External Illumination Enables Coaxial Sensing of Surface and Subsurface Molten Pool Geometry in LPBF

Abstract

:1. Introduction

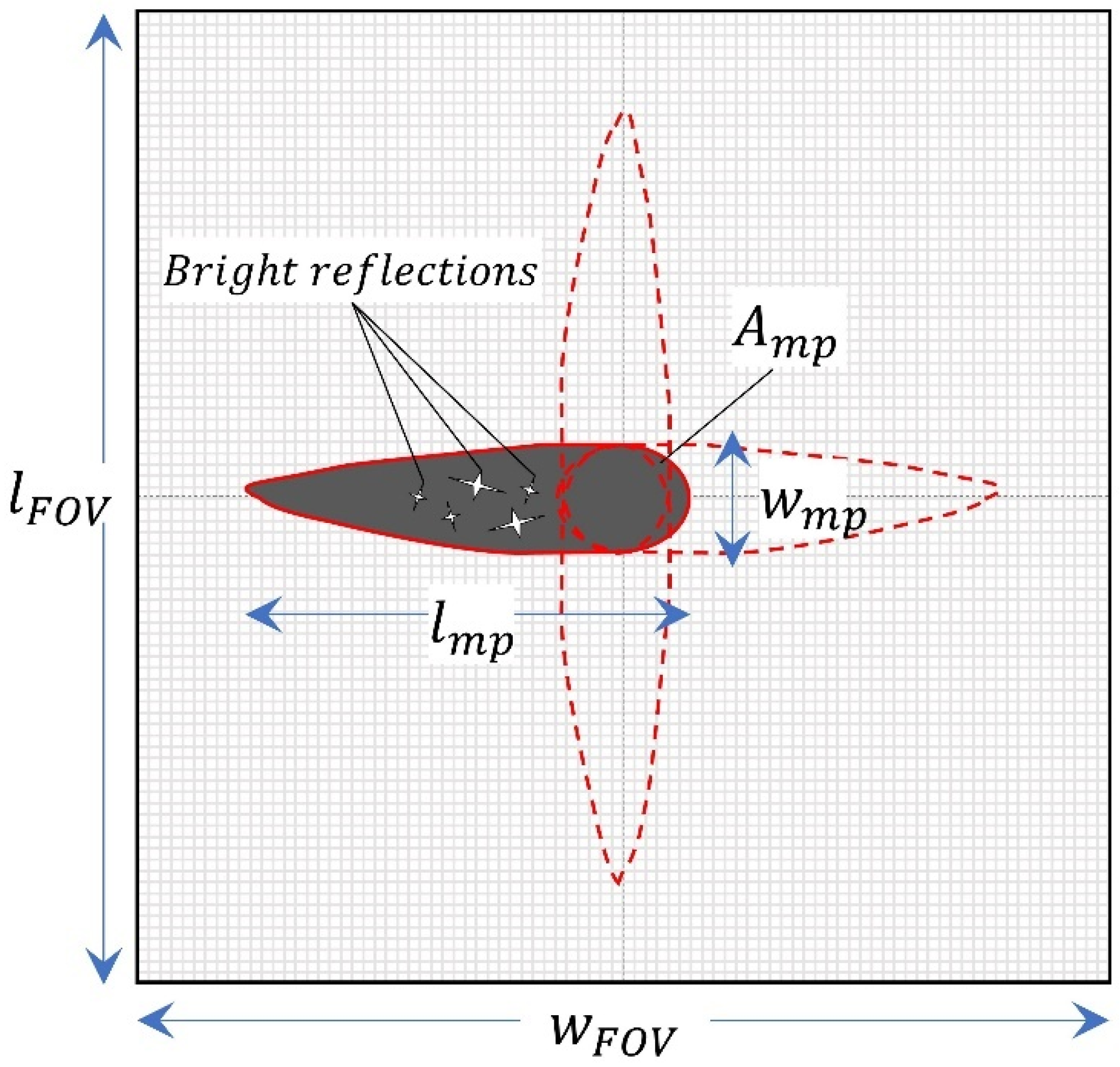

2. Design Criteria for a Coaxial Monitoring System for the Simultaneous Estimation of the Molten Pool’s Surface and Subsurface Geometry

3. Materials and Method

3.1. LPBF System

3.2. Imaging and Illumination Equipment

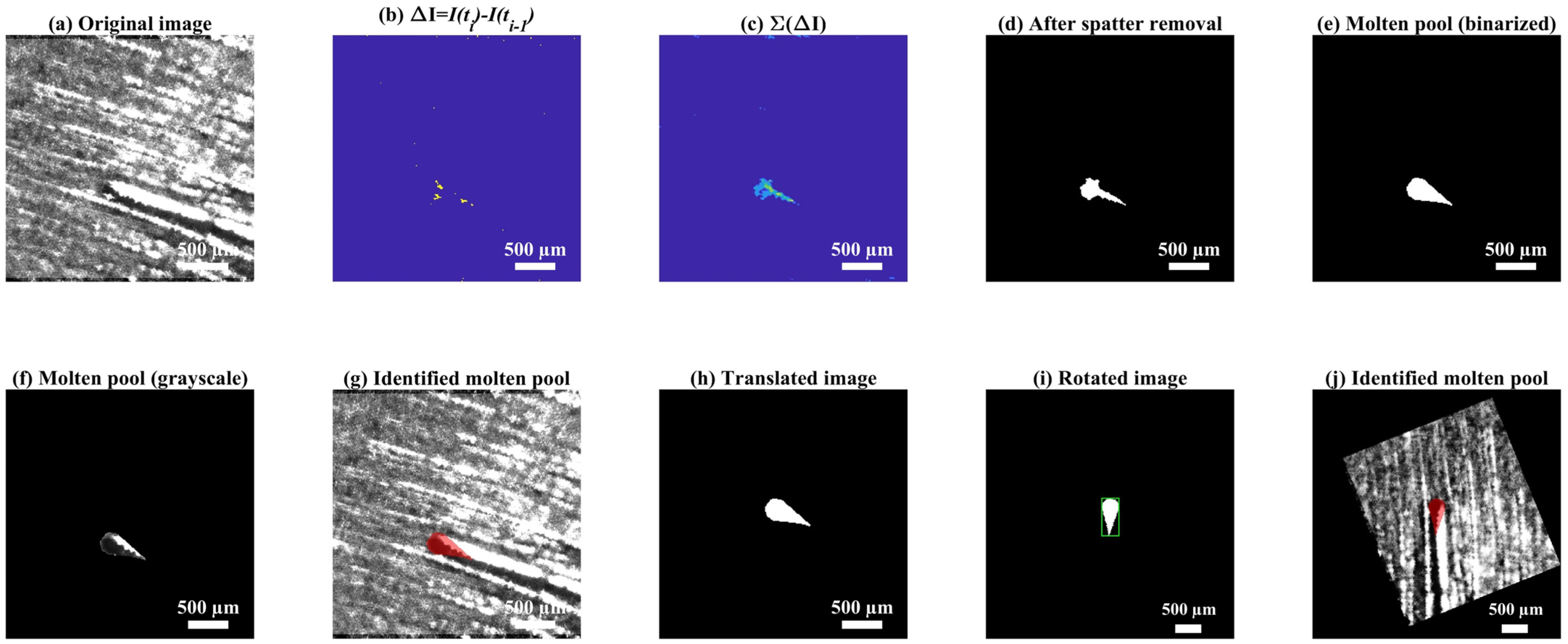

3.3. Image Processing Algorithm

3.4. Material

3.5. Characterisation Equipment

3.6. Experimental Design

4. Results

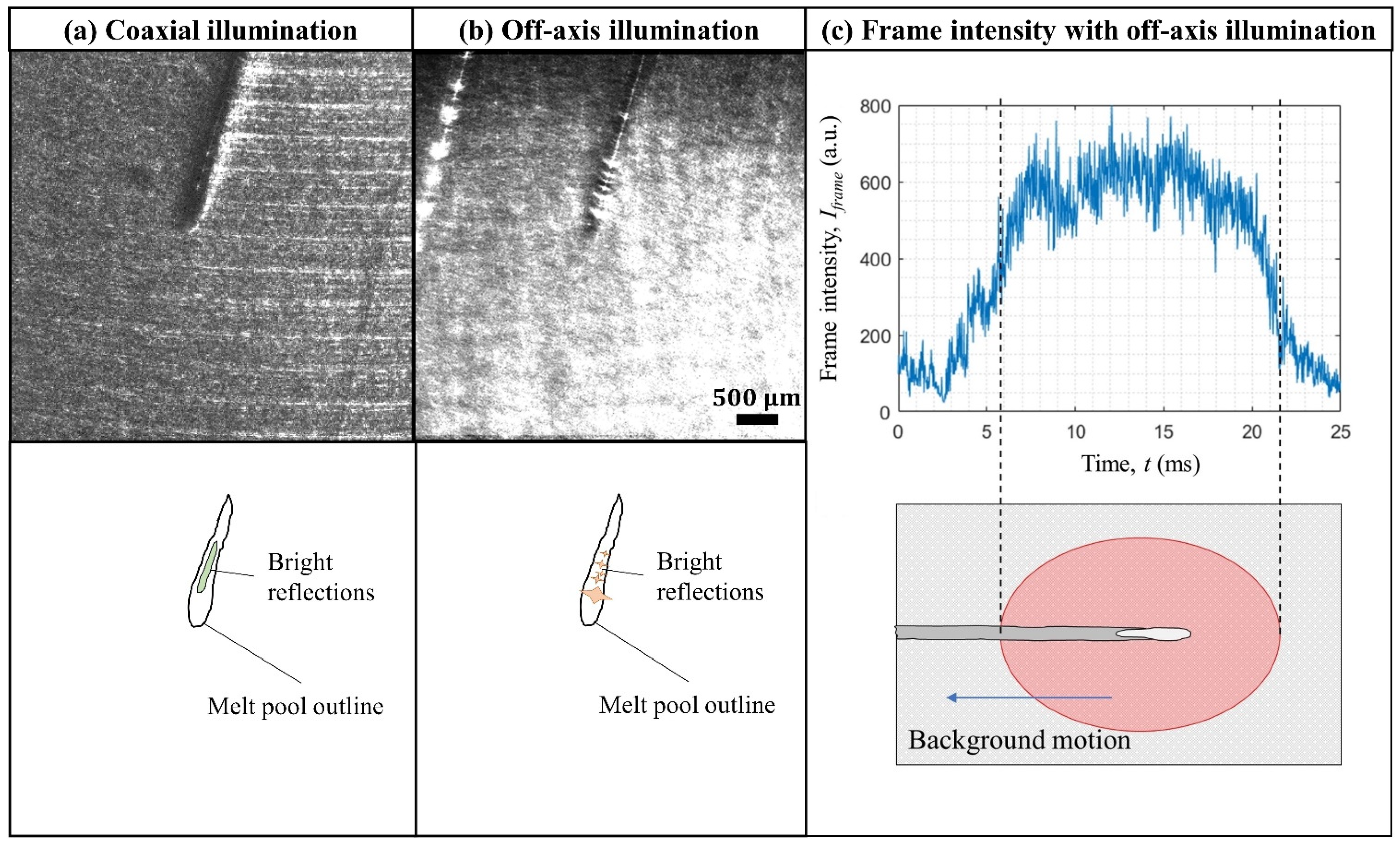

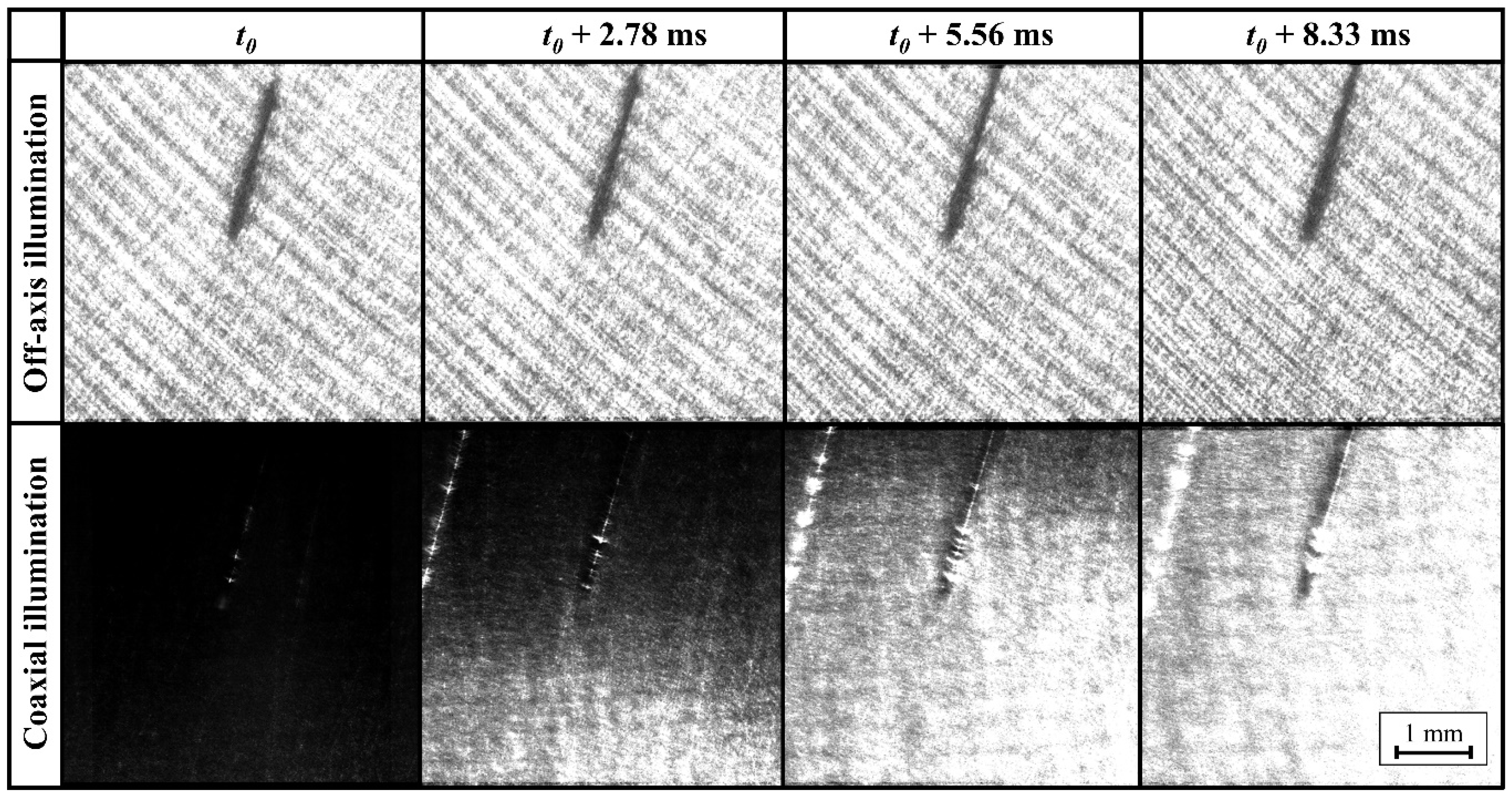

4.1. Effect of Different Illumination Configurations on the High-Speed Imaging Acquisitions

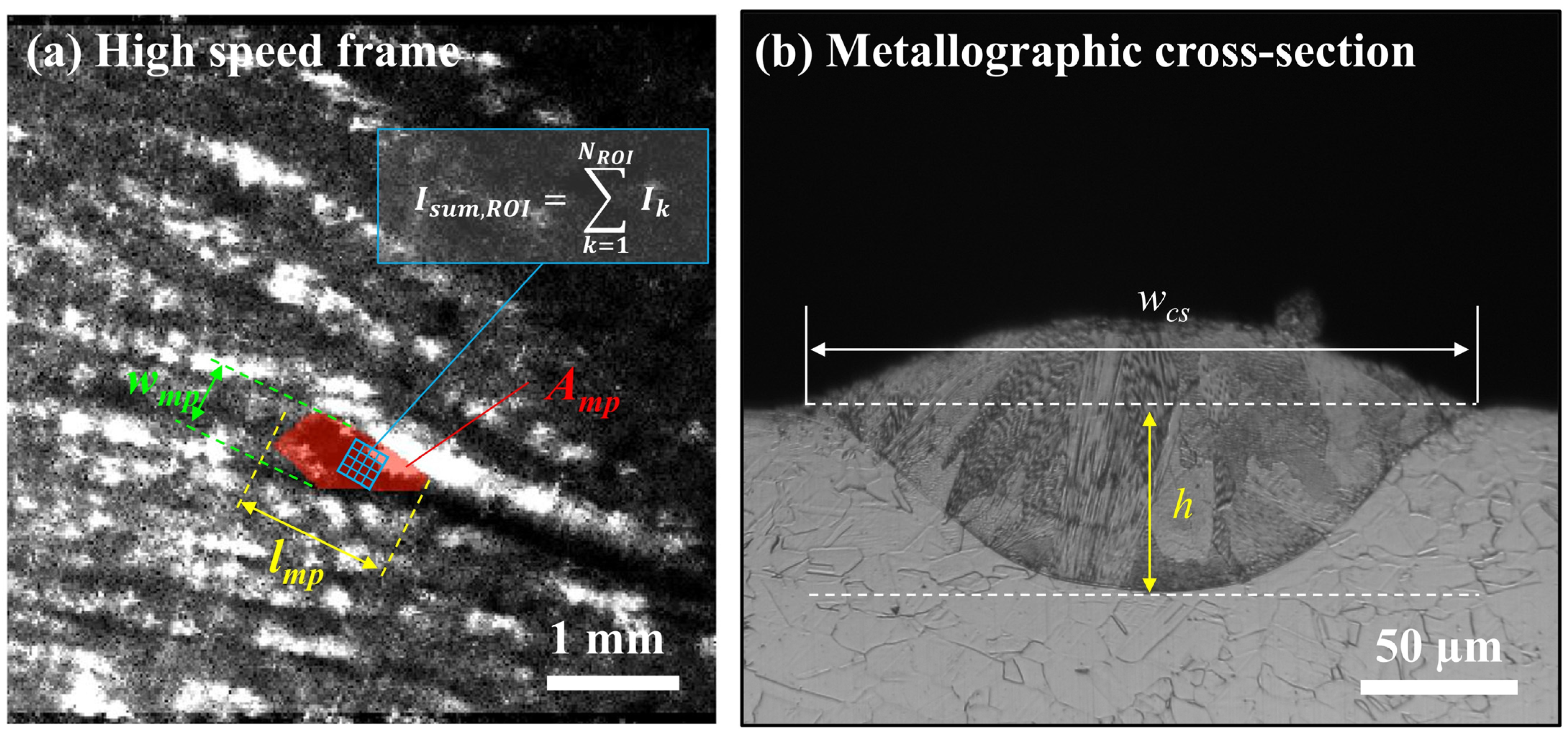

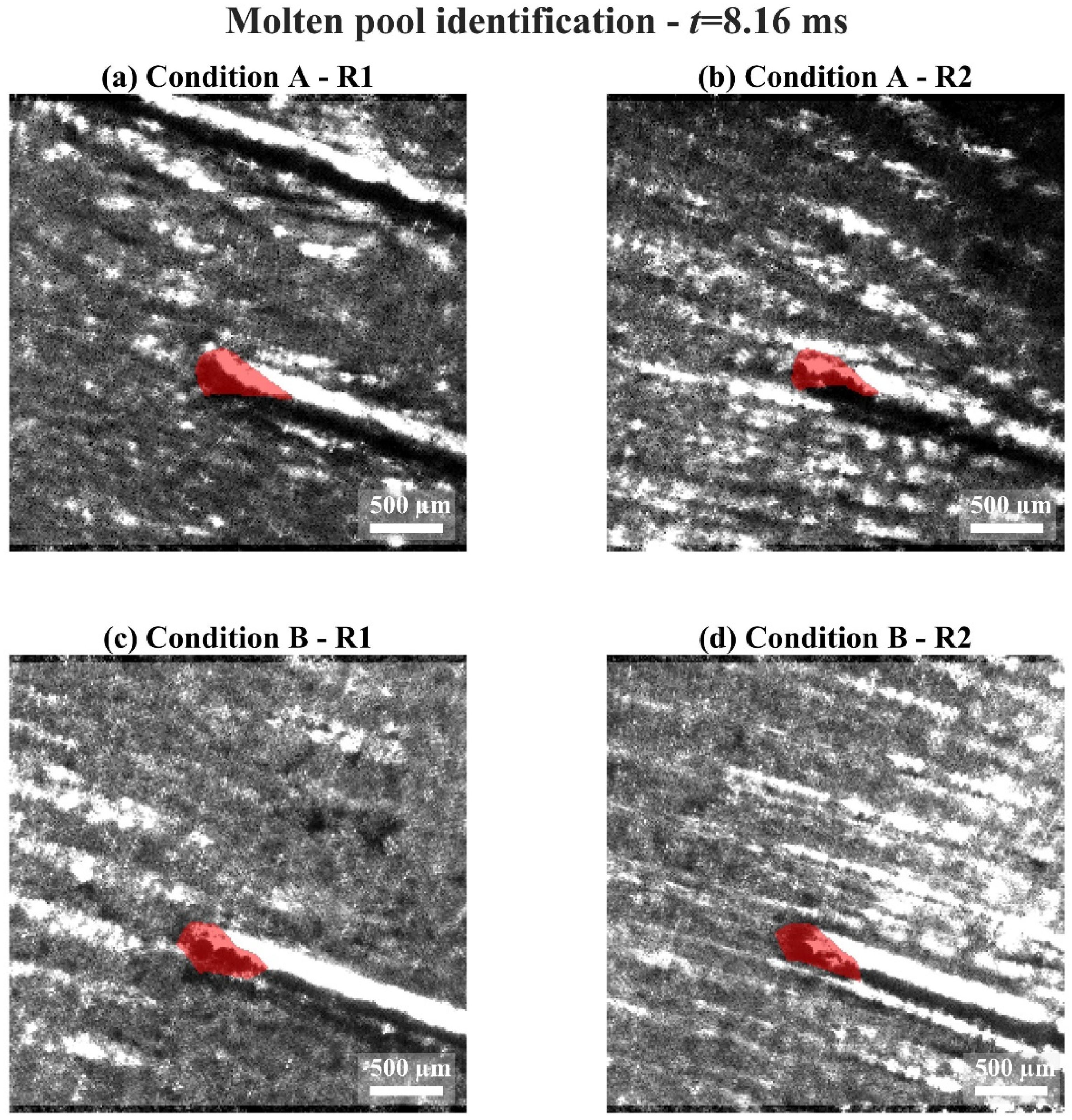

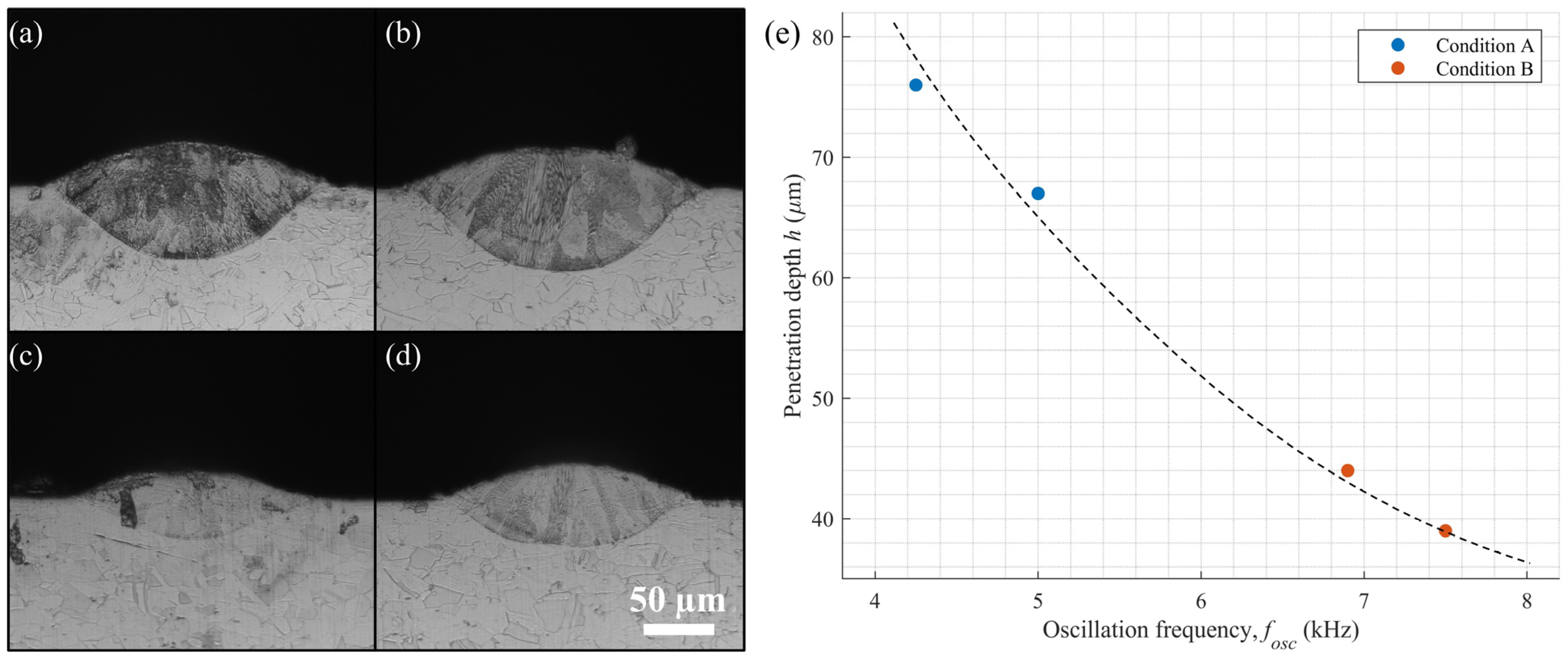

4.2. Measurement of Molten Pool Geometrical Features

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghidini, T. Materials for space exploration and settlement. Nat. Mater. 2018, 17, 846–850. [Google Scholar] [CrossRef] [PubMed]

- Caltanissetta, F.; Grasso, M.; Petrò, S.; Colosimo, B.M. Characterization of in-situ measurements based on layerwise imaging in laser powder bed fusion. Addit. Manuf. 2018, 24, 183–199. [Google Scholar] [CrossRef]

- Clijsters, S.; Craeghs, T.; Buls, S.; Kempen, K.; Kruth, J.-P. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int. J. Adv. Manuf. Technol. 2014, 75, 1089–1101. [Google Scholar] [CrossRef]

- Wu, Z.; Narra, S.P.; Rollett, A. Exploring the fabrication limits of thin-wall structures in a laser powder bed fusion process. J. Adv. Manuf. Technol. 2020, 110, 191–207. [Google Scholar] [CrossRef]

- Bruna-Rosso, C.; Caprio, L.; Mazzoleni, L.; Pacher, M.; Demir, A.G.; Previtali, B. Influence of Temporal Laser Emission Profile on the Selective Laser Melting (SLM) of Thin Structures. Lasers Eng. 2020, 47, 161–182. [Google Scholar]

- Zadpoor, A.A. Additively manufactured porous metallic biomaterials. J. Mater. Chem. B 2019, 7, 4088–4117. [Google Scholar] [CrossRef] [Green Version]

- Guaglione, F.; Caprio, L.; Previtali, B.; Demir, A.G. Demir, Single point exposure LPBF for the production of biodegradable Zn-alloy lattice structures. Addit. Manuf. 2021, 48, 102426. [Google Scholar] [CrossRef]

- Maffia, S.; Finazzi, V.; Berti, F.; Migliavacca, F.; Petrini, L.; Previtali, B.; Demir, A.G. Selective laser melting of NiTi stents with open-cell and variable diameter. Smart Mater. Struct. 2021, 30, 105010. [Google Scholar] [CrossRef]

- Finazzi, V.; Demir, A.G.; Biffi, C.A.; Migliavacca, F.; Petrini, L.; Previtali, B. Design and functional testing of a novel balloon-expandable cardiovascular stent in CoCr alloy produced by selective laser melting. Manuf. Process. 2020, 55, 161–173. [Google Scholar] [CrossRef]

- Jafari, D.; Wits, W.W. The utilization of selective laser melting technology on heat transfer devices for thermal energy conversion applications: A. review. Renew. Sustain. Energy Rev. 2018, 91, 420–442. [Google Scholar] [CrossRef]

- Catchpole-Smith, S.; Sélo, R.R.J.; Davis, A.W.; Ashcroft, I.A.; Tuck, C.J.; Clare, A. Thermal conductivity of TPMS lattice structures manufactured via laser powder bed fusion. Addit. Manuf. 2019, 30, 100846. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Garzon, V.A.; Dowling, D.P.; McNally, P.J.; et al. In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Grasso, M.L.G.; Remani, A.; Dickins, A.; Colosimo, B.M.; Leach, R.K. In-situ measurement and monitoring methods for metal powder bed fusion: An updated review. Meas. Sci. Technol. 2021, 32, 112001. [Google Scholar] [CrossRef]

- Forien, J.-B.; Calta, N.P.; DePond, P.J.; Guss, G.M.; Roehling, T.T.; Matthews, M.J. Detecting keyhole pore defects and monitoring process signatures during laser powder bed fusion: A correlation between in situ pyrometry and ex situ X-ray radiography. Addit. Manuf. 2020, 35, 101336. [Google Scholar] [CrossRef]

- Gutknecht, K.; Cloots, M.; Sommerhuber, R.; Wegener, K. Mutual comparison of acoustic, pyrometric and thermographic laser powder bed fusion monitoring. Mater. Des. 2021, 210, 110036. [Google Scholar] [CrossRef]

- Domankevitz, Y.; Nishioka, N.S. Measurement of Laser Ablation Threshold with a High-Speed Framing Camera. IEEE J. Quantum Electron. 1990, 26, 2276–2278. [Google Scholar] [CrossRef]

- Dietrich, J.; Brajdic, M.; Walther, K.; Horn, A.; Kelbassa, I.; Poprawe, R. Investigation of increased drilling speed by online high-speed photography. Opt. Lasers Eng. 2008, 46, 705–710. [Google Scholar] [CrossRef]

- Leung, B.Y.C.; Webster, P.J.L.; Fraser, J.M.; Yang, V.X.D. Real-time guidance of thermal and ultrashort pulsed laser ablation in hard tissue using inline coherent imaging. Lasers Surg. Med. 2012, 44, 249–256. [Google Scholar] [CrossRef]

- Hosoya, N.; Umino, R.; Kajiwara, I.; Maeda, S.; Onuma, T.; Mihara, A. Damage Detection in Transparent Materials Using Non-Contact Laser Excitation by Nano-Second Laser Ablation and High-Speed Polarization-imaging Camera. Exp. Mech. 2016, 56, 339–343. [Google Scholar] [CrossRef]

- Craeghs, T.; Bechmann, F.; Berumen, S.; Kruth, J.-P. Feedback control of Layerwise Laser Melting using optical sensors. Phys. Proc. 2010, 5, 505–514. [Google Scholar] [CrossRef] [Green Version]

- Craeghs, T.; Clijsters, S.; Yasa, E.; Bechmann, F.; Berumen, S.; Kruth, J.-P. Determination of geometrical factors in Layerwise Laser Melting using optical process monitoring. Opt. Lasers Eng. 2011, 49, 1440–1446. [Google Scholar] [CrossRef]

- Mazzoleni, L.; Demir, A.G.; Caprio, L.; Pacher, M.; Previtali, B. Real-Time Observation of Melt Pool in Selective Laser Melting: Spatial, Temporal and Wavelength Resolution Criteria. IEEE Trans. Instrum. Meas. 2019, 69, 1179–1190. [Google Scholar] [CrossRef]

- Thombansen, U.; Abels, P. Observation of melting conditions in selective laser melting of metals (SLM). High-Power Laser Mater. Process. Lasers. Beam Deliv. Diagn. 2016, 9741, 209–215. [Google Scholar] [CrossRef]

- Demir, A.G.; Mazzoleni, L.; Caprio, L.; Pacher, M.; Previtali, B. Complementary use of pulsed and continuous wave emission modes to stabilize melt pool geometry in laser powder bed fusion. Opt. Laser Technol. 2018, 113, 15–26. [Google Scholar] [CrossRef]

- Criales, L.E.; Arısoy, Y.M.; Lane, B.; Moylan, S.; Donmez, A.; Özel, T. Laser powder bed fusion of nickel alloy 625: Experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int. J. Mach. Tools Manuf. 2017, 121, 22–36. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Krishna, C.; Vallabh, P.; Sridar, S.; Xiong, W.; Zhao, X. Predicting melt pool depth and grain length using multiple signatures from in-situ single camera two-wavelength imaging pyrometry for laser powder bed fusion. J. Mater. Process. Tech. 2022, 308, 117724. [Google Scholar]

- Ma, H.; Mao, Z.; Feng, W.; Yang, Y.; Hao, C.; Zhou, J.; Liu, S.; Xie, H.; Guo, G.; Liu, Z. Online in-situ monitoring of melt pool characteristic based on a single high-speed camera in laser powder bed fusion process. Appl. Therm. Eng. 2022, 211, 118515. [Google Scholar] [CrossRef]

- Vasileska, E.; Demir, A.G.; Colosimo, B.M.; Previtali, B. Layer-Wise Control of Selective Laser Melting By Means of Inline Melt Pool Area Measurements. J. Laser Appl. 2020, 32, 022057. [Google Scholar] [CrossRef]

- Vasileska, E.; Demir, A.G.; Colosimo, B.M.; Previtali, B. Previtali, A novel paradigm for feedback control in LPBF: Layer-wise correction for overhang structures. Adv. Manuf. 2022, 10, 326–344. [Google Scholar] [CrossRef]

- Yang, L.; Lo, L.; Ding, S.; Özel, T. Monitoring and detection of meltpool and spatter regions in laser powder bed fusion of super alloy Inconel 625. Prog. Addit. Manuf. 2020, 5, 367–378. [Google Scholar] [CrossRef]

- Eriksson, I.; Powell, J.; Kaplan, A.F.H. Ultra high speed camera investigations of laser beam welding. In Proceedings of the 29th International Congress on Applications of Lasers and Electro-Optics, ICALEO 2010, Anaheim, CA, USA, 26–30 September 2010; pp. 172–178. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Guss, G.; Wu, S.; Matthews, M.J.; Schoenung, J.M. In-situ characterization of laser-powder interaction and cooling rates through high-speed imaging of powder bed fusion additive manufacturing. Mater. Des. 2017, 135, 385–396. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J. Mater. Process. Technol. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Bidare, P.; Maier, R.R.J.; Beck, R.; Shephard, J.; Moore, A. An open-architecture metal powder bed fusion system for in-situ process measurements. Addit. Manuf. 2017, 16, 177–185. [Google Scholar] [CrossRef]

- Bidare, P.; Bitharas, I.; Ward, R.; Attallah, M.; Moore, A. Laser powder bed fusion at sub-atmospheric pressures. Int. J. Mach. Tools Manuf. 2018, 130–131, 65–72. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Previtali, B. Observing molten pool surface oscillations during keyhole processing in laser powder bed fusion as a novel method to estimate the penetration depth. Addit. Manuf. 2020, 36, 101470. [Google Scholar] [CrossRef]

- Parab, N.D.; Zhao, C.; Cunningham, R.; Escano, L.I.; Fezzaa, K.; Everhart, W.; Rollett, A.D.; Chen, L.; Sun, T. Ultrafast X-ray imaging of laser–metal additive manufacturing processes. J. Synchrotron Radiat. 2018, 25, 1467–1477. [Google Scholar] [CrossRef] [Green Version]

- Bruna-Rosso, C.; Demir, A.G.; Previtali, B. Selective laser melting finite element modeling: Validation with high-speed imaging and lack of fusion defects prediction. Mater. Des. 2018, 156, 143–153. [Google Scholar] [CrossRef] [Green Version]

- Malekipour, E.; El-Mounayri, H. Common defects and contributing parameters in powder bed fusion AM process and their classification for online monitoring and control: A review. Int. J. Adv. Manuf. Technol. 2017, 95, 527–550. [Google Scholar] [CrossRef]

- Cunningham, R.; Narra, S.P.; Montgomery, C.; Beuth, J.; Rollett, A.D. Synchrotron-Based X-ray Microtomography Characterization of the Effect of Processing Variables on Porosity Formation in Laser Power-Bed Additive Manufacturing of Ti-6Al-4V. JOM 2017, 69, 479–484. [Google Scholar] [CrossRef]

- Yu, G.; Gu, D.; Dai, D.; Xia, M.; Ma, C.; Chang, K. Influence of processing parameters on laser penetration depth and melting/re-melting densification during selective laser melting of aluminum alloy. Appl. Phys. A 2016, 122, 891. [Google Scholar] [CrossRef]

- Boley, M.; Abt, F.; Weber, R.; Graf, T. X-ray and optical videography for 3D measurement of capillary and melt pool geometry in laser welding. Phys. Procedia 2013, 41, 488–495. [Google Scholar] [CrossRef] [Green Version]

- Goossens, L.R.; Hooreweder, B.V. A virtual sensing approach for monitoring melt-pool dimensions using high speed coaxial imaging during laser powder bed fusion of metals. Addit. Manuf. 2021, 40, 101923. [Google Scholar] [CrossRef]

- Mazzoleni, L.; Caprio, L.; Pacher, M.; Demir, A.G.; Previtali, B. External Illumination Strategies for Melt Pool Geometry Monitoring in SLM. JOM 2018, 71, 928–937. [Google Scholar] [CrossRef]

- Semak, V.; Hopkins, J.A.; McCay, M.H. A technique for melt pool oscillation monitoring during laser spot welding. In Proceedings of the International Congress on Applications of Lasers and Electro-Optics, San Diego, CA, USA, 17–20 November 1997; pp. C11–C20. [Google Scholar] [CrossRef]

- Richter, B.; Blanke, N.; Werner, C.; Parab, N.; Sun, T.; Vollertsen, F.; Pfefferkorn, F.E. High-speed X-ray investigation of melt dynamics during continuous-wave laser remelting of selective laser melted Co-Cr alloy. CIRP Ann. 2019, 68, 229–232. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, C.; Ji, X.; Li, F.; Zhang, Y.; Hua, X. Correlation Between Gas-Dynamic Behaviour of a Vapour Plume and Oscillation of Keyhole Size During Laser Welding of 5083 Al-Alloy; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Carter, G.; Nuttall, A.H. A brief summary of a generalized framework for power spectral estimation. Signal Process. 1980, 2, 387–390. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Previtali, B.; Colosimo, B.M. Determining the feasible conditions for processing lunar regolith simulant via laser powder bed fusion. Addit. Manuf. 2019, 32, 101029. [Google Scholar] [CrossRef]

- Demir, A.G.; Monguzzi, L.; Previtali, B. Selective laser melting of pure Zn with high density for biodegradable implant manufacturing. Addit. Manuf. 2017, 15, 20–28. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Previtali, B. Non-intrusive estimation of subsurface geometrical attributes of the melt pool through the sensing of surface oscillations in laser powder bed fusion. J. Laser Appl. 2021, 33, 012035. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.P.R.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater Des. 2017, 113, 331–340. [Google Scholar] [CrossRef] [Green Version]

- Rombouts, M.; Kruth, J.P.; Froyen, L.; Merce, P. Fundamentals of Selective Laser Melting of alloyed steel powders Fundamentals of Selective Laser Melting of alloyed steel powders. CIRP Ann. Manuf Technol. 2006, 55, 187–192. [Google Scholar] [CrossRef]

- Klein, T.; Vicanek, M.; Simon, G. Oscillations of the keyhole in penetration laser beam welding. J. Phys. D Appl. Phys. 1994, 29, 322–332. [Google Scholar] [CrossRef]

- Andersen, K.; Cook, G.E.; Barnett, R.J.; Strauss, A.M. Synchronous weld pool oscillation for monitoring and control. IEEE Trans. Ind. Appl. 1997, 33, 464–471. [Google Scholar] [CrossRef]

- Sorensen, C.D.; Eagar, T.W. Modeling of oscillations in partially penetrated weld pools. J. Dyn. Syst. Meas. Control. 1990, 112, 469–474. [Google Scholar] [CrossRef]

- Xiao, Y.H.; Ouden, G.d. A Study of GTA Weld Pool Oscillation. Weld J. 1990, 69, 289–293. [Google Scholar]

| Parameter | Lower Limit | Upper Limit | Defining Eq. |

|---|---|---|---|

| Field of view width, wFOV | >2·lmp | Data transfer rate limited | - |

| Field of view length, lFOV | >2·lmp | Data transfer rate limited | |

| Spatial resolution, SR | Optically limited | - | |

| Acquisition frequency, facq | Data transfer rate limited | - | |

| Frequency resolution, Δfres | As small as possible | , Process limited |

| Configuration | Coaxial | Off-Axis |

|---|---|---|

| Advantage |

|

|

| Disadvantage |

|

|

| Parameter | Value |

|---|---|

| Maximum laser power, Pmax (W) | 300 |

| Emission wavelength, λ (nm) | 1070 |

| Beam quality factor, M2 | 1.05 |

| Collimated beam diameter, dcol (mm) | 5 |

| Beam expander magnification, m | 2 |

| Expanded beam diameter, dexp (mm) | 10 |

| Beam divergence, θ (mrad) | 20.9 |

| Beam waist diameter, d0 (µm) | 43 |

| Parameter | Value |

|---|---|

| High-speed camera configuration | Coaxial |

| Illumination and observation wavelength, λobs | 640 nm |

| Exposure time, texp | Variable (260 ns–1/facq) |

| Illumination time, tillumination | Variable |

| Spatial resolution, SR | 12.4 µm/pixel |

| Max. field of view, FOV | 1024 pixels × 1024 pixels |

| Max. acquisition frequency at full frame, facq,max | 6.4 kHz |

| Fixed Factors (Imaging System) | Value |

|---|---|

| Exposure time, texp | 0.66 µs |

| Illumination time, tillumination | 0.55 µs |

| Field of View, FOV | 384 pixels × 384 pixels 4.76 mm × 4.76 mm |

| Acquisition frequency, facq | 36 kHz |

| Fixed Factors (Process) | Value |

| Process | Material remelting |

| Process gas | Argon |

| Material | AISI316L |

| Power, P (W) | 300 |

| Scan speed, v (mm/s) | 900 |

| Focal position, Δf | 0 |

| Variable Factor | Value |

| Illumination light | Coaxial—Off-axis |

| Fixed Factors (Imaging System) | Value |

|---|---|

| Illumination light configuration | Off-axis |

| Exposure time, texp | 0.49 µs |

| Illumination time, tillumination | 0.39 µs |

| Field of View, FOV | 256 pixels × 256 pixels 3.15 mm × 3.15 mm |

| Acquisition frequency, facq | 50 kHz |

| Fixed Factors (Process) | Value |

| Process | Single-track LPBF |

| Process gas | Argon |

| Material | AISI316L |

| Layer thickness, lt (µm) | 50 |

| Focal position, Δf (mm) | 0 |

| Replicates, n | 2 |

| Variable Factors | Value |

| Condition A | p = 275 W, v = 225 mm/s |

| Condition B | p = 300 W, v = 450 mm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caprio, L.; Demir, A.G.; Previtali, B. External Illumination Enables Coaxial Sensing of Surface and Subsurface Molten Pool Geometry in LPBF. Metals 2022, 12, 1762. https://doi.org/10.3390/met12101762

Caprio L, Demir AG, Previtali B. External Illumination Enables Coaxial Sensing of Surface and Subsurface Molten Pool Geometry in LPBF. Metals. 2022; 12(10):1762. https://doi.org/10.3390/met12101762

Chicago/Turabian StyleCaprio, Leonardo, Ali Gökhan Demir, and Barbara Previtali. 2022. "External Illumination Enables Coaxial Sensing of Surface and Subsurface Molten Pool Geometry in LPBF" Metals 12, no. 10: 1762. https://doi.org/10.3390/met12101762