707–2711. [Google Scholar] [CrossRef]

- Putatunda, S.K. Influence of austempering temperature on fracture toughness of a low manganese austempered ductile iron (ADI). Mater. Manuf. Process. 2001, 16, 245–263. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Li, Q.; Hong, X. Mechanical properties and rolling-sliding wear performance of dual phase austempered ductile iron as potential metro wheel material. Wear 2018, 406–407, 156–165. [Google Scholar] [CrossRef]

- Han, C.F.; Sun, Y.F.; Wu, Y.; Ma, Y.H. Effects of Vanadium and Austempering Temperature on Microstructure and Properties of CADI. Metallogr. Microstruct. Anal. 2015, 4, 135–145. [Google Scholar] [CrossRef]

- Han, C.F.; Wang, Q.Q.; Sun, Y.F.; Li, J. Effects of Molybdenum on the Wear Resistance and Corrosion Resistance of Carbidic Austempered Ductile Iron. Metallogr. Microstruct. Anal. 2015, 4, 298–304. [Google Scholar] [CrossRef]

- Yang, P.; Fu, H.; Lin, J.; Cheng, H.; Lei, Y. Experimental and ab initio study of the influence of a compound modifier on carbidic ductile iron. Metall. Res. Technol. 2019, 116, 306–316. [Google Scholar] [CrossRef]

- Peng, Y.C.; Jin, H.J.; Liu, J.H.; Li, G.L. Influence of cooling rate on the microstructure and properties of a new wear resistant carbidic austempered ductile iron (CADI). Mater. Charact. 2012, 72, 53–58. [Google Scholar] [CrossRef]

- Penghui, Y.; Hanguang, F.; Guolu, L.; Jinhai, L.; Xuebo, Z. Microstructures and properties of carbidic austempered ductile Iron containing Fe3C particles and superfine ausferrite. Mater. Des. 2020, 186, 108363. [Google Scholar] [CrossRef]

- Sadeghi, F.; Jalalahmadi, B.; Slack, T.S.; Raje, N.; Arakere, N.K. A Review of Rolling Contact Fatigue. J. Tribol. 2009, 131. [Google Scholar] [CrossRef]

- Wang, B.; He, M.; Barber, G.C.; Schall, J.D.; Tao, C.; Sun, X. Rolling contact fatigue resistance of austempered ductile iron processed at various austempering holding times. Wear 2018, 398–399, 41–46. [Google Scholar] [CrossRef]

- Colombo, D.A.; Dommarco, R.C.; Basso, A.D. Rolling contact fatigue behavior of dual-phase austempered ductile iron. Wear 2019, 418–419, 208–214. [Google Scholar] [CrossRef] [Green Version]

- Zammit, A.; Abela, S.; Betts, J.C.; Michalczewski, R.; Kalbarczyk, M.; Grech, M. Scuffing and rolling contact fatigue resistance of discrete laser spot hardened austempered ductile iron. Wear 2019, 422–423, 100–107. [Google Scholar] [CrossRef]

- Samaddar, S.; Das, T.; Chowdhury, A.K.; Singh, M. Manufacturing of Engineering components with Austempered Ductile Iron—A Review. Mater. Today Proc. 2018, 5, 25615–25624. [Google Scholar] [CrossRef]

- Fatahalla, N.; Hussein, O. Microstructure, Mechanical Properties, Toughness, Wear Characteristics and Fracture Phenomena of Austenitised and Austempered Low-Alloyed Ductile Iron. Open Access Libr. J. 2015, 2, 1–16. [Google Scholar] [CrossRef]

- Belarus standard STB 2544-2019. High Fatigue Resistance Ductile Cast Iron with Nodular Shaped Graphite. Grades and mechanical properties. Introduced from 2019.10.01. Minsk, Republic of Belarus. 2019; 12p. (In Russian)

- Bahdanovich, A.; Bendikiene, R.; Cesnavicius, R.; Ciuplys, A.; Grigas, V.; Jutas, A.; Marmysh, D.; Mazaleuski, A.; Nasan, A.; Shemet, L.; et al. Research on tensile behaviour of new structural material MoNiCa. Medziagotyra 2019, 25, 292–296. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Barber, G.C.; Qiu, F.; Zou, Q.; Yang, H. A review: Phase transformation and wear mechanisms of single-step and dual-step austempered ductile irons. J. Mater. Res. Technol. 2020, 9, 1054–1069. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Bogdanovich, A.V.; Yelovoy, O.M.; Tyurin, S.A.; Komissarov, V.V.; Sherbakov, S.S. Methods and main results of Tribo-Fatigue tests. Int. J. Fatigue 2014, 66, 207–219. [Google Scholar] [CrossRef]

- Saal, P.; Meier, L.; Li, X.; Hofmann, M.; Hoelzel, M.; Wagner, J.N.; Volk, W. In Situ Study of the Influence of Nickel on the Phase Transformation Kinetics in Austempered Ductile Iron. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 661–671. [Google Scholar] [CrossRef]

- Konca, E.; Tur, K.; Koç, E. Effects of alloying elements (Mo, Ni, and Cu) on the austemperability of GGG-60 ductile cast Iron. Metals 2017, 7, 320. [Google Scholar] [CrossRef] [Green Version]

- Elmasry, N.; Mahdy, A.; Kandil, A. Influence of austempering temperature on microstructure and properties of ductile irons. J. Al-Azhar Univ. Eng. Sect. 2013, 8, 122–128. [Google Scholar]

- Nan, R.; Fu, H.; Yang, P.; Lin, J.; Lei, Y. Effect of austenitizing temperature on the microstructure evolution and properties of Cu-bearing CADI. Mater. Test. 2019, 61, 865–874. [Google Scholar] [CrossRef]

- Sujakhu, S.; Castagne, S.; Sakaguchi, M.; Kasvayee, K.A.; Ghassemali, E.; Jarfors, A.E.W.; Wang, W. On the fatigue damage micromechanisms in Si-solution–strengthened spheroidal graphite cast iron. Fatigue Fract. Eng. M 2018, 41, 625–641. [Google Scholar] [CrossRef] [Green Version]

- Iacoviello, F.; Di Cocco, V.; Rossi, A.; Cavallini, M. Damaging micromechanisms characterization in pearlitic ductile cast irons. Proc. Mat. Sci. 2014, 3, 295–300. [Google Scholar] [CrossRef] [Green Version]

- Borgström, H. Influence of strain rate, temperature and chemical composition on high silicon ductile iron. Mineral 2021, 11, 391. [Google Scholar] [CrossRef]

- Batra, U. Fracture behavior and mechanism in austempered ductile iron. J. Fail. Anal. Prev. 2005, 5, 75–81. [Google Scholar] [CrossRef]

- Putatunda, S.K. Influence of austempering temperature on microstructure and fracture toughness of a high-carbon, high-silicon and high-manganese cast steel. Mater. Des. 2003, 24, 435–443. [Google Scholar] [CrossRef]

- Refaey, A.; Fatahalla, N. Effect of microstructure on properties of ADI and low alloyed ductile iron. J. Mater. Sci. 2003, 38, 351–362. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | Ni | Cu | Mg | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 3.6 | 2.7 | 0.3 | 0.04 | 0.5 | 0.6 | 1.2 | 0.05 | 0.1 | Bal. |

| Tensile strength, MPa | Plasticity limit, MPa | Elongation, % | Modulus of elasticity, GPa | |||||||

| 1115–1435 | 841–971 | 0.7–3.0 | 142–152 | |||||||

| σa | 800 | 700 | 600 | 500 | 400 | 300 | 243 | |

|---|---|---|---|---|---|---|---|---|

| σ11 | A | +800 | +700 | +600 | +500 | +400 | +300 | +243 |

| C | −800 | −700 | −600 | −500 | −400 | −300 | −243 | |

| B, D | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| σ12 | A, C | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| B, D | 13.333 | 11.667 | 10.0 | 8.333 | 6.667 | 5.0 | 4.05 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bendikiene, R.; Ciuplys, A.; Cesnavicius, R.; Jutas, A.; Bahdanovich, A.; Marmysh, D.; Nasan, A.; Shemet, L.; Sherbakov, S. Influence of Austempering Temperatures on the Microstructure and Mechanical Properties of Austempered Ductile Cast Iron. Metals 2021, 11, 967. https://doi.org/10.3390/met11060967

Bendikiene R, Ciuplys A, Cesnavicius R, Jutas A, Bahdanovich A, Marmysh D, Nasan A, Shemet L, Sherbakov S. Influence of Austempering Temperatures on the Microstructure and Mechanical Properties of Austempered Ductile Cast Iron. Metals. 2021; 11(6):967. https://doi.org/10.3390/met11060967

Chicago/Turabian StyleBendikiene, Regita, Antanas Ciuplys, Ramunas Cesnavicius, Audrius Jutas, Aliaksandr Bahdanovich, Dzianis Marmysh, Aleh Nasan, Liudmila Shemet, and Sergei Sherbakov. 2021. "Influence of Austempering Temperatures on the Microstructure and Mechanical Properties of Austempered Ductile Cast Iron" Metals 11, no. 6: 967. https://doi.org/10.3390/met11060967

APA StyleBendikiene, R., Ciuplys, A., Cesnavicius, R., Jutas, A., Bahdanovich, A., Marmysh, D., Nasan, A., Shemet, L., & Sherbakov, S. (2021). Influence of Austempering Temperatures on the Microstructure and Mechanical Properties of Austempered Ductile Cast Iron. Metals, 11(6), 967. https://doi.org/10.3390/met11060967