Microstructure Evolution and Recrystallization Temperature Change of Cold-Rolled Fe–19Mn–0.6C Twinning-Induced Plasticity Steel during Annealing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mechanical Testing

2.3. Characterizations

3. Results

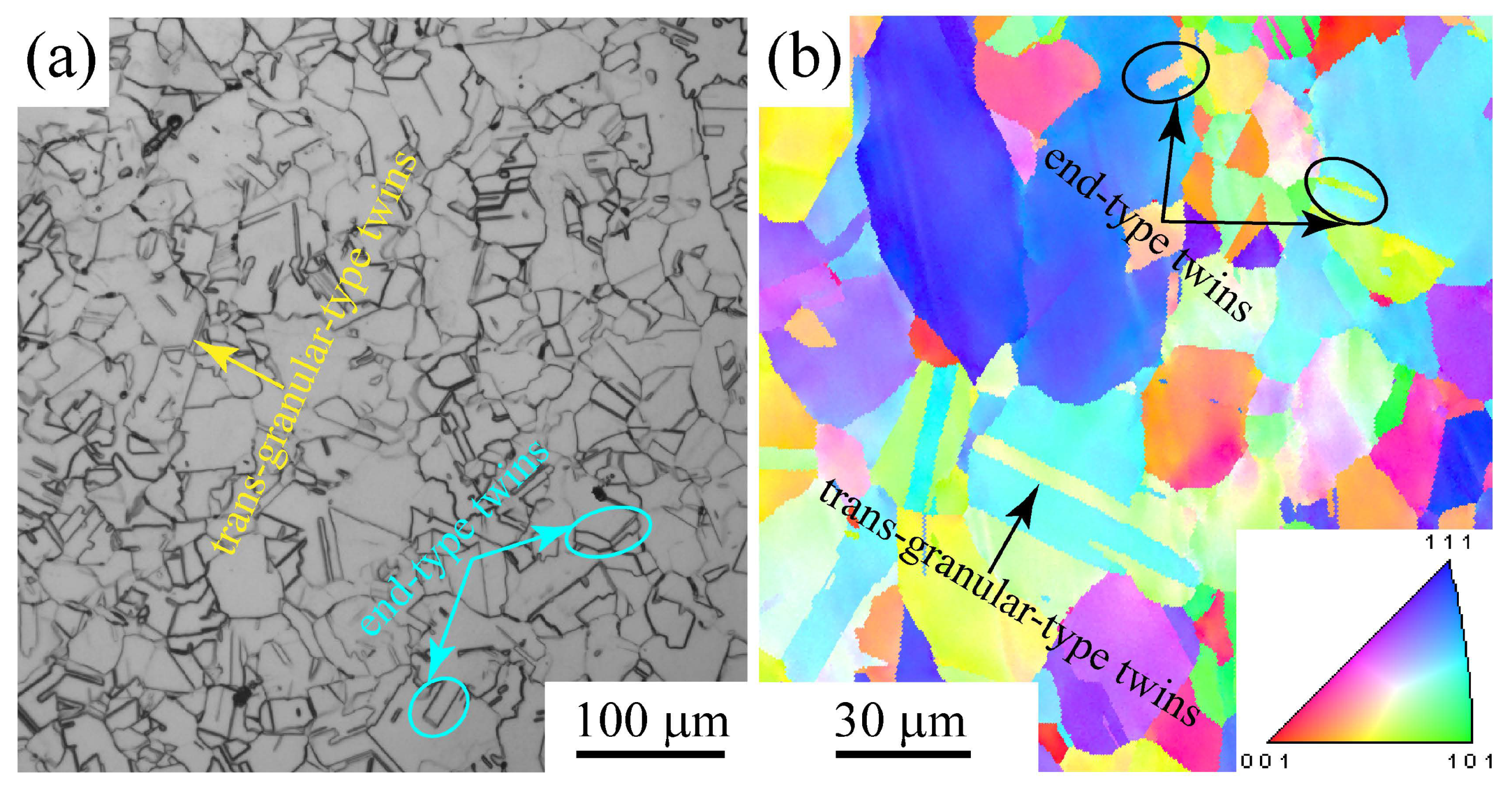

3.1. The Microstructure of Non-CR Fe–19Mn–0.6C TWIP Steel

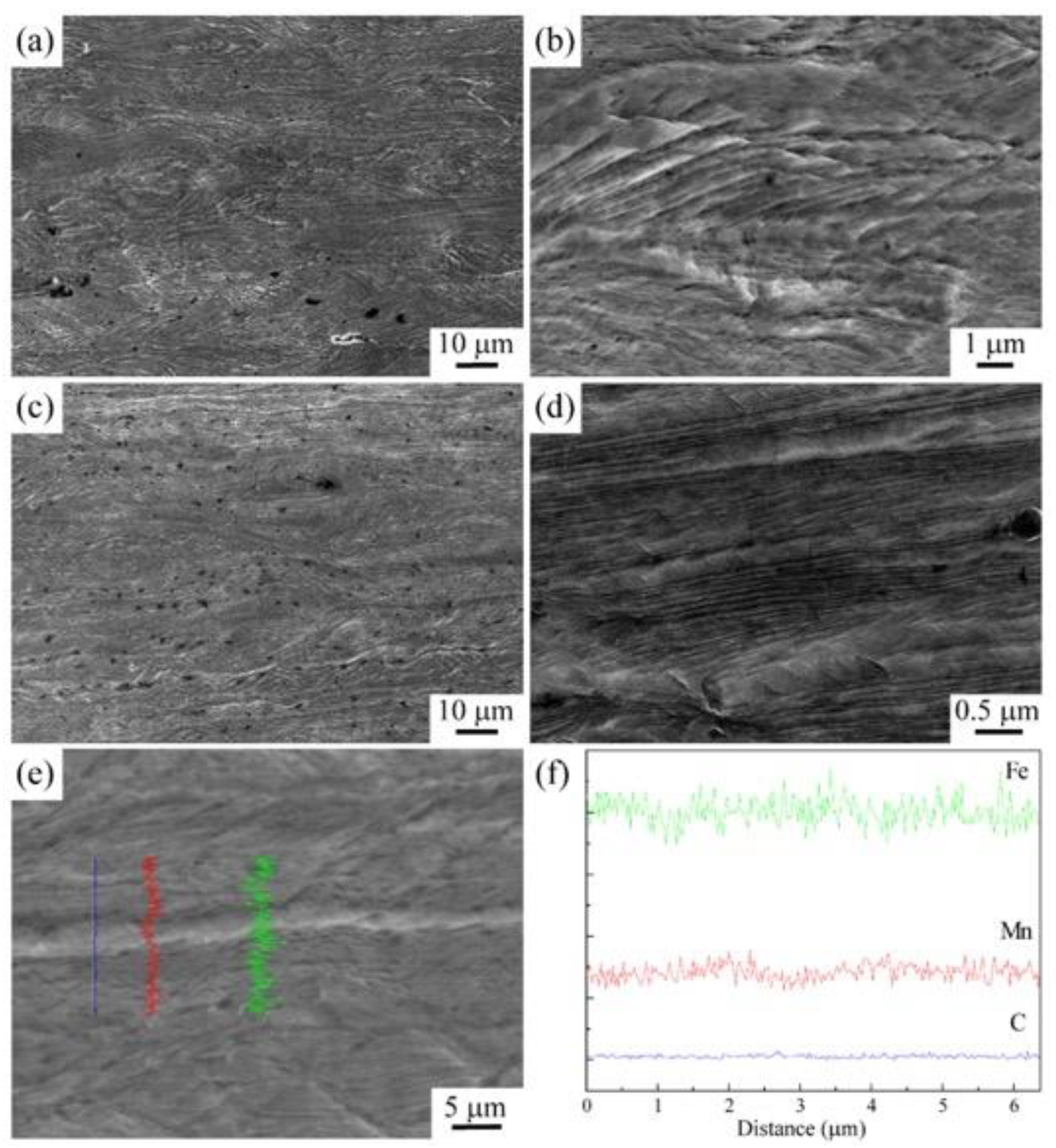

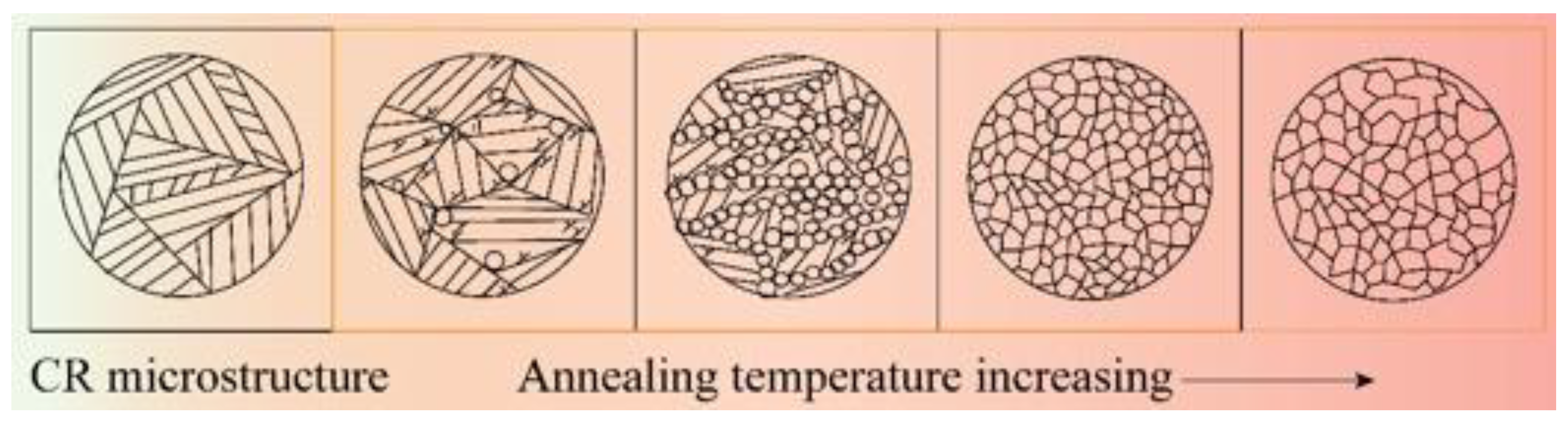

3.2. Microstructural Evolution of CR Fe–19Mn–0.6C TWIP Steel

3.3. Recrystallization Temperature Determination of CR Fe–19Mn–0.6C TWIP Steel

3.3.1. Recrystallization Starting Temperature at Various CR Deformation Levels

3.3.2. Recrystallization Ending Temperature at Various CR Deformation Levels

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, F.; Song, W.; Ma, Y.; Li, C.; Bleck, W.; Wang, G. Recrystallization behavior in a low-density high-Mn high-Al austenitic steel undergone thin strip casting process. Mater. Sci. Eng. A 2018, 733, 87–97. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Kwon, O.; Chin, K.G. State of the knowledge on TWIP steel. Mater. Sci. Technol. 2012, 28, 513–527. [Google Scholar] [CrossRef]

- Dai, Y.J.; Tang, D.; Mi, Z.L.; Lu, J.C. Microstructure characteristics of an Fe-Mn-C TWIP steel after deformation. J. Iron Steel Res. Int. 2010, 17, 53–59. [Google Scholar] [CrossRef]

- Dini, G.; Najafizadeh, A.; Ueji, R.; Monir-Vaghefi, S.M. Tensile deformation behavior of high manganese austenitic steel: The role of grain size. Mater. Des. 2010, 31, 3395–3402. [Google Scholar] [CrossRef]

- Lee, Y.K. Microstructural evolution during plastic deformation of twinning-induced plasticity steels. Scripta Mater. 2012, 66, 1002–1006. [Google Scholar] [CrossRef]

- Lee, J.; Sohn, S.; Hong, S.; Suh, B.C.; Kyu, S. Effects of Mn addition on tensile and charpy impact properties in austenitic Fe-Mn-C-Al-based steels for cryogenic applications. Metall. Mater. Trans. A 2014, 45, 5419–5430. [Google Scholar] [CrossRef] [Green Version]

- Frommeyer, G.; Brux, U.; Neuman, P. Supra-ductile and high-strength manganese-TRIP/TWIP for high energy absorption purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef] [Green Version]

- Sato, K.; Ichinose, M.; Hirotsu, Y.; Inoue, Y. Effects of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe-Mn-AI alloys. ISIJ Int. 1989, 29, 868–877. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng. A 2004, 387, 158–162. [Google Scholar] [CrossRef]

- Dμmaya, A.; Chateau, J.P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an Austenitic Fe-Mn-C steel. Mater. Sci. Eng. A 2008, 483–484, 184–187. [Google Scholar]

- Kim, J.; Lee, S.J.; Cooman, B.C.D. Effect of Al on the stacking fault energy of Fe-18Mn-0.6C twinning-induced plasticity. Scripta Mater. 2011, 65, 363–366. [Google Scholar] [CrossRef]

- Mi, Z.; Tang, D.; Zhao, A.; Jiang, H. Mechanical properties and microstructure evolution during deformation of Fe-Mn-C TWIP steel. Steel Res. Int. 2012, 83, 346–351. [Google Scholar]

- Kusakin, P.; Belyakov, A.; Haase, C.; Kaibyshev, R.; Molodov, D.A. Microstructure evolution and strengthening mechanisms of Fe-23Mn-0.3C-1.5Al TWIP steel during cold rolling. Mater. Sci. Eng. A 2014, 617, 52–60. [Google Scholar] [CrossRef]

- Yang, H.K.; Zhang, Z.J.; Zhang, Z.F. Comparison of work hardening and deformation twinning evolution in Fe-22Mn-0.6C-(1.5Al) twinning-induced plasticity steels. Scripta Mater. 2013, 68, 992–995. [Google Scholar] [CrossRef]

- Dini, G.; Najafizadeh, A.; Ueji, R.; Monir-Vaghefi, S.M. Improved tensile properties of partially recrystallized submicron grained TWIP Steel. Mater. Lett. 2010, 64, 15–18. [Google Scholar] [CrossRef]

- Jin, J.E.; Lee, U.K. Strain hardening behavior of a Fe-18Mn-0.6C-1.5Al TWIP steel. Mater. Sci. Eng. A 2009, 527, 157–161. [Google Scholar] [CrossRef]

- Yuan, G.W.; Huang, M.X. Supper strong nanostructured TWIP steels for automotive applications. Prog. Nat. Sci. Mater. 2014, 24, 50–55. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.; Li, R.H.; Kádas, K.; Zhang, H.; Tian, Y.; Kwon, S.K.; Kokko, K.; Hu, Q.M.; Hertzman, S.; Vitos, L. Stacking fault energy of C-alloyed steels: The effect of magnetism. Acta Mater. 2017, 122, 72–81. [Google Scholar] [CrossRef]

- Marandi, A.; Zarei-Hanzaki, R.; Zarei-Hanzaki, A.; Abedi, R.H. Dynamic recrystallization behavior of new transformation-twinning induced plasticity steel. Mater. Sci. Eng. A 2014, 607, 397–408. [Google Scholar] [CrossRef]

- Salas-Reyes, A.E.; Mejía, I.; Bedolla-Jacuinde, A.; Boulaajaj, A.; Calvo, J.; Cabrera, J.M. Hot ductility behavior of high-Mn austenitic Fe-22Mn-1.5Al-1.5Si-0.45C TWIP steels microalloyed with Ti and V. Mater. Sci. Eng. A 2014, 611, 77–89. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P. Hot ductility behaviour of high-Mn TWIP Steels. Mater. Sci. Eng. A 2011, 528, 1819–1827. [Google Scholar] [CrossRef]

- Mi, Z.L.; Tang, D.; Dai, Y.J.; Huang, H.Q.; Li, S.S. Influence of cold rolling reduction on microstructure and mechanical proprerties of TWIP steel. Acta Mater. 2007, 20, 441–447. [Google Scholar]

- Ueji, R.; Tsuchida, N.; Terada, D.; Tsuji, N.; Tanaka, Y.; Takemura, A.; Kunishige, K. Tensile properties and twinning behavior of high manganese austenitic steel with fine-grained structure. Scripta Mater. 2008, 59, 963–966. [Google Scholar] [CrossRef]

- Bouaziz, O.; Scott, C.P.; Petitgand, G. Nanostructured steel with high work-hardening by the exploitation of the thermal stability of mechanically induced twin. Scripta Mater. 2009, 60, 714–716. [Google Scholar] [CrossRef]

- Ding, H.; Ding, H.; Song, D.; Tang, Z.; Ping, Y. Strain hardening behavior of a TRIP/TWIP Steel with 18.8% Mn. Mater. Sci. Eng. A 2011, 528, 868–873. [Google Scholar] [CrossRef]

- Kim, J.K.; Kwon, M.H.; Cooman, B.C.D. On the deformation twinning mechanisms in twinning-induced plasticity steel. Acta Mater. 2017, 141, 444–555. [Google Scholar] [CrossRef]

- Fabrèguea, D.; Bouaziz, O.; Barbier, D. Nano-twinned steel exhibits high mechanical properties obtained through ultra-rapid heat treatment. Mater. Sci. Eng. A 2018, 712, 765–771. [Google Scholar] [CrossRef]

- Yang, H.K.; Tian, Y.Z.; Zhang, Z.F. Revealing the mechanical properties and microstructure evolutions of Fe-22Mn-0.6C-(x)Al TWIP steels via Al alloying control. Mater. Sci. Eng. A 2018, 731, 61–70. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Y. Dislocation and hardness of hard coatings. Thin Solid Films 1992, 214, 4–5. [Google Scholar] [CrossRef]

- Mittemeijer, E.J. Recovery, recrystallization and grain growth. Fundam. Mater. Sci. 2011, 463–496. [Google Scholar]

- Yanushkevich, Z.; Belyakov, A.; Kaibyshev, R.; Haase, C.; Molodov, D.A. Effect of cold rolling on recrystallization and tensile behavior of a high-Mn steel. Mater. Charact. 2016, 112, 180–187. [Google Scholar] [CrossRef]

- Kalinenko, A.; Kusakin, P.; Belyakov, A.; Kaibyshev, R.; Molodov, D. Microstructure and mechanical properties of a high-Mn TWIP steel subjected to cold rolling and annealing. Metals 2017, 7, 571. [Google Scholar] [CrossRef] [Green Version]

- Haase, C.; Kühbach, M.; Barrales-Mora, L.A.; Wong, S.L.; Roters, F.; Molodov, D.A.; Gottstein, G. Recrystallization behavior of a high-manganese steel: Experiments and simulations. Acta Mater. 2015, 100, 155–168. [Google Scholar] [CrossRef]

- Rahman, K.M.; Jones, N.G.; Dye, D. Micromechanics of twinning in a TWIP steel. Mater. Sci. Eng. A 2015, 35, 133–142. [Google Scholar] [CrossRef] [Green Version]

| C | Mn | Si | S | Cu | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|

| 0.590 | 19.120 | 0.124 | 0.012 | 0.025 | 0.019 | 0.006 | Bal. |

| CR Deformation (%) | RST (°C) | RET (°C) |

|---|---|---|

| 25 | 500–525 | 580–600 |

| 50 | 400–425 | 530–550 |

| 75 | 400–415 | 520–540 |

| 88 | 400–410 | 500–520 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, H.; Yuan, H.; Guo, K.; Zhang, Z.; Zhang, M. Microstructure Evolution and Recrystallization Temperature Change of Cold-Rolled Fe–19Mn–0.6C Twinning-Induced Plasticity Steel during Annealing. Metals 2021, 11, 1181. https://doi.org/10.3390/met11081181

Xue H, Yuan H, Guo K, Zhang Z, Zhang M. Microstructure Evolution and Recrystallization Temperature Change of Cold-Rolled Fe–19Mn–0.6C Twinning-Induced Plasticity Steel during Annealing. Metals. 2021; 11(8):1181. https://doi.org/10.3390/met11081181

Chicago/Turabian StyleXue, Hui, Hui Yuan, Kai Guo, Zhijia Zhang, and Mengmeng Zhang. 2021. "Microstructure Evolution and Recrystallization Temperature Change of Cold-Rolled Fe–19Mn–0.6C Twinning-Induced Plasticity Steel during Annealing" Metals 11, no. 8: 1181. https://doi.org/10.3390/met11081181

APA StyleXue, H., Yuan, H., Guo, K., Zhang, Z., & Zhang, M. (2021). Microstructure Evolution and Recrystallization Temperature Change of Cold-Rolled Fe–19Mn–0.6C Twinning-Induced Plasticity Steel during Annealing. Metals, 11(8), 1181. https://doi.org/10.3390/met11081181