Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

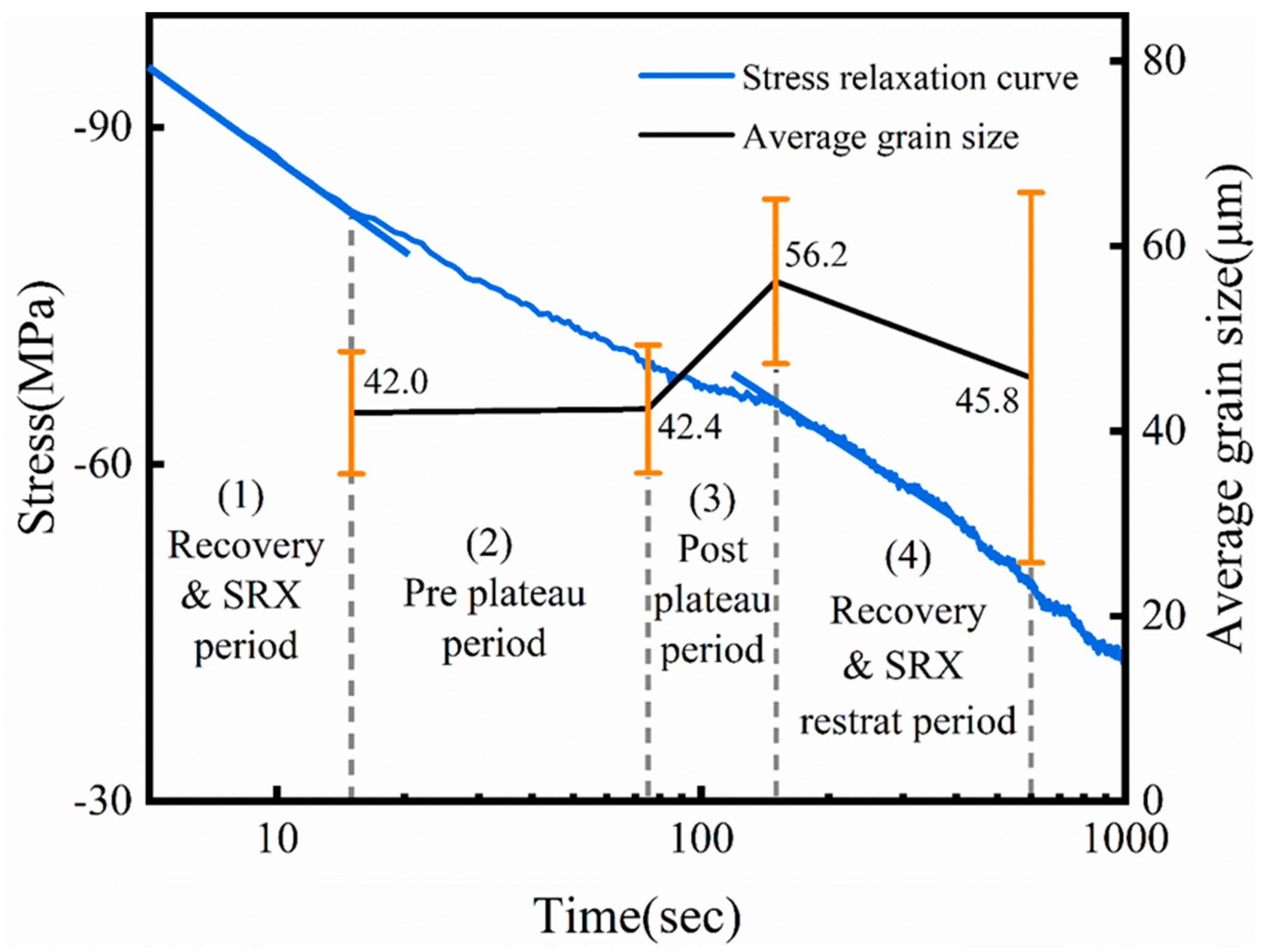

3.1. Stress Relaxation Curves

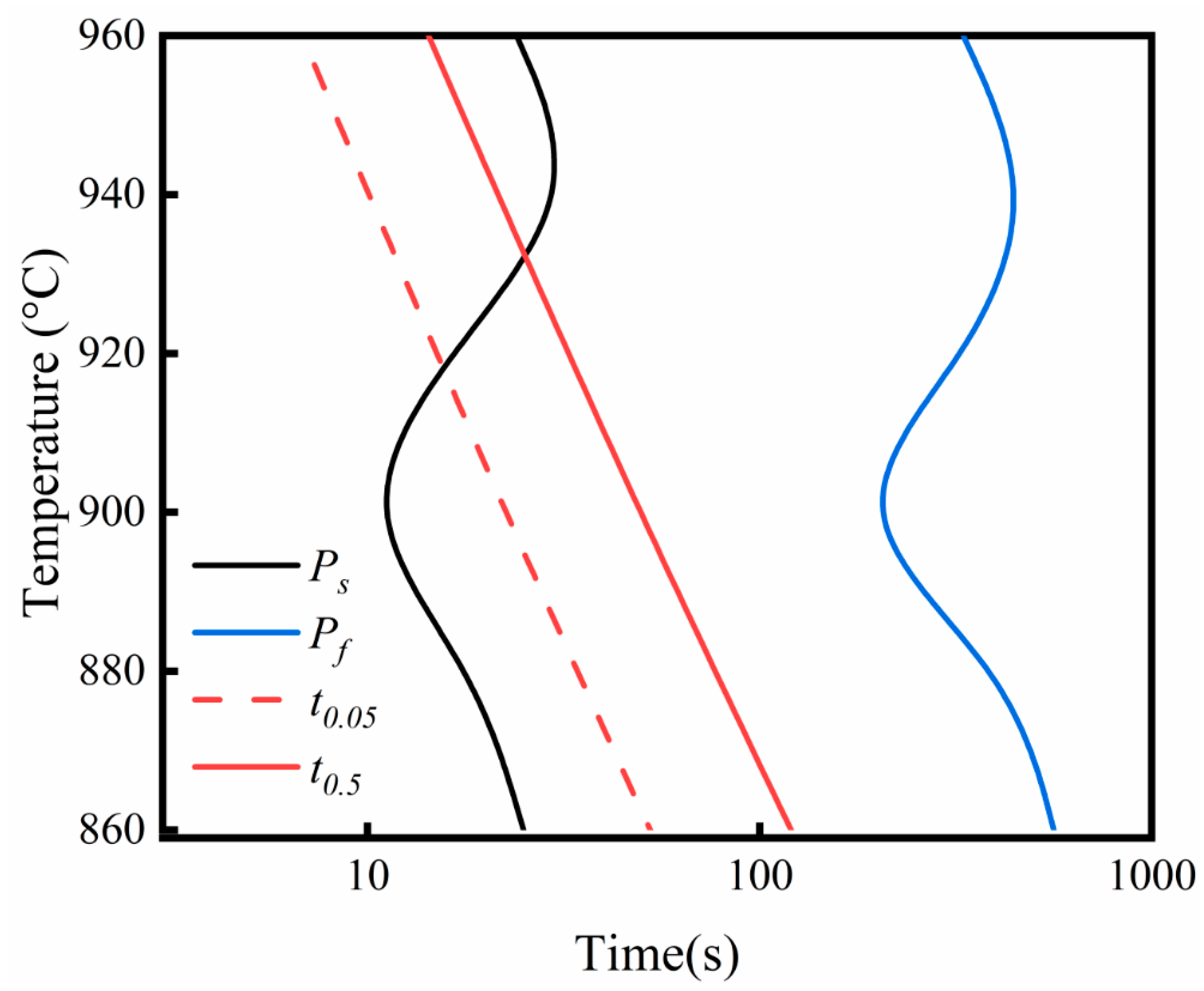

3.2. PTT Curve

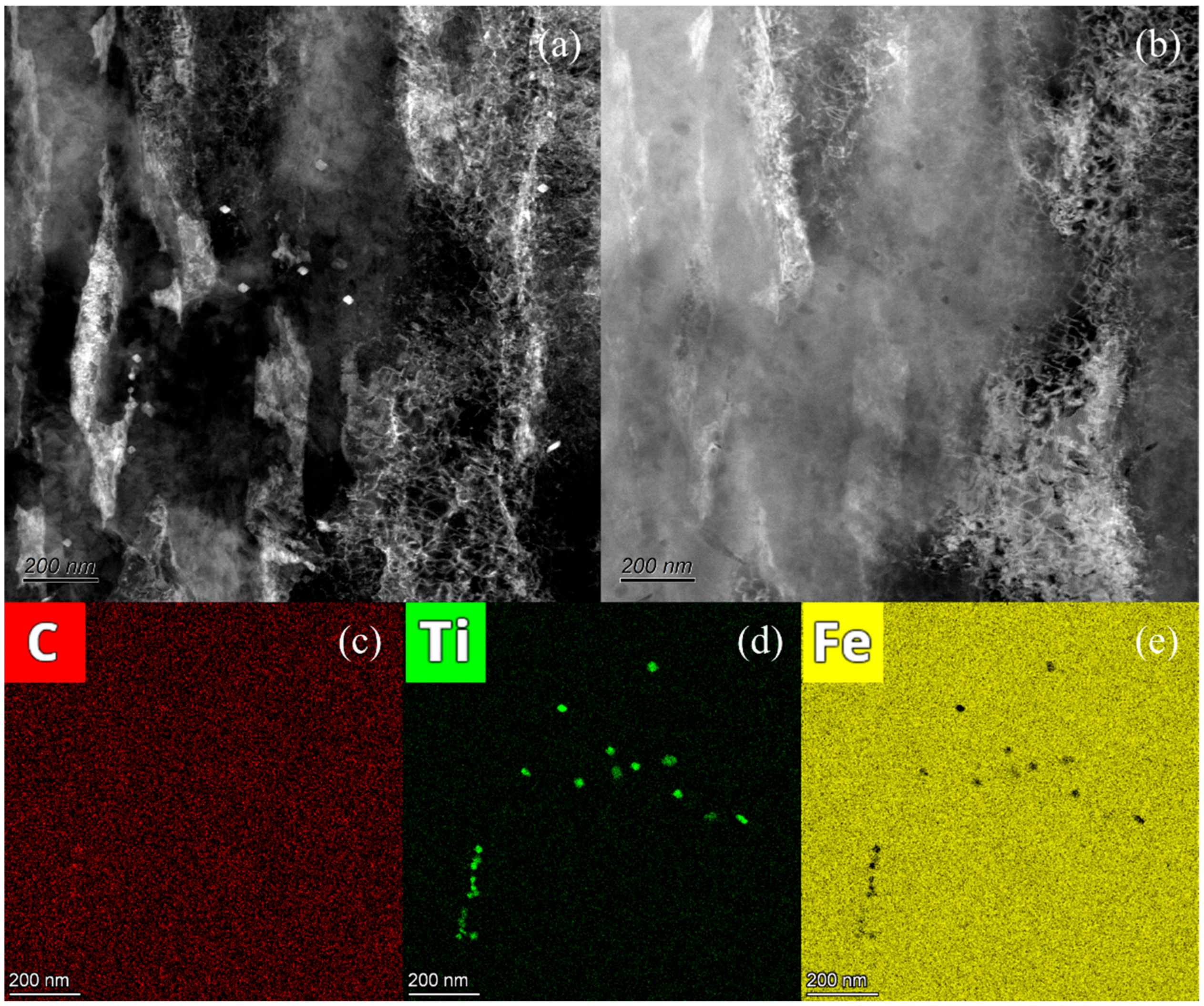

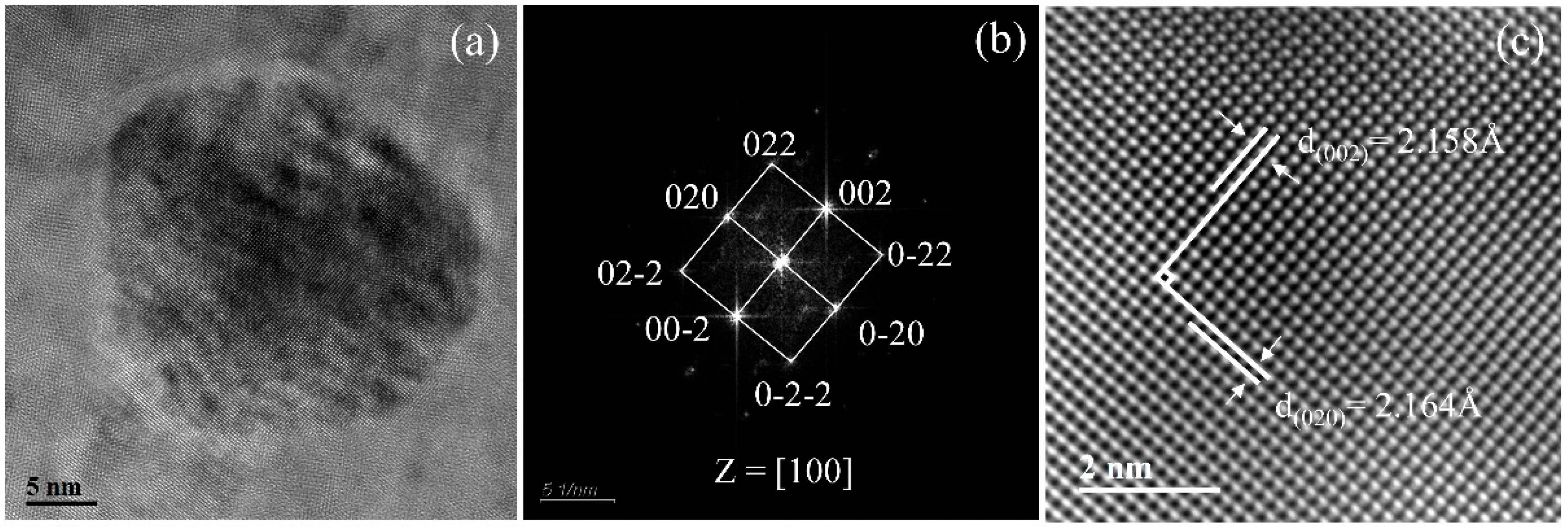

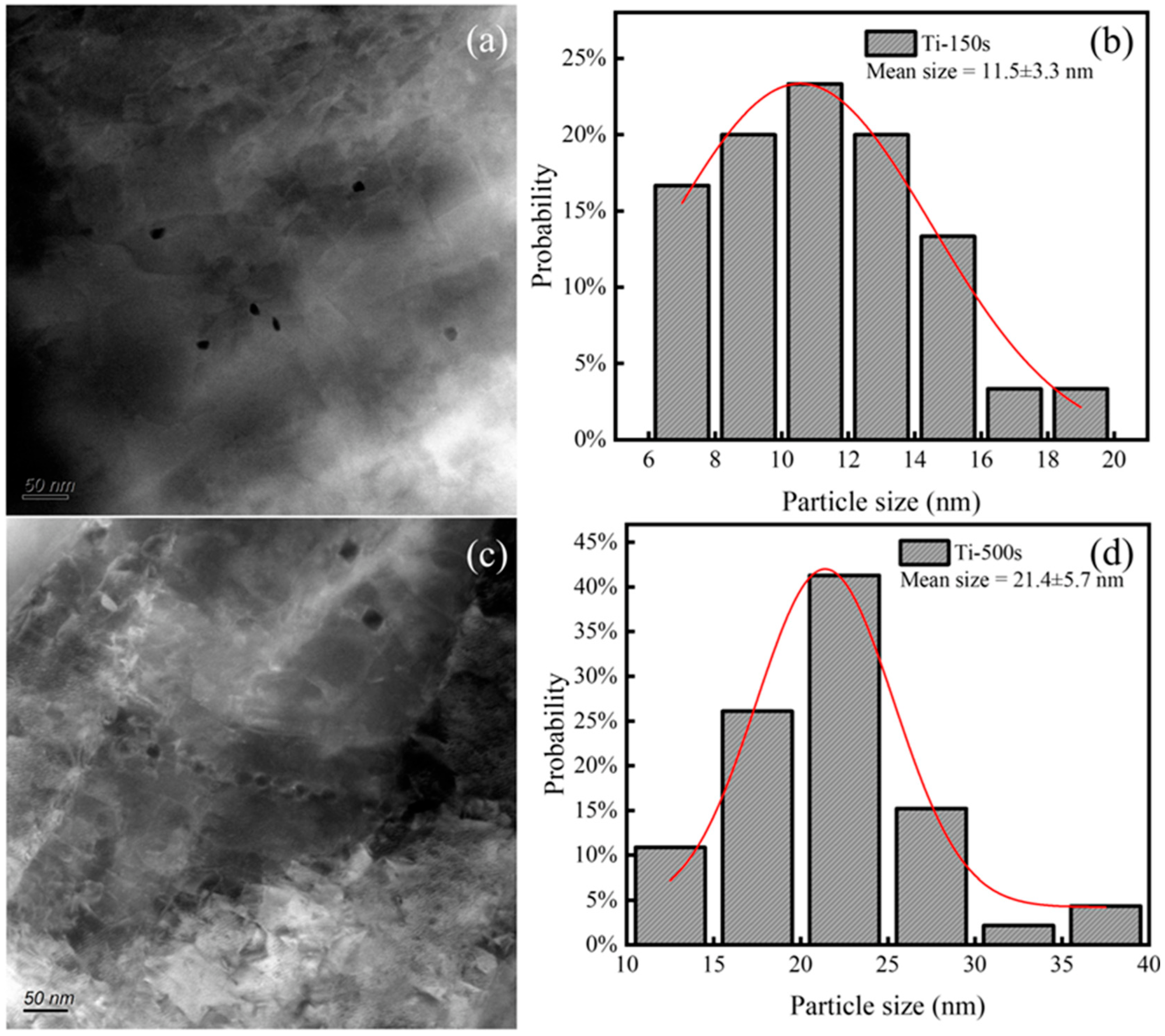

3.3. TEM Analysis of Precipitated Particles

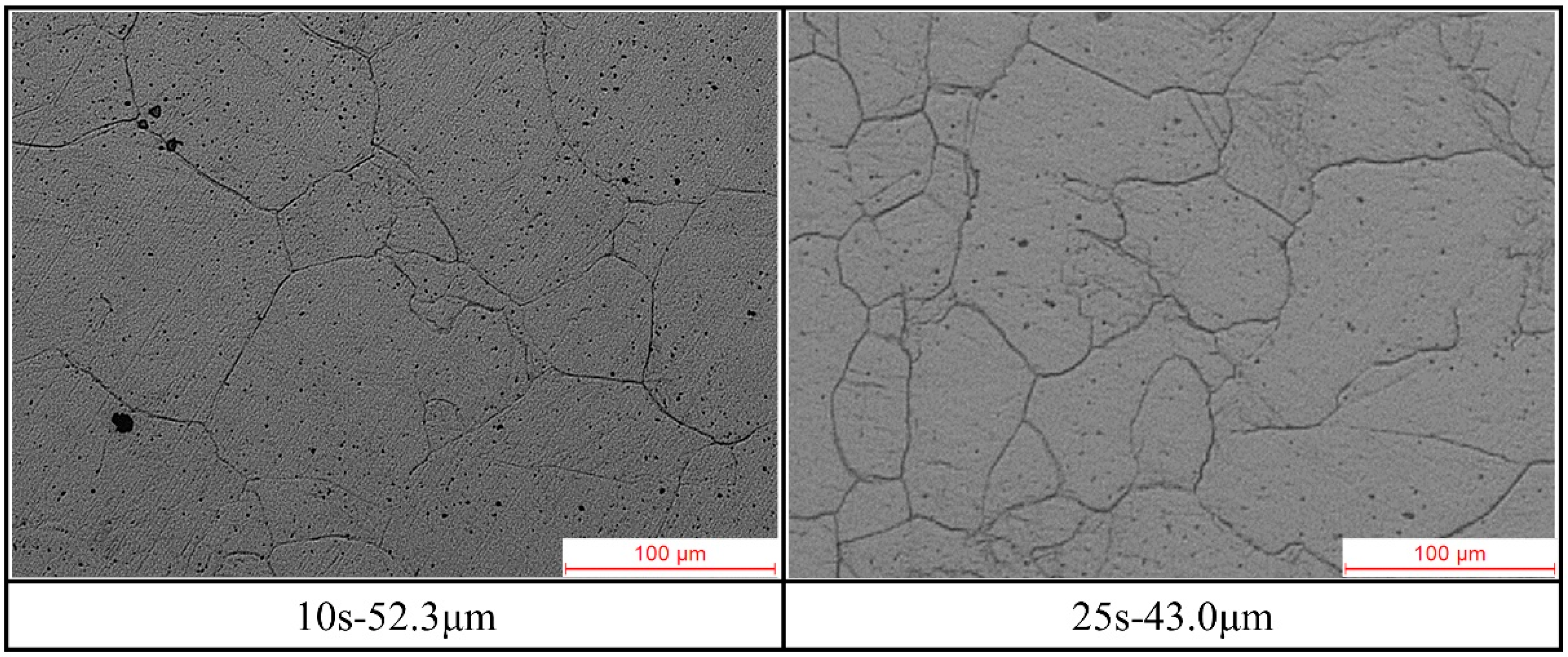

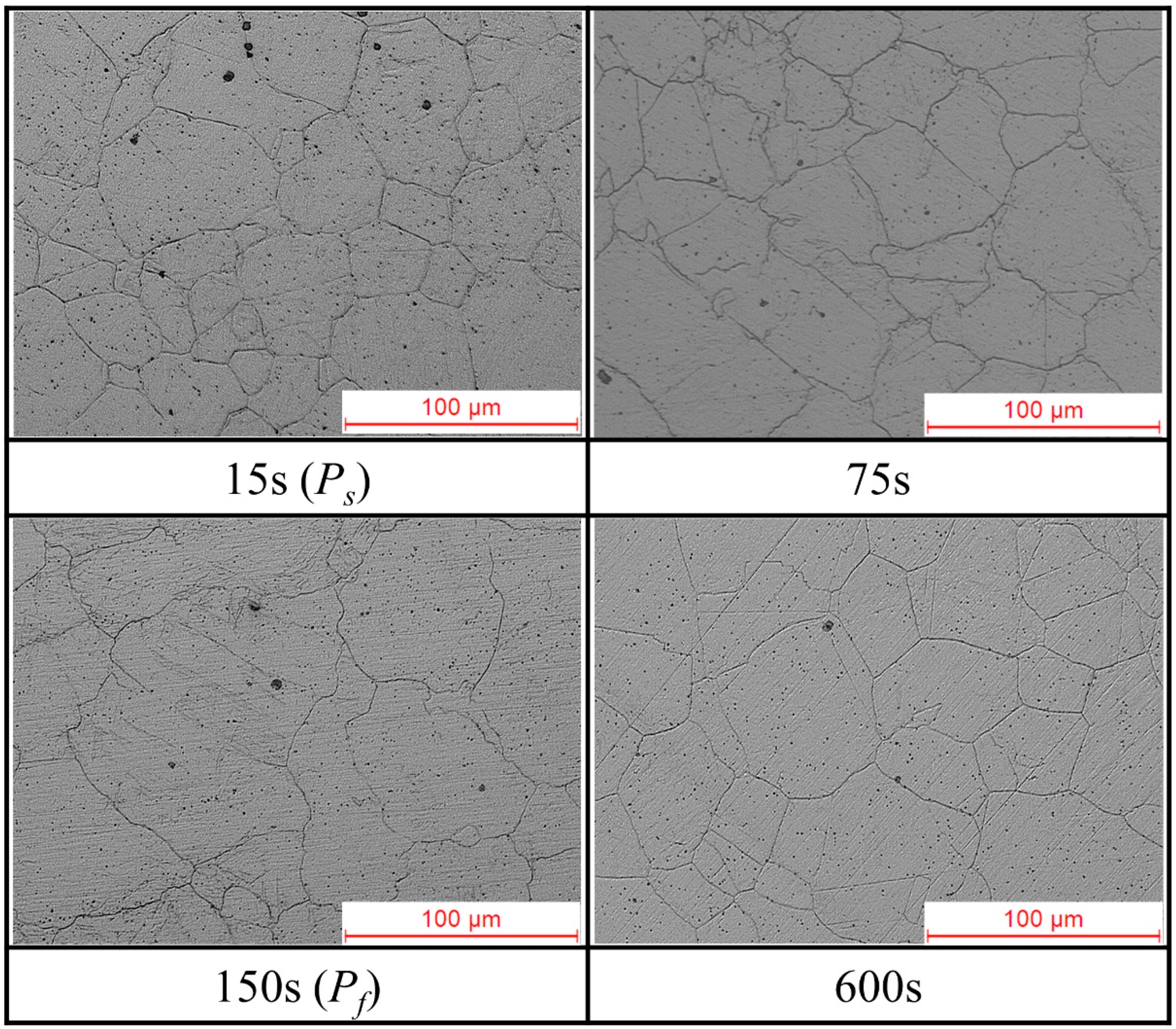

3.4. Evolution of Austenitic Microstructure

4. Discussion

4.1. Recrystallization-Precipitation-Time-Temperature Curve

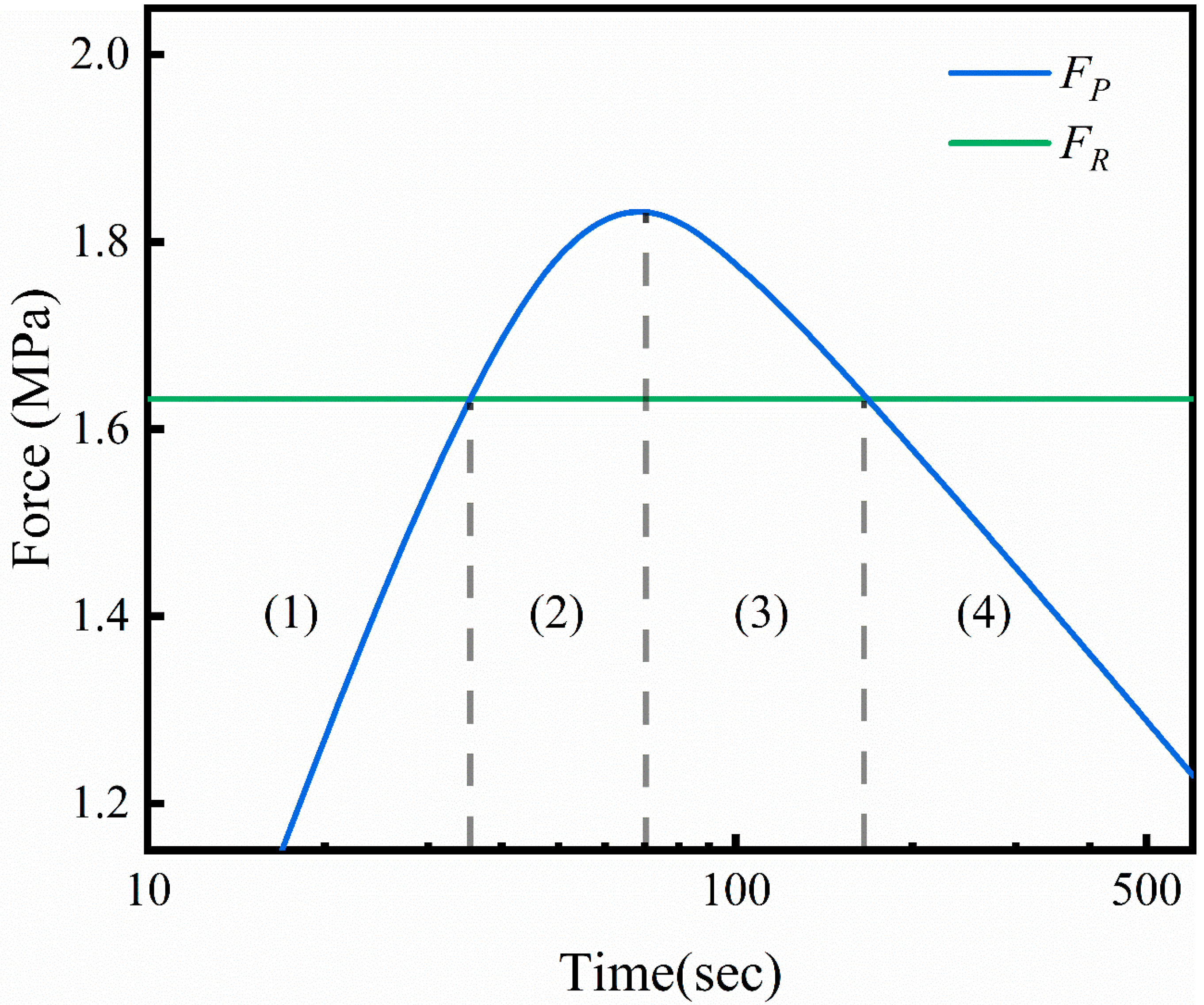

4.2. Recrystallization driving Force FR and Precipitation Pinning Force FP

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Villalobos, J.C.; Del-Pozo, A.; Campillo, B.; Mayen, J.; Serna, S. Microalloyed Steels through History until 2018: Review of Chemical Composition, Processing and Hydrogen Service. Metals 2018, 8, 351. [Google Scholar] [CrossRef] [Green Version]

- Nasiri, Z.; Ghaemifar, S.; Naghizadeh, M.; Mirzadeh, H. Thermal Mechanisms of Grain Refinement in Steels: A Review. Met. Mater. Int. 2021, 27, 2078–2094. [Google Scholar] [CrossRef]

- Vervynckt, S.; Verbeken, K.; Lopez, B.; Jonas, J.J. Modern HSLA steels and role of non-recrystallisation temperature. Int. Mater. Rev. 2012, 57, 187–207. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar]

- Kyzioł, K.; Kluska, S.; Januś, M.; Środa, M.; Jastrzębski, W.; Kaczmarek, L. Chemical composition and selected mechanical properties of Al–Zn alloy modified in plasma conditions by RF CVD. Appl. Surf. Sci. 2014, 311, 33–39. [Google Scholar] [CrossRef]

- Huo, X.; Xia, J.; Li, L.; Peng, Z.; Chen, S.; Peng, C. A review of research and development on titanium microalloyed high strength steels. Mater. Res. Express 2018, 5, 062002. [Google Scholar] [CrossRef]

- Xia, J.; Huo, X.; Li, L.; Peng, Z.; Chen, S. Development of Ti microalloyed high strength steel plate by controlling thermo-mechanical control process schedule. Mater. Res. Express 2017, 4, 126504. [Google Scholar] [CrossRef]

- Mao, X.; Huo, X.; Sun, X. Strengthening mechanisms of a new 700 MPa hot rolled Ti-microalloyed steel produced by compact strip production. J. Mater. Process. Technol. 2010, 210, 1660–1666. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Sun, X.; Yong, Q.; Yang, J.; Li, Y.; Zhao, P. Development of Ti–V–Mo Complex Microalloyed Hot-Rolled 900-MPa-Grade High-Strength Steel. Acta Metall. Sin. 2015, 28, 641–648. [Google Scholar] [CrossRef] [Green Version]

- Larzabal, G.; Isasti, N.; Rodriguez-Ibabe, J.M.; Uranga, P. Evaluating Strengthening and Impact Toughness Mechanisms for Ferritic and Bainitic Microstructures in Nb, Nb-Mo and Ti-Mo Microalloyed Steels. Metals 2017, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- Huo, X.; Li, L.; Peng, Z.; Chen, S. Effects of TMCP Schedule on Precipitation, Microstructure and Properties of Ti-microalloyed High Strength Steel. J. Iron. Steel Res. Int. 2016, 23, 593–601. [Google Scholar] [CrossRef]

- Zaitsev, A.; Arutyunyan, N. Low-Carbon Ti-Mo Microalloyed Hot Rolled Steels: Special Features of the Formation of the Structural State and Mechanical Properties. Metals 2021, 11, 1584. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, H.; Yang, Z.; Jiang, F. Decelerated Coarsening of (Ti, Mo)C Particles with a Core–Shell Structure in Austenite of a Ti-Mo-Bearing Steel. Metall. Mater. Trans. A 2018, 49, 1455–1459. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, X.; Yang, Z.; Yong, Q.; Zhang, C.; Li, Z.; Weng, Y. Carbide precipitation in austenite of a Ti–Mo-containing low-carbon steel during stress relaxation. Mater. Sci. Eng. A 2013, 573, 84–91. [Google Scholar] [CrossRef]

- Funakawa, Y.; Shiozaki, T.; Tomita, K.; Yamamoto, T.; Maeda, E. Development of High Strength Hot-rolled Sheet Steel Consisting of Ferrite and Nanometer-sized Carbides. ISIJ Int. 2004, 44, 1945–1951. [Google Scholar] [CrossRef]

- Andrade, H.L.; Akben, M.G.; Jonas, J.J. Effect of molybdenum, niobium, and vanadium on static recovery and recrystallization and on solute strengthening in microalloyed steels. Metall. Trans. A 1983, 14, 1967–1977. [Google Scholar] [CrossRef]

- Wang, Z.; Mao, X.; Yang, Z.; Sun, X.; Yong, Q.; Li, Z.; Weng, Y. Strain-induced precipitation in a Ti micro-alloyed HSLA steel. Mater. Sci. Eng. A 2011, 529, 459–467. [Google Scholar] [CrossRef]

- Liu, W.J.; Jonas, J.J. A stress relaxation method for following carbonitride precipitation in austenite at hot working temperatures. Metall. Trans. A 1988, 19, 1403–1413. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Peng, Z.; Huo, X.; Gao, J. Strain-induced precipitation in Ti microalloyed steel by two-stage controlled rolling process. J. Mater. Res. Technol. 2020, 9, 15759–15770. [Google Scholar] [CrossRef]

- Huo, X.; Lv, Z.; Ao, C.; Li, L.; Xia, J.; Chen, S. Effect of strain-induced precipitation on microstructure and properties of titanium micro-alloyed steels. J. Iron Steel Res. Int. 2022, 29, 983–993. [Google Scholar] [CrossRef]

- Jung, J.-G.; Park, J.-S.; Kim, J.; Lee, Y.-K. Carbide precipitation kinetics in austenite of a Nb–Ti–V microalloyed steel. Mater. Sci. Eng. A 2011, 528, 5529–5535. [Google Scholar] [CrossRef]

- Liu, W.J. A Review of the Stress-Relaxation Method for Following the Kinetics of Precipitation, Recovery and Recrystallization. Mater. Sci. Forum 2012, 706–709, 2758–2763. Available online: www.scientific.net/MSF.706-709.2758 (accessed on 1 November 2022).

- Kwon, O.; DeArdo, A.J. Interactions between recrystallization and precipitation in hot-deformed microalloyed steels. Acta Metall. Mater. 1991, 39, 529–538. [Google Scholar] [CrossRef]

- Medina, S.F.; Quispe, A. Static Recrystallisation-Precipitation Interaction in Microalloyed Steels. Mater. Sci. Forum 2003, 426–432, 1139–1144. Available online: www.scientific.net/MSF.426-432.1139 (accessed on 1 November 2022).

- Jian, Z.; Kang, Y.; Mao, X.; Lin, Z.; Li, L. Effect of Ti on the mechanical properties of high strength weathering steel. J. Univ. Sci. Technol. B 2006, 28, 926–930. [Google Scholar]

- Yang, Z.; Enomoto, M. Calculation of the interfacial energy of B1-type carbides and nitrides with austenite. Metall. Mater. Trans. A 2001, 32, 267–274. [Google Scholar] [CrossRef]

- Fujiyama, N.; Nishibata, T.; Seki, A.; Hirata, H.; Kojima, K.; Ogawa, K. Austenite grain growth simulation considering the solute-drag effect and pinning effect. Sci. Technol. Adv. Mater. 2017, 18, 88–95. [Google Scholar] [CrossRef]

- Goins, P.E.; Frazier, W.E. A model of grain boundary complexion transitions and grain growth in Yttria-doped alumina. Acta Mater. 2020, 188, 79–91. [Google Scholar] [CrossRef]

- Gong, P.; Palmiere, E.J.; Rainforth, W.M. Characterisation of strain-induced precipitation behaviour in microalloyed steels during thermomechanical controlled processing. Mater. Charact. 2017, 124, 83–89. [Google Scholar] [CrossRef]

- Medina, S.; Quispe, A. Improved Model for Static Recrystallization Kinetics of Hot Deformed Austenite in Low Alloy and Nb/V Microalloyed Steels. ISIJ Int. 2001, 41, 774–781. [Google Scholar] [CrossRef]

- Gómez, M.; Rancel, L.; Fernández, B.J.; Medina, S.F. Evolution of austenite static recrystallization and grain size during hot rolling of a V-microalloyed steel. Mater. Sci. Eng. A 2009, 501, 188–196. [Google Scholar] [CrossRef] [Green Version]

- Beck, P.A.; Sperry, P.R.; Hu, H. The Orientation Dependence of the Rate of Grain Boundary Migration. J. Appl. Phys. 1950, 21, 420–425. [Google Scholar] [CrossRef]

- Gómez, M.; Medina, S.F.; Chaves, J.I. Static Recrystallization of Austenite in a Medium-Carbon Vanadium Microalloyed Steel and Inhibition by Strain-Induced Precipitates. Mater. Sci. Forum 2007, 550, 417–422. Available online: www.scientific.net/MSF.550.417 (accessed on 1 November 2022).

- Zener, C. Theory of Growth of Spherical Precipitates from Solid Solution. J. Appl. Phys. 1949, 20, 950–953. [Google Scholar] [CrossRef]

- Vervynckt, S.; Verbeken, K.; Thibaux, P.; Houbaert, Y. Recrystallization–precipitation interaction during austenite hot deformation of a Nb microalloyed steel. Mater. Sci. Eng. A 2011, 528, 5519–5528. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | S | P | N | Ti | dγ |

|---|---|---|---|---|---|---|---|---|

| Ti | 0.061 | 0.28 | 1.61 | 0.047 | 0.0030 | 0.0029 | 0.11 | 58 |

| Xr | 860 °C | 880 °C | 900 °C | 920 °C | 940 °C | 960 °C |

|---|---|---|---|---|---|---|

| 5% | 66.8 | 43.3 | 28.5 | 19.0 | 12.8 | 8.8 |

| 50% | 152.6 | 97.1 | 62.7 | 41.1 | 27.4 | 18.4 |

| 75% | 372.3 | 232.1 | 147.1 | 94.7 | 61.9 | 41.1 |

| Parameter | fe | C | q |

|---|---|---|---|

| Value | 0.0013 | 0.0070 | 1.3395 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Huo, X.; Li, L.; Chen, S.; Lu, C. Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel. Metals 2022, 12, 1920. https://doi.org/10.3390/met12111920

Zhang Q, Huo X, Li L, Chen S, Lu C. Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel. Metals. 2022; 12(11):1920. https://doi.org/10.3390/met12111920

Chicago/Turabian StyleZhang, Qifan, Xiangdong Huo, Liejun Li, Songjun Chen, and Chao Lu. 2022. "Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel" Metals 12, no. 11: 1920. https://doi.org/10.3390/met12111920

APA StyleZhang, Q., Huo, X., Li, L., Chen, S., & Lu, C. (2022). Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel. Metals, 12(11), 1920. https://doi.org/10.3390/met12111920