Microstructure and Texture Development in Thermomechanically Processed Leaded Brass

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

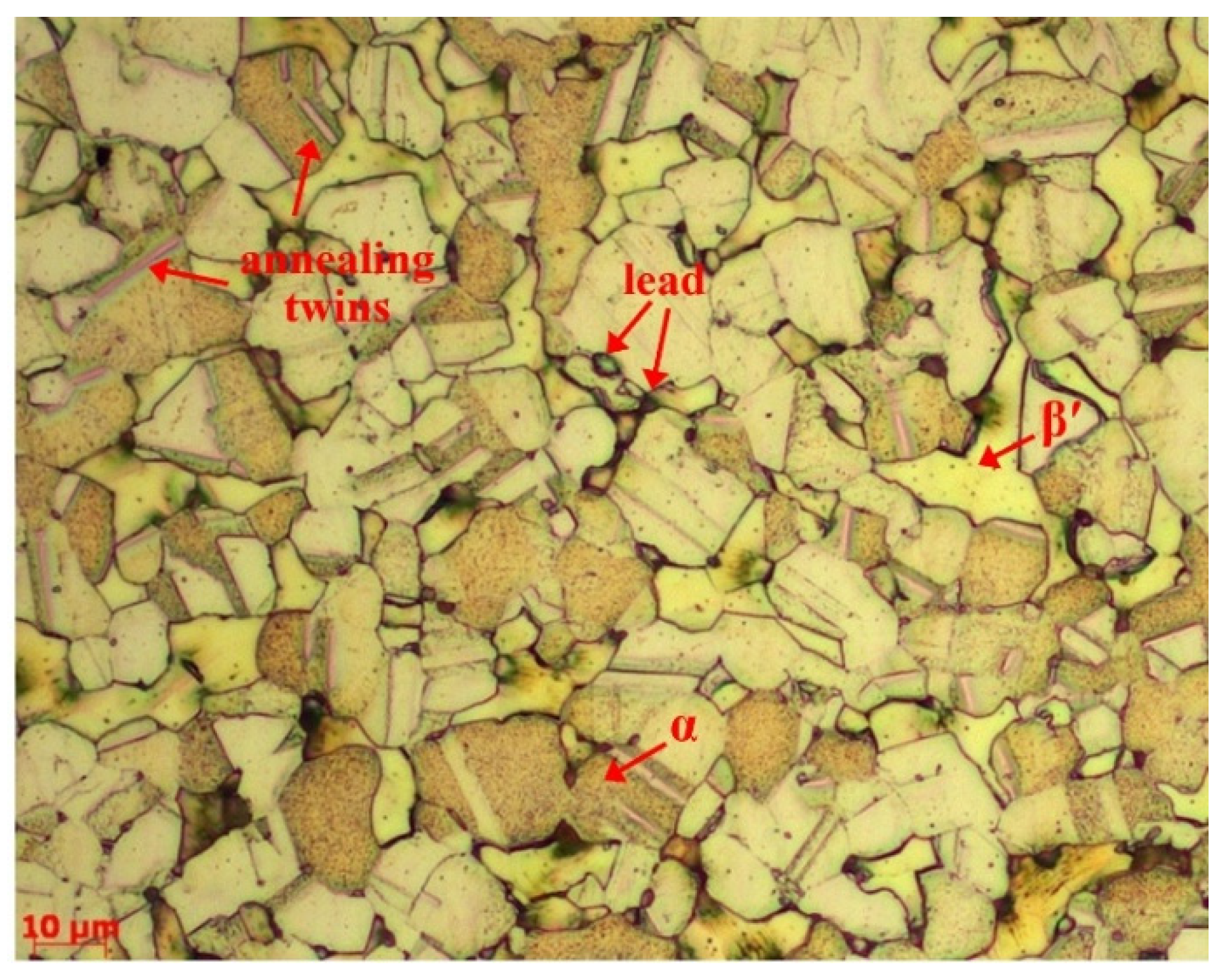

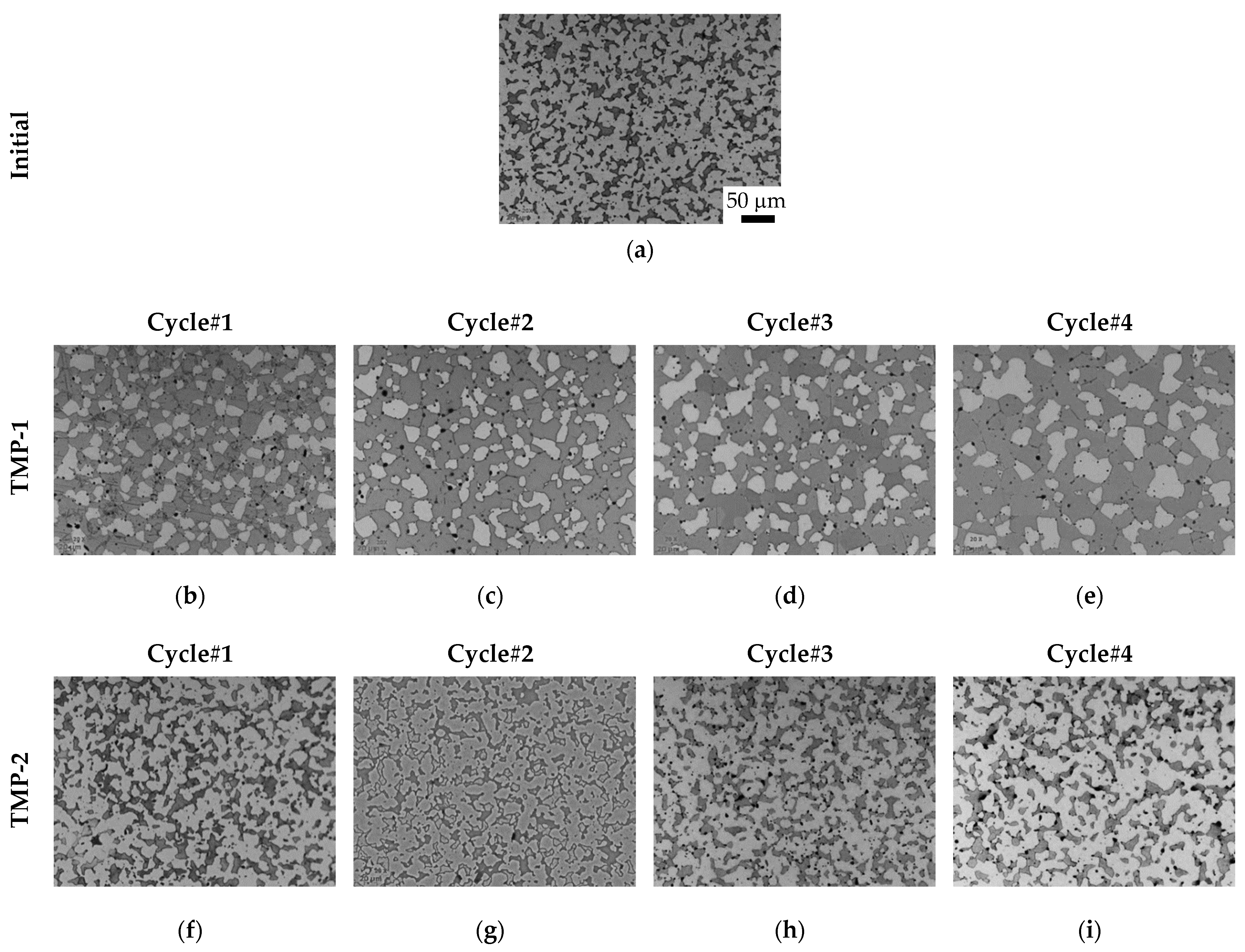

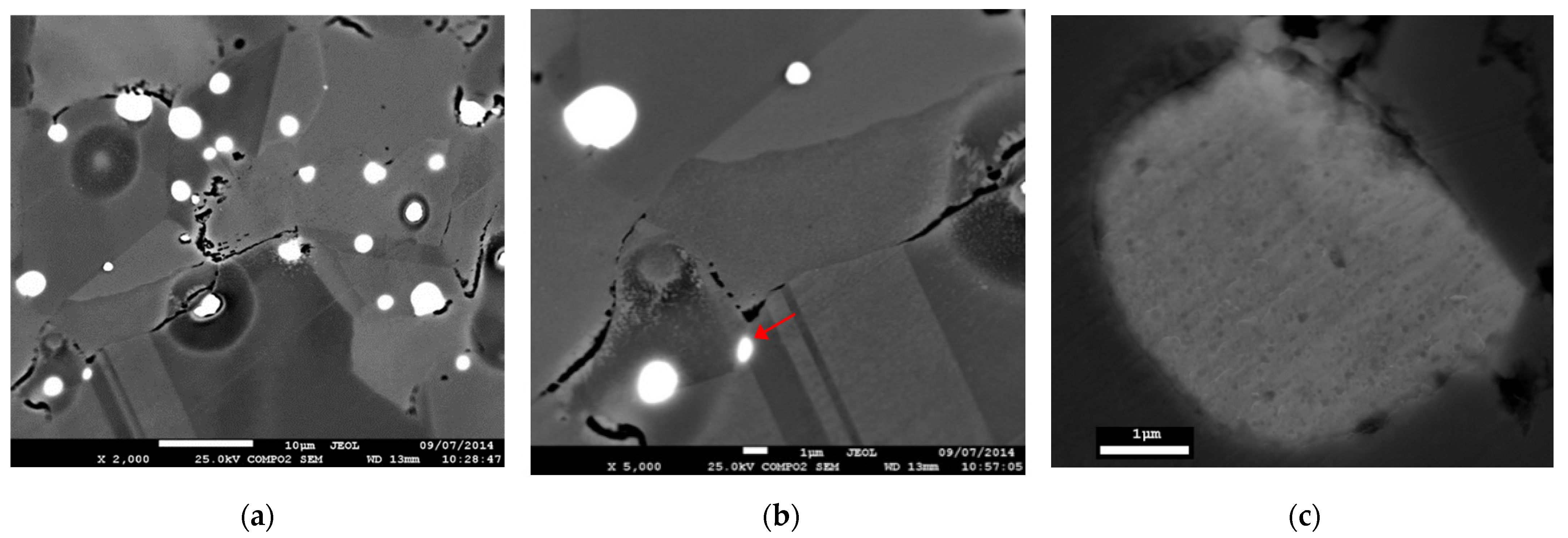

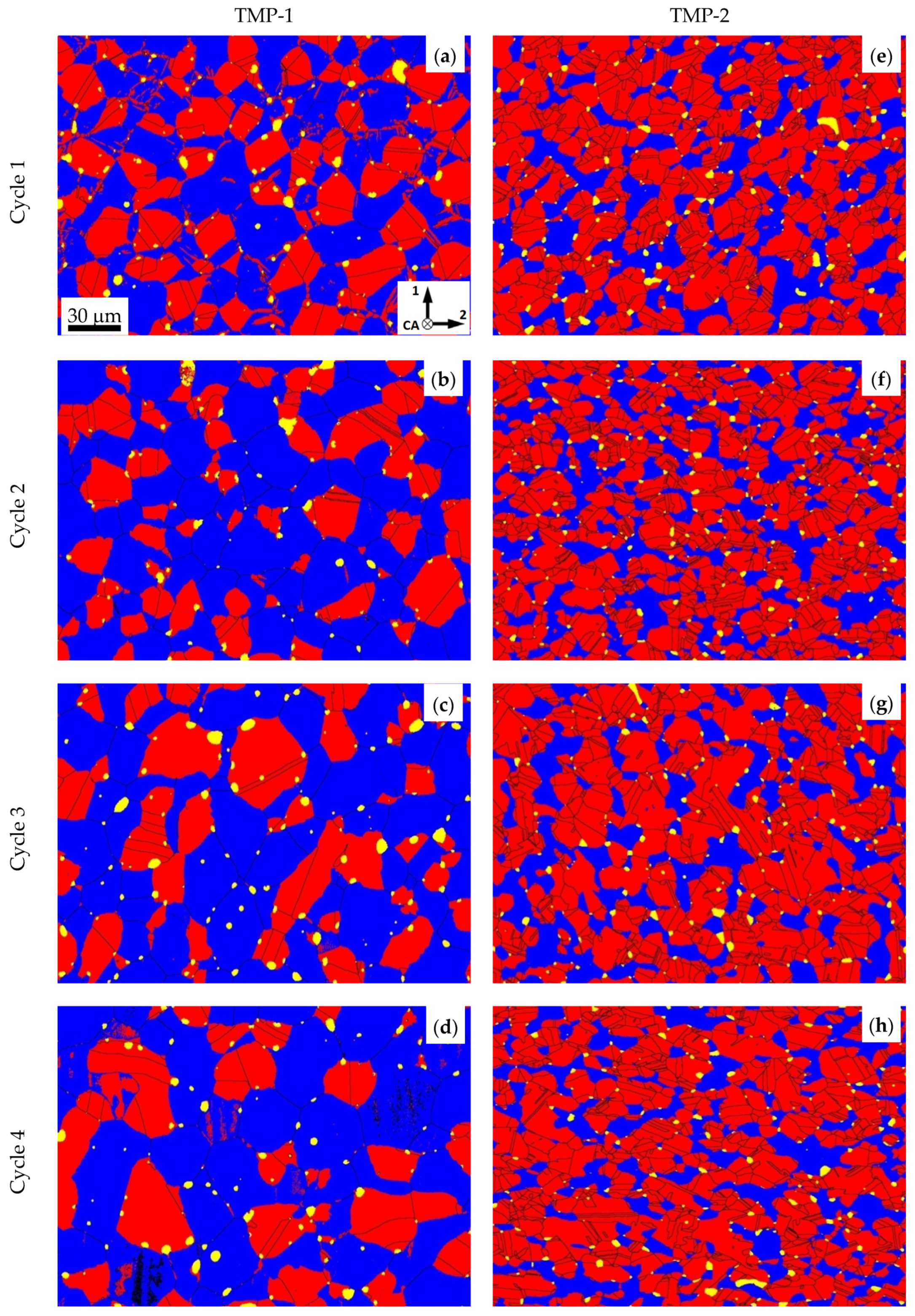

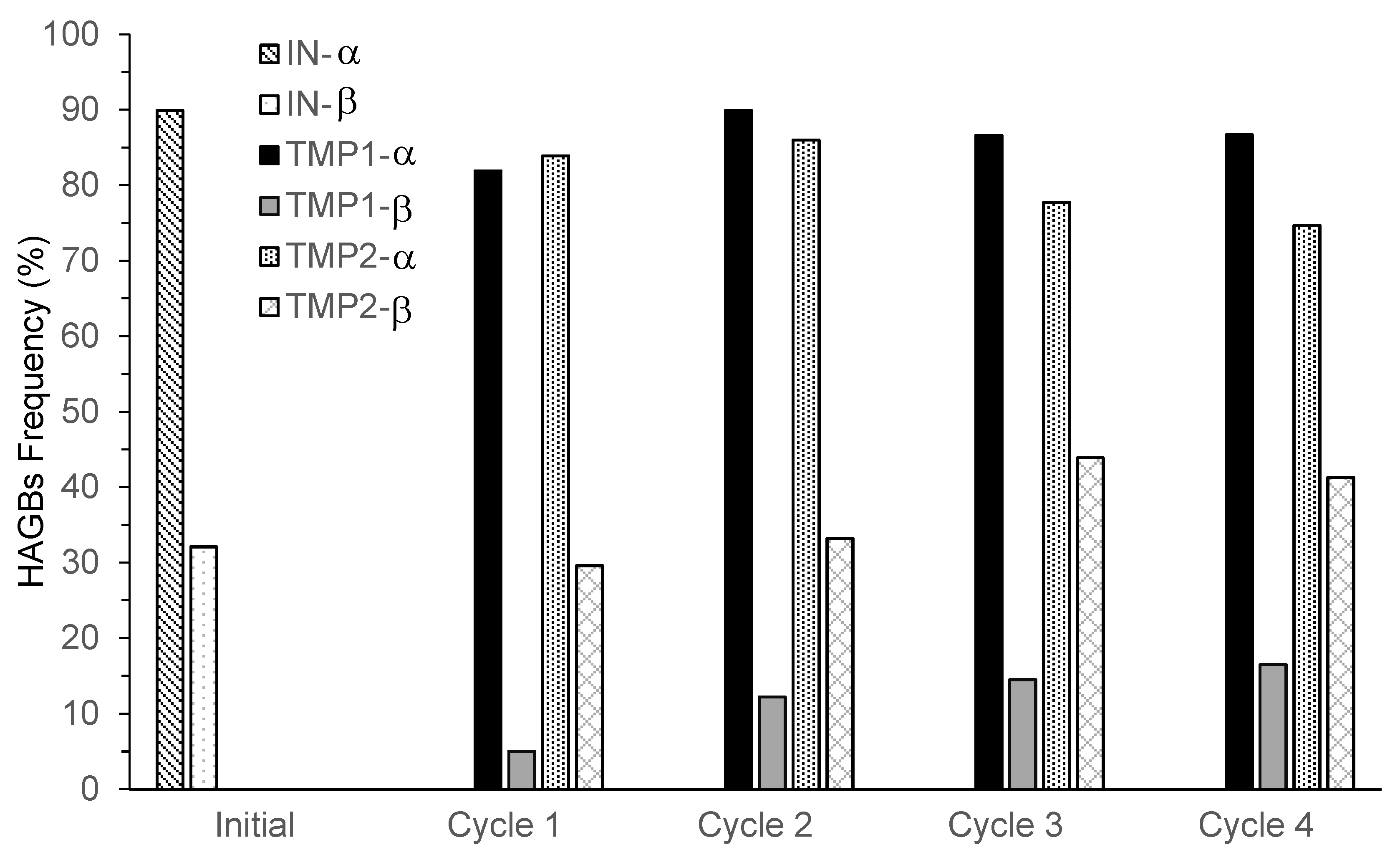

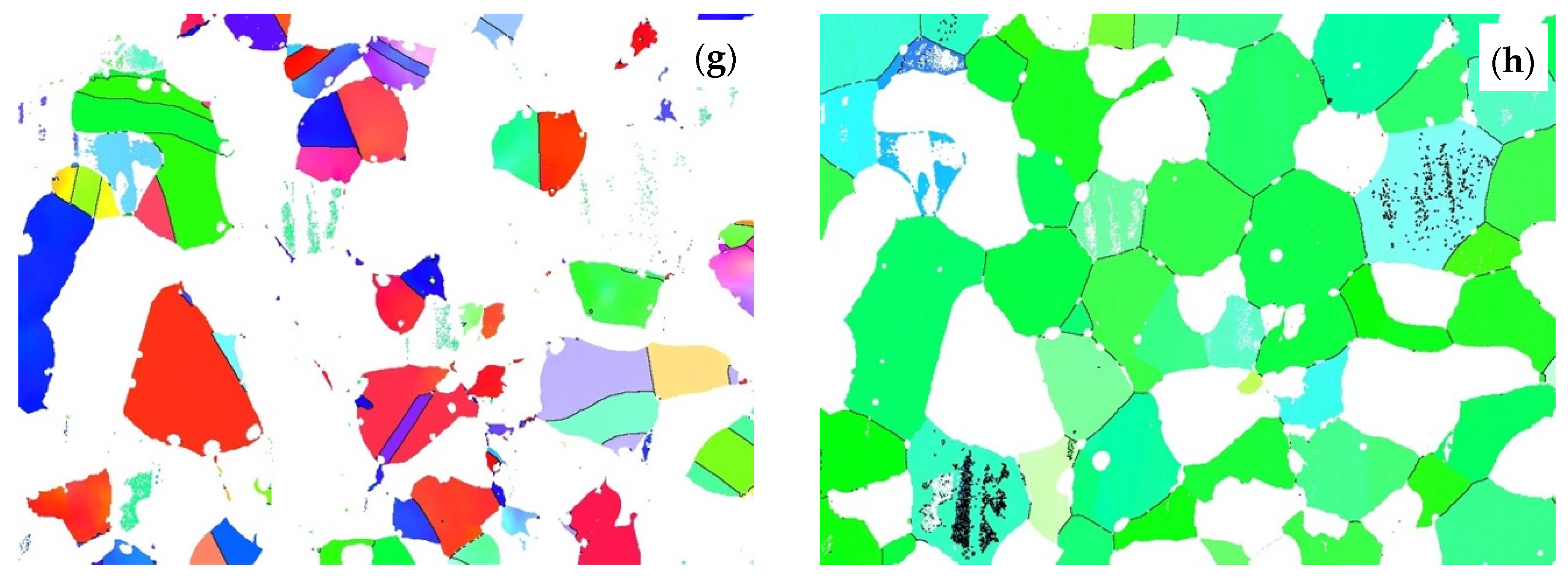

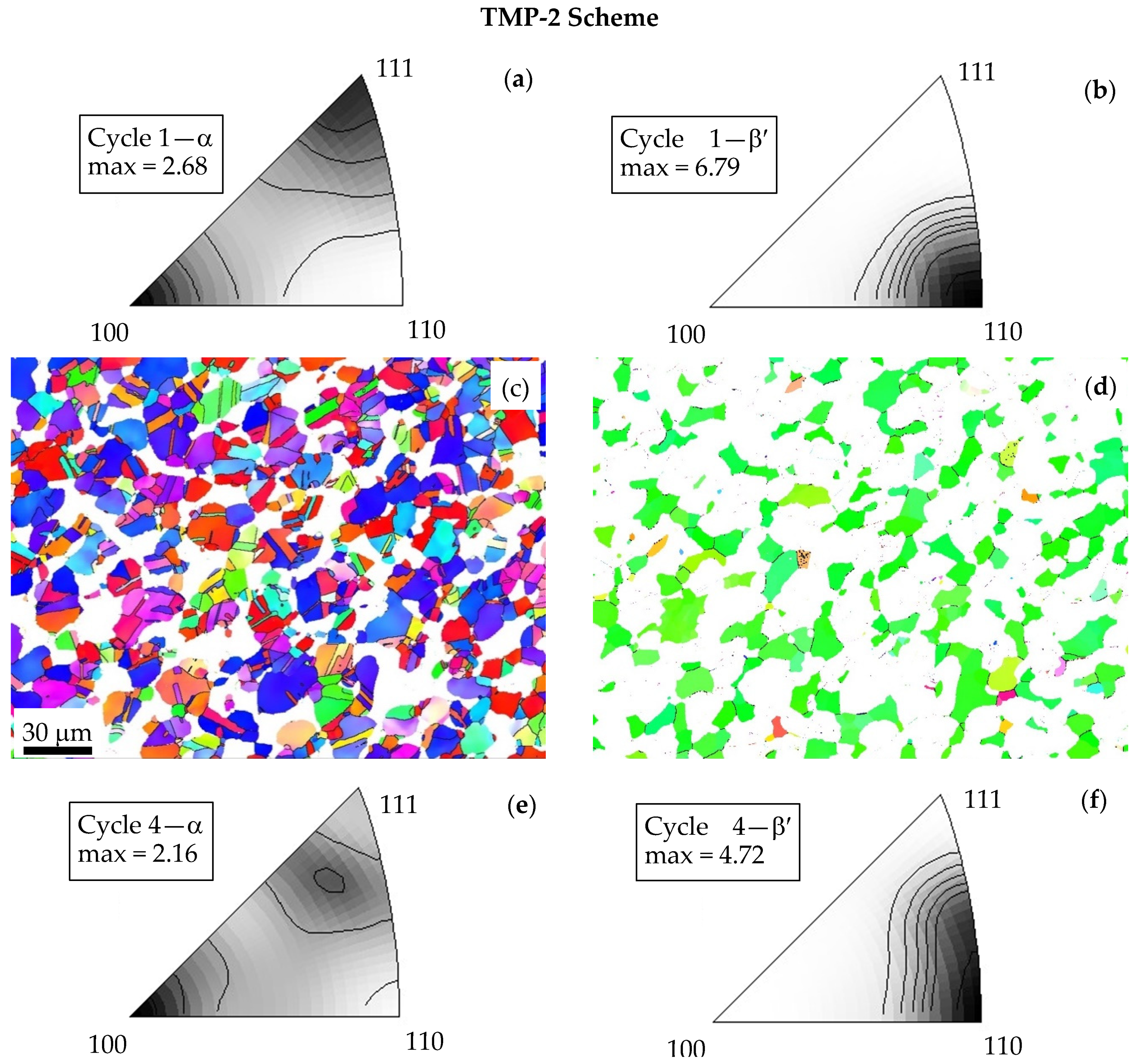

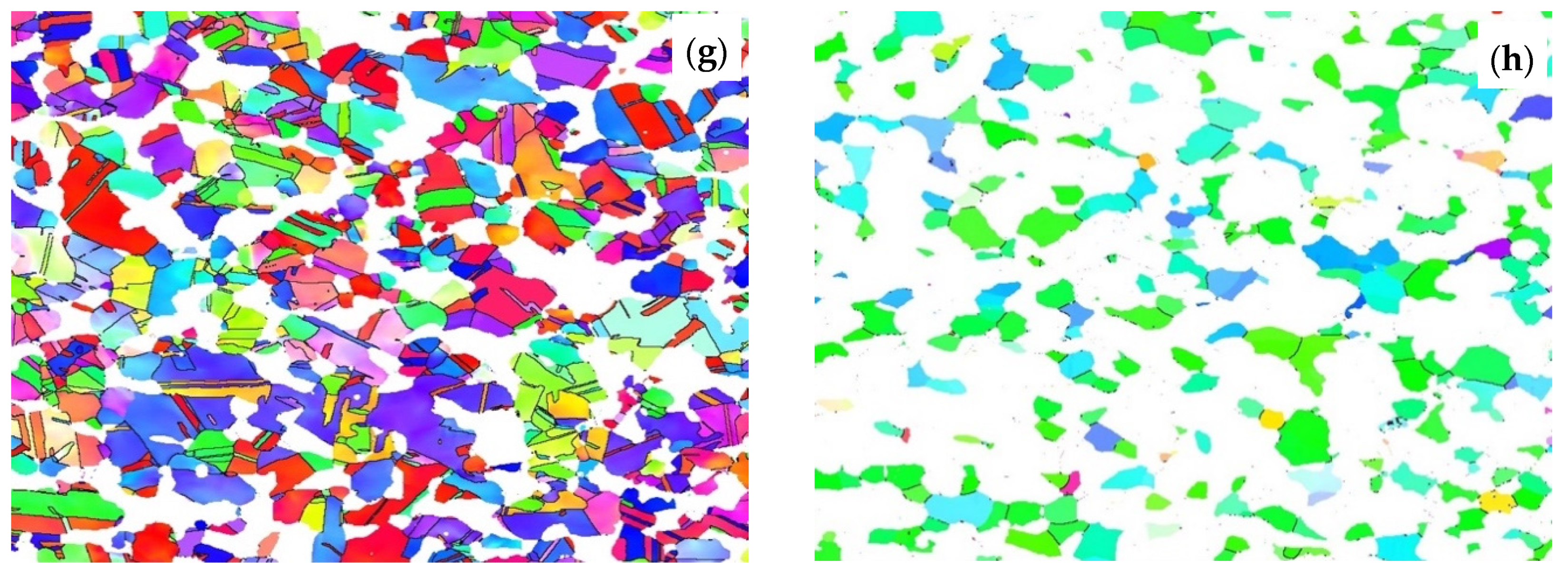

3.1. Microstructure

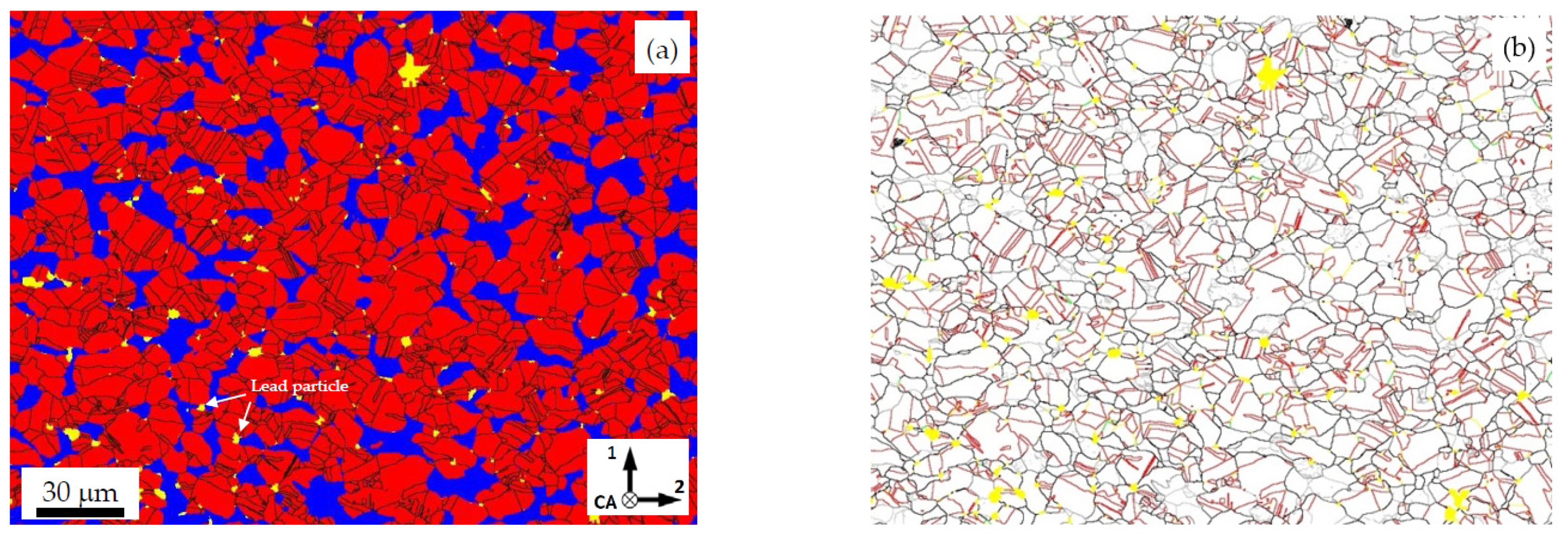

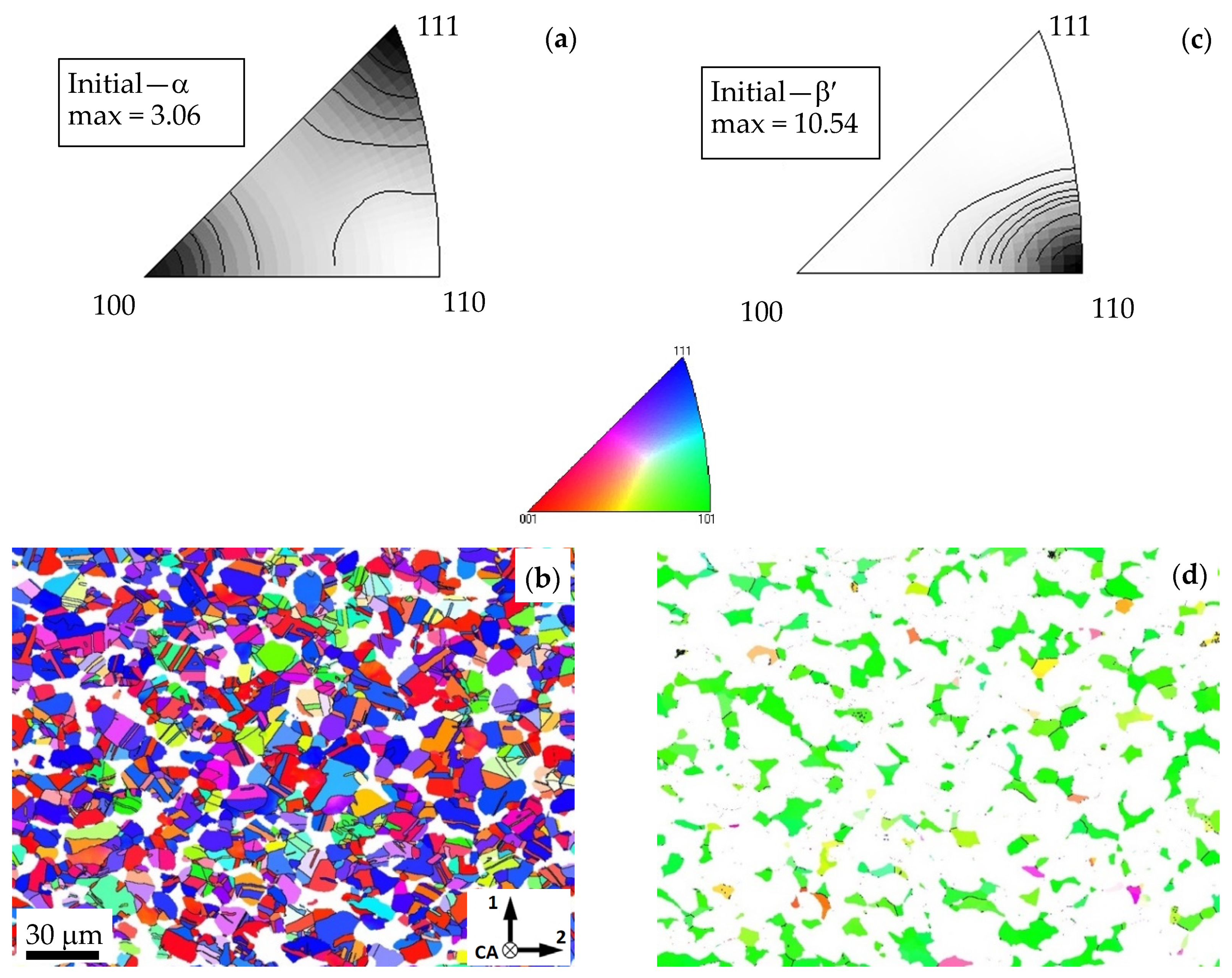

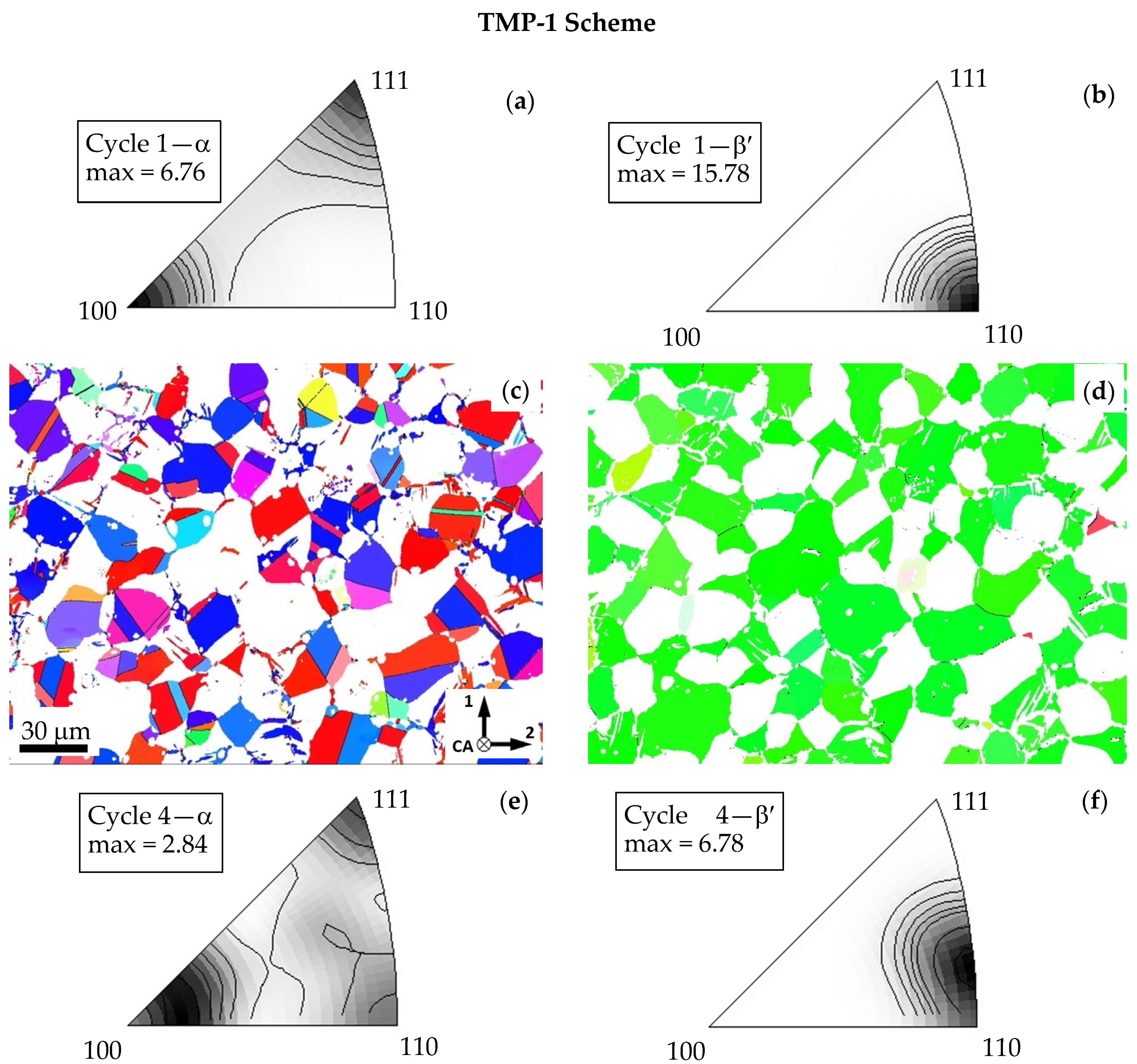

3.2. Texture

4. Conclusions

- (i)

- TMP-1 scheme promoted undesirable growth of β′ phase, from an initial area fraction of 27% to 70%, while small β′ growth to 38% occurred using TMP-2 scheme. Moreover, coarser α and β′ grains were produced for samples processed by the TMP-1 scheme. For both schemes, lead particles were mainly located at the α-β interfaces, implying the contribution of lead particles in suppressing grain growth by limiting grain boundary migration via particle-dragging effect.

- (ii)

- As demonstrated in the TMP-2 scheme, hindering α → β′ phase transformation and grain coarsening are critical factors for developing GBE structure in leaded brass. Achieving such structure without excessive recrystallization is possible via strain-induced boundary migration mechanism. TMP-2 scheme aided in promoting cluster formation of α grains characterized by an enormous fraction of Σ3n boundaries, enhancing the interaction and generation of Σ3n boundaries and thus leading to the breakup of the random HAGBs network with increasing TMP cycles.

- (iii)

- In general, both TMP schemes strongly maintained the initial textures produced by cold drawing. Despite the remarkable β′ growth and grain coarsening in the TMP-1 scheme, the product β′ grains preserved the orientation relationship of the parent α grains following the Kurdjumov–Sachs. In the TMP-2 scheme, more texture randomization of the α phase occurred due to the increase in the fraction of Σ3n boundaries (and thus HAGBs) with successive cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palumbo, G.; King, P.J.; Aust, K.T.; Erb, U.; Lichtenberger, P.C. Grain boundary design and control for intergranular stress-corrosion resistance. Scr. Met. Mater. 1991, 25, 1775–1780. [Google Scholar] [CrossRef]

- Lin, P.; Palumbo, G.; Erb, U.; Aust, K.T. Influence of grain boundary character distribution on sensitization and intergranular corrosion of alloy 600. Scr. Met. Mater. 1995, 33, 1387–1392. [Google Scholar] [CrossRef]

- Lehockey, E.M.; Palumbo, G. On the creep behaviour of grain boundary engineered nickel. Mater. Sci. Eng. A 1997, 237, 168–172. [Google Scholar] [CrossRef]

- Watanabe, T. Approach to Grain Boundary Design for Strong and Ductile Polycrystals. Res. Mech. Int. J. Struct. Mech. Mater. Sci. 1984, 11, 47–84. [Google Scholar]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Lehockey, E.M.; Palumbo, G.; Brennenstuhl, A.; Lin, P. Grain boundary engineered lead alloys. Mater. Res. Soc. Symp. Proc. 1997, 458, 243–248. [Google Scholar] [CrossRef]

- Was, G.S.; Thaveeprungsriporn, V.; Crawford, D.C. Grain boundary misorientation effects on creep and cracking in Ni-based alloys. JOM 1998, 50, 44–49. [Google Scholar] [CrossRef]

- Davies, P.; Randle, V.; Watkins, G.; Davies, H. Triple junction distribution profiles as assessed by electron backscatter diffraction. J. Mater. Sci. 2002, 37, 4203–4209. [Google Scholar] [CrossRef]

- Davies, D.; Randle, V. The effect of low strain and annealing cycles on the ductility of alpha-brass. Philos. Mag. A 2001, 81, 2553–2564. [Google Scholar] [CrossRef]

- Randle, V.; Davies, H. Evolution of Microstructure and Properties in Alpha-Brass after Iterative Processing. Metall. Mater. Trans. A 2002, 33, 1853–1857. [Google Scholar] [CrossRef]

- Rohrer, G.S.; Randle, V.; Kim, C.S.; Hu, Y. Changes in the five-parameter grain boundary character distribution in α-brass brought about by iterative thermomechanical processing. Acta Mater. 2006, 54, 4489–4502. [Google Scholar] [CrossRef]

- Pinto, A.L.; Viana, C.S.; Luiz, H.A. Micromechanisms involved in grain boundary engineering of alpha-brass. Mater. Sci. Eng. A 2007, 445–446, 14–19. [Google Scholar] [CrossRef]

- Goehner, R.P.; Michael, J.R. Electron backscatter diffraction: A powerful tool for phase identification in the SEM. Mater. Res. Soc. Symp. Proc. 2001, 589, 39–49. [Google Scholar]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. Binary Alloy Phase Diagrams, 2nd ed.; ASM International: Materials Park, OH, USA, 1990; Volume 2. [Google Scholar]

- Pantazopoulos, G.; Vazdirvanidis, A. Characterization of the Microstructural Aspects of Machinable α-β Phase Brass. Microsc. Anal. 2008, 22, 13–16. [Google Scholar]

- Lee, S.Y.; Chun, Y.B.; Han, J.W.; Hwang, S.K. Effect of thermomechanical processing on grain boundary characteristics in two-phase brass. Mater. Sci. Eng. A 2003, 363, 307–315. [Google Scholar] [CrossRef]

- Vilarinho, C.; Davim, J.P.; Soares, D.; Castro, F.; Barbosa, J. Influence of the chemical composition on the machinability of brasses. J. Mater. Process. Technol. 2005, 170, 441–447. [Google Scholar] [CrossRef] [Green Version]

- Fadhil, A.A.; Ghattas, M.S.; Iskander, B.A.; Ajeel, S.A.; Enab, T.A. Structural characterization and detecting processes of defects in leaded brass alloy used for gas valves production. Alex. Eng. J. 2018, 57, 1301–1311. [Google Scholar] [CrossRef]

- Pantazopoulos, G.; Vazdirvanidis, A. Failure Analysis of a Fractured Leaded-Brass (CuZn39Pb3) Extruded Hexagonal Rod. J. Fail. Anal. Preven. 2008, 8, 218–222. [Google Scholar] [CrossRef]

- Buršíková, V.; Buršík, J.; Navrátil, V.; Milička, K. Creep behaviour of leaded brass. Mater. Sci. Eng. A 2002, 324, 235–238. [Google Scholar] [CrossRef]

- Hussein, R.M.; Abd, O.I. Influence of Al and Ti Additions on Microstructure and Mechanical Properties of Leaded Brass Alloys. Indian J. Mater. Sci. 2014, 2014, 909506. [Google Scholar] [CrossRef] [Green Version]

- Egole, C.P.; Nzebuka, G.C. Effect of Aluminium Addition and Grain Refinement on the Microstructure, Mechanical and Physical Properties of Leaded Brass Alloys. J. Phys. Conf. Ser. 2019, 1378, 022043. [Google Scholar] [CrossRef]

- Mousavia, S.E.; Naghshekesha, N.; Ahmadib, F.; Sadeghic, B.; Cavaliere, P. Effect of lead on the crack propagation and the mechanical properties of Brass processed by ECAP at different temperatures. Mater. Sci. Eng. A 2018, 728, 231–238. [Google Scholar] [CrossRef]

- EN 12164:1998: Copper and Copper Alloys: Rod for Free Machining Purposes; European Committee for Standardization(CEN): Brussels, Belgium, 1998.

- Abramoff, M.D.; Magalhaes, P.J.; Ram, S.J. Image processing with Image. J. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Randle, V.; Coleman, M. A study of low-strain and medium-strain grain boundary engineering. Acta Mater. 2009, 57, 3410–3421. [Google Scholar] [CrossRef]

- Shibayanagi, T.; Takada, K.; Matsumoto, K.; Umakoshi, Y. Effect of Secondary Phase on Grain Growth Process of α/β Dual-Phase CuZn Alloy. Scr. Mater. 1997, 37, 667–672. [Google Scholar] [CrossRef]

- Konkova, T.; Mironov, S.; Korznikov, A.; Korznikova, G.; Myshlyaev, M.M.; Semiatin, S.L. Grain growth during annealing of cryogenically-rolled Cu-30Zn brass. J. Alloys Compd. 2016, 666, 170–177. [Google Scholar] [CrossRef] [Green Version]

- Kurdjumov, G.; Sachs, G. Crystallographic orientation relationship between α-and γ-Fe. Ann Phys. 1930, 64, 325. [Google Scholar]

- Al-Fadhalah, K. Microstructure and Texture Development in Alpha-Brass Using Repetitive Thermomechanical Processing. ASME J. Eng. Mater. Technol. 2018, 140, 021007. [Google Scholar] [CrossRef]

- Garg, R.; Gurao, N.P.; Ranganathan, S.; Suwas, S. Evolution of texture and grain boundary microstructure in two-phase (α + β) brass during recrystallization. Philos. Mag. 2011, 91, 4089–4108. [Google Scholar] [CrossRef]

- Mishin, O.V. Distributions of Grain Boundaries and Triple Junctions in Variously Textured Copper. Scr. Mater. 1998, 38, 423–428. [Google Scholar] [CrossRef]

- Humphreys, J.; Rohrer, G.S.; Rollett, A. Recrystallization and Related Annealing Phenomena, 3rd ed.; Elsevier: London, UK, 2017; pp. 640–641. [Google Scholar]

| Material | Cu | Pb | Sn | Fe | Ni | Al | Zn |

|---|---|---|---|---|---|---|---|

| EN 12164 (CuZn39Pb3/CW614N) | 57–59 | 2.5–3.5 | 0.30 max | 0.30 max | 0.30 max | 0.05 max | Rem |

| Leaded brass | 57.67 | 2.69 | 0.79 | 0.36 | 0.35 | 0.01 | Rem |

| Sample ID. | TMP-1 Scheme | Sample ID. | TMP-2 Scheme |

|---|---|---|---|

| A1 | Initial + 1 cycle (ε = 0.1 + 670 °C/15 min) | B1 | Initial + 1 cycle (ε = 0.1 + 525 °C/15 min) |

| A2 | Initial + 2 cycles (ε = 0.1 + 670 °C/15 min) | B2 | Initial + 2 cycles (ε = 0.1 + 525 °C/15 min) |

| A3 | Initial + 3 cycles (ε = 0.1 + 670 °C/15 min) | B3 | Initial + 3 cycles (ε = 0.1 + 525 °C/15 min) |

| A4 | Initial + 4 cycles (ε = 0.1 + 670 °C/15 min) | B4 | Initial + 4 cycles (ε = 0.1 + 525 °C/15 min) |

| TMP Scheme | Parameter | Initial | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 |

|---|---|---|---|---|---|---|

| TMP-1 | Average particle size (μm) | 2.47 | 2.78 | 3.47 | 3.07 | 3.11 |

| Particle area fraction (%) | 3.11 | 2.30 | 2.36 | 2.23 | 1.71 | |

| TMP-2 | Average particle size (μm) | ------ | 2.55 | 2.51 | 2.75 | 2.89 |

| Particle area fraction (%) | ------ | 2.87 | 2.84 | 2.42 | 2.33 |

| TMP Scheme | Parameter | Initial | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 |

|---|---|---|---|---|---|---|

| TMP-1 | Grain “island” size (μm) | 19.3 | 23.9 | 24.3 | 29.0 | 32.5 |

| Area fraction (%) | 26.9 | 66.6 | 74.2 | 68.9 | 70.1 | |

| TMP-2 | Grain “island” size (μm) | ------ | 25.1 | 26.8 | 24.8 | 29.2 |

| Area fraction (%) | ------ | 35.7 | 35.8 | 34.9 | 35.9 |

| Cycle No. | Grain Size (μm) | Σ3 (%) | Σ9 (%) | Σ27 (%) | Σ3n (%) | Σ3n/HAGBs |

|---|---|---|---|---|---|---|

| Annealed | 3.76 | 58.91 | 3.49 | 1.54 | 63.9 | 0.711 |

| Cycle 1 | 3.49 | 53.00 | 3.63 | 0.87 | 57.5 | 0.685 |

| Cycle 2 | 3.58 | 54.82 | 2.08 | 0.67 | 57.6 | 0.670 |

| Cycle 3 | 3.42 | 54.41 | 2.63 | 1.03 | 58.1 | 0.748 |

| Cycle 4 | 3.91 | 55.11 | 3.02 | 1.69 | 59.8 | 0.801 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Fadhalah, K.J.; Aleem Rafeeq, M.; Thomas, N. Microstructure and Texture Development in Thermomechanically Processed Leaded Brass. Metals 2021, 11, 998. https://doi.org/10.3390/met11070998

Al-Fadhalah KJ, Aleem Rafeeq M, Thomas N. Microstructure and Texture Development in Thermomechanically Processed Leaded Brass. Metals. 2021; 11(7):998. https://doi.org/10.3390/met11070998

Chicago/Turabian StyleAl-Fadhalah, Khaled J., Muhammad Aleem Rafeeq, and Nicky Thomas. 2021. "Microstructure and Texture Development in Thermomechanically Processed Leaded Brass" Metals 11, no. 7: 998. https://doi.org/10.3390/met11070998

APA StyleAl-Fadhalah, K. J., Aleem Rafeeq, M., & Thomas, N. (2021). Microstructure and Texture Development in Thermomechanically Processed Leaded Brass. Metals, 11(7), 998. https://doi.org/10.3390/met11070998