Effect of V Addition on Microstructure and Mechanical Properties in C–Mn–Si Steels after Quenching and Partitioning Processes

Abstract

:1. Introduction

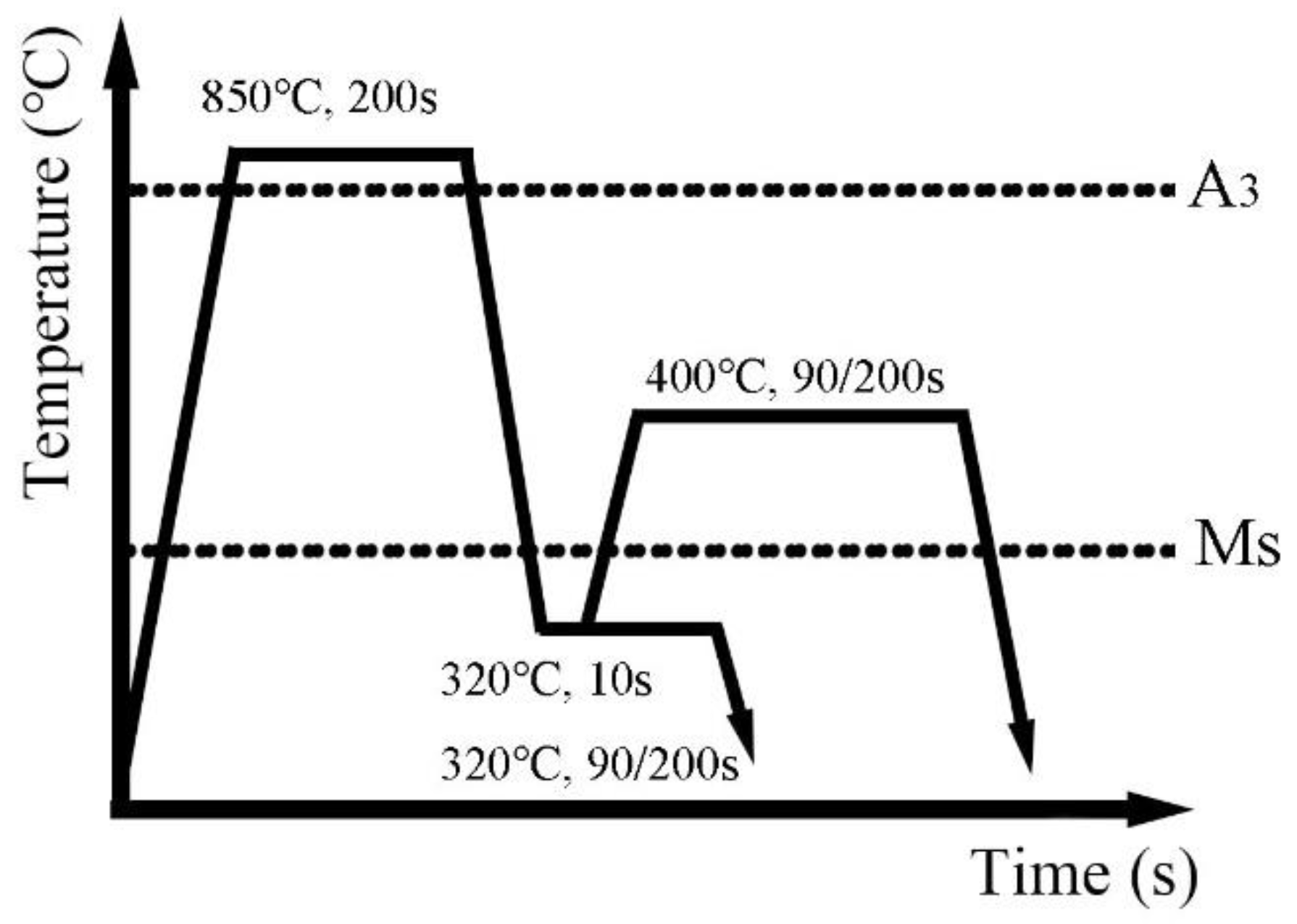

2. Experimental Procedure

3. Results

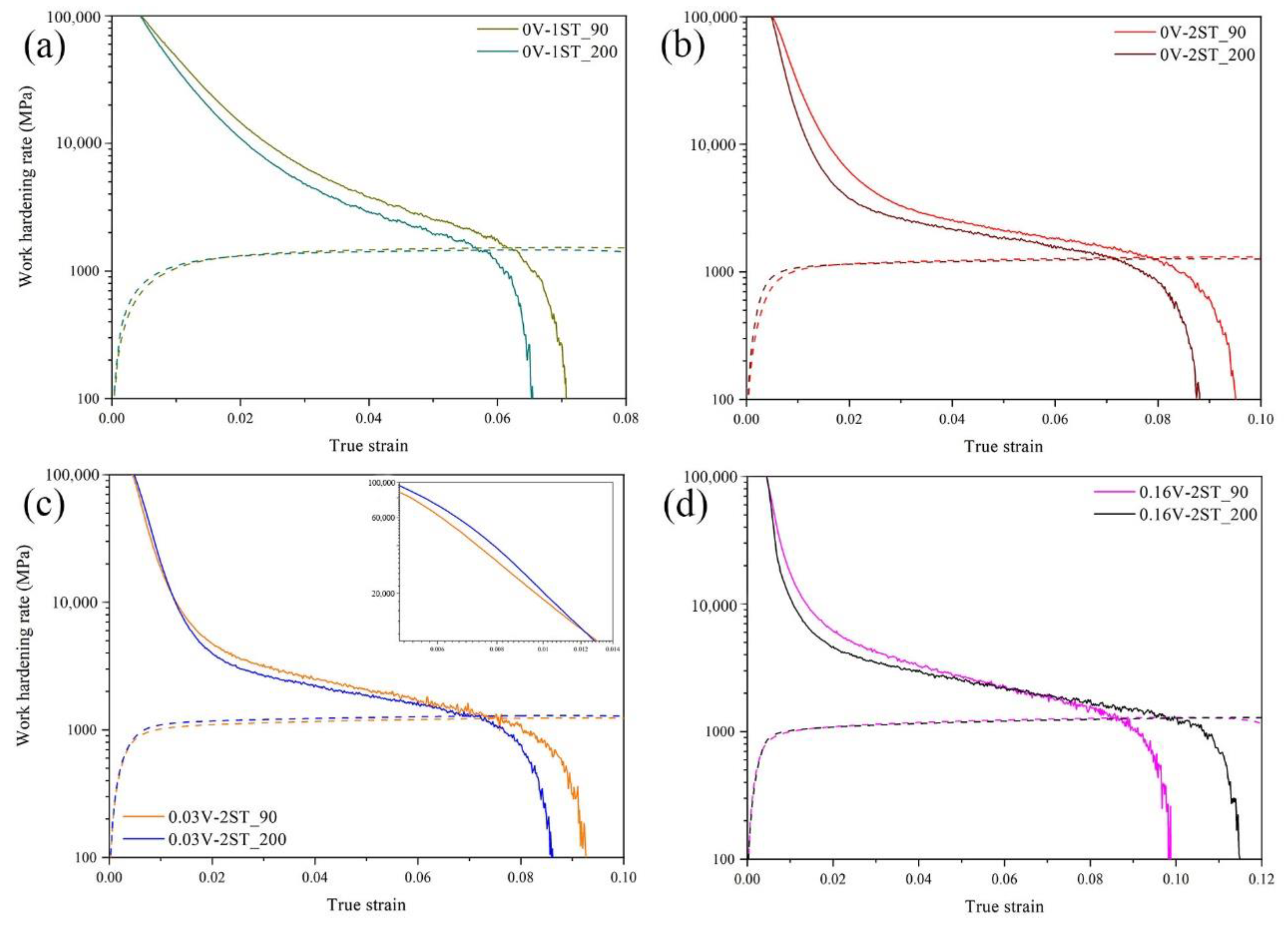

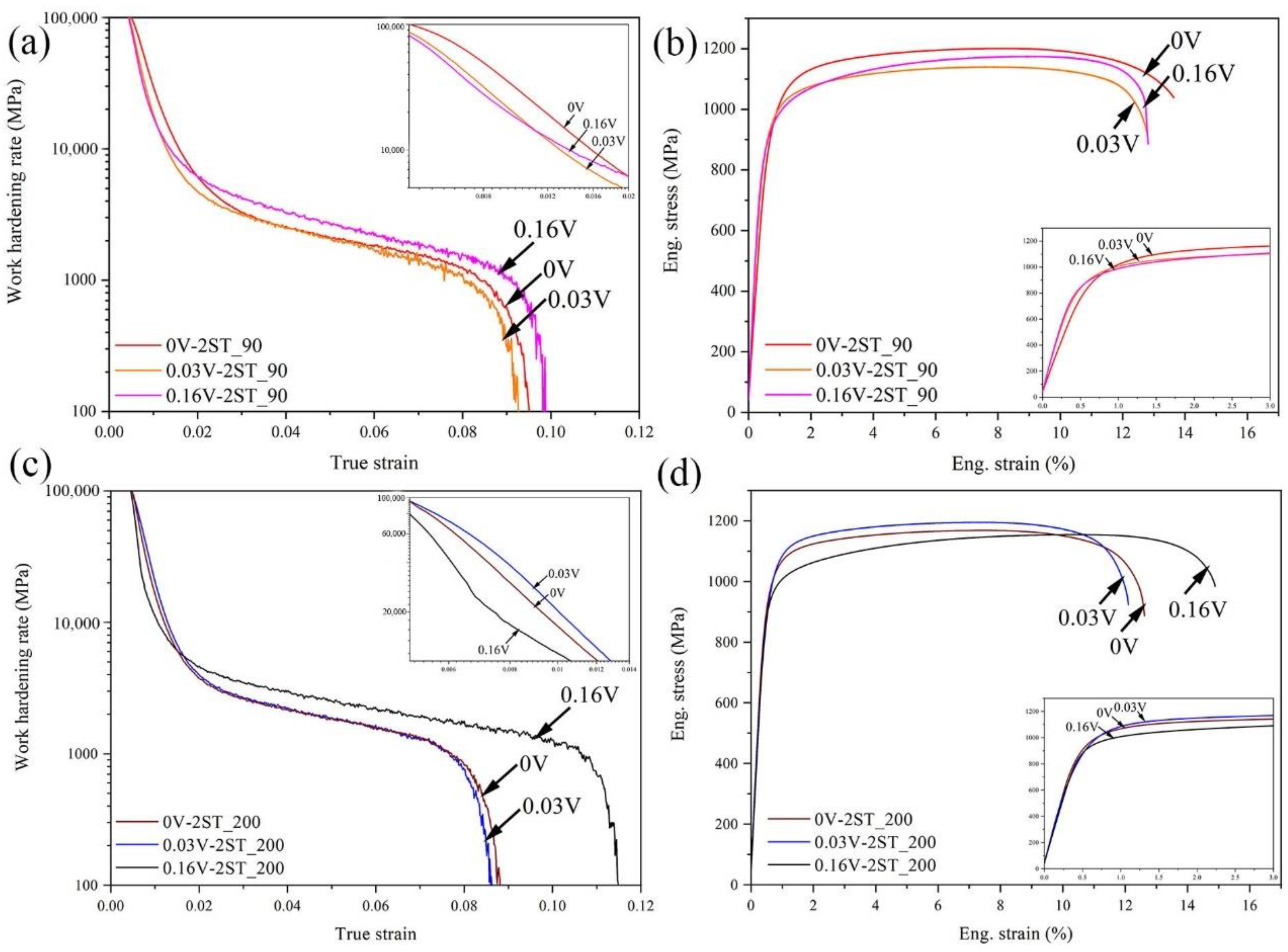

3.1. Mechanical Properties

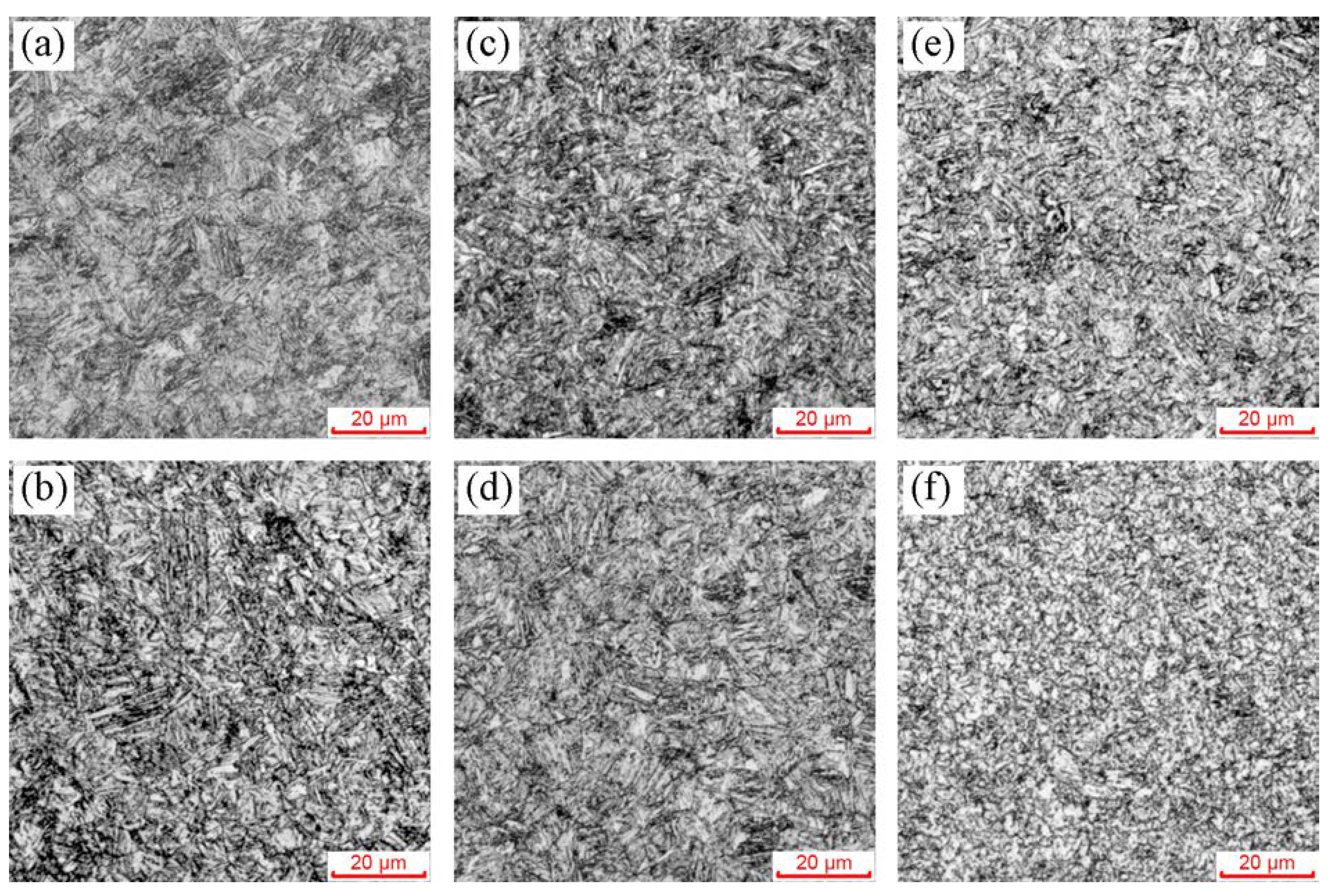

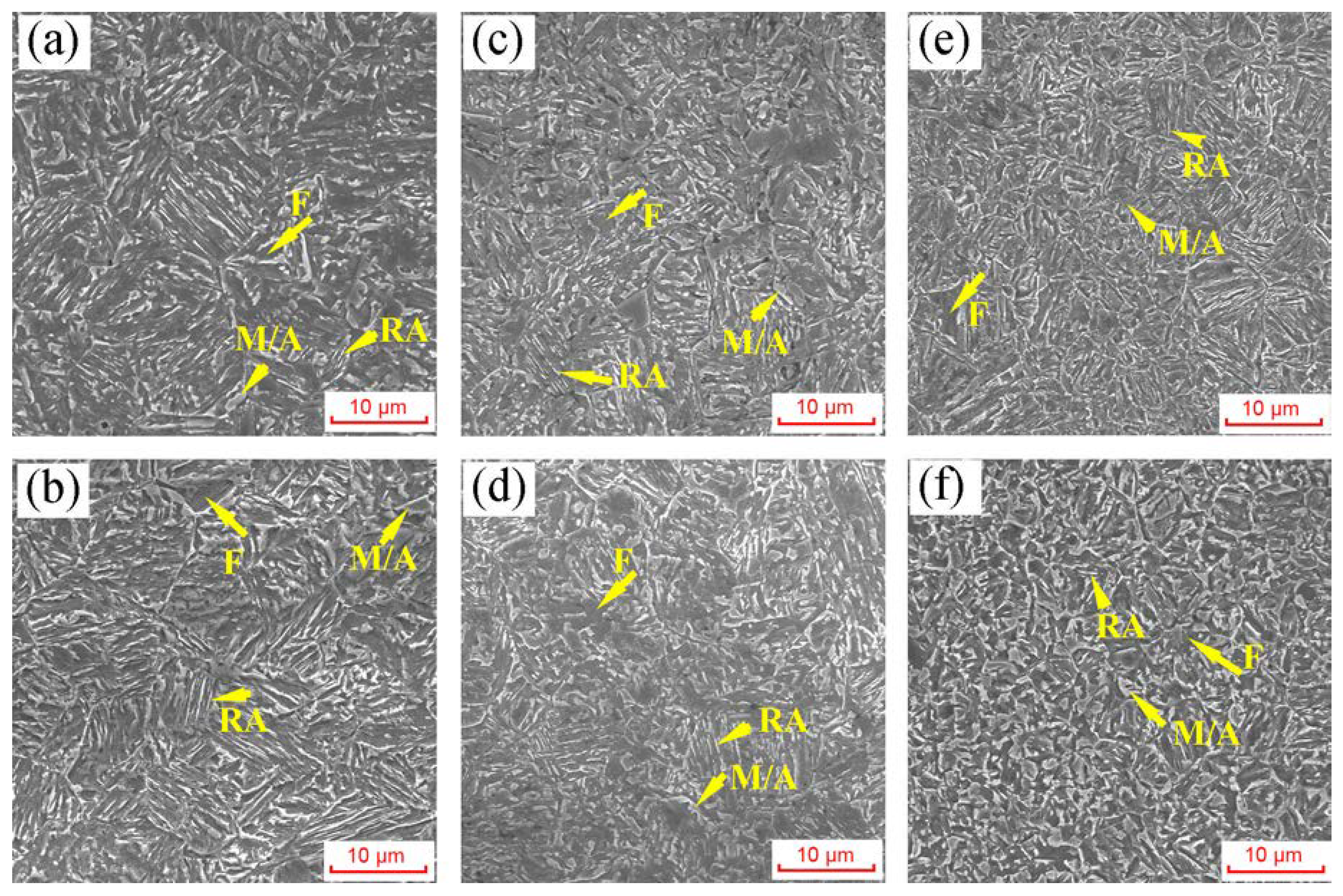

3.2. Microstructure Observation

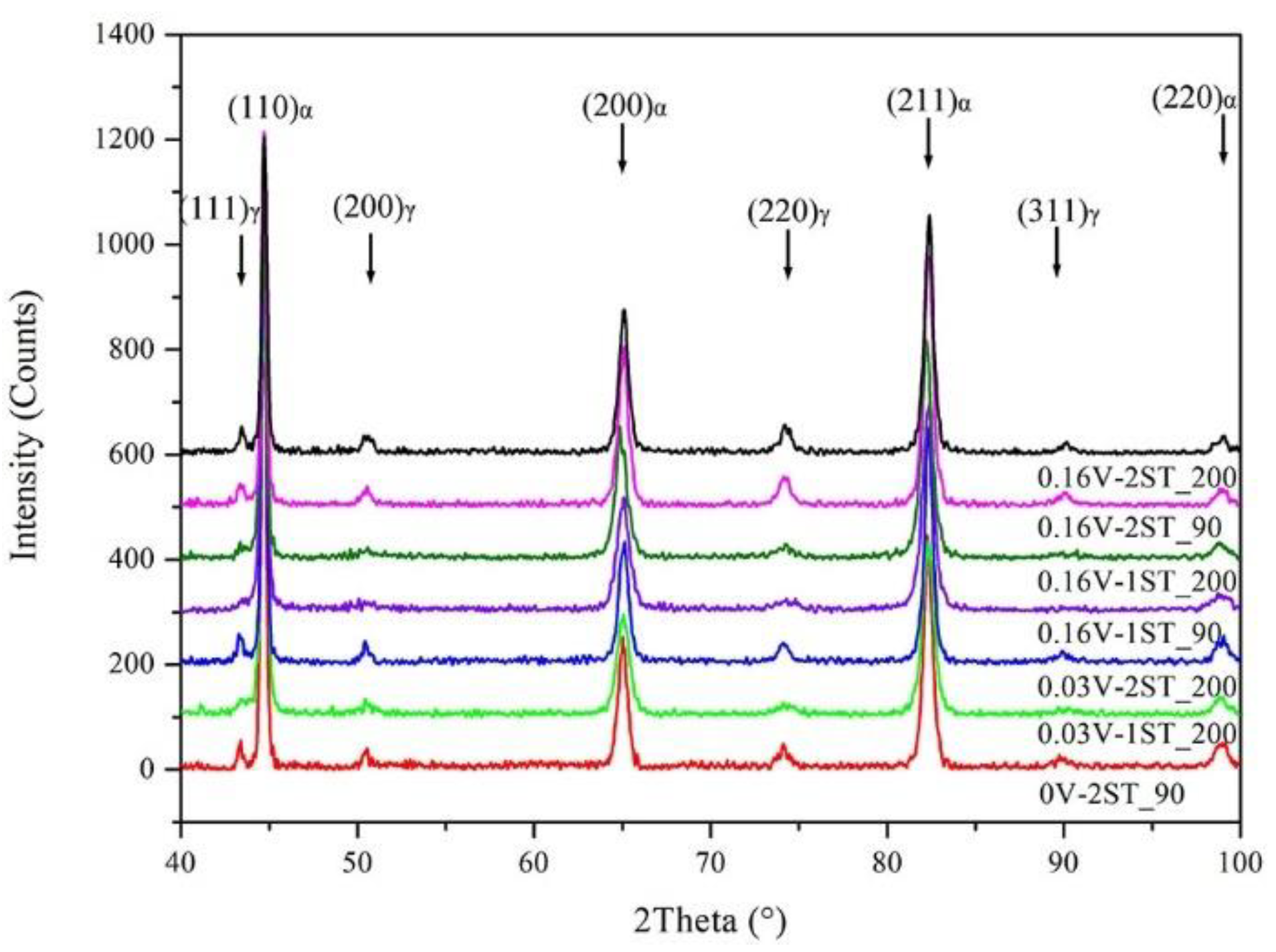

3.3. XRD Measurement and Analysis

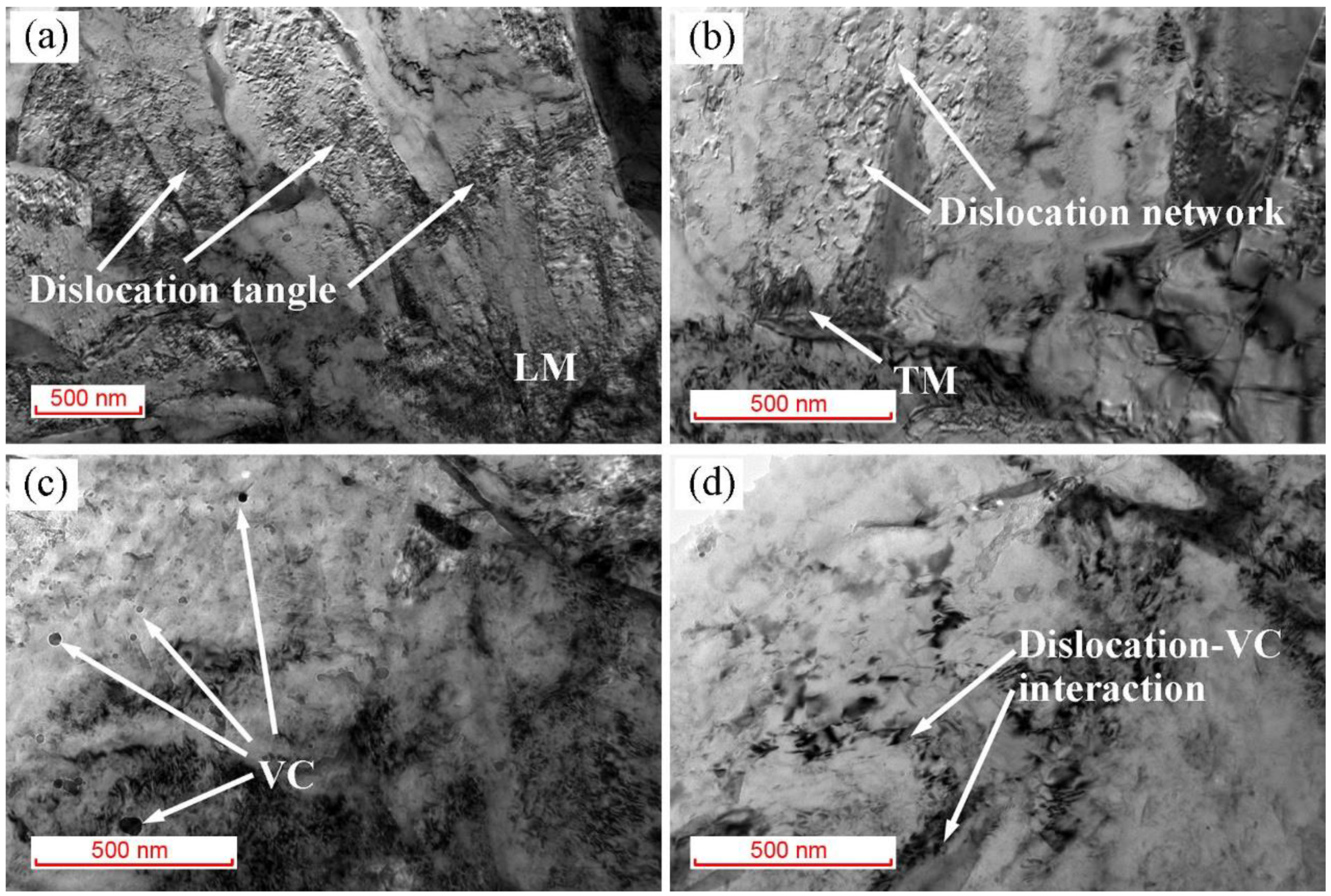

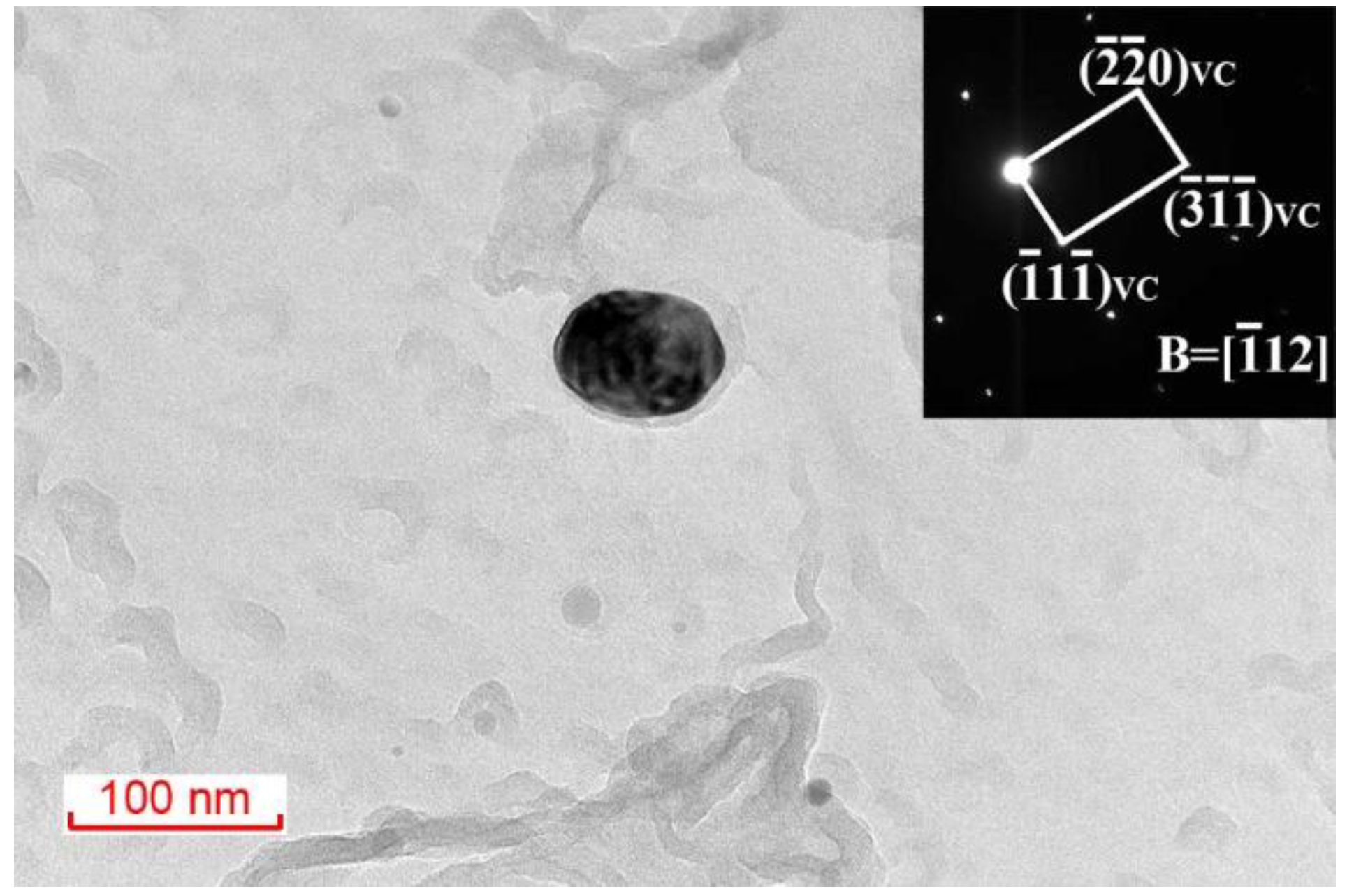

3.4. TEM Characterization

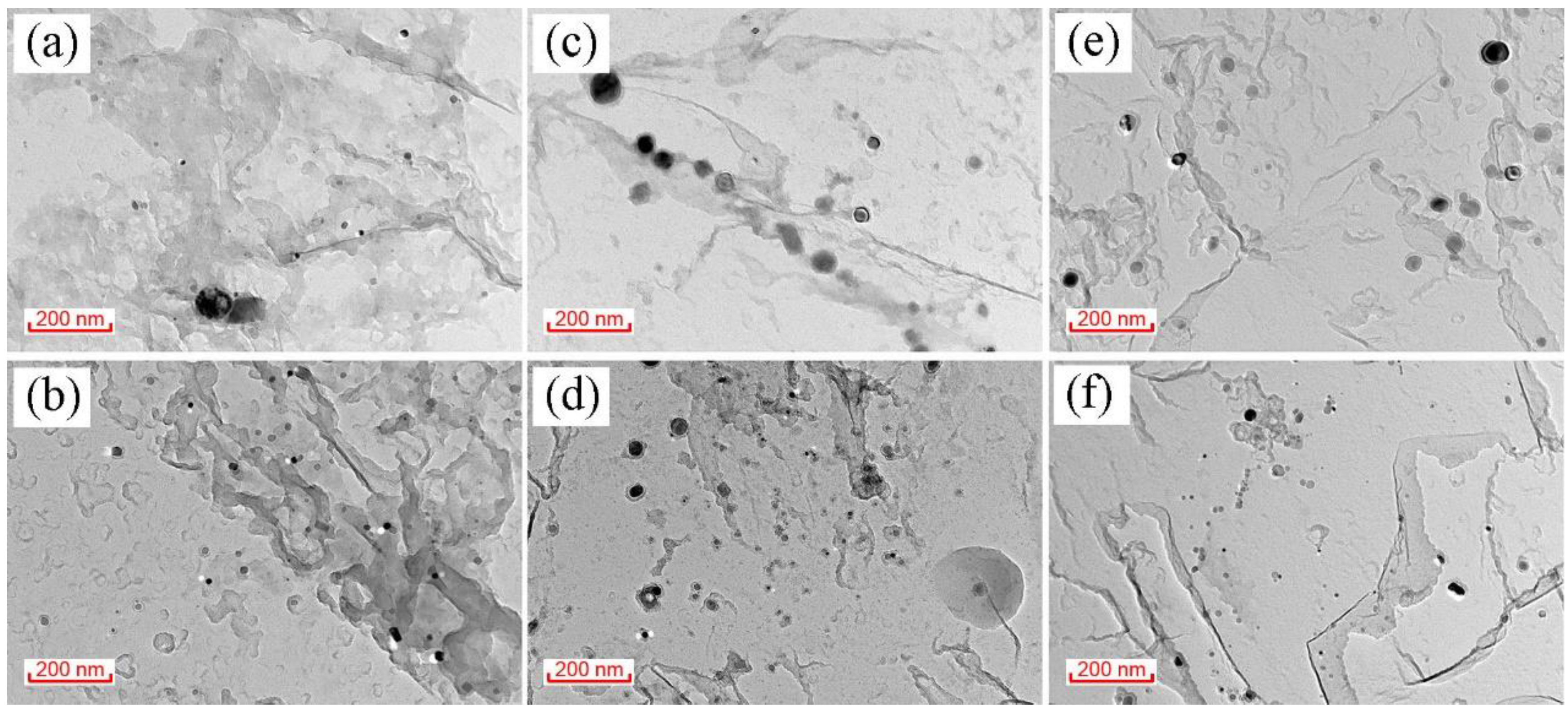

3.5. Particle Size Distribution Analysis

4. Discussions

5. Conclusions

- In this work, quenching from the austenizing temperature instead of intercritical annealing temperature was applied. V addition up to 0.16 wt% greatly refines the microstructure by the pinning effect of undissolved vanadium carbides during the hot rolling process. Two main processes, martensite tempering and carbon partitioning, were ongoing simultaneously during the partitioning stage. In V microalloyed steels, the precipitation, growth, and coarsening of VC carbides were observed. The Q&P microstructures consist of tempered martensite and retained austenite, while V addition inhibits the cementite formation.

- After one-step Q&P treatment, a low volume fraction of retained austenite was obtained. The mechanical properties changing with partitioning time are mainly controlled by the tempering behavior of the dominating phase, i.e., tempered martensite. The decreasing dislocation density and carbon supersaturation in tempered martensite with increasing partitioning time result in the decrease in martensite strength and work hardening rate. The corresponding decrease of UTS, TE, and PSE values is obtained. In V microalloyed steels, the precipitation strengthening as well as grain refinement strengthening can offset the effects of martensite tempering contributing to a slower decreasing trend.

- Compared to one-step Q&P treatment, a high volume fraction of retained austenite and highly tempered martensite after two-step Q&P treatment present the lower UTS, higher TE and PSE values. During partitioning at 400 °C, the more sufficient carbon partitioning as well as the promoted carbide growth and coarsening leads to the quite differentiated changes in mechanical properties with partitioning time. With V addition of 0.03 wt%, the precipitation strengthening effect performed by the high density of small-sized VC carbides greatly increases the UTS value. However, the higher V content of 0.16 wt% demonstrates an obvious growth and coarsening of VC carbides and the resultant carbon consumption in tempered martensite. The weakened precipitation strengthening effect and the reduction of martensite strength decrease the UTS and YS values. In addition, the refined microstructure of 0.16V steel can effectively promote the carbon partitioning. The more sufficient carbon-enriched small-sized retained austenite with high stability can perform the TRIP effect to maintain the high work hardening rate at high strain regime which contributes to the higher plasticity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Maheswari, N.; Chowdhury, S.G.; Kumar, K.H.; Sankaran, S. Influence of alloying elements on the microstructure evolution and mechanical properties in quenched and partitioned steels. Mater. Sci. Eng. A 2014, 600, 12–20. [Google Scholar] [CrossRef]

- Liu, L.; He, B.; Huang, M. The Role of Transformation-Induced Plasticity in the Development of Advanced High Strength Steels. Adv. Eng. Mater. 2018, 20, 1701083. [Google Scholar] [CrossRef]

- YU, J.; Wang, H.; Zheng, W.; He, Y.; Wu, Y.; Li, L. Effect of the Interface Microstructure of Hot-Dip Galvanizing High-Strength Automobile Steel on Its Tensile Fracture Behaviors. Acta Metall. Sin. 2020, 56, 863–873. [Google Scholar] [CrossRef]

- Yi, H.L.; Chen, P.; Hou, Z.; Hong, N.; Cai, H.; Xu, Y.; Wu, D.; Wang, G. A novel design: Partitioning achieved by quenching and tempering (Q–T & P) in an aluminium-added low-density steel. Scr. Mater. 2013, 68, 370–374. [Google Scholar] [CrossRef]

- Findley, K.; Hidalgo-García, J.; Huizenga, R.; Santofimia, M. Controlling the work hardening of martensite to increase the strength/ductility balance in quenched and partitioned steels. Mater. Des. 2017, 117, 248–256. [Google Scholar] [CrossRef]

- Tan, X.; Xu, Y.; Yang, X.; Wu, D. Microstructure–properties relationship in a one-step quenched and partitioned steel. Mater. Sci. Eng. A 2014, 589, 101–111. [Google Scholar] [CrossRef]

- Tan, X.D.; Yang, X.L.; Xu, Y.B.; Hu, Z.P.; Peng, F.; Zhang, H.; Yu, Y.M.; Wu, D. Effect of Ferrite Status on Mechanical Properties of Hot-Rolled Directly Quenched and Partitioned Steel. Mater. Sci. Forum 2015, 816, 736–742. [Google Scholar] [CrossRef]

- Peng, F.; Xu, Y.; Gu, X.; Wang, Y.; Liu, X.; Li, J. The relationships of microstructure-mechanical properties in quenching and partitioning (Q&P) steel accompanied with microalloyed carbide precipitation. Mater. Sci. Eng. A 2018, 723, 247–258. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, Z.-P.; Zou, Y.; Tan, X.-D.; Han, D.-T.; Chen, S.-Q.; Ma, D.-G.; Misra, R. Effect of two-step intercritical annealing on microstructure and mechanical properties of hot-rolled medium manganese TRIP steel containing δ-ferrite. Mater. Sci. Eng. A 2017, 688, 40–55. [Google Scholar] [CrossRef]

- Perrard, F.; Scott, C. Vanadium Precipitation during Intercritical Annealing in Cold Rolled TRIP Steels. ISIJ Int. 2007, 47, 1168–1177. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Zhao, Z.; Long, J.; Sheng, G.; Zheng, Z.; Tang, D. The relationship between microstructures and mechanical properties of vanadium microalloyed cold rolled ultrahigh strength steel treated by austempering. Mater. Res. Express 2019, 6, 126543. [Google Scholar] [CrossRef]

- Krizan, D.; Spiradek-Hahn, K.; Pichler, A. Relationship between microstructure and mechanical properties in Nb–V microalloyed TRIP steel. Mater. Sci. Technol. 2014, 31, 661–668. [Google Scholar] [CrossRef]

- Shi, W.; Li, L.; Yang, C.-X.; Fu, R.-Y.; Wang, L.; Wollants, P. Strain-induced transformation of retained austenite in low-carbon low-silicon TRIP steel containing aluminum and vanadium. Mater. Sci. Eng. A 2006, 429, 247–251. [Google Scholar] [CrossRef]

- He, B.B.; Huang, M.X. Simultaneous Increase of Both Strength and Ductility of Medium Mn Transformation-Induced Plasticity Steel by Vanadium Alloying. Met. Mater. Trans. A 2018, 49, 1433–1438. [Google Scholar] [CrossRef]

- Bai, S.; Xiao, W.; Niu, W.; Li, D.; Liang, W. Microstructure and Mechanical Properties of a Medium-Mn Steel with 1.3 GPa-Strength and 40%-Ductility. Materials 2021, 14, 2233. [Google Scholar] [CrossRef] [PubMed]

- Park, T.M.; Jeong, M.S.; Jung, C.; Choi, W.S.; Choi, P.-P.; Han, J. Improved strength of a medium-Mn steel by V addition without sacrificing ductility. Mater. Sci. Eng. A 2021, 802, 140681. [Google Scholar] [CrossRef]

- Pushkareva, I.; Shalchi-Amirkhiz, B.; Allain, S.Y.P.; Geandier, G.; Fazeli, F.; Sztanko, M.; Scott, C. The Influence of Vanadium Additions on Isothermally Formed Bainite Microstructures in Medium Carbon Steels Containing Retained Austenite. Metals 2020, 10, 392. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Liu, P.; Li, W.; Guo, Z.-H.; Rong, Y.-H. High Strength-Ductility Nb-microalloyed Low Martensitic Carbon Steel: Novel Process and Mechanism. Acta Met. Sin. Engl. Lett. 2015, 28, 1264–1271. [Google Scholar] [CrossRef] [Green Version]

- Yan, S.; Liu, X.; Liang, T.; Chen, J.; Zhao, Y. Effect of Micro-Alloying Elements on Microstructure and Mechanical Properties in C-Mn-Si Quenching and Partitioning (Q&P) Steels. Steel Res. Int. 2019, 90, 1800257. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Ding, H.; Misra, R.; Wang, C. Microstructural evolution and consequent strengthening through niobium-microalloying in a low carbon quenched and partitioned steel. Mater. Sci. Eng. A 2015, 641, 242–248. [Google Scholar] [CrossRef]

- Aoued, S.; Danoix, F.; Allain, S.Y.; Gaudez, S.; Geandier, G.; Hell, J.C.; Soler, M.; Gouné, M. Microstructure Evolution and Competitive Reactions during Quenching and Partitioning of a Model Fe–C–Mn–Si Alloy. Metals 2020, 10, 137. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharya, D. Role of Niobium in Advanced High Strength Steels for Automotive Applications. J. Iron Steel Res. Int. 2011, 18, 712–717. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Dong, Y.; Meng, Q.-W.; Misra, R. Effect of Ti variation on microstructure evolution and mechanical properties of low carbon medium Mn heavy plate steel. Mater. Charact. 2019, 152, 21–35. [Google Scholar] [CrossRef]

- Thermo-Calc Software TCFE9 Steels/Fe-alloys Database. Available online: https://thermocalc.com/content/uploads/Documentation/Databases/TCFE_History/tcfe-historytcfe8totcfe9.pdf (accessed on 23 July 2017).

- Peet, M.; Bhadeshia, H.K.D.H. Materials Algorithms Project. Available online: https://www.phase-trans.msm.cam.ac.uk/map/steel/programs/mucg83.html (accessed on 2 January 2021).

- Li, Z.; Wu, D. Effects of Hot Deformation and Subsequent Austempering on the Mechanical Properties of Si-Mn TRIP Steels. ISIJ Int. 2006, 46, 121–128. [Google Scholar] [CrossRef] [Green Version]

- Saeglitz, M.; Krauss, G. Deformation, fracture, and mechanical properties of low-temperature-tempered martensite in SAE 43xx steels. Met. Mater. Trans. A 1997, 28, 377–387. [Google Scholar] [CrossRef]

- Matlock, D.K.; Speer, J.G. Microstructure and Texture in Steels; Haldar, A., Suwas, S., Bhattacharjee, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 185–205. [Google Scholar]

- Ebner, S.; Suppan, C.; Stark, A.; Schnitzer, R.; Hofer, C. Austenite decomposition and carbon partitioning during quenching and partitioning heat treatments studied via in-situ X-ray diffraction. Mater. Des. 2019, 178, 107862. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- He, B.; Pan, S.; Huang, M. Extra work hardening in room-temperature quenching and partitioning medium Mn steel enabled by intercritical annealing. Mater. Sci. Eng. A 2020, 797, 140106. [Google Scholar] [CrossRef]

- Dai, J.; Meng, Q.; Zheng, H. An innovative pathway to produce high-performance quenching and partitioning steel through ultra-fast full austenitization annealing. Mater. Today Commun. 2020, 25, 101272. [Google Scholar] [CrossRef]

| Steels | C | Si | Mn | V | A1 | A3 | Ms |

|---|---|---|---|---|---|---|---|

| 0V | 0.24 | 1.50 | 1.90 | 0 | 715 | 823 | 373 |

| 0.03V | 0.24 | 1.47 | 1.88 | 0.03 | 716 | 826 | 373 |

| 0.16V | 0.24 | 1.52 | 1.83 | 0.16 | 715 | 840 | 370 |

| Sample ID | UTS (MPa) | YS (MPa) | TE (%) | PSE (GPa.%) |

|---|---|---|---|---|

| 0V-1ST_90 | 1430.8 ± 4.4 | 907.8 ± 6.4 | 10.6 ± 0.2 | 15.2 |

| 0V-1ST_200 | 1374.8 ± 5.4 | 878.2 ± 4.6 | 9.2 ± 0.1 | 12.6 |

| 0V-2ST_90 | 1201.0 ± 5.4 | 959.0 ± 17.5 | 13.6 ± 1.5 | 16.3 |

| 0V-2ST_200 | 1168.7 ± 5.5 | 981.1 ± 8.6 | 12.6 ± 1.4 | 14.7 |

| 0.03V-1ST_90 | 1419.0 ± 1.8 | 953.1 ± 15.7 | 8.2 ± 0.0 | 11.6 |

| 0.03V-1ST_200 | 1407.8 ± 10.7 | 989.6 ± 14.9 | 7.8 ± 0.0 | 11.0 |

| 0.03V-2ST_90 | 1141.1 ± 12.5 | 883.9 ± 17.1 | 12.8 ± 0.1 | 14.6 |

| 0.03V-2ST_200 | 1193.2 ± 8.4 | 945.9 ± 13.2 | 12.1 ± 1.0 | 14.4 |

| 0.16V-1ST_90 | 1405.1 ± 9.4 | 886.5 ± 16.0 | 8.6 ± 0.4 | 12.1 |

| 0.16V-1ST_200 | 1404.6 ± 3.3 | 973.8 ± 4.0 | 8.7 ± 0.3 | 12.2 |

| 0.16V-2ST_90 | 1175.8 ± 4.5 | 867.8 ± 12.0 | 12.8 ± 0.3 | 15.1 |

| 0.16V-2ST_200 | 1154.7 ± 7.1 | 946.1 ± 13.7 | 14.9 ± 1.0 | 17.2 |

| Sample ID | |

|---|---|

| 0V-2ST_90 | 8.4 |

| 0.03V-1ST_200 | 5.6 |

| 0.03V-2ST_200 | 8.0 |

| 0.16V-1ST_90 | 3.8 |

| 0.16V-1ST_200 | 4.3 |

| 0.16V-2ST_90 | 10.3 |

| 0.16V-2ST_200 | 9.9 |

| Sample ID | Density | |||

|---|---|---|---|---|

| 0.03V-2ST_200 | 5.0 | 83.5 | 15.5 | 20 ± 8 |

| 0.16V-2ST_90 | 3.6 | 82.3 | 23.2 | 25 ± 9 |

| 0.16V-2ST_200 | 7.4 | 70.7 | 28.7 | 17 ± 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.-T.; Zhu, N.-Q.; Sun, B.-W.; Zhao, Z.-Z.; Zheng, Z.-W.; Tang, D.; Li, L. Effect of V Addition on Microstructure and Mechanical Properties in C–Mn–Si Steels after Quenching and Partitioning Processes. Metals 2021, 11, 1306. https://doi.org/10.3390/met11081306

Zhang G-T, Zhu N-Q, Sun B-W, Zhao Z-Z, Zheng Z-W, Tang D, Li L. Effect of V Addition on Microstructure and Mechanical Properties in C–Mn–Si Steels after Quenching and Partitioning Processes. Metals. 2021; 11(8):1306. https://doi.org/10.3390/met11081306

Chicago/Turabian StyleZhang, Gong-Ting, Na-Qiong Zhu, Bo-Wei Sun, Zheng-Zhi Zhao, Zhi-Wang Zheng, Di Tang, and Lin Li. 2021. "Effect of V Addition on Microstructure and Mechanical Properties in C–Mn–Si Steels after Quenching and Partitioning Processes" Metals 11, no. 8: 1306. https://doi.org/10.3390/met11081306

APA StyleZhang, G.-T., Zhu, N.-Q., Sun, B.-W., Zhao, Z.-Z., Zheng, Z.-W., Tang, D., & Li, L. (2021). Effect of V Addition on Microstructure and Mechanical Properties in C–Mn–Si Steels after Quenching and Partitioning Processes. Metals, 11(8), 1306. https://doi.org/10.3390/met11081306