Improving the Wear and Corrosion Resistance of Maraging Part Obtained by Cold Gas Spray Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Spray Deposition

2.3. Coating Characterization

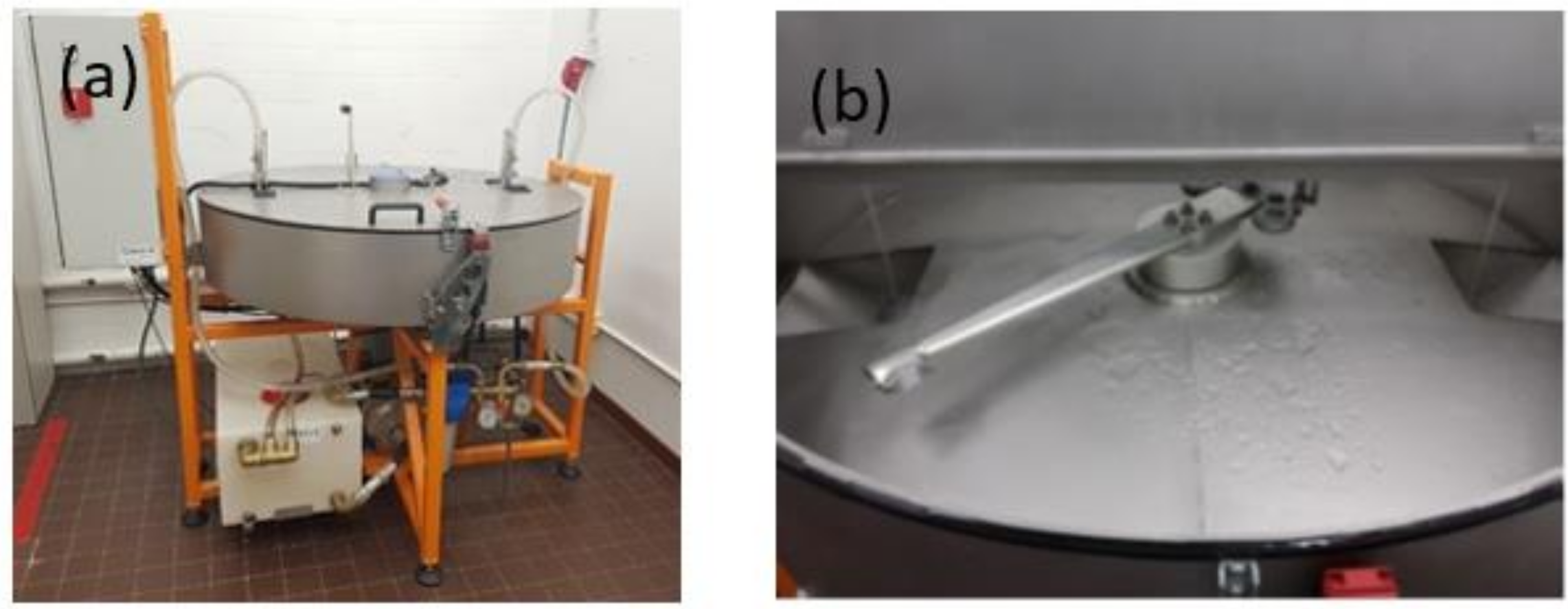

2.4. Wear Testing

2.5. Corrosion Testing

3. Results and Discussion

3.1. Characterization of Powders

3.2. Characterization of Coatings

3.3. Wear Performance

3.4. Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Ahmed, G.M.S.; Badruddin, I.A.; Tirth, V.; Algahtani, A.; Ali, M.A. Wear resistance of maraging steel developed by direct metal laser sintering. Mater. Express 2020, 10, 1079–1090. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc welding processes for additive manufacturing: A review. In Transactions on Intelligent Welding Manufacturing; Chen, S., Zang, Y., Feng, Z., Eds.; Springer: Singapore, 2018; pp. 3–24. ISBN 9789811053559. [Google Scholar]

- Karayel, E.; Bozkurt, Y. Additive manufacturing method and different welding applications. J. Mater. Res. Technol. 2020, 9, 11424–11438. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Yin, S.; Yang, X.; Xu, Y.; Lupoi, R. Solid-state additive manufacturing and repairing by cold spraying: A review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef] [Green Version]

- Oyinbo, S.T.; Jen, T.-C. A comparative review on cold gas dynamic spraying processes and technologies. Manuf. Rev. 2019, 6, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Bagherifard, S.; Monti, S.; Zuccoli, M.V.; Riccio, M.; Kondás, J.; Guagliano, M. Cold spray deposition for additive manufacturing of freeform structural components compared to selective laser melting. Mater. Sci. Eng. A 2018, 721, 339–350. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Verdy, C.; Liao, H. Cold gas dynamic spray additive manufacturing today: Deposit possibilities, technological solutions and viable applications. Mater. Des. 2017, 133, 266–287. [Google Scholar] [CrossRef]

- Yan, X.; Huang, C.; Chen, C.; Bolot, R.; Dembinski, L.; Huang, R.; Ma, W.; Liao, H.; Liu, M. Additive manufacturing of WC reinforced maraging steel 300 composites by cold spraying and selective laser melting. Surf. Coat. Technol. 2019, 371, 161–171. [Google Scholar] [CrossRef]

- Bae, G.; Kumar, S.; Yoon, S.; Kang, K.; Na, H.; Kim, H.; Lee, C. Bonding features and associated mechanisms in kinetic sprayed titanium coatings. Acta Mater. 2009, 57, 5654–5666. [Google Scholar] [CrossRef]

- Yin, S.; Cizek, J.; Cupera, J.; Hassani, M.; Luo, X.; Jenkins, R.; Xie, Y.; Li, W.; Lupoi, R. Formation conditions of vortex-like intermixing interfaces in cold spray. Mater. Des. 2021, 200, 1–10. [Google Scholar] [CrossRef]

- Cormier, Y.; Dupuis, P.; Jodoin, B.; Corbeil, A. Pyramidal fin arrays performance using streamwise anisotropic materials by cold spray additive manufacturing. J. Therm. Spray Technol. 2016, 25, 170–182. [Google Scholar] [CrossRef] [Green Version]

- Vaz, R.F.; Silvello, A.; Sanchez, J.; Albaladejo, V.; Cano, I.G. The influence of the powder characteristics on 316L stainless steel coatings sprayed by cold gas spray. Coatings 2021, 11, 168. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Chung, Y.W.; Liu, C.T. Co-precipitation of nanoscale particles in steels with ultra-high strength for a new era. Mater. Today 2017, 20, 142–154. [Google Scholar] [CrossRef]

- Würzinger, P.; Rabitsch, R.; Meyer, W. Production of maraging steel grades and the influence of specified and nonspecified elements for special applications. J. Mater. Sci. 2004, 39, 7295–7302. [Google Scholar] [CrossRef]

- Chen, C.; Yan, X.; Xie, Y.; Huang, R.; Kuang, M.; Ma, W.; Zhao, R.; Wang, J.; Liu, M.; Ren, Z.; et al. Microstructure evolution and mechanical properties of maraging steel 300 fabricated by cold spraying. Mater. Sci. Eng. A 2019, 743, 482–493. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Yan, X.; Huang, R.; Kuang, M.; Ma, W.; Zhao, R.; Wang, J.; Liu, M.; Ren, Z.; et al. Cold sprayed WC reinforced maraging steel 300 composites: Microstructure characterization and mechanical properties. J. Alloys Compd. 2019, 785, 499–511. [Google Scholar] [CrossRef]

- Turk, C.; Zunko, H.; Aumayr, C.; Leitner, H.; Kapp, M. Advances in Maraging steels for additive manufacturing. BHM Berg- und Hüettenmännische Mon. 2019, 164, 112–116. [Google Scholar] [CrossRef] [Green Version]

- Jägle, E.A.; Sheng, Z.; Kürnsteiner, P.; Ocylok, S.; Weisheit, A.; Raabe, D. Comparison of maraging steel micro- and nanostructure produced conventionally and by laser additive manufacturing. Materials 2017, 10, 8. [Google Scholar] [CrossRef] [Green Version]

- Takata, N.; Nishida, R.; Suzuki, A.; Kobashi, M.; Kato, M. Crystallographic features of microstructure in Maraging steel fabricated by selective laser melting. Metals 2018, 8, 440. [Google Scholar] [CrossRef] [Green Version]

- Ansell, T.Y.; Ricks, J.P.; Park, C.; Tipper, C.S.; Luhrs, C.C. Mechanical properties of 3D-printed maraging steel induced by environmental exposure. Metals 2020, 10, 218. [Google Scholar] [CrossRef] [Green Version]

- Sun, K.; Peng, W.; Wei, B.; Yang, L.; Fang, L. Friction and wear characteristics of 18Ni(300) maraging steel under high-speed dry sliding conditions. Materials 2020, 13, 1485. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Qiu, Q.; Gee, M.; Hou, C.; Liu, X.; Song, X. Wear resistance enhancement of HVOF-sprayed WC-Co coating by complete densification of starting powder. Mater. Des. 2020, 191, 1–13. [Google Scholar] [CrossRef]

- Lamana, M.S.; Pukasiewicz, A.G.M.; Sampath, S. Influence of cobalt content and HVOF deposition process on the cavitation erosion resistance of WC-Co coatings. Wear 2018, 398–399, 209–219. [Google Scholar] [CrossRef]

- Magnani, M.; Suegama, P.H.; Espallargas, N.; Dosta, S.; Fugivara, C.S.; Guilemany, J.M.; Benedetti, A. V Influence of HVOF parameters on the corrosion and wear resistance of WC-Co coatings sprayed on AA7050 T7. Surf. Coat. Technol. 2008, 202, 4746–4757. [Google Scholar] [CrossRef]

- Pulsford, J.; Venturi, F.; Kamnis, S.; Hussain, T. Sliding wear behaviour of WC-Co reinforced NiCrFeSiB HVOAF thermal spray coatings against WC-Co and Al2O3 counterbodies. Surf. Coat. Technol. 2020, 386, 1–11. [Google Scholar] [CrossRef]

- Mahdipoor, M.S.; Tarasi, F.; Moreau, C.; Dolatabadi, A.; Medraj, M. HVOF sprayed coatings of nano-agglomerated tungsten-carbide/cobalt powders for water droplet erosion application. Wear 2015, 330–331, 338–347. [Google Scholar] [CrossRef]

- Shipway, P.H.; Gupta, K. The potential of WC-Co hardmetals and HVOF sprayed coatings to combat water-droplet erosion. Wear 2011, 271, 1418–1425. [Google Scholar] [CrossRef]

- ASTM. B822-02—Standard Test. Method for Particle Size Distribution of Metal. Powders and Related Compounds by Laser Scattering; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ISO. 17836:2004—Thermal Spraying—Determination of Deposition Efficiency for Thermal Spraying; ISO: Geneva, Switzerland, 2004. [Google Scholar]

- ASTM. E1920-03—Standard Guide for Metallographic Preparation of Thermal Sprayed Coatings; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM. E3-01—Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- ASTM. B487-85—Standard Test. Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of a Cross Section; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM. E2109-01—Standard Test. Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM. E384-99—Standard Test. Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- ASTM. C633-13—Standard Test. Method for Adhesion or Cohesion Strength of Thermal Spray Coatings; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. G65-00—Standard Test. Method for Measuring Abrasion Using the Dry Sand Rubber Wheel Apparatus; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- ASTM. G99-04—Standard Test. Method for Wear Testing with A Pin-on-Disk Apparatus; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM. G73-10—Standard Test. Method for Liquid Impingement Erosion Using Rotating Apparatus; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM. G59-97—Standard Test. Method for Conducting Potentiodynamic Polarization Resistance Measurements; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- ASTM. G102-89—Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements; ASTM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Ahmed, R.; Vourlias, G.; Algoburi, A.; Vogiatzis, C.; Chaliampalias, D.; Skolianos, S.; Berger, L.-M.; Paul, S.; Faisal, N.H.; Toma, F.-L.; et al. Comparative study of corrosion performance of HVOF-sprayed coatings produced using conventional and suspension WC-Co feedstock. J. Therm. Spray Technol. 2018, 27, 1579–1593. [Google Scholar] [CrossRef] [Green Version]

- Bulnes, A.G.; Fuentes, V.A.; Cano, I.G.; Dosta, S. Understanding the influence of high velocity thermal spray techniques on the properties of different anti-wear WC-based coatings. Coatings 2020, 10, 1157. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; DeRosset, W.S.; Helfritch, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Ko, K.H.; Choi, J.O.; Lee, H. Intermixing and interfacial morphology of cold-sprayed Al coatings on steel. Mater. Lett. 2014, 136, 45–47. [Google Scholar] [CrossRef]

- Qin, W.; Kang, J.; Li, J.; Yue, W.; Liu, Y.; She, D.; Mao, Q.; Li, Y. Tribological behavior of the 316L stainless steel with heterogeneous lamella structure. Materials 2018, 11, 1839. [Google Scholar] [CrossRef] [Green Version]

- Jianxin, D.; Hui, Z.; Ze, W.; Yunsong, L.; Jun, Z. Friction and wear behaviors of WC/Co cemented carbide tool materials with different WC grain sizes at temperatures up to 600 °C. Int. J. Refract. Met. Hard Mater. 2012, 31, 196–204. [Google Scholar] [CrossRef]

- Gant, A.J.; Gee, M.G.; May, A.T. The evaluation of tribo-corrosion synergy for WC-Co hardmetals in low stress abrasion. Wear 2004, 256, 500–516. [Google Scholar] [CrossRef]

- Gee, M.G.; Gant, A.; Roebuck, B. Wear mechanisms in abrasion and erosion of WC/Co and related hardmetals. Wear 2007, 263, 137–148. [Google Scholar] [CrossRef]

- Gokul Lakshmi, S.; Reddy, G.M.; Roy, M. A Comparison of Wear Due to Abrasion of WC–Ni Coatings on Aluminium Alloy Sprayed by HVOF and Detonation Gun. Trans. Indian Inst. Met. 2018, 71, 1389–1399. [Google Scholar] [CrossRef]

- Merrick, S.J.; Miller, R.F. The role of carbides in iron base hardsurfacing deposits. In Proceedings of the Advances in Thermal Spraying; Pergamon Press: Montreal, QC, Canada, 1986; pp. 633–642. [Google Scholar]

- Ibrahim, M.E.; Medraj, M. Water droplet erosion ofwind turbine blades: Mechanics, testing, modeling and future perspectives. Materials 2020, 13, 157. [Google Scholar] [CrossRef] [Green Version]

- Vaz, R.F.; Sucharski, G.B.; Chicoski, A.; Siqueira, I.B.A.F.; Tristante, R.; Pukasiewicz, A.G.M. Comparison of FeMnCrSi cavitation resistance coatings deposited by Twin-Wire Electric Arc and High-Velocity Oxy-Fuel processes. J. Therm. Spray Technol. 2021, 30, 754–771. [Google Scholar] [CrossRef]

- Bellie, V.; Suresh, J.; Ragunath, L. HVOF sprayed mullite coatings for use in extreme environments. J. Therm. Spray Eng. 2020, 2, 43–49. [Google Scholar] [CrossRef]

- Othman, N.K.; Yahya, S.; Awizar, D.A. Anticorrosive properties of nano silicate from paddy husk in salt medium. Sains Malays. 2016, 45, 1253–1258. [Google Scholar]

| Parameter | CGS | HVOF |

|---|---|---|

| N2 Pressure (MPa) | 7.0 | / |

| N2 Temperature (°C) | 975 | / |

| H2 Pressure (MPa) | / | 1.0 |

| O2 Temperature (MPa) | / | 1.2 |

| Standoff Distance (mm) | 25 | 225 |

| Powder Feeding (g·s−1) | 0.43 | 0.50 |

| Robot Speed (m·s−1) | 0.5 | 0.5 |

| Layers | 4 | 10 |

| Powder | Nominal Composition (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cr | Ni | Mo | Mn | Co | Ti | Al | Fe | |

| Dycomet 1008 | 17.8 | 4.9 | 14.7 | 2.7 | - | - | - | Bal. |

| Maraging | 7.5 | 11.4 | 3.3 | 1.6 | 3.9 | 1.8 | 1.1 | Bal. |

| Material | Thickness (μm) | Hardness (HV0.3) | Porosity (%) |

|---|---|---|---|

| Maraging | 874 ± 71 | 378 ± 63 | <1.0 |

| WC-12Co | 242 ± 5 | 1249 ± 72 | <1.0 |

| WC-10Co4Cr | 234 ± 23 | 1345 ± 133 | <1.0 |

| 316L bulk | - | 350 ± 13 | - |

| C-steel bulk | - | 241 ± 9 | - |

| Material | Abrasion Rate (mm3·N−1·m−1) | CoF (N N−1) | Friction Wear Rate (mm3·N−1·m−1) | Jet Erosion Rate (mg·min−1) |

|---|---|---|---|---|

| Maraging | 21.61 × 10−5 | 0.86 ± 0.08 | 2.302 × 10−5 | 1654.67 ± 115.64 |

| WC-12Co | 0.76 × 10−5 | 0.38 ± 0.03 | 0.013 × 10−5 | 15.66 ± 1.69 |

| WC-10Co4Cr | 1.29 × 10−5 | 0.14 ± 0.01 | 0.032 × 10−5 | 137.33 ± 3.46 |

| 316L bulk | 16.73 × 10−5 | 0.67 ± 0.11 | 17.051 × 10−5 | 2.55 ± 0.00 |

| C-steel bulk | 23.94 × 10−5 | 0.46 ± 0.03 | 2.841 × 10−5 | 69.88 ± 3.22 |

| Material | Current Density Icorr (μA·cm−2) | Potential of Corrosion Ecorr (mV) | Polarization Resistance Rp (kΩ) |

|---|---|---|---|

| Maraging | 0.41 | −457.19 | 39.08 |

| WC-12Co | 1.47 | −381.50 | 16.34 |

| WC-10Co4Cr | 1.79 | −339.48 | 10.25 |

| 316L bulk | 0.07 | −179.80 | 58.00 |

| C-steel bulk | 0.53 | −753.97 | 8.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaz, R.F.; Silvello, A.; Albaladejo, V.; Sanchez, J.; Cano, I.G. Improving the Wear and Corrosion Resistance of Maraging Part Obtained by Cold Gas Spray Additive Manufacturing. Metals 2021, 11, 1092. https://doi.org/10.3390/met11071092

Vaz RF, Silvello A, Albaladejo V, Sanchez J, Cano IG. Improving the Wear and Corrosion Resistance of Maraging Part Obtained by Cold Gas Spray Additive Manufacturing. Metals. 2021; 11(7):1092. https://doi.org/10.3390/met11071092

Chicago/Turabian StyleVaz, Rodolpho F., Alessio Silvello, Vicente Albaladejo, Javier Sanchez, and Irene García Cano. 2021. "Improving the Wear and Corrosion Resistance of Maraging Part Obtained by Cold Gas Spray Additive Manufacturing" Metals 11, no. 7: 1092. https://doi.org/10.3390/met11071092

APA StyleVaz, R. F., Silvello, A., Albaladejo, V., Sanchez, J., & Cano, I. G. (2021). Improving the Wear and Corrosion Resistance of Maraging Part Obtained by Cold Gas Spray Additive Manufacturing. Metals, 11(7), 1092. https://doi.org/10.3390/met11071092