Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints

Abstract

:1. Introduction

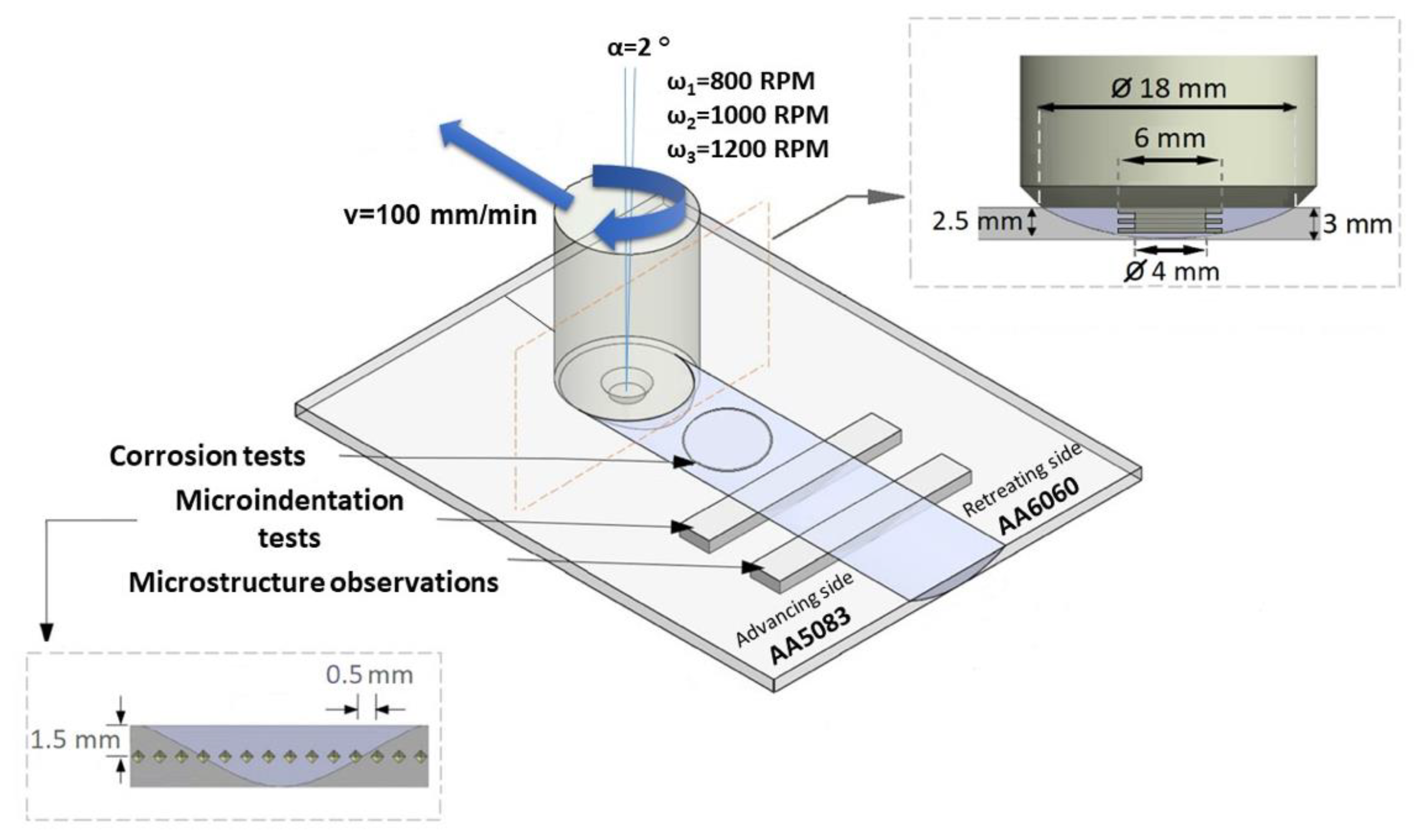

2. Materials and Methods

3. Results and Discussion

4. Conclusions

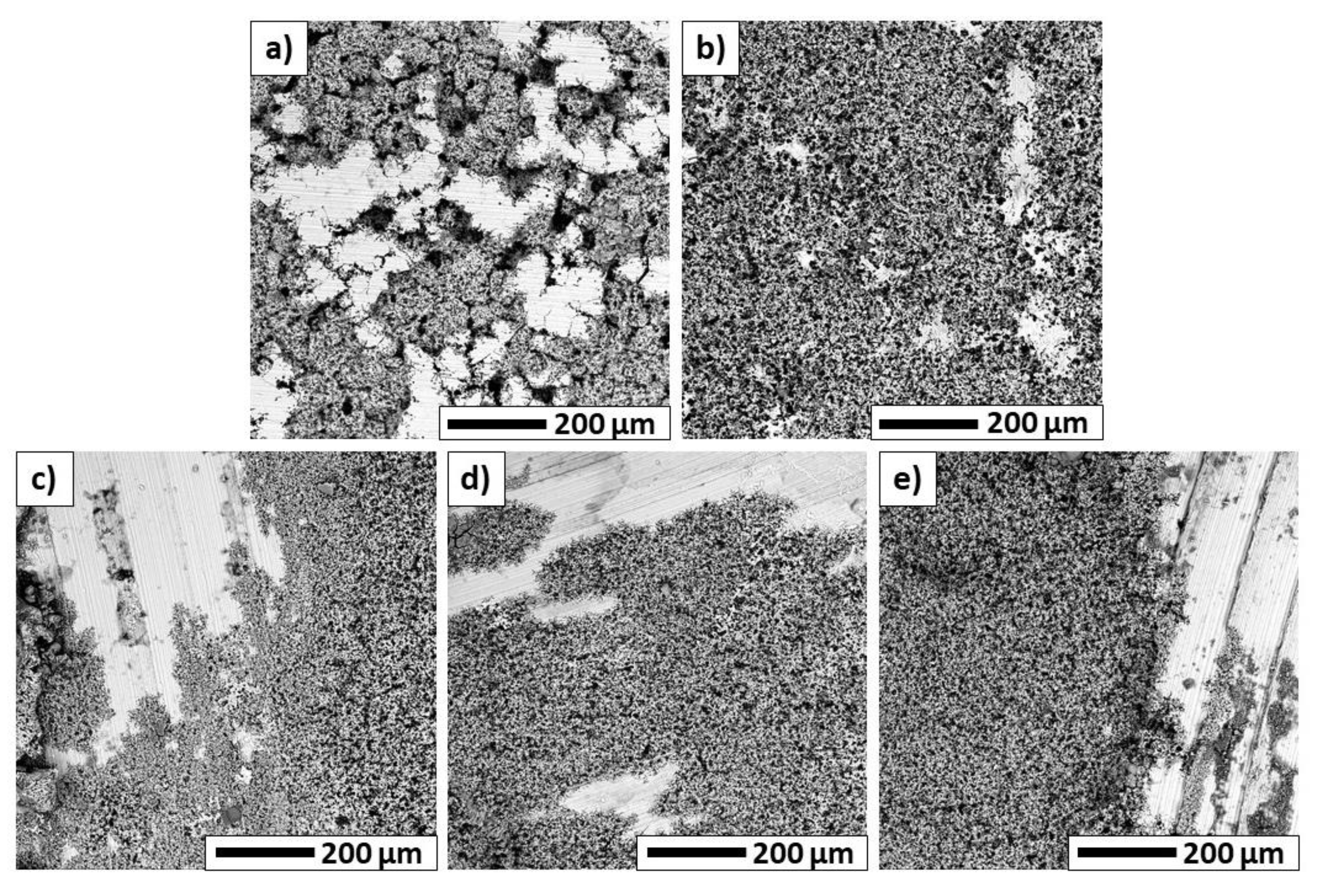

- The use of a hexagonal tool with grooves, along with the selection of the above process parameters, yielded sound welds that were characterized by an absence of surface defects. The typical microstructure characterized by zones of HAZ, TMAZ and fine-grained WN was revealed.

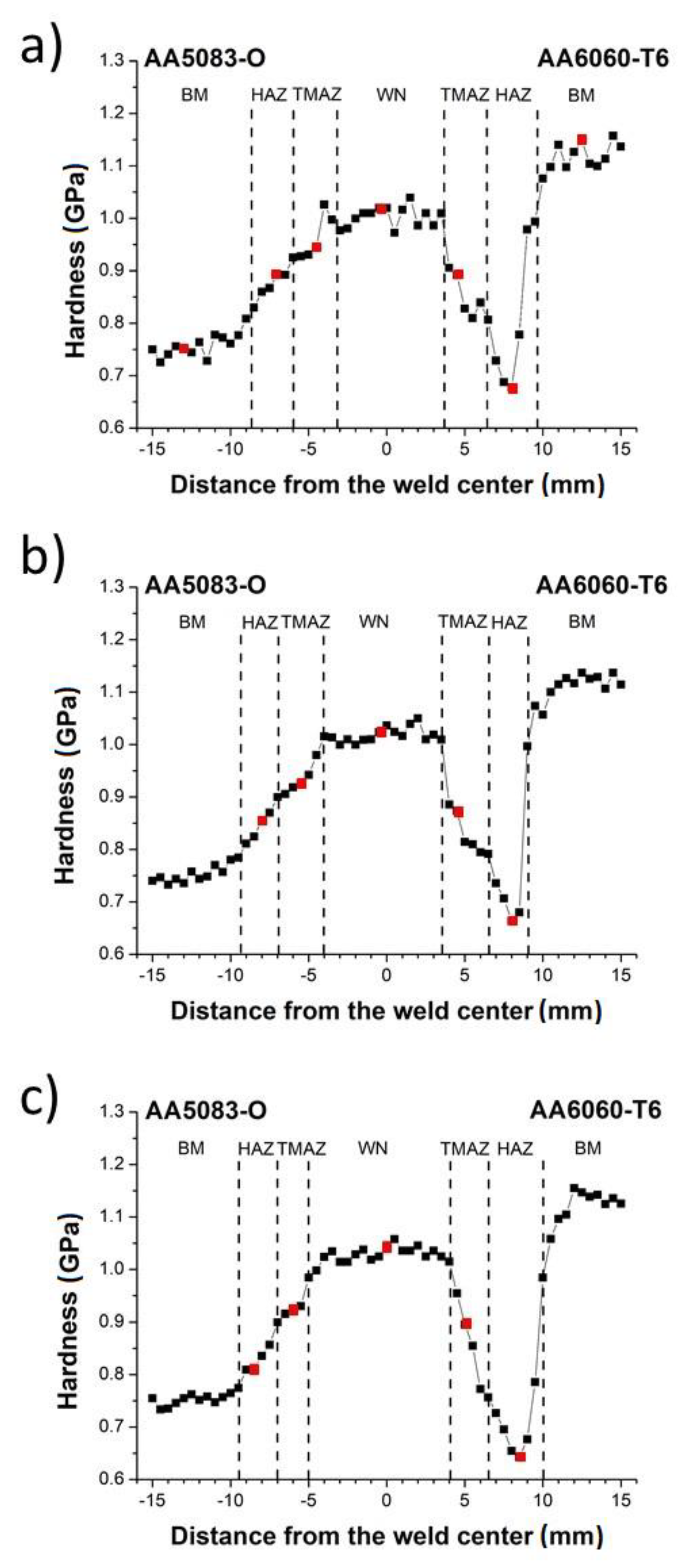

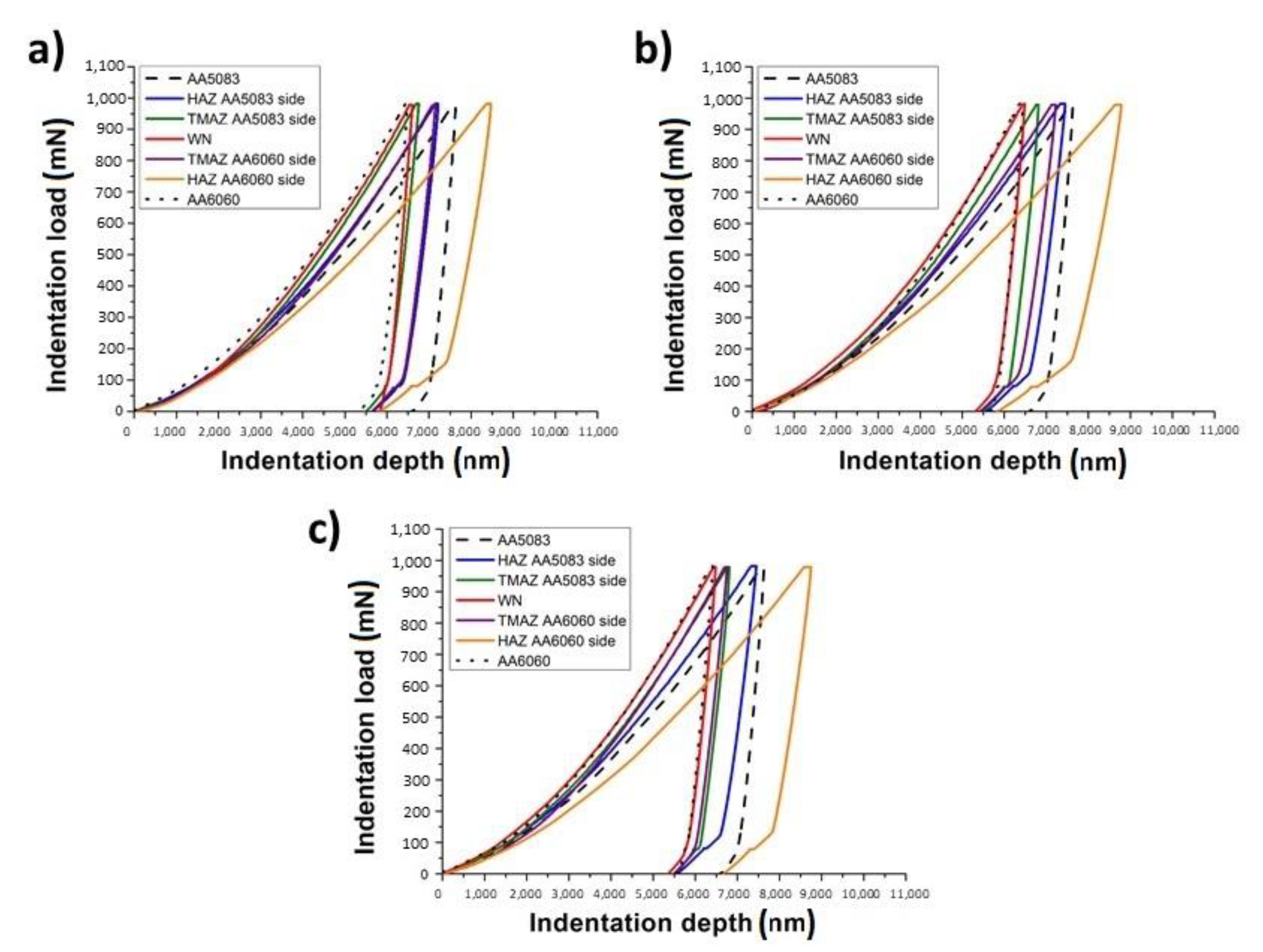

- Hardness measurements were taken on cross sections of the joints using indentation tests. A reduction in hardness values was observed in the heat-affected zones on the AA6060 alloy side of the produced welds. The lowest hardness was noted for the HAZ of the weld that was produced with a tool rotational speed of 1200 RPM, and was equal to 0.64 GPa. In addition, it was observed that the maximum hardness of the nugget zone increased with increasing tool rotational speed. This is explained by a more efficient recrystallization process occurring as a result of higher heat input. The highest hardness of the WN zone was observed for the weld that was produced with the highest tool rotational speed of 1200 RPM, and was equal to 1.07 GPa.

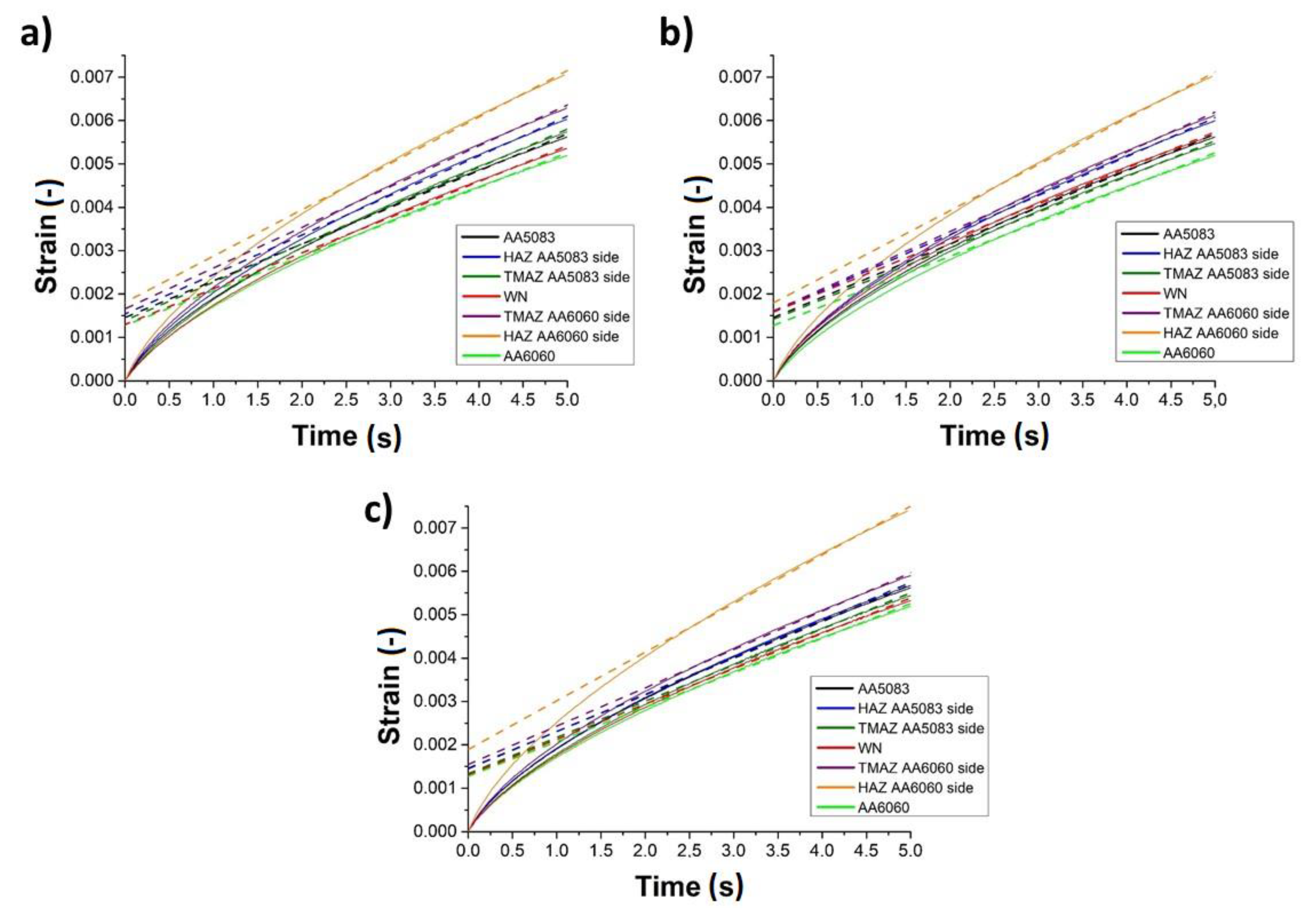

- Based on the results of the indentation tests, in particular, the dwell time period, the densities and mobilities of dislocations in the individual zones of weld cross sections were calculated. The lowest dislocation density of 5.597 × 1014 m−2, with the highest mobility of 7.009 × 10−9 , was observed in the heat-affected zones on the AA6060 side of the resulting welds, which may explain the significant strength reduction in this zone.

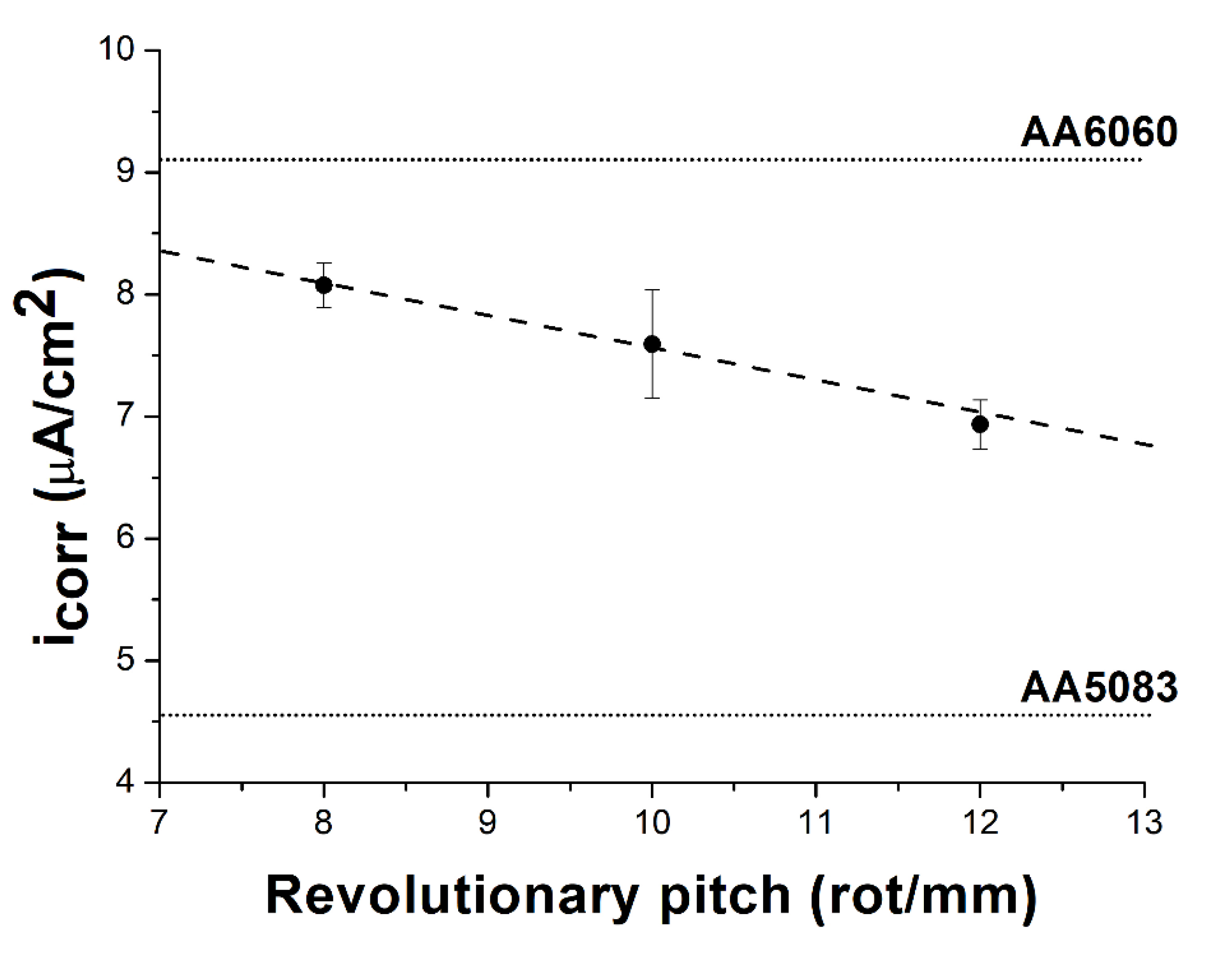

- The conducted potentiodynamic tests in 3.5 wt% NaCl revealed that the AA5083 base material was characterized by the highest corrosion resistance, and the corrosion current density was equal to 4.506 ± 0.278 µA·cm−2. The highest corrosion current density 9.047 ± 0.768 µA·cm−2 was noted for the base metal AA6060. The corrosion current densities for all welded samples yielded average values that fell between both parent materials. By increasing the tool rotational speed, there was higher heat input. This resulted in more effective recrystallization, and better corrosion resistance of the welds.

Author Contributions

Funding

Conflicts of Interest

References

- Ghaffarpour, M.; Kolahgar, S.; Dariani, B.M.; Dehghani, K. Evaluation of dissimilar welds of 5083-H12 and 6061-T6 produced by friction stir welding. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 3697–3707. [Google Scholar] [CrossRef]

- Ancona, A.; Daurelio, G.; De Filippis, L.A.C.; Ludovico, A.D.; Spera, A.M. CO2 Laser Welding of Aluminium Shipbuilding Industry Alloys: AA 5083, AA 5383, AA 5059, and AA 6082. In Proceedings of the XIV International Symposium on Gas Flow Chemical Lasers, and High-Power Lasers, Wroclaw, Poland, 25–30 August 2002; pp. 577–587. [Google Scholar]

- Kawasaki, T.; Makino, T.; Masai, K.; Ohba, H.; Ina, Y.; Ezumi, M. Application of friction stir welding to construction of railway vehicles. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2004, 47, 502–511. [Google Scholar] [CrossRef]

- Vasudevan, N.; Bhaskar, G.B.; Rajendra Prasad, A.; Suresh, S.M. Corrosion study on AA5083 aluminum alloy—Boron carbide composite. Mater. Today Proc. 2019, 16, 1124–1129. [Google Scholar] [CrossRef]

- Samuel Ratna Kumar, P.S.; Robinson Smart, D.S.; John Alexis, S. Corrosion behaviour of Aluminium Metal Matrix reinforced with Multi-wall Carbon Nanotube. J. Asian Ceram. Soc. 2017, 5, 71–75. [Google Scholar] [CrossRef]

- Liu, Q.; Han, R.; Gao, Y.; Ke, L. Numerical investigation on thermo-mechanical and material flow characteristics in friction stir welding for aluminum profile joint. Int. J. Adv. Manuf. Technol. 2021, 114, 2457–2469. [Google Scholar] [CrossRef]

- Chen, X.; Peng, Y.; Peng, S.; Yao, S.; Chen, C.; Xu, P. Flow and fracture behavior of aluminum alloy 6082-T6 at different tensile strain rates and triaxialities. PLoS ONE 2017, 12, e0181983. [Google Scholar] [CrossRef] [PubMed]

- Baratzadeh, F.; Boldsaikhan, E.; Nair, R.; Burford, D.; Lankarani, H. Investigation of mechanical properties of AA6082-T6/AA6063-T6 friction stir lap welds. J. Adv. Join. Processes 2020, 1, 100011. [Google Scholar] [CrossRef]

- Varma, K.V.K.; Baig, I.; Kumar, B.V.R.R.; Ramana, M.V. Effect of friction stir welding parameters on tool geometry and metallurgical properties of AA 6082-T6 weldments at different weld zones. Mater. Today Proc. 2021, 45, 3195–3200. [Google Scholar] [CrossRef]

- Maciel, R.; Bento, T.; Braga, D.F.O.; da Silva, L.F.M.; Moreira, P.M.G.P.; Infante, V. Fatigue properties of combined friction stir and adhesively bonded AA6082-T6 overlap joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2169–2180. [Google Scholar] [CrossRef]

- Li, Y.; Zou, W.; Lee, B.; Babkin, A.; Chang, Y. Research progress of aluminum alloy welding technology. Int. J. Adv. Manuf. Technol. 2020, 109, 1207–1218. [Google Scholar] [CrossRef]

- Safeen, M.W.; Spena, P.R. Main issues in quality of friction stir welding joints of aluminum alloy and steel sheets. Metals 2019, 9, 610. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M. Manufacturing Parameters, Materials, and Welds Properties of Butt Friction Stir Welded Joints–Overview. Materials 2020, 13, 4940. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, V.M.; Leitão, C.; Rodrigues, D.M. Friction stir welding industrialisation and research status. Sci. Technol. Weld. Join. 2018, 23, 400–409. [Google Scholar] [CrossRef]

- Devaiah, D.; Kishore, K.; Laxminarayana, P. Optimal FSW process parameters for dissimilar aluminium alloys (AA5083 and AA6061) Using Taguchi Technique. Mater. Today Proc. 2018, 5, 4607–4614. [Google Scholar] [CrossRef]

- Peel, M.J.; Steuwer, A.; Withers, P.J.; Dickerson, T.; Shi, Q.; Shercliff, H. Dissimilar friction stir welds in AA5083-AA6082. Part I: Process parameter effects on thermal history and weld properties. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2006, 37, 2183–2193. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2008, 148, 82–87. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N.; Dinaharan, I. Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Mater. Des. 2012, 40, 7–16. [Google Scholar] [CrossRef]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Dissimilar Friction Stir Welds in AA2219-AA5083 Aluminium Alloys: Effect of Process Parameters on Material Inter-Mixing, Defect Formation, and Mechanical Properties. Trans. Indian Inst. Met. 2016, 69, 1397–1415. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, D.; Zhang, W.; Zhang, W.; Qiu, C. Microstructure evolution during dissimilar friction stir welding of AA7003-T4 and AA6060-T4. Materials 2018, 11, 342. [Google Scholar] [CrossRef] [Green Version]

- Husain, M.M.; Sarkar, R.; Pal, T.K.; Prabhu, N.; Ghosh, M. Friction Stir Welding of Steel: Heat Input, Microstructure, and Mechanical Property Co-relation. J. Mater. Eng. Perform. 2015, 24, 3673–3683. [Google Scholar] [CrossRef]

- Krishnan, M.; Subramaniam, S.K. Investigation of Mechanical and Metallurgical Properties of Friction Stir Corner Welded Dissimilar Thickness AA5086-AA6061 Aluminium Alloys. Mater. Res. 2018, 21, e20171045. [Google Scholar] [CrossRef]

- Liu, F.J.; Fu, L.; Chen, H.Y. Effect of high rotational speed on temperature distribution, microstructure evolution, and mechanical properties of friction stir welded 6061-T6 thin plate joints. Int. J. Adv. Manuf. Technol. 2018, 96, 1823–1833. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Wei, X.; Sun, W. Microstructure and mechanical properties of friction stir welded AA6092/SiC metal matrix composite. Mater. Sci. Eng. A 2019, 742, 78–88. [Google Scholar] [CrossRef]

- Morozova, I.; Obrosov, A.; Naumov, A.; Królicka, A.; Golubev, I.; Bokov, D.O.; Doynov, N.; Weiß, S.; Michailov, V. Impact of impulses on microstructural evolution and mechanical performance of al-mg-si alloy joined by impulse friction stir welding. Materials 2021, 14, 347. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M.; Koszelow, D.; Cavaliere, P. Effect of Processing Parameters on Strength and Corrosion Resistance of Friction Stir-Welded AA6082. Metals 2022, 12, 192. [Google Scholar] [CrossRef]

- Naik, S.N.; Walley, S.M. The Hall–Petch and inverse Hall–Petch relations and the hardness of nanocrystalline metals. J. Mater. Sci. 2020, 55, 2661–2681. [Google Scholar] [CrossRef]

- Bahrami, M.; Dehghani, K.; Besharati Givi, M.K. A novel approach to develop aluminum matrix nano-composite employing friction stir welding technique. Mater. Des. 2014, 53, 217–225. [Google Scholar] [CrossRef]

- Sangalli, G.; Lemos, G.V.B.; Martinazzi, D.; De Lima Lessa, C.R.; Beskow, A.B.; Reguly, A. Towards qualification of friction stir welding to AA5083-O and AA5052-O aluminum alloys. Mater. Res. 2019, 22, e20190349. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H. Friction Stir Welding of Aluminium Alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Sato, Y.S.; Onuma, T.; Ikeda, K.; Kokawa, H. Experimental verification of heat input during friction stir welding of Al alloy 5083. Sci. Technol. Weld. Join. 2016, 21, 325–330. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Zhang, H. Numerical investigations of size effects on residual states of friction stir weld. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 572–581. [Google Scholar] [CrossRef]

- Sedmak, A.S.; Kumar, R.; Chattopadhyaya, S.; Hloch, S.; Tadić, S.S.; Djurdjević, A.A.; Čeković, I.R.; Dončeva, E. Heat input effect of friction stir welding on aluminum alloy AA 6061-T6 welded joint. Therm. Sci. 2016, 20, 637–641. [Google Scholar] [CrossRef]

- Thirathipviwat, P.; Song, G.; Bednarcik, J.; Kühn, U.; Gemming, T.; Nielsch, K.; Han, J. Compositional complexity dependence of dislocation density and mechanical properties in high entropy alloy systems. Prog. Nat. Sci. Mater. Int. 2020, 30, 545–551. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Franke, O.; Göken, M. Indentation size effect in metallic materials: Modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 2006, 54, 2547–2555. [Google Scholar] [CrossRef]

- Yamada, H.; Ogasawara, N.; Shimizu, Y.; Horikawa, H.; Kobayashi, H. Effect of high strain rate on micro-indentation test in pure aluminum. EPJ Web Conf. 2012, 26, 2–6. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M.; Pawłowski, Ł.; Gajowiec, G. Corrosion properties of dissimilar AA6082/AA6060 friction stir welded butt joints in different NaCl concentrations. Int. J. Precis. Eng. Manuf. Green Technol. 2022. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; ISBN 9780521255769. [Google Scholar]

- Cho, J.; Molinari, J.F.; Anciaux, G. Mobility law of dislocations with several character angles and temperatures in FCC aluminum. Int. J. Plast. 2017, 90, 66–75. [Google Scholar] [CrossRef]

- Zhuang, Z.; Liu, Z.; Cui, Y. Strain Gradient Plasticity Theory at the Microscale. In Dislocation Mechanism-Based Crystal Plasticity; Academic Press: Cambridge, UK, 2019; pp. 57–90. ISBN 9780128145913. [Google Scholar]

- Voyiadjis, G.Z.; Abed, F.H. Effect of dislocation density evolution on the thermomechanical response of metals with different crystal structures at low and high strain rates and temperatures. Arch. Mech. 2005, 57, 299–343. [Google Scholar] [CrossRef]

- Jata, K.V.; Sankaran, K.K.; Ruschau, J.J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Heason, C.P. Grain structure formation during friction stir welding observed by the “stop action technique”. Acta Mater. 2005, 53, 3179–3192. [Google Scholar] [CrossRef]

- Woo, W.; Balogh, L.; Ungár, T.; Choo, H.; Feng, Z. Grain structure and dislocation density measurements in a friction-stir welded aluminum alloy using X-ray peak profile analysis. Mater. Sci. Eng. A 2008, 498, 308–313. [Google Scholar] [CrossRef]

- Woo, W.; Ungár, T.; Feng, Z.; Kenik, E.; Clausen, B. X-ray and neutron diffraction measurements of dislocation density and subgrain size in a friction-stir-welded aluminum alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 1210–1216. [Google Scholar] [CrossRef]

- Yuzbekova, D.; Kulitskiy, V.; Mogucheva, A.; Kaibyshev, R. Effect of friction stir welding on microstructure of a 5024 alloy. Mater. Sci. Forum 2017, 879, 2249–2254. [Google Scholar] [CrossRef]

- Ni, D.R.; Chen, D.L.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Tensile properties and strain-hardening behaviour of friction stir welded SiCp/AA2009 composite joints. Mater. Sci. Eng. A 2014, 608, 1–10. [Google Scholar] [CrossRef]

- Nişancioǧlu, K. Corrosion and protection of aluminum alloys in seawater. In Corrosion Behaviour and Protection of Copper and Aluminium Alloys in Seawater; European Federation of Corrosion (EFC) Series; Woodhead Publishing: Sawston, UK, 2007; pp. 145–155. ISBN 9781845692414. [Google Scholar]

- Sukiman, N.L.; Zhou, X.; Birbilis, N.; Hughes, A.E.; Mol, J.M.C.; Garcia, S.J.; Thompson, G.E. Durability and Corrosion of Aluminium and Its Alloys: Overview, Property Space, Techniques and Developments. In Aluminium Alloys—New Trends in Fabrication and Applications; IntechOpen: London, UK, 2012; pp. 47–97. ISBN 978-953-51-0861-0. [Google Scholar]

- Kartsonakis, I.A.; Dragatogiannis, D.A.; Koumoulos, E.P.; Karantonis, A.; Charitidis, C.A. Corrosion behaviour of dissimilar friction stir welded aluminium alloys reinforced with nanoadditives. Mater. Des. 2016, 102, 56–67. [Google Scholar] [CrossRef]

- Qin, H.; Zhang, H.; Sun, D.; Zhuang, Q. Corrosion behavior of the friction-stir-welded joints of 2A14-T6 aluminum alloy. Int. J. Miner. Metall. Mater. 2015, 22, 627–638. [Google Scholar] [CrossRef]

- Zucchi, F.; Trabanelli, G.; Grassi, V. Pitting and stress corrosion cracking resistance of friction stir welded AA 5083. Werkst. Und Korros. 2001, 52, 853–859. [Google Scholar] [CrossRef]

- Maggiolino, S.; Schmid, C. Corrosion resistance in FSW and in MIG welding techniques of AA6XXX. J. Mater. Process. Technol. 2008, 197, 237–240. [Google Scholar] [CrossRef]

- Ralston, K.D.; Fabijanic, D.; Birbilis, N. Effect of grain size on corrosion of high purity aluminium. Electrochim. Acta 2011, 56, 1729–1736. [Google Scholar] [CrossRef]

- Song, D.; Ma, A.; Jiang, J.; Lin, P.; Yang, D. Corrosion behavior of ultra-fine grained industrial pure Al fabricated by ECAP. Trans. Nonferrous Met. Soc. China 2009, 19, 1065–1070. [Google Scholar] [CrossRef]

| Chemical Composition (wt%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | |

| AA5083 | 0.40 | 0.40 | 0.10 | 0.60 | 4.50 | 0.15 | 0.25 | 0.15 | balance |

| AA6060 | 0.40 | 0.20 | 0.10 | 0.10 | 0.40 | 0.05 | 0.15 | 0.10 | balance |

| Material | Traverse Speed (mm/min) | Rotational Speed (RPM) | Tilt Angle (º) | Revolutionary Pitch (rot/mm) |

|---|---|---|---|---|

| AA5083/AA6060 | 100 | 800 | 2 | 8 |

| AA5083/AA6060 | 100 | 1000 | 2 | 10 |

| AA5083/AA6060 | 100 | 1200 | 2 | 12 |

| Sample | HISE (GPa) | hmax (µm) | V | |||

|---|---|---|---|---|---|---|

| - | AA5083 | 0.754 | 7.629 | 5.386 × 1012 | 6.679 × 1014 | 4.429 × 10−9 |

| - | AA6060 | 1.103 | 6.283 | 6.540 × 1012 | 9.785 × 1014 | 2.844 × 10−9 |

| ω = 800 RPM | HAZ AA5083 side | 0.881 | 7.226 | 5.687 × 1012 | 7.811 × 1014 | 4.082 × 10−9 |

| ω = 800 RPM | TMAZ AA5083 side | 0.945 | 6.693 | 6.140 × 1012 | 8.378 × 1014 | 3.681 × 10−9 |

| ω = 800 RPM | WN | 1.034 | 6.518 | 6.305 × 1012 | 9.171 × 1014 | 3.142 × 10−9 |

| ω = 800 RPM | TMAZ AA6060 side | 0.896 | 7.143 | 5.753 × 1012 | 7.945 × 1014 | 4.137 × 10−9 |

| ω = 800 RPM | HAZ AA6060 side | 0.687 | 8.356 | 4.918 × 1012 | 6.086 × 1014 | 6.142 × 10−9 |

| ω = 1000 RPM | HAZ AA5083 side | 0.843 | 7.338 | 5.600 × 1012 | 7.124 × 1014 | 4.403 × 10−9 |

| ω = 1000 RPM | TMAZ AA5083 side | 0.932 | 6.922 | 5.937 × 1012 | 8.264 × 1014 | 3.482 × 10−9 |

| ω = 1000 RPM | WN | 1.060 | 6.503 | 6.319 × 1012 | 9.404 × 1014 | 3.090 × 10−9 |

| ω = 1000 RPM | TMAZ AA6060 side | 0.883 | 7.219 | 5.692 × 1012 | 7.829 × 1014 | 4.095 × 10−9 |

| ω = 1000 RPM | HAZ AA6060 side | 0.652 | 8.641 | 4.755 × 1012 | 5.775 × 1014 | 6.442 × 10−9 |

| ω = 1200 RPM | HAZ AA5083 side | 0.845 | 7.333 | 5.604 × 1012 | 7.490 × 1014 | 4.015 × 10−9 |

| ω = 1200 RPM | TMAZ AA5083 side | 0.943 | 6.910 | 5.947 × 1012 | 8.362 × 1014 | 3.487 × 10−9 |

| ω = 1200 RPM | WN | 1.071 | 6.435 | 6.386 × 1012 | 9.501 × 1014 | 3.003 × 10−9 |

| ω = 1200 RPM | TMAZ AA6060 side | 0.925 | 7.049 | 5.830 × 1012 | 8.203 × 1014 | 3.768 × 10−9 |

| ω = 1200 RPM | HAZ AA6060 side | 0.632 | 8.742 | 4.700 × 1012 | 5.597 × 1014 | 7.009 × 10−9 |

| Sample | ω = 800 RPM | ω = 1000 RPM | ω = 1200 RPM | AA5083 | AA6060 |

|---|---|---|---|---|---|

| OCP (V) | −0.697 ± 0.039 | −0.694 ± 0.039 | −0.679 ± 0.007 | −0.661 ± 0.017 | −0.738 ± 0.013 |

| Ecorr (V) | −1.328 ± 0.015 | −1.312 ± 0.014 | −1.299 ± 0.015 | −1.356 ± 0.009 | −1.196 ± 0.001 |

| icorr (µA·cm−2) | 8.075 ± 0.182 | 7.592 ± 0.442 | 6.935 ± 0.199 | 4.506 ± 0.278 | 9.047 ± 0.768 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laska, A.; Szkodo, M.; Cavaliere, P.; Perrone, A. Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints. Metals 2022, 12, 1658. https://doi.org/10.3390/met12101658

Laska A, Szkodo M, Cavaliere P, Perrone A. Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints. Metals. 2022; 12(10):1658. https://doi.org/10.3390/met12101658

Chicago/Turabian StyleLaska, Aleksandra, Marek Szkodo, Pasquale Cavaliere, and Angelo Perrone. 2022. "Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints" Metals 12, no. 10: 1658. https://doi.org/10.3390/met12101658

APA StyleLaska, A., Szkodo, M., Cavaliere, P., & Perrone, A. (2022). Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints. Metals, 12(10), 1658. https://doi.org/10.3390/met12101658