Effect of Rolling Temperature on the Structural Refinement and Mechanical Properties of Dual-Phase Heterostructured Low-Carbon Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Processing Route

2.2. Microstructural Characterization

2.3. Tests of Mechanical Properties

3. Results

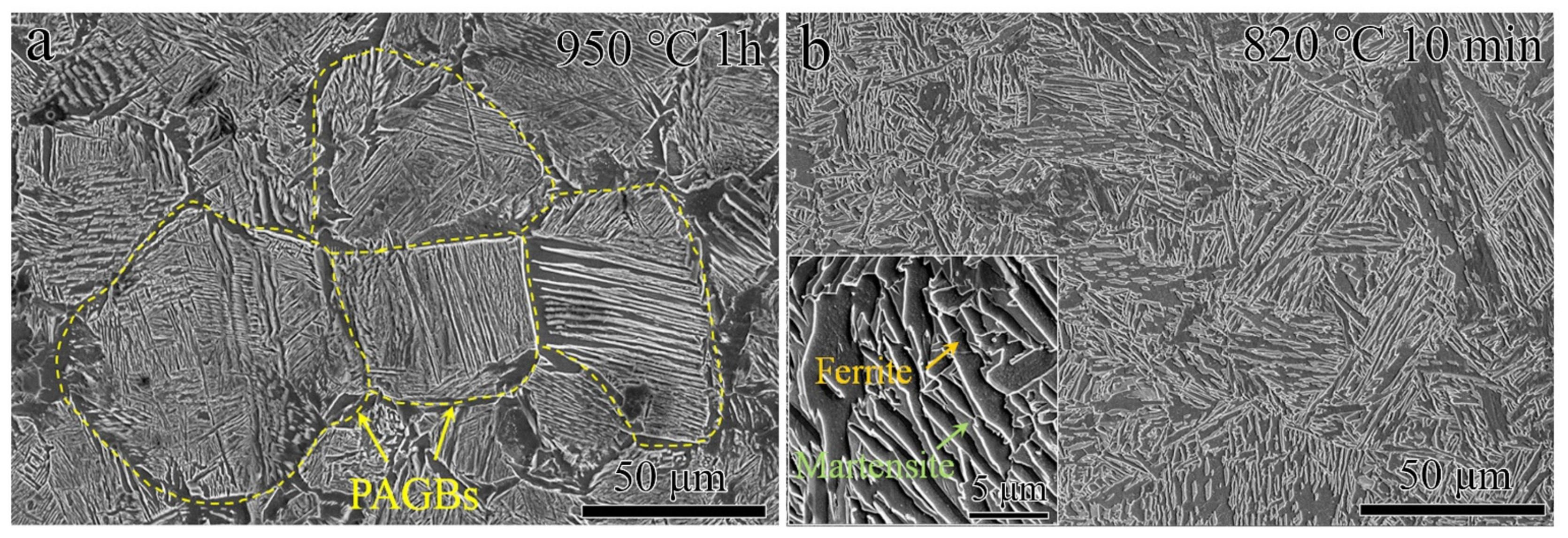

3.1. Microstructure Prior to Warm Rolling

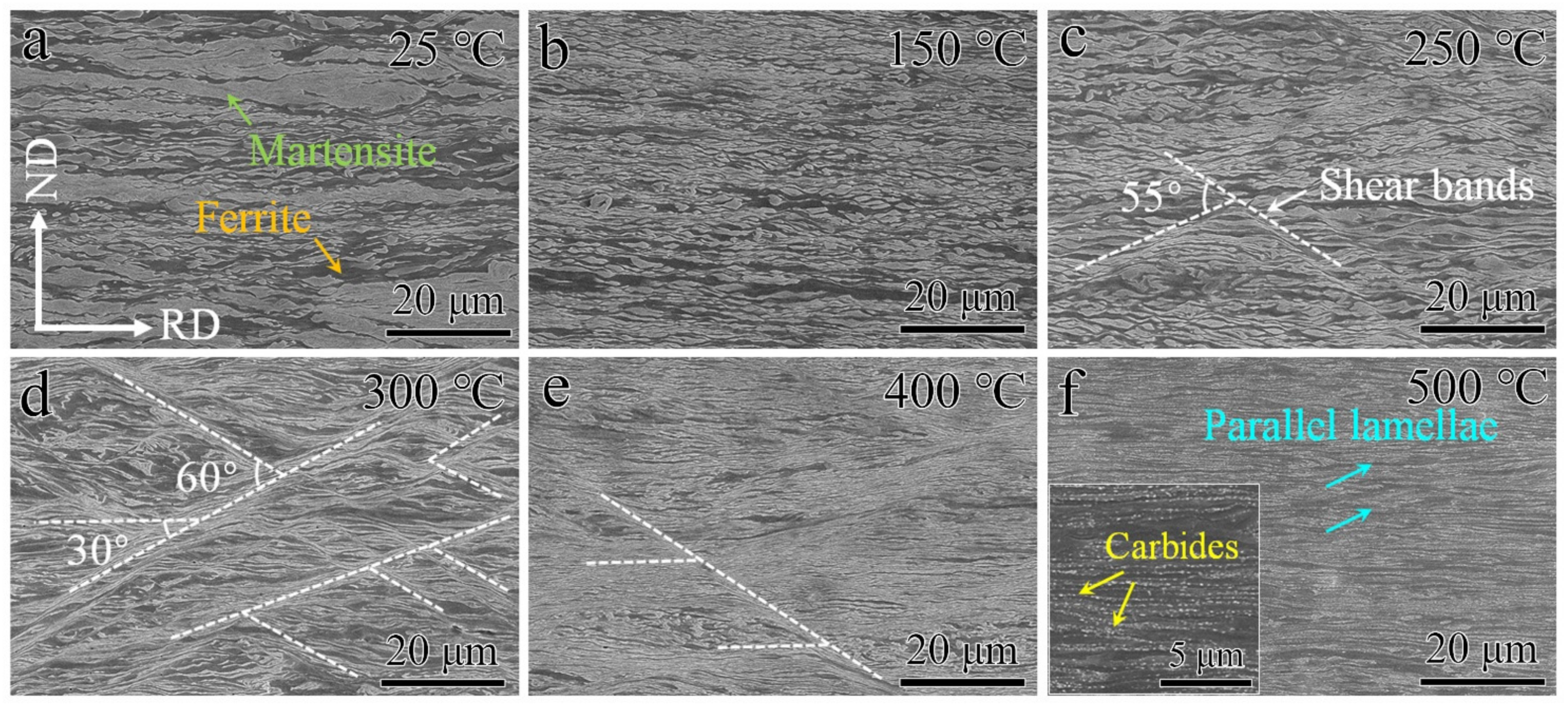

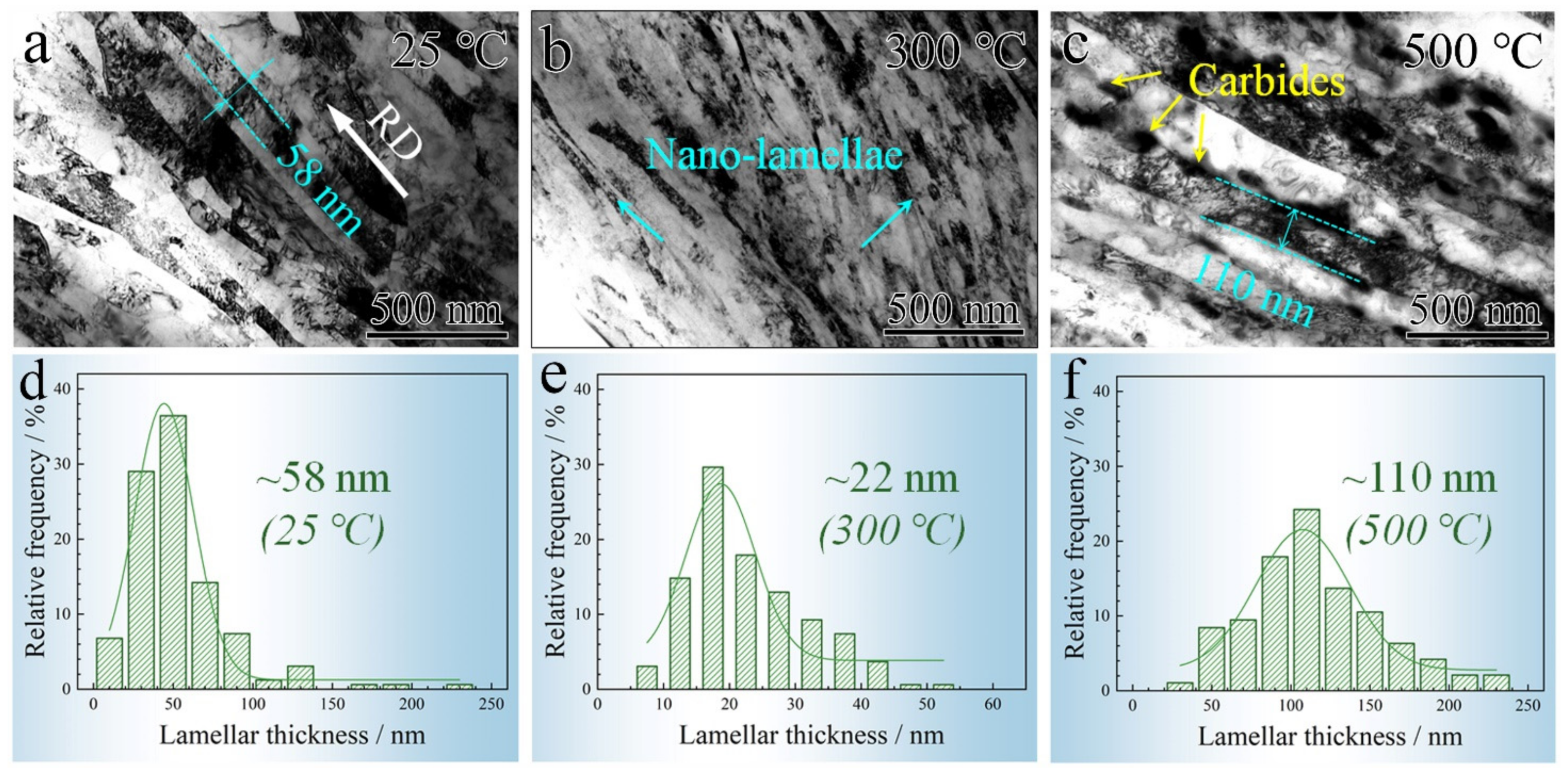

3.2. Microstructures after Warm Rolling

3.3. Microhardness Evolution of the Rolled Samples

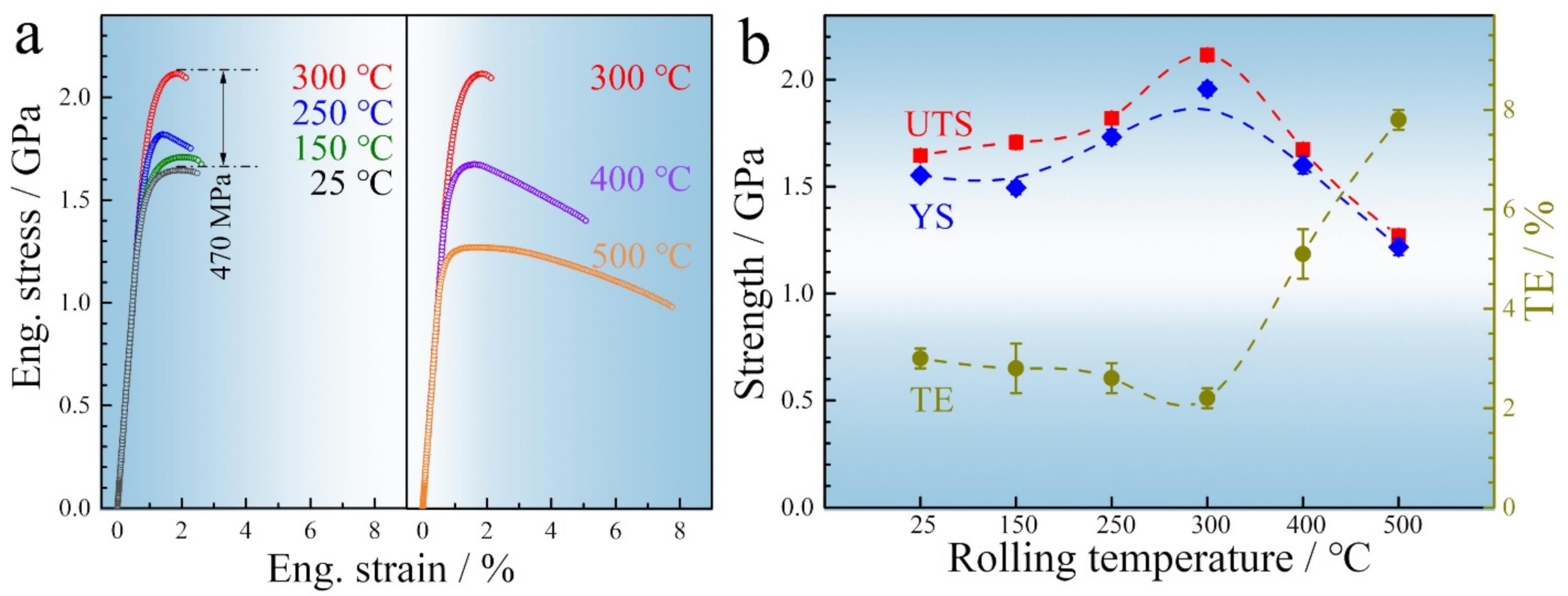

3.4. Mechanical Properties

4. Discussion

4.1. Structural Refinement by Warm Rolling

4.2. Strengthening of the Nano-Lamellar Steels

5. Conclusions

- The rolling temperature has a great influence on the microstructural refinement of low-carbon dual-phase steel. The average lamellar thickness does not deteriorate with increasing deformation temperature. Warm rolling at 300 °C produces a much finer nano-lamellar structure (22 nm) than that formed at both room temperature and elevated temperatures.

- The microhardness and strength first increase and then decrease with rolling temperature, reaching the maximum at 300 °C. The nano-lamellar steel has an extremely high hardness of 601 HV and UTS of 2.1 GPa. The microhardness of the nano-lamellar steel also remains stable when annealed at 300 °C.

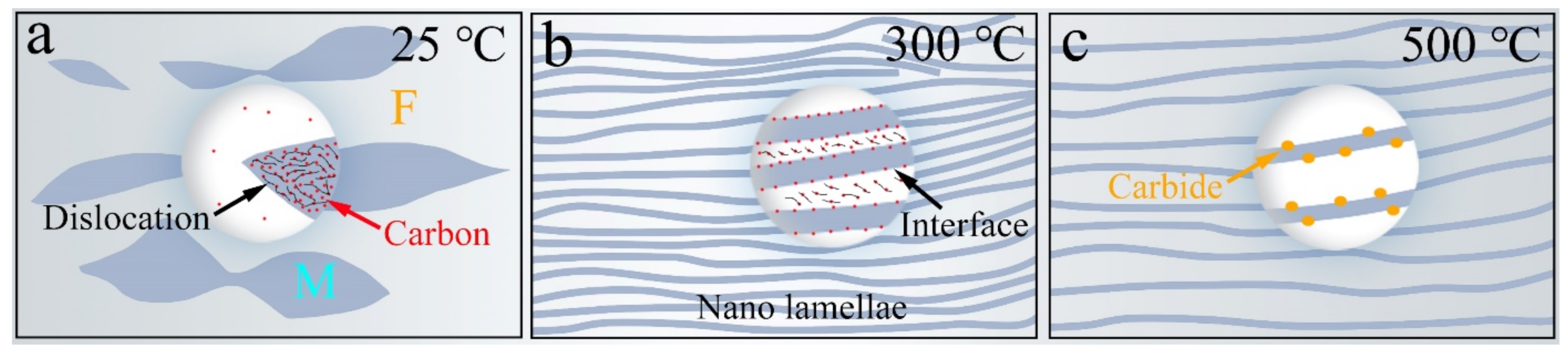

- The structural refinement of the heterostructured low-carbon steel is mainly influenced by the responses of C atoms in martensite at different rolling temperatures. At 25 °C, the supersaturated C in martensite leads to a huge difference in strength between martensite and ferrite. Therefore, the martensite cannot be deformed sufficiently. At an elevated temperature of 300 °C, the motion of C atoms is promoted, which tends to be segregated at lamellar boundaries and mobile to dislocations. These interactions between C atoms and defects promote dislocation accumulation and improve the stability of nano-structure, helping with grain refinement. At a higher temperature of 500 °C, carbides formation in the tempered martensite and enhanced dynamic recovery results in an increase in the average lamellar thickness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, L.; Yu, Q.; Wang, Z.; Ell, J.; Huang, M.X.; Ritchie, R.O. Making ultrastrong steel tough by grain-boundary delamination. Science 2020, 368, 1347–1352. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Chew, Y.; Duan, R.; Weng, F.; Sui, S.; Ng, F.L.; Du, Z.; Bi, G. Additive manufacturing of multi-scale heterostructured high-strength steels. Mater. Res. Lett. 2021, 9, 291–299. [Google Scholar] [CrossRef]

- Lesch, C.; Kwiaton, N.; Klose, F.B. Advanced High Strength Steels (AHSS) for Automotive Applications—Tailored Properties by Smart Microstructural Adjustments. Steel Res. Inter. 2017, 88, 1700210. [Google Scholar] [CrossRef]

- Jiang, S.H.; Xu, X.Q.; Li, W.; Peng, B.; Wu, Y.; Liu, X.J.; Wang, H.; Wang, X.Z.; Lu, Z.P. Strain hardening mediated by coherent nanoprecipitates in ultrahigh-strength steels. Acta Mater. 2021, 213, 116984. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef]

- Li, X.; Lu, K. Playing with defects in metals. Nat. Mater. 2017, 16, 700–701. [Google Scholar] [CrossRef]

- Li, X.; Lu, K. Improving sustainability with simpler alloys. Science 2019, 364, 733–734. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Fundamentals of Superior Properties in Bulk NanoSPD Materials. Mater. Res. Lett. 2016, 4, 1–21. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Estrin, Y.; Beygelzimer, Y.; Kulagin, R.; Gumbsch, P.; Fratzl, P.; Zhu, Y.; Hahn, H. Architecturing materials at mesoscale: Some current trends. Mater. Res. Lett. 2021, 9, 399–421. [Google Scholar] [CrossRef]

- Müller, T.; Kapp, M.W.; Bachmaier, A.; Felfer, P.; Pippan, R. Ultrahigh-strength low carbon steel obtained from the martensitic state via high pressure torsion. Acta Mater. 2019, 166, 168–177. [Google Scholar] [CrossRef]

- Gao, B.; Hu, R.; Pan, Z.; Chen, X.; Liu, Y.; Xiao, L.; Cao, Y.; Li, Y.; Lai, Q.; Zhou, H. Strengthening and ductilization of laminate dual-phase steels with high martensite content. J. Mater. Sci. Technol. 2021, 65, 29–37. [Google Scholar] [CrossRef]

- Gao, B.; Chen, X.; Pan, Z.; Li, J.; Ma, Y.; Cao, Y.; Liu, M.; Lai, Q.; Xiao, L.; Zhou, H. A high-strength heterogeneous structural dual-phase steel. J. Mater. Sci. 2019, 54, 12898–12910. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Cao, Y.; Gao, B.; Li, Y.; Zhu, Y. Superior strength and ductility of 316L stainless steel with heterogeneous lamella structure. J. Mater. Sci. 2018, 53, 10442–10456. [Google Scholar] [CrossRef]

- Yang, Z.; Jiang, F.; Wang, Y.; Wang, Q.; Huang, M.; Wang, Y.; Chen, C.; Zhang, F. Making composite steel higher strength and higher ductility via introducing carbon diffusion strategy. Mater. Res. Lett. 2021, 9, 391–397. [Google Scholar] [CrossRef]

- Ueji, R.; Tsuji, N.; Minamino, Y.; Koizumi, Y. Ultragrain refinement of plain low carbon steel by cold-rolling and annealing of martensite. Acta Mater. 2002, 50, 4177–4189. [Google Scholar] [CrossRef]

- Yuan, Q.; Wang, Z.; Zhang, Y.; Ye, J.; Huang, Y.; Huang, A. Effect of Warm Rolling Temperature on the Microstructure and Texture of Microcarbon Dual-Phase (DP) Steel. Metals 2020, 10, 566. [Google Scholar] [CrossRef]

- Xu, W.; Liu, X.C.; Li, X.Y.; Lu, K. Deformation induced grain boundary segregation in nanolaminated Al–Cu alloy. Acta Mater. 2020, 182, 207–214. [Google Scholar] [CrossRef]

- Darling, K.A.; Srinivasan, S.; Koju, R.K.; Hornbuckle, B.C.; Smeltzer, J.; Mishin, Y.; Solanki, K.N. Stress-driven grain refinement in a microstructurally stable nanocrystalline binary alloy. Scripta Mater. 2021, 191, 185–190. [Google Scholar] [CrossRef]

- Blum, W.; Dvořák, J.; Král, P.; Eisenlohr, P.; Sklenička, V. Strain Rate Contribution due to Dynamic Recovery of Ultrafine-Grained Cu–Zr as Evidenced by Load Reductions during Quasi-Stationary Deformation at 0.5 Tm. Metals 2019, 9, 1150. [Google Scholar] [CrossRef] [Green Version]

- Xie, S.L.; Divinski, S.V.; Lei, Y.B.; Wang, Z.B. Accelerated grain boundary migration in nanolaminated interstitial-free steel during chromizing. Mater. Res. Lett. 2021, 9, 84–90. [Google Scholar] [CrossRef]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nature Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Yan, C.K.; Feng, A.H.; Qu, S.J.; Cao, G.J.; Sun, J.L.; Shen, J.; Chen, D.L. Dynamic recrystallization of titanium: Effect of pre-activated twinning at cryogenic temperature. Acta Mater. 2018, 154, 311–324. [Google Scholar] [CrossRef]

- Gao, B.; Lai, Q.; Cao, Y.; Hu, R.; Xiao, L.; Pan, Z.; Liang, N.; Li, Y.; Sha, G.; Liu, M.; et al. Ultrastrong low-carbon nanosteel produced by heterostructure and interstitial mediated warm rolling. Sci. Adv. 2020, 6, eaba8169. [Google Scholar] [CrossRef]

- Araki, S.; Mashima, K.; Masumura, T.; Tsuchiyama, T.; Takaki, S.; Ohmura, T. Effect of grain boundary segregation of carbon on critical grain boundary strength of ferritic steel. Scripta Mater. 2019, 169, 38–41. [Google Scholar] [CrossRef]

- Ahmadian, A.; Scheiber, D.; Zhou, X.; Gault, B.; Liebscher, C.H.; Romaner, L.; Dehm, G. Aluminum depletion induced by co-segregation of carbon and boron in a bcc-iron grain boundary. Nat. Commun. 2021, 12, 6008. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Guo, W.; Poplawsky, J.D.; Liu, C.T. Atom-probe study of Cu and NiAl nanoscale precipitation and interfacial segregation in a nanoparticle-strengthened steel. Mater. Res. Lett. 2017, 5, 562–568. [Google Scholar] [CrossRef] [Green Version]

- Lai, Q.; Brassart, L.; Bouaziz, O.; Gouné, M.; Verdier, M.; Parry, G.; Perlade, A.; Bréchet, Y.; Pardoen, T. Influence of martensite volume fraction and hardness on the plastic behavior of dual-phase steels: Experiments and micromechanical modeling. Inter. J. Plast. 2016, 80, 187–203. [Google Scholar] [CrossRef]

- Xu, S.S.; Liu, Y.W.; Zhang, Y.; Luan, J.H.; Li, J.P.; Sun, L.X.; Jiao, Z.B.; Zhang, Z.W.; Liu, C.T. Precipitation kinetics and mechanical properties of nanostructured steels with Mo additions. Mater. Res. Lett. 2020, 8, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Du, C.; Hoefnagels, J.P.M.; Vaes, R.; Geers, M.G.D. Block and sub-block boundary strengthening in lath martensite. Scr. Mater. 2016, 116, 117–121. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Zhu, G.; Kang, Y. Effect of substructure on mechanical properties and fracture behavior of lath martensite in 0.1C–1.1Si–1.7Mn steel. J. Alloy. Compd. 2016, 675, 104–115. [Google Scholar] [CrossRef]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 273–275, 40–57. [Google Scholar] [CrossRef]

- Ismail, K.; Perlade, A.; Jacques, P.J.; Pardoen, T. Outstanding cracking resistance of fibrous dual phase steels. Acta Mater. 2021, 207, 116700. [Google Scholar] [CrossRef]

- Xu, Y.; Dan, W.; Ren, C.; Huang, T.; Zhang, W. Study of the Mechanical Behavior of Dual-Phase Steel Based on Crystal Plasticity Modeling Considering Strain Partitioning. Metals 2018, 8, 782. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Jung, M.; Lee, S.J.; Lee, Y.K. Microstructural and Dilatational Changes during Tempering and Tempering Kinetics in Martensitic Medium-Carbon Steel. Metall. Mater. Trans. A 2009, 40, 551–559. [Google Scholar] [CrossRef]

- Waterschoot, T.; Verbeken, K.; De Cooman, B.C. Tempering Kinetics of the Martensitic Phase in DP Steel. ISIJ Inter. 2006, 46, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Morsdorf, L.; Emelina, E.; Gault, B.; Herbig, M.; Tasan, C.C. Carbon redistribution in quenched and tempered lath martensite. Acta Mater. 2021, 205, 116521. [Google Scholar] [CrossRef]

- Han, Q.; Kang, Y.; Hodgson, P.D.; Stanford, N. Quantitative measurement of strain partitioning and slip systems in a dual-phase steel. Scr. Mater. 2013, 69, 13–16. [Google Scholar] [CrossRef]

- Diehl, M.; An, D.; Shanthraj, P.; Zaefferer, S.; Roters, F.; Raabe, D. Crystal plasticity study on stress and strain partitioning in a measured 3D dual phase steel microstructure. Phys. Mesomech. 2017, 20, 311–323. [Google Scholar] [CrossRef]

- Djaziri, S.; Li, Y.; Nematollahi, G.A.; Grabowski, B.; Goto, S.; Kirchlechner, C.; Kostka, A.; Doyle, S.; Neugebauer, J.; Raabe, D.; et al. Deformation-Induced Martensite: A New Paradigm for Exceptional Steels. Adv. Mater. 2016, 28, 7753–7757. [Google Scholar] [CrossRef]

- Li, Y.J.; Choi, P.; Borchers, C.; Westerkamp, S.; Goto, S.; Raabe, D.; Kirchheim, R. Atomic-scale mechanisms of deformation-induced cementite decomposition in pearlite. Acta Mater. 2011, 59, 3965–3977. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, L.; Li, W.D.; Tong, Y.; Tseng, K.K.; Tsai, C.W.; Yeh, J.W.; Ren, Y.; Guo, W.; Poplawsky, J.D.; et al. Peierls barrier characteristic and anomalous strain hardening provoked by dynamic-strain-aging strengthening in a body-centered-cubic high-entropy alloy. Mater. Res. Lett. 2019, 7, 475–481. [Google Scholar] [CrossRef]

- Aboulfadl, H.; Deges, J.; Choi, P.; Raabe, D. Dynamic strain aging studied at the atomic scale. Acta Mater. 2015, 86, 34–42. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Kim, B.J.; Stach, E.A.; Cheng, G.J. Fatigue performance improvement in AISI 4140 steel by dynamic strain aging and dynamic precipitation during warm laser shock peening. Acta Mater. 2011, 59, 1014–1025. [Google Scholar] [CrossRef]

- Bayramin, B.; Şimşir, C.; Efe, M. Dynamic strain aging in DP steels at forming relevant strain rates and temperatures. Mater. Sci. Eng. A 2017, 704, 164–172. [Google Scholar] [CrossRef]

- Ekrami, A. High temperature mechanical properties of dual phase steels. Mater. Lett. 2005, 59, 2070–2074. [Google Scholar] [CrossRef]

- Queiroz, R.R.U.; Cunha, F.G.G.; Gonzalez, B.M. Study of dynamic strain aging in dual phase steel. Mater. Sci. Eng. A 2012, 543, 84–87. [Google Scholar] [CrossRef]

- Yan, N.; Li, Z.; Xu, Y.; Meyers, M.A. Shear localization in metallic materials at high strain rates. Prog. Mater. Sci. 2021, 119, 100755. [Google Scholar] [CrossRef]

- Malheiros, L.R.C.; Rodriguez, E.A.P.; Arlazarov, A. Mechanical behavior of tempered martensite: Characterization and modeling. Mater. Sci. Eng. A 2017, 706, 38–47. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, Y.; Niezgoda, S.R. Microstructural and micromechanical evolution during dynamic recrystallization. Inter. J. Plast. 2018, 100, 52–68. [Google Scholar] [CrossRef]

- Souza, R.C.; Silva, E.S.; Jorge, A.M.; Cabrera, J.M.; Balancin, O. Dynamic recovery and dynamic recrystallization competition on a Nb- and N-bearing austenitic stainless steel biomaterial: Influence of strain rate and temperature. Mater. Sci. Eng. A 2013, 582, 96–107. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, F.; Wu, X. Smaller critical size and enhanced strength by nano-laminated structure in nickel. Comp. Mater. Sci. 2015, 110, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Zeng, L.F.; Gao, R.; Fang, Q.F.; Wang, X.P.; Xie, Z.M.; Miao, S.; Hao, T.; Zhang, T. High strength and thermal stability of bulk Cu/Ta nanolamellar multilayers fabricated by cross accumulative roll bonding. Acta Mater. 2016, 110, 341–351. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Huang, M.; Liu, Y. Strengthening mechanisms of the nanolayered polycrystalline metallic multilayers assisted by twins. Inter. J. Plast. 2015, 72, 168–184. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, T.; Pan, Z.; Gao, B.; Huang, J.; Chen, X.; Liu, Y.; Xiao, L.; Zhou, H. Effect of Rolling Temperature on the Structural Refinement and Mechanical Properties of Dual-Phase Heterostructured Low-Carbon Steel. Metals 2022, 12, 115. https://doi.org/10.3390/met12010115

Xu T, Pan Z, Gao B, Huang J, Chen X, Liu Y, Xiao L, Zhou H. Effect of Rolling Temperature on the Structural Refinement and Mechanical Properties of Dual-Phase Heterostructured Low-Carbon Steel. Metals. 2022; 12(1):115. https://doi.org/10.3390/met12010115

Chicago/Turabian StyleXu, Tao, Zhiyi Pan, Bo Gao, Jiaxi Huang, Xuefei Chen, Yi Liu, Lirong Xiao, and Hao Zhou. 2022. "Effect of Rolling Temperature on the Structural Refinement and Mechanical Properties of Dual-Phase Heterostructured Low-Carbon Steel" Metals 12, no. 1: 115. https://doi.org/10.3390/met12010115

APA StyleXu, T., Pan, Z., Gao, B., Huang, J., Chen, X., Liu, Y., Xiao, L., & Zhou, H. (2022). Effect of Rolling Temperature on the Structural Refinement and Mechanical Properties of Dual-Phase Heterostructured Low-Carbon Steel. Metals, 12(1), 115. https://doi.org/10.3390/met12010115