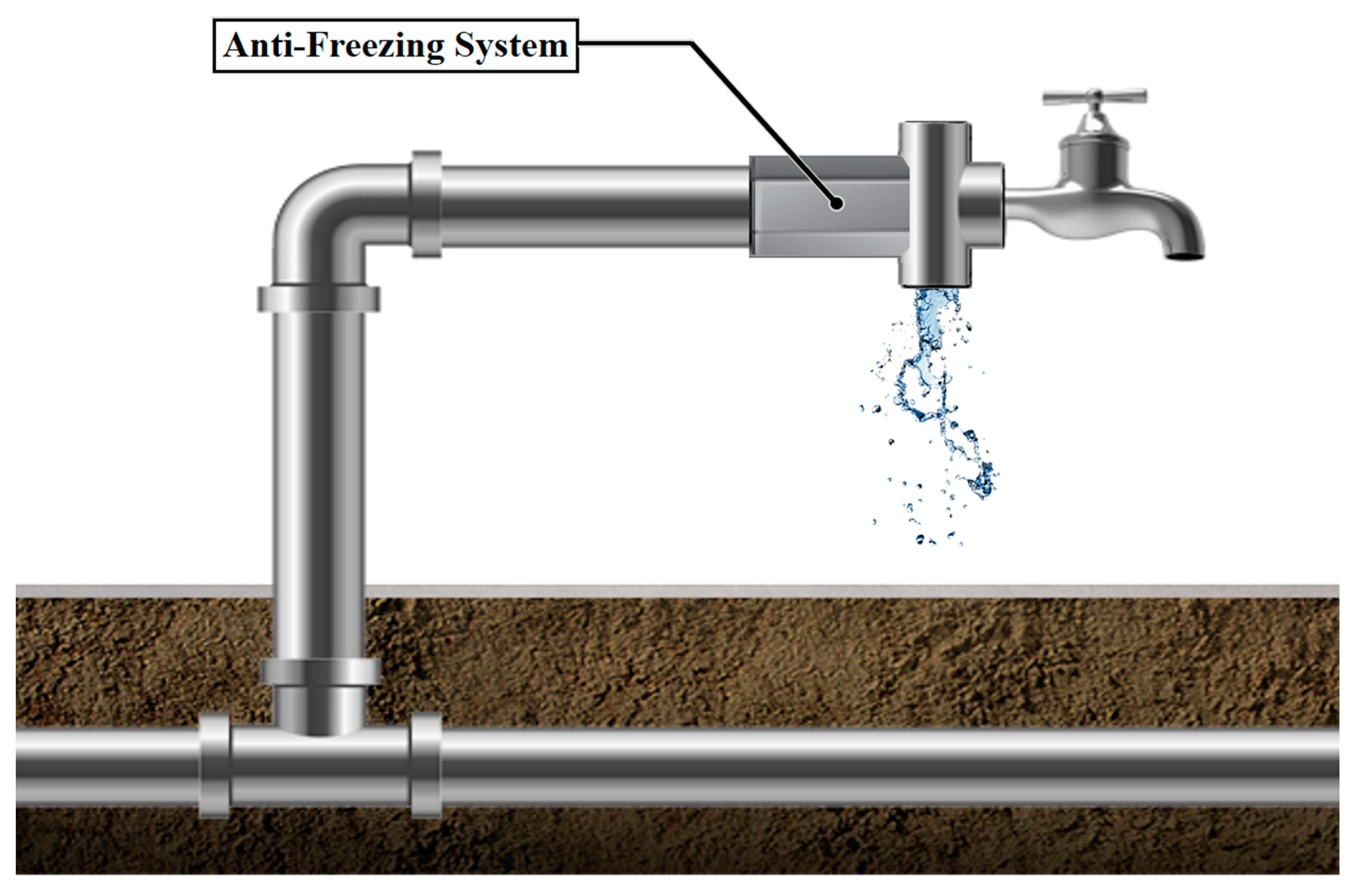

Automatic Actuation of the Anti-Freezing System Using SMA Coil Springs

Abstract

:1. Introduction

2. Design and Fabrication of SMA Springs

2.1. SMA Alloys

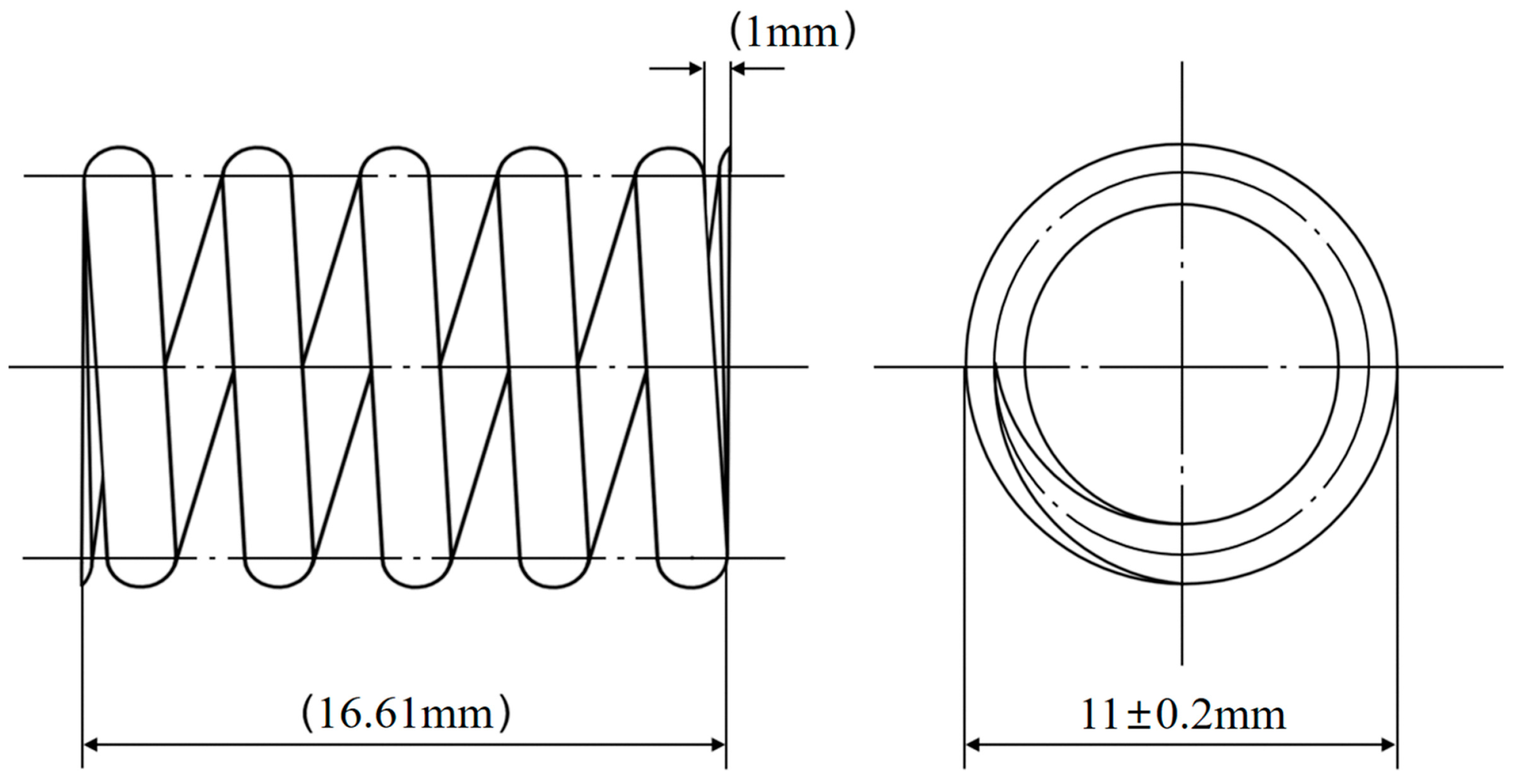

2.2. Design and Fabrication

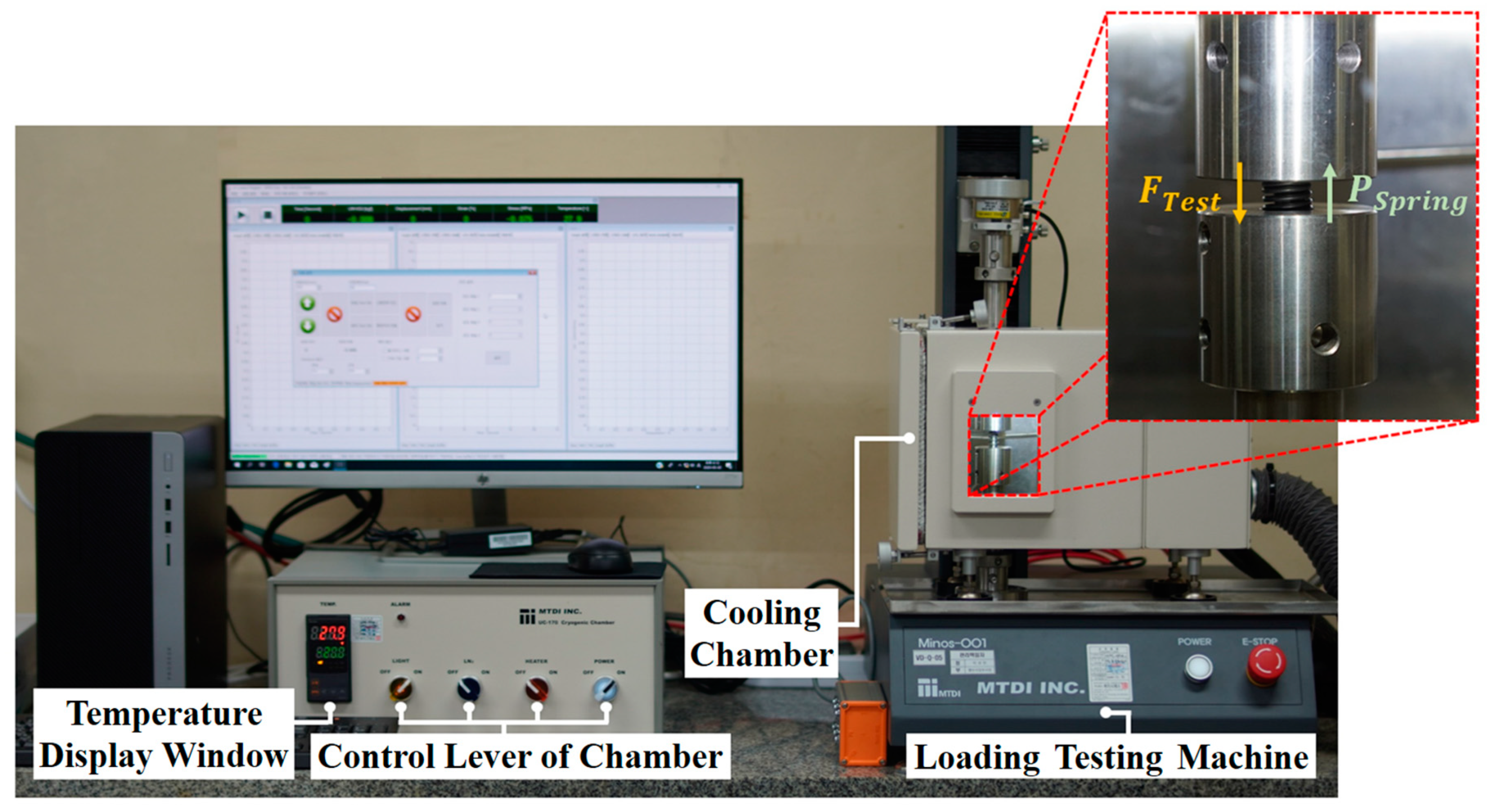

3. Experimental Measurement of SMA Springs

3.1. Spring Loading Test

3.2. Results of Spring Loading Test

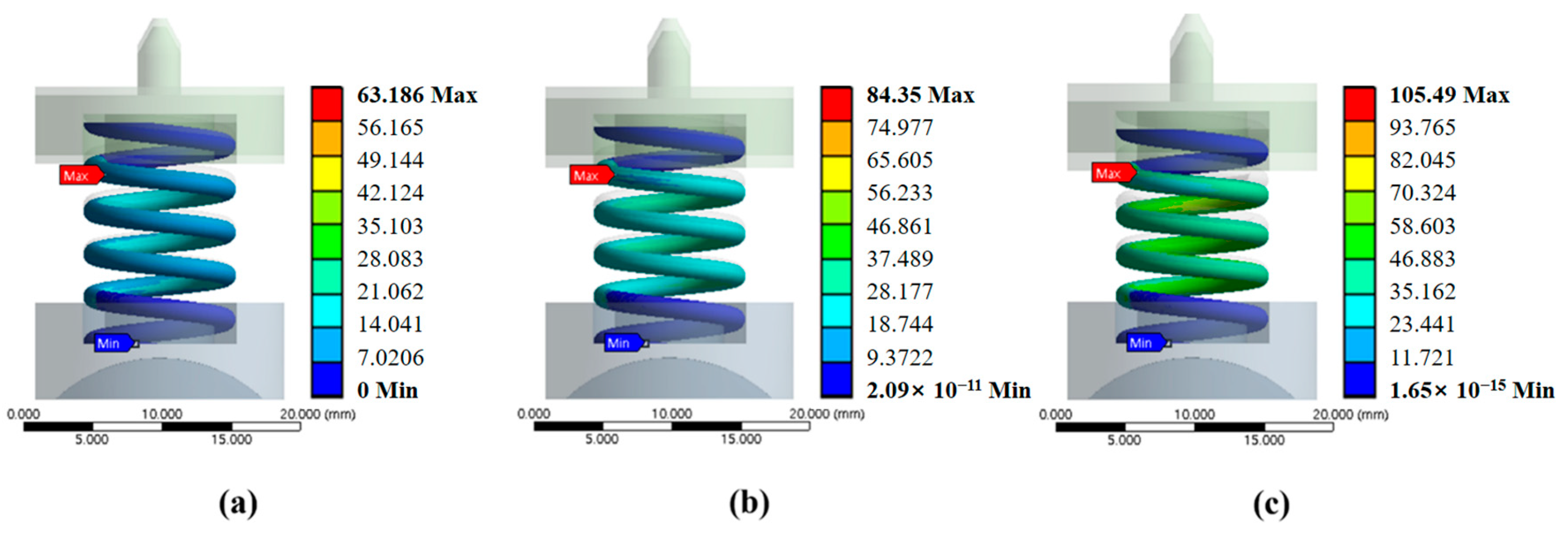

4. Actuation Evaluation of SMA Springs Using Structural Analysis

4.1. Model and Boundary Conditions of Structural Analysis

4.2. Results of Structural Analysis

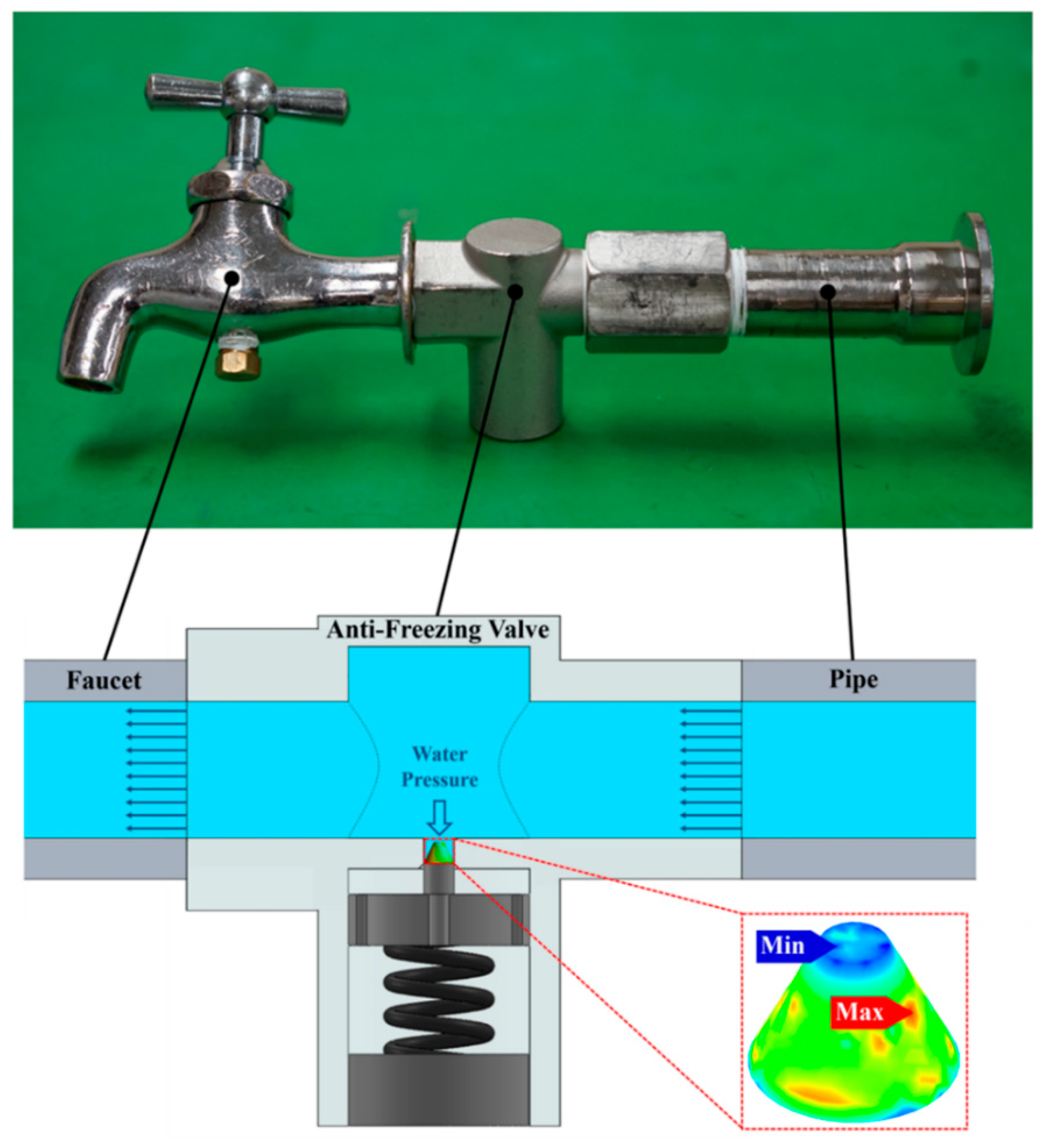

5. Application of Anti-Freezing Systems to Water Pipeline

5.1. Actuation Evaluation of Anti-Freezing Systems

5.1.1. Theoretical Method

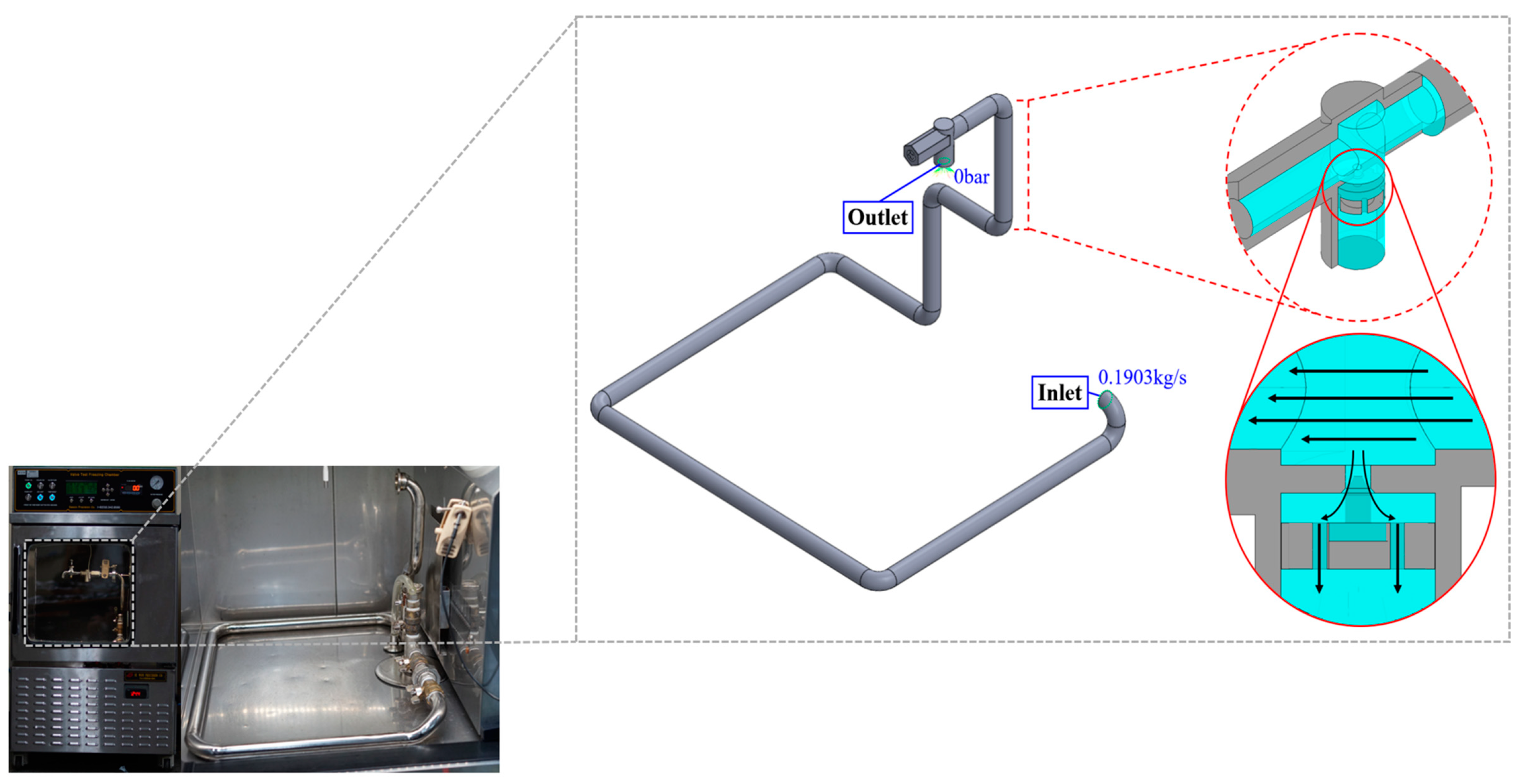

5.1.2. Calculation of Water Discharge Using Fluid Analysis

5.2. Water Discharge Experiments

6. Results

7. Discussion

8. Conclusions

- (1)

- It was confirmed that anti-freezing systems proposed using Ni-44.08Ti-1.46Co (wt.%) SMA coil spring actuates near the sub-zero temperature to prevent freezing of water. The results of WDT and fluid analysis showed that water discharge started at 5 °C and increased as the temperature of SMA coil springs decreased. The freezing phenomenon of a pipe did not occur even with water discharge of 18 mL/min at 0 °C. Consequently, the design of optimal anti-freezing systems is possible based on minimum water discharge that can prevent freezing of water.

- (2)

- The results of SLT showed that the different recovery forces according to changes in temperature work due to the SME of springs. When a static load of 1.6 kgf was applied to the SMA coil spring, a maximum deflection of 3.28 mm at −10 °C occurred. The deflection measurement value at −5 °C differed from the value predicted using the theoretical equations by 5.08 mm, and the reason for this difference is that the change in static load due to the recovery force of the SMA coil spring could not be considered when using the theoretical equations for the measurement of spring deflection. It can be seen that the recovery force is more than 1.56 kgf at 5 °C and 0.94 kgf at –10 °C, resulting from theoretical equations that consider the recovery force.

- (3)

- Water discharge was suddenly stopped due to the contact between water and SMA coil springs when water discharge occurred in the anti-freezing system at the temperature of 5 °C or less. Based on the results of this experiment, it is assessed that there should be a structural change in the anti-freezing system that can block the contact between the SMA coil spring and discharged water. The structural shape and chemical composition ratio of automatically actuated anti-freezing systems can be optimized in further research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, J.J.; Zhi, Z.; Mohammadreza, N.; Norbert, S.; Emad, M.; Vasin, R.N.; Keyvan, S.; Behrang, P.; Mohammad, E.; Oliveira, J.P. In-Situ synchrotron X-ray diffraction analysis of the elastic behaviour of martensite and H-phase in a NiTiHf high temperature shape memory alloy fabricated by laser powder bed fusio. Addit. Manuf. Lett. 2021, 1, 1–9. [Google Scholar]

- Oliveira, J.P.; Shen, J.J.; Escobar, J.D.; Salvador, C.A.F.; Schell, N.; Zhou, N.; Benafan, O. Laser welding of H-phase strengthened Ni-rich NiTi-20Zr high temperature shape memory alloy. Mater. Des. 2021, 202, 1–10. [Google Scholar] [CrossRef]

- Ramaiah, K.V.; Saikrishna, C.N.; Sujata, M.; Madan, M.; Bhaumik, S.K. NiTiPt shape memory alloy: Microstructure and transformation behavior. ISSS J. Micro Smart Syst. 2019, 8, 81–88. [Google Scholar] [CrossRef]

- Follador, M.; Cianchetti, M.; Arienti, A.; Laschi, C. A general method for the design and fabrication of shape memory alloy active spring actuators. Smart Mater. Struct. 2012, 21, 1–10. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Fumagalli, L.; Butera, F.; Coda, A. SmartFlex® NiTi wires for shape memory actuators. J. Mater. Eng. Perform. 2009, 18, 691–695. [Google Scholar] [CrossRef]

- Tiboni, M.; Borboni, A.; Mor, M.; Pomi, D. An innovative pneumatic mini-valve actuated by SMA Ni-Ti wires: Design and analysis. J. Syst. Control. Eng. 2011, 225, 443–451. [Google Scholar] [CrossRef]

- Abhinaba, R.; Narendranath, S.; Alokesh, P. Effect of peak current and peak voltage on machined surface morphology during WEDM of TiNiCu shape memory alloys. J. Mech. Sci. Technol. 2020, 34, 1–5. [Google Scholar]

- Choi, M.Y.; Lee, D.W.; Choi, H.G. Numerical analysis of unsteady heat transfer for the location selection of anti-freeze for the fire protection piping with electrical heat trace. J. Korean Inst. Fire Sci. Eng. 2014, 28, 52–57. [Google Scholar] [CrossRef] [Green Version]

- Yun, J.H.; Kim, J.H.; Jeong, S.Y.; Yang, Y.S.; Kim, S.H.; Song, D.Y. An experimental study on the freezing protection valve using phase change material(PCM) for the HVAC system. Korean Sol. Energy Soc. 2012, 31, 51–56. [Google Scholar]

- Kim, J.H.; Hong, H.; Chung, J.D. Freeze protection for passive solar water heating system. Korean J. Air Cond. Refrig. Eng. 2011, 23, 327–333. [Google Scholar]

- Lee, D.S.; Kwak, J.S. Bellow tube design to prevent a water meter breakage caused by volume expansion during a phase transition. Korean Soc. Mech. Eng. 2018, 42, 831–836. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Yun, J.H.; Kim, J.H.; Yang, Y.S.; Kim, S.H.; Song, D.Y. An experimental study on the freezing protection valve using phase change material(PCM) for the HVAC system. Korean Sol. Energy Soc. 2012, 32, 51–56. [Google Scholar]

- Tallos, N. Winter’s coming–use freeze protection valves to keep lines flowing. Chem. Eng. Prog. 1997, 93, 66–69. [Google Scholar]

- Mathew, R.Y.; Babu, G.B. A real time experimental set up to analyse automatic actuation of a fire sprinkler using a shape memory alloy (NiTinol). Trans. Famena 2015, 39, 9–22. [Google Scholar]

- Matsui, H.; Enoki, M.; Kato, T. Application of shape memory alloy to thermostatic mixing valve. J. De Phys. IV 1995, 5, 1253–1258. [Google Scholar] [CrossRef]

- Reddy, R.A.; Umapathy, M.; Ezhilarasi, D.; Uma, G. Piezoelectric energy harvester with shape memory alloy actuator using solar energy. IEEE Trans. Sustain. Energy 2015, 6, 1409–1415. [Google Scholar] [CrossRef]

- Sharifi, M.E.; Kermanpur, A. Superelastic behavior of nanostruc-tured Ti50Ni48Co2 shape memory alloy with cold rolling processing. Trans. Nonferrous Met. Soc. China 2018, 28, 1351–1359. [Google Scholar] [CrossRef]

- Naila, M.; Al, H.; Huilong, H.; Tieren, G.; Jonathan, C.; Suchismita, S.; Sigurd, T.; Edward, W.; Peer, D.; Apurva, M.; et al. Combinatorial exploration and mapping of phase transformation in a Ni-Ti-Co thin film library. ACS Comb. Sci. 2020, 22, 641–648. [Google Scholar]

- Korean Industrial Standard. Helical Compression and Extension Springs—Requirements for Design; KS B 2400; Korean Standards Association: Seoul, Korea, 2007; pp. 1–21. [Google Scholar]

- Korean Industrial Standard. Technical Drawings—Representation of Springs; KS B 0005; Korean Standards Association: Seoul, Korea, 2014; pp. 1–28. [Google Scholar]

- Korean Industrial Standard. Glossary of Terms Used in Springs; KS B 0103; Korean Standards Association: Seoul, Korea, 2000; pp. 1–18. [Google Scholar]

- Swamee, K.P.; Sharma, K.A. Design of Water Supply Pipe Networks, 1st ed.; Wiley-Interscience: Hoboken, NJ, USA, 2008; pp. 13–32. [Google Scholar]

- Brown, O.G. The history of the Darcy-Weisbach Equation for pipe flow resistance. Environ. Water Resour. Hist. 2002, 4, 34–43. [Google Scholar]

- DNDE Inc. ANSYS CFX; release 17.0.; DNDE: Busan, Korea, 2016; pp. 1–136. [Google Scholar]

- ANSYS Inc. ANSYS CFX-Solver Theory Guide; release 19.2.; ANSYS: Pittsburgh, PA, USA, 2018; pp. 1–376. [Google Scholar]

| Composition | Ni | Ti | Co |

|---|---|---|---|

| wt.% | 54.46 | 44.08 | 1.46 |

| Parameters | Symbols | Values | Units |

|---|---|---|---|

| Total No. of coils | Nt | 6 | turns |

| No. of active coils | Na | 4 | turns |

| No. of turns on the left edge | Nl | 1 | turns |

| No. of turns on the right edge | Nr | 1 | turns |

| Wire diameter | d | 1.5 | mm |

| Inside diameter | Di | 8 | mm |

| Outside diameter | Do | 11 | mm |

| Mean diameter of coil | D | 9.5 | mm |

| Height | Ht | 16.61 | mm |

| Pitch | p | 3 | mm |

| Pitch angle | α | 5.08 | degree |

| Spring index | C | 6.33 | - |

| Poisson’s ratio | ν | 0.33 | - |

| Temperature [°C] | −10 | −5 | 0 | 5 | 10 | 15 | 20 | |

| Deflection [mm] | Experiment | 7.98 | 7.24 | 6.18 | 5.43 | 5.0 | 4.78 | 4.7 |

| Theoretical | 8.00 | 7.62 | 6.15 | 5.33 | 5.16 | 4.99 | 4.85 | |

| Symbol | ||||

| Units | °C | mL/min | m/s | bar |

| Theoretical Values | 5 | 1 | 0.0011 | 2.999 |

| 0 | 18 | 0.0203 | 2.982 | |

| −5 | 30 | 0.0567 | 2.951 | |

| −10 | 53 | 0.0614 | 2.946 | |

| Simulation Values | 5 | 1.7 | 0.0019 | 2.999 |

| 0 | 17.5 | 0.0202 | 2.989 | |

| −5 | 49 | 0.0568 | 2.917 | |

| −10 | 54 | 0.0625 | 2.899 | |

| Experiments | 5 | 1 | 0.0016 | 2.999 |

| 0 | 17 | 0.0197 | 2.971 | |

| −5 | 30 | 0.0347 | 2.901 | |

| −10 | 53 | 0.0613 | 2.719 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, D.; Park, J.; Kim, J. Automatic Actuation of the Anti-Freezing System Using SMA Coil Springs. Metals 2021, 11, 1424. https://doi.org/10.3390/met11091424

Cho D, Park J, Kim J. Automatic Actuation of the Anti-Freezing System Using SMA Coil Springs. Metals. 2021; 11(9):1424. https://doi.org/10.3390/met11091424

Chicago/Turabian StyleCho, Daehwan, Joonhong Park, and Jaeil Kim. 2021. "Automatic Actuation of the Anti-Freezing System Using SMA Coil Springs" Metals 11, no. 9: 1424. https://doi.org/10.3390/met11091424

APA StyleCho, D., Park, J., & Kim, J. (2021). Automatic Actuation of the Anti-Freezing System Using SMA Coil Springs. Metals, 11(9), 1424. https://doi.org/10.3390/met11091424