Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review

Abstract

1. Introduction

- Due to the low ability to conduct heat, the thermal generated while processing of workpieces is not passed to the chips or the rough part but is concentrated on the cutting edges, which leads to crater wear and extensive plastic deformation of the cutting tool edge;

- Increased crater wear results in severe damage of cutting instrument and plastic strain causes high resistance of the material against during the intrusion of the cutting tool;

- Metal pickup and coating delamination due to the chemical reaction of Ni-based superalloys during machining reduces tool life;

- High wear on the cutting edge of the tool generated by friction because of the occurrence of solid and abrasive intermetallic compounds in the microstructure of these alloys;

- Changes in the microstructure of the alloys due to high heat generation during machining and generated residual stresses cause a further reduction in the cyclic life of the component;

- In addition, the machining of these alloys also leads to high cutting emulsion consumption, the cost of which corresponds to the cost of cutting instruments [75].

2. Type of Tool Materials for Machining Nickel-Based Alloys

2.1. Carbide for Machining Nickel-Based Alloys

2.2. Cubic Boron Nitride for Machining Nickel-Based Alloys

2.3. Ceramic Instruments for Machining Nickel-Based Superalloys

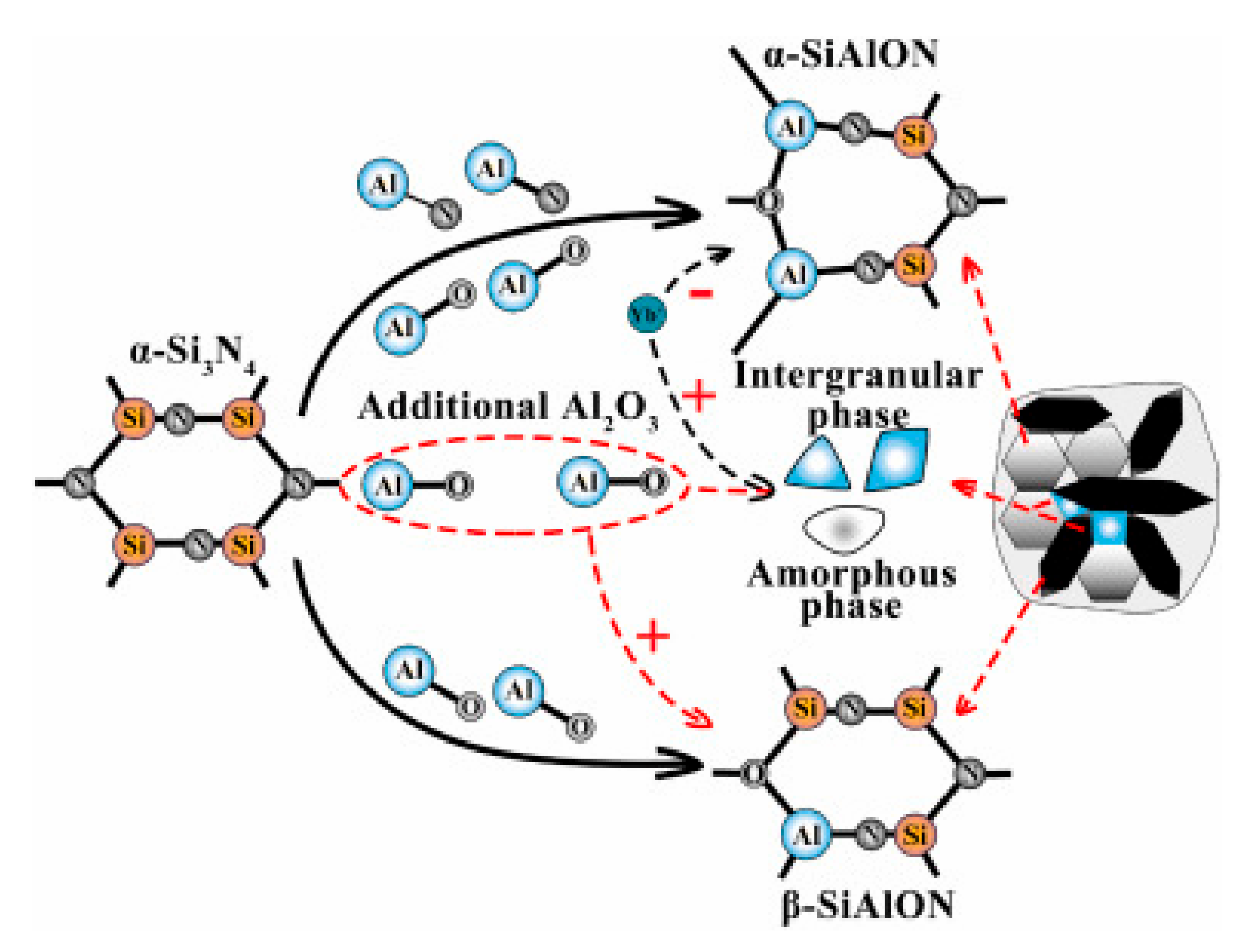

3. Features of SiAlONs and Their Application in the Processing of Nickel-Based HRSA

3.1. α-SiAlON

- α-SiAlON can be used as a base in a composite material with the addition of silicon carbide or molybdenum-disilicide-reinforcing fibres, which have sufficient chemical compatibility. However, with the introduction of SiCw, it was not possible to increase the strength, and with the addition of MoSi2, a sharp drop in hardness is observed, which is unacceptable.

- It was found that it is impossible to use rare earth elements with large ion sizes (for example, Sm, and Nd) as a stabiliser of α-phases in ceramics used at temperatures above 1000 °C since they decompose. However, these types of ceramics can be used at low temperatures.

- The most favourable alloying elements, from the point of view of stability at high temperatures, are rare earth elements with small ion sizes, such as yttrium or ytterbium, which form α-phases.

3.2. β-SiAlON

3.3. (α + β) SiAlON

3.4. SiAlON Application in Machining Nickel-Based Alloys

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sommitsch, C.; Radis, R.; Krumphals, A.; Stockinger, M.; Grill, D. Microstructure control in processing nickel, titanium and other special alloys. Microstructure evolution in metal forming processes. In Woodhead Publishing Series in Metals and Surface Engineering; Woodhead: Cambridge, UK, 2012; pp. 337–383. [Google Scholar]

- Pollock, T.M. Nickel-Based Superalloys for advanced turbine engines. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Richards, N.; Aspinwall, D. Use of ceramic tools for machining nickel-based alloys. Int. J. Mach. Tools Manf. 1989, 10, 575–588. [Google Scholar] [CrossRef]

- Nowotnik, A. Nickel-based superalloys. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–7. [Google Scholar]

- Thellaputta, G.R.; Chandra Bose, P.S.; Rao, C.S. Machinability of nickel-based superalloys: A Review. Mat. Today Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mat. Process. Tech. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Pervaiz, S.; Rashid, A.; Deiab, I.; Nicolescu, M. Influence of tool materials on machinability of titanium- and nickel-based alloys: A review. Mat. Manuf. Proc. 2014, 29, 219–252. [Google Scholar] [CrossRef]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Residual stress and surface roughness when facing age hardened Inconel 718 with cBN and ceramic cutting tools. Int. J. Mach. Tools Manuf. 2004, 44, 879–887. [Google Scholar] [CrossRef]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Surface integrity when machining age hardened Inconel 718 with coated carbide cutting tools. Int. J. Mach. Tools Manuf. 2004, 44, 1481–1491. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Hughes, J.J.; Ridgway, K. Workpiece surface integrity and tool life issues when turning Inconel 718 nickel-based superalloy. Mach. Sci. Technol. 2004, 8, 399–414. [Google Scholar] [CrossRef]

- Sadat, A.B.; Reddy, M.Y.; Wang, B. Plastic deformation analysis in machining of Inconel 718 nickel base superalloy using both experimental and numerical methods. Int. J. Mech. Sci. 1991, 33, 829–842. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Okeke, C.I. Tool life and surface integrity when machining Inconel 718 with PVD-and CVD-coated tools. Tribology 1999, 42, 353–360. [Google Scholar] [CrossRef]

- Schlauer, C.; Peng, R.L.; Oden, M. Residual stresses in a nickel-based superalloy introduced by turning. Mater. Sci. Forum. 2002, 404–407, 173–178. [Google Scholar] [CrossRef]

- Sadat, A.B. Surface region damage of machined Inconel 718 nickel base superalloy using natural and controlled contact length tools. Wear 1987, 119, 225–235. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Tang, S.H. Surface abuse when machining cast iron (G-17) and nickel-base superalloy (Inconel 718) with ceramic tools. J. Mater. Process. Technol. 1995, 55, 63–69. [Google Scholar] [CrossRef]

- Ulutan, D.; Sima, M.; Özel, T. Prediction of Machining Induced Surface Integrity Using Elastic-Viscoplastic Simulations and Temperature-Dependent Flow Softening Material Models in Titanium and Nickel-Based Alloys. Adv. Mater. Res. 2011, 223, 401–410. [Google Scholar] [CrossRef]

- Soo, S.L.; Aspinwall, D.K.; Dewes, R.C. Three-Dimensional, Finite element modelling of high-speed milling of Inconel 718. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2004, 218, 1555–1561. [Google Scholar] [CrossRef]

- Darwish, S.M. The impact of tool material and the cutting parameters on surface roughness of supermet 718 nickel superalloy. J. Mater. Process. Technol. 2000, 97, 10–18. [Google Scholar] [CrossRef]

- Aspinwall, D.K.; Soo, S.L.; Berrisford, A.E.; Walder, G. Workpiece surface roughness and integrity after WEDG of Ti-6Al-4V and Inconel 718 using minimum damage generator technology. CIRP Ann.-Manuf. Technol. 2008, 57, 187–190. [Google Scholar] [CrossRef]

- Attia, H.; Tavakoli, S.; Vargas, R.; Thomson, V. Laser-Assisted High-Speed Finish Turning of Superalloy Inconel 718 under Dry Conditions. CIRP Ann.-Manuf. Technol. 2010, 59, 83–88. [Google Scholar] [CrossRef]

- Axinte, D.; Chiffre, D.L. Effectiveness and resolution of tests for evaluating the performance of cutting fluids in machining aerospace alloys. Ann. CIR 2008, 57, 129–132. [Google Scholar] [CrossRef]

- Axinte, D.; Axinte, M.; Tannock, J.D.T. A multicriteria model for cutting fluid evaluation. Proc. Inst. Mech. Eng. Part B 2003, 217, 1341–1353. [Google Scholar] [CrossRef]

- Jin, D.; Liu, Z.; Yi, W.; Su, G. Influence of cutting speed on surface integrity for powder metallurgy nickel-based superalloy FGH95. Int. J. Adv. Manuf. Technol. 2011, 56, 553–559. [Google Scholar] [CrossRef]

- Jin, D.; Liu, Z. Effect of cutting speed on surface integrity and chip morphology in high-speed machining of PM nickel-based super alloy FGH95. Int. J. Adv. Manuf. Technol. 2012, 60, 893–899. [Google Scholar] [CrossRef]

- Jin, D.; Liu, Z. Damage of the machined surface and subsurface in orthogonal milling of FGH95 superalloy. Int. J. Adv. Manuf. Technol. 2013, 68, 1573–1581. [Google Scholar] [CrossRef]

- Jin, D.; Shaoyu, L. Deformation-phase transformation coupling mechanism of white layer formation in high speed machining of FGH95 Ni-based superalloys. Appl. Surf. Sci. 2014, 292, 197–203. [Google Scholar]

- Veldhuis, S.C.; Dosbaeva, G.K.; Elfizy, A.; Fox-Rabinovich, G.S.; Wagg, T. Investigations of white layer formation during machining of powder metallurgical Nibased ME 16 super alloy. J. Mater. Eng. Perform. 2010, 19, 1031–1036. [Google Scholar] [CrossRef]

- Soo, S.L.; Hood, R.; Aspinwall, D.K.; Voice, W.E.; Sage, C. Machinability and surface integrity of RR1000 nickel-based super alloy. CIRP Ann.-Manuf. Technol. 2011, 60, 89–92. [Google Scholar] [CrossRef]

- Herbert, C.R.J.; Kwong, J.; Kong, M.C.; Axinte, D.A.; Hardy, M.C.; Withers, P.J. An evaluation of the evolution of workpiece surface integrity in hole making operations for a nickel-based super alloy. J. Mater. Process. Technol. 2012, 212, 1723–1730. [Google Scholar] [CrossRef]

- Herbert, C.R.J.; Axinte, D.A.; Hardy, M.C.; Brown, P.D. Investigation into the characteristics of white layers produced in a nickel-based super alloy from drilling operations. Mach. Sci. Technol. Int. J. 2012, 16, 40–52. [Google Scholar] [CrossRef]

- Kwong, J.; Axinte, D.A.; Withers, P.J.; Hardy, M.C. Minor cutting edge–workpiece interactions in drilling of an advanced nickel-based superalloy. Int. J. Mach. Tools Manuf. 2009, 49, 645–658. [Google Scholar] [CrossRef]

- Kwong, J.; Axinte, D.A.; Withers, P.J. The sensitivity of Ni-based superalloy to hole making operations: Influence of process parameters on subsurface damage and residual stress. J. Mater. Process. Technol. 2009, 209, 3968–3977. [Google Scholar] [CrossRef]

- Axinte, D.A.; Andrews, P.; Li, W.; Gindy, N.; Withers, P.J. Turning of advanced Ni based alloys obtained via powder metallurgy route. Ann. CIR 2006, 55, 117–120. [Google Scholar] [CrossRef]

- Ranganath, S.; Guo, C.; Hegde, P. A finite element modeling approach to predicting white layer formation in nickel superalloys. CIRP Ann.-Manuf. Technol. 2009, 58, 77–80. [Google Scholar] [CrossRef]

- Ozel, T.; Arisoy, Y.M. Experimental and Numerical investigations on machining induced surface integrity in Inconel-100 nickel-base alloy. Procedia CIR 2014, 13, 302–307. [Google Scholar] [CrossRef][Green Version]

- Ulutan, D.; Arisoy, Y.M.; Ozel, T.; Mears, L. Empirical modeling of residual stress profile in machining nickel-based superalloys using the sinusoidal decay function. Procedia CIR 2014, 13, 365–370. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Multi objective optimization of experimental and simulated residual stresses in turning of nickel-alloy IN100. Mater. Manuf. Process. 2013, 28, 835–841. [Google Scholar] [CrossRef]

- Joshi, S.V.; Vizhian, S.P.; Sridhar, B.R.; Jayaram, K. Parametric study of machining effect on residual stress and surface roughness of nickel-base super alloy Udimet 720. Adv. Mater. Res. 2008, 47–50, 13–16. [Google Scholar] [CrossRef]

- Cui, C.; Gu, Y.; Harada, H.; Sato, A. Microstructure and yield strength of Udimet 720LI alloyed with Co-16.9 Wt Pct Ti. Metall. Mater. Trans. A 2005, 36, 2921–2927. [Google Scholar]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti–6Al–6V–2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Rahman, M.; Seah, W.K.H.; Teo, T.T. The machinability of Inconel 718. J. Mater. Process. Technol. 1997, 63, 199–204. [Google Scholar] [CrossRef]

- Dudzinski, D.; Devillez, A.; Moufki, A.; Larrouquerre, D.; Zerrouki, V.; Vigneau, J. A review of developments towards dry and high speed machining of Inconel 718 alloy. Int. J. Mach. Tools Manuf 2004, 44, 439–456. [Google Scholar] [CrossRef]

- Li, L.; He, N.; Wang, M.; Wang, Z.G. High speed cutting of Inconel 718 with coated carbide and ceramic inserts. J. Mater. Process. Technol. 2002, 129, 127–130. [Google Scholar] [CrossRef]

- Mitrofanov, A.V.; Babitsky, V.I.; Silberschmidt, V.V. Finite element analysis of ultrasonically assisted turning of Inconel 718. J. Mater. Process. Technol. 2004, 153–154, 233–239. [Google Scholar] [CrossRef]

- Zhang, B.; Mynors, D.J.; Mugarra, A.; Ostolaza, K. Representing the superplasticity of Inconel 718. J. Mater. Process. Technol. 2004, 153–154, 694–698. [Google Scholar] [CrossRef]

- Uhlmann, E.; von der Schulenburg, M.G.; Zettier, R. Finite element modeling and cutting simulation of Inconel 718. Ann. CIR 2007, 56, 61–64. [Google Scholar] [CrossRef]

- Courbon, C.; Kramar, D.; Krajnik, P.; Pusavec, F.; Rech, J.; Kopac, J. Investigation of machining performance in high-pressure jet assisted turning of Inconel 718: Anexperimental study. Int. J. Mach. Tools Manuf. 2009, 49, 1114–1125. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, C. Finite element modeling of multi-pass machining of Inconel 718. In Proceedings of the 2009 ASME International Conference on Manufacturing Science and Engineering, Lafayette, IN, USA, 5–7 October 2009. Paper No. 84086. [Google Scholar]

- Sunulahpa, R.; Oru, M.; Had, M.; Rimac, M. Optimization of the mechanical properties of the superalloy nimonic 80a. Mater. Tehnologije 2012, 46, 263. [Google Scholar]

- Zou, B.; Chen, M.; Huang, C. An study on surface damages caused by turning NiCr20TiAl nickel-based alloy. J. Mater. Process. Technol. 2009, 209, 5802–5809. [Google Scholar] [CrossRef]

- Aytekin, H.; Akcin, Y. Characterization of borided Inconel 825 alloy. Mater. Des. 2013, 50, 515–521. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S.; Maity, K. Effect of cutting speed and CVD multilayer coating on machinability of Inconel 825. Surf. Eng. 2014, 30, 516–523. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S.; Mohanty, A. Investigation on Some Machinability Aspects of Inconel 825 during Dry Turning. Mater. Manuf. Process. 2014, 30, 1026–1034. [Google Scholar] [CrossRef]

- Thakur, A.; Mohanty, A.; Gangopadhyay, S. Comparative study of surface integrity aspects of Incoloy 825 during machining with uncoated and CVD multilayer coated inserts. Appl. Surf. Sci. 2014, 320, 829–837. [Google Scholar] [CrossRef]

- Ezilarasan, C.; Kumar, V.S.; Velayudham, A. An experimental analysis and measurement of process performances in machining of Nimonic C-263 super alloy. Measurement 2013, 46, 185–199. [Google Scholar] [CrossRef]

- Ezilarasan, C.; Velayudham, A. Effect of machining parameters on surface integrity in machining Nimonic C-263 super alloy using whisker-reinforced ceramic insert. J. Mater. Eng. Perform. 2013, 22, 1619–1628. [Google Scholar] [CrossRef]

- Ezilarasan, C.; Kumar, V.S.; Velayudham, A.; Palanikumar, K. Modeling and analysis of surface roughness on machining of Nimonic C 263 alloy by PVD coated carbide insert. Transactions Nonferr. Met. Soc. 2011, 21, 1986–1994. [Google Scholar] [CrossRef]

- Ezilarasan, C.; Kumar, V.S. Effect of machining parameters on micro hardness and residual stresses. Int. Rev. Mech. Eng. 2012, 6, 91–97. [Google Scholar]

- Ezilarasan, C.; Kumar, V.S.; Velayudham, A.; Palanikumar, K. Surface roughness analysis on machining of nimonic C-263 alloy using ANN and RSM techniques. Int. J. Precis. Technol. 2011, 2, 340–354. [Google Scholar] [CrossRef]

- Ezilarasan, C.; Kumar, V.S.; Velayudham, A.; Palanikumar, K. Assessment of factors influencing tool wear on machining of nimonic C-263 alloy with PVD coated carbide inserts. Adv. Mater. Res. 2011, 291–294, 794–799. [Google Scholar] [CrossRef]

- Ezilarasan, C.V.; Kumar, V.S.; Velayudham, A. Theoretical predictions and experimental validations on machining the Nimonic C-263 super alloy. Simul. Model. Pract. Theory 2014, 40, 192–207. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S.; Mohanty, A.; Maity, K. Performance evaluation of CVD multilayer coating on tool wear characteristics during dry machining of Nimonic C-263. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Guwahati, India, 12–14 December 2014. [Google Scholar]

- Podder, B.; Paul, S. Improvement of machinability in end milling of Nimonic C-263 by application of high pressure coolant. IJMMM 2012, 11, 418–433. [Google Scholar] [CrossRef]

- Podder, B.; Paul, S. Effect of machining environment on machinability of Nimonic 263 during end milling with uncoated carbide tool. IJMMM 2008, 3, 104–119. [Google Scholar] [CrossRef]

- Wright, P.K.; Chow, J.G. Deformation characteristics of nickel alloys during machining. J. Eng. Mater. Technol. ASME 1982, 104, 85–93. [Google Scholar] [CrossRef]

- Lee, S.M.; Chow, H.M.; Yan, B.H. Friction Drilling of IN-713LC Cast Superalloy. Mater. Manuf. Proces. 2007, 2, 893–897. [Google Scholar] [CrossRef]

- Ludvík, K.; Lukáš, P.; Konečná, R. High-cycle fatigue of Ni-base superalloy Inconel 713LC. Int. J. Fatigue 2010, 32, 908–913. [Google Scholar]

- Zielińska, M.; Yavorska, M.; Poręba, M.; Sieniawski, J. Thermal properties of cast nickel based superalloys. Arch. Mater Sci. Eng. 2010, 44, 35–38. [Google Scholar]

- Zlá, S.; Smetana, B.; Žaludová, M.; Dobrovská, J.; Vodárek, V.; Konečná, K.; Matějka, V.; Francová, H. Determination of thermophysical properties of high temperature alloy IN713LC by thermal analysis. J. Therm. Anal. Calorim. 2012, 110, 211–219. [Google Scholar] [CrossRef]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Noor, M.M.; Kadirgama, K.; Habeeb, H.N.; Rahman, M.M.; Mohammad, B. Performance of carbide cutting tools when machining of nickel-based alloy. Int. J. Mat. Form. 2010, 3, 475–478. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; López de Lacalle, L.N.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Proc. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Kraus, L.; Zrnik; Wangyao, P.; Nemecek, S. Materials properties of modifeied Ni-based alloy. Metalurgija 2007, 46, 169–172. [Google Scholar]

- Devillez, A.; Le Coz, G.; Dominiak, S.; Dudzinski, D. Dry machining of Inconel 718, workpiece surface integrity. J. Mat. Proc. Technol. 2011, 211, 1590–1598. [Google Scholar] [CrossRef]

- Eckart, U. Cutting of Inconel and Nickel Base Materials. In CIRP Encyclopedy of Production Engineering; Springer: Cham, Switzerland, 2015; pp. 329–334. [Google Scholar]

- Brandt, G. Ceramic cutting tools. Ind. Ceramics. 2007, 21, 21–26. [Google Scholar]

- Tian, X.; Zhao, J.; Zhao, J.; Gong, Z.; Dong, Y. Effect of cutting speed on cutting forces and wear in high-speed face milling of Inconel 718 with Sialon ceramic tools. Int. J. Adv. Manuf. Technol. 2013, 69, 2669–2678. [Google Scholar] [CrossRef]

- Yazid, M.; Che Haron, C.H.; Ghani, J.A. Tool wear of PVD Coated Carbide Tool when Finish Turning Inconel 718 under high Speed Machining. Advanced Materials Research. 2010, 129, 1004–1008. [Google Scholar] [CrossRef]

- Nalbant, M.; Altin, A.; Gökkaya, H. The effect of cutting speed and cutting tool geometry on machinability properties of nickel-base Inconel 718 super alloys. Mater. Des. 2007, 28, 1334–1338. [Google Scholar] [CrossRef]

- Zheng, G.M.; Zhao, J.; Song, X.Y.; Yan, C.Q.; Li, Y.E. Ultra high speed turning of Inconel 718 with SiAlON ceramic tools. Adv. Mater. Res. 2010, 126–128, 653–657. [Google Scholar] [CrossRef]

- Zhuang, K.; Zhu, D.; Zhang, X.; Ding, H. Notch wear prediction model in turning of Inconel 718 with ceramic tools considering the influence of work hardened layer. Wear 2014, 313, 63–74. [Google Scholar] [CrossRef]

- Altin, A.; Nalbant, M.; Taskesen, A. The effects of cutting speed on tool wear and tool life when machining Inconel 718 with ceramic tools. Mater. Des. 2007, 28, 2518–2522. [Google Scholar] [CrossRef]

- Zheng, G.; Zhao, J.; Zhou, Y.; Li, A.; Cui, X.; Tian, X. Performance of graded nanocomposite ceramic tools in ultra-high-speed milling of Inconel 718. Int. J. Adv. Manuf. Technol. 2013, 67, 2799–2810. [Google Scholar] [CrossRef]

- Uludag, A.; Turan, D. High temperature bending creep behavior of a multi-cation doped α/β-SiAlON composite. Ceram. Int. 2011, 37, 921–926. [Google Scholar] [CrossRef]

- Çelik, A.; Alağaç, M.S.; Turan, S.; Kara, A.; Kara, F. Wear behavior of solid SiAlON milling tools during high speed milling of Inconel 718. Wear 2017, 378, 58–67. [Google Scholar] [CrossRef]

- Grigoriev, S.; Pristinskiy, Y.; Volosova, M.; Fedorov, S.; Okunkova, A.; Peretyagin, P.; Smirnov, A. Wire electrical discharge machining, mechanical and tribological performance of TiN reinforced multiscale SiAlON ceramic composites fabricated by Spark Plasma Sintering. Appl. Sci. 2021, 11, 657. [Google Scholar] [CrossRef]

- Deshpande, Y.; Andhare, A.; Sahu, N.K. Estimation of surface roughness using cutting parameters, force, sound, and vibration in turning of Inconel 718. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 5087–5096. [Google Scholar] [CrossRef]

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Technol. 1998, 300, 278–284. [Google Scholar] [CrossRef]

- Mišković, Z.; Lukić, B.; Gligić, M.; Jovanović, M. The casting and heat treatment of superalloy “444” under vacuum. Vacuum 1990, 40, 125–129. [Google Scholar] [CrossRef]

- Tsuda, O.; Kanamaru, N.; Furuta, S.; Takigawa, H.; Iwai, K. PM nickel-base superalloy dual-property disks produced by superplastic forging. Metal. Powder Rep. 1991, 46, 31–35. [Google Scholar] [CrossRef]

- Rosen, G.I.; Dirnfield, S.F.; Bamberger, M.; Rosen, A.; Prinz, B. Creep investigation of commercial and improved nickel-based wrought superalloys. Mater. Sci. Eng. A 1993, 172, 15–21. [Google Scholar] [CrossRef]

- Wakai, T.; Sakane, M.; Ohnami, M.; Okita, K.; Fukuchi, Y. High Temperature Low-Cycle Fatigue of Friction Welded Joints-Type 304-304 Stainless Steel and Alloy 718-718 Nickel Base Superalloy. J. Eng. Mater. Technol. 1993, 115, 109. [Google Scholar] [CrossRef]

- Branco, C.M.; Byrne, J. Fatigue behaviour of the nickel-bassed superalloy IN718 at elevated temperature. Fuel Energy Abstr. 1995, 36, 283. [Google Scholar]

- Österle, W.; Li, P.X. Mechanical and thermal response of a nickel-base superalloy upon grinding with high removal rates. Mater. Sci. Eng. A 1997, 238, 357–366. [Google Scholar] [CrossRef]

- Darwish, S. Machining of difficult-to-cut materials with bonded tools. Int. J. Adhes. Adhes. 2000, 20, 279–289. [Google Scholar] [CrossRef]

- Zaretsky, E.B.; Kanel, G.I.; Razorenov, S.V.; Baumung, K. Impact strength properties of nickel-based refractory superalloys at normal and elevated temperatures. Int. J. Impact Eng. 2005, 31, 41–54. [Google Scholar] [CrossRef]

- Alniak, M.O.; Bedir, F. Hot forging behavior of nickel based superalloys under elevated temperatures. Mater. Des. 2010, 31, 1588–1592. [Google Scholar] [CrossRef]

- He, D.-G.; Lin, Y.C.; Chen, M.-S.; Chen, J.; Wen, D.-X.; Chen, X.-M. Effect of pre-treatment on hot deformation behavior and processing map of an aged nickel-based superalloy. J. Alloy. Compd. 2015, 649, 1075–1084. [Google Scholar] [CrossRef]

- Mignanelli, P.M.; Jones, N.G.; Perkins, K.M.; Hardy, M.C.; Stone, H.J. Microstructural evolution of a delta containing nickel-base superalloy during heat treatment and isothermal forging. Mater. Sci. Eng. A 2015, 621, 265–271. [Google Scholar] [CrossRef]

- Lei, Y.; Li, X.; Sun, R.; Tang, Y.; Niu, W. Effect of sintering temperature and heat treatment on microstructure and properties of nickel-based superalloy. J. Alloy. Compd. 2020, 818, 152882. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, C.; Han, B.; Qiu, J.; Li, H.; Qin, S.; Zhou, H. Evolution of grain boundary character distributions in a cold-deformed Nickel-based superalloy during electropulsing treatment. J. Mater. Res. Technol. 2020, 9, 5723–5734. [Google Scholar] [CrossRef]

- Sreenu, B.; Sarkar, R.; Kumar, S.S.S.; Chatterjee, S.; Rao, G.A. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater. Sci. Eng. A 2020, 797, 140254. [Google Scholar] [CrossRef]

- Bushlya, V.; Zhou, J.; Ståhl, J.-E. Modeling and experimentation on multistage work-hardening mechanism in machining with nose-radiused tools and its influence on machined subsurface quality and tool wear. Int. J. Adv. Manuf. Technol. 2014, 73, 545–555. [Google Scholar] [CrossRef]

- Sharman, A.; Dewes, R.C.; Aspinwall, D.K. Tool life when high speed ball nose end milling Inconel 718. J. Mater. Process. Technol. 2001, 118, 29–35. [Google Scholar] [CrossRef]

- Prasad, K.; Nagendra, K.; Adarsha, H.; Nagaraj, A.; Ravinarayan, V.; Sandeep, V.; Ranganatha, S.M. Analysis on the Effects of Cut-Outs in Hollow Inconel 718 Gas Turbine Shafts. Open J. Appl. Sci. 2018, 8, 304–313. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- Arunachalam, R.; Mannan, M.A. Machinability of nickel-based high temperature alloys. Mach. Sci. Technol. Int. J. 2000, 4, 127–168. [Google Scholar] [CrossRef]

- Wei, F.; Wei, J.; Wang, L.; Zheng, L.; Wang, Y. A review on cutting tool technology in machining of Ni-based superalloys. Int. J. Adv. Manuf. Technol. 2020, 110, 2863–2879. [Google Scholar]

- Settineri, L.; Levi, R. Surface Properties and Performance of Multilayer Coated Tools in Turning lnconel. CIRP Ann.-Manuf. Technol. 2005, 54, 515–551. [Google Scholar] [CrossRef]

- Khidhir, B.A.; Mohamed, B. Machining of nickel based alloys using different cemented carbide tools. J. Eng. Sci. Technol. 2010, 5, 264–271. [Google Scholar]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Andreev, N.; Milovich, F. Investigation of wear and diffusion processes on rake faces of carbide inserts with Ti-TiN-(Ti,Al,Si)N composite nanostructured coating. Wear 2018, 416–417, 72–80. [Google Scholar] [CrossRef]

- Costes, J.P.; Guillet, Y.; Poulachon, G.; Dessoly, M. Tool-life and wear mechanisms of CBN tools in machining of Inconel 718. Int. J. Mach. Tools Manuf. 2007, 47, 1081–1087. [Google Scholar] [CrossRef]

- Bushlya, V.; Gutnichenko, O.; Zhou, J.; Avdovic, P.; Ståhl, J.-E. Effects of cutting speed when turning age hardenedinconel 718with pcbn tools of binderless and low-cbn grades. Mach. Sci. Technol. 2013, 17, 497–523. [Google Scholar] [CrossRef]

- Xikun, L.; Jing, L.; Like, Q.; Tong, C.; Guanming, Q.; Yanbin, S. Composition, Characteristics and Development of Advanced Ceramic Cutting Tools. J. Rare Earths 2007, 25, 287–294. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of Titanium Nitride Coating on Stress Structural Inhomogeneity in Oxide-Carbide Ceramic. Part 4. Action of Heat Flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of Tinaium Nitride Coatings on Stress Structural Inhomogeneity in Oxide-Carbide Ceramic. Part 2. Concentrated Force Action1. Refract. Ind. Ceram. 2015, 55, 487–491. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N.; Fedorov, M.Y. Role of the thermal factor in the wear mechanism of ceramic tools. Part 2: Microlevel. J. Frict. Wear 2015, 36, 40–44. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N.; Volosova, M.A. Effect of a TiC Coating on the Stress-Strain State of a Plate of a High-Density Nitride Ceramic Under Nonsteady Thermoelastic Conditions. Refract. Ind. Ceram. 2014, 54, 376–380. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, J.; Zhou, Y. and Zheng, G. Damage mechanics analysis of failure mechanisms for ceramic cutting tools in intermittent turning. Eur. J. Mech.-A/Solids. 2013, 37, 139–149. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N.; Volosova, M.A. The role of the thermal factor in the wear mechanism of ceramic tools: Part 1. Macrolevel. J. Frict. Wear 2014, 35, 505–510. [Google Scholar] [CrossRef]

- Bushlya, V.; Zhou, J.; Avdovic, P.; Ståhl, J.-E. Wear mechanisms of silicon carbide-whisker-reinforced alumina (Al2O3–SiCw) cutting tools when high-speed machining aged Alloy 718. Int. J. Adv. Manuf. Technol. 2013, 68, 1083–1093. [Google Scholar] [CrossRef]

- Byrne, G.; Dornfeld, D.; Denkena, B. Advancing Cutting Technology. CIRP Ann.-Manuf. Technol. 2003, 52, 483–507. [Google Scholar] [CrossRef]

- Conaway, H.R. Machining the High Nickel Alloys. In Influence of Metallurgy on Machinability; ASM International: Almere, The Netherlands, 1975; pp. 247–256. [Google Scholar]

- Koseki, S.; Inoue, K.; Usuki, H. Damage of Physical Vapor Deposition Coatings of Cutting Tools during Alloy 718 Turning. Precis. Eng. 2015, 44, 41–54. [Google Scholar] [CrossRef]

- Hu, Z.; Qin, C.; Chen, X.; Tang, A.; Fang, T.; Yang, Z.; Luo, S.; Mao, M. Chemical–Mechanical Polishing of Cemented Carbide Insert Surface for Extended Tool Life in Turning of GH4169 Nickel-Based Superalloy. Int. J. Precis. Eng. Manuf. 2020, 21, 1421–1435. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Vereschaka, A.A.; Savushkin, G.J.; Sivenkov, A.S. Multilayer nanostructured coatings for cutting tools. Inorg. Mater. Appl. Res. 2014, 5, 522–529. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZRN -(ZR,AL,SI) N coatings. Surf. Coat. Technol. 2019, 357, 218–234. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Grigoriev, S.N.; Tabakov, V.P.; Sotova, E.S.; Vereschaka, A.A.; Kulikov, M.Y. Improving the Efficiency of the Cutting Tool Made of Ceramic when Machining Hardened Steel by Applying Nano-Dispersed Multi-Layered Coatings. Key Eng. Mater. 2013, 581, 68–73. [Google Scholar] [CrossRef]

- Arunachalam, R.M.; Mannan, M.A. Performance of CBN cutting tools in facing of age hardened Inconel 718. Conf. Trans. NAMRI/SME 2004, 32, 525–532. [Google Scholar]

- Harris, T.K.; Brookes, E.J.; Taylor, C.J. The effect of temperature on the hardness of polycrystalline cubic boron nitride cutting tool materials. Int. J. Refract. Met. Hard Mater. 2004, 22, 105–110. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. Tool wear progression of PCD and PCBN cutting tools in high speed machining of NiTi shape memory alloy under various cutting speeds. Diam. Relat. Mater. 2020, 105, 107810. [Google Scholar] [CrossRef]

- Zhao, J. The use of ceramic matrix composites for metal cutting applications. Adv. Ceram. Matrix Compos. 2014, 623–654. [Google Scholar]

- Coelho, R.T.; Silva, L.R.; Braghini, A.; Bezerra, A.A. Some effects of cutting edge preparation and geometric modifications when turning INCONEL 718™ at high cutting speeds. J. Mater. Process. Technol. 2004, 148, 147–153. [Google Scholar] [CrossRef]

- Cui, E.; Zhao, J.; Wang, X.; Song, S. Cutting performance, failure mechanisms and tribological properties of GNPs reinforced Al2O3/Ti(C,N) ceramic tool in high speed turning of Inconel 718. Ceram. Int. 2020, 47, 18075–18083. [Google Scholar] [CrossRef]

- Guo, F.; Yuan, J.; Hong, D.; Yin, Z. Influence of powder mixing process on phase composition, microstructure, and mechanical properties of α/β-SiAlON ceramic tool materials. Ceram. Int. 2021, 47, 30256–30265. [Google Scholar]

- Joshi, B.; Gyawali, G.; Lee, S.W. Recent advances in transparent/translucent polycrystalline Sialon ceramics. Lett. Mater. 2020, 10, 158–163. [Google Scholar] [CrossRef]

- Kshetri, Y.K.; Kamiyama, T.; Torii, S.; Jeong, S.H.; Kim, T.-H.; Choi, H.; Lee, S.W. Electronic structure, thermodynamic stability and high-temperature sensing properties of Er-α-SiAlON ceramics. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef]

- Cao, G.Z.; Metselaar, R. .alpha.’-Sialon ceramics: A review. Chem. Mater. 1991, 3, 242–252. [Google Scholar] [CrossRef]

- Hakeem, A.S.; Khan, M.; Ahmed, B.A.; Ghanim, A.A.; Patel, F.; Ehsan, M.A.; Ali, S.; Laoui, T.; Ali, S. Synthesis and characterization of alkaline earth and rare earth doped sialon Ceramics by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2021, 97, 105500. [Google Scholar] [CrossRef]

- Holzer, S.; Häntsche, J.P.; Spicher, U.; Badenheim, D.; Oberacker, R.; Hoffmann, M.J. Development of sialon ceramics for lubricated sliding applications. Materialwissenschaft Werkstofftechnik 2005, 36, 117–121. [Google Scholar] [CrossRef]

- Falk, L.K.L.; Shen, Z.-J.; Ekström, T. Microstructural stability of duplex α-β-sialon ceramics. J. Eur. Ceram. Soc. 1997, 17, 1099–1112. [Google Scholar] [CrossRef]

- Hampshire, S. Silicon Nitride Ceramics-review of structure, processing and properties. J. Achiev. Mater. Manuf. Eng. 2007, 24. [Google Scholar]

- Ekström, T. α SiAlON and α-βSiAlON Composites Recent Research. Eng. Ceram. ’96 High. Reliab. Through Process. 1997, 25, 147–167. [Google Scholar]

- Salamon, D.; Šajgalík, P.; Liška, M. Mechanical Properties and Microstructure of α-SiAlON Based Cutting Tools. Key Eng. Mater. 2005, 290, 250–253. [Google Scholar] [CrossRef]

- Rosenflanz, A.; Chen, I.-W. Phase Relationships and Stability of α′-SiAlON. J. Am. Ceram. Soc. 1999, 82, 1025–1036. [Google Scholar] [CrossRef]

- Mandal, H.; Hoffmann, M.J. Preparation of Multiple-Cation alpha-SiAlON Ceramics Containing Lanthanum. J. Am. Ceram. Soc. 1999, 82, 229–232. [Google Scholar] [CrossRef]

- Cozzan, C.; Griffith, K.J.; Laurita, G.; Hu, J.G.; Grey, C.P.; Seshadri, R. Structural evolution and atom clustering in β-SiAlON: β-Si6–zAlzOzN8–z. Inorg. Chem. 2017, 56, 2153–2158. [Google Scholar] [CrossRef]

- Hou, X.M.; Yue, C.S.; Zhang, M.; Chou, K.C. Thermal oxidation of SiAlON powders synthesized from coal gangue. Int. J. Miner. Metall. Mater. 2011, 18, 77–82. [Google Scholar] [CrossRef]

- Li, Y.; Liu, D.; Jin, H.; Ding, D.; Xiao, G.; Shi, Z.; Jin, Z. Effect of Z values on the microstructure and mechanical properties of post-sintered reaction bonded β-SiAlON. High Tem. Mater. Process. 2017, 36, 453–458. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, Z.; Huang, J.; Wang, S.; Xiong, Q.; Feng, Z.; Liu, Q.; Sun, Z.; Li, X. In situ nitriding reaction formation of β-Sialon with fibers using transition metal catalysts. Ceram. Int. 2019, 45, 21923–21930. [Google Scholar] [CrossRef]

- Xiong, Q.M.; Chen, Z.; Huang, J.T.; Zhang, M.; Song, H.; Hou, X.F.; Li, X.B.; Feng, Z.J. Preparation, structure and mechanical properties of sialon ceramics by transition metal-catalyzed nitriding reaction. Rare Met. 2020, 39, 589–596. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon nitride and related materials. J. Am. Ceram. Soc. 2004, 83, 245–265. [Google Scholar] [CrossRef]

- Izhevskiy, V.A.; Genova, L.A.; Bressiani, J.C.; Aldinger, F. Progress in SiAlON ceramics. J. Eur. Ceram. Soc. 2000, 20, 2275–2295. [Google Scholar] [CrossRef]

- Jack, K.H. Review: Sialon and related nitrogen ceramics. J. Mater. Sci. 1976, 11, 1135–1158. [Google Scholar] [CrossRef]

- Zhuo, T.; Yuping, Y.; Yong, W.; Haidong, W.; Wei, L.; Shanghua, W. The shrinkage, phase composition and mechanical properties of ceramics with different β-sialon main crystalline phases prepared by stereolithography. Ceram. Silik. 2020, 64, 1–9. [Google Scholar]

- Low, I.M. Ceramic-Matrix Composites. Microstructure, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2006; pp. 491–513. ISBN 1855739429. [Google Scholar]

- Ekström, T. Effect of composition, phase content and microstructure on the performance of Yttrium–Si–Al–O–N ceramics. Mater. Sci. Eng. 1989, A109, 341–349. [Google Scholar] [CrossRef]

- Mandal, H.; Kara, F.; Turan, S.; Kara, A. Novel SiAlON Ceramics for Cutting Tool Applications. Key Eng. Mater. 2003, 237, 193–202. [Google Scholar] [CrossRef]

- Bitterlich, B.; Bitsch, S.; Friederich, K. SiAlON based ceramic cutting tools. J. Eur. Ceram. Soc. 2008, 28, 989–994. [Google Scholar] [CrossRef]

- Fernandez-Lucio, P.; Neto, O.P.; Gomez-Escudero, G.; Fuertes, F.J.A.; Valdivielso, A.F.; Lopez de Lacalle Marcaide, L.N. Roughing milling with ceramic tools in comparison with sintered carbide on nickel-based alloys. Coatings 2021, 11, 34. [Google Scholar] [CrossRef]

- Krebs, G.; Polli, M.L. Cutting Parameters for Roughing Turning of Alloy 625 Clad Using Ceramic Inserts. Mater. Res. 2019, 22, e20190535. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Tu, G.; Long, Y. Cutting performance and wear mechanism of Sialon ceramic cutting inserts with TiCN coating. Surf. Coat. Technol. 2016, 307, 146–150. [Google Scholar] [CrossRef]

- Zheng, G.; Zhao, J.; Cheng, X.; Xu, R.; Zhao, G. Experimental Investigation on Sialon Ceramic Inserts for Ultra-high-speed Milling of Inconel 718. Mater. Manuf. Process. 2015, 31, 633–640. [Google Scholar] [CrossRef]

- Ingelström, N.; Ekström, T. Relation between composition, microstructure and cutting tool performance of Alpha-Beta-SiAlONs. J. Phys. Colloq. 1986, 47, 347–352. [Google Scholar] [CrossRef]

- Lima, F.F.; Sales, W.F.; Costa, E.S.; da Silva, F.J.; Machado, Á.R. Wear of ceramic tools when machining Inconel 751 using argon and oxygen as lubri-cooling atmospheres. Ceram. Int. 2017, 43, 677–685. [Google Scholar] [CrossRef]

- Kasim, M.S.; Haron, C.H.; et al. Multi-Objective Optimization Using Box-Behken of Response Surface Methodology for High-Speed Machining of Inconel 718. Appl. Mater. 2014, 629, 487–492. [Google Scholar] [CrossRef]

- Sarkar, B.; Reddy, M.M.; Debnath, S. Effect of machining parameters on surface finish of Inconel 718 in end milling. MATEC Web Conf. 2017, 02009, 1–6. [Google Scholar] [CrossRef]

- Zheng, G.; Zhao, J.; Zhou, Y. Friction and wear behaviors of Sialon–Si3N4 graded nano-composite ceramic materials in sliding wear tests and in cutting processes. Wear 2012, 290–291, 41–50. [Google Scholar] [CrossRef]

- Shalaby, M.A.; Veldhuis, S. Effect of Cutting Speed on Chipping and Wear of the SiAlON Ceramic Tool in Dry Finish Turning of the Precipitation Hardenable IN100 Aerospace Superalloy. J. Tribol. 2018, 141, 021604. [Google Scholar] [CrossRef]

- Zhou, J.; Bushlya, V.; Peng, R.L.; Chen, Z.; Johansson, S.; Stahl, J.E. Analysis of Subsurface Microstructure and Residual Stresses in Machined Inconel 718 with PCBN and Al2O3-SiCw Tools. Procedia CIRP 2014, 13, 150–155. [Google Scholar] [CrossRef]

- Ibrahim, G.A.; Che Haron, C.H.; Ghani, G.A.; Said, A.Y.M. Performance of PVD and CVD coated tools when machining nickel-based, Inconel 718 alloy. Adv. Mech. Eng. 2011, 3, 1–10. [Google Scholar]

| Various Categories of Nickel-Based Superalloys | Composition | Properties |

|---|---|---|

| Inconel 718 | Ni 54.48, Cr 17.50, Fe 22.3, Nb 4.90, Al 0.66, Ti 0.96 | Precipitation hardenable, high creep–rupture strength at high temperatures to about 700 °C, and excellent strength. Precipitates of primary niobium carbide (NbC), titanium carbide (TiC) disk-shaped gamma double prime (γ″) precipitates (Ni3Nb), and needle-like precipitates of δ (Ni3Nb) present. |

| Inconel 100 | Ni 60, Cr 10, Co 15, Mo 3, Al 5.5, Ti 4.7, C 0.18, B 0.014, Zr 0.06 | Precipitation hardenable, high rupture strength through 870 °C. The high percentages of titanium, aluminium, and low refractory metal increase strength-to-density ratio. |

| Inconel 825 | Ni 37.1, Fe 32.2, Cr 22.8, Mo 3.24, Cu 2.07, Ti 0.859, C 0.0155 | Good resistance to pitting, intergranular corrosion, chloride-ion stress-corrosion cracking, and general corrosion in a wide range of oxidising and reducing environments. |

| IN-713LC | Ni 74.2, Cr 12.6, Mo 4.9, Nb 1.96, Al 5.7, Zr 0.1, Ti 0.63, C 0.047, B 0.007 | Good combination of tensile and creep–rupture properties as a result of gamma-prime strengthening enhanced by solid solution and grain-boundary strengthening, and good castability. |

| Udimet 720LI | Ni 57.4, Cr 16, Co 15, Mo 3, Ti 5, Al 2.5, W1, C 0.1 | Solid solution strengthened with tungsten and molybdenum and precipitation-hardened with titanium and aluminium. High strength, excellent impact strength retention at elevated temperatures, good oxidation and corrosion resistance, and high degree of work hardening. |

| FGH95 | Ni 62.5, Cr 12.98, Co 8.00, Nb, 3.50, Al 3.48, Ti 2.55, W 3.40, Mo 3.40, C 0.060, B 0.012 | Precipitation hardened having higher tensile and yield strength at 650 °C. A compact structure after hot isostatic pressing (HIP) consisting of coarse gamma prime phase (γ′) precipitated along previous particle boundaries (PPB) appear in the grain. |

| ME-16 | Ni 56.3, Cr 10.4, Co 20.5, Al 3.1, Ti 2.6, W 3, Ta 1.4, Mo 1.3, Nb 1.4 | Good strength and creep resistance at high temperatures (600–800 °C). Good resistance to fatigue crack initiation at the lower temperatures (300–600 °C). Can maintain strength and lower density at elevated temperature. |

| RR1000 | Ni 52.4, Cr 15, Co 18.5, Mo 5, Ti 3.6, Al 3, Ta 2, Hf 0.5, C 0.03 | Solid solution strengthened with chromium, molybdenum, and cobalt. Good strength, good toughness, creep resistance, good oxidation, and corrosion resistance at high temperatures. |

| Nimonic C-263 | Ni 51.0, Cr 20.0, Co 20.0, Mo 5.8, Ti 2.2, Al 0.5 | A readily weldable, age-hardenable superalloy with excellent strength, ductility, and corrosion resistance up to around 850 °C. Molybdenum for solid-solution strengthening. |

| Nimonic 105 | Ni 54.0, Co 20.0, Cr 15.0, Mo 5.0, Al 4.7, Ti 1.3 | An age-hardenable superalloy within creased aluminium for improved oxidation-resistance and strength, and high creep–rupture properties up to around 950 °C. Strengthened by additions of molybdenum, aluminium, and titanium. |

| Nimonic 75 | Ni 80.5, Cr 19.5 | Good corrosion and heat resistance, high-temperature strength, and outstanding oxidation resistance. |

| Nimonic 80 A | Ni 76.0, Cr 19.5, Ti 2.4, Al 1.4 | An age-hardenable creep-resistant alloy for service at temperatures up to around 815 °C. |

| Hastelloy alloy C-2000 | Ni 47, Cr 22, Fe 18, Mo 9, Co 1.5, W 0.6 | Localised corrosion resistance, good resistance to hot acids, and excellent resistance to stress-corrosion cracking. |

| Haynes 282 | Ni 57, Cr 20, Co 10, Mo 8.5, Ti 2.1, Al 1.5, Fe 1.5, Mn 0.3, Si 0.15, C 0.06, B 0.005 | γ′ precipitation strengthened nickel-based superalloy along with excellent creep properties, fabricability, and thermal stability. |

| Composite | Producer/Country | Grade | Density (g∙cm3) | Hardness (HRA) | Flexural Strength (MPa) | Fracture Toughness (MPa∙m1/2) | Applications |

|---|---|---|---|---|---|---|---|

| Shandong University (China) | AT | 4.6 | 2040 HV | 820 | 7.4 | ||

| Al2O3/(W, Ti)C | SG-4 | 6.65 | 94.7–95.3 | 850 | 4.94 | Machining hardened steels | |

| FG-2(graded) | 94.7–95.5 | 830 | |||||

| AWT10 | 6.65 | 2350 HV | 930 | 7.55 | |||

| Al2O3/WC/TiCn | Shandong University (China) | LWT-1 | 6.5 | 2340 HV | 840 | 7.87 | |

| Shandong University (China) | JX-1 | 3.63 | 94–95 | 800 | 8.5 | ||

| Al2O3/SiCw | Sandvik Coromant (Sweden) | CC670 | 3.74 | 2000 HV | 900 | 8.0 | Machining heat- resistant alloys |

| Kennametal (USA) | KY4300 | 3.74 | 2000 HV | 700 | 7.7 | ||

| Al2O3/TiB2/SiCw | Shandong University (China) | LP-2 | 3.94 | 94–95 | 700–800 | 7.8 |

| Brand | Composition | Hardness (HRA) | Bending Strength (GPa) | Density (g∙ cm3) | Fracture Toughness (MPa∙ m1/2) | Company/Country |

|---|---|---|---|---|---|---|

| HDM1 | Si3N4 matrix | 92.5 | 0.93 | China | ||

| HDM2 | Si3N4 matrix, fiber | 93 | 0.98 | |||

| HDM3 | Si3N4 matrix | 92.5 | 0.83 | |||

| N55555 | Si3N4 matrix | (≥96.5) | ||||

| CC680 | Si3N4- Al2O3- Y2O3 | 93.5~94.5 | 1.0~1.3 | Sandvik Coromant (Sweden) | ||

| KY3000 | 77% Si3N4-13% Al2O3-10% Y2O3 | 1800 (uniaxial HV) | 1.0~1.3 | Kennametal (USA) | ||

| Kyon2000 | No pressure sintered Sialon | 1800 (HV) | 765 | 3.2~3.4 | 6.5 | USA |

| Quantum5000 | Hot pressing Si3N4-TiC | 93.5 | 750 | 3.4 | 4.3 | |

| Lsay | Hot pressing Si3N4+ Y2O3 | 2150 (HV) | 714 | 3.2 | ||

| SX7 | 93.0 | 1100 | 7.0 | Japan | ||

| FX920 | 92.8 | 960 | 3.27 | 9.4 | ||

| FX910 | 94.7 | 760 | 3.32 | 6.7 | ||

| Naycon | 92.8 | 1000 | 3.23 | |||

| NCT | Hot pressing Si3N4 | 92.6 | 816 | 3.3 | 6.7 | Germany |

| KY1540 | α/β- SiAlON | 18.24 | 3.35 | 7.45 | Kennametal (USA) |

| Number | Sample | Base | Phases |

|---|---|---|---|

| 1 | A039–HIP1 | α- sialon | - |

| 2 | A039–HIP1 | α- Sialon | Y2O3, La5Si3NO12, Y10Al2Si3O18N4 |

| 3 | A057–HIP1 | α- Sialon | SiAl6O2N6, Y2O3, La2O3 |

| 4 | A057–HIP3 | β- Sialon, α- Sialon | SiAl6O2N6 |

| 5 | A057–HIP4 | α- Sialon | SiAl6O2N6 |

| 6 | B069–HIP3 | β- Sialon | - |

| 7 | A039–HIP5 | β-Sialon | SiAl6O2N6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seleznev, A.; Pinargote, N.W.S.; Smirnov, A. Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review. Metals 2021, 11, 1385. https://doi.org/10.3390/met11091385

Seleznev A, Pinargote NWS, Smirnov A. Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review. Metals. 2021; 11(9):1385. https://doi.org/10.3390/met11091385

Chicago/Turabian StyleSeleznev, Anton, Nestor Washington Solis Pinargote, and Anton Smirnov. 2021. "Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review" Metals 11, no. 9: 1385. https://doi.org/10.3390/met11091385

APA StyleSeleznev, A., Pinargote, N. W. S., & Smirnov, A. (2021). Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review. Metals, 11(9), 1385. https://doi.org/10.3390/met11091385