The Interaction between the Sheet/Tool Surface Texture and the Friction/Galling Behaviour on Aluminium Deep Drawing Operations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sheet Material

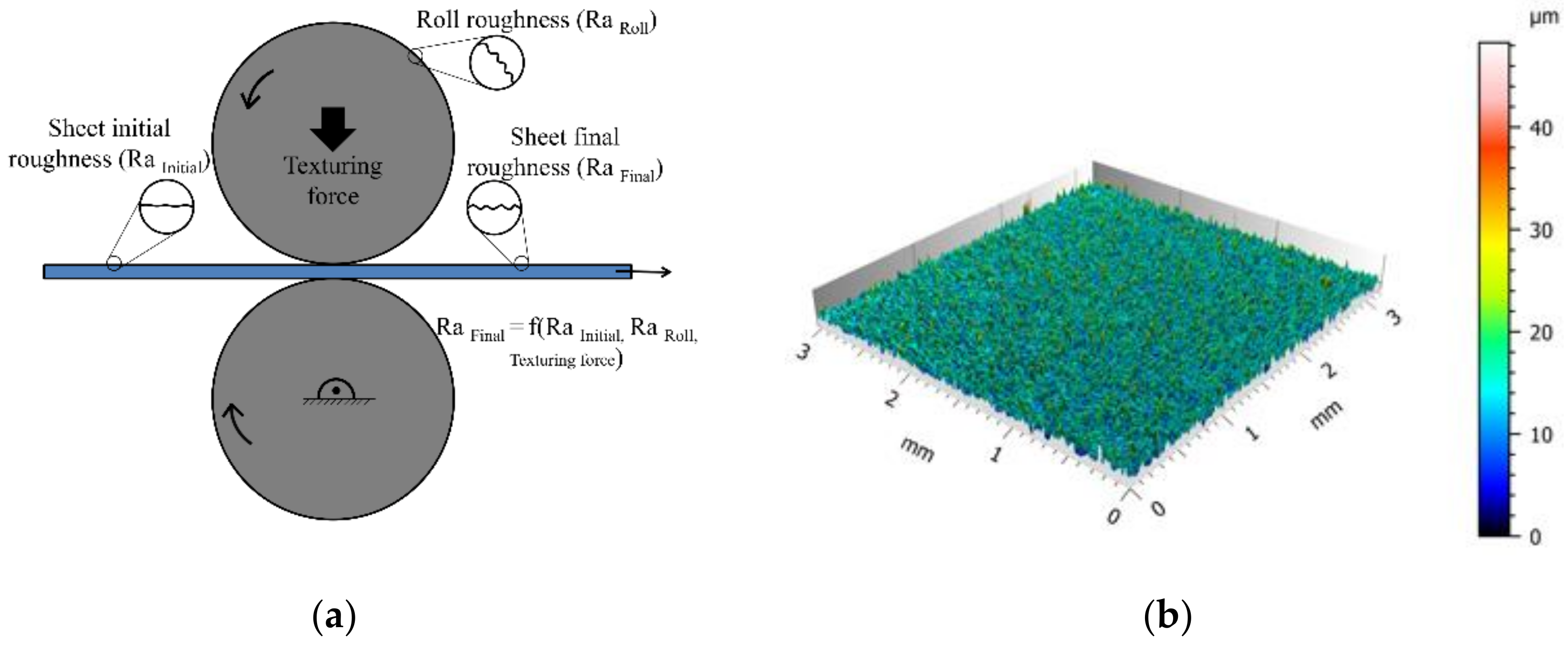

2.2. Sheet Texturing

2.3. Strip Drawing Test

2.4. Galling Analysis

2.5. Benchmark: Cup Drawing Test

3. Results

3.1. Surface Topography Analysis

3.2. Galling

3.3. Coefficient of Friction

3.4. Cup Drawing Benchmark

4. Discussion

5. Conclusions

- Friction is reduced as the EDT texture degree is increased. This effect is probably attributable to the greater ability to retain lubricant in the pockets.

- Low initial friction is not a guarantee for good galling prevention.

- A new galling severity index (GSI) is presented, which is directly computed from the friction curve and provides a quick and quantitative determination of both galling occurrence and severity.

- A minimum EDT texture on the aluminium strip is required for galling prevention, but the die surface topography is the dominant factor controlling galling in forming process.

- Ra is not a good performance indicator. The use of functional 3D parameters from ISO 25178 is suggested for a good understanding of the surface functionality: Vmp, Vvv, Spk.

- Findings were corroborated by a cup-drawing benchmark study.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hirsch, J. Aluminium in innovative light-weight car design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef] [Green Version]

- Blanco, D.; Rubio, E.M.; Marín, M.M.; Davim, J.P. Advanced materials and multi-materials applied in aeronautical and automotive fields: A systematic review approach. Procedia CIRP 2021, 99, 196–201. [Google Scholar] [CrossRef]

- Peppas, A.; Kollias, K.; Dragatogiannis, D.A.; Charitidis, C.A. Sustainability analysis of aluminium hot forming and quenching technology for lightweight vehicles manufacturing. Int. J. Thermofluids 2021, 10, 100082. [Google Scholar] [CrossRef]

- Van der Aa, H.C.E.; Van der Aa, M.A.H.; Schreurs, P.J.G.; Baaijens, F.P.T.; Van Veenen, W.J. An experimental and numerical study of the wall ironing process of polymer coated sheet metal. Mech. Mater. 2000, 32, 423–443. [Google Scholar] [CrossRef]

- Jeswiet, J.; Geiger, M.; Engel, U.; Kleiner, M.; Schikorra, M.; Duflou, J.; Neugebauer, R.; Bariani, P.; Bruschi, S. Metal forming progress since 2000. CIRP J. Manuf. Sci. Technol. 2008, 1, 2–17. [Google Scholar] [CrossRef]

- Hetz, P.; Suttner, S.; Merklein, M. Investigation of the Springback Behaviour of High-strength Aluminium Alloys Based on Cross Profile Deep Drawing Tests. Procedia Manuf. 2020, 47, 1223–1229. [Google Scholar] [CrossRef]

- Makhkamov, A. Tribology in Sheet Metal Forming; Universidad de Porto: Porto, Portugal, 2017. [Google Scholar]

- Heinrichs, J.; Olsson, M.; Jacobson, S. Mechanisms of material transfer studied in situ in the SEM: Explanations to the success of DLC coated tools in aluminium forming. Wear 2012, 292–293, 49–60. [Google Scholar] [CrossRef]

- D’Amato, C.; Buhagiar, J.; Betts, J.C. Tribological characteristics of an A356 aluminium alloy laser surface alloyed with nickel and Ni–Ti–C. Appl. Surf. Sci. 2014, 313, 720–729. [Google Scholar] [CrossRef]

- Button, S.T. Tribology in Manufacturing Technology; Springer: Berlin, Germany, 2013; pp. 103–120. [Google Scholar]

- Hou, Y.-K.; Yu, Z.-Q.; Li, S.-H. Galling failure analysis in sheet metal forming process. J. Shanghai Jiaotong Univ. 2010, 15, 245–249. [Google Scholar] [CrossRef]

- Clarysse, F.; Lauwerens, W.; Vermeulen, M. Tribological properties of PVD tool coatings in forming operations of steel sheet. Wear 2008, 264, 400–404. [Google Scholar] [CrossRef]

- Daure, J.L.; Carrington, M.J.; Shipway, P.H.; McCartney, D.G.; Stewart, D.A. A comparison of the galling wear behaviour of PVD Cr and electroplated hard Cr thin films. Surf. Coat. Technol. 2018, 350, 40–47. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Effects of die surface patterning on lubrication in strip drawing. J. Mater. Process. Technol. 2009, 209, 1175–1180. [Google Scholar] [CrossRef]

- Kijima, H.; Bay, N. Skin-pass rolling I—Studies on roughness transfer and elongation under pure normal loading. Int. J. Mach. Tools Manuf. 2008, 48, 1313–1317. [Google Scholar] [CrossRef]

- Gorbunov, A.V.; Belov, V.K.; Begletsov, D.O. Texturing of rollers for the production of auto-industry sheet. Steel Transl. 2009, 39, 696–699. [Google Scholar] [CrossRef]

- Aspinwall, D.K.; Wise, M.L.H.; Stout, K.J.; Goh, T.H.A.; Zhao, F.L.; El-Menshawy, M.F. Electrical discharge texturing. Int. J. Mach. Tools Manuf. 1992, 32, 183–193. [Google Scholar] [CrossRef]

- Vorholt, J.; Shimizu, T.; Kobayashi, H.; Heinrich, L.; Flosky, H.; Vollertsen, F.; Yang, M. In-situ observation of lubricant flow on laser textured die surface in sheet metal forming. Procedia Eng. 2017, 207, 2209–2214. [Google Scholar] [CrossRef]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Varenberg, M.; Halperin, G.; Etsion, I. Different aspects of the role of wear debris in fretting wear. Wear 2002, 252, 902–910. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef] [Green Version]

- Franzen, V.; Witulski, J.; Brosius, A.; Trompeter, M.; Tekkaya, A.E. Textured surfaces for deep drawing tools by rolling. Int. J. Mach. Tools Manuf. 2010, 50, 969–976. [Google Scholar] [CrossRef]

- Steitz, M.; Stein, P.; Groche, P. Influence of Hammer-Peened Surface Textures on Friction Behavior. Tribol. Lett. 2015, 58, 1–8. [Google Scholar] [CrossRef]

- Šugár, P.; Šugárová, J.; Frnčík, M. Laser surface texturing of tool steel: Textured surfaces quality evaluation. Open Eng. 2016, 6, 90–97. [Google Scholar] [CrossRef]

- Brecher, C. Hochglanzende Freiformflaächen auf Stahlw- erkzeugen. VDI-Z Werkzeug-/Formenba 2010, 16–19. [Google Scholar]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Xu, W.; Gao, X.; Zhang, B.; Yang, L.; Du, C.; Zhou, D.; Rawya, B.; Szymanski, M. Study on Frictional Behavior of AA 6XXX with Three Lube Conditions in Sheet Metal Forming. SAE Tech. Pap. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- Liewald, M.; Wagner, S.; Becker, D. Influence of surface topography on the tribological behaviour of aluminium alloy 5182 with EDT surface. Tribol. Lett. 2010, 39, 135–142. [Google Scholar] [CrossRef]

- Ju, L.; Mao, T.; Malpica, J.; Altan, T. Evaluation of lubricants for stamping of Al 5182-O aluminum sheet using cup drawing test. J. Manuf. Sci. Eng. 2015, 137, 1–8. [Google Scholar] [CrossRef]

- Batalha, G.F.; Stipkovic Filho, M. Quantitative characterization of the surface topography of cold rolled sheets—New approaches and possibilities. J. Mater. Process. Technol. 2001, 113, 732–738. [Google Scholar] [CrossRef]

- Sulaima, M.H.B. Development and Testing of Tailored Tool Surfaces for Sheet Metal Forming. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, 2017. [Google Scholar]

- Schedin, E. Galling mechanisms in sheet forming operations. Wear 1994, 179, 123–128. [Google Scholar] [CrossRef]

- Hanson, M.; Hogmark, S.; Jacobson, S. Influence from tool roughness on the risk of work material adhesion and transfer. Mater. Manuf. Process. 2009, 24, 913–917. [Google Scholar] [CrossRef]

- Podgornik, B.; Hogmark, S. Surface modification to improve friction and galling properties of forming tools. J. Mater. Process. Technol. 2006, 174, 334–341. [Google Scholar] [CrossRef]

- Han, L.; Thornton, M.; Boomer, D.; Shergold, M. Effect of aluminium sheet surface conditions on feasibility and quality of resistance spot welding. J. Mater. Process. Technol. 2010, 210, 1076–1082. [Google Scholar] [CrossRef] [Green Version]

- Scholz, P.; Börner, R.; Kühn, R.; Müller, R.; Schubert, A. Dry forming of aluminium sheet metal: Influence of different types of forming tool microstructures on the coefficient of friction. Key Eng. Mater. 2015, 651, 516–521. [Google Scholar] [CrossRef]

- Merklein, M.; Zöller, F.; Sturm, V. Experimental and numerical investigations on frictional behaviour under consideration of varying tribological conditions. Adv. Mater. Res. 2014, 966–967, 270–278. [Google Scholar] [CrossRef]

- Popov, V.L. Coulomb’s Law of Friction. In Contact Mechanics and Friction; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Cillaurren, J.; Galdos, L.; Sanchez, M.; Zabala, A.; Saenz de Argandoña, E.; Mendiguren, J. Contact pressure and sliding velocity ranges in sheet metal forming simulations. In Proceedings of the ESAFORM 2021 24th International Conference on Material Forming, Belgium 14–16 April 2021. [Google Scholar]

- ASTM. ASTM G98-17 Standard Test Method for Galling Resistance of Materials; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. ASTM G 196-Standard Test Method for Galling Resistance of Material Couples; ASTM: West Conshohocken, PA, USA, 2021. [Google Scholar]

- Van der Heide, E.; Huis, A.J.; Schipper, D.J. The effect of lubricant selection on galling in a model wear test. Wear 2001, 251, 973–979. [Google Scholar] [CrossRef]

- Andreasen, J.L.; Bay, N.; De Chiffre, L. Quantification of galling in sheet metal forming by surface topography characterisation. Int. J. Mach. Tools Manuf. 1998, 38, 503–510. [Google Scholar] [CrossRef]

- Deng, L.; Pelcastre, L.; Hardell, J.; Prakash, B.; Oldenburg, M. Experimental Evaluation of Galling Under Press Hardening Conditions. Tribol. Lett. 2018, 66, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.R.; Gharbi, M.M.; Liang, V.; Zheng, Y.; Politis, D.J.; Wang, L.L. The galling behavior of advanced coating contacts with aluminium alloy during sliding wear. Key Eng. Mater. 2018, 767, 117–123. [Google Scholar] [CrossRef]

- Podgornik, B.; Kafexhiu, F.; Kosec, T.; Jerina, J.; Kalin, M. Friction and anti-galling properties of hexagonal boron nitride (h-BN) in aluminium forming. Wear 2017, 388–389, 2–8. [Google Scholar] [CrossRef]

- Harsha, A.P.; Limaye, P.K.; Tyagi, R.; Gupta, A. Development of tribological test equipment and measurement of galling resistance of various grades of stainless steel. J. Tribol. 2016, 138, 024501. [Google Scholar] [CrossRef]

- Siefert, J.A.; Babu, S.S. Experimental observations of wear in specimens tested to ASTM G98. Wear 2014, 320, 111–119. [Google Scholar] [CrossRef]

- Voss, B.M.; Pereira, M.P.; Rolfe, B.F.M.; Doolan, M.C. A new methodology for measuring galling wear severity in high strength steels. Wear 2017, 390–391, 334–345. [Google Scholar] [CrossRef] [Green Version]

- Karlsson, P.; Gåård, A.; Krakhmalev, P.; Bergström, J. Galling resistance and wear mechanisms for cold-work tool steels in lubricated sliding against high strength stainless steel sheets. Wear 2012, 286–287, 92–97. [Google Scholar] [CrossRef]

- Giedenbacher, J.; Raab, A.E.; Walch, C.; Huskic, A. The quantification of galling in forming operations of hot dip galvanized sheet metal under laboratory conditions. Mater. Sci. Forum 2017, 879, 607–612. [Google Scholar] [CrossRef]

- Grüner, M.; Merklein, M. Determination of friction coefficients in deep drawing by modification of Siebel’s formula for calculation of ideal drawing force. Prod. Eng. 2014, 8, 577–584. [Google Scholar] [CrossRef]

- ISO. ISO 13565-3:1998 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 3: Height Characterization Using the Material Probability Curve; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- Zhou, R.; Cao, J.; Wang, Q.J.; Meng, F.; Zimowski, K.; Xia, Z.C. Effect of EDT surface texturing on tribological behavior of aluminum sheet. J. Mater. Process. Technol. 2011, 211, 1643–1649. [Google Scholar] [CrossRef]

- Decrozant-Triquenaux, J.; Pelcastre, L.; Courbon, C.; Prakash, B.; Hardell, J. Effect of Surface Engineered Tool Steel and Lubrication on Aluminium Transfer at High Temperature. Wear 2021, 203879. [Google Scholar] [CrossRef]

- Dohda, K.; Yamamoto, M.; Hu, C.; Dubar, L.; Ehmann, K.F. Galling phenomena in metal forming. Friction 2021, 9, 664–685. [Google Scholar] [CrossRef]

- Shi, R.; Wang, B.; Yan, Z.; Wang, Z.; Dong, L. Effect of Surface Topography Parameters on Friction and Wear of Random Rough Surface. Materials 2019, 12, 2762. [Google Scholar] [CrossRef] [Green Version]

- Zabala, A.; Blunt, L.; Tato, W.; Aginagalde, A.; Gomez, X.; Llavori, I. The use of areal surface topography characterisation in relation to fatigue performance. MATEC Web Conf. 2018, 165, 14013. [Google Scholar] [CrossRef] [Green Version]

| Property | Symbol | Unit | Value |

|---|---|---|---|

| Yield strength | Rp0.2 | MPa | 127.29 |

| Tensile strength | Rm | MPa | 135.79 |

| Strain hardening exponent | n | - | 0.0403 |

| Total elongation | A | % | 3.49 |

| Anisotropy factor (RD/45/TD) | r | - | 0.338/0.612/0.969 |

| Sheet Textures | |||||

|---|---|---|---|---|---|

| Work Roll | Not Textured | Low Textured | Medium Textured | High Textured | |

| Ra [µm] | 0.140 ± 0.023 | 0.920 ± 0.072 | 1.230 ± 0.066 | 1.710 ± 0.144 | |

| Sq [µm] | 3.498 ± 0.07 | 0.511 ± 0.029 | 1.611 ± 0.066 | 1.987 ± 0.096 | 2.200 ± 0.310 |

| Sa [µm] | 2.713 ± 0.05 | 0.417 ± 0.020 | 0.999 ± 0.055 | 1.276 ± 0.119 | 1.562 ± 0.300 |

| Ssk [-] | 0.719 ± 0.01 | 0.271 ± 0.088 | −2.934 ± 0.331 | −2.276 ± 0.224 | −2.029 ± 0.366 |

| Str [-] | 0.959 ± 0.005 | 0.028 ± 7.5 × 10−4 | 0.910 ± 0.01 | 0.871 ± 0.12 | 0.873 ± 0.03 |

| Sdq [°] | 0.893 ± 0.032 | 0.128 ± 0.006 | 0.559 ± 0.017 | 0.653 ± 0.11 | 0.666 ± 0.05 |

| Sdr [%] | 18.516 ± 1.026 | 0.758 ± 0.066 | 6.749 ± 0.111 | 8.108 ± 0.669 | 10.022 ± 1.564 |

| Vmp × 10−2 [µm3/ µm2] | 24.300 ± 0.525 | 1.369 ± 0.230 | 2.376± 1.534 | 3.656 ± 1.915 | 3.891 ± 1.345 |

| Vvv × 10−2 [µm3/ µm2] | 30.100± 1.500 | 46.500 ± 0.329 | 43.600 ±0. 66 | 48.300 ± 0.5.26 | 49.800 ± 0.1.8 |

| Surface | Ra0.2-Die | Ra0.4-Die |

|---|---|---|

| Sq [µm] | 0.545 ± 0.108 | 0.907 ± 0.197 |

| Sa [µm] | 0.401 ± 0.073 | 0.527 ± 0.062 |

| Ssk [-] | −1.424 ± 0.317 | −4.229 ± 0.668 |

| Str [-] | 0.130 ± 0.05 | 0.250 ± 0.110 |

| Sdq [°] | 0.121 ± 0.07 | 0.184 ± 0.011 |

| Sdr [%] | 0.670 ± 0.075 | 1.307 ± 0.137 |

| Vmp × 10−02 [µm3/ µm2] | 1.620 ± 0.186 | 1.230± 0.071 |

| Vvv × 10−02 [µm3/ µm2] | 9.470 ± 2.740 | 18.200± 5.050 |

| Surface | Average Quantity [g/m2] | Lubricant Thickness [µm] | Standard Deviation [g/m2] | Min Quantity [g/m2] | Max Quantity [g/m2] |

|---|---|---|---|---|---|

| Not textured | 1.74 | 1.89 | 0.2178 | 1.48 | 2.00 |

| Low textured | 2.26 | 2.45 | 0.1890 | 2.00 | 2.40 |

| Medium textured | 2.80 | 3.04 | 0.3200 | 2.48 | 3.12 |

| High textured | 2.90 | 3.15 | 0.4412 | 2.48 | 3.32 |

| Surface | Not Textured | Low Textured | Medium Textured | High Textured |

|---|---|---|---|---|

| Ra0.2-Die | 0.95 (G*) | 2.22 (G**) | 1.9 (G**) | 1.4 (G**) |

| Ra0.4-Die | 0.45 (G*) | 0.13 (NG) | 0.06 (NG) | 0.15 (NG) |

| 90 | 54 | 50 | 6.5 | 6.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zabala, A.; Galdos, L.; Childs, C.; Llavori, I.; Aginagalde, A.; Mendiguren, J.; Saenz de Argandoña, E. The Interaction between the Sheet/Tool Surface Texture and the Friction/Galling Behaviour on Aluminium Deep Drawing Operations. Metals 2021, 11, 979. https://doi.org/10.3390/met11060979

Zabala A, Galdos L, Childs C, Llavori I, Aginagalde A, Mendiguren J, Saenz de Argandoña E. The Interaction between the Sheet/Tool Surface Texture and the Friction/Galling Behaviour on Aluminium Deep Drawing Operations. Metals. 2021; 11(6):979. https://doi.org/10.3390/met11060979

Chicago/Turabian StyleZabala, Alaitz, Lander Galdos, Chris Childs, Iñigo Llavori, Andrea Aginagalde, Joseba Mendiguren, and Eneko Saenz de Argandoña. 2021. "The Interaction between the Sheet/Tool Surface Texture and the Friction/Galling Behaviour on Aluminium Deep Drawing Operations" Metals 11, no. 6: 979. https://doi.org/10.3390/met11060979

APA StyleZabala, A., Galdos, L., Childs, C., Llavori, I., Aginagalde, A., Mendiguren, J., & Saenz de Argandoña, E. (2021). The Interaction between the Sheet/Tool Surface Texture and the Friction/Galling Behaviour on Aluminium Deep Drawing Operations. Metals, 11(6), 979. https://doi.org/10.3390/met11060979