Influence of Cementite Precipitation on Work Hardening Behavior in Ultrafine Grain Steels Rolled at Room and Cryogenic Temperatures

Abstract

:1. Introduction

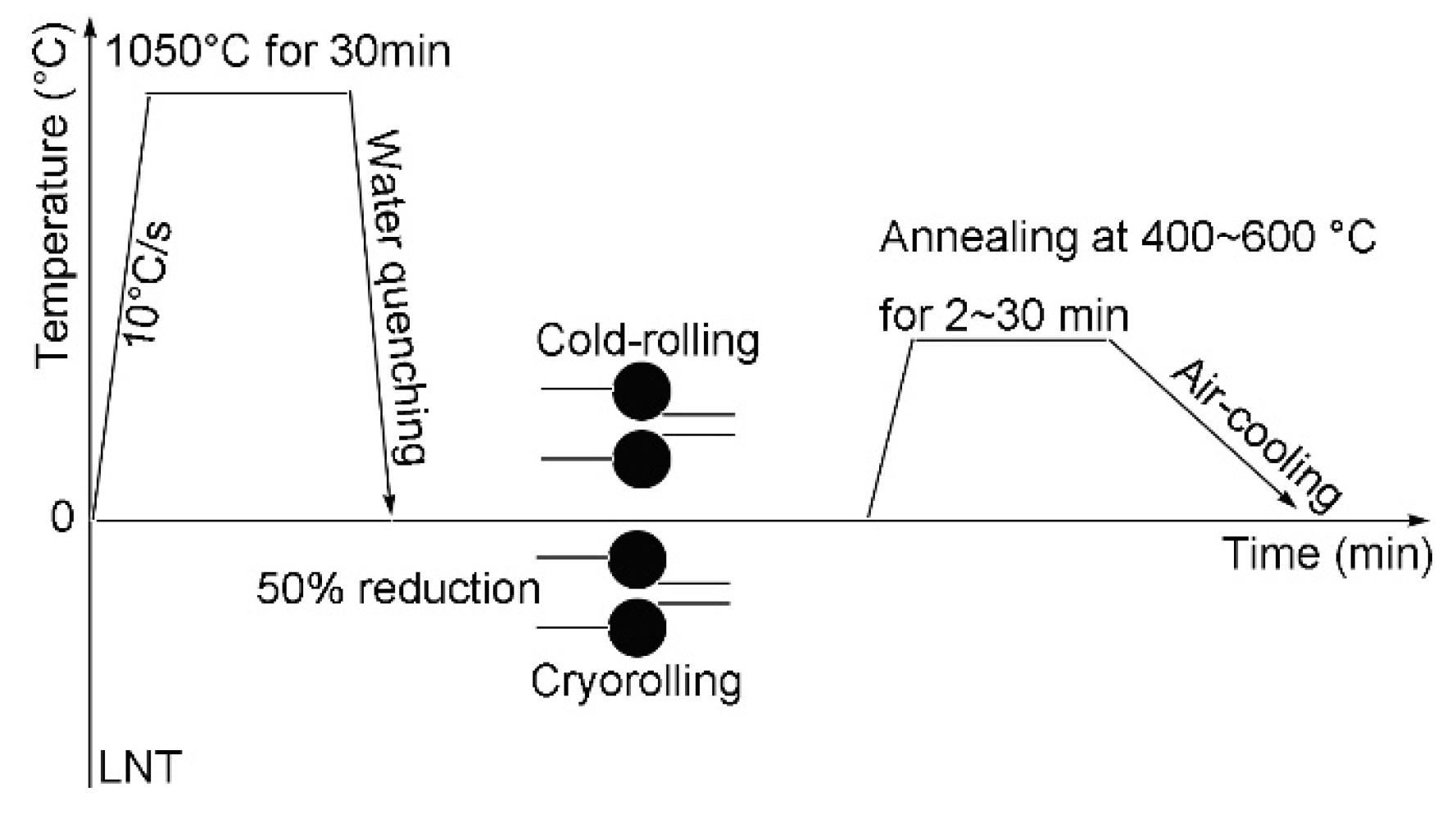

2. Materials and Methods

3. Results

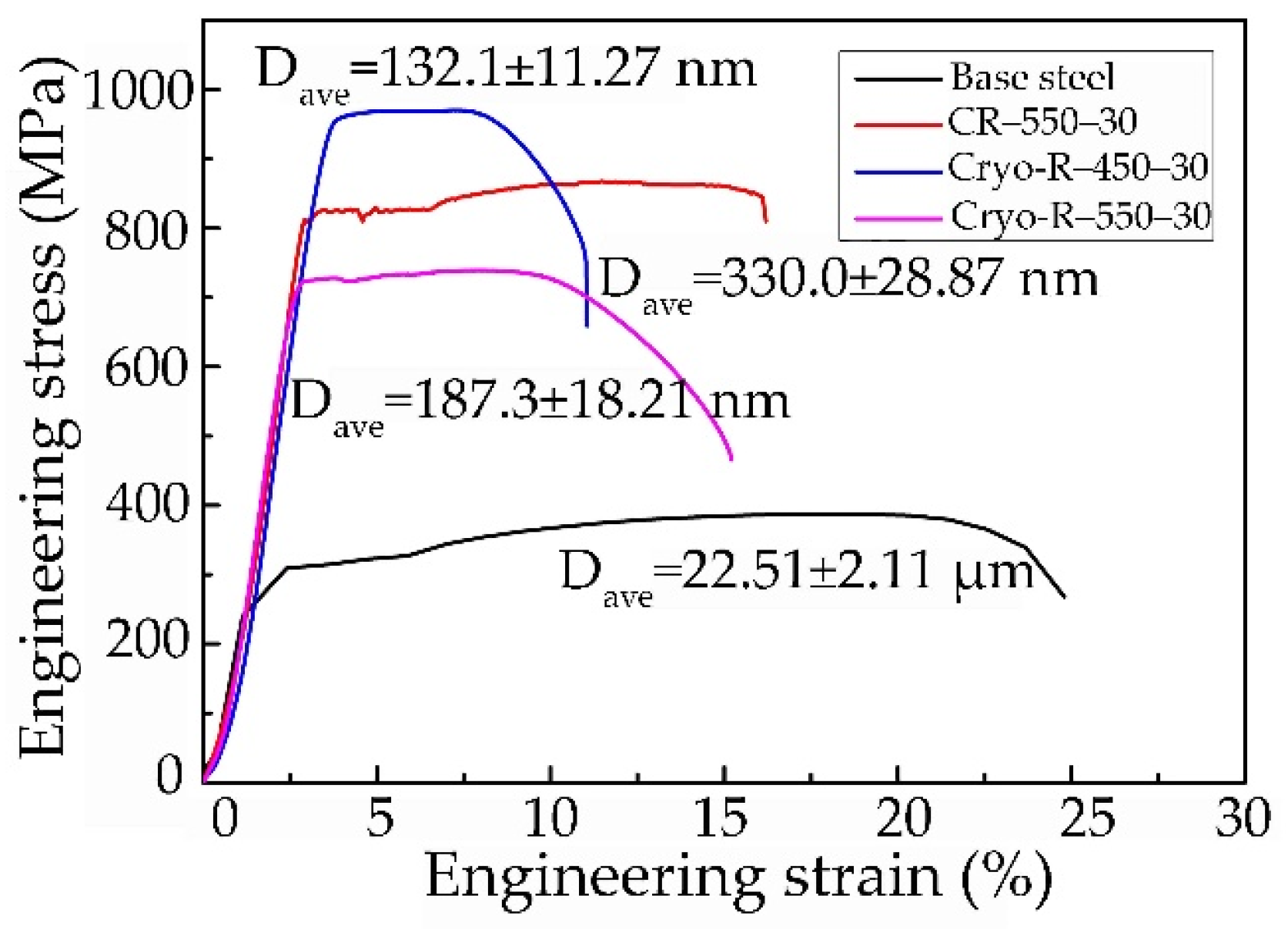

3.1. Mechanical Property

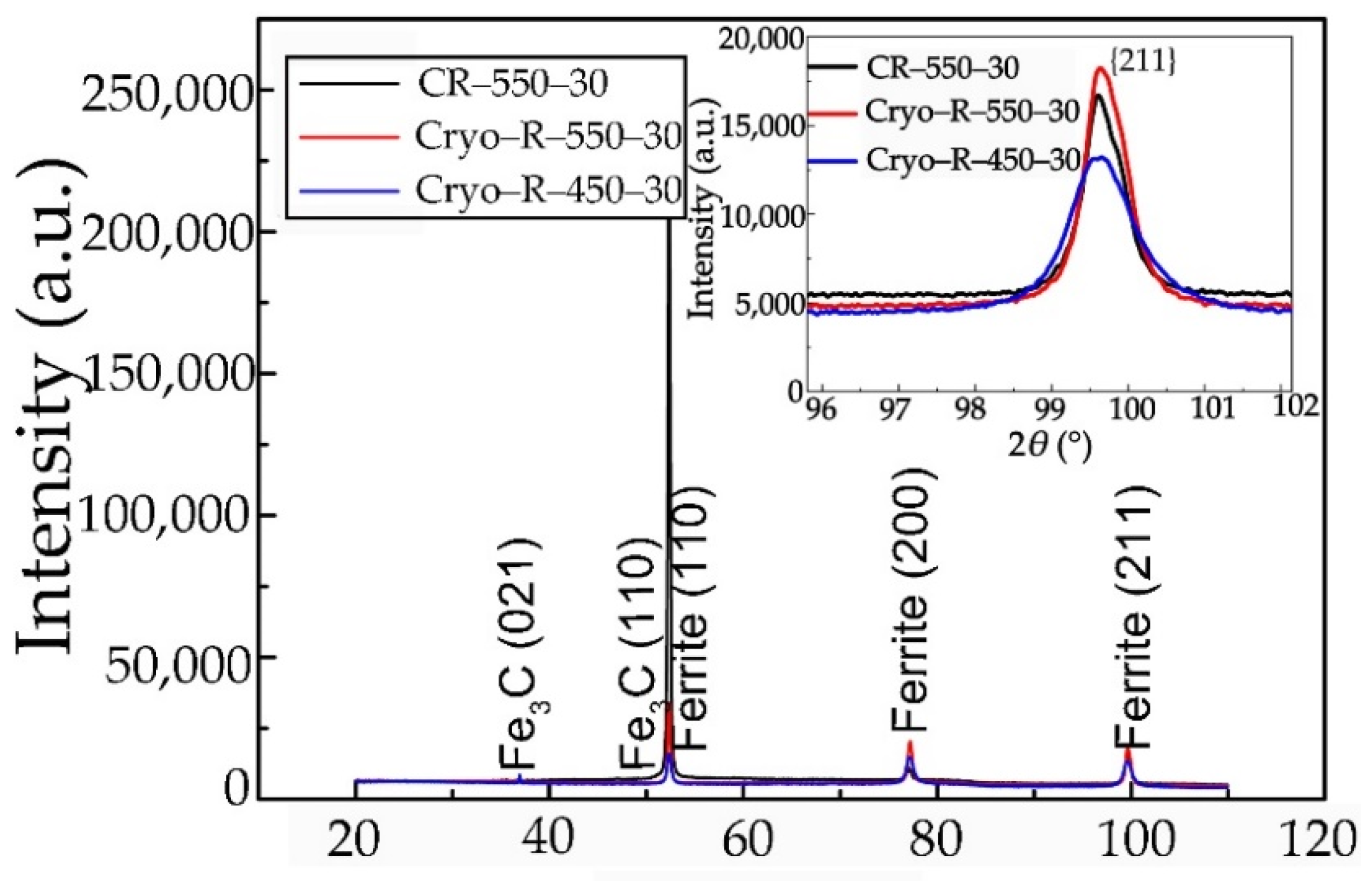

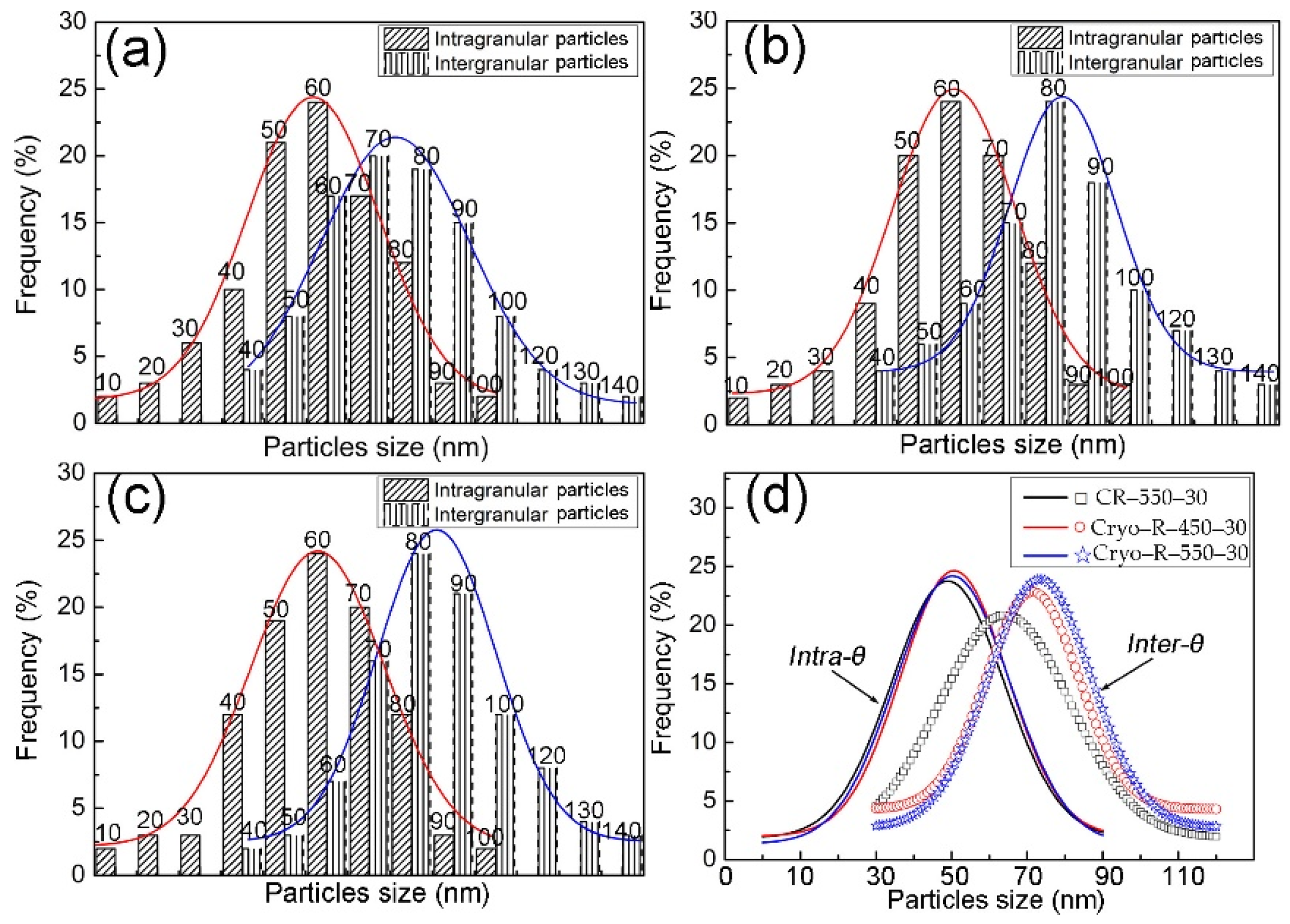

3.2. Microstructure Evolution

3.3. Work Hardening

4. Conclusions

- (1)

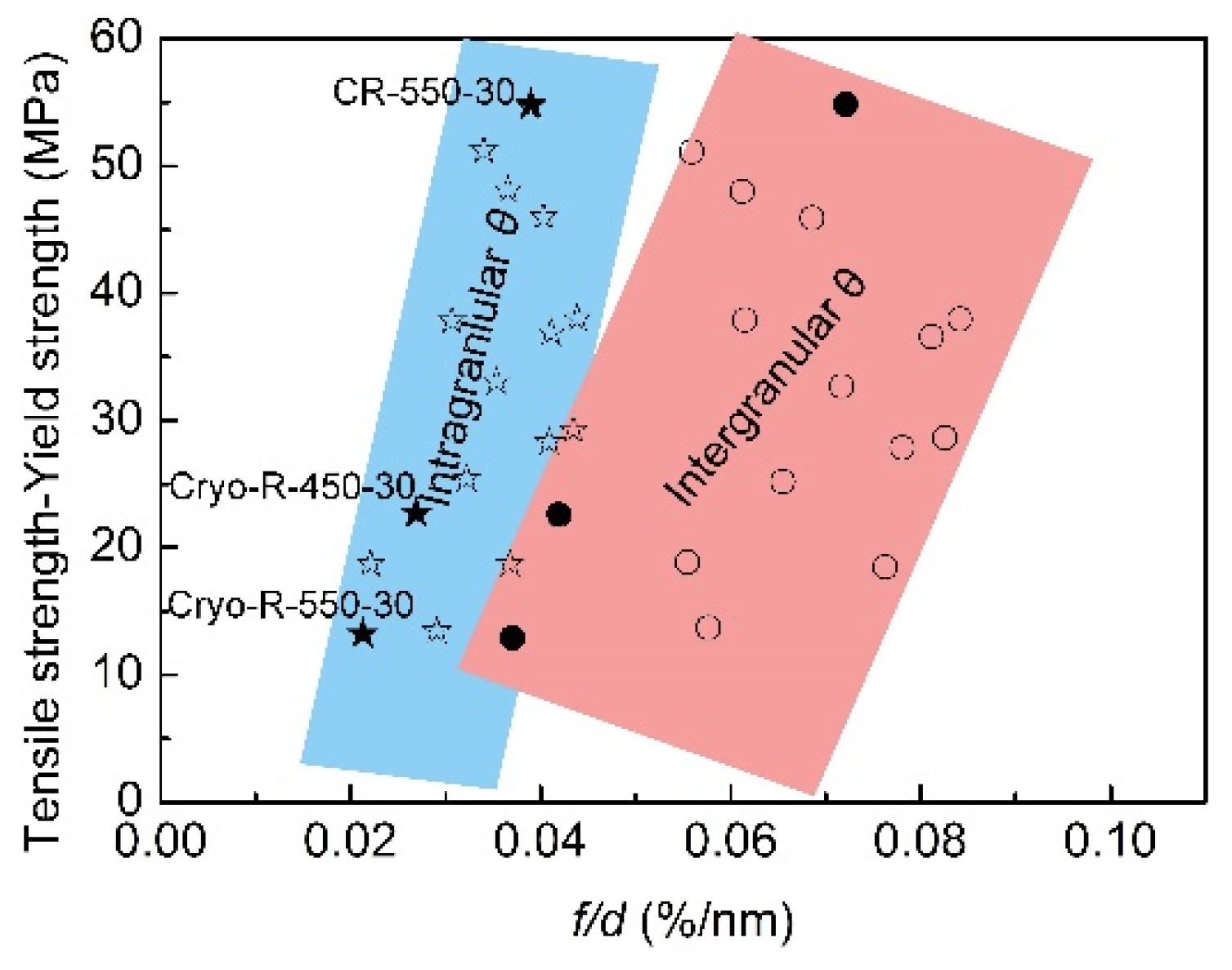

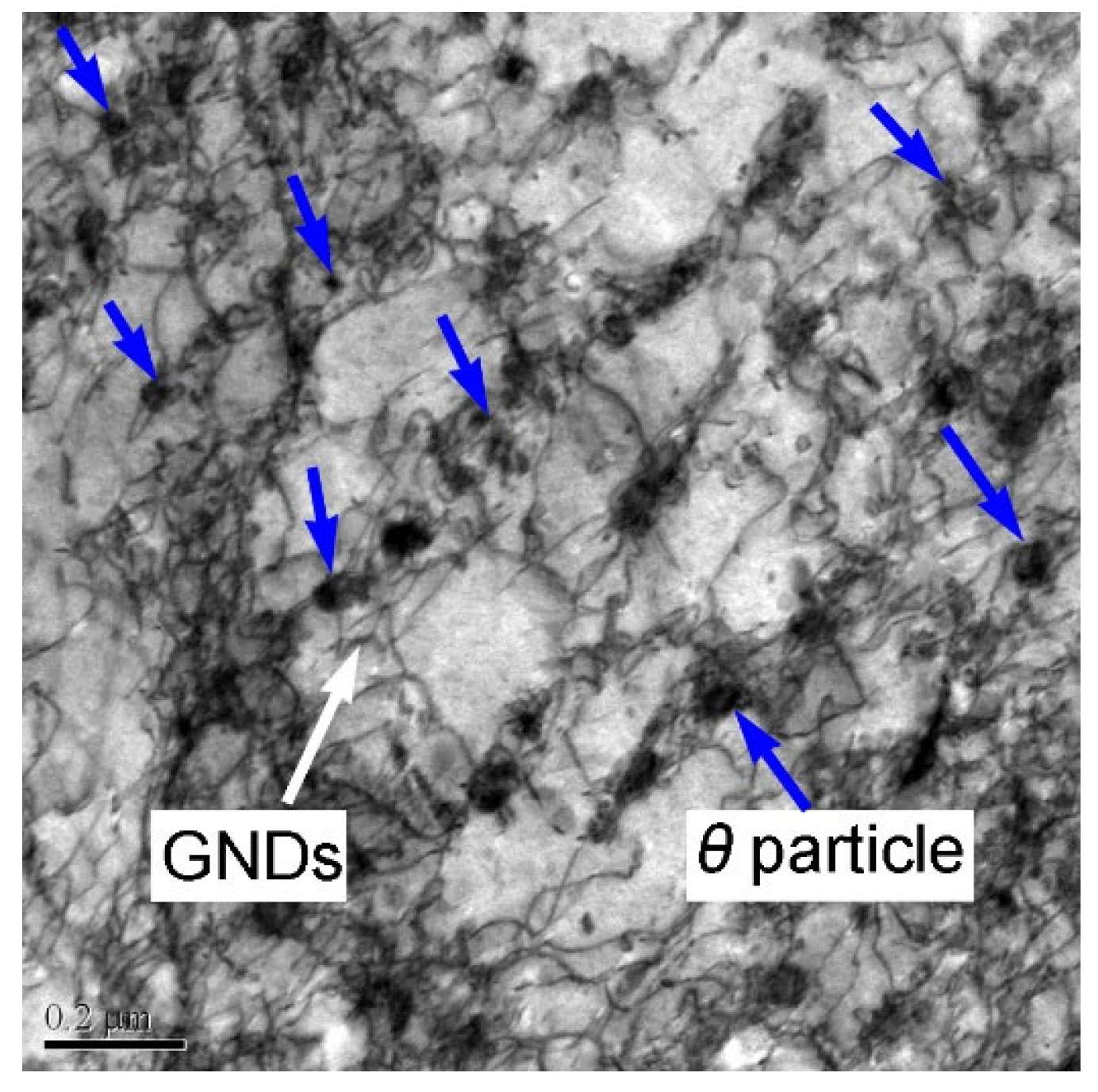

- Optimal balance between the strength and work hardening in the low-carbon UFG steels is realized by the α and θ phases. It was important to adjust the rolling and annealing processes from the viewpoint of industrial production in order to fabricate the UFG steels with a relative coarsening α phase and dispersedly distributed intragranular θ particles, which guarantees the better work hardening of UFG steels.

- (2)

- The cryorolling process substantially improved the tensile strength of low-carbon UFG steel, but concurrently deteriorated the work hardening behavior. The work hardening ability increased with the rise of the volume fraction and the decreased size of cementite particles. The highest work hardening rate, at the stage I of 1.46 (GPa), was obtained in the specimen CR–550–30 (cold-rolled and annealed at 550 °C for 30 min), while it decreased to 0.36 (GPa) and 0.26 (GPa) in the specimens Cryo–R–450–30 (cryorolled and annealed at 450 °C for 30 min) and Cryo–R–550–30 (cryorolled and annealed at 550 °C for 30 min).

- (3)

- The α grain size was decreased to 132 ± 11 nm and 200 ± 19 nm in specimens Cryo–R–450–30 and Cryo–R–550–30, which were smaller than that obtained in specimen CR–550–30. The specimen Cryo–R–550–30 had a tensile strength of 740.3 MPa, which was lower than that in the specimens Cryo–R–450–30 (970.2 MPa) and CR–550–30 (867.3 MPa).

- (4)

- The intergranular θ particles, without well dislocation accumulation ability, impair the strength of grain boundaries and the work hardening of α + θ ultrafine grain steels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, R.W.; Cao, Q.; Peng, Z.J.; Shi, J.; Dong, H.; Huang, C.X. Intercritical rolling induced ultrafine microstructure and excellent mechanical properties of the medium-Mn steel. Mater. Sci. Eng. A 2013, 58, 84–88. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef]

- Tsuji, N.; Ueji, R.; Minamino, Y.; Saito, Y. A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property. Scr. Mater. 2002, 46, 305–310. [Google Scholar]

- Ueji, R.; Tsuji, N.; Minamino, Y.; Koizumi, Y. Ultragrain refinement of plain low carbon steel by cold rolling and annealing of martensite. Acta Mater. 2002, 50, 4177–4189. [Google Scholar] [CrossRef]

- Liang, J.W.; Shen, Y.F.; Misra, R.D.K.; Liaw, P.K. High strength-superplasticity combination of ultrafine-grained ferritic steel: The significant role of nanoscale carbides. J. Mater. Sci. Technol. 2021, 83, 131–144. [Google Scholar]

- Kalashami, A.G.; Kermanpur, A.; Ghassemali, E.; Najafizadeh, A.; Mazaheri, Y. Correlation of microstructure and strain hardening behavior in the ultrafine-grained Nb-bearing dual phase steels. Mater. Sci. Eng. A 2016, 678, 215–226. [Google Scholar]

- Hamzeh, M.; Kermanpur, A.; Najafizadeh, A. Fabrication of the ultrafine-grained ferrite with good resistance to grain growth and evaluation of its tensile properties. Mater. Sci. Eng. A 2014, 593, 24–30. [Google Scholar] [CrossRef]

- Wang, H.T.; Tao, N.R.; Lu, K. Strengthening an austenitic Fe-Mn steel using nanotwinned austenitic grains. Acta Mater. 2012, 60, 4027–4040. [Google Scholar]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Song, R.; Ponge, D.; Raabe, D.; Speer, J.G.; Matlock, D.K. Overview of processing, microstructure and mechanical properties of ultrafine grained bcc steels. Mater. Sci. Eng. A 2006, 441, 1–17. [Google Scholar] [CrossRef]

- Zhao, L.J.; Park, N.; Tian, Y.Z.; Chen, S.; Shibata, A.; Tsuji, N. Novel thermomechanical processing methods for achieving ultragrain refinement of low-carbon steel without heavy plastic deformation. Mater. Res. Lett. 2016, 5, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.Q.; Jin, J.E.; Lee, Y.K. A repetitive thermomechanical process to produce nano-crystalline in a metastable austenitic steel. Scr. Mater. 2005, 52, 1311–1315. [Google Scholar] [CrossRef]

- Gazder, A.A.; Hazra, S.S.; Perefoim, E.V. Annealing behaviour and mechanical properties of severely deformed interstitial free steel. Mater. Sci. Eng. A 2011, 530, 492–503. [Google Scholar] [CrossRef]

- Yu, C.Y.; Kao, P.W.; Chang, C.P. Transition of tensile deformation behaviours in ultrafine-grained aluminium. Acta Mater. 2005, 53, 4019–4028. [Google Scholar] [CrossRef]

- Ma, E. Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scr. Mater. 2003, 49, 663–668. [Google Scholar] [CrossRef]

- Rao, P.N.; Singh, D.; Jayaganthan, R. Mechanical properties and microstructural evolution of Al 6061 alloy processed by multidirectional forging at liquid nitrogen temperature. Mater. Des. 2014, 56, 97–104. [Google Scholar] [CrossRef]

- Wang, Y.M.; Chen, M.W.; Zhou, F.H.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Wang, J.F.; Zhou, S.; Wang, X.D. Effects of rare earth addition on microstructure and mechanical properties of a Fe-15Mn-1.5A1-0.6C TWIP steel. Mater. Sci. Eng. A 2014, 608, 106–113. [Google Scholar]

- Song, R.; Ponge, D.; Raabe, D. Mechanical properties of an ultrafine grained C-Mn steel processed by warm deformation and annealing. Acta Mater. 2005, 53, 4881–4892. [Google Scholar] [CrossRef]

- Li, X.; Jing, T.F.; Lu, M.M.; Zhang, J.W. Microstructure and mechanical properties of ultrafine lath-shaped low carbon steel. J. Mater. Eng. Perform. 2012, 21, 1496–1499. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Alishahi, M.; Najafizadeh, A.; Kermanpur, A. The improvement of ductility in nano/ultrafine grained low carbon steels via high temperature short time annealing. Mater. Lett. 2012, 74, 206–208. [Google Scholar]

- Tsuji, N.; Maki, T. Enhanced structural refinement by combining phase transformation and plastic deformation in steels. Scr. Mater. 2009, 60, 1044–1049. [Google Scholar] [CrossRef]

- Yuan, Q.; Xu, G.; Liu, M.; Hu, H.J.; Tian, J.Y. Effects of rolling temperature on the microstructure and mechanical properties in an ultrafine-grained low-carbon steel. Steel Res. Int. 2018, 2, 1800318. [Google Scholar] [CrossRef]

- Park, K.T.; Kim, Y.S.; Lee, J.G.; Shin, D.H. Thermal stability and mechanical properties of ultrafine grained low carbon steel. Mater. Sci. Eng. A 2000, 293, 165–172. [Google Scholar] [CrossRef]

- Furuhara, T.; Mizoguchi, T.; Maki, T. Ultra-fine (α+θ) Duplex Structure Formed by Cold Rolling and Annealing of Pearlite. ISIJ Int. 2005, 45, 392–398. [Google Scholar] [CrossRef] [Green Version]

- Syn, C.K.; Lesuer, D.R.; Sherby, O.D. Influence of microstructure on tensile properties of spheroidized ultrahigh-carbon (1.8 Pct C) steel. Met. Mater. Trans. A 1994, 25, 1481–1493. [Google Scholar] [CrossRef]

- Yuan, Q.; Xu, G.; Liu, S.; Liu, M.; Hu, H.J. Effect of strain rate on the microstructure of warm-deformed ultrafined medium-carbon steel. Arch. Met. Mater. 2018, 4, 1805–1813. [Google Scholar]

- Yuan, Q.; Xu, G.; Liu, S.; Liu, M.; Hu, H.J.; Li, G.Q. Effect of rolling reduction on microstructure and property of ultrafine grained low-carbon steel processed by cryorolling martensite. Metals 2018, 8, 518. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Q.; Xu, G.; Liu, M.; Liu, S.; Hu, H.J. Evaluation of mechanical properties and microstructures of ultrafine grain low-carbon steel processed by cryorolling and annealing. Trans. Indian Inst. Met. 2019, 72, 741–749. [Google Scholar]

- Avishan, B.; Garcia-Mateo, C.; Morales-Rivas, L.; Yazdani, S.; Caballero, F.G. Strengthening and mechanical stability mechanisms in nanostructured bainite. J. Mater. Sci. 2013, 48, 6121–6132. [Google Scholar] [CrossRef] [Green Version]

- Belde, M.; Springer, H.; Raabe, D. Vessel microstructure design: A new approach for site-specific core shell micromechanical tailoring of TRIP-assisted ultra-high strength steels. Acta Mater. 2016, 113, 19–31. [Google Scholar] [CrossRef]

- Gan, X.L.; Yuan, Q.; Zhao, G.; Ma, H.W.; Liang, W.; Xue, Z.L.; Qiao, W.W.; Xu, G. Quantitative analysis of microstructures and strength of Nb-Ti microalloyed steel with different Ti additions. Met. Mater. Trans. A 2020, 5, 2084–2096. [Google Scholar] [CrossRef]

- Zheng, C.S.; Li, L.F. Effect of microstructure on mechanical behavior for eutectoid steel with ultrafine- or fine-grained ferrite+cementite structure. Mater. Sci. Eng. A 2017, 688, 83–91. [Google Scholar] [CrossRef]

- Zheng, C.S.; Li, L.F.; Wang, Y.D.; Yang, W.Y.; Sun, Z.Q. Micromechanical behaviour of eutectoid steel quantified by ananalytical model calibrated by in situ synchrotron-based X-ray diffraction. Mater. Sci. Eng. A 2015, 631, 181–188. [Google Scholar] [CrossRef]

| Specimens | CR–550–30 | Cryo–R–450–30 | Cryo–R–550–30 |

|---|---|---|---|

| dα (nm) 1 | 330 ± 30 | 132 ± 11 | 200 ± 19 |

| dintra-θ (nm) | 50 ± 10 | 52 ± 13 | 53 ± 14 |

| fintra-θ (%) | 1.8 | 1.3 | 1.1 |

| dinter-θ (nm) | ~57.7 | ~100.2 | ~121.4 |

| finter-θ (%) 2 | 5.1 | 5.7 | 5.9 |

| f/dintra-θ (%/nm) | 0.036 | 0.025 | 0.021 |

| f/dinter-θ (%/nm) | 0.078 | 0.070 | 0.066 |

| f/d (%/nm) 3 | 0.119 | 0.069 | 0.058 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yuan, Q.; Zhang, Z.; Zhang, Q.; Xu, G. Influence of Cementite Precipitation on Work Hardening Behavior in Ultrafine Grain Steels Rolled at Room and Cryogenic Temperatures. Metals 2022, 12, 1845. https://doi.org/10.3390/met12111845

Wang Z, Yuan Q, Zhang Z, Zhang Q, Xu G. Influence of Cementite Precipitation on Work Hardening Behavior in Ultrafine Grain Steels Rolled at Room and Cryogenic Temperatures. Metals. 2022; 12(11):1845. https://doi.org/10.3390/met12111845

Chicago/Turabian StyleWang, Zhoutou, Qing Yuan, Zhicheng Zhang, Qingxiao Zhang, and Guang Xu. 2022. "Influence of Cementite Precipitation on Work Hardening Behavior in Ultrafine Grain Steels Rolled at Room and Cryogenic Temperatures" Metals 12, no. 11: 1845. https://doi.org/10.3390/met12111845

APA StyleWang, Z., Yuan, Q., Zhang, Z., Zhang, Q., & Xu, G. (2022). Influence of Cementite Precipitation on Work Hardening Behavior in Ultrafine Grain Steels Rolled at Room and Cryogenic Temperatures. Metals, 12(11), 1845. https://doi.org/10.3390/met12111845