Numerical Simulation and Experimental Investigation on 2205 Duplex Stainless Steel K-TIG Welded Joint

Abstract

:1. Introduction

2. Materials and Methods

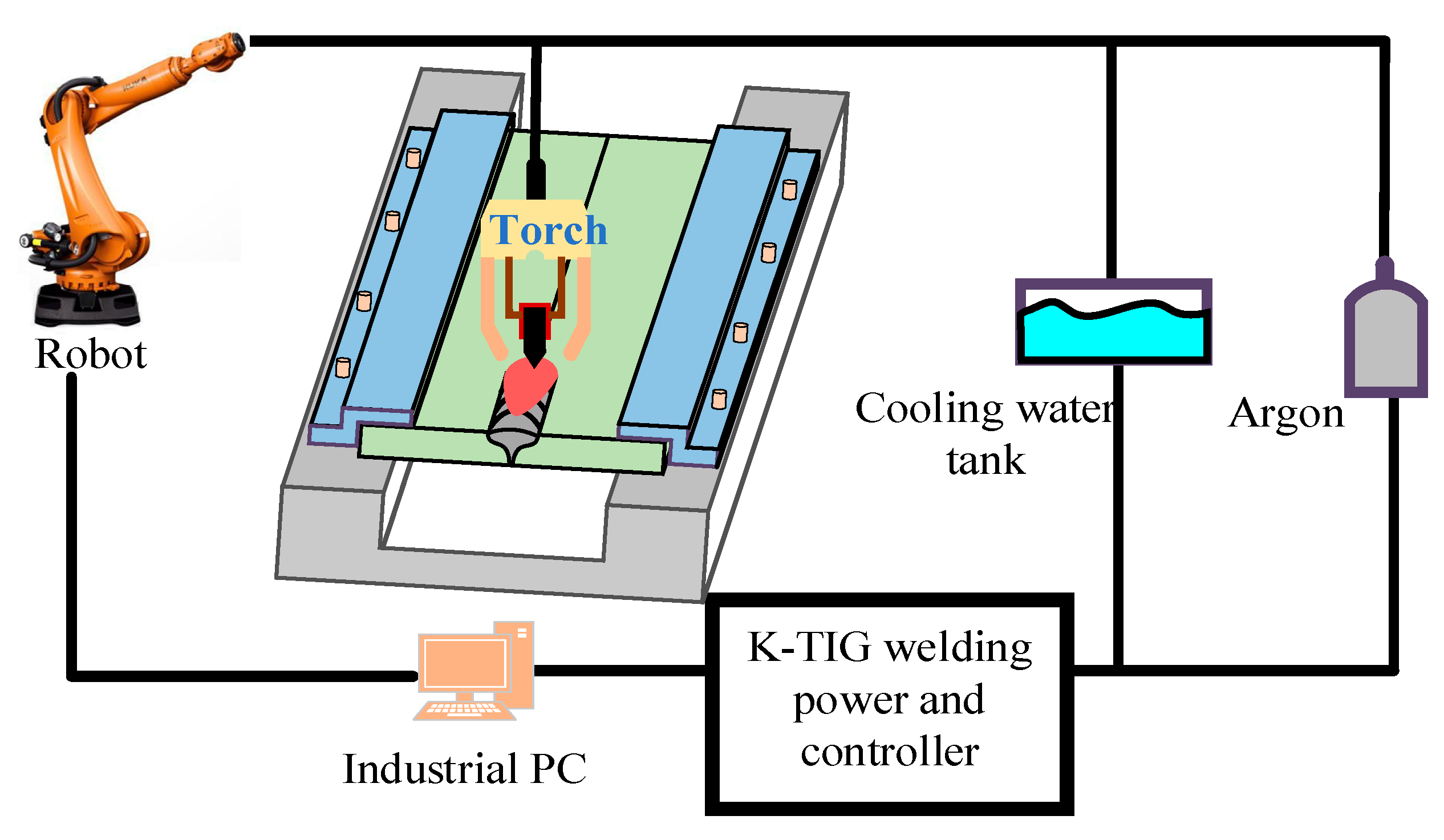

2.1. Experimental Procedure

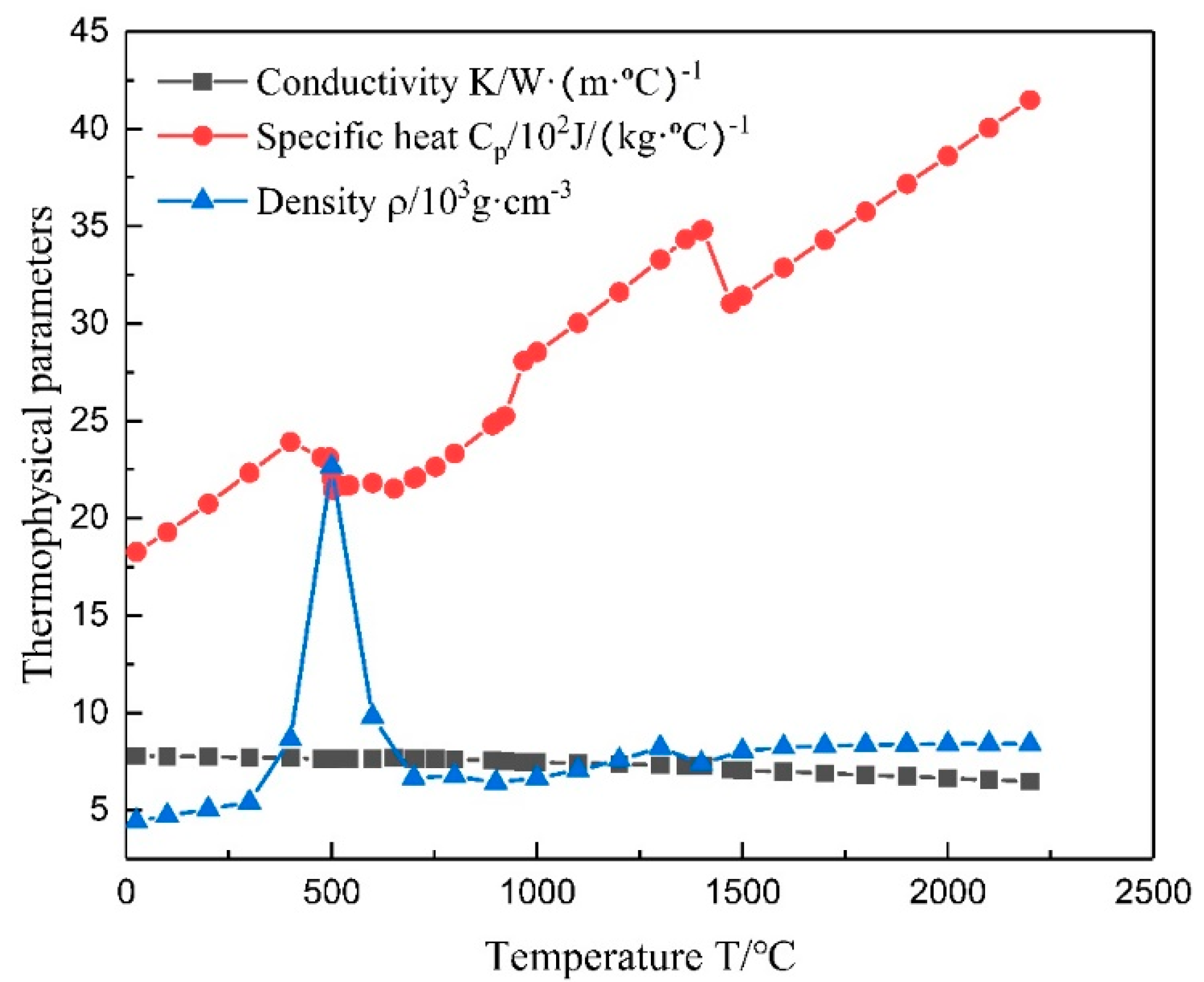

2.2. Materials

3. Numerical Simulation

3.1. Modeling

3.1.1. Basic Formulas of Temperature Distribution Calculations

3.1.2. Heat Source Model

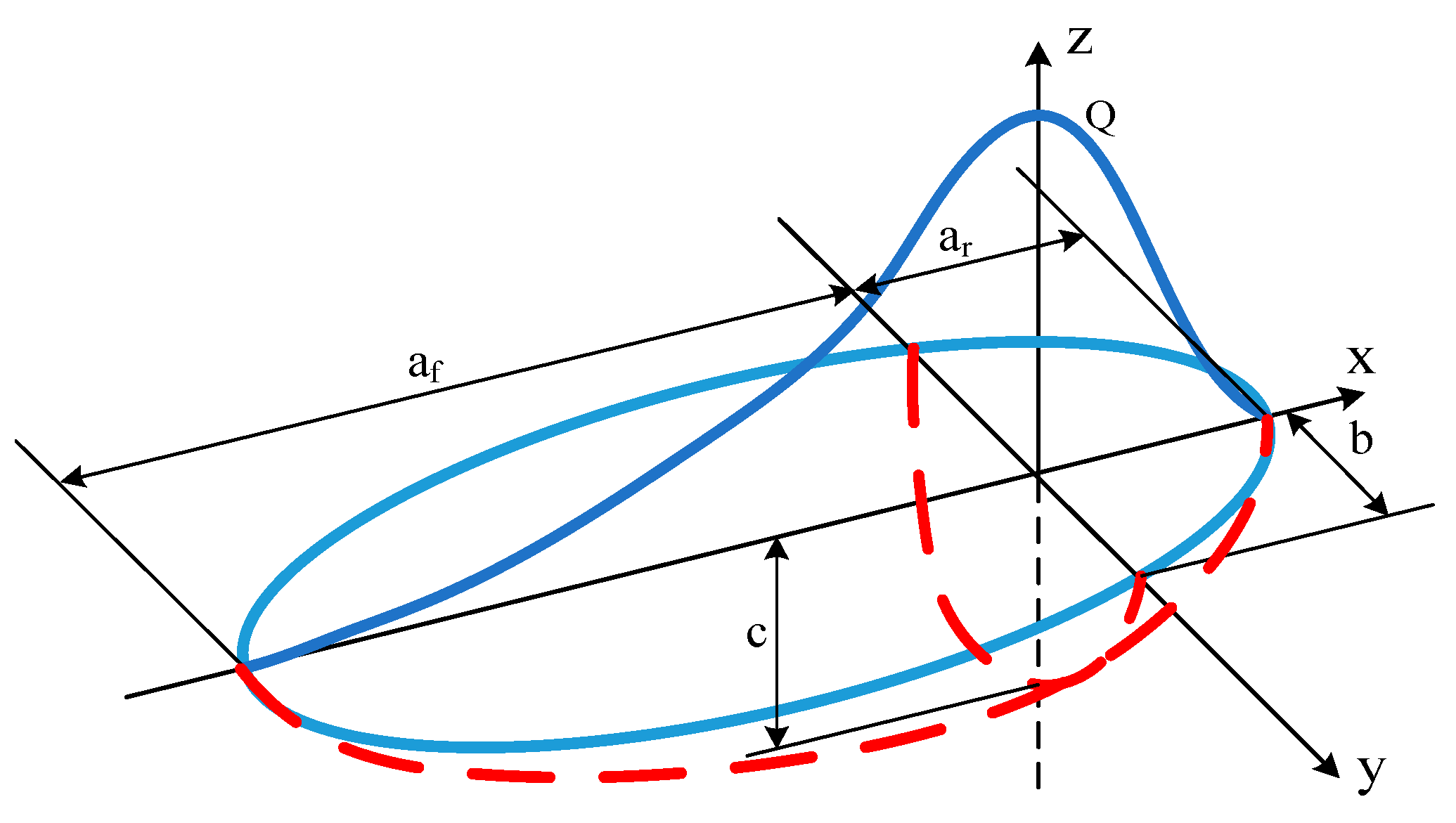

- The ellipsoid + the cylindrical heat source model

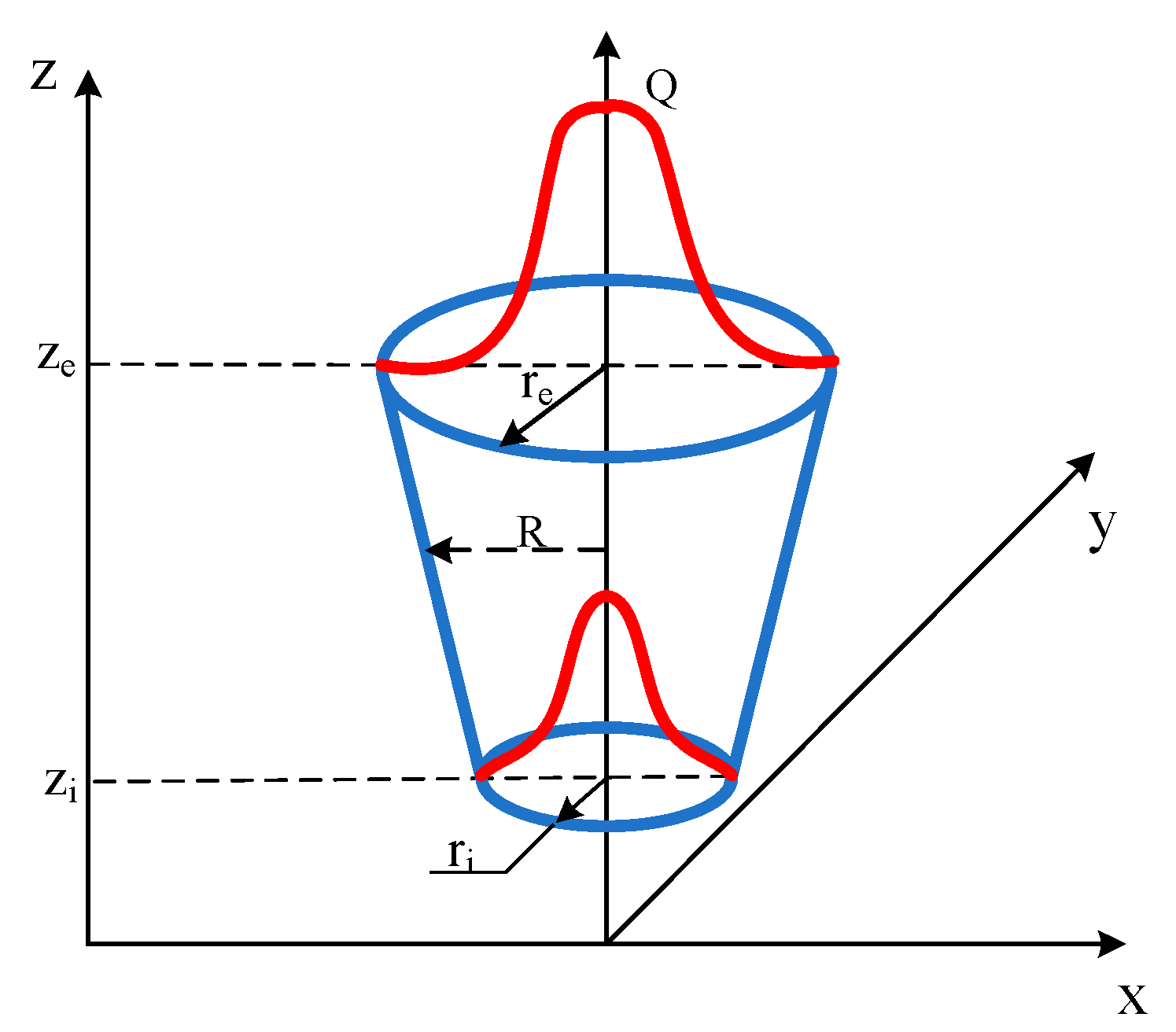

- The ellipsoid + the conical heat source model

- The ellipsoid + the columnar peak increasing heat source model

3.1.3. Mesh Model

4. Results and Discussion

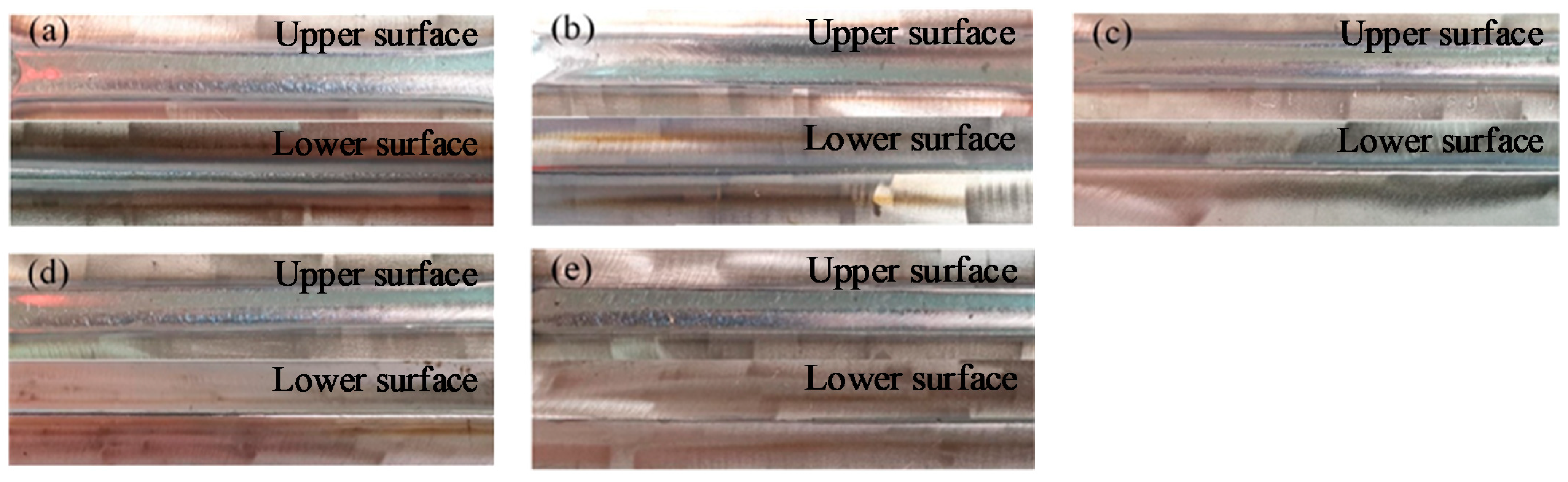

4.1. Weld Morphology

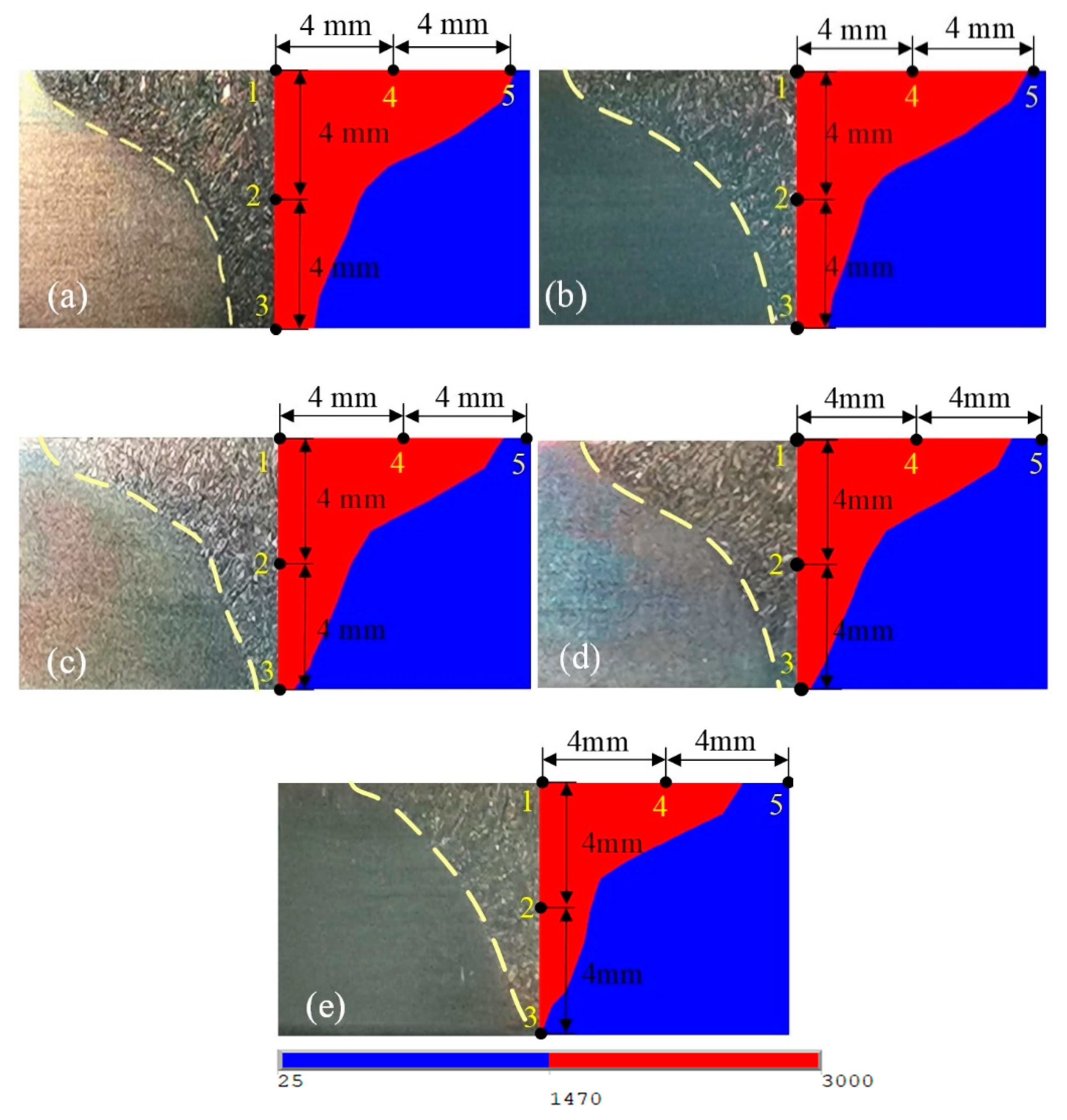

4.2. Simulation and Verification

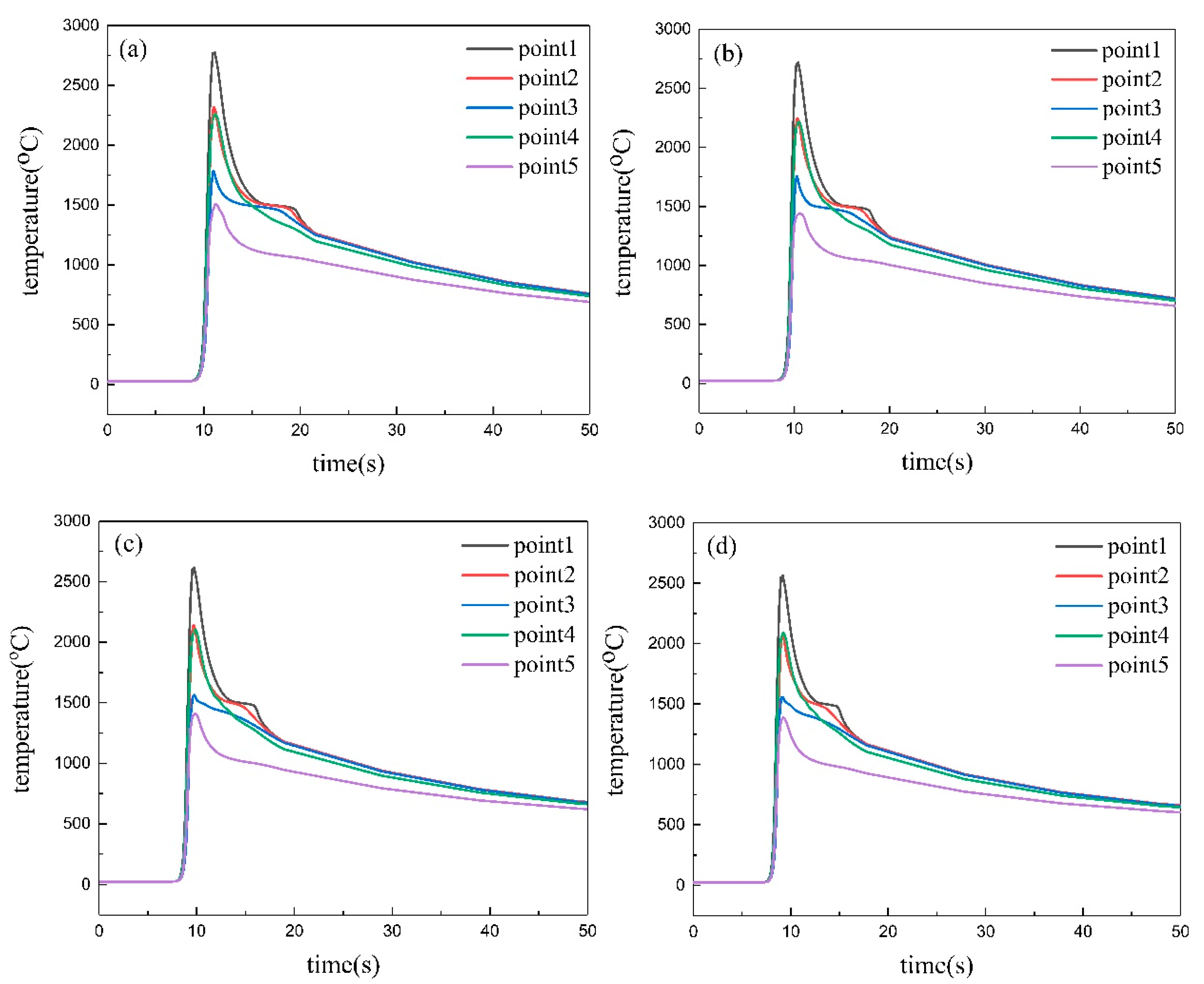

4.3. Results of Numerical Simulation

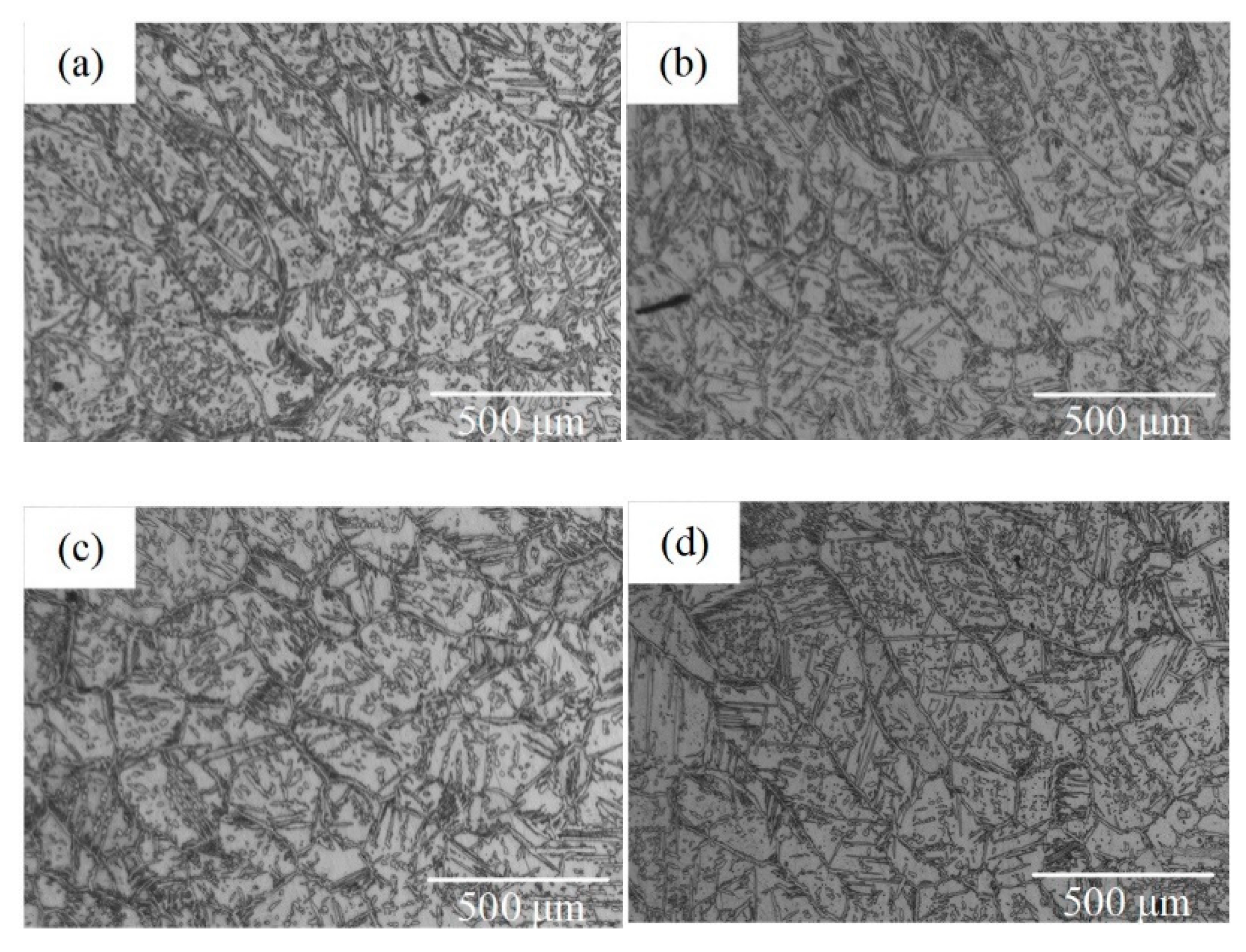

4.4. Microstructure

5. Conclusions

- A combined heat source model form using the ellipsoid heat source as the upper part and the conical heat source as the lower part is more suitable in numerical simulation of K-TIG welding.

- When the welding speeds are 280–340 mm/min, the K-TIG welds are bright silver and continuous. The width of the welds is relatively uniform, and there are no welding defects on the surface of the welds.

- When the welding speeds are 280–340 mm/min, the simulated molten pool morphologies are close to the actual weld morphologies. The cooling rates of other points were lower than point 1. The cooling rate at the same point increases as the welding speed increases.

- When the welding speed is increased from 280 mm/min to 340 mm/min, the austenite content and the ferrite and austenite grain size decrease.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wierczyńska, A.; Fydrych, D.; Landowski, M.; Rogalski, G.; Łabanowski, J. Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mater. 2020, 238, 117697. [Google Scholar] [CrossRef]

- Varbai, B.; Pickle, T.; Májlinger, K. Effect of heat input and role of nitrogen on the phase evolution of 2205 duplex stainless steel weldment. Int. J. Press. Vessel. Pip. 2019, 176, 103952. [Google Scholar] [CrossRef]

- Cui, S.W.; Shi, Y.H.; Zhang, C.S. Microstructure and mechanical properties of TC4 titanium alloy K-TIG welded joints. Trans. Nonferrous Met. Soc. China 2021, 31, 416–425. [Google Scholar] [CrossRef]

- Cui, S.W.; Shi, Y.H.; Sun, K.; Gu, S. Microstructure evolution and mechanical properties of keyhole deep penetration TIG welds of S32101 duplex stainless steel. Mater. Sci. Eng. A 2018, 709, 214–222. [Google Scholar] [CrossRef]

- Cui, S.W.; Shi, Y.H.; Zhu, T.; Liu, W. Microstructure, texture, and mechanical properties of Ti-6Al-4V joints by K-TIG welding. J. Manuf. Process. 2019, 37, 418–424. [Google Scholar] [CrossRef]

- Feng, Y.Q.; Luo, Z.; Liu, Z.; Li, Y.; Luo, Y.; Huang, Y. Keyhole gas tungsten arc welding of AISI 316L stainless steel. Mater. Des. 2015, 85, 24–31. [Google Scholar] [CrossRef]

- Fan, W.F.; Luo, Z.; Feng, Y.Q.; Li, Y.; Ao, S.S. Study on the Deep Penetration TIG Welding of Q345 Steel. J. Shanghai Jiaotong Univ. 2016, 50, 100–105. [Google Scholar]

- Cui, S.L.; Liu, Z.M.; Fang, Y.X.; Luo, Z.; Manladan, S.M.; Yi, S. Keyhole process in K-TIG welding on 4mm thick 304 stainless steel. J. Mater. Process. Technol. 2017, 243, 217–228. [Google Scholar] [CrossRef]

- Lange, F.; Artinov, A.; Bachmann, M.; Rethmeier, M.; Hilgenberg, K. Numerical simulation of the weld pool dynamics during pulsed laser welding using adapted heat source models. Procedia CIRP 2018, 74, 679–682. [Google Scholar] [CrossRef]

- Chen, S.Y.; Liu, Z.M.; Zhao, X.C.; Lv, Z.Y.; Fan, X.G. Cathode-focused high-current arc: Heat source development with stable keyhole in stationary welding. Int. J. Heat Mass Transf. 2019, 143, 118475.1–118475.13. [Google Scholar] [CrossRef]

- Han, T.; Gu, S.W.; Xu, L.; Zhang, H.J.; Ou, Y.K. Study on stress and deformation of keyhole gas tungsten arc-welded joints. Trans. China Weld. Inst. 2019, 29, 21–29. [Google Scholar]

- Zhang, R.H.; Li, H.X.; Li, M.; Wang, R.; Leng, X.B. Numerical analysis on keyhole gas tungsten arc welding. Electr. Weld. Machine 2012, 42, 7–11. [Google Scholar]

- ASTM International. Designation: E1245-03 (2016) Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Kik, T.; Moravec, J.; Novakova, I. New method of processing heat treatment experiments with numerical simulation support. IOP Conf. Ser. Mater. Sci. Eng. 2017, 227, 12069. [Google Scholar] [CrossRef] [Green Version]

- Devaux, J.; Leblond, J.B.; Bergheau, J.M. Numerical Study of the Plastic Behaviour of a Low Alloy Steel during Phase Transformation. J. Shanghai Jiaotong Univ. 2000, 5, 206–212. [Google Scholar]

- Casalino, G.; Mortello, M. A FEM model to study the fiber laser welding of Ti6Al4V thin sheets. Int. J. Adv. Manuf. Technol. 2016, 86, 5–8. [Google Scholar] [CrossRef]

- Nadh, H.; Edison, G.; Akella, S.; Buddu, R.K. Simulation of hybrid laser-tig welding process using fea. J. Eng. Sci. Technol. 2018, 13, 1782–1792. [Google Scholar]

- Musa, I.U.; Afolayan, M.O.; Dagwa, I.M. Finite element model for predicting residual stresses in shielded manual metal arc welding of mild steel plates. Niger. J. Technol. 2015, 35, 85–90. [Google Scholar] [CrossRef] [Green Version]

- Casalino, G.; Michele, D.; Perulli, P. FEM model for TIG hybrid laser butt welding of 6 mm thick austenitic to martensitic stainless steels. Procedia CIRP 2020, 88, 116–121. [Google Scholar] [CrossRef]

- Kik, T. Computational Techniques in Numerical Simulations of Arc and Laser Welding Processes. Materials 2020, 13, 608–625. [Google Scholar] [CrossRef] [Green Version]

- Cui, S.W.; Shi, Y.H.; Cui, Y.X.; Zhu, T. The influence of microstructure and chromium nitride precipitations on the mechanical and intergranular corrosion properties of K-TIG weld metals. Constr. Build. Mater. 2019, 210, 71–77. [Google Scholar] [CrossRef]

- Cui, S.W.; Shi, Y.H.; Cui, Y.X.; Zhu, T. The impact toughness of novel keyhole TIG welded duplex stainless steel joints. Eng. Fail. Anal. 2018, 94, 226–231. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Jing, H.Y.; Xu, L.Y.; Han, Y.; Zhao, L.; Lv, X.; Zhang, J. The impact of annealing temperature on improving microstructure and toughness of electron beam welded duplex stainless steel. J. Manuf. Process. 2018, 31, 568–582. [Google Scholar] [CrossRef]

| Test | Arc Voltage (V) | Welding Current (A) | Welding Efficiency | Welding Speed (mm/min) |

|---|---|---|---|---|

| 1 | 17.5 | 480 | 0.9 | 280 |

| 2 | 17.5 | 480 | 0.9 | 300 |

| 3 | 17.5 | 480 | 0.9 | 320 |

| 4 | 17.5 | 480 | 0.9 | 340 |

| 5 | 17.5 | 480 | 0.9 | 360 |

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt. % | 0.0192 | 0.569 | 1.428 | 0.021 | 0.0005 | 22.46 | 5.7 | 3.02 | 0.156 | Bal. |

| Parameter | The Double Ellipsoid | The Cylindrical | The Gaussian Cone Heat Source | The Columnar Peak Increasing |

|---|---|---|---|---|

| af/mm | 4 | –– | –– | –– |

| ar/mm | 6 | –– | –– | –– |

| b/mm | 17 | –– | –– | –– |

| c/mm | 4 | –– | –– | –– |

| m | –– | –– | –– | 1 |

| H/mm | –– | 4 | 4 | 4 |

| R/mm | –– | 3 | –– | 3.5 |

| re/mm | –– | –– | 3.5 | –– |

| ri/mm | –– | –– | 1.5 | –– |

| Welding Speed (mm/min) | Grain Size (μm) | Austenite Content (%) | |

|---|---|---|---|

| Ferrite | Austenite | ||

| 280 | 17.8 | 13.2 | 44.8 |

| 300 | 16.8 | 13.1 | 42.1 |

| 320 | 16.3 | 13.0 | 37.4 |

| 340 | 16.1 | 12.7 | 32.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Pang, S.; Pang, D.; Zhang, Q.; Zhang, Z. Numerical Simulation and Experimental Investigation on 2205 Duplex Stainless Steel K-TIG Welded Joint. Metals 2021, 11, 1323. https://doi.org/10.3390/met11081323

Cui S, Pang S, Pang D, Zhang Q, Zhang Z. Numerical Simulation and Experimental Investigation on 2205 Duplex Stainless Steel K-TIG Welded Joint. Metals. 2021; 11(8):1323. https://doi.org/10.3390/met11081323

Chicago/Turabian StyleCui, Shuwan, Shuwen Pang, Dangqing Pang, Qin Zhang, and Zhiqing Zhang. 2021. "Numerical Simulation and Experimental Investigation on 2205 Duplex Stainless Steel K-TIG Welded Joint" Metals 11, no. 8: 1323. https://doi.org/10.3390/met11081323

APA StyleCui, S., Pang, S., Pang, D., Zhang, Q., & Zhang, Z. (2021). Numerical Simulation and Experimental Investigation on 2205 Duplex Stainless Steel K-TIG Welded Joint. Metals, 11(8), 1323. https://doi.org/10.3390/met11081323