Process Modelling Applied to Aluminium-Steel Butt Welding by Hybrid Metal Extrusion and Bonding (HYB)

Abstract

1. Introduction

2. Components of Process Model

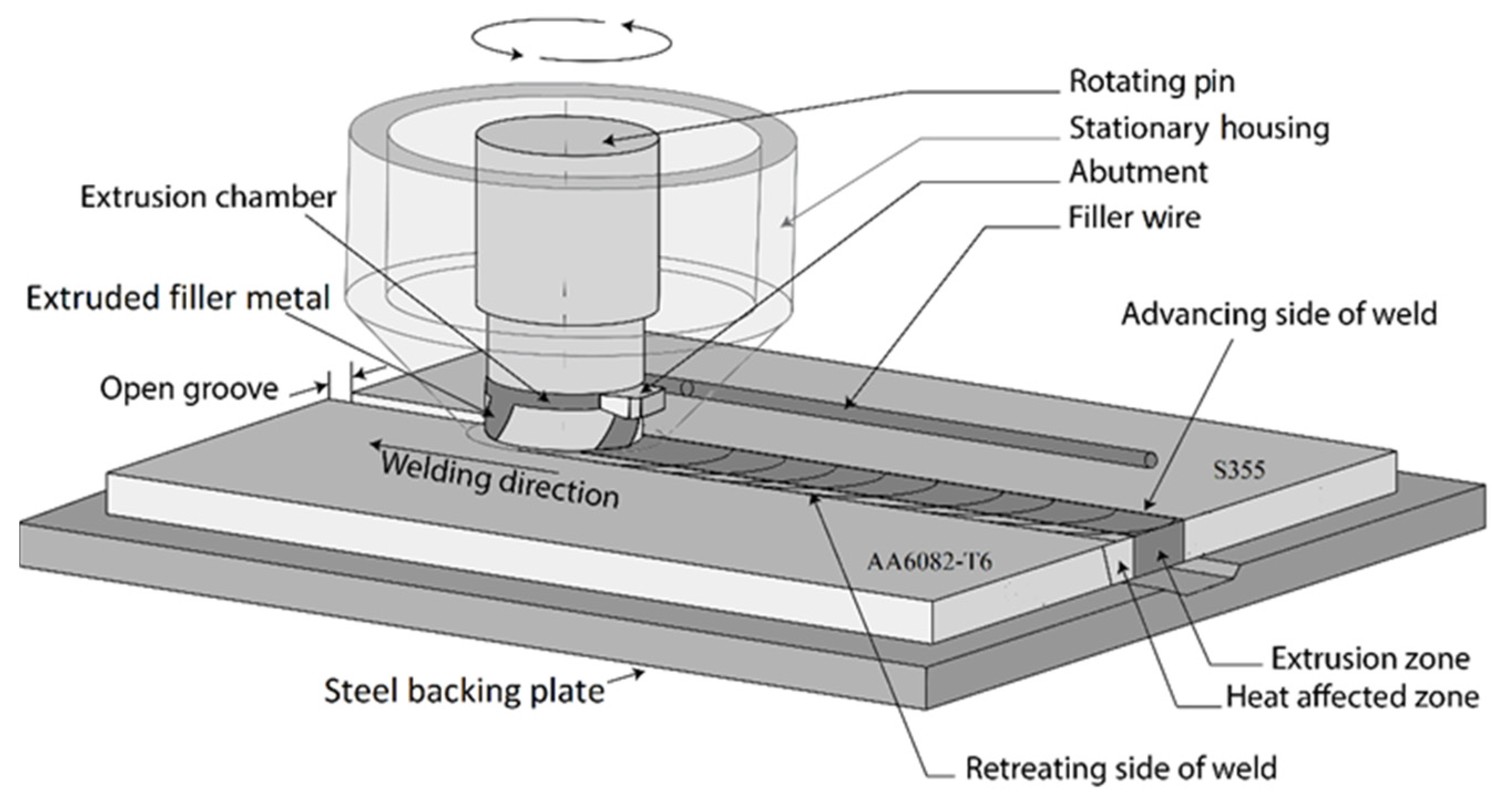

2.1. The HYB PinPoint Extruder

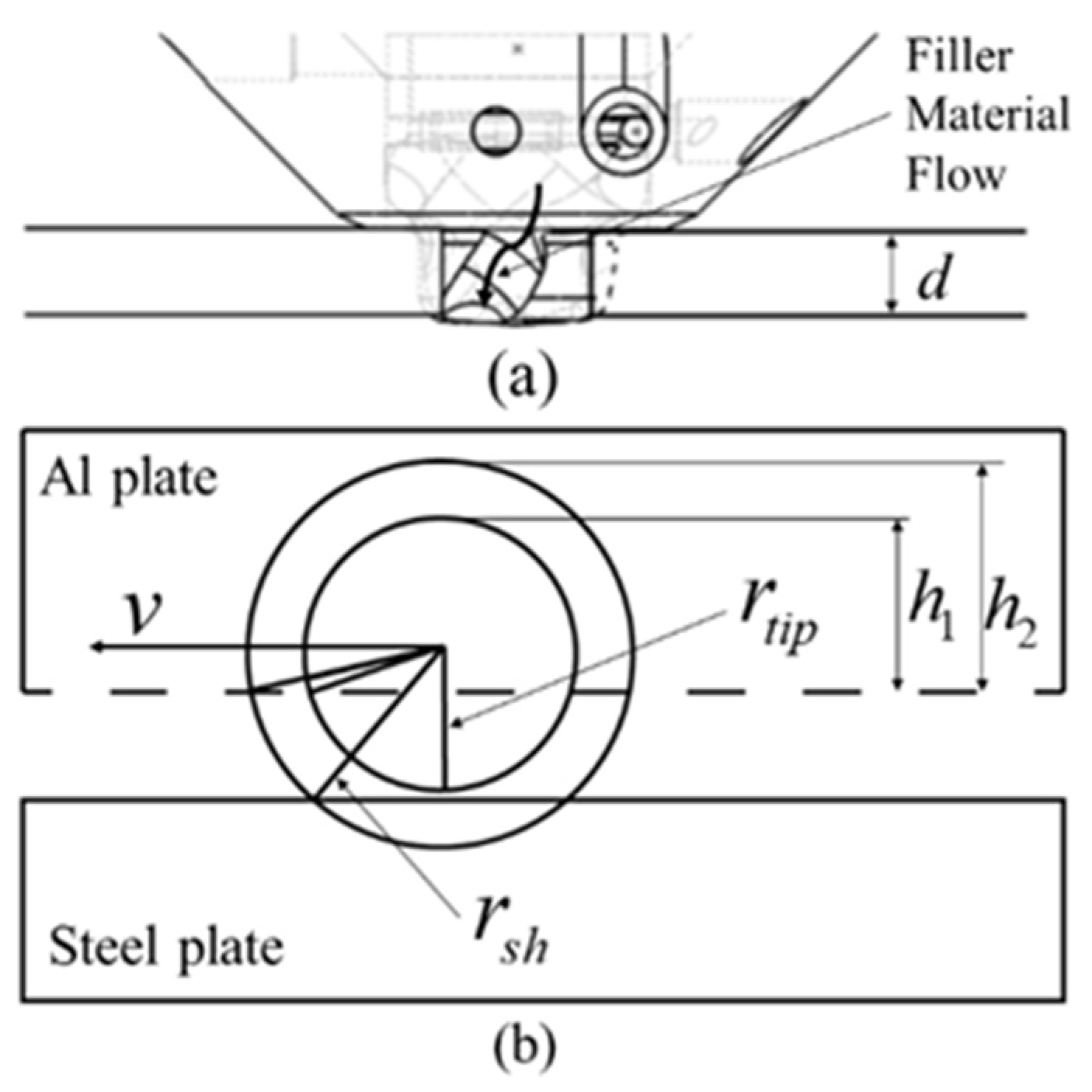

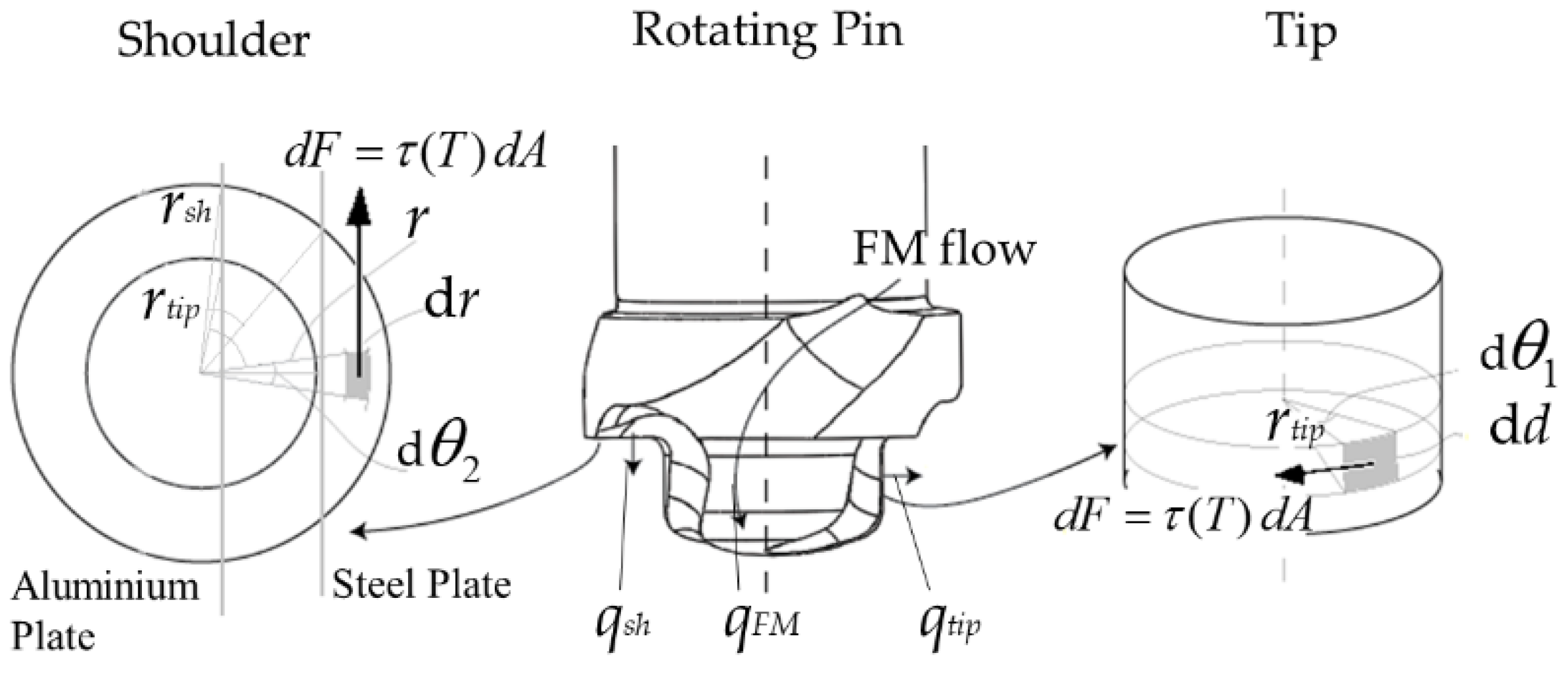

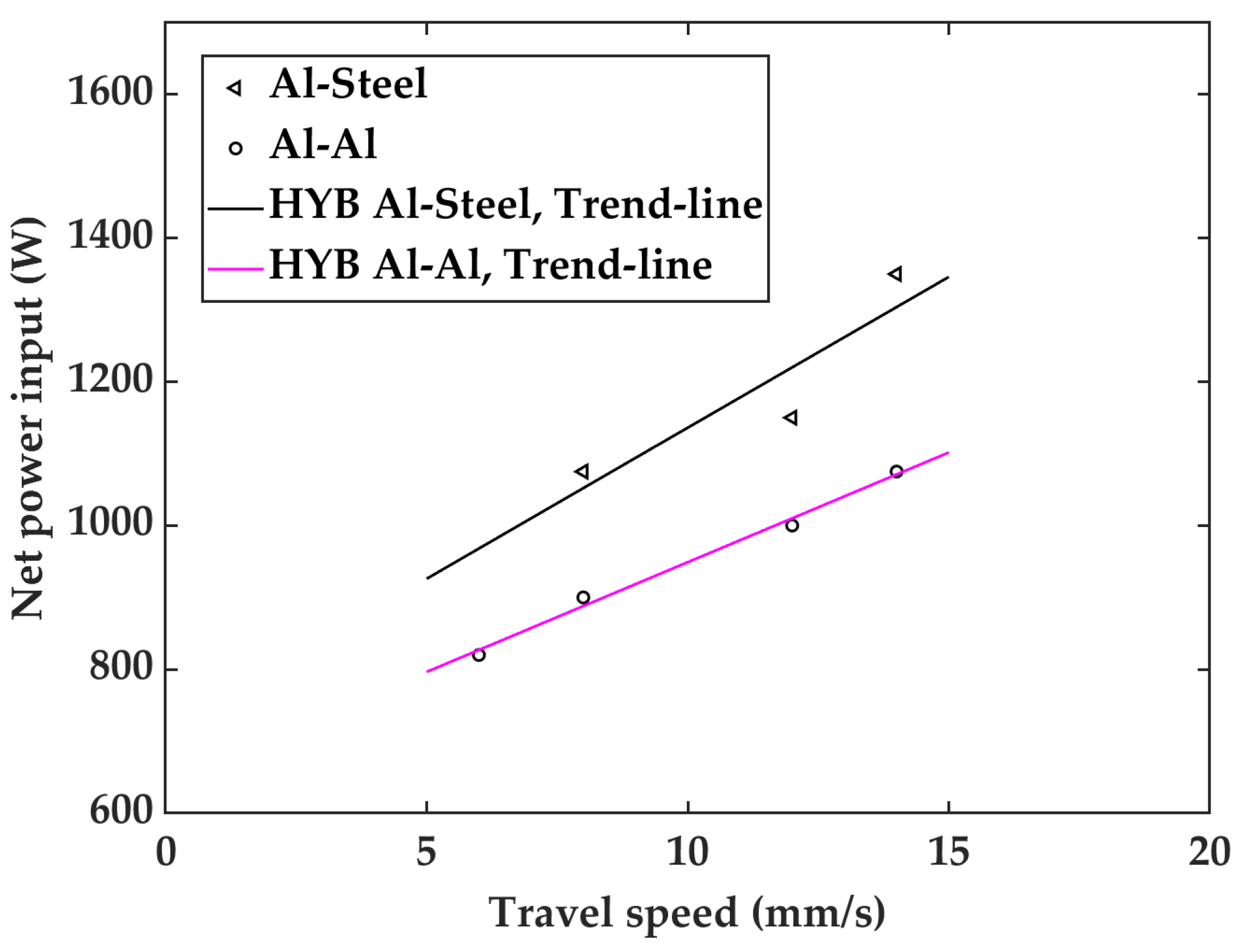

2.2. Heat Generation Model

2.3. Combined HAZ Microstructure and Strength Evolution Model

- A nucleation law, which predicts the number of stable nuclei that form at each time-step.

- A rate law, which calculates either the dissolution or the growth rate of each discrete particle size class.

- A continuity equation, which keeps record of the amount of solute being tied up as precipitates.

- Precipitation hardening due to shearing and bypassing of particles

- Solid solution hardening effects which include the four major strengthening elements Si, Mg, Mn and Cu.

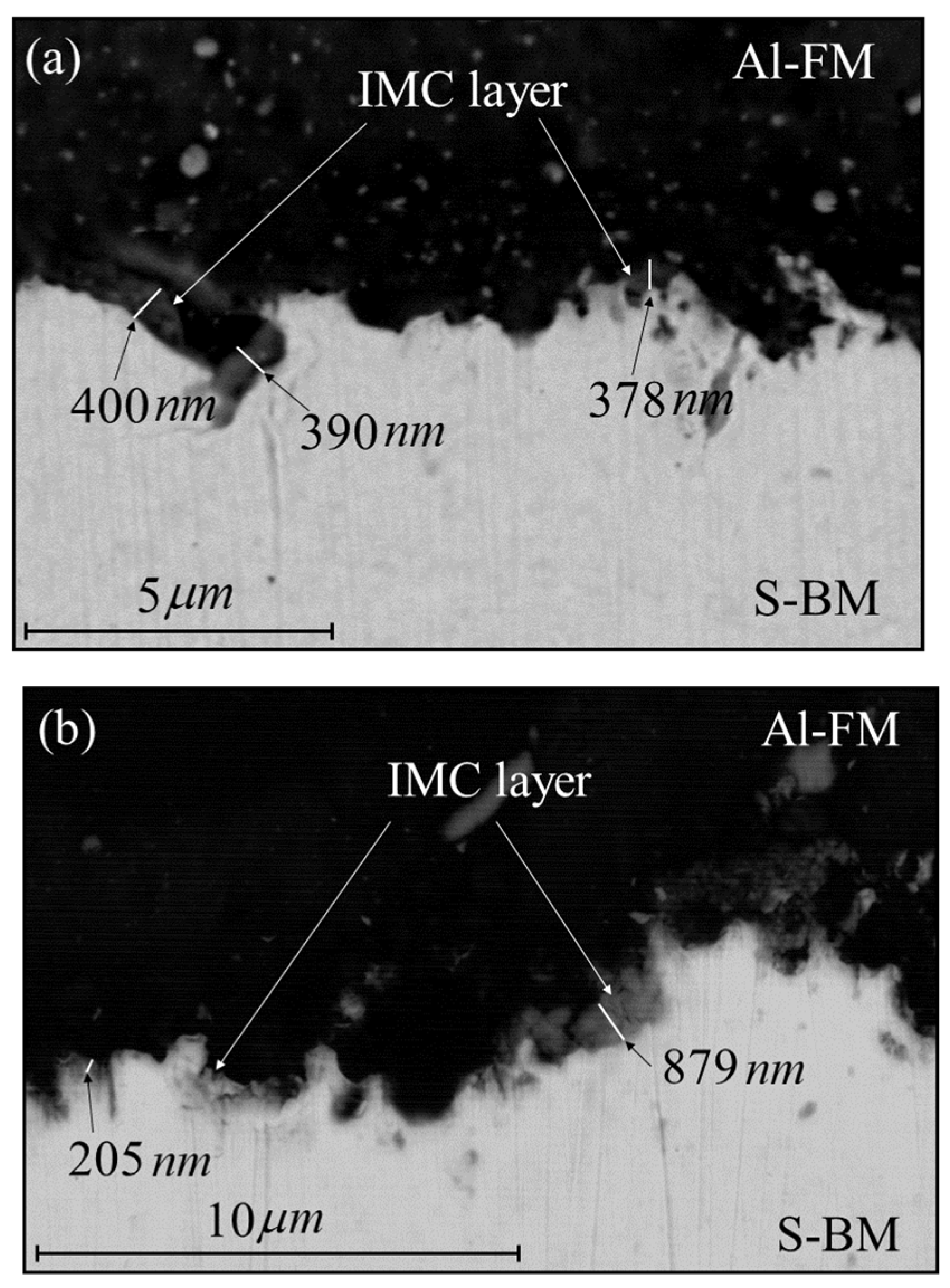

2.4. Isokinetic Diffusion Model Capturing the IMC Formation

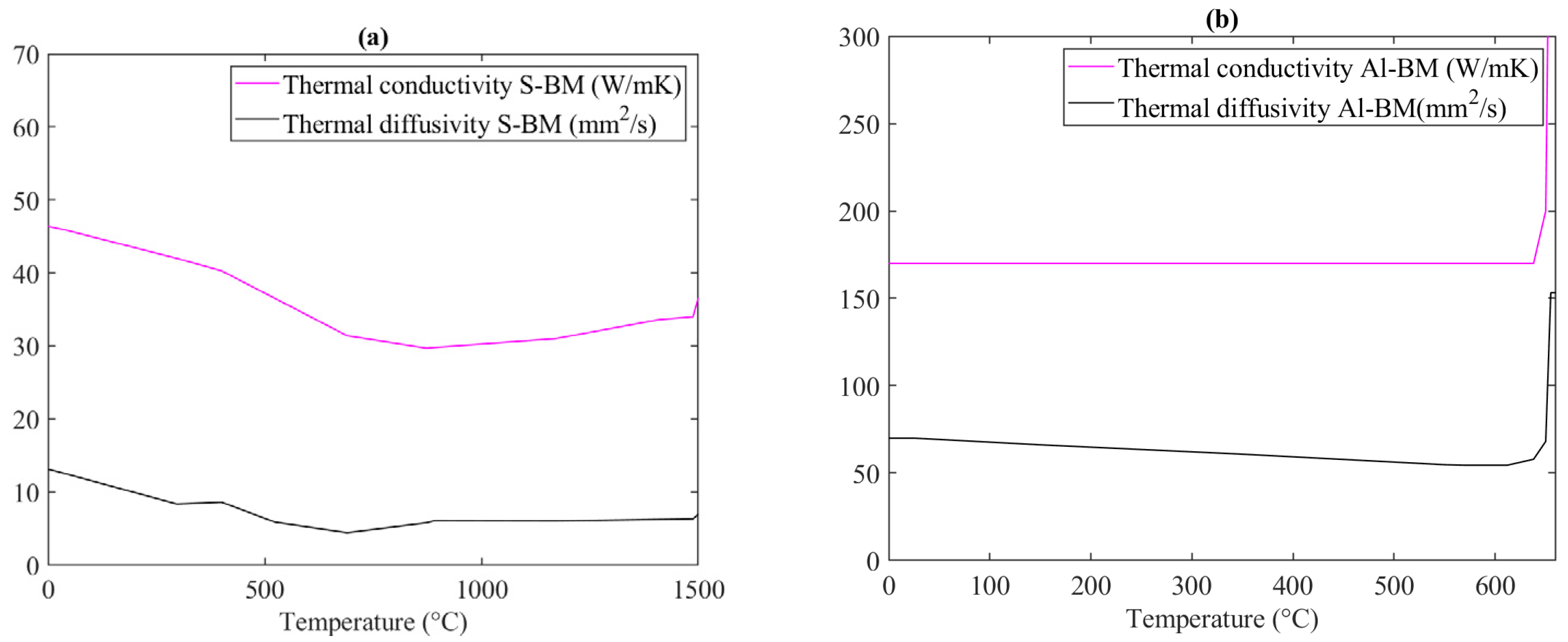

2.5. Numerical Heat Flow Model

3. Experimental Program

3.1. Base Materials

3.2. Welding Conditions

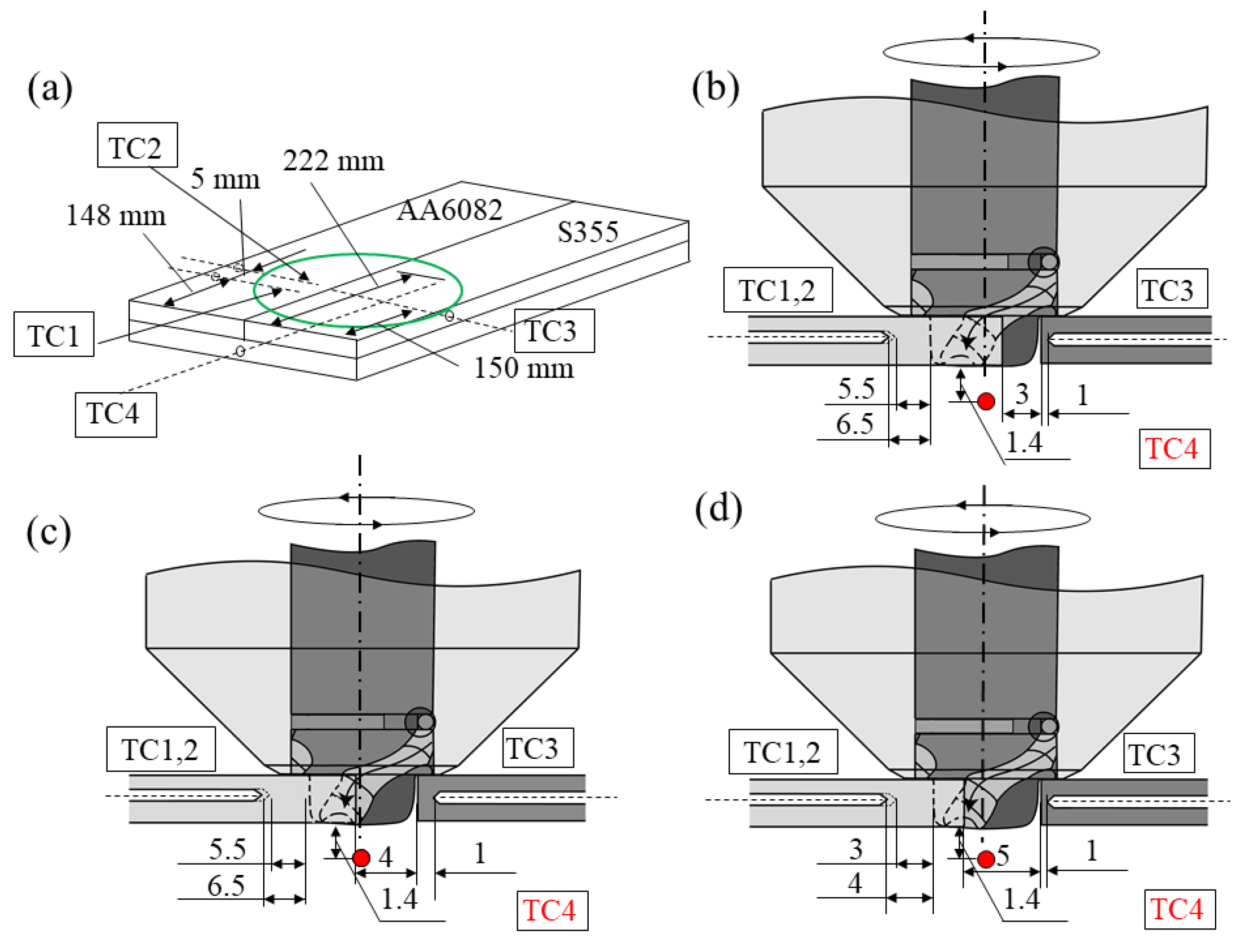

3.3. In-Situ Thermocouple Measurements

3.4. Hardness Measurements

3.5. Scanning Electron Microscopy

4. Experimental Validation of the Process Model

4.1. Predictive Power of Combined Heat Generation and Heat Flow Models

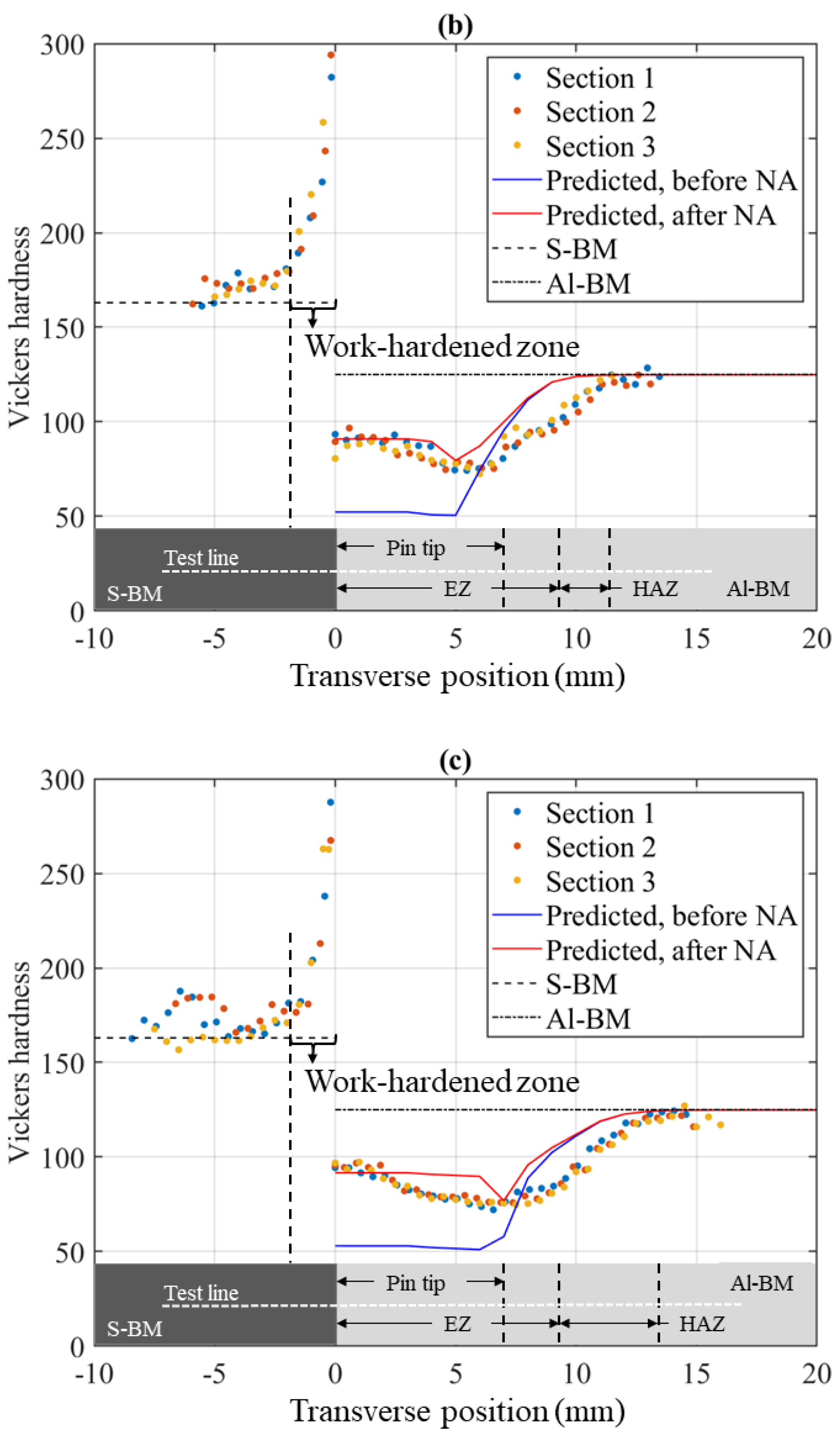

4.2. Predictive Power of Combined Microstructure and Strength Evolution Models

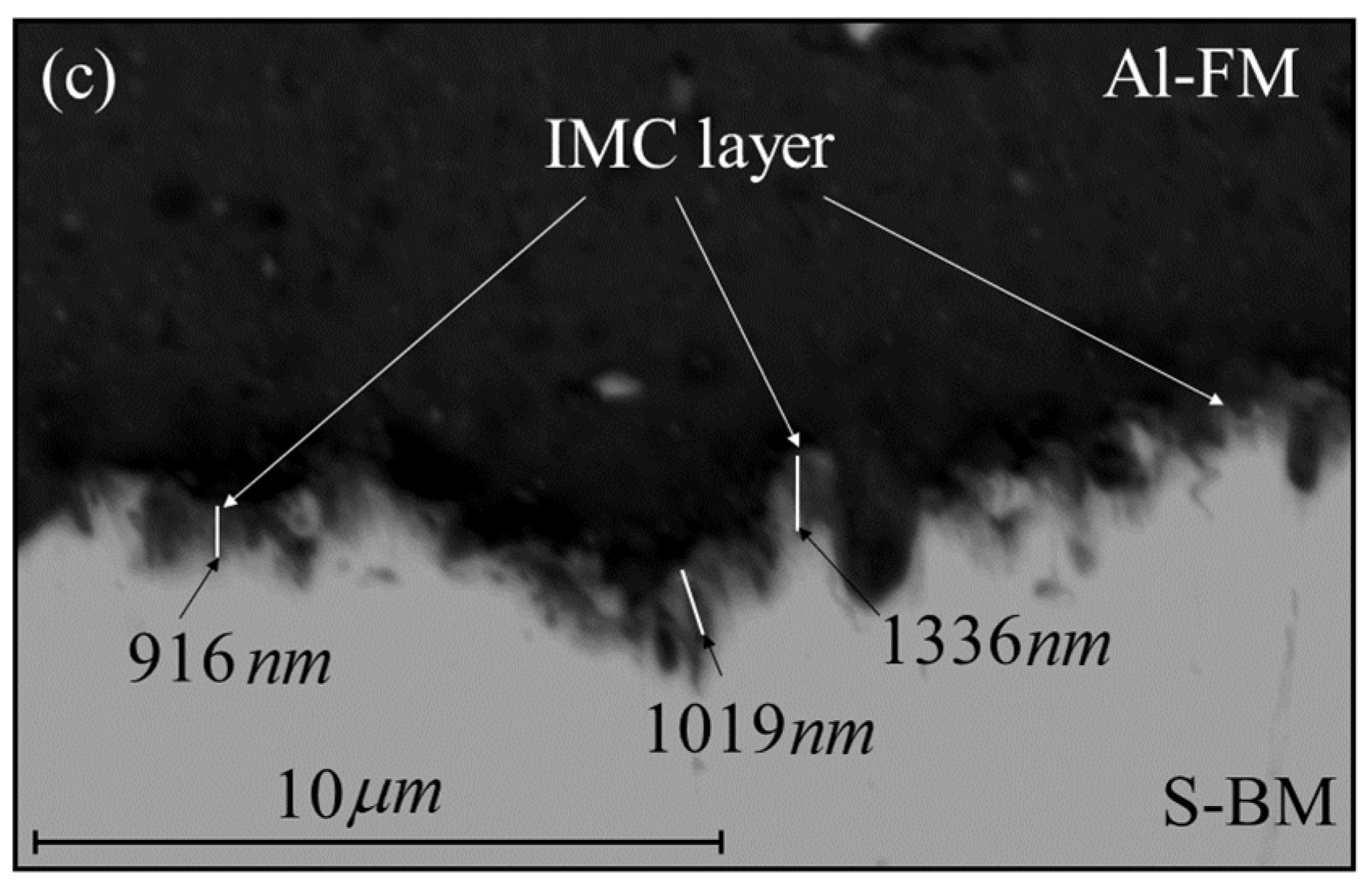

4.3. Predictive Power of Isokinetic Diffusion Model for the IMC Formation

5. Applications of the Process Model

5.1. Temperature Distribution during Al-Steel HYB Butt Welding

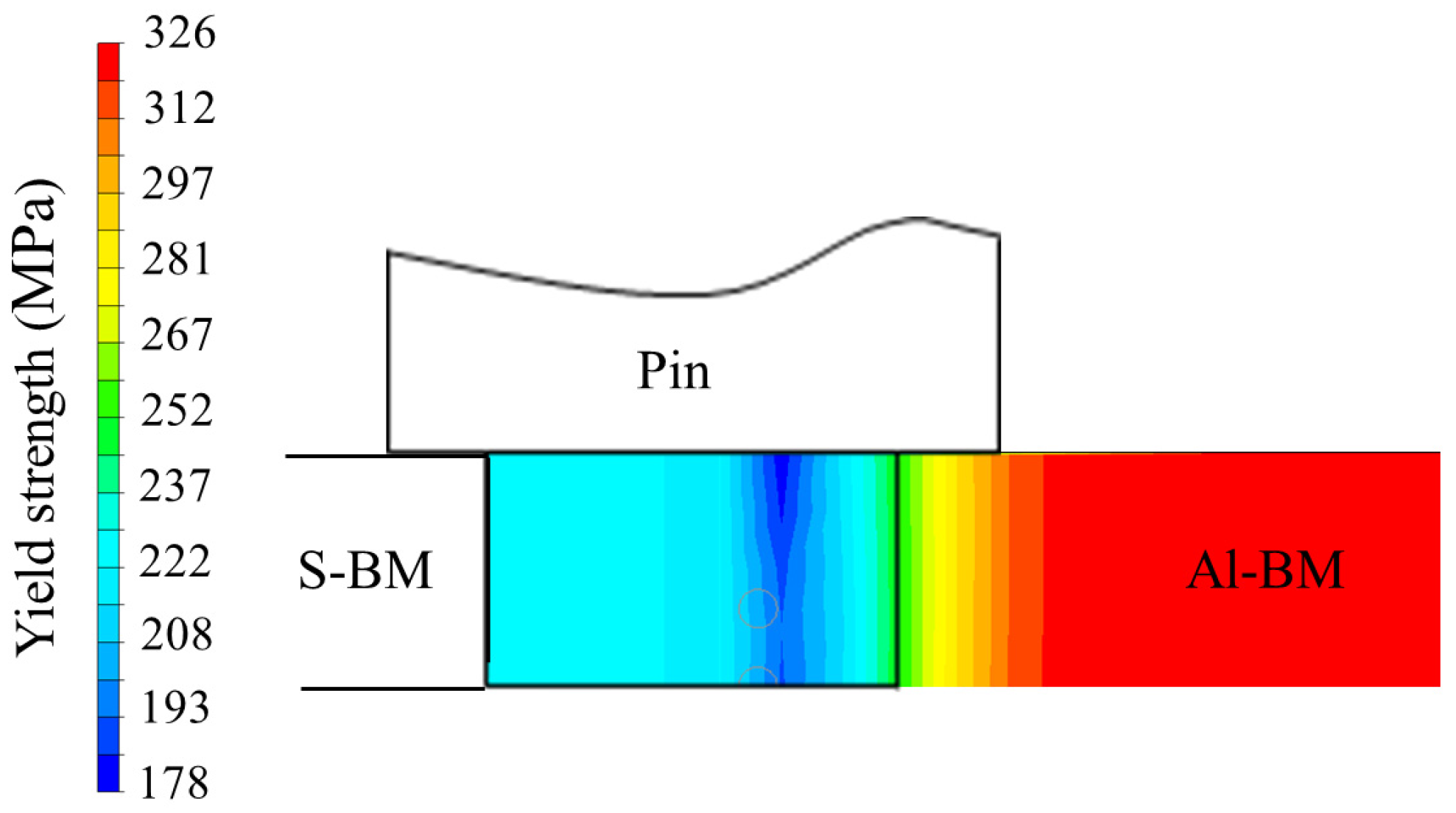

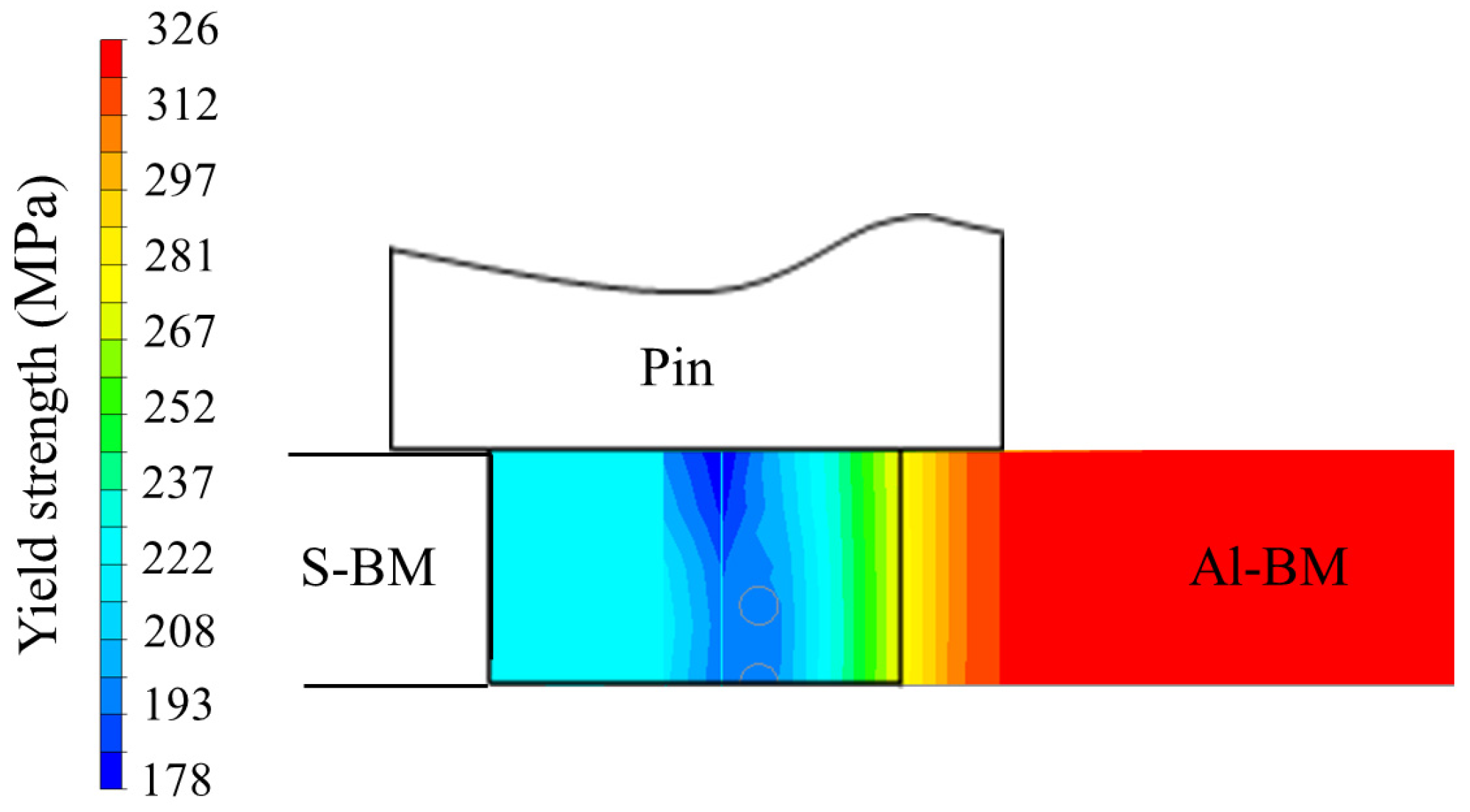

5.2. Strength Distribution inside the Al-Steel HYB Butt Weld

5.3. Case Study on Optimising the Load-Bearing Capacity of Al-Steel HYB Butt Welds

6. Conclusions

- (1)

- The numerical code WELDSIM has proved useful to capture both the temperature-time pattern, the interface microstructure development and the yield strength evolution in different Al-steel butt welds made by HYB. In WELDSIM the finite element (FE) heat flow model is coupled to a frictional heating model, an isokinetic diffusion model for the interfacial intermetallic compound (IMC) formation and a nanostructure model (NaMo) for simulating reversion and re-precipitation of hardening phases inside the aluminium part of the joints during welding and subsequent natural ageing (NA).

- (2)

- In total, three different exploratory butt welding trials have been conducted (referred to as Series I, II and III), using 4 mm thick rolled plates of S355 steel and AA6082-T6 as base metals (BMs). As a starting point, the recorded thermal data, as obtained for in-situ thermocouple measurements, are used to calibrate the coupled frictional heating and FE heat flow models. Subsequently, the measured data for the IMC layer thickness at Al-steel interface along with the transverse HAZ hardness profiles are employed for validating the isokinetic IMC diffusion model and the NaMo model, respectively.

- (3)

- In a calibrated form WELDSIM adequately reproduces the thermal program during Al-steel butt welding using the HYB process. The characteristic asymmetrical thermal field of the Al-steel butt welds is clearly visible in the computed contour plots, showing that most of the absorbed heat diffuses into and through the aluminium plate. At the Al-steel interface the simulation results show that the temperature reaches a value close to 400 °C.

- (4)

- In Al-steel HYB butt welds, where the interfacial bond strength is not a limiting factor, the tensile strength will be determined by the minimum strength level inside either the HAZ or the extrusion zone (EZ) on the aluminium side of the joints. This makes simulations of the yield strength distribution in the transverse direction particularly relevant when it comes to evaluating the maximal load-bearing capacity of such joints. However, the results reveal no such positive effect of lowering the gross heat input besides that the width of the soft zone becomes slightly narrower. An alternative approach to solve this intricate softening problem, based on the results obtain in the case study, is presented towards the end of the paper.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Symbols | |

| plates thickness (mm) | |

| diffusion coefficient of magnesium in aluminium (m2/s) | |

| gross heat input during extrusion and joining (kJ/mm) | |

| difference between tool tip diameter and groove width (mm) | |

| difference between tool shoulder diameter and groove width (mm) | |

| I-groove width (mm) | |

| drive spindle rotational speed (RPM) | |

| filler metal mass flow rate (kg/s) | |

| net power input (W) | |

| tip contribution to the net power input (W) | |

| shoulder contribution to the net power input (W) | |

| filler metal contribution to the net power input (W) | |

| activation energy for diffusion of magnesium in aluminium (kJ/mol) | |

| radius of the tip (mm) | |

| radius of the shoulder (mm) | |

| temperature at tool-matrix interface (°C) | |

| time constant in diffusion model for the IMC formation (s) | |

| reference time in expression for (s) | |

| temperature (°C) | |

| filler metal temperature (°C) | |

| reference temperature in expression for (°C) | |

| extruder travel speed (mm/s) | |

| total power input during extrusion and welding (W) | |

| IMC layer thickness (µm) | |

| reference value for the IMC layer thickness (µm) | |

| hardening precipitates in Al-Mg-Si alloys | |

| thermal efficiency factor of PinPoint extruder | |

| angular rotation speed (rad/s) | |

| maximum yield stress increase in reference alloy after natural ageing | |

| intrinsic yield stress of pure aluminium (MPa) | |

| contribution form precipitation hardening in NaMo (MPa) | |

| contribution from solid solution hardening in NaMo (MPa) | |

| aluminium yield strength (MPa) | |

| local yield shear stress at tool/aluminium interface (MPa) | |

| Abbreviations | |

| Ac1 | lowest temperature at which phase transformation occurs on heating |

| Al-Al | monometallic Al-Al component |

| Al-BM | aluminium base metal |

| Al-FM | aluminium filler metal |

| Al-FW | aluminium filler wire |

| Al-steel | aluminium-steel component or aluminium-steel interface |

| AS | advancing side |

| BM | base metal |

| BSE | backscattered electrons |

| CMTW | cold metal transfer welding |

| DIC | digital image correlation |

| EZ | extrusion zone |

| FE | finite element |

| FM | filler metal |

| FSW | friction stir welding |

| FW | filler wire |

| GMAW | gas metal arc welding |

| GP-zones | Guinier–Preston zones |

| HAZ | heat-affected zone |

| HYB | hybrid metal extrusion and bonding |

| HV | Vickers hardness |

| IMC | intermetallic compound |

| LBW | laser beam welding |

| NA | natural ageing |

| NaMo | nanostructure model |

| RS | retreating side |

| RT | room temperature |

| S-BM | steel base metal |

| SEM | scanning electron microscope |

| TC1 | thermocouple 1 |

| TC2 | thermocouple 2 |

| TC3 | thermocouple 3 |

| TC4 | thermocouple 4 |

References

- Robson, J.; Panteli, A.; Prangnell, P.B. Modelling intermetallic phase formation in dissimilar metal ultrasonic welding of aluminium and magnesium alloys. Sci. Technol. Weld. Join. 2012, 17, 447–453. [Google Scholar] [CrossRef]

- Cai, W.; Daehn, G.; Vivek, A.; Li, J.; Khan, H.; Mishra, R.S.; Komarasamy, M. A state-of-the-art review on solid-state metal joining. J. Manuf. Sci. Eng. 2019, 141, 31012. [Google Scholar] [CrossRef]

- Gullino, A.; Matteis, P.; D’Aiuto, F. Review of aluminium-to-steel welding technologies for car-body applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef]

- Joseph, A.; Rai, S.K.; Jayakumar, T.; Murugan, N. Evaluation of residual stresses in dissimilar weld joints. Int. J. Press. Vessel. Pip. 2005, 82, 700–705. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y. Friction stir welding of dissimilar aluminum alloys and steels: A review. Int. J. Adv. Manuf. Technol. 2018, 99, 1781–1811. [Google Scholar] [CrossRef]

- Uematsu, Y.; Kakiuchi, T.; Tozaki, Y.; Kojin, H. Comparative study of fatigue behaviour in dissimilar Al alloy/steel and Mg alloy/steel friction stir spot welds fabricated by scroll grooved tool without probe. Sci. Technol. Weld. Join. 2012, 17, 348–356. [Google Scholar] [CrossRef]

- Ohhama, S.; Hata, T.; Yahaba, T.; Kobayashi, T.; Miyahara, T.; Sayama, M. Application of an FSW Continuous Welding Technology for Steel and Aluminum to an Automotive Subframe; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Colwell, K.C. Two metals enter, one leaves: The miracle of friction stir welding. Car Driv. 2013, 15. [Google Scholar]

- Kusuda, Y. Honda develops robotized FSW technology to weld steel and aluminum and applied it to a mass-production vehicle. Ind. Robot. Int. J. 2013, 40, 208–212. [Google Scholar] [CrossRef]

- Sandnes, L.; Grong, Ø.; Torgersen, J.; Welo, T.; Berto, F. Exploring the hybrid metal extrusion and bonding process for butt welding of Al–Mg–Si alloys. Int. J. Adv. Manuf. Technol. 2018, 98, 1059–1065. [Google Scholar] [CrossRef]

- Grong, Ø.; Sandnes, L.; Ferro, P.; Berto, F. Hybrid Metal Extrusion & Bonding. In Handbook of Welding (HOW-2021); Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2021; pp. 2–54. [Google Scholar]

- Grong, Ø.; Sandnes, L.; Bergh, T.; Vullum, P.E.; Holmestad, R.; Berto, F. An Analytical Framework for Modelling Intermetallic Compound (IMC) Formation and Optimizing Bond Strength in Aluminium-Steel Welds. Mater. Des. Process. Commun. 2019, 1, e57. [Google Scholar] [CrossRef]

- Bergh, T.; Sandnes, L.; Johnstone, D.N.; Grong, Ø.; Berto, F.; Holmestad, R.; Midgley, P.A.; Vullum, P.E. Microstructural and mechanical characterization of a second generation hybrid metal extrusion & bonding aluminium-steel butt joint. Mater. Charact. 2021, 173, 110761. [Google Scholar] [CrossRef]

- Sandnes, L.; Bergh, T.; Grong, Ø.; Holmestad, R.; Vullum, P.E.; Berto, F. Interface microstructure and tensile properties of a third generation aluminium-steel butt weld produced using the Hybrid Metal Extrusion & Bonding (HYB) process. Mater. Sci. Eng. A 2021, 809, 140975. [Google Scholar] [CrossRef]

- Sandnes, L.; Welo, T.; Grong, Ø.; Berto, F. On the fatigue properties of a third generation aluminium-steel butt weld made by hybrid metal extrusion & bonding (HYB). Int. J. Fatigue 2021, 155, 106586. [Google Scholar] [CrossRef]

- Grong, Ø.; Sandnes, L.; Berto, F. A status report on the hybrid metal extrusion & bonding (HYB) process and its applications. Mater. Des. Process. Commun. 2019, 1, e41. [Google Scholar] [CrossRef]

- Frigaard, Ø.; Grong, Ø.; Midling, O.T. A process model for friction stir welding of age hardening aluminium alloys. Metall. Mater. Trans. A 2001, 32, 1189–1200. [Google Scholar] [CrossRef]

- Khandkar, M.Z.H.; Khan, J.A.; Reynolds, A.P. Prediction of temperature distribution and thermal history during friction stir welding: Input torque based model. Sci. Technol. Weld. Join. 2003, 8, 165–174. [Google Scholar] [CrossRef]

- El-Moayed, M.H.; Shash, A.Y.; Abd Rabou, M.; El-Sherbiny, M.G.D. A coupled statistical and numerical analysis of the residual properties of AA6063 friction stir welds. J. Adv. Join. Process. 2021, 3, 100042. [Google Scholar] [CrossRef]

- Fjær, H.G.; Bjørneklett, B.; Myhr, O.R. Microstructure based modelling of Al-Mg-Si alloys in development of local heating processes for automotive structures. In Proceedings of the 2005 TMS Annual Meeting, San Francisco, CA, USA, 13–17 February 2005. [Google Scholar]

- Tang, X.; Fjær, H.G. Integrated Forming, Welding and Crash Simulations for an Aluminum Crash Management System. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; Volume 57045. [Google Scholar] [CrossRef]

- Leoni, F.; Grong, Ø.; Ferro, P.; Berto, F. Simulating the dependence of the filler wire feeding on the wire size in the hybrid metal extrusion & bonding (HYB) process. Procedia Struct. Integr. 2020, 26, 321–329. [Google Scholar] [CrossRef]

- Leoni, F.; Grong, Ø.; Ferro, P.; Berto, F. A Semi-Analytical Model for the Heat Generation during Hybrid Metal Extrusion and Bonding (HYB). Materials 2021, 14, 170. [Google Scholar] [CrossRef]

- Leoni, F.; Grong, Ø.; Fjær, H.G.; Ferro, P.; Berto, F. A First Approach on Modelling the Thermal and Microstructure Fields During Aluminium Butt Welding Using the HYB PinPoint Extruder. Procedia Struct. Integr. 2020, 28, 2253–2260. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Andersen, S.J. Modelling of the age hardening behaviour of Al–Mg–Si alloys. Acta Mater. 2001, 49, 65–75. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Fjær, H.G.; Marioara, C.D. Modelling of the microstructure and strength evolution in Al–Mg–Si alloys during multistage thermal processing. Acta Mater. 2004, 52, 4997–5008. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø. Novel modelling approach to optimization of welding conditions and heat treatment schedules for age hardening Al alloys. Sci. Technol. Weld. Join. 2009, 14, 321–332. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Pedersen, K.O. A combined precipitation, yield strength, and work hardening model for Al-Mg-Si alloys. Metall. Mater. Trans. A 2010, 41, 2276–2289. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Schäfer, C. An extended age-hardening model for Al-Mg-Si alloys incorporating the room-temperature storage and cold deformation process stages. Metall. Mater. Trans. A 2015, 46, 6018–6039. [Google Scholar] [CrossRef]

- Grong, Ø. Metallurgical Modelling of Welding; Institute of Materials: London, UK, 1997. [Google Scholar]

- Ramachandran, K.K.; Murugan, N.; Kumar, S.S. Friction stir welding of aluminum alloy AA5052 and HSLA steel. Weld. J. 2015, 94, 291–300. [Google Scholar]

- MSCsoftware. 2021. Available online: https://www.mscsoftware.com/ (accessed on 26 August 2022).

- Outinen, J.; Kesti, J.; Mäkeläinen, P. Fire design model for structural steel S355 based upon transient state tensile test results. J. Constr. Steel Res. 1997, 42, 161–169. [Google Scholar] [CrossRef]

- Goyal, R.; Johnson, E.; El-Zein, M. A model equation for the convection coefficient for thermal analysis of welded structures. In Trends in Welding Research: Proceedings of the 8th International Conference, 1–6 June 2008; ASM International: Pine Mountain, GA, USA, 2009; p. 321. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- GLview. 2021. Available online: https://ceetron.com/ceetron-glview-inova/ (accessed on 26 August 2022).

- ASTM E92-17; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Jacquin, D.; De Meester, B.; Simar, A.; Deloison, D.; Montheillet, F.; Desrayaud, C. A simple Eulerian thermomechanical modeling of friction stir welding. J. Mater. Process. Technol. 2011, 211, 57–65. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Rajasekaran, T.; Pandey, C.; Menaka, M. Influence of tool probe profiles on the microstructure and mechanical properties of underwater friction stir welded AA5083 material. J. Mater. Eng. Perform. 2022, 1–18. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Rajasekaran, T.; Pandey, C.; Menaka, M. Mechanical and microstructural characteristics of underwater friction stir welded AA5083 armor-grade aluminum alloy joints. J. Mater. Eng. Perform. 2022, 1–14. [Google Scholar] [CrossRef]

- Grzegorz Rogalski, G.; Swierczy, A.; Landowski, M.; Fydryc, D. Mechanical and microstructural characterization of TIG welded dissimilar joints between 304L austenitic stainless steel and Incoloy 800HT nickel alloy. Metals 2020, 10, 559. [Google Scholar] [CrossRef]

| Material | Si | Mg | Fe | Cu | Mn | Cr | Zn | Ti | Zr | B | Others | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al-BM | 1.14 | 0.76 | 0.22 | 0.06 | 0.62 | 0.08 | 0.09 | 0.03 | - | - | <0.15 | Balance |

| Al-FW | 1.11 | 0.61 | 0.20 | 0.002 | 0.51 | 0.14 | - | 0.043 | 0.13 | 0.006 | 0.029 | Balance |

| Material | C | Si | Mn | P | S | Cr | Ni | Cu | Al | Nb | B | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-BM | 0.059 | 0.01 | 0.61 | 0.01 | 0.002 | 0.03 | 0.04 | 0.01 | 0.065 | 0.025 | 0 | 0.003 | Balance |

| Material | Yield Strength | Ultimate Tensile Strength | Elongation |

|---|---|---|---|

| Al-BM | 324 MPa | 333 MPa | 11.8% |

| S-BM | 410 MPa | 481 MPa | 34.5% |

| Al-FW | 367 MPa | 388 MPa | 4% |

| Series No. | I-Groove Width | Extruder Travel Speed | Spindle Rotational Speed |

|---|---|---|---|

| I | 3 mm | 14 mm/s | 350 RPM * |

| II | 4 mm | 12 mm/s | 350 RPM * |

| III | 5 mm | 8 mm/s | 350 RPM * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leoni, F.; Grong, Ø.; Celotto, A.; Fjær, H.G.; Ferro, P.; Berto, F. Process Modelling Applied to Aluminium-Steel Butt Welding by Hybrid Metal Extrusion and Bonding (HYB). Metals 2022, 12, 1656. https://doi.org/10.3390/met12101656

Leoni F, Grong Ø, Celotto A, Fjær HG, Ferro P, Berto F. Process Modelling Applied to Aluminium-Steel Butt Welding by Hybrid Metal Extrusion and Bonding (HYB). Metals. 2022; 12(10):1656. https://doi.org/10.3390/met12101656

Chicago/Turabian StyleLeoni, Francesco, Øystein Grong, Ambra Celotto, Hallvard Gustav Fjær, Paolo Ferro, and Filippo Berto. 2022. "Process Modelling Applied to Aluminium-Steel Butt Welding by Hybrid Metal Extrusion and Bonding (HYB)" Metals 12, no. 10: 1656. https://doi.org/10.3390/met12101656

APA StyleLeoni, F., Grong, Ø., Celotto, A., Fjær, H. G., Ferro, P., & Berto, F. (2022). Process Modelling Applied to Aluminium-Steel Butt Welding by Hybrid Metal Extrusion and Bonding (HYB). Metals, 12(10), 1656. https://doi.org/10.3390/met12101656