One-Step Sintering Process for the Production of Magnetocaloric La(Fe,Si)13-Based Composites

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

3.1. Phase Analysis

3.2. Microstructure Evolution

3.3. Kinetics of Diffusion of Ce and Co

3.4. Thermal Conductivity, Mechanical and Magnetic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, V.; Chen, X.; Ramanujan, R.V. Iron and manganese based magnetocaloric materials for near room temperature thermal management. Prog. Mater. Sci. 2019, 100, 64–98. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Giant Magnetocaloric Effect in Gd5(Si2Ge2). Phys. Rev. Lett. 1997, 78, 4494–4497. [Google Scholar] [CrossRef]

- Virgil, P.; Alexander, J.S.; Robert, D.S. Reduction of hysteresis losses in the magnetic refrigerant Gd5Ge2Si2 by the addition of iron. Nature 2004, 429, 853–857. [Google Scholar]

- Tegus, O.; Brück, E.; Buschow, K.H.J.; De Boer, F.R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 2002, 415, 150–152. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zeng, Q.Q.; Wei, Z.Y.; Liu, E.K.; Han, X.L.; Du, Z.W.; Li, L.W.; Xi, X.K.; Wang, W.H.; Wang, S.G.; et al. An efficient scheme to tailor the magnetostructural transitions by staged quenching and cyclical ageing in hexagonal martensitic alloys. Acta Mater. 2019, 174, 289–299. [Google Scholar] [CrossRef]

- Hu, F.X.; Shen, B.G.; Sun, J.R.; Cheng, Z.H.; Rao, G.H.; Zhang, X.X. Influence of negative lattice expansion and meta-magnetic transition on magnetic entropy change in the compound LaFe11.4Si1.6. Appl. Phys. Lett. 2001, 78, 3675–3677. [Google Scholar] [CrossRef]

- Fujita, A.; Fujieda, S.; Fukamichi, K.; Mitamura, H.; Goto, T. Itinerant-electron metamagnetic transition and large magne-tovolume effects in La(FexSi1–x)13 compounds. Phys. Rev. 2001, B65, 014410. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A. Inverse magnetocaloric effect in ferro-magnetic Ni-Mn-Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef] [Green Version]

- Li, L.W.; Xu, P.; Ye, S.K.; Li, Y.; Liu, G.D.; Huo, D.X.; Yan, M. Magnetic properties and excellent cryogenic magnetocaloric performances in B-site ordered RE2ZnMnO6 (RE=Gd, Dy and Ho) perovskites. Acta Mater. 2020, 194, 354–365. [Google Scholar] [CrossRef]

- Wu, B.B.; Zhang, Y.K.; Guo, D.; Wang, J.; Ren, Z.M. Structure, magnetic properties and cryogenic magneto-caloric effect (MCE) in RE2FeAlO6 (RE=Gd, Dy, Ho) oxides. Ceram. Int. 2021, 47, 6290–6297. [Google Scholar] [CrossRef]

- Wang, Y.M.; Guo, D.; Wu, B.B.; Geng, S.H.; Zhang, Y.K. Magnetocaloric effect and refrigeration performance in RE60Co20Ni20 (RE = Ho and Er) amorphous ribbons. J. Magn. Magn. Mater. 2019, 498, 166179. [Google Scholar] [CrossRef]

- Ma, Z.P.; Dong, X.S.; Zhang, Z.Q.; Li, L.W. Achievement of promising cryogenic magnetocaloric performances in La1−xPrxFe12B6 compounds. J. Mater. Sci. Technol. 2021, 92, 138–142. [Google Scholar] [CrossRef]

- Li, L.W.; Yan, M. Recent progresses in exploring the rare earth based intermetallic compounds for cryogenic magnetic refrigeration. J. Alloys Compd. 2020, 823, 153810. [Google Scholar] [CrossRef]

- Zou, J.D.; Shen, B.G.; Gao, B.; Shen, J.; Sun, J.R. The magnetocaloric effect of LaFe11.6Si1.4, La0.8Nd0.2Fe11.5Si1.5, and Ni43Mn46Sn11 compounds in the vicinity of the first-order phase transition. Adv. Mater. 2009, 21, 693–696. [Google Scholar] [CrossRef]

- Shen, B.G.; Sun, J.R.; Hu, F.X.; Zhang, H.W.; Cheng, Z.H. Recent Progress in Exploring Magnetocaloric Materials. Adv. Mater. 2009, 21, 4545–4564. [Google Scholar] [CrossRef] [Green Version]

- Lyubina, J.; Schafer, R.; Martin, N.; Schultz, L.; Gutfleisch, O. Novel design of La(Fe,Si)13 alloys towards high magnetic refrigeration performance. Adv. Mater. 2010, 22, 3735–3739. [Google Scholar] [CrossRef] [PubMed]

- Hu, F.X.; Shen, B.G.; Sun, J.R.; Zhang, X.X. Great magnetic entropy change in La(Fe,M)13 (M=Si, Al) with Co doping. Chin. Phys. 2000, 9, 550–556. [Google Scholar]

- Gutfleisch, O.; Yan, A.; Müller, K.H. Large magnetocaloric effect in melt-spun LaFe13−xSix. J. Appl. Phys. 2005, 97, 10M305. [Google Scholar] [CrossRef]

- Zhong, X.C.; Feng, X.L.; Huang, J.H.; Zhang, H.; Huang, Y.L.; Liu, Z.W.; Jiao, D.L. Microstructure evolution and large magnetocaloric effect of La0.8Ce0.2(Fe0.95Co0.05)11.8Si1.2 alloy prepared by strip-casting and annealing. Aip Adv. 2018, 8, 048102. [Google Scholar]

- Liu, X.B.; Altounian, Z. Effect of Co content on magnetic entropy change and structure of La(Fe1−xCox)11.4Si1.6. J. Magn. Magn. Mater. 2003, 264, 209–213. [Google Scholar] [CrossRef]

- Hu, F.X.; Gao, J.; Qian, X.L.; Ilyn, M.; Tishin, A.M.; Sun, J.R.; Shen, B.G. Magnetocaloric effect in itinerant electron metamagnetic systems La(Fe1−xCox)11.9Si1.1. J. Appl. Phys. 2005, 97, 10M303. [Google Scholar] [CrossRef] [Green Version]

- Fujita, A.; Fujieda, S.; Hasegawa, Y.; Fukamichi, K. Itinerant-electron metamagnetic transition and large magnetocaloric effects in La(FexSi1−x)13 compounds and their hydrides. Phys. Rev. 2003, B67, 104416. [Google Scholar] [CrossRef] [Green Version]

- Fujieda, S.; Fujita, A.; Fukamichi, K. Enhancements of magnetocaloric effects in La(Fe0.90Si0.10)13 and Its hydride by partial substitution of Ce for La. Mater. Trans. 2004, 45, 3228–3231. [Google Scholar] [CrossRef]

- Mandal, K.; Pal, D.; Gutfleisch, O.; Kerschl, P.; Müller, K.H. Magnetocaloric effect in reactively-milled LaFe11.57Si1.43Hy intermetallic compounds. J. Appl. Phys. 2007, 102, 053906. [Google Scholar] [CrossRef]

- Krautz, M.; Moore, J.D.; Skokov, K.P.; Liu, J.; Teixeira, C.S.; Schäfer, R.; Schultz, L.; Gutfleisch, O. Reversible solid-state hydrogen-pump driven by magnetostructural transformation in the prototype system La(Fe,Si)13Hy. J. Appl. Phys. 2012, 112, 083918. [Google Scholar] [CrossRef]

- Lyubina, J.; Hannemann, U.; Ryan, M.P.; Cohen, L.F. Electrolytic hydriding of LaFe13−xSix alloys for energy efficient magnetic cooling. Adv. Mater. 2012, 24, 2042–2046. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Tang, Y.; Chen, Y.; Wu, J.; Wang, H.; Xue, X.; Wang, J.; Pang, W. The high-temperature hydrogenation behavior of LaFe11.6Si1.4 and splitting of LaFe11.6Si1.4Hy magnetocaloric transition. J. Alloys Compd. 2015, 646, 124–128. [Google Scholar] [CrossRef]

- Hu, F.X.; Chen, L.; Wang, J.; Bao, L.F.; Sun, J.R.; Shen, B.G. Particle size dependent hysteresis loss in La0.7Ce0.3Fe11.6Si1.4C0.2 first-order systems. Appl. Phys. Lett. 2012, 100, 072403. [Google Scholar] [CrossRef] [Green Version]

- Skokov, K.; Karpenkov, D.; Kuz’Min, M.D.; Radulov, I.A.; Gottschall, T.; Kaeswurm, B.; Fries, M.; Gutfleisch, O. Heat exchangers made of polymer-bonded La(Fe,Si)13. J. Appl. Phys. 2014, 115, 17A941. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, M.X.; Shao, Y.Y.; Yan, A.R. LaFe11.6Si1.4/Cu magnetocaloric composites prepared by hot pressing. IEEE Trans. Magn. 2015, 51, 2501502. [Google Scholar]

- Zhang, H.; Liu, J.; Zhang, M.; Shao, Y.; Li, Y.; Yan, A. LaFe11.6Si1.4Hy/Sn magnetocaloric composites by hot pressing. Scr. Mater. 2016, 120, 58–61. [Google Scholar] [CrossRef]

- Dong, X.T.; Zhong, X.C.; Peng, D.R.; Huang, J.H.; Zhang, H.; Jiao, D.L.; Liu, Z.W.; Ramanujan, R.V. La0.8Ce0.2(Fe0.95Co0.05)11.8Si1.2/Sn42Bi58 magnetocaloric composites prepared by low temperature hot pressing. J. Alloys Compd. 2018, 737, 568–574. [Google Scholar] [CrossRef]

- Zhong, X.C.; Peng, D.R.; Dong, X.T.; Huang, J.H.; Zhang, H.; Jiao, D.L.; Liu, Z.W.; Ramanujan, R.V. Improvement in the magnetocaloric properties of sintered La(Fe,Si)13 based composites processed by La-Co grain boundary diffusion. J. Alloys Compd. 2019, 780, 873–880. [Google Scholar] [CrossRef]

- Zhong, X.C.; Peng, D.R.; Dong, X.T.; Huang, J.H.; Zhang, H.; Huang, Y.L.; Wu, S.M.; Yu, H.Y.; Qiu, W.Q.; Liu, Z.W.; et al. Improvement in mechanical and magnetocaloric properties of hot-pressed La(Fe,Si)13/La70Co30 composites by grain boundary engineering. Mater. Sci. Eng. B 2021, 263, 114900. [Google Scholar] [CrossRef]

- Zhang, R.F.; Zhang, S.H.; He, Z.J.; Jing, J.; Sheng, S.H. Miedema Calculator: A thermodynamic platform for predicting formation enthalpies of alloys within framework of Miedema’s Theory. Comput. Phys. Commun. 2016, 209, 58–69. [Google Scholar] [CrossRef]

- Guo, Q.W.; Wang, G.S.; Guo, G.C. Non-Ferrous Metal Atlas of Binary Alloy Phase; Chemical Industry Press: Beijing, China, 2010. [Google Scholar]

- Zhou, Q.; Liu, Z.W.; Zhong, X.C.; Zhang, G.Q. Properties improvement and structural optimization of sintered NdFeB magnets by non-rare earth compound grain boundary diffusion. Mater. Des. 2015, 86, 114–120. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.G.; Tang, Y.B. The effect of high-temperature annealing on LaFe11.5Si1.5 and the magnetocaloric properties of La1−xCexFe11.5Si1.5 compounds. Rare Metals 2011, 30, 343–347. [Google Scholar] [CrossRef]

- Fan, W.B.; Hou, Y.H.; Ge, X.J.; Huang, Y.L.; Luo, J.M.; Zhong, Z.C. Microstructure and improved magnetocaloric properties: LaFeSi/LaAl magnets prepared by spark plasma sintering technique. J. Phys. D Appl. Phys. 2018, 51, 115003. [Google Scholar] [CrossRef]

- Zhong, X.C.; Dong, X.T.; Peng, D.R.; Huang, J.H.; Zhang, H.; Jiao, D.L.; Zhang, H.; Liu, Z.W.; Ramanujan, R.V. Table-like magnetocaloric effect and enhanced refrigerant capacity of HPS La(Fe,Si)13 based composites by Ce-Co grain boundary diffusion. J. Mater. Sci. 2020, 55, 5908–5919. [Google Scholar] [CrossRef]

- Löwe, K.; Liu, J.; Skokov, K.; Moore, J.D.; Amin, H.S.; Hono, K.; Katter, M.; Gutfleisch, O. The effect of the thermal decom-position reaction on the mechanical and magnetocaloric properties of La(Fe,Si,Co)13. Acta Mater. 2012, 60, 4268–4276. [Google Scholar] [CrossRef]

- Liu, J.; Krautz, M.; Skokov, K.; Woodcock, T.G.; Gutfleisch, O. Systematic study of the microstructure, entropy change and adiabatic temperature change in optimized La-Fe-Si alloys. Acta Mater. 2011, 59, 3602–3611. [Google Scholar] [CrossRef]

- Predel, B. Ce-Co (Cerium-Cobalt) phase diagram. In Phase Equilibria, Crystallographic and Thermodynamic Data of Binary Alloys Landolt-Börnstein: Numerical Data and Functional Relationships in Science and Technology-New Series; Springer: Berlin/Heidelberg, Germany, 1993; Volume 3, ISBN 9783540614333. [Google Scholar]

- Laptev, A.V. Structure and properties of WC-Co alloys in solid-phase sintering. I. Geometrical evolution. Powder Met. Met. Ceram. 2007, 46, 415–422. [Google Scholar] [CrossRef]

- Pribytkov, G.A.; Andreeva, I.A.; Korzhova, V.V. Bulk changes and structure formation in solid-phase sintering of Ti − TiAl3 powder mixtures. Powder Met. Met. Ceram. 2008, 47, 687–692. [Google Scholar] [CrossRef]

- Itoh, M.; Machida, K.I.; Hirose, K.; Adachi, G.Y. Nitrogen absorption and desorption characteristics for CeFe7. Chem. Lett. 2001, 30, 294–295. [Google Scholar] [CrossRef]

- Hou, X.L.; Lampen-Kelley, P.; Xue, Y.; Liu, C.Y.; Xu, H.; Han, N.; Ma, C.W.; Srikanth, H.; Phan, M.H. Formation mechanisms of NaZn13-type phase in giant magnetocaloric La–Fe–Si compounds during rapid solidification and annealing. J. Alloys Compd. 2015, 646, 503–511. [Google Scholar] [CrossRef] [Green Version]

- Krypiakewytsch, P.I.; Zaretschniuk, O.S.; Hladyschewskyj, E.I. Ternäre verbindungen vom NaZn13-type. Z. Anorg. Allg. Chem. 1968, 358, 90–96. [Google Scholar] [CrossRef]

- Passamani, E.C.; Larica, C.; Proveti, J.R.; Takeuchi, A.Y.; Gomes, A.M.; Ghivelder, L. Magnetic and magnetocaloric properties of La(Fe,Co)11.4SP1.6 compounds (SP=Al or Si). J. Magn. Magn. Mater. 2007, 312, 65–71. [Google Scholar] [CrossRef]

- Shao, Y.Y.; Liu, Y.F.; Wang, K.; Zhang, M.X.; Liu, J. Impact of interface structure on functionality in hot-pressed La-Fe-Si/Fe magnetocaloric composites. Acta Mater. 2020, 195, 163–171. [Google Scholar] [CrossRef]

- Zhang, M.X.; Ouyang, Y.; Zhang, Y.F.; Liu, J. LaFe11Co0.8Si1.2/Al magnetocaloric composites prepared by hot pressing. J. Alloys Compd. 2020, 823, 153846. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, H.; Liu, E.K.; Zhong, X.C.; Tao, K.; Wu, M.L.; Xing, C.F.; Xiao, Y.N.; Liu, J.; Long, Y. Outstanding comprehensive performance of La(Fe,Si)13Hy/In composite with durable service life for magnetic refrigeration. Adv. Electron. Mater. 2018, 4, 1700636. [Google Scholar] [CrossRef]

- Gschneidner, K.A., Jr.; Pecharsky, V.K. Magnetocaloric materials. Annu. Rev. Mater. Sci. 2000, 30, 387–429. [Google Scholar] [CrossRef] [Green Version]

- Fujieda, S.; Fukamichi, K.; Suzuki, S. Microstructure and isothermal magnetic entropy change of La(Fe0.89Si0.11)13 in a single-phase formation process by annealing. J. Alloys Compd. 2013, 566, 196–200. [Google Scholar] [CrossRef]

- Wu, S.M.; Zhong, X.C.; Dong, X.T.; Liu, C.L.; Huang, J.H.; Huang, Y.L.; Yu, H.Y.; Liu, Z.W.; Huang, Y.S.; Ramanujan, R.V. LaFe11.6Si1.4/Pr40Co60 magnetocaloric composites for refrigeration near room temperature. J. Alloys Compd. 2021, 873, 159796. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, N.Z.; Cui, Y.T.; Wu, Z.M.; Wen, L.; Zeng, Z.Y.; Xia, L. Achieving better magneto-caloric effect near room temperature in amorphous Gd50Co50 alloy by minor Zn addition. J. Non-Crystall. Solids 2016, 434, 36–40. [Google Scholar] [CrossRef]

- Dan’Kov, S.Y.; Tishin, A.M.; Pecharsky, V.K.; Gschneidner, K.A., Jr. Magnetic phase transitions and the magnetothermal properties of gadolinium. Phys. Rev. B 1998, 57, 3478–3490. [Google Scholar] [CrossRef]

- Zhong, X.C.; Tian, H.C.; Wang, S.S.; Liu, Z.W.; Zheng, Z.G.; Zeng, D.C. Thermal, magnetic and magnetocaloric properties of Fe80−xMxB10Zr9Cu1 (M = Ni, Ta; x = 0, 3, 5) amorphous alloys. J. Alloys Compd. 2015, 633, 188–193. [Google Scholar] [CrossRef]

- Banerjee, B.K. On a generalised approach to first and second order magnetic transitions. Phys. Lett. 1964, 12, 16–17. [Google Scholar] [CrossRef]

- Hu, F.X. Magnetic and Magnetic Entropy Changes of Fe-Based La(Fe,M)13 Compounds and Ni-Mn-Ga Alloys; Institute of Physics, Chinese Academy of Sciences: Beijing, China, 2002. (In Chinese) [Google Scholar]

| Sample | Sintering@1373 K | Weight Percentage (wt.%) | Fit Coefficient | ||||||

| 1:13 phase | α-Fe Phase | 1:7 Phase | Rp | Rwp | Rexp | χ2 | |||

| Annealed LaFe11.6Si1.4 flakes | 84.69(5) | 15.31(2) | 0.95 | 1.62 | 0.80 | 4.16 | |||

| LaFe11.6Si1.4/x wt.%Ce2Co7 composites | x = 0 | 1 h | 89.36(5) | 10.64(2) | / | 0.95 | 1.44 | 1.10 | 1.71 |

| 3 h | 87.74(5) | 12.26(2) | / | 1.28 | 1.73 | 1.42 | 1.49 | ||

| 6 h | 89.26(5) | 10.82(2) | / | 0.87 | 1.36 | 1.01 | 1.80 | ||

| x = 5 | 6 h | 93.21(5) | 5.90(1) | 0.89 | 0.87 | 1.20 | 1.01 | 1.43 | |

| x = 10 | 1 h | 87.28(5) | 4.72(1) | 8.00 | 1.08 | 1.46 | 1.26 | 1.33 | |

| 3 h | 87.02(5) | 6.28(1) | 6.70 | 0.98 | 1.27 | 1.23 | 1.07 | ||

| 6 h | 93.93(5) | 3.30(1) | 2.77 | 0.90 | 1.19 | 0.98 | 1.46 | ||

| x = 15 | 6 h | 88.29(5) | 4.96(1) | 6.75 | 1.19 | 1.53 | 1.09 | 1.98 | |

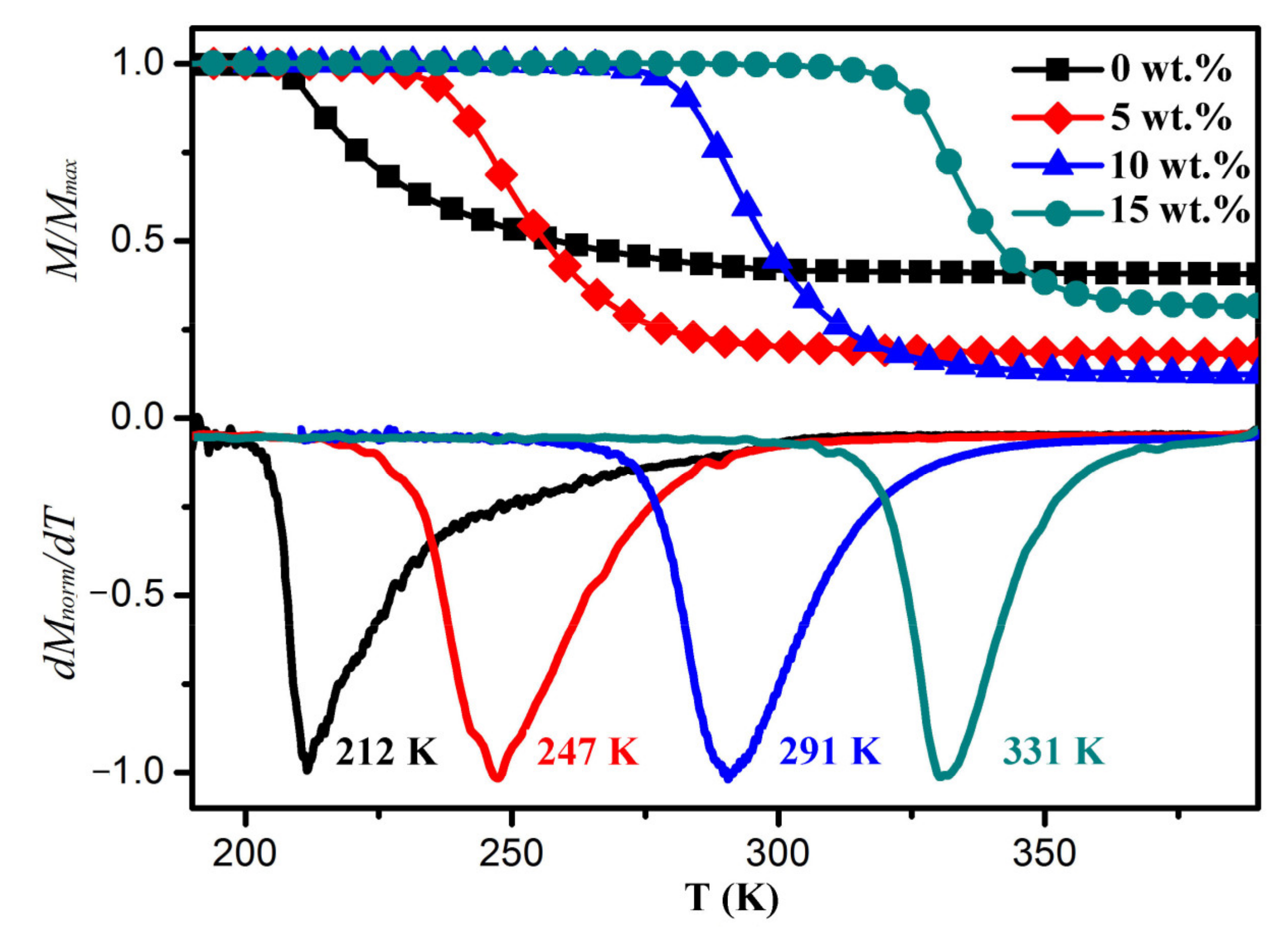

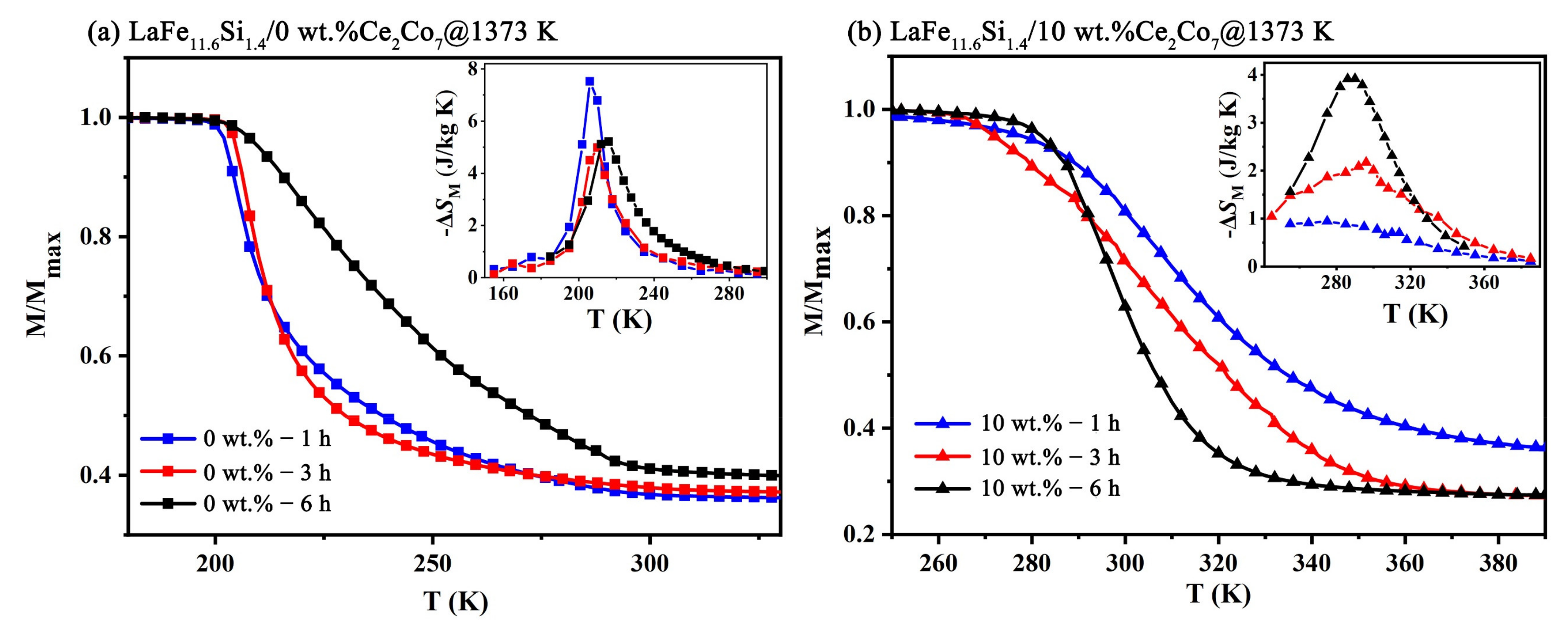

| LaFe11.6Si1.4/Ce2Co7 Composites | 1:13 Phase a (Å) | Phase Composition | TC (K) | (−ΔSM)max J/(kg·K) ΔH = 2 T (5 T) | RCP J/kg ΔH = 2 T (5 T) | ||

|---|---|---|---|---|---|---|---|

| Binder Content | Sintering | 1:7 Phase | 1:13 Phase | ||||

| Binder- free | 1373 K/1 h | 11.49282(6) | ------ | LaFe10.95Si1.59 | 206 | 7.5 (/) | 122.4 (/) |

| 1373 K/3 h | 11.49015(9) | ------ | LaFe10.73Si1.57 | 210 | 5.0 (/) | 106.6 (/) | |

| 1373 K/6 h | 11.49209(9) | ------ | LaFe10.53Si1.60 | 212 | 5.2 (8.8) | 146.7 (339.0) | |

| 5 wt.% | 1373 K/6 h | 11.49190(0) | La0.26Ce0.74Fe6.02Co0.56Si0.93 | La0.87Ce0.13Fe9.70Co0.56Si1.35 | 247 | 4.0 (8.6) | 158.4 (428.7) |

| 10 wt.% | 1373 K/1 h | 11.49271(9) | La0.28Ce0.72Fe5.75Co1.27Si0.87 | La0.89Ce0.11Fe9.71Co0.91Si1.35 | 275 | 0.9 (/) | ------ |

| 1373 K/3 h | 11.49559(8) | La0.27Ce0.73Fe6.14Co0.82Si0.90 | La0.83Ce0.17Fe9.82Co0.95Si1.29 | 296 | 2.2 (/) | 185.2 (/) | |

| 1373 K/6 h | 11.49301(7) | La0.27Ce0.73Fe6.32Co0.72Si1.04 | La0.82Ce0.18Fe9.24Co0.91Si1.34 | 291 | 3.9 (7.6) | 209.2 (457.7) | |

| 15 wt.% | 1373 K/6 h | 11.51400(9) | La0.28Ce0.72Fe5.71Co0.98Si0.91 | La0.75Ce0.25Fe9.10Co1.30Si1.28 | 331 | 3.2 (6.0) | 178.3 (399.2) |

| Sample | Porosity (%) | λ (W/m·K) | (σbc)max (MPa) | Strain (%) |

|---|---|---|---|---|

| Binder free | 5.14 | 13.71 | 458 | 5.0 |

| 5 wt.% | 4.02 | 7.81 | 474 | 4.7 |

| 10 wt.% | 4.78 | 8.21 | 530 | 6.1 |

| 15 wt.% | 4.56 | 7.50 | 457 | 4.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, X.-C.; Dong, X.-T.; Huang, J.-H.; Liu, C.-L.; Zhang, H.; Huang, Y.-L.; Yu, H.-Y.; Ramanujan, R.V. One-Step Sintering Process for the Production of Magnetocaloric La(Fe,Si)13-Based Composites. Metals 2022, 12, 112. https://doi.org/10.3390/met12010112

Zhong X-C, Dong X-T, Huang J-H, Liu C-L, Zhang H, Huang Y-L, Yu H-Y, Ramanujan RV. One-Step Sintering Process for the Production of Magnetocaloric La(Fe,Si)13-Based Composites. Metals. 2022; 12(1):112. https://doi.org/10.3390/met12010112

Chicago/Turabian StyleZhong, Xi-Chun, Xu-Tao Dong, Jiao-Hong Huang, Cui-Lan Liu, Hu Zhang, You-Lin Huang, Hong-Ya Yu, and Raju V. Ramanujan. 2022. "One-Step Sintering Process for the Production of Magnetocaloric La(Fe,Si)13-Based Composites" Metals 12, no. 1: 112. https://doi.org/10.3390/met12010112

APA StyleZhong, X.-C., Dong, X.-T., Huang, J.-H., Liu, C.-L., Zhang, H., Huang, Y.-L., Yu, H.-Y., & Ramanujan, R. V. (2022). One-Step Sintering Process for the Production of Magnetocaloric La(Fe,Si)13-Based Composites. Metals, 12(1), 112. https://doi.org/10.3390/met12010112