Abstract

Nowadays, solving the problem of rational, integrated use of the mined raw materials, the transition to waste-free technologies for its processing is a crucial task. The sulfuric acid technology used for the processing of apatite concentrates on a large industrial scale does not provide the associated extraction of accompanying valuable components—rare earth metals (REM). During apatite concentrate processing, rare-earth metals are affected by the technology-related dispersion, being distributed between the insoluble leaching residue and phosphoric acid solution sent to the production of fertilizers. The necessity of a cost-effective method development for the extraction of rare earth metals is quite obvious already in connection with the indicated significance of the problem. Phosphoric acid solutions that simulate the composition of industrial phosphoric acid solutions of the following composition 4.5 mol/L H3PO4, 0.19 mol/L H2SO4 and 0.10–0.12% REM were selected as the object of research. The extraction of rare earth metals was carried out using polymers containing a fixed layer of an extractant—di-2-ethylhexylphosphoric acid (D2EHPA). Fixed layer was obtained by impregnation-saturation (solvent-impregnated resin (SIR)) or by the introduction of an extractant at the stage of polymer matrix synthesis (extractant-resin extraction (ERE)). The work determined the thermodynamic and technological characteristics of the solid-phase extraction of rare earth elements from phosphoric acid solutions with polymers impregnated with D2EHPA and containing a rigidly fixed extractant in a styrene-divinylbenzene resin matrix. The possibility of effective multiple use of polymeric resins containing D2EHPA, regenerated with a solution of 1 mol/L sodium citrate, was revealed.

1. Introduction

Individual rare earth metals (REM) can be obtained alongside the processing of apatite ores into phosphorus mineral fertilizers. Although the total content of rare-earth metals in apatite ores, as a rule, does not exceed 1 wt. %, (for example, in apatite of the Kola Peninsula), the scale of apatite concentrates processing makes it possible to consider them as a very promising raw material source of lanthanides.

During the apatite concentrates processing by the most common sulfuric acid technology, 20–40% of REM are transferred into solutions of phosphoric acid, which is used for the production of phosphoric fertilizers. In this case, the most demanded heavy lanthanides group mainly goes into solutions, which determines the expediency of organizing the associated extraction of rare-earth metals. Nevertheless, real solutions of phosphoric acid have a very complex composition, which causes significant difficulties in the development of technology for the selective extraction of REM from them.

The use of the classical precipitation method, which consists of neutralizing phosphoric acid by ammonia, makes it possible to transfer into the solid phase no more than 50–80% of the REM present in the process solution to obtain solid products containing 6–20% of lanthanides, the further processing of which is quite laborious.

Thereby, sulfuric acid technology widely used for the processing of apatite concentrates on a large industrial scale does not provide the associated recovery of rare-earth metals, resulting in their technology-related dispersion.

Sorption methods [1] and liquid extraction methods [2] are among the most effective methods for the extraction and separation of rare-earth metals from solutions of various compositions. In order to increase the efficiency of sorption, inorganic materials impregnated with substances that form strong complex compounds with rare-earth metals in an aqueous medium are used.

Novel and inexpensive activated carbon impregnated with EDTA (EDTA-AC) was synthesized by Babu et al. [3] by adding N–[(3-trimethoxysilyl) propyl] ethylenediaminetriacetic acid (TMS-EDTA) to oxidized activated carbon (AC). The affinity of EDTA-AC for each of the lanthanide ions was determined, and from binary mixtures La/Ni, Sm/Co, Eu/Y and Dy/Nd, the highest selectivity was observed for heavy rare earth elements (REE). Equilibrium adsorption isotherms with a high coefficient of determination was described by the Langmuir model. In this work, the reduction of adsorbed metal ions and the regeneration of the adsorbent by treatment with a dilute HCl solution were carried out, which shows the large-scale potential of the EDTA-functionalized sorbent for the extraction of rare earth elements from aqueous solutions.

Silica nanoparticles and porous microparticles functionalized with a monolayer of ligands obtained from diethylenetriaminepentaacetic acid (DTPA) were proposed as sorbents for the extraction of REE from solutions by Ashour et al. [4]. The possibility of using DTPA-functionalized microparticles for chromatographic separation of rare-earth elements at various sample concentrations, elution modes, eluent concentrations, eluent flow rates, and process temperatures was investigated. Optimal separation of La (III), Ce (III), Pr (III), Nd (III) and Dy (III) ions was achieved using HNO3 as eluent with a linear concentration gradient from 0 to 0.15 mol/L for 55 min. The results of this study demonstrate the potential of using DTPA-functionalized silica particles in the chromatographic process for the recovery and separation of REE from waste as an environmentally friendly alternative to standard processes.

The adsorption capacity of nanogoethite (NG) synthesized by co-precipitation and modified by a composite formation with activated carbon and sodium alginate to increase the adsorption capacity in relation to La (III) was investigated by Sayed et al. [5]. The adsorption process was carried out under optimal conditions: pH 5.0, contact time 6.0 h, dosage of sorbent (0.1 g/20 mL) and initial concentration of La3+ (500 ppm). The sorption capacity of goethite was 49.5 mg/g, goethite modified with activated carbon: from 44.0 mg/g to 56.8 mg/g; goethite modified with sodium alginate–from 63.9 mg/g to 77.8 mg/g.

The sorption of ions of three rare earth elements (Yb (III), Dy (III), and Nd (III)) was studied by Galhoum et al. [6] using hybrid particles based on chitosan impregnated with diethylenetriamine (DETA). The effect of pH on the sorption characteristics is analyzed: the optimal initial pH value is equal to 5, and the equilibrium value is 6.5. Sorption isotherms were effectively described by the Langmuir equation: the maximum sorption capacities reached 50 mg/g for each of the rare earth metals. The sorption process is characterized by an endothermic behavior; the obtained negative values of the Gibbs energy determine the spontaneous direction of the adsorption.

Nevertheless, the use of sorbents modified with substances exhibiting a high capability to form complex compounds with rare earth metals in aqueous media is ineffective in phosphoric acid solutions.

Efficient extraction of rare-earth metals from complex-salt phosphate solutions, characterized by a high acidity of the medium and a low concentration of target components is provided by the liquid extraction method using such extractants as tributyl phosphate (TBP) [7], di-2-ethyl-hexylphosphoric acid [8] and Bis (2, 4,4-trimethyl pentyl) phosphinic acid (Cyanex 272) [9].

However, the use of flammable organic solvents in liquid extraction has a negative environmental effect due to their high toxicity and the capability to form fire-explosive mixtures. Solid-phase extraction is characterized by simpler technological process implementation in comparison with solvent extraction.

Solid-phase extraction is free from this drawback, since it excludes the use of any accompanying solvents. The use of solid-phase extraction in comparison with liquid extraction has an undoubted technological advantage in the compatibility of this method with the main technology for the phosphoric acid production with a capacity of at least 45 m3/h (along one technological line of the PhosAgro group enterprise), which will ensure the scalability of the REM compounds production process.

To ensure selective extraction of Eu (III) and Y (III) from aqueous solutions, Morillo Martín et al. [10] used polyacrylonitrile (PAN) nanofibers impregnated with an organic extractant Cyanex 272 in order to increase their chemical affinity for rare earth metal ions. The maximum extraction capacity was 200 and 400 mg/g for Y (III) and Eu (III), respectively. In terms of thermodynamics, the equilibrium adsorption is best described by the Langmuir model, in terms of kinetics-by the pseudo-second order model. Continuous sorption experiments showed that the adsorption of the target elements is close to 100%.

Mohammedi et al. [11] proposed a composite sorbent for extracting Eu (III). The sorbent is a mesoporous silicon dioxide coated with a surface layer of Cyanex 272 extractant impregnated and immobilized in an alginate matrix.

The sorption efficiency of this material was studied in batch and continuous mode. The competitive extraction between rare earth elements (europium, lanthanum, and lutetium), as well as between rare earth ions and calcium/sodium ions, was investigated. It was found that high calcium concentrations strongly reduce the adsorption capacity of the alginate matrix, which the hybrid material is composed of, while the Cyanex 272 modification improves the sorption characteristics of the material.

The capacity values of sorption materials containing an organic extractant layer significantly exceed the sorption capacity of sorbents impregnated with aqueous solutions of complexing agents. The advantage of using solid-phase extraction lies in the long-term operation of materials obtained by introducing organic extractants into their polymer matrix at the stage of synthesis.

This work was carried out in order to reveal the thermodynamic and technological features of solid-phase extraction of rare-earth metals and its difference from liquid extraction and the process characteristics of extracting lanthanides of light, medium and heavy groups from phosphoric acid by polymeric materials containing the organophosphorus extractant D2EHPA.

2. Materials and Methods

The research on the extraction of rare earth metals from phosphate solutions was carried out using two types of polymers. One type of polymer was a polymer resin (polystyrene-based porous inert material) in the form of spherical opaque white granules with physicochemical characteristics according to the certificate:

- -

- Mass fraction (not less than 97%) and size of working fraction granules: from 0.63 to 2.5 mm;

- -

- Mechanical strength not less than 96%;

- -

- Phosphorus mass fraction not less than 5.3%,

- -

- The impregnation degree of polymer with D2EHPA is not less than 55.1%.

This was impregnated with D2EHPA by prolonged wetting to saturation (solvent-impregnated resin (SIR)).

Another polymer produced by the Smoly Group of Companies, Moscow, was synthesized by copolymerization of D2EHPA in a mixture with styrene and divinylbenzene [12] (extractant extraction resin (ERE)). The polymer particle has a macroporos structure and represents an opaque spherical white granule with the following physicochemical characteristics:

- -

- Ionic form: H+;

- -

- The grain size in the swollen state is 0.63–1.6 mm;

- -

- The volume percentage of the working fraction is not less than 90%;

- -

- Phosphorus mass content not less than 90%;

- -

- The mass content of moisture air-dry basis of the polymer is not more than 10%;

- -

- Operational temperature no more than 80 °C;

- -

- Mechanical strength not less than 90%;

- -

- Bulk density (±5%) 0.6 g/cm3;

- -

- The operational pH range is from 1 to 4;

- -

- The impregnation degree of polymer with D2EHPA is not less than 36.0%.

The studied polymers are stable under neutral (distilled water), weakly acidic and weakly alkaline solutions treatment.

Impregnation of polymeric materials with D2EHPA for SIR samples was carried out at the A.N. Frumkin Institute of Physical chemistry and Electrochemistry Russian academy of sciences (IPCE RAS), D2EHPA impregnation for ERE samples was carried out at the Smoly Group of Companies.

Impregnated polymers obtained by impregnating of initial polymer resins with extractant solutions are characterized by an increased tendency to wash out the extractant into the liquid phase during their operation, which shortens the operational life of the sorbent and leads to the side effect of “contamination” of the liquid phase.

Solid extractants obtained by immobilizing the active organic phase with a styrene-divinylbenzene matrix are characterized by the presence of closed micropores and the absence of macropores, which can lead to low sorption kinetics and, consequently, dynamic exchange capacity.

Solid-phase extraction of rare earth metals was carried out from phosphoric acid solutions simulating the composition of industrial phosphoric acid obtained during the processing of apatite concentrate at the enterprises of PhosAgro, with following composition 4.5 mol/L of H3PO4, 0.19 mol/L of H2SO4 and from 0.99 to 89.10 mmol/L of REM. The content of the main components in industrial solutions of phosphoric acid is presented as follows: Ln (0.07–0.1%), where Ln–total REE content, P2O5 (16–28% or 4.5 mol/L H3PO4), SO3 (1.2–1.5%), Al2O3 (0.1–0.4%), CaO (0.3–0.8%), Fe2O3 (0.3–0.4%), SiO2 (0.7–1.4%), F (0.8–1.1%).

The concentration of rare earth metals in phosphoric acid solutions before and after the solid-phase extraction process was determined by the X-ray fluorescence method using an Epsilon 3 energy-dispersive X-ray fluorescence spectrometer manufactured by PANalytical (Netherlands) and by inductively coupled plasma mass spectrometry method using a Shimadzu Japan ICPE 9000 spectrometer (Shimadzu Corporation, Kyoto, Japan).

2.1. Extraction of Rare Earth Metals in Static Conditions

The sorption capacity under static conditions was determined at a temperature of 298 K by the method of variable concentrations at a solid to liquid phase ratio of 1:10 (2 g of polymer and 20 mL of solution) in a Shaking Incobator 3032 thermostat cabinet manufactured by GFL (Germany) with constant stirring at frequency of 75 min−1 for at least 3 h, which is longer than the time needed to reach equilibrium. The concentration of rare earth metals was varied from 0.14 to 63.0 mmol/L for the following cations Pr(H2PO4)2+, Eu(H2PO4)2+, Dy(H2PO4)2+, Ho(H2PO4)2+, Er(H2PO4)2+, Yb(H2PO4)2+, representing elements of all groups of lanthanides.

The sorption capacity for each element was calculated by the equation:

where C0 and C∞ are initial and equilibrium concentration of rare earth metals in solution correspondently, mol/L; V is the volume of the solution, L; m is the mass of the polymer, kg.

2.2. Extraction of Rare Earth Metals under Dynamic Conditions and Regeneration of the Organic Layer

To reveal the regeneration possibility of the polymer organic layer and its reuse potential for the extraction of rare earth metals, the sorption process was carried out under dynamic conditions. The concentration of Yb(H2PO4)2+ in the initial solution was 0.01 mol/L. The solution containing ytterbium cations was passed through a sorbing polymer material weighing 3 g in sorption columns (polymer layer height 36 mm) at a dosage of 0.5 rpm, after which the content of Yb(H2PO4)2+ at the column outlet was analyzed.

To regenerate the stationary phase of the extractant, an H2SO4 solution with a concentration of 2 mol/L was used. The acid solution was passed through a polymer saturated with ytterbium at a speed of 1 rpm, during this process portions of the solution were taken from the column outlet to determine the concentration of REM. The regenerated material was used for further extraction of lanthanides from phosphoric acid solutions.

3. Results and Discussion

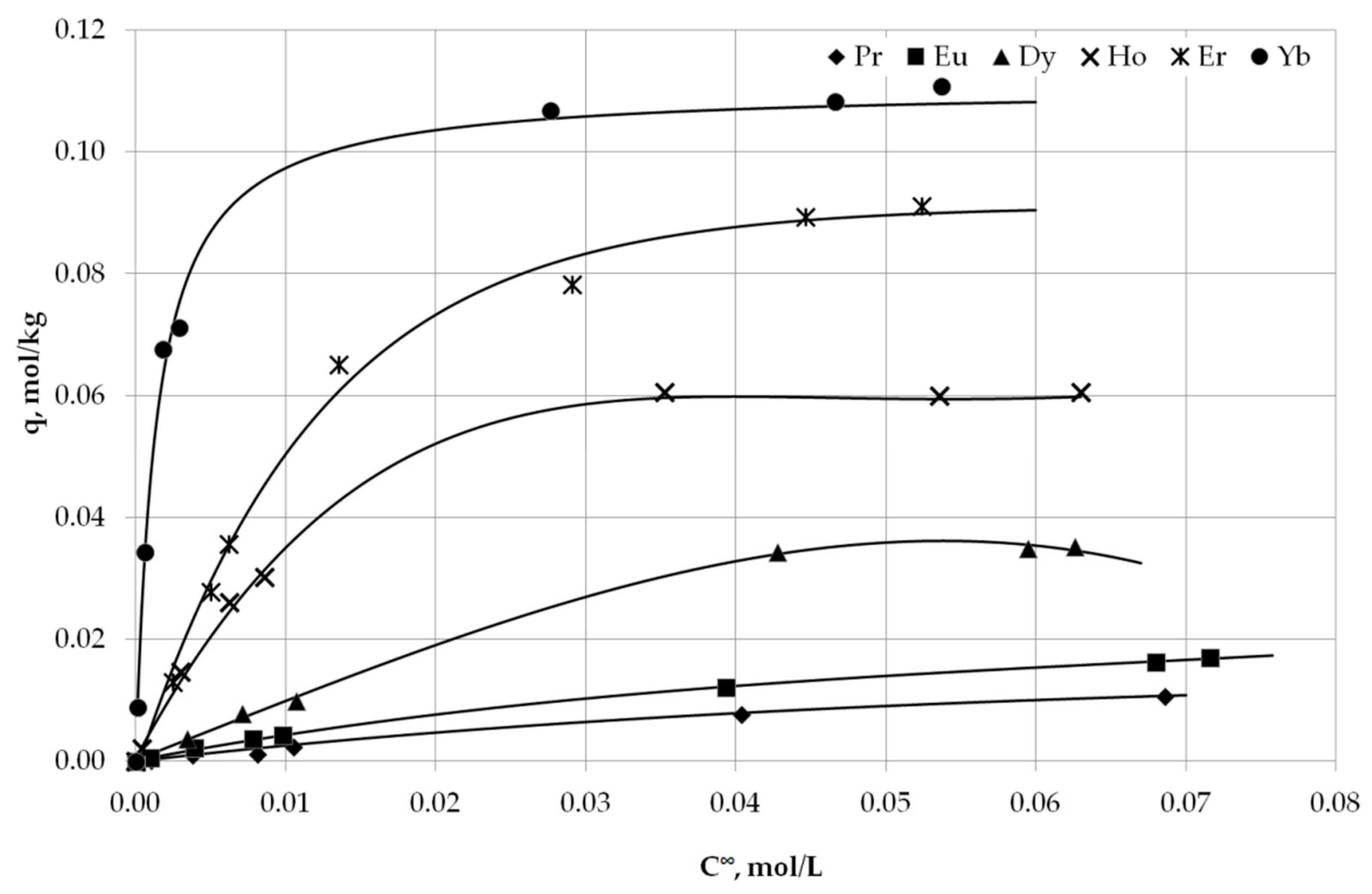

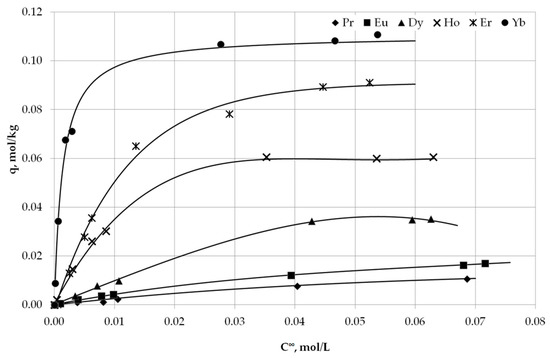

Based on the experimental data obtained, isotherms of the extraction of rare-earth metals ions (Pr(H2PO4)2+, Eu(H2PO4)2+, Dy(H2PO4)2+, Ho(H2PO4)2+, Er(H2PO4)2+, Yb(H2PO4)2+) from phosphoric acid solutions simulating the composition of technological phosphoric acid on a styrene-divinylbenzene matrix impregnated with D2EHPA (Figure 1) were constructed.

Figure 1.

Isotherms of REM cations extraction by D2EHPA impregnated (SIR) polymer from phosphoric acid solutions.

Despite the high coefficients of determination (R2 = 0.99) of the linear dependences of the inverse sorption value on the inverse equilibrium concentration of rare earth metals, obtained by mathematical description of sorption isotherms using the Langmuir model, implication of concentration constants does not ensure the reliability of the calculated thermodynamic characteristics.

Therefore, to describe thermodynamic equilibria, the mass-action law, adapted to extraction processes, was used. It is known that D2EHPA extracts rare earth metals by the mechanism of ion exchange. However, due to the fact that the oxygen of the polar phosphoryl group P = O is an electron donor, additional solvation of the extractant molecules can occur, up to the maximum coordination number of rare-earth elements equal to 6.

An increase in the solvation numbers from 2 for neodymium to 5 for ytterbium is observed with an increase in the effective atomic charge in the series of lanthanides. Solvation numbers were calculated on the basis of experimental data in [13]:

Taking into account the occurrence of lanthanides in the form of dihydrogen phosphate ions in concentrated solutions of phosphoric acid and an extractant in dimerized form [14], the extraction process is expressed by the following equation:

where S is the number of organic acid solvating molecules.

Taking into account the occurrence of lanthanides in the form of dihydrogen phosphate ions in concentrated solutions of phosphoric acid and an extractant in dimerized form [14], the extraction process is expressed by the following equation:

where , is the activity of hydrogen ions and dihydrogen phosphate ions of rare-earth metals in an aqueous solution, mol/kg; , equilibrium concentrations of rare earth metals and D2EHPA in the solid phase of the polymer matrix, mol/kg.

The activity coefficients were calculated using the experimental equation [15], taking into account the high ionic strength of concentrated phosphoric acid solutions. By expressing the value of the equilibrium concentration of D2EHPA in the terms of the limiting sorption: equal to the sum of the equilibrium concentrations of the extractant and the solvate of the rare earth element in the solid phase of the resin, Equation (6) was obtained:

the linear form of which after a series of transformations has the following form:

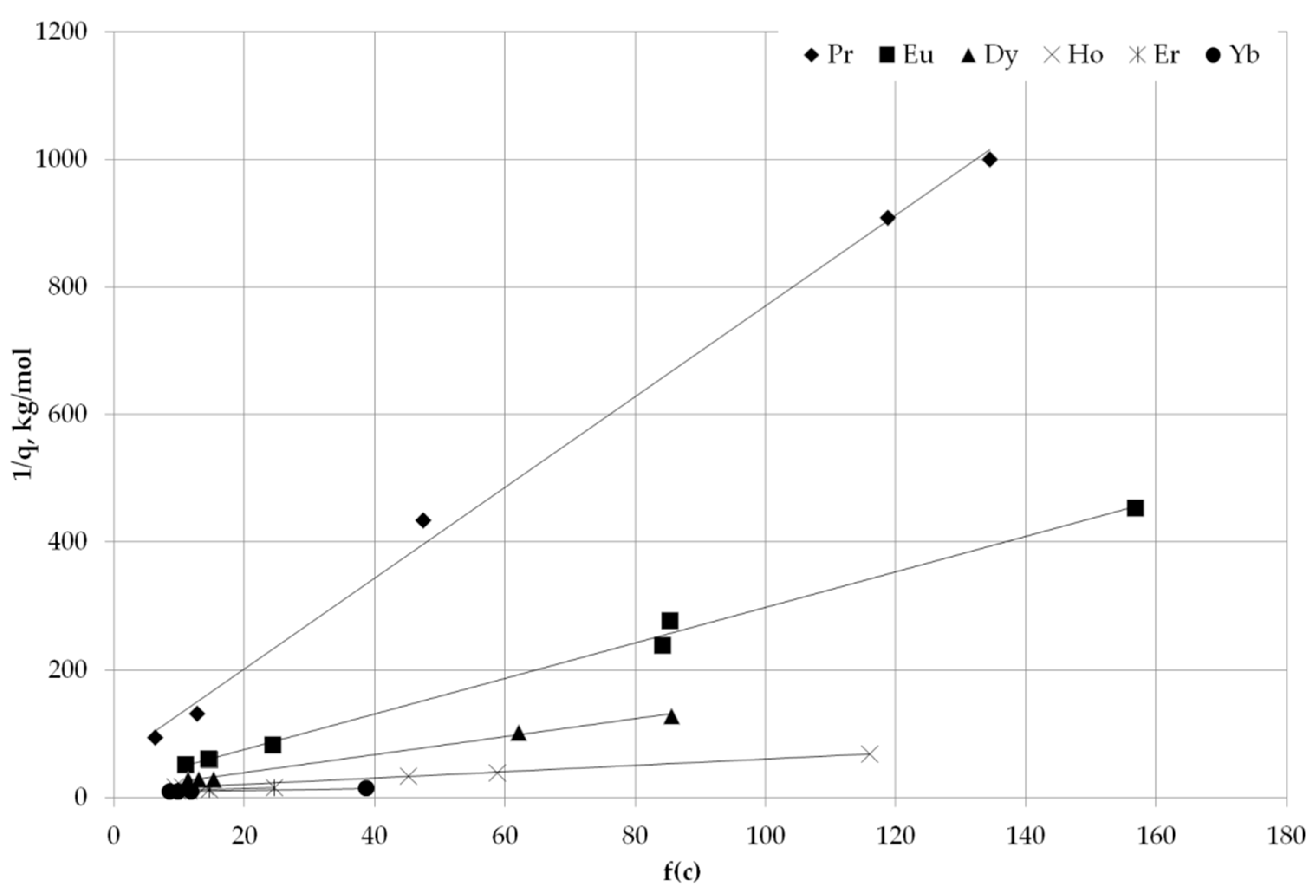

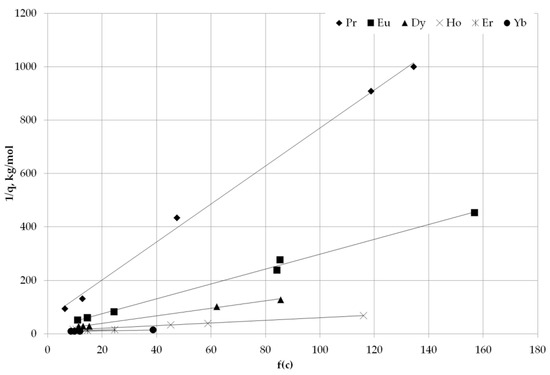

The graphical solution of the dependence of the concentration argument on the inverse rare-earth element concentration in the extractant phase argument , shown in Figure 2, are the values of the effective constant of extraction equilibrium K and the limiting sorption q∞ by the solid phase of the resin.

Figure 2.

Linear forms of the rare-earth metals extraction isotherms by an impregnated polymer.

The obtained values of the effective constants of the extraction equilibrium, the limiting values of the rare earth metals sorption and the Gibbs energies of the extraction process, calculated by the equation:

where R is the universal gas constant, 8.314; J/(mol·K); T is the temperature of the experiment, 298 K, are presented in Table 1:

Table 1.

The obtained values of the effective constants of the extraction equilibrium, the limiting values of the rare earth metals sorption and the Gibbs energies of the extraction process.

According to the results obtained, in full accordance with the mechanism of the liquid extraction process, the value of the extraction equilibrium constant increases with an increase in the effective charge on the REM atom and its solvation number, which is explained by the formation of strong chemical complexes of lanthanides with D2EHPA [13].

Depending on the concentration of rare-earth metals in phosphate solutions, the separation coefficients of lanthanides D reach the following values: D(Yb/Pr) = 131.1; D(Yb/Eu) = 975.2; D(Yb/Dy) = 53.3; D(Yb/Ho) = 87.1; D(Yb/Er) = 12.2, which characterizes the technological efficiency of solid-phase extraction.

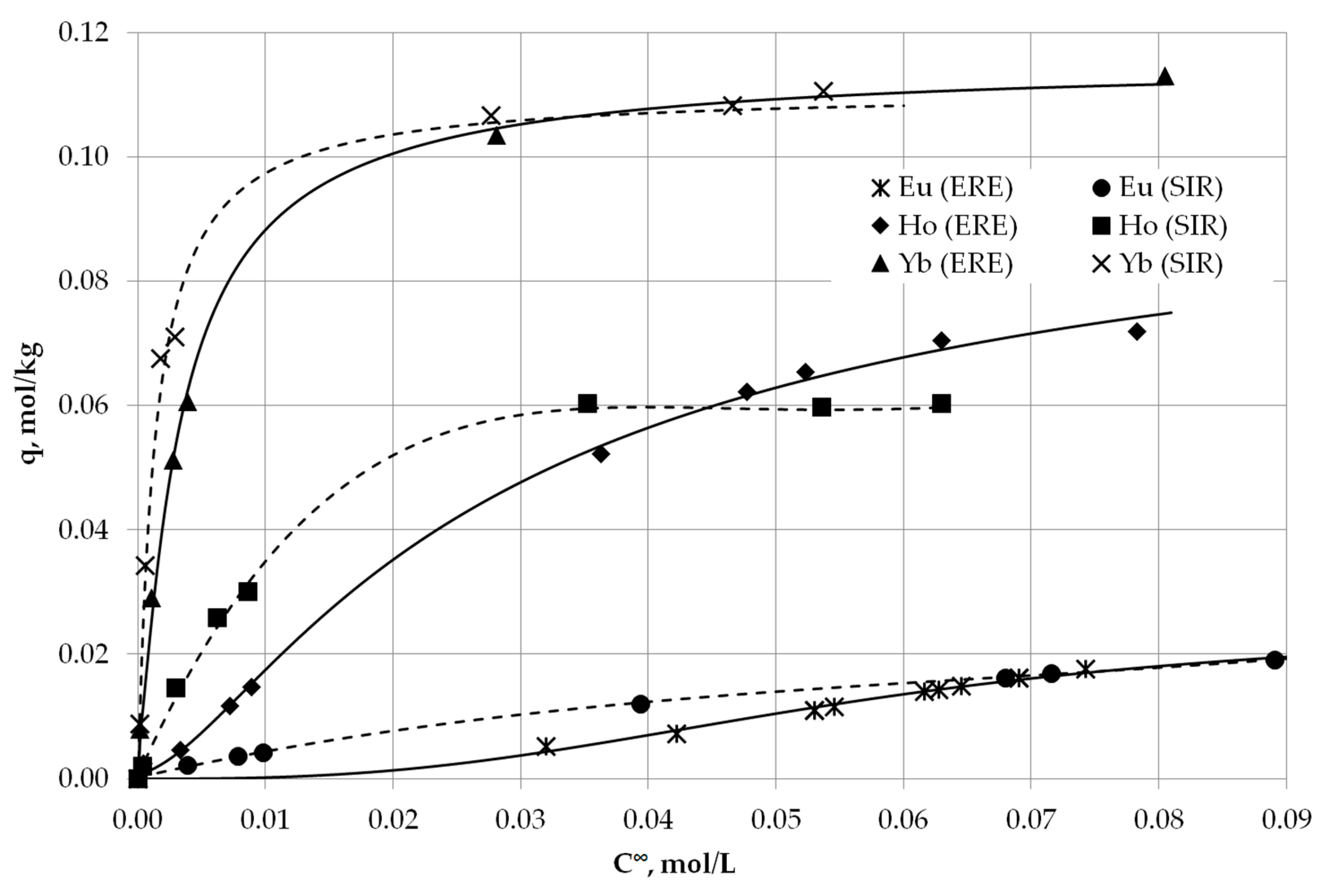

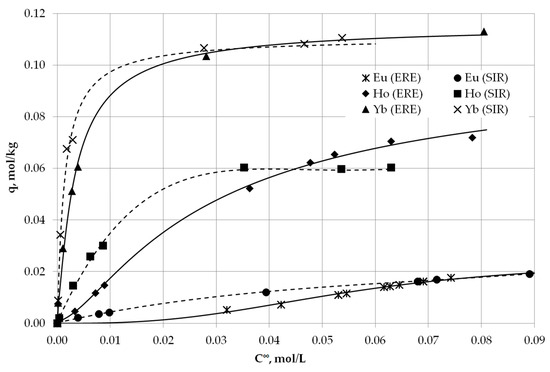

To compare the results of the rare earth metals extraction with polymeric materials impregnated and immobilized with D2EHPA, isotherms of the extraction of ytterbium, holmium, and europium were obtained using a polymer with an organophosphorus extractant, which was rigidly fixed during the synthesis of the material (Figure 3).

Figure 3.

Linear forms of the rare-earth metals extraction isotherms by a polymer with immobilized D2EHPA.

Crosslinking D2EHPA with styrene and divinylbenzene disrupts the dimerized form of organic acid molecules due to the presence of electronic effects. During the synthesis process of a polymer matrix with a dimer of organic extractant, dimer of D2EHPA decomposes, therefore, the rare-earth metals extraction process proceeds only by the cation-exchange mechanism and is described by the following equation:

The linear form of the equation of mass-action law, modified for the extraction process, has the following form:

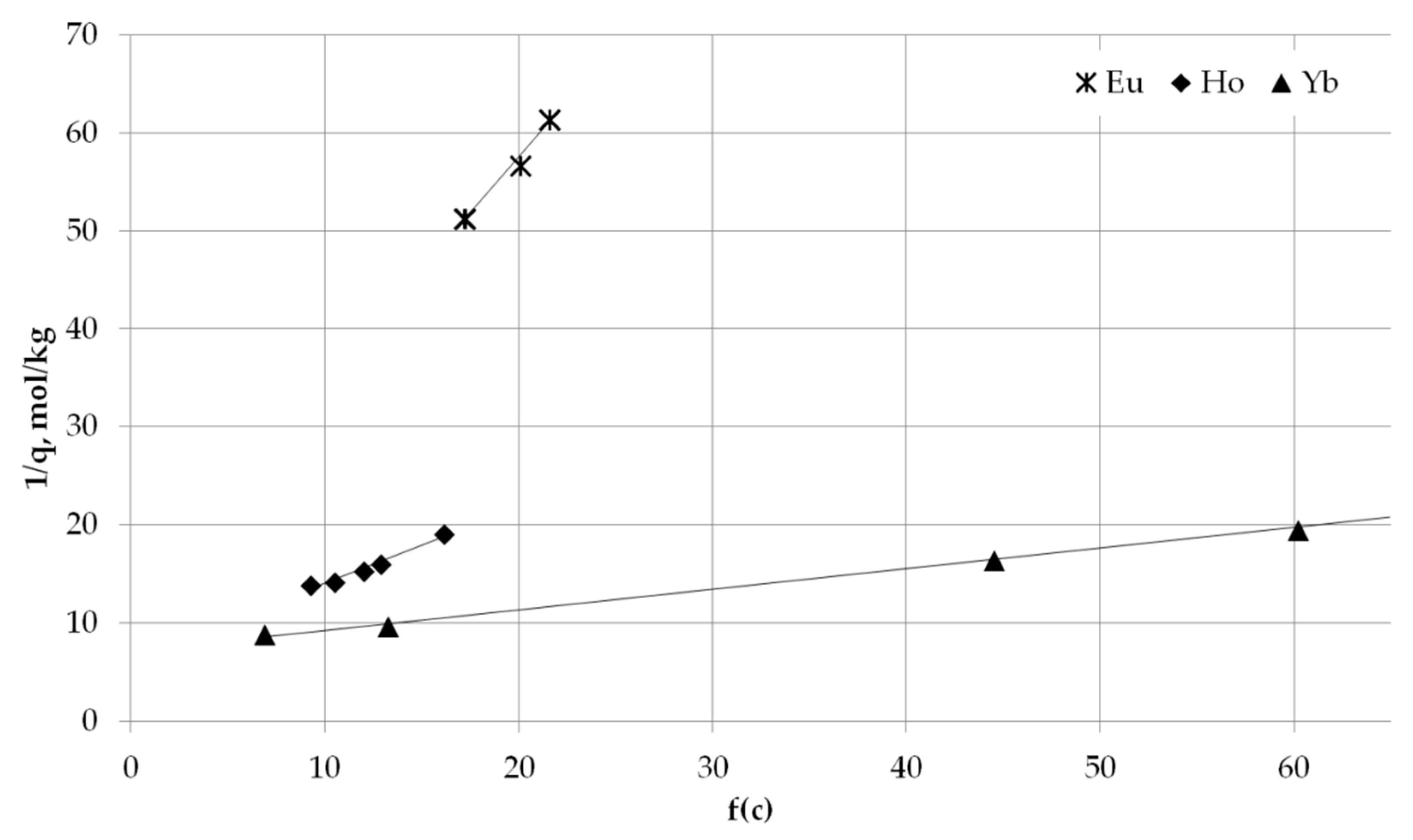

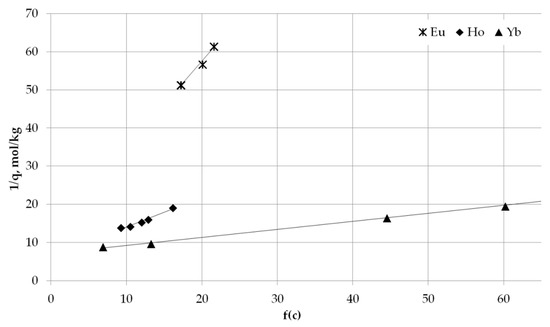

The values of the effective constants of thermodynamic equilibrium and Gibbs energies were calculated by the graphical dependence (Figure 4) of the concentration argument: on the value of inverse sorption , are given in Table 2.

Figure 4.

Linear forms of the rare-earth metals extraction isotherms by a polymer with immobilized D2EHPA.

Table 2.

Thermodynamic characteristics of the rare earth metals extraction by a polymer with immobilized D2EHPA.

The values of the equilibrium constant logarithm lnK and Gibbs energies of the liquid extraction process, which were obtained in previous studies [13], and solid-phase extraction by an impregnated polymer and a polymer with immobilized D2EHPA (Table 3): lnK(Yb) = 6.56 ± 0.12, = −16.16 ± 0.29 kJ/mol; lnK(Ho) = 1.21 ± 0.03, = −3.00 ± 0.07kJ/mol.

Table 3.

Thermodynamic characteristics of and solid-phase extraction processes.

The extraction of REM by D2EHPA, immobilized at the stage of polymer synthesis, in comparison with the impregnated extractant, is characterized by an insignificant difference in the values of effective equilibrium constants and Gibbs energies, while with an increase in the ordinal number of the element, a dependency in the growth of thermodynamic parameters is observed.

The insignificant difference in thermodynamic constants is explained by the special aspects of chemical interactions in the solid phase of the polymer resin. Dimerized D2EHPA in the surface layer of the solid phase forms strong solvates with rare-earth metals due to the replacement of the hydrogen ion and donor-acceptor interactions between the lone electrons of the oxygen atom of the phosphoryl group and free orbitals of lanthanide ions. At the same time, D2EHPA molecules, fixed by hydrocarbon radicals by the polymer matrix of the resin, are capable of extracting rare-earth metals only by the mechanism of cation-exchange extraction.

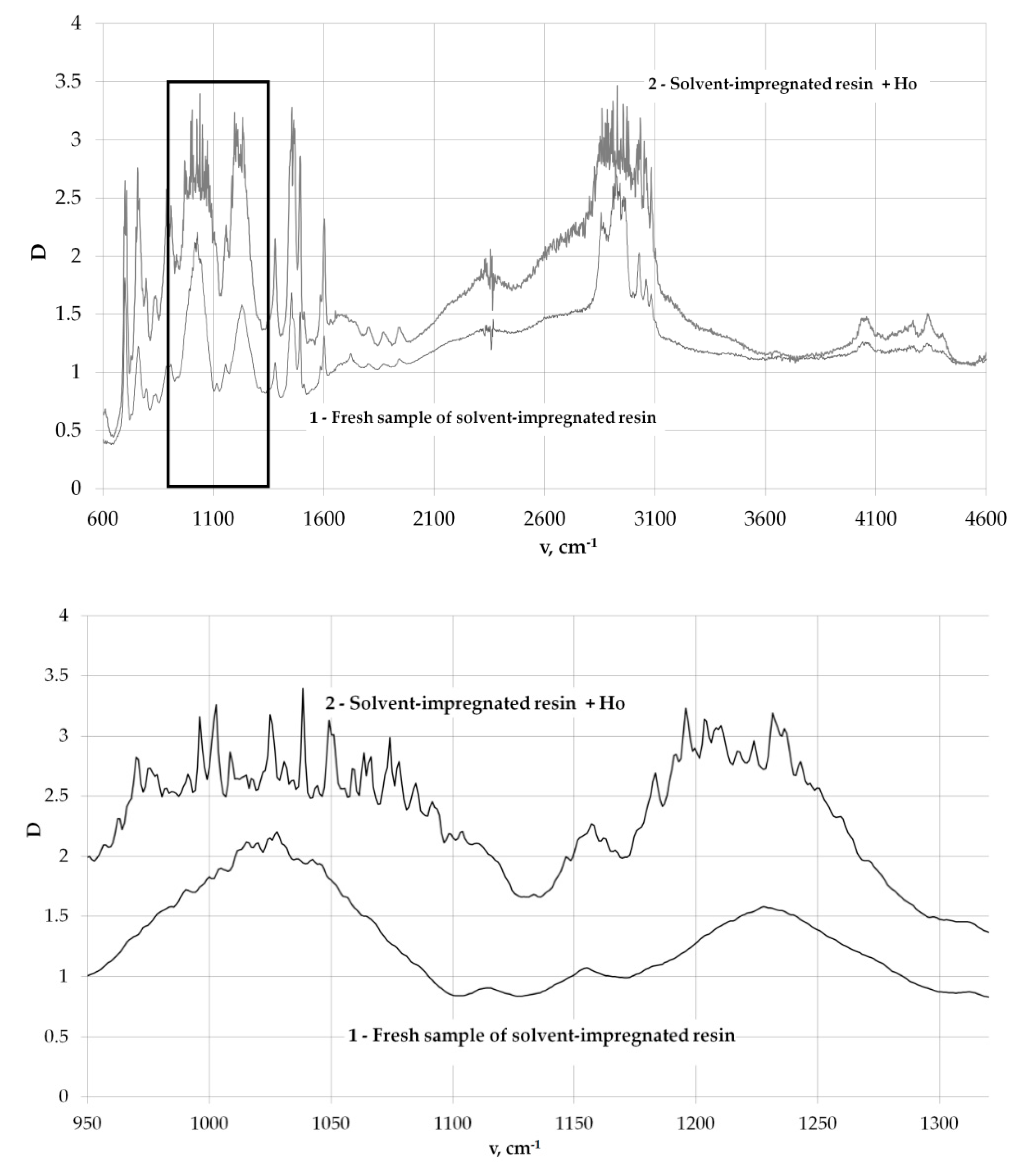

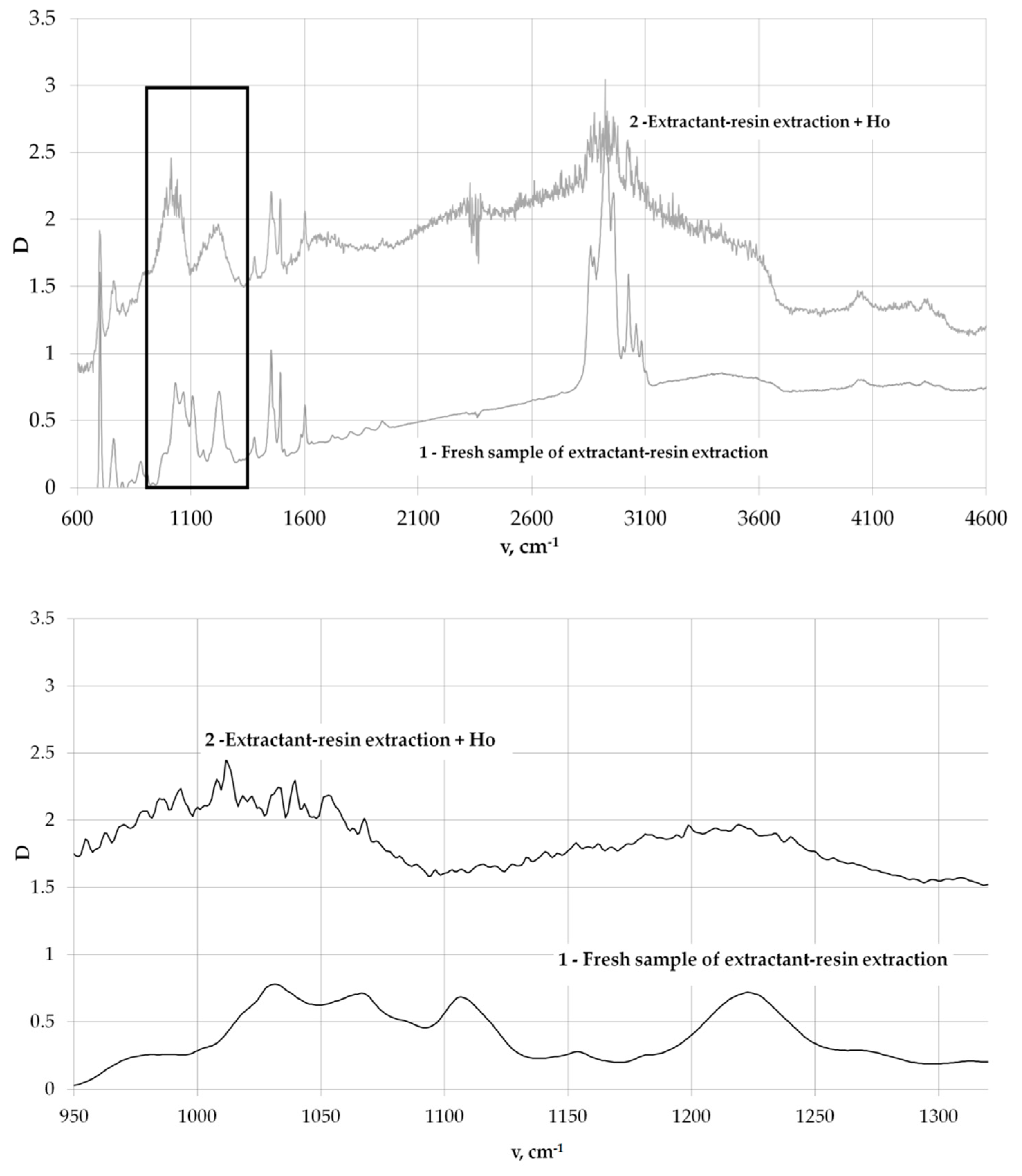

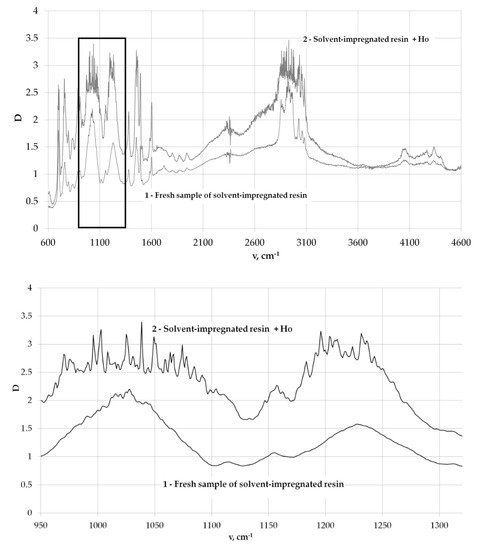

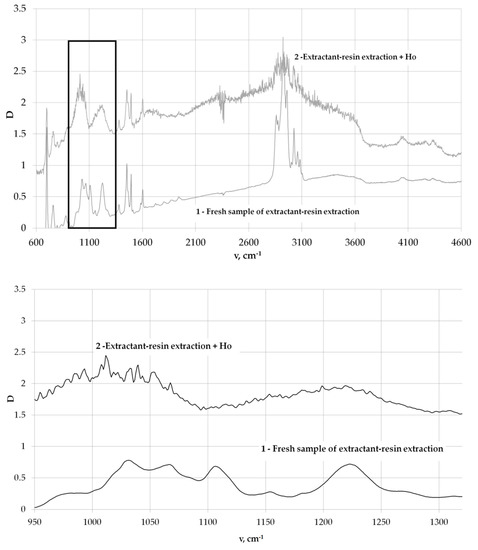

The spectral analysis of both samples before and after the extraction of rare-earth metals is presented by the IR spectra on Figure 5. The range of spectral measurements ranged from 7500 to 600 cm−1, but the most informative are the regions with characteristic frequencies of 1100–950 cm−1 (Figure 6).

Figure 5.

IR spectra of samples impregnated with D2EHPA before and after holmium extraction. IR spectra of samples impregnated with D2EHPA before and after holmium extraction in the range of characteristic frequencies of 1320–950 cm−1.

Figure 6.

IR spectra of samples immobilized with D2EHPA before and after holmium extraction. IR spectra of samples immobilized with D2EHPA before and after holmium extraction in the range of characteristic frequencies of 1320–950 cm−1.

The shift of the electron density is due to the participation of the oxygen atom electron pair in the donor-acceptor bond with the REM ion [16].

The spectral analysis of both samples before and after the extraction of rare-earth metals is presented by the IR spectra on Figure 5 and Figure 6. The range of spectral measurements ranged from 7500 to 600 cm−1, but the most informative are the regions with characteristic frequencies of 1100–950 cm−1 (Figure 5a and Figure 6a).

Thus, the change in the dipole moment (IR spectra) is explained by the formation of a donor-acceptor bond with the REM ion.

In order to determine the amount of extractant in the polymer matrix, resin samples were treated with toluene at 70 °C for 5 h followed by kerosene and n-heptane treatment at room temperature for a day. The extractant content, regardless of the solvent, was 58.8–60.5% in the impregnated polymer and 35.7–36.3% in the immobilized D2EHPA polymer.

Despite the different amount of D2EHPA in the solid phase of the resin, both extractants are characterized by almost the same values of the extraction capacity in relation to rare-earth metals, due to the ion-exchange mechanism of extraction.

Extraction of Rare Earth Metals under Dynamic Conditions and Regeneration of Solid Extractants

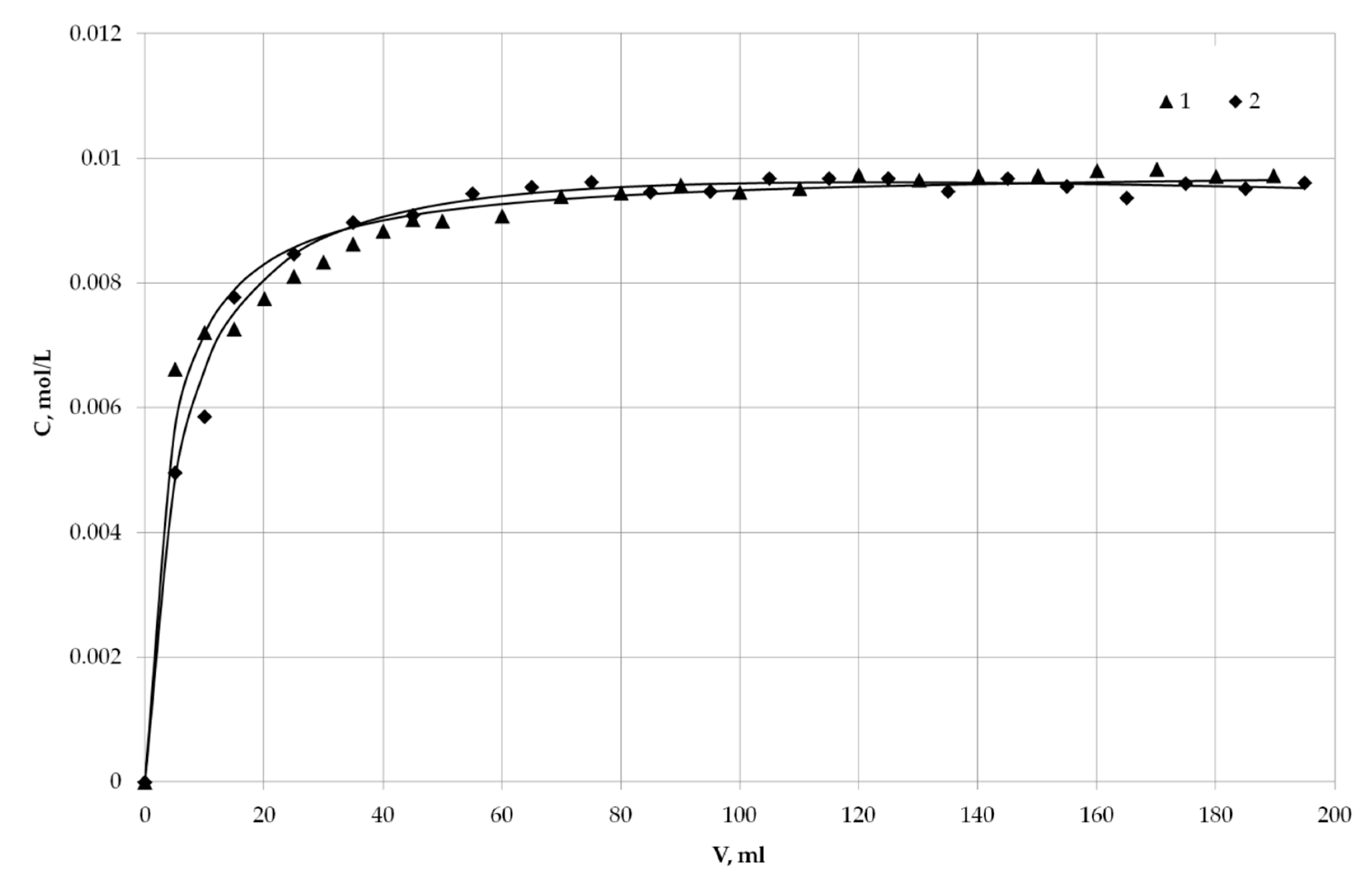

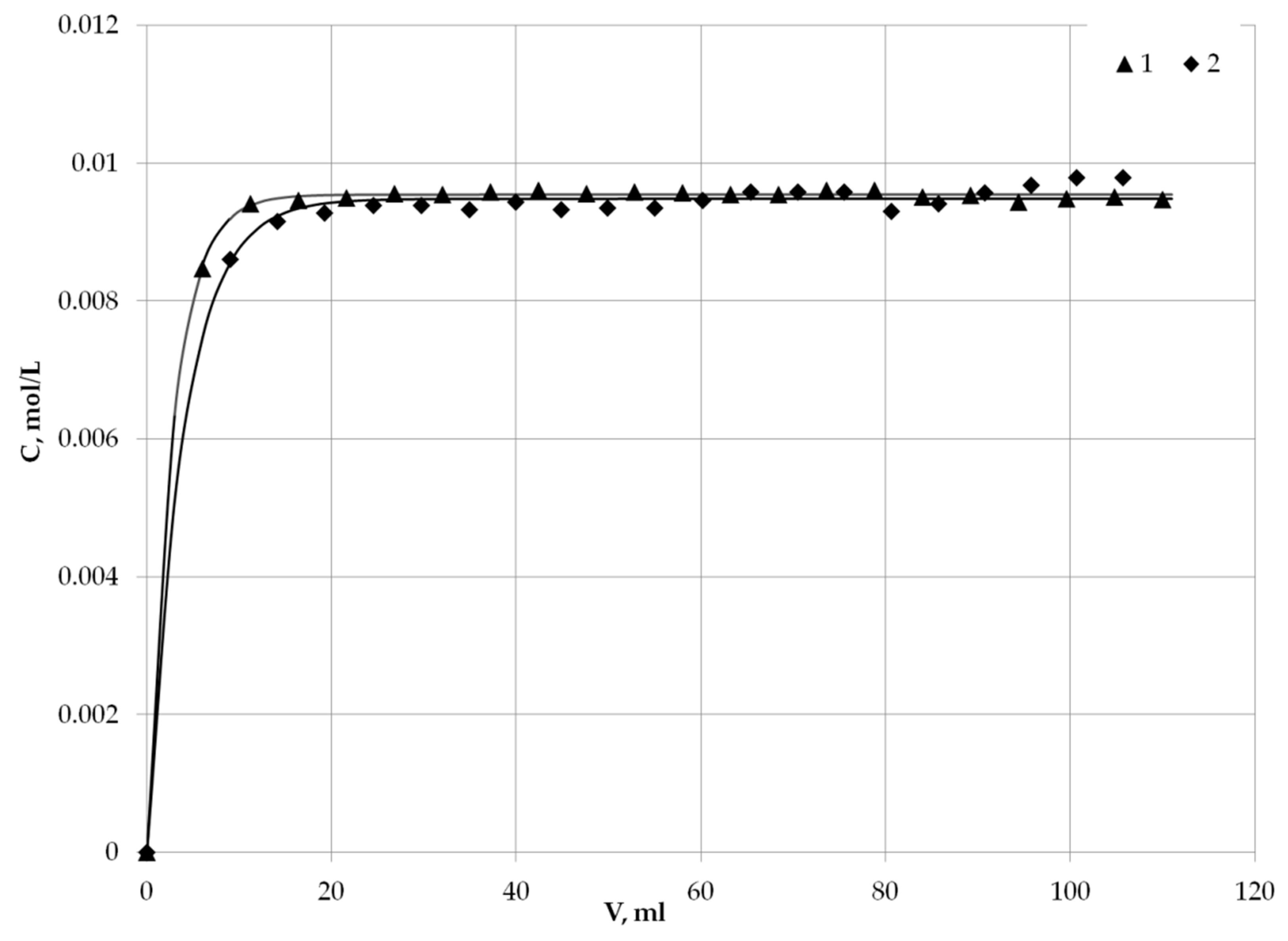

Extraction under dynamic conditions was studied using two types of polymers. The extraction of Yb(H2PO4)2+ from phosphate solutions is considered as an example. The value of the extraction capacity under dynamic conditions was calculated by Equation (4):

where m is the mass of the polymer, g; C0 and Cn—initial and current concentration of ytterbium at the exit from the column, mg/mL; Vn+1, Vn is the volume of the solution, mL, corresponding to the concentration of the element at the exit from the column Cn+1 and Cn.

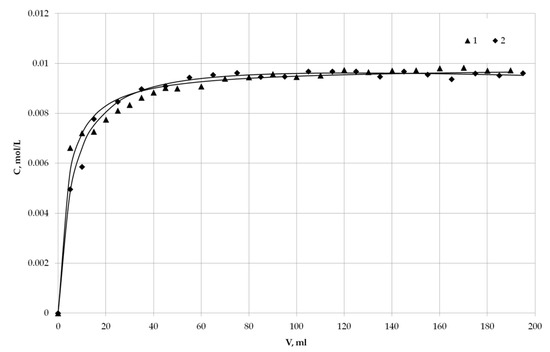

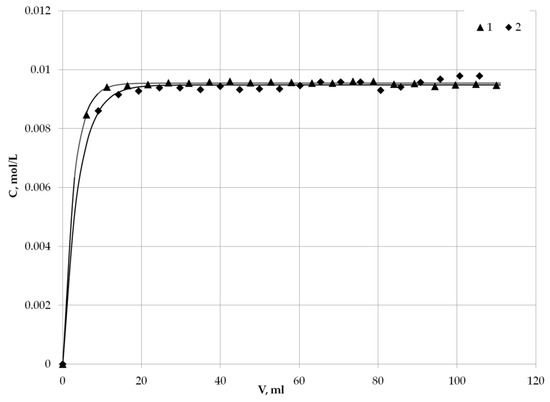

After saturation of the resin with ytterbium ions, the regeneration was carried out by a sulfuric acid solution at concentration of 2 mol/kg. The dependencies of the ytterbium concentration at the column outlet on the volume of the passed solution are shown in Figure 7 for the impregnated polymer and in Figure 8 for the immobilized D2EHPA polymer before and after regeneration by a solution of H2SO4 with a concentration of 2 mol/L.

Figure 7.

Saturation curve of the impregnated polymer by Yb(H2PO4)2+ cations from phosphoric acid solutions. 1—fresh sample of polymer; 2—polymer after regeneration with a solution of H2SO4 2 mol/L.

Figure 8.

Saturation curve of the immobilized polymer by Yb(H2PO4)2+ cations from phosphoric acid solutions. 1—fresh sample of polymer; 2—polymer after regeneration with a solution of H2SO4 2 mol/L.

The full capacity value at a saturated state of the new impregnated-type polymer was 0.1320 ± 0.0066 mol/kg and 0.0950 ± 0.0048 mol/kg after regeneration. The decrease in the extractant capacity occurs only due to the partial loss of D2EHPA during sulfuric acid treatment. The absorbed ytterbium amount of the (1.32 ± 0.07) × 10−4 mol satisfactory converged with its amount extracted from the aqueous solution of (1.24 ± 0.06) × 10−4 mol.

For the polymer with immobilized D2EHPA, the dynamic capacity of 0.0433 ± 0.0022 mol/kg is an order of magnitude lower than dynamic capacity of the fresh polymer impregnated with the extractant, but is compliant with its regenerated state capacity of 0.0419 ± 0.0022 mol/kg. The loss of D2EHPA during extraction process was not exceed 3.2%.

The lower value of the dynamic capacity in comparison with the static capacity is explained by the kinetic features, in particular, the mass transfer limitation of the ytterbium in the extractant layer rigidly fixed at the polymer synthesis stage.

It is possible to efficiently extract rare-earth metals from the organic phase by using compounds that form strong complexes with lanthanides in an aqueous medium. Sodium citrate solutions with a concentration range of 0.1 to 1 mol/L were used as a stripping agent. With an increase in the concentration of citrate ions to 1 mol/L, the ytterbium stripping degree from the organic phase increased to more than 95% without loss of the extractant layer.

4. Conclusions

To describe the thermodynamic equilibria of extraction process in the solid phase of polymeric materials, a mathematical model was developed based on the linearization of the mass action law equation, modified by the authors to describe the extraction processes. According to the obtained thermodynamic characteristics of the extraction of Pr(H2PO4)2+, Eu(H2PO4)2+, Dy(H2PO4)2+, Ho(H2PO4)2+, Er(H2PO4)2+, Yb(H2PO4)2+: (the values of the equilibrium constants and Gibbs energies), the rare earth metals extraction process by polymeric materials based on a styrene-divinylbenzene matrix impregnated and immobilized with an extractant-D2EHPA from a phosphoric acid solution, simulating the composition of industrial phosphoric acid solutions. With an increase in the solvation complex strength of rare-earth elements, an increase in the extraction equilibrium constants values is observed, regardless of the D2EHPA fixation mechanism in the polymer matrix. The obtained values of the static capacity of the polymer obtained by copolymerization with the extractant, due to diffusion restrictions, exceed the dynamic capacity.

To effectively regenerate the organic phase of the extractant, a sodium citrate solution with a concentration of 2 mol/L was used. The use of complexing agents provides a high degree of rare-earth metals extraction into the aqueous phase while retaining the integrity of the organic extractant layer. It is possible to regenerate the material copolymerized with D2EHPA by sulfuric acid.

Comparison of the IR spectra of organic phases impregnated (SIR) and immobilized (ERE) into the polymer matrix shows the polarization of the P=O bond during the rare-earth metals extraction, due to the participation of the D2EHPA phosphoryl group, which is weakly fixed in the polymer matrix. The obtained thermodynamic and capacitive characteristics of solid-phase extraction make it possible to recommend the implementation of polymeric materials impregnated or copolymerized with D2EHPA for the rare earth metals extraction from technological solutions of phosphoric acid.

The use of solid-phase extraction will allow the extraction of rare-earth metals at enterprises that process apatite ore using sulfuric acid technology to obtain a large amount of technological phosphoric acid.

Author Contributions

Conceptualization, O.C. and V.S.; methodology, M.P.; software, D.B.; validation, M.P. and O.C.; formal analysis, V.S.; investigation, Y.M. and D.B.; resources, O.C. and M.P.; data curation, O.C. and V.S.; writing—original draft preparation, O.C. and M.P.; writing—review and editing, V.S. and Y.M.; visualization, Y.M. and D.B.; supervision, M.P.; project administration, O.C.; funding acquisition, O.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was carried out as part of project No. 19-19-00377 “Technological basis for the extraction and selection of strategically important rare earth elements from apatite products” dated 22 April 2019, supported by the Russian Science Foundation in the 2019 competition “Conducting basic scientific research and exploratory research by individual scientific groups”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the current article.

Acknowledgments

The research was carried out with the involvement of the laboratory facilities of the Saint-Petersburg Mining University Collective Use Center.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lutskiy, D.S.; Ignatovich, A.S.; Sulimova, M.A. Determination of the sorption characteristics of ammonium perrenate ions on anion exchange resin AV-17-8. J. Phys. Conf. Ser. 2019, 1399, 055069. [Google Scholar] [CrossRef]

- Litvinova, T. Separation of the heavy and light rare earth metals concentrate after sulfuric acid eudialyte concentrate treatment. FOG Freib. Online Geosci. 2015, 40, 159–166. [Google Scholar]

- Babu, C.M.; Binnemans, K.; Roosen, J. Ethylenediaminetriacetic Acid-Functionalized Activated Carbon for the Adsorption of Rare Earths from Aqueous Solutions. Ind. Eng. Chem. Res. 2018, 57, 1487–1497. [Google Scholar] [CrossRef]

- Ashour, R.M.; Samouhos, M.; Polido Legaria, E.; Svärd, M.; Högblom, J.; Forsberg, K.; Palmlöf, M.; Kessler, V.G.; Seisenbaeva, G.A.; Rasmuson, Å.C. DTPA-Functionalized Silica Nano- and Microparticles for Adsorption and Chromatographic Separation of Rare Earth Elements. ACS Sustain. Chem. Eng. 2018, 6, 6889–6900. [Google Scholar] [CrossRef] [Green Version]

- Sayed, M.A.; Aly, H.F.; Mahmoud, H.H.; Abdelwahab, S.M.; Helal, A.I.; Wilson, L.D. Design of hybrid goethite nanocomposites as potential sorbents for lanthanum from aqueous media. Sep. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Galhoum, A.A.; Mahfouz, M.G.; Abdel-Rehem, S.T.; Gomaa, N.A.; Atia, A.A.; Vincent, T.; Guibal, E. Diethylenetriamine-functionalized chitosan magnetic nano-based particles for the sorption of rare earth metal ions [Nd(III), Dy(III) and Yb(III)]. Cellulose 2015, 22, 2589–2605. [Google Scholar] [CrossRef]

- Voropanova, L.A.; Pukhova, V.P. Extraction of copper, cobalt and nickel ions from aqueous solutions by extractant cyanex 272. J. Min. Inst. 2018, 233, 498. [Google Scholar] [CrossRef]

- Abu Elgoud, E.M.; Ismail, Z.H.; El-Nadi, Y.A.; Aly, H.F. Separation of cerium(IV) and yttrium(III) from citrate medium by solvent extraction using D2EHPA in kerosene. Chem. Pap. 2020, 74, 2461–2469. [Google Scholar] [CrossRef]

- Stefaniak, J.; Karwacka, S.; Janiszewska, M.; Dutta, A.; Rene, E.R.; Regel-Rosocka, M. Co(II) and Ni(II) transport from model and real sulfate solutions by extraction with bis(2,4,4-trimethylpentyl)phosphinic acid (Cyanex 272). Chemosphere 2020, 254, 126869. [Google Scholar] [CrossRef] [PubMed]

- Morillo Martín, D.; Diaz Jalaff, L.; García, M.A.; Faccini, M. Selective Recovery of Europium and Yttrium Ions with Cyanex 272-Polyacrylonitrile Nanofibers. Nanomaterials 2019, 9, 1648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohammedi, H.; Miloudi, H.; Boos, A.; Bertagnolli, C. Lanthanide recovery by silica-Cyanex 272 material immobilized in alginate matrix. Environ. Sci. Pollut. Res. 2020, 27, 26943–26953. [Google Scholar] [CrossRef] [PubMed]

- TVEKS-D2EHPA (di-2-ethylhexyl phosphate). Available online: https://gp-smoly.ru/tveks-d2ehpa-di-2-etilgeksil-fosfat (accessed on 2 May 2021).

- Cheremisina, O.; Sergeev, V.; Fedorov, A.; Iliyna, A. Specific features of solvent extraction of REM from phosphoric acid solutions with DEHPA. Miner. Process. Extr. Metall. 2019. [Google Scholar] [CrossRef]

- Wang, L.; Long, Z.; Huang, X.; Yu, Y.; Cui, D.; Zhang, G. Recovery of rare earths from wet-process phosphoric acid. Hydrometallurgy 2010, 101, 41–47. [Google Scholar] [CrossRef]

- Lebedev, I.A.; Kulyako, Y.M. Termodinamicheskiye konstanty ustoychivosti fosfatnykh kompleksov. ZHNKH 1978, 23, 3215–3227. [Google Scholar]

- Ravikumar, B.; Ramaswamy, S.; Pandiarajan, S. FTIR and laser RAMAN spectral analysis of crystalline DL–valinium dihydrogen phosphate. Int. J. Eng. Sci. Technol. 2012, 4, 1658–1666. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).