Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy

Abstract

:1. Introduction

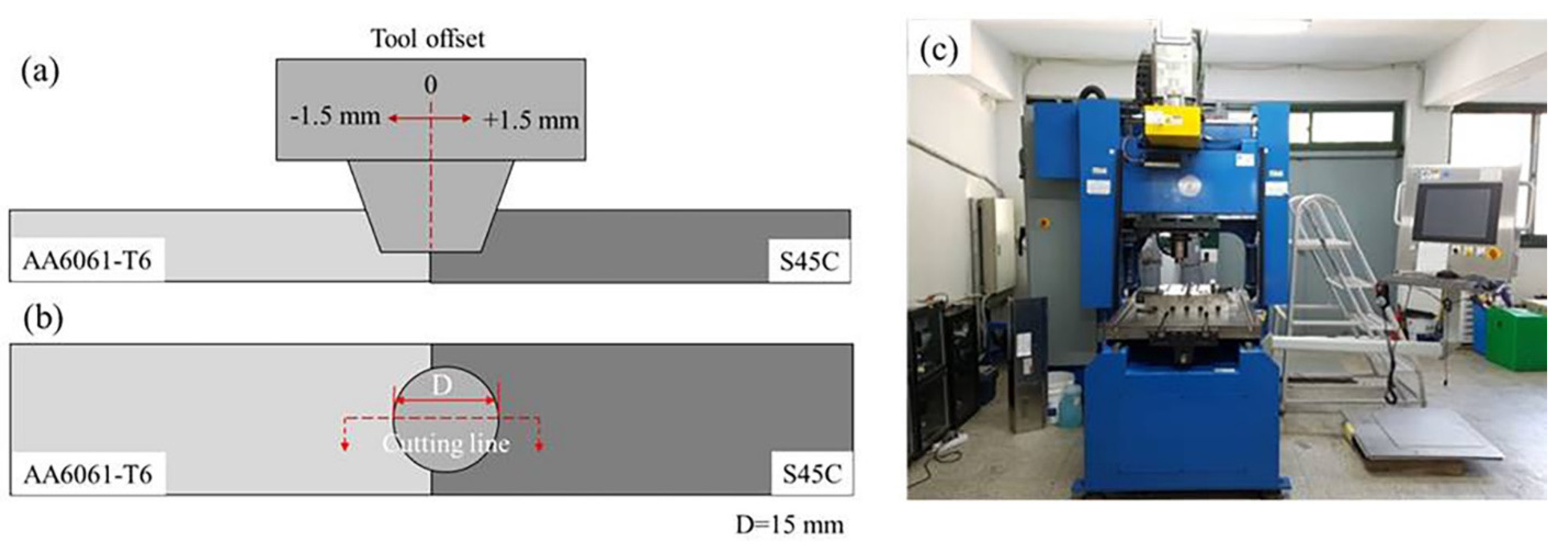

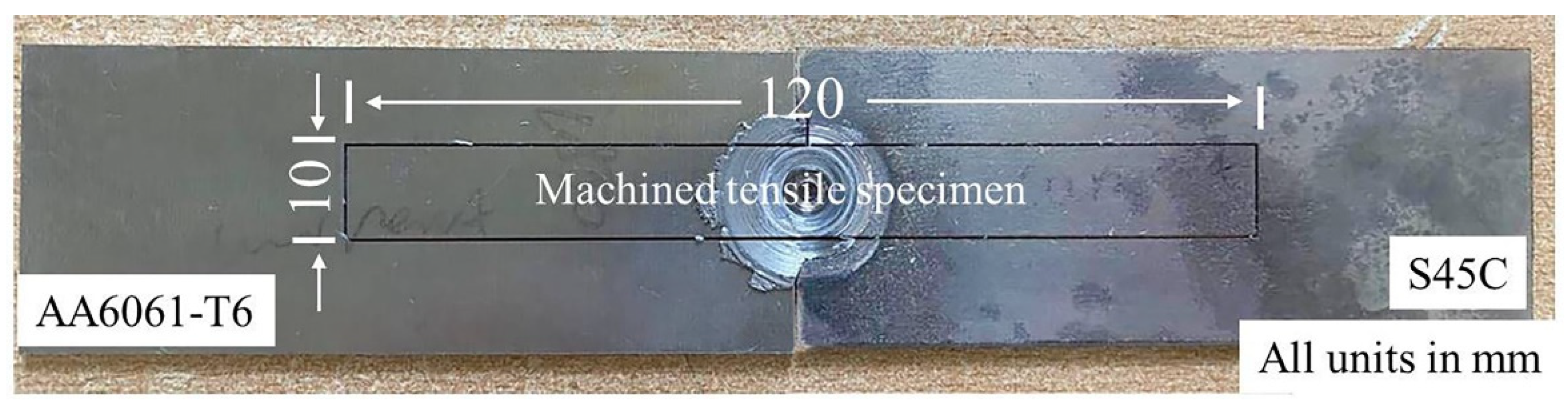

2. Experimental Set-Up

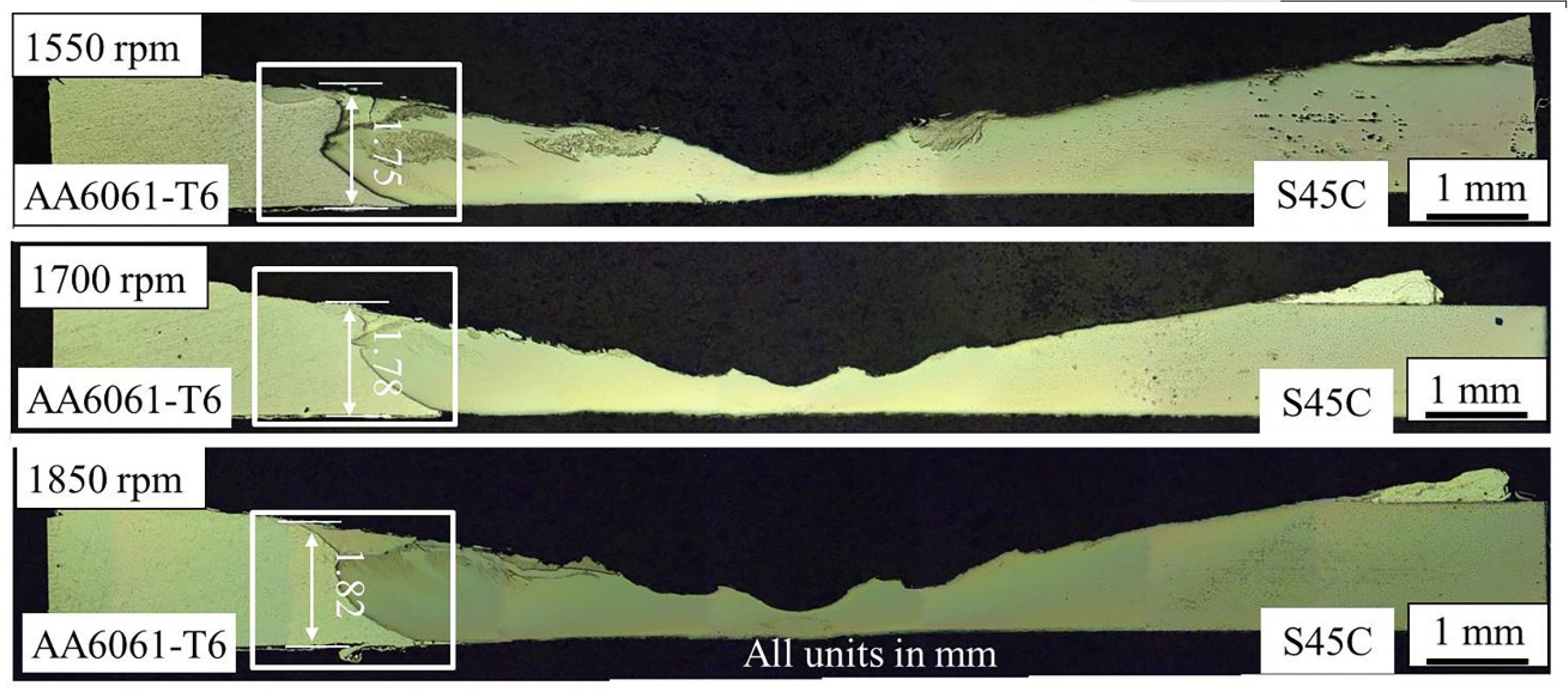

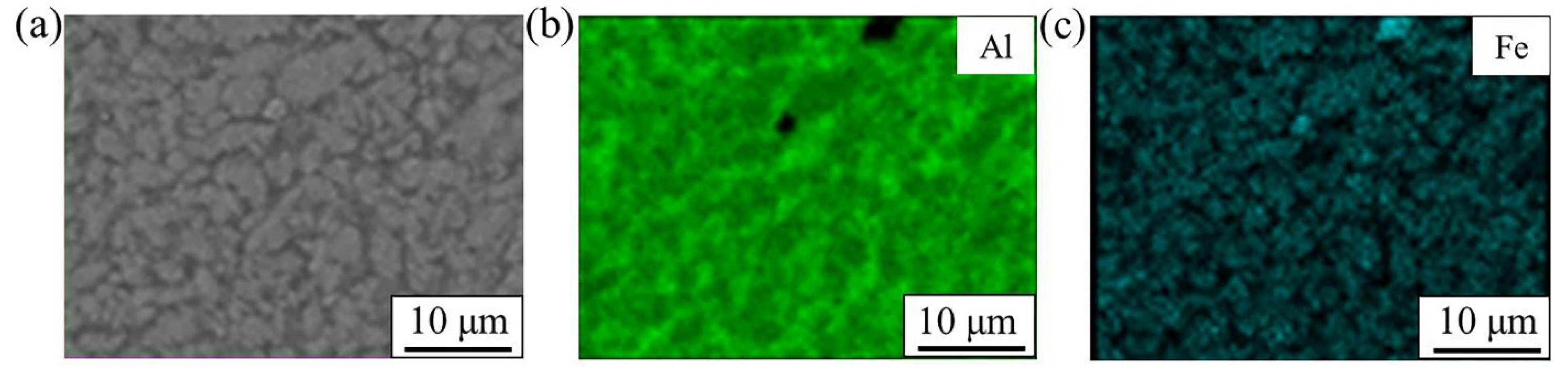

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cole, G.S.; Sherman, A.M. Light weight materials for automotive applications. Mater. Charact. 1995, 35, 3–9. [Google Scholar] [CrossRef]

- Schubert, E.; Klassen, M.; Zerner, I.; Walz, C.; Sepold, G. Light-weight structures produced by laser beam joining for future applications in automobile and aerospace industry. J. Mater. Process. Technol. 2001, 115, 2–8. [Google Scholar] [CrossRef]

- Hussein, S.A.; Tahir, A.S.M.; Hadzley, A.B. Characteristics of Aluminum-to-Steel Joint Made by Friction Stir Welding: A review. Mater. Today Commun. 2015, 5, 32–49. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.H.; Ni, J. Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater. Des. 2014, 59, 50–62. [Google Scholar] [CrossRef]

- Qiu, R.; Shi, H.; Zhang, K.; Tu, Y.; Iwamoto, C.; Satonaka, S. Interfacial characterization of joint between mild steel and aluminum alloy welded by resistance spot welding. Mater. Charact. 2010, 61, 684–688. [Google Scholar] [CrossRef]

- Lin, S.B.; Song, J.L.; Ma, G.C.; Yang, C.L. Dissimilar metals TIG welding-brazing of aluminium alloy to galvanized steel. Front. Mater. Sci. China 2009, 3, 78–83. [Google Scholar] [CrossRef]

- Chen, H.C.; Pinkerton, A.J.; Li, L.; Liu, Z.; Mistry, A.T. Gap-free fibre laser welding of Zn-coated steel on Al alloy for light-weight automotive applications. Mater. Des. 2011, 32, 495–504. [Google Scholar] [CrossRef]

- Peyre, P.; Sierra, G.; Deschaux-Beaume, F.; Stuart, D.; Fras, G. Generation of aluminium-steel joints with laser-induced reactive wetting. Mater. Sci. Eng. A 2007, 444, 327–338. [Google Scholar] [CrossRef]

- Mathieu, A.; Shabadi, R.; Deschamps, A.; Suery, M.; Mattei, S.; Grevey, D.; Cicala, E. Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire). Opt. Laser Technol. 2007, 39, 652–661. [Google Scholar] [CrossRef]

- Arghavani, M.R.; Movahedi, M.; Kokabi, A.H. Role of zinc layer in resistance spot welding of aluminium to steel. Mater. Des. 2016, 102, 106–114. [Google Scholar] [CrossRef]

- Chen, N.; Wang, H.P.; Carlson, B.E.; Sigler, D.R.; Wang, M. Fracture mechanisms of Al/steel resistance spot welds in lap shear test. J. Mater. Process Technol. 2017, 243, 347–354. [Google Scholar] [CrossRef]

- Miyamoto, K.; Nakagawa, S.; Sugi, C.; Sakurai, H.; Hirose, A. Dissimilar joining of aluminum alloy and steel by resistance spot welding. SAE Int. J. Mater. Manuf. 2009, 2, 58–67. [Google Scholar] [CrossRef]

- Mustafa, A.; Bilge, D. An investigation of mechanical and metallurgical properties of explosive welded aluminum-dual phase steel. Mater. Lett. 2008, 62, 4158–4160. [Google Scholar]

- Xue, J.Y.; Li, Y.X.; Chen, H.; Zhu, Z.T. Wettability, microstructure and properties of 6061 aluminum alloy/304 stainless steel butt joint achieved by laser-metal inert-gas hybrid welding-brazing. Trans. Nonferrous Met. Soc. China 2018, 28, 1938–1946. [Google Scholar] [CrossRef]

- Meshram, S.D.; Mohandas, T.; Reddy, G.M. Friction welding of dissimilar pure metals. J. Mater. Process. Technol. 2007, 184, 330–337. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, K.; Hong, S.-T.; Ahn, H.; Choi, Y.; Lee, S.; Han, H.N. Electrically assisted solid state lap joining of dissimilar steel S45C and aluminum 6061-T6 alloy. J. Mater. Res. Technol. 2021, 12, 271–282. [Google Scholar] [CrossRef]

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1193. [Google Scholar] [CrossRef]

- Jiang, H.; Liao, Y.; Gao, S.; Li, G.; Cui, J. Comparative study on joining quality of electromagnetic driven self-piecing riveting, adhesive and hybrid joints for Al/steel structure. Thin-Walled Struct. 2021, 164, 107903. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB92/02203 and GB Patent Application No. 9125978.8, 6 December 1991. [Google Scholar]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction stir welding tools. Sci. Technol. Weld Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.X. Friction stir welding of dissimilar aluminum alloys and steels: A review. Int. J. Adv. Manuf. Technol. 2018, 99, 1781–1811. [Google Scholar]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Lap Joint of A5083 aluminum alloy and SS400 steel by friction stir welding. Mater. Trans. 2005, 46, 835–841. [Google Scholar] [CrossRef] [Green Version]

- Fereiduni, E.; Movahedi, M.; Kokabi, A.H. Aluminum/steel joints made by an alternative friction stir spot welding process. J. Mater. Process. Technol. 2015, 224, 1–10. [Google Scholar] [CrossRef]

- Coelho, R.S.; Kostka, A.; Dos Santos, J.F.; Kaysser-Pyzalla, A. Friction-stir dissimilar welding of aluminum alloy to high strength steels: Mechanical properties and their relation to microstructure. Mater. Sci. Eng. A 2012, 556, 175–183. [Google Scholar] [CrossRef]

- Bozzi, S.; Helbert-Etter, A.L.; Baudin, T.; Criqui, B.; Kerbiguet, J.G. Intermetallic compounds in Al 6016/IF-steel friction stir spot welds. Mater. Sci. Eng. A 2010, 527, 4505–4509. [Google Scholar] [CrossRef]

- Pourali, M.; Abdollah-zadeh, A.; Saeid, T.; Kargar, F. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J. Alloys Compd. 2017, 715, 1–8. [Google Scholar] [CrossRef]

- Kaushik, P.; Dwivedi, D.K. Effect of tool geometry in dissimilar Al-steel friction stir welding. J. Manuf. Process. 2021, 68, 198–208. [Google Scholar] [CrossRef]

- Jeon, C.S.; Hong, S.-T.; Kwon, Y.J.; Cho, H.H.; Han, H.N. Material properties of friction stir spot welded joints of dissimilar aluminum alloys. Trans. Nonferrous Met. Soc. China. 2012, 22, s605–s613. [Google Scholar] [CrossRef]

- Yuan, W.; Mishra, R.S.; Webb, S.; Chen, Y.L.; Carlson, B.; Herling, D.R.; Grant, G.J. Effect of tool design and process parameters on properties of Al alloy 6016 friction stir spot welds. J. Mater. Process. Technol. 2011, 211, 972–977. [Google Scholar] [CrossRef]

- Zandsalimi, S.; Heidarzadeh, A.; Saeid, T. Dissimilar friction-stir welding of 430 stainless steel and 6061 aluminum alloy: Microstructure and mechanical properties of the joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1791–1801. [Google Scholar] [CrossRef]

- Sina, H.; Corneliusson, J.; Turba, K.; Iyengar, S. A study on the formation of iron aluminide (FeAl) from elemental powders. J. Alloys Compds. 2015, 636, 261–269. [Google Scholar] [CrossRef]

- Sundman, B.; Ohnuma, I.; Dupin, N.; Kattner, U.R.; Fries, S.G. An assessment of the entire Al-Fe system including D03 ordering. Acta Mater. 2009, 57, 2896–2908. [Google Scholar] [CrossRef]

- Chmielewski, T.; Marcin Chmielewski, O.; Piątkowska, A.; Grabias, A.; Beata Skowrońska, O.; Siwek, P. Phase Structure Evolution of the Fe-Al Arc-Sprayed Coating Stimulated by Annealing. Materials 2021, 14, 3210. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, T.; Nezu, M.; Uchida, S.; Hirata, T. Mechanism of intermetallic compound formation during the dissimilar friction stir welding of aluminum and steel. J. Mater. Sci. 2020, 55, 3064–3072. [Google Scholar] [CrossRef]

- Tanaka, T.; Hirata, T.; Shinomiya, N.; Shirakawa, N. Analysis of material flow in the sheet forming of friction-stir welds on alloys of mild steel and aluminum. J. Mater. Process. Technol. 2015, 226, 115–124. [Google Scholar] [CrossRef]

| Chemical Composition (wt%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials | C | P | S | Al | Si | Mn | Fe | Mg | Cu | Cr | Zn | ||

| S45C | 0.04 | 0.01 | 0.003 | 0.02 | 0.002 | 0.15 | Bal. | - | - | - | - | ||

| AA6061-T6 | - | - | - | Bal. | 0.6 | 0.11 | 0.4 | 0.9 | 0.23 | 0.17 | 0.04 | ||

| Mechanical properties | |||||||||||||

| Materials | Yield stress (MPa) | Tensile strength (MPa) | Elongation at fracture (%) | ||||||||||

| S45C | 343 | 569 | 16 | ||||||||||

| AA6061-T6 | 276 | 310 | 17 | ||||||||||

| Tool Geometry | Dimension |

|---|---|

| Shoulder diameter (mm) | 14.3 mm |

| Pin height (mm) | 0.6 mm |

| Pin diameter (mm) | 2.0 mm |

| Shoulder type | Convex scrolled shoulder |

| No. | Penetration Depth (mm) | Dwell Time (s) | Temperature Condition (°C) | Tool Plunging Rate (mm/min) | Tool Offset | Rotational Speed (rpm) |

|---|---|---|---|---|---|---|

| 1 | 1.7 | 3 | Room temperature (~25) | 10 | −1.5 mm | 1400 |

| 2 | 1550 | |||||

| 3 | 1700 | |||||

| 4 | 0 | 1400 | ||||

| 5 | 1550 | |||||

| 6 | 1700 | |||||

| 7 | +1.5 mm | 1400 | ||||

| 8 | 1550 | |||||

| 9 | 1700 | |||||

| 10 | 1850 |

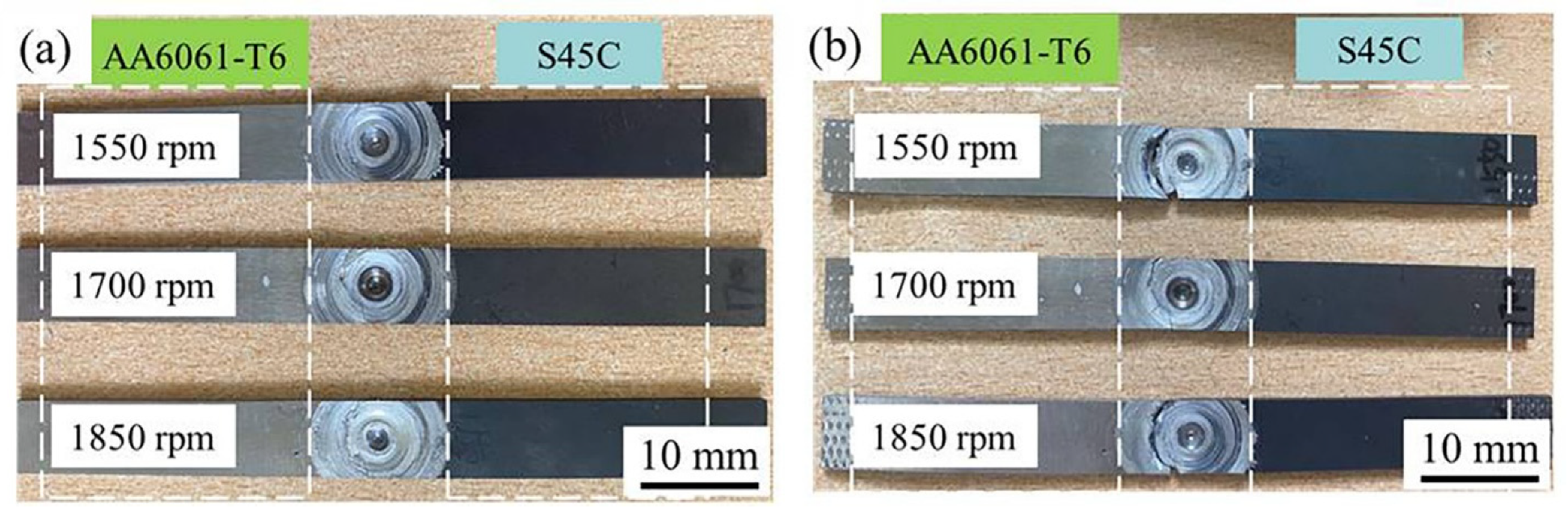

| No. | Tool Offset | Tool Rotational Speed (rpm) | Weld Quality |

|---|---|---|---|

| 1 | 1.5 mm toward Al side | 1400 | Defective and melted |

| 2 | 1550 | Melted | |

| 3 | 1700 | Melted | |

| 4 | 0 | 1400 | Defective and melted |

| 5 | 1550 | Defective and melted | |

| 6 | 1700 | Melted | |

| 7 | +1.5 mm toward steel side | 1400 | Defective |

| 8 | 1550 | Good | |

| 9 | 1700 | Good | |

| 10 | 1850 | Good |

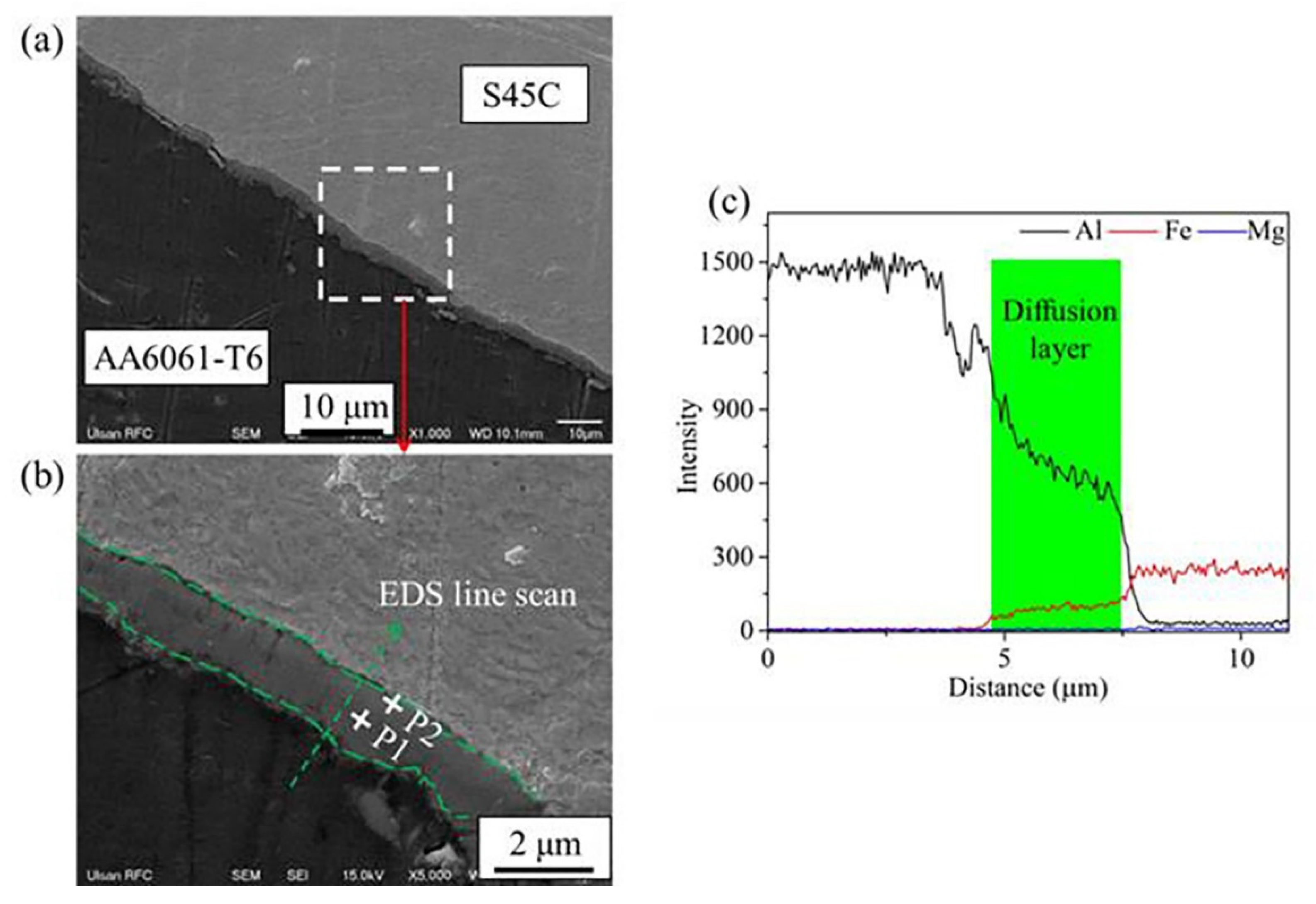

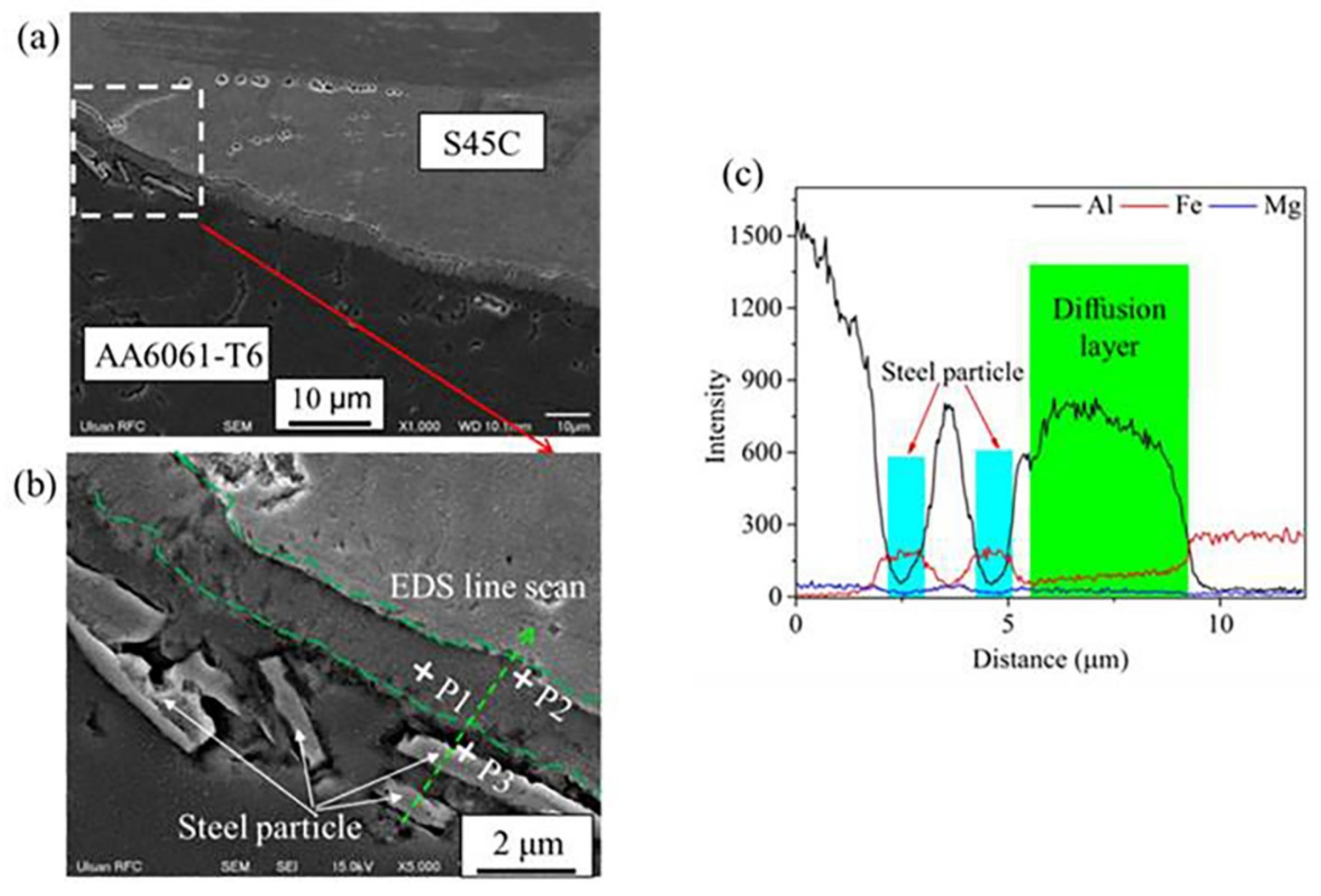

| Tool Rotational Speed (rpm) | Location | Composition (at.%) | Possible Phases | IMC Layer Thickness (μm) * | ||

|---|---|---|---|---|---|---|

| Al | Fe | Al/Fe Ratio | ||||

| 1550 | P1 | 74.46 | 25.54 | 3.11 | FeAl3 | 2.7 (± 0.8) |

| P2 | 69.68 | 29.46 | 2.36 | Fe2Al5 | ||

| 1700 | P1 | 72.75 | 27.25 | 2.70 | FeAl3 | 3.3 (± 1.0) |

| P2 | 50.28 | 49.72 | ~1 | FeAl | ||

| P3 | 48.43 | 51.57 | ~1 | FeAl | ||

| 1850 | P1 | 72.90 | 27.10 | 2.70 | FeAl3 | 4.1 (± 1.1) |

| P2 | 49.75 | 50.25 | ~1 | FeAl | ||

| P3 | 46.25 | 53.75 | ~1 | FeAl | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, K.; Zhang, S.; Mondal, M.; Basak, S.; Hong, S.-T.; Shim, H. Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy. Metals 2021, 11, 1252. https://doi.org/10.3390/met11081252

Gao K, Zhang S, Mondal M, Basak S, Hong S-T, Shim H. Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy. Metals. 2021; 11(8):1252. https://doi.org/10.3390/met11081252

Chicago/Turabian StyleGao, Kun, Shengwei Zhang, Mounarik Mondal, Soumyabrata Basak, Sung-Tae Hong, and Heechan Shim. 2021. "Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy" Metals 11, no. 8: 1252. https://doi.org/10.3390/met11081252

APA StyleGao, K., Zhang, S., Mondal, M., Basak, S., Hong, S.-T., & Shim, H. (2021). Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy. Metals, 11(8), 1252. https://doi.org/10.3390/met11081252