Optimization of Residual Stress Field and Improvement of Fatigue Properties of Thin-Walled Pipes by Filling Laser Shock Peening

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

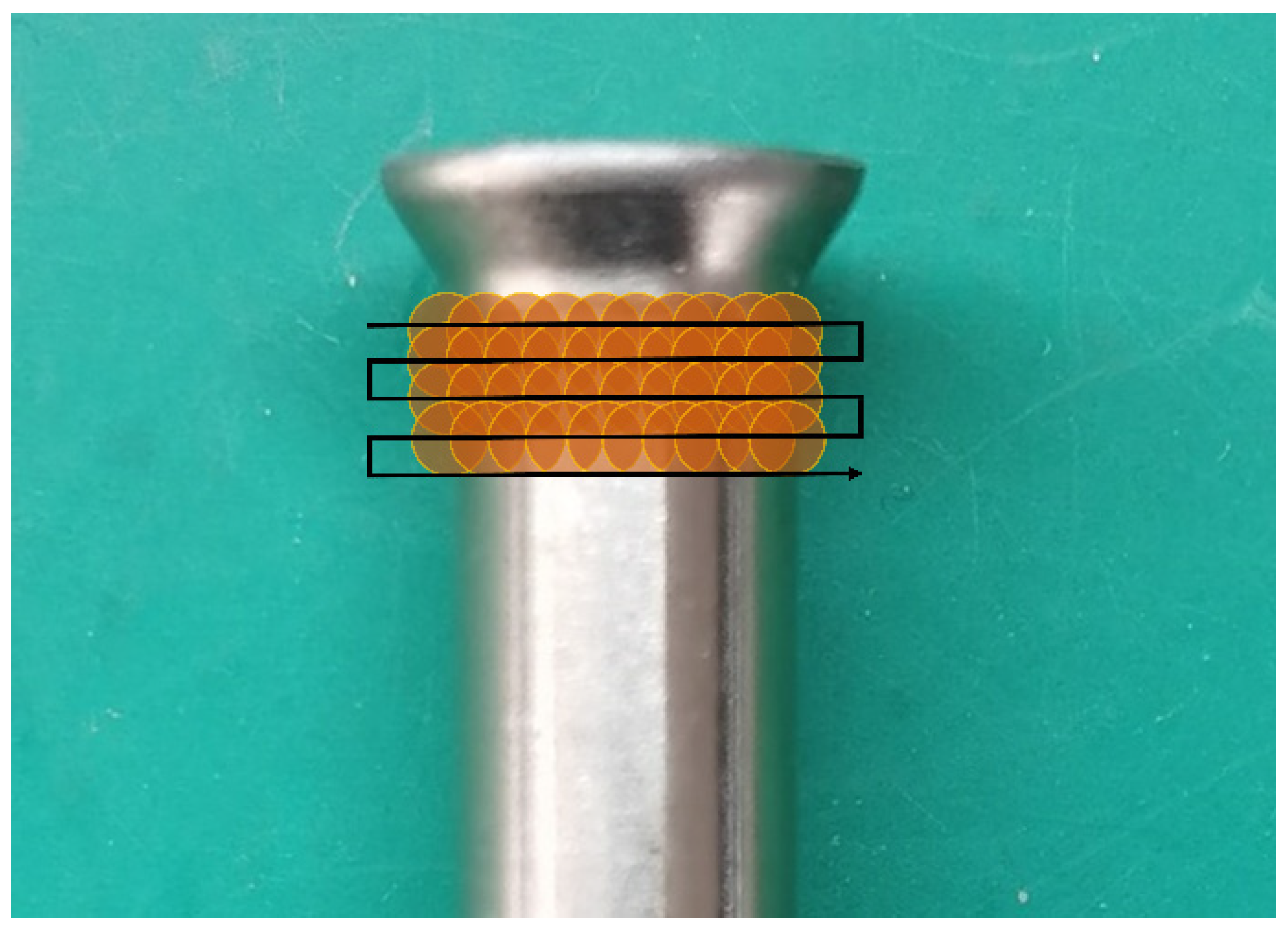

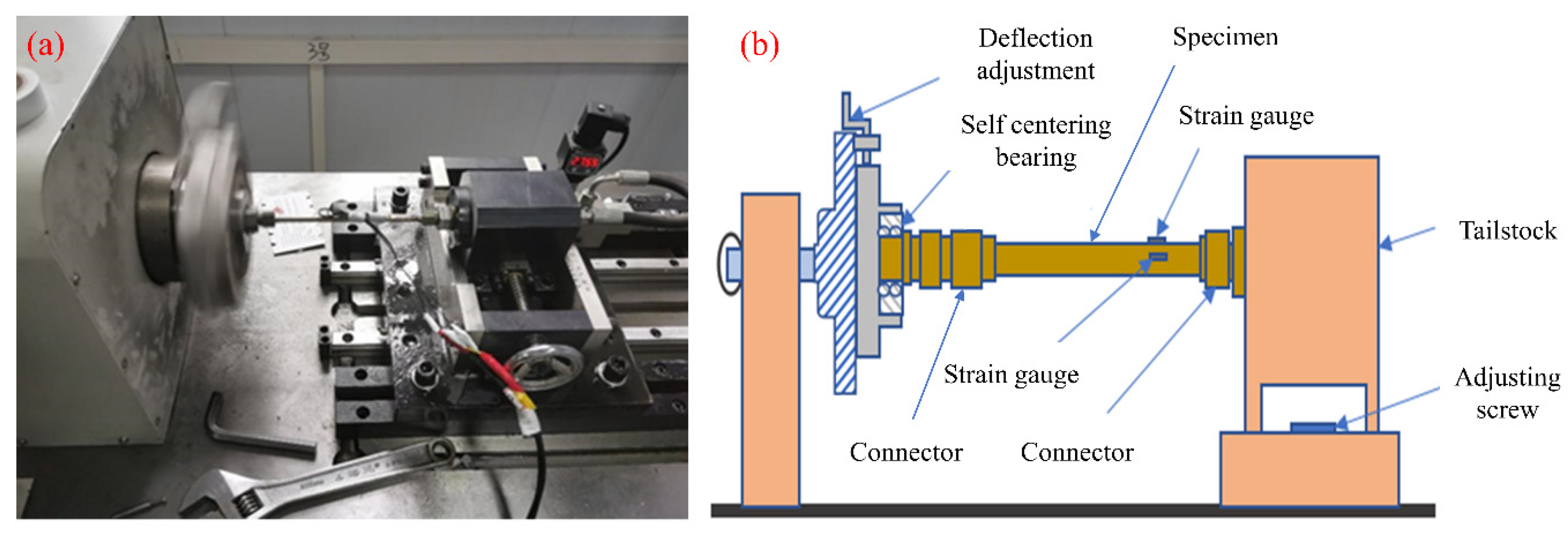

2.2. Experiment

2.3. Measurements

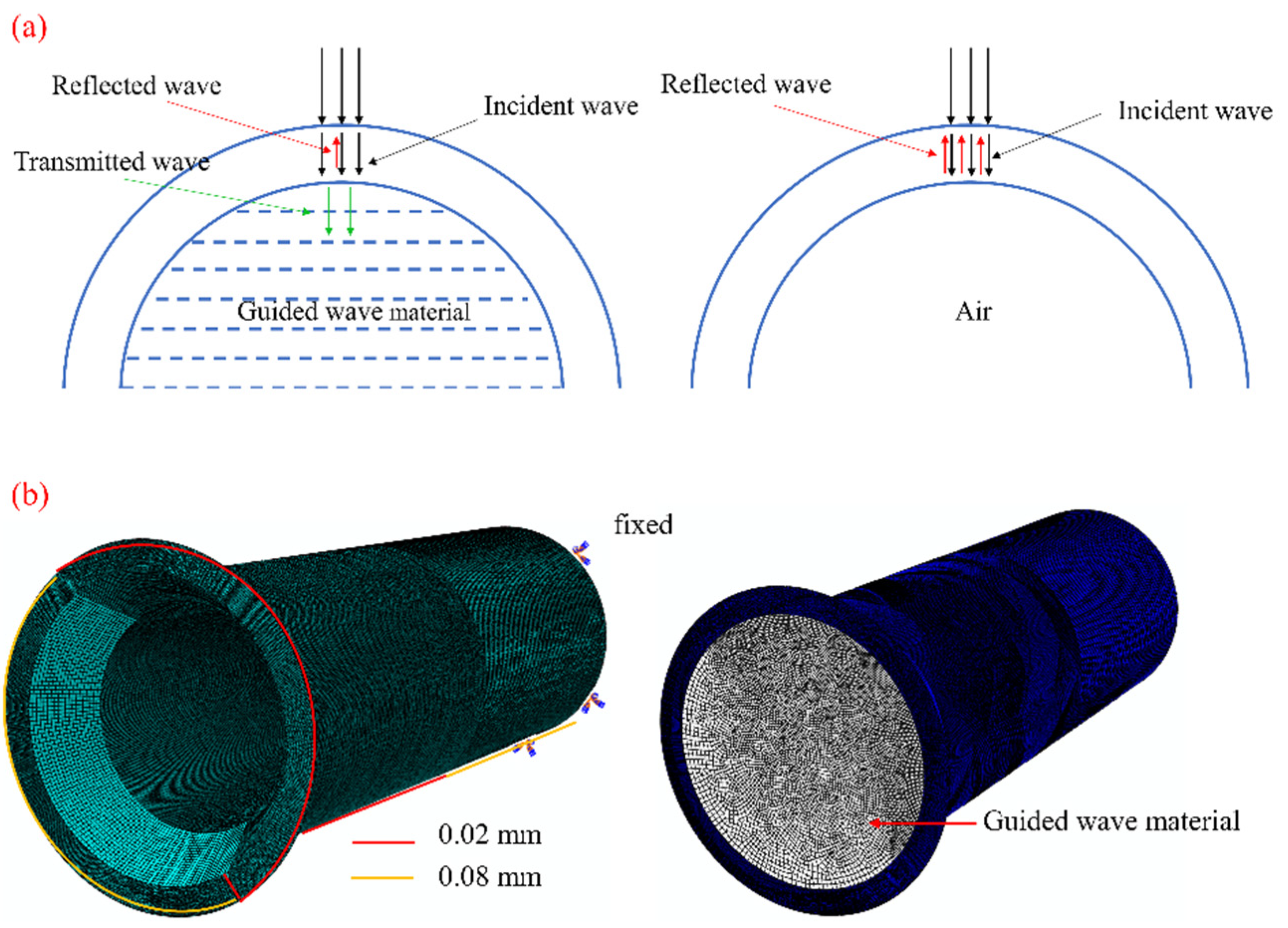

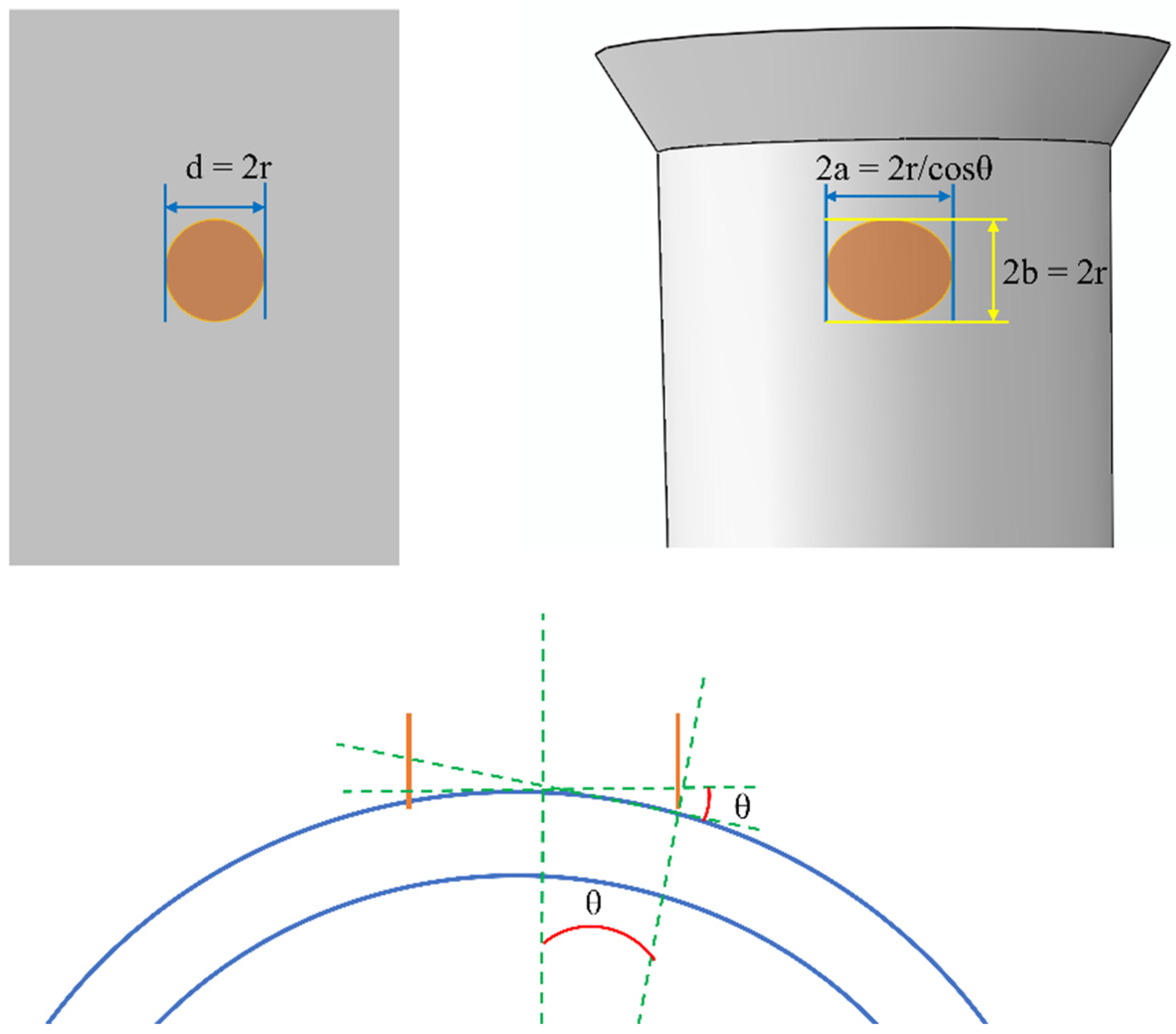

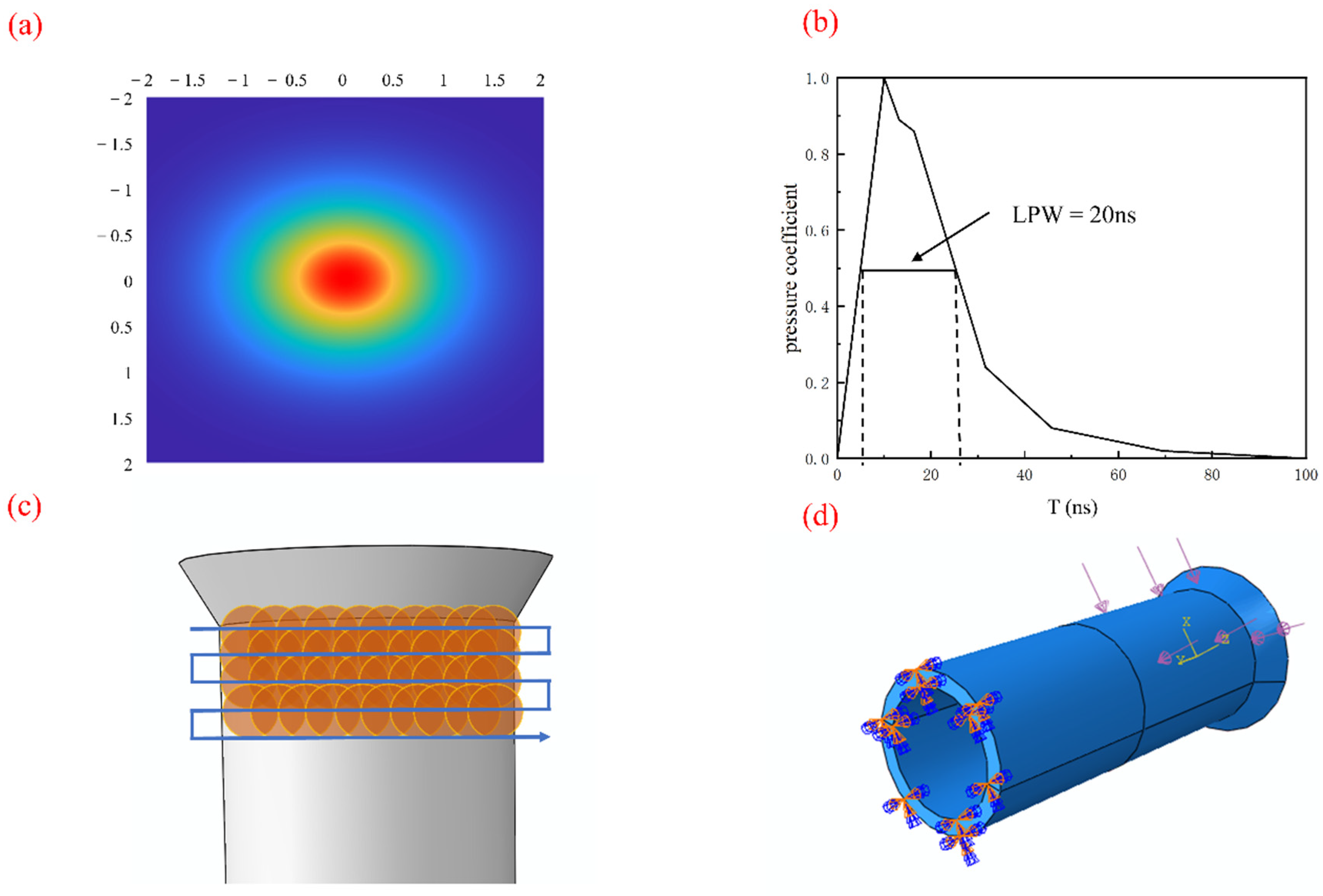

2.4. Numerical Simulation Model of Pipe

2.5. Laser Impact Parameters

3. Results

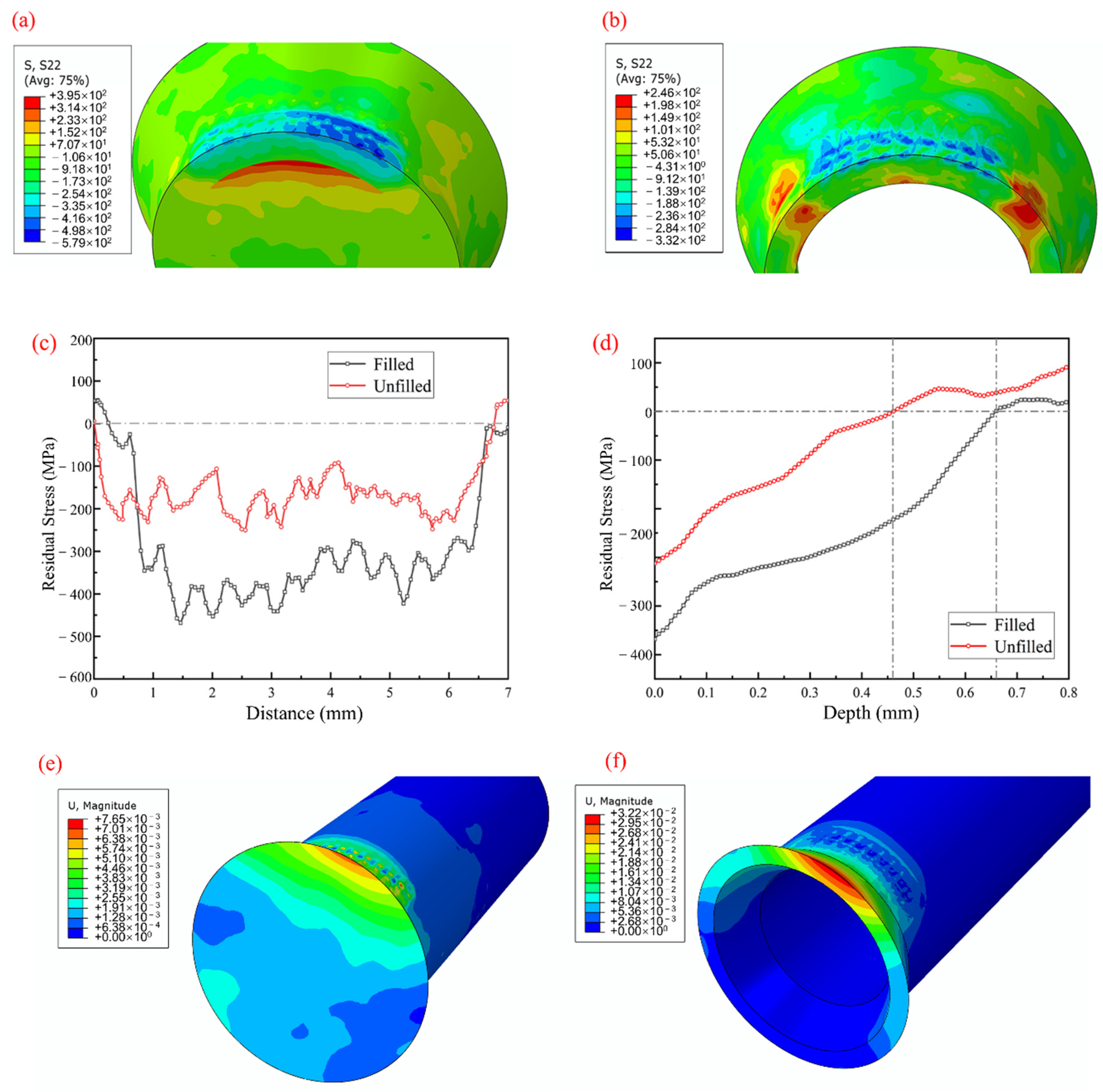

3.1. Numerical Simulation Results and Discussion

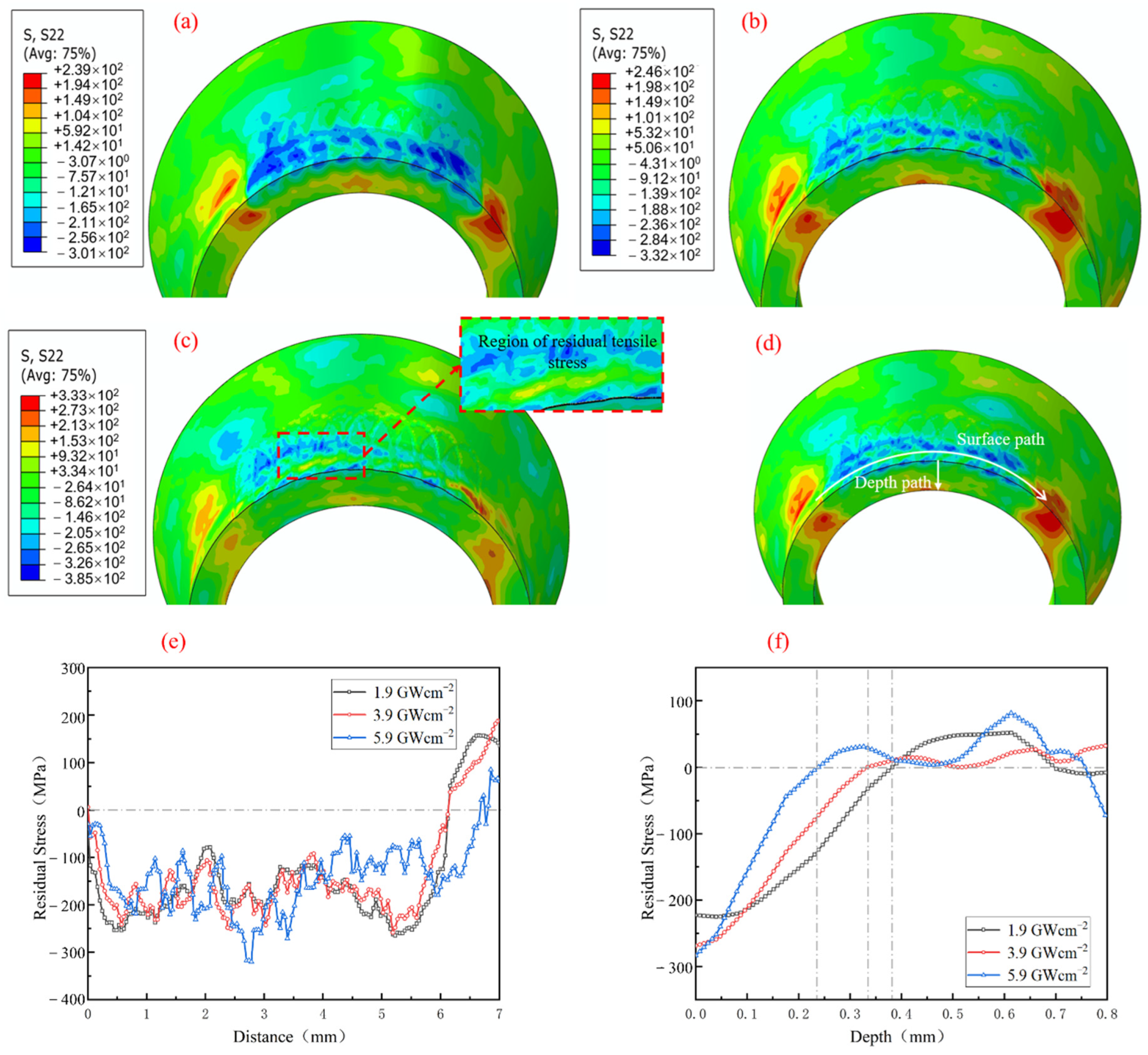

3.1.1. Influence of LSP Power Density on the Residual Stress Field

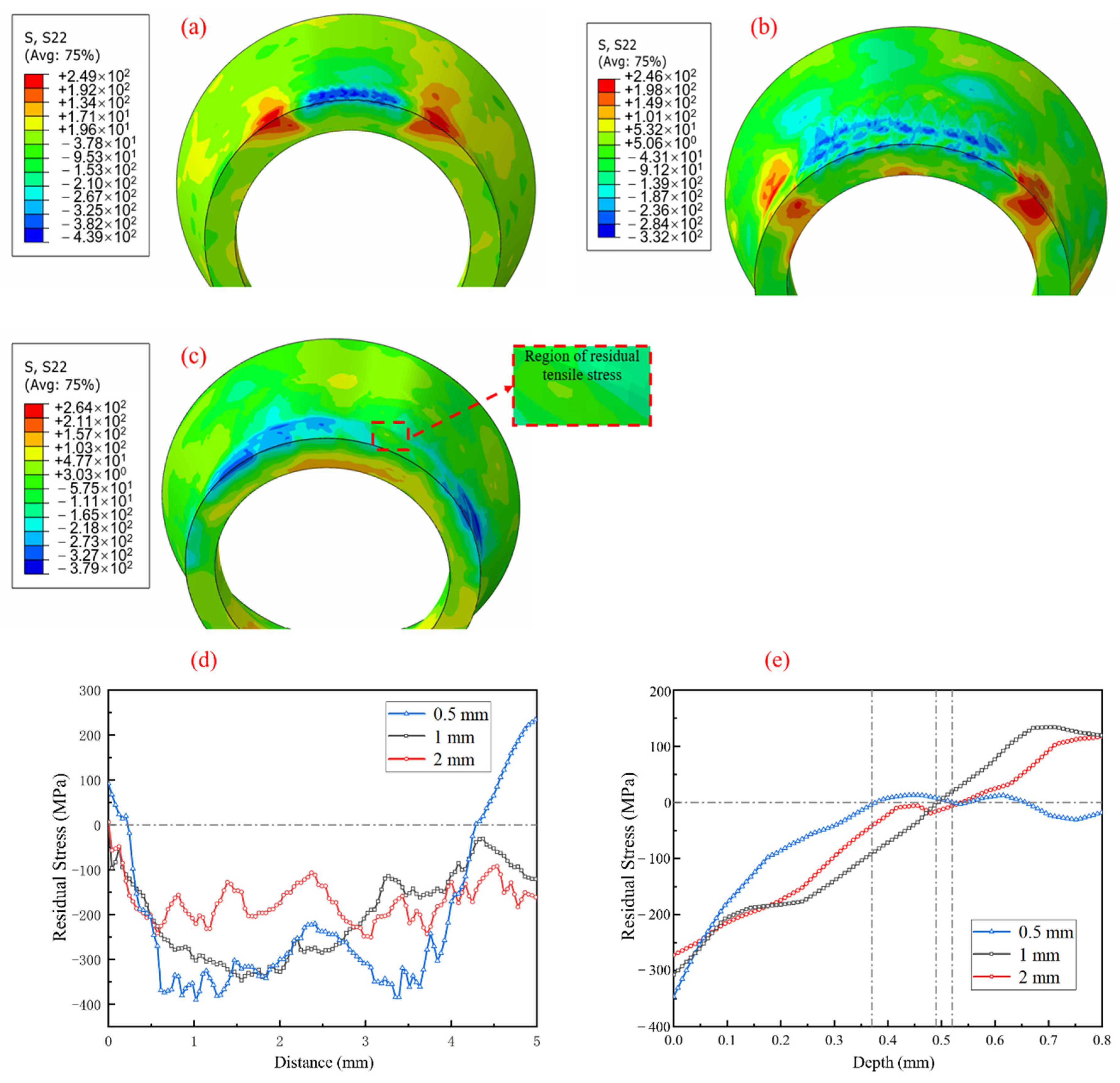

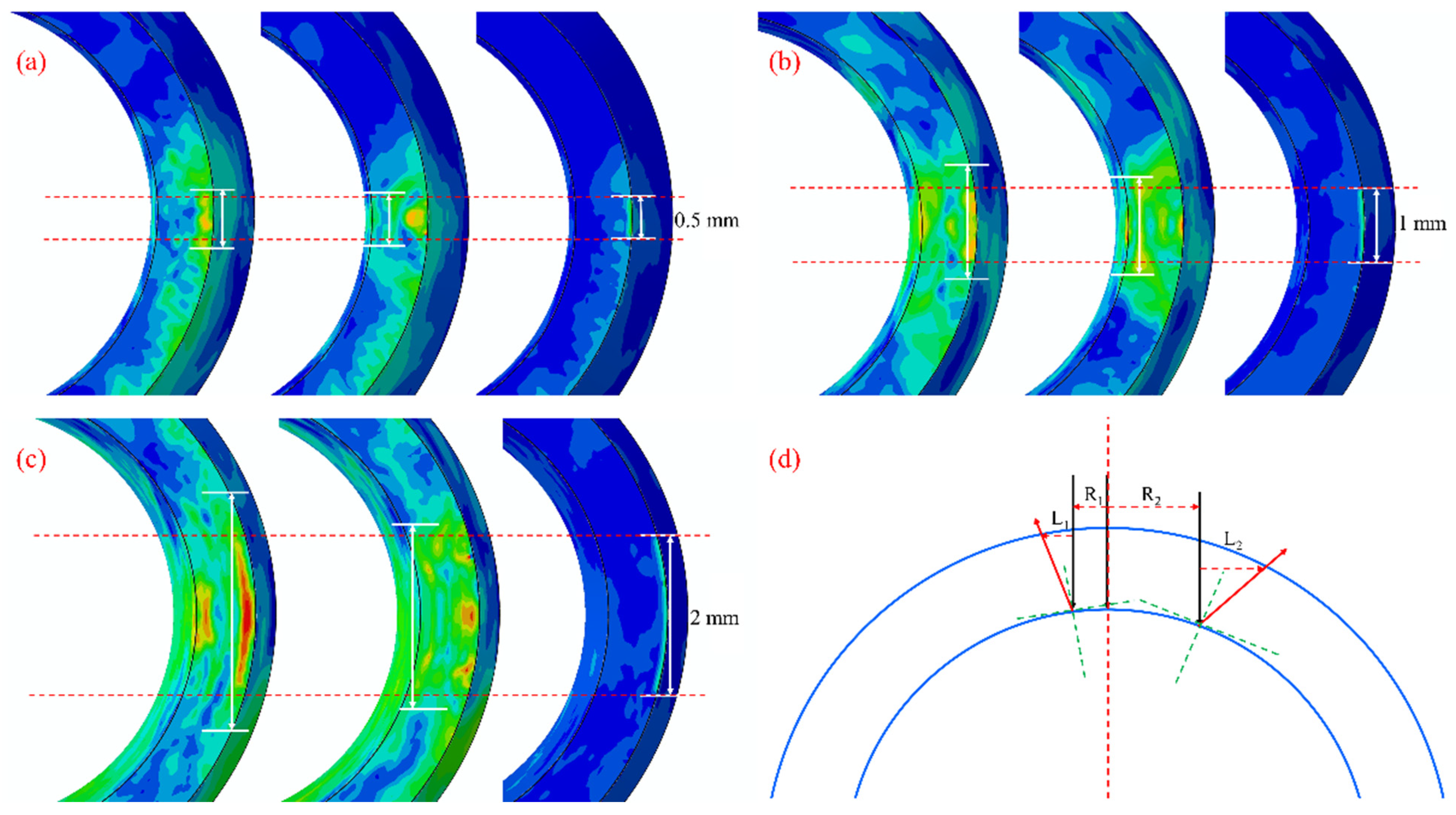

3.1.2. Effect of Spot Size on Residual Stress Field by LSP

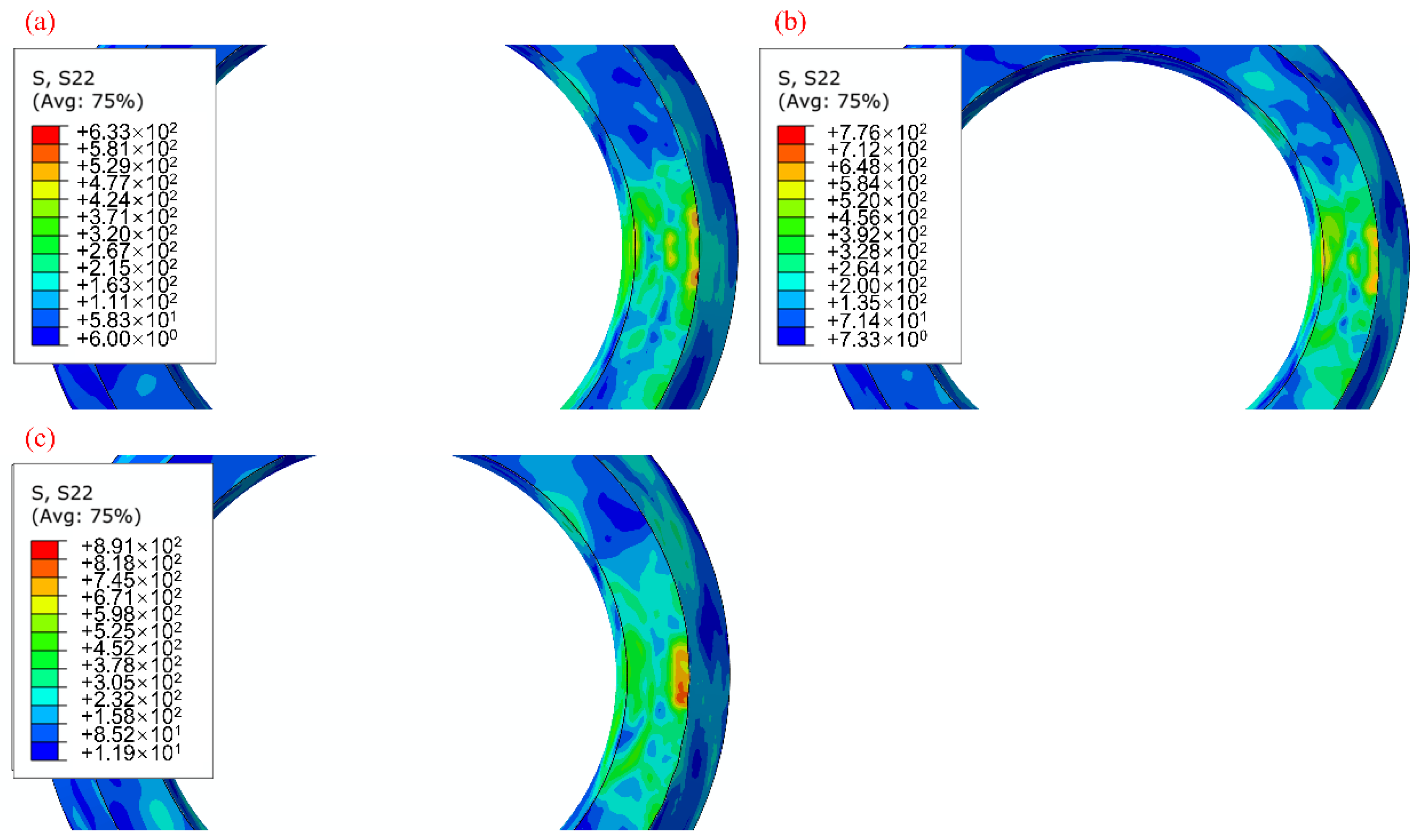

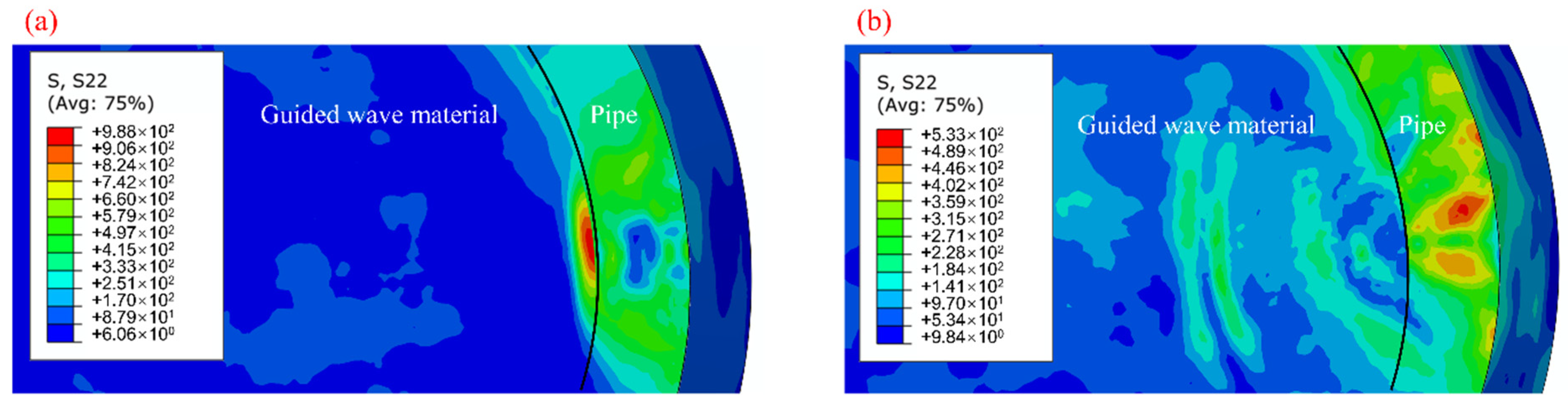

3.1.3. Influence of the Guided-Wave Material on the Residual Stress Field by LSP

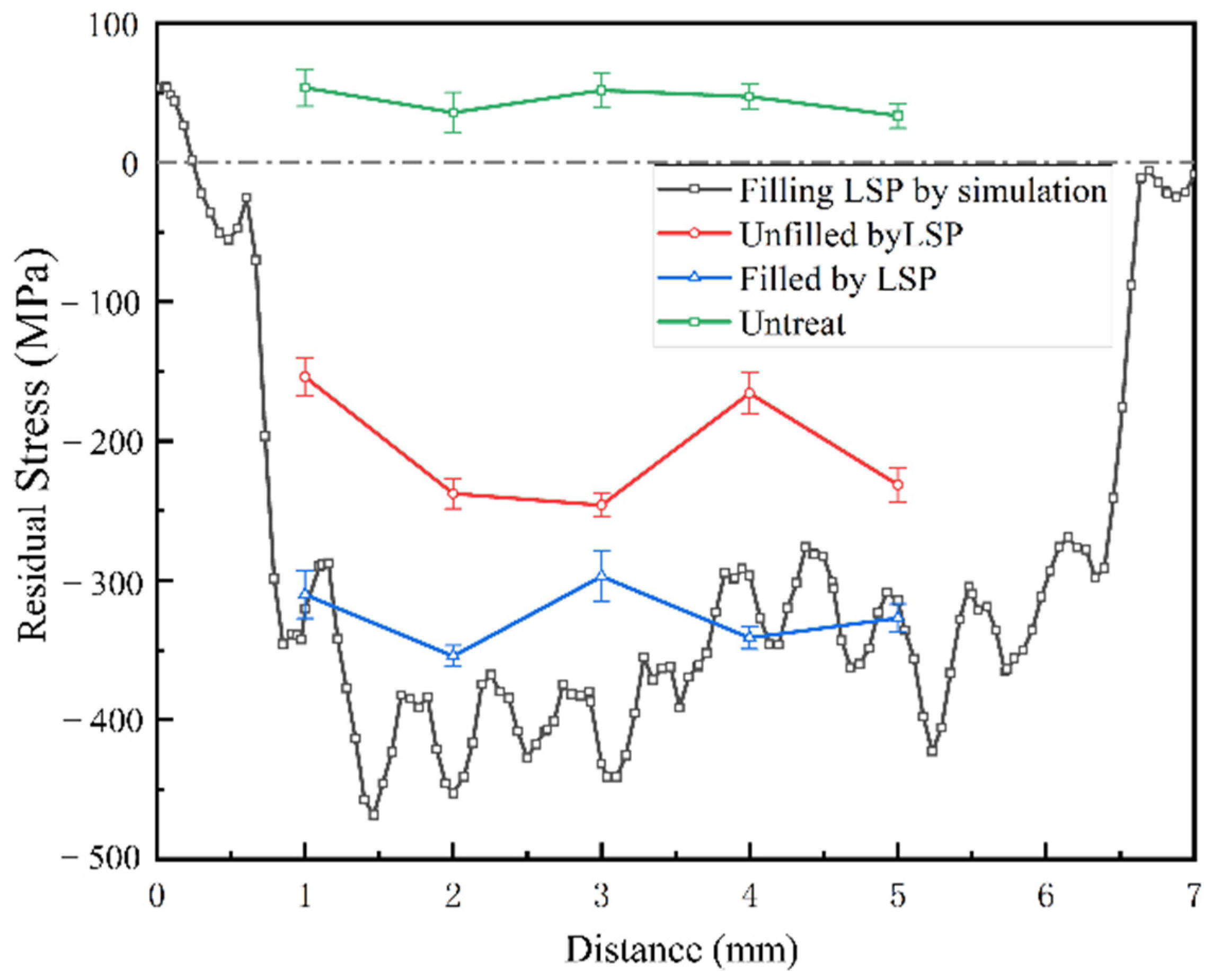

3.2. Experimental Results and Discussion

3.2.1. Residual Stress Results

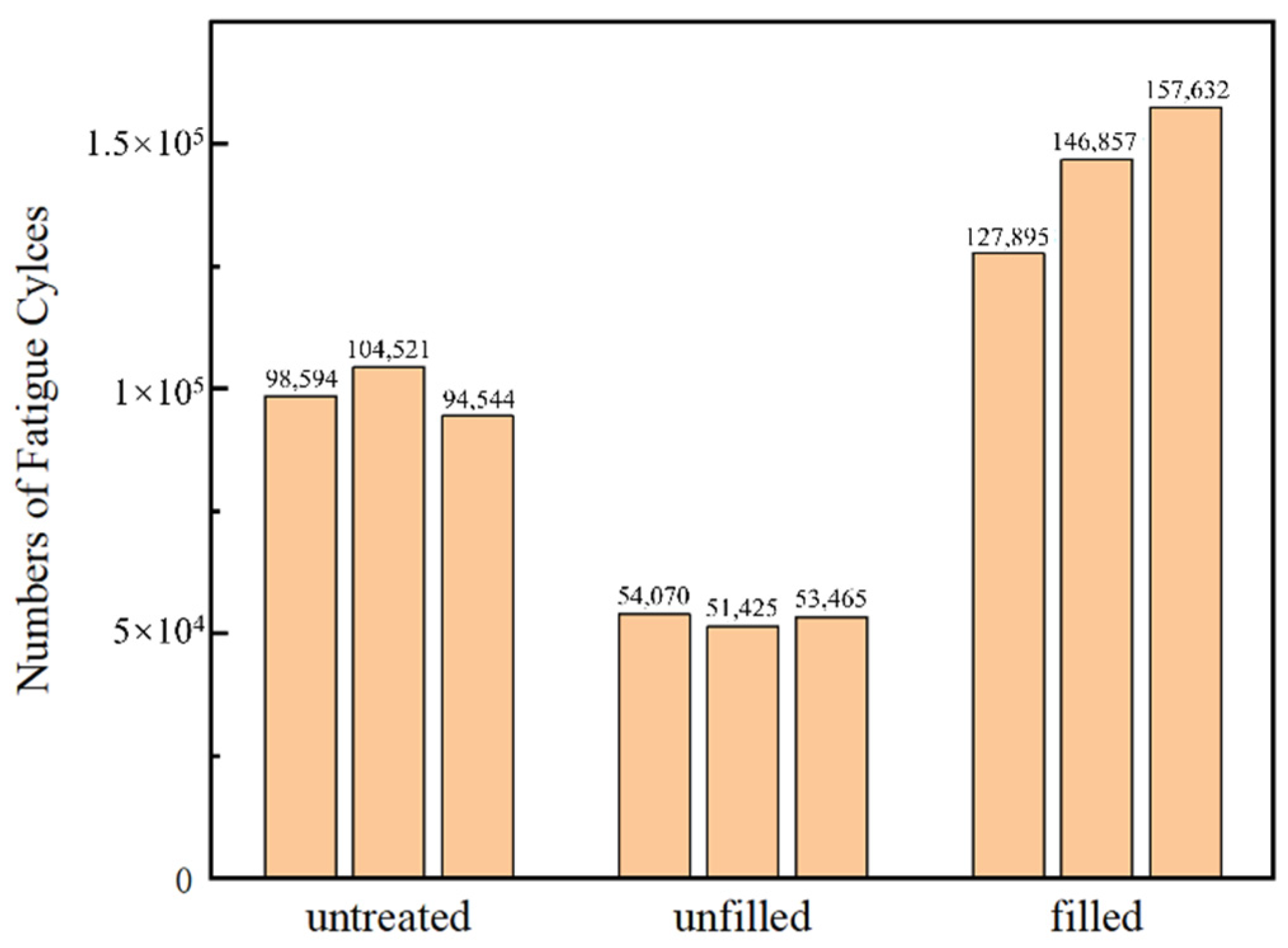

3.2.2. Fatigue Test Results

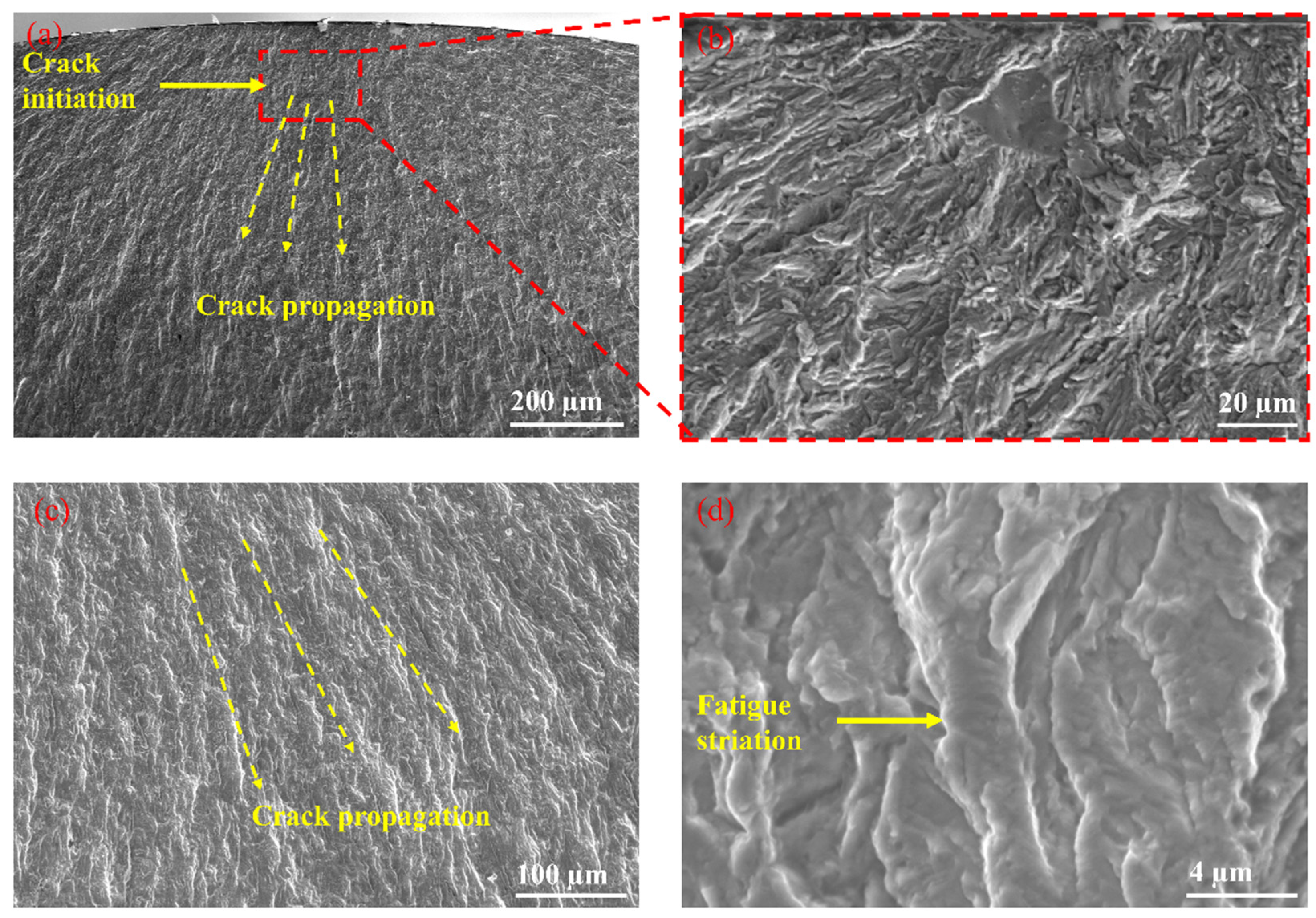

3.2.3. SEM Observation Results of the Fracture

4. Conclusions

- (1)

- It was found that, with the increase in laser power density, the residual compressive stress first increased first and then decreased according to the numerical simulation, while the residual compressive stress field had a higher value and a more uniform distribution at 3.9 GW·cm−2.

- (2)

- The numerical simulation results showed that, with the increase in the spot diameter, the reflected wave’s effect range expanded, causing the unloaded region to be increasingly influenced by the reflected tensile wave. The tensile wave that was reflected could result in a residual tensile stress area in the surrounding region.

- (3)

- After filling with the guided wave material, the effect of the stress wave reflection on the residual stress field could be greatly reduced. The residual compressive stress on the pipe’s surface increased by 57.6%, while the influence depth increased by 43%.

- (4)

- The fatigue performance of a pipe treated with filling LSP was 48.9% better than that of an untreated pipe, according to the bending fatigue test. Through fracture observation, it could be seen that the crack initiation of the specimen after LSP was initiated from the subsurface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Li, W.; Lin, J.; Qiu, Y.; Yuan, Y.; Zhou, T. Failure analysis of a high-pressure fuel pipe of engine. Eng. Fail. Anal. 2019, 103, 70–81. [Google Scholar] [CrossRef]

- Peng, X.; Yu, H.; Lian, Z.; Dong, B.; Zhong, W.; Zhang, Y.; Hu, Z. Material optimization of drill pipe in complex wellbore environments by comparing fatigue life and cost. Energy Rep. 2021, 7, 5420–5430. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Huang, H.; Gan, J.; Yang, Y.; He, J.; Shi, M. Effect of High-Energy Shot Peening on Surface Nanocrystallization and Integrity of AISI 4140 Steel: A Numerical and Experimental Investigation. J. Mater. Eng. Perform. 2021, 30, 5579–5592. [Google Scholar] [CrossRef]

- Jian-Bin, Z.; Ding, F.; Shu-Rong, Y.; Jing-Yi, W. Influence of mechanical surface treatments on fatigue strength of commercial purity titanium. J. Mater. Sci. 2003, 38, 3455–3459. [Google Scholar] [CrossRef]

- Inamke, G.V.; Pellone, L.; Ning, J.; Shin, Y.C. Enhancement of weld strength of laser-welded joints of AA6061-T6 and TZM alloys via novel dual-laser warm laser shock peening. Int. J. Adv. Manuf. Technol. 2019, 104, 907–919. [Google Scholar] [CrossRef]

- Xin, R.; Lan, L.; Bai, C.; Gao, S.; He, B.; Wang, J. Fatigue properties of selective laser melted Ti-6Al-4V alloy subjected to laser shock processing. J. Mater. Sci. 2022, 57, 9619–9630. [Google Scholar] [CrossRef]

- Peyre, P.; Carboni, C.; Forget, P.; Beranger, G.; Lemaitre, C.; Stuart, D. Influence of thermal and mechanical surface modifications induced by laser shock processing on the initiation of corrosion pits in 316L stainless steel. J. Mater. Sci. 2007, 42, 6866–6877. [Google Scholar] [CrossRef]

- Irizalp, S.G.; Saklakoglu, N.; Akman, E.; Demir, A. Pulsed Nd:YAG laser shock processing effects on mechanical properties of 6061-T6 alloy. Opt. Laser Technol. 2014, 56, 273–277. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, W.; Huang, Z.; Lu, Z. Effects of residual stress and surface roughness on the fatigue life of nickel aluminium bronze alloy under laser shock peening. Eng. Fract. Mech. 2021, 244, 107524. [Google Scholar] [CrossRef]

- Kattoura, M.; Mannava, S.R.; Qian, D.; Vasudevan, V.K. Effect of laser shock peening on residual stress, microstructure and fatigue behavior of ATI 718Plus alloy. Int. J. Fatigue 2017, 102, 121–134. [Google Scholar] [CrossRef]

- Qin, Z.; Li, B.; Huang, X.; Zhang, H.; Chen, R.; Adeel, M.; Xue, H. The effect of laser shock peening on surface integrity and high and very high cycle fatigue properties of 2024-T351 aluminum alloy. Opt. Laser Technol. 2022, 149, 107897. [Google Scholar] [CrossRef]

- Peyre, P.; Berthe, L.; Scherpereel, X.; Fabbro, R. Laser-shock processing of aluminium-coated 55C1 steel in water-confinement regime, characterization and application to high-cycle fatigue behaviour. J. Mater. Sci. 1998, 33, 1421–1429. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, L.; Nie, X.; Li, Y.; He, W. The compound process of laser shock peening and vibratory finishing and its effect on fatigue strength of Ti-3.5Mo-6.5Al-1.5Zr-0.25 Si titanium alloy. J. Alloy Compd. 2019, 783, 828–835. [Google Scholar] [CrossRef]

- Rodopoulos, C.A.; Romero, J.S.; Curtis, S.A.; Rios, E.R.D.L.; Peyre, D.P. Effect of Controlled Shot Peening and Laser Shock Peening on the Fatigue Performance of 2024-T351 Aluminum Alloy. J. Mater. Eng. Perform. 2003, 12, 414–419. [Google Scholar] [CrossRef]

- Granados-Alejo, V.; Rubio-González, C.; Vázquez-Jiménez, C.; Banderas, J.; Gómez-Rosas, G. Influence of specimen thickness on the fatigue behavior of notched steel plates subjected to laser shock peening. Opt. Laser Technol. 2018, 101, 531–544. [Google Scholar] [CrossRef]

- Nalla, R.K.; Altenberger, I.; Noster, U.; Liu, G.Y.; Scholtes, B.; Ritchie, R.O. On the influence of mechanical surface treatments—deep rolling and laser shock peening—on the fatigue behavior of Ti-6Al-4V at ambient and elevated temperatures. Mater. Sci. Eng. A 2003, 355, 216–230. [Google Scholar] [CrossRef]

- Feng, X.; Pan, X.; He, W.; Liu, P.; An, Z.; Zhou, L. Improving high cycle fatigue performance of gas tungsten arc welded Ti6Al4V titanium alloy by warm laser shock peening. Int. J. Fatigue 2021, 149, 106270. [Google Scholar] [CrossRef]

- William, B.; Robert, B. Finite element simulation of laser shock peening. Int. J. Fatigue 1999, 21, 719–724. [Google Scholar]

- Hu, Y.; Yao, Z.; Hu, J. 3-D FEM simulation of laser shock processing. Surf. Coatings Technol. 2006, 201, 1426–1435. [Google Scholar] [CrossRef]

- Yang, C.; Hodgson, P.D.; Liu, Q.; Ye, L. Geometrical effects on residual stresses in 7050-T7451 aluminum alloy rods subject to laser shock peening. J. Mater. Process. Technol. 2008, 201, 303–309. [Google Scholar] [CrossRef]

- Vasu, A.; Grandhi, R.V. Effects of curved geometry on residual stress in laser peening. Surf. Coat. Technol. 2013, 218, 71–79. [Google Scholar] [CrossRef]

- Ivetic, G. Three-dimensional FEM analysis of laser shock peening of aluminium alloy 2024-T351 thin sheets. Surf. Eng. 2011, 27, 445–453. [Google Scholar] [CrossRef]

- Cellard, C.; Retraint, D.; Francois, M.; Rouhaud, E.; Le Saunier, D. Laser shock peening of Ti-17 titanium alloy: Influence of process parameters. Mater. Sci. Eng. A 2012, 532, 362–372. [Google Scholar] [CrossRef]

- Shi, X.; Feng, X.; Teng, J.; Zhang, K.; Zhou, L. Effect of laser shock peening on microstructure and fatigue properties of thin-wall welded Ti-6Al-4V alloy. Vacuum 2021, 184, 109986. [Google Scholar] [CrossRef]

- Fang, Y. Simulation and Experiment of Impact Effects of Nanosecond Pulse Laser-Generated Processing Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2021, 30, 5515–5523. [Google Scholar] [CrossRef]

- Vasu, A.; Hu, Y.; Grandhi, R.V. Differences in plasticity due to curvature in laser peened components. Surf. Coatings Technol. 2013, 235, 648–656. [Google Scholar] [CrossRef]

- Johnsin, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large Strains, high strain rates and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

- Zhou, W.; Ren, X.; Yang, Y.; Tong, Z.; Larson, E.A. Finite element analysis of laser shock peening induced near-surface deformation in engineering metals. Opt. Laser Technol. 2019, 119, 105608. [Google Scholar] [CrossRef]

- Li, X.; He, W.; Luo, S.; Nie, X.; Tian, L.; Feng, X.; Li, R. Simulation and Experimental Study on Residual Stress Distribution in Titanium Alloy Treated by Laser Shock Peening with Flat-Top and Gaussian Laser Beams. Materials 2019, 12, 1343. [Google Scholar] [CrossRef]

- Giddaluri, R.; Rajyalakshmi, G. FE simulation for stress distribution and surface deformation in Ti-6Al-4V induced by interaction of multi scale laser shock peening parameters. Optik 2020, 206, 164280. [Google Scholar]

- Laakso, S.V.; Agmell, M.; Ståhl, J.-E. The mystery of missing feed force—The effect of friction models, flank wear and ploughing on feed force in metal cutting simulations. J. Manuf. Process. 2018, 33, 268–277. [Google Scholar] [CrossRef]

- Lee, S.; Barthelat, F.; Hutchinson, J.W.; Espinosa, H.D. Dynamic Failure of Metallic Pyramidal Truss Core Materials-Experiments and Modeling. Int. J. Plast. 2006, 22, 2118–2145. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physicl study of laser produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Ballard, P.; Fournier, J.; Fabbro, R. Residual stresses induced by laser-shock. J. Phys. IV 1991, 1, 132. [Google Scholar] [CrossRef]

- Fabbro, R.; Peyre, P.; Berthe, L.; Scherpereel, X. Physics and applications of laser-shock processing. J. Laser Appl. 1998, 10, 265–279. [Google Scholar] [CrossRef]

- Peyre, P.; Berthe, L.; Fabbro, R.; Sollier, A. Experimental determination by PVDF and EMV techniques of shock waves induced by 0.6 to 3 ns laser pulses in confined regime with water. J. Phys. D Appl. Phys. 2000, 33, 498–503. [Google Scholar] [CrossRef]

- Sano, Y.; Masaki, K.; Gushi, T.; Sano, T. Improvement in fatigue performance of friction stir welded A6061-T6 aluminum alloy by laser peening without coating. Mater. Des. 2012, 36, 809–814. [Google Scholar] [CrossRef]

| ρ (kg/m3) | Σ (MPa) | σ0.2 (MPa) | E (GPa) | ν |

|---|---|---|---|---|

| 7800 | 520 | 205 | 200 | 0.29 |

| A (MPa) | B (MPa) | C | n | m | t0 (K) | tm (K) |

|---|---|---|---|---|---|---|

| 310 | 1000 | 0.07 | 0.65 | 1 | 293 | 1673 |

| ρ (kg/m3) | E (GPa) | ν |

|---|---|---|

| 7800 | 200 | 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, K.; Wang, L.; Zhao, T.; Shu, S.; Zhou, L. Optimization of Residual Stress Field and Improvement of Fatigue Properties of Thin-Walled Pipes by Filling Laser Shock Peening. Metals 2022, 12, 1733. https://doi.org/10.3390/met12101733

Yu K, Wang L, Zhao T, Shu S, Zhou L. Optimization of Residual Stress Field and Improvement of Fatigue Properties of Thin-Walled Pipes by Filling Laser Shock Peening. Metals. 2022; 12(10):1733. https://doi.org/10.3390/met12101733

Chicago/Turabian StyleYu, Kun, Lingfeng Wang, Tianxiao Zhao, Song Shu, and Liucheng Zhou. 2022. "Optimization of Residual Stress Field and Improvement of Fatigue Properties of Thin-Walled Pipes by Filling Laser Shock Peening" Metals 12, no. 10: 1733. https://doi.org/10.3390/met12101733

APA StyleYu, K., Wang, L., Zhao, T., Shu, S., & Zhou, L. (2022). Optimization of Residual Stress Field and Improvement of Fatigue Properties of Thin-Walled Pipes by Filling Laser Shock Peening. Metals, 12(10), 1733. https://doi.org/10.3390/met12101733