Effect of Ho Substitution on Magnetic Properties and Microstructure of Nanocrystalline Nd-Pr-Fe-B Alloys

Abstract

1. Introduction

2. Experimental

3. Results and discussion

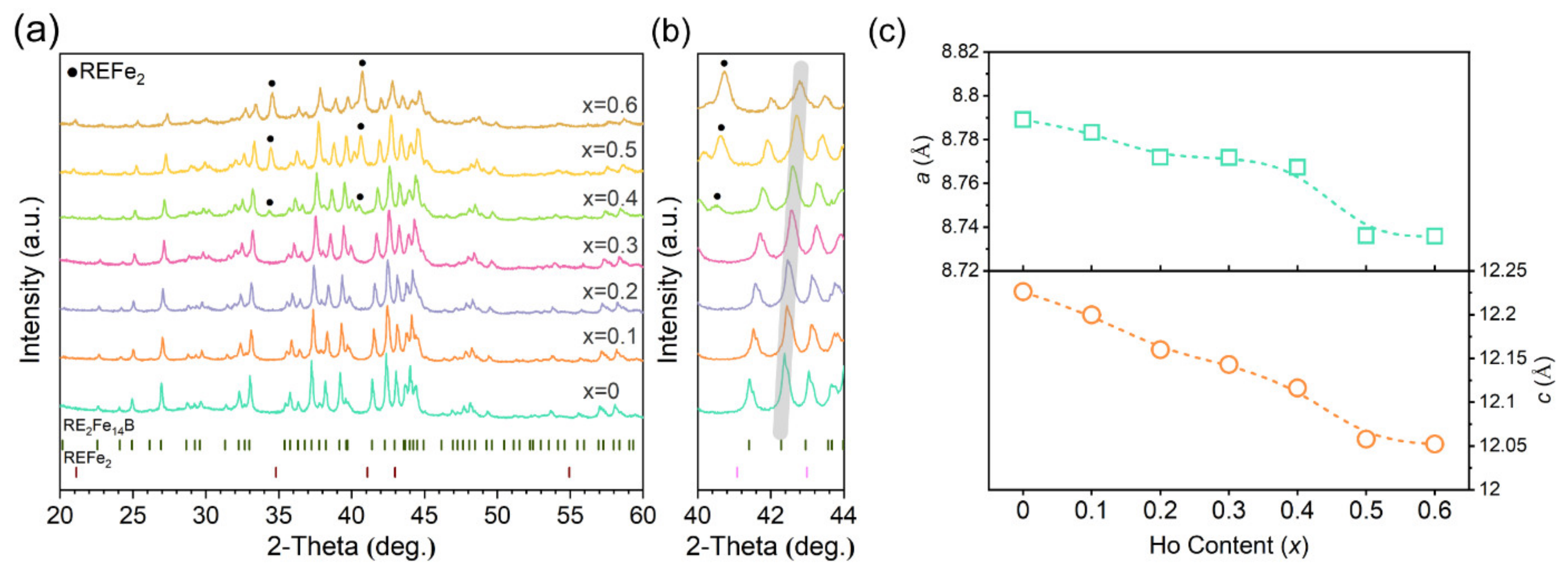

3.1. Phase Constitution

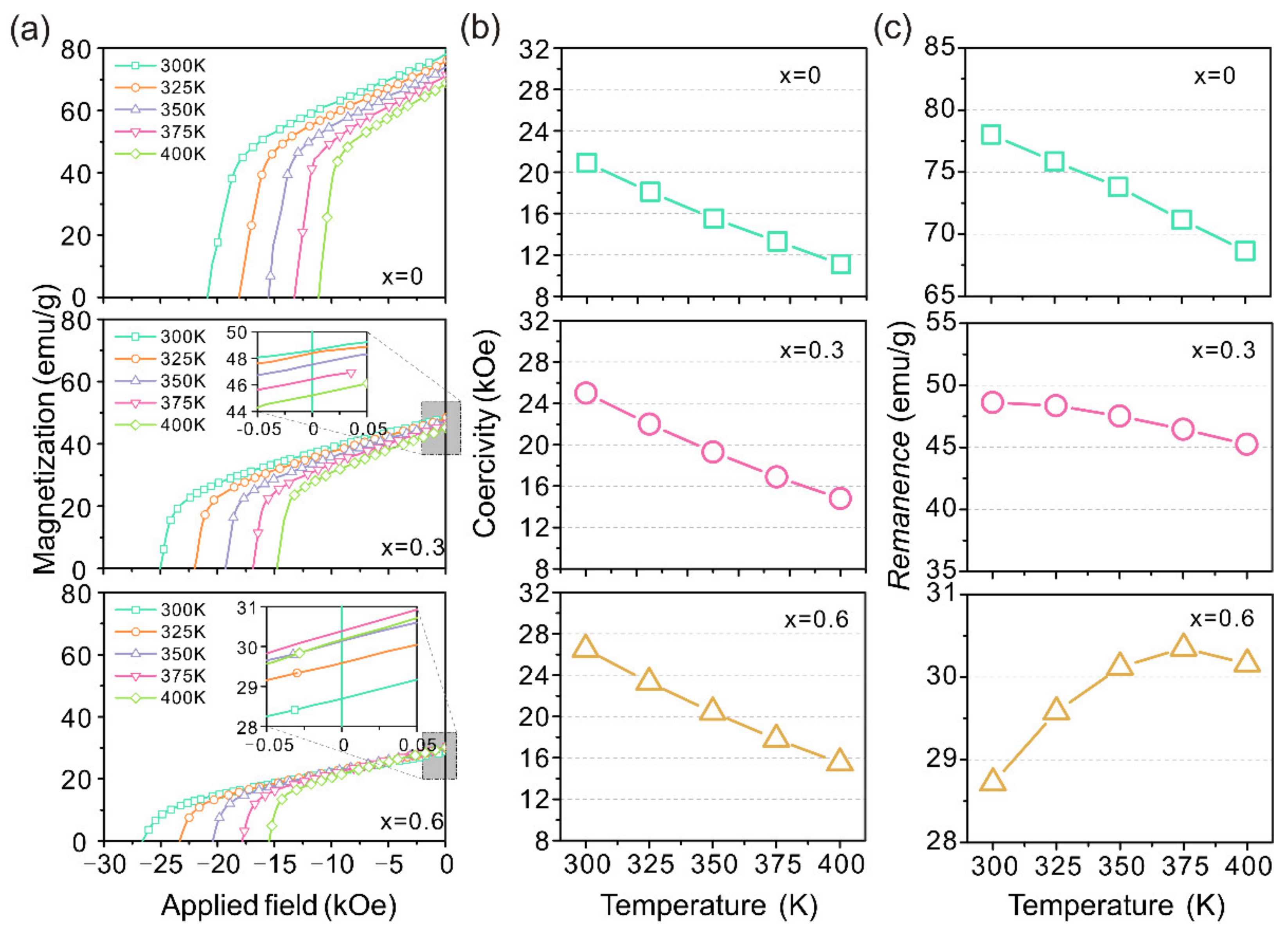

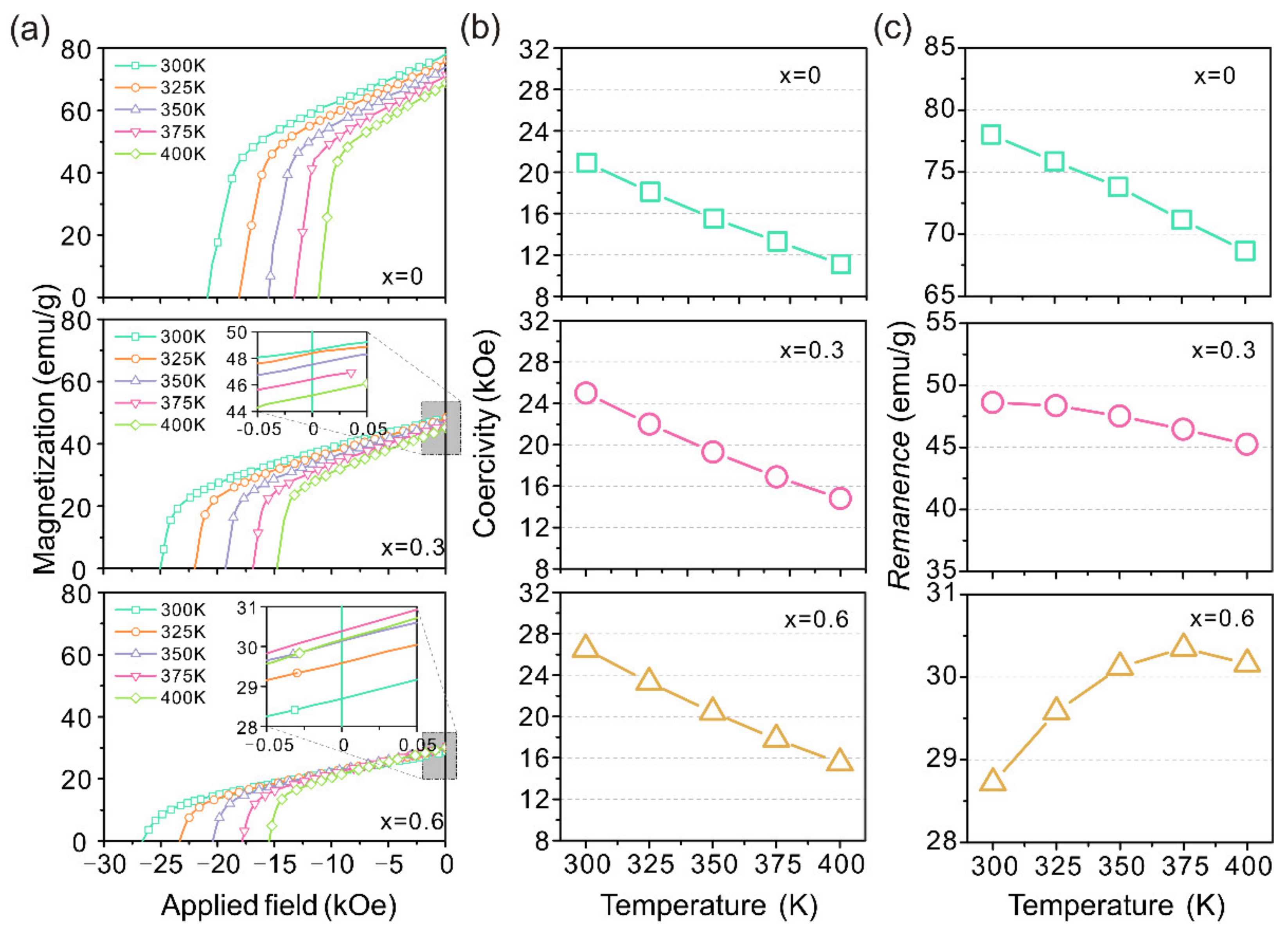

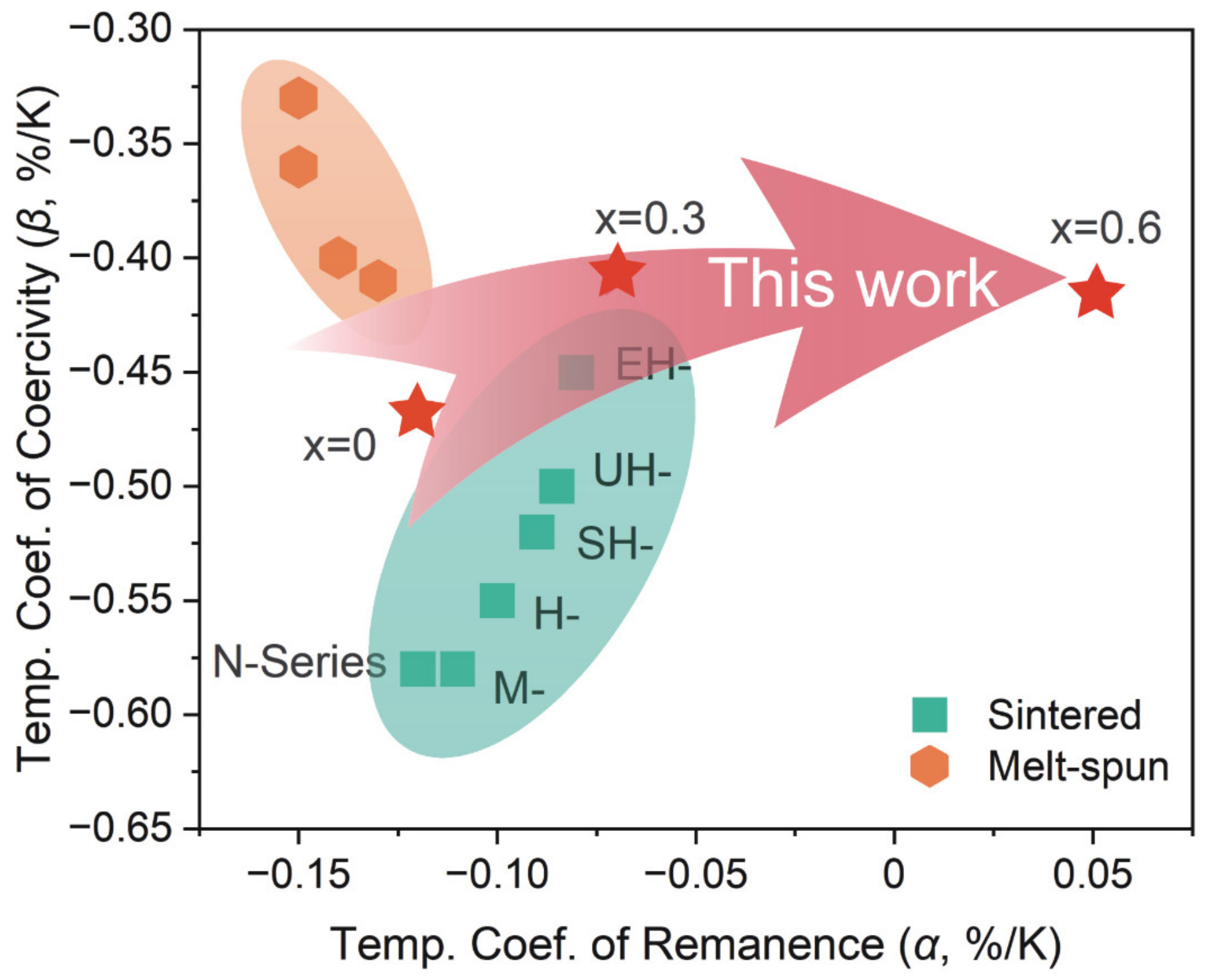

3.2. Magnetic Properties

3.3. Microstructure

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Coey, J.M.D. Perspective and Prospects for Rare Earth Permanent Magnets. Engineering 2020, 6, 119–131. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Bruck, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef] [PubMed]

- Hono, K.; Sepehri-Amin, H. Prospect for HRE-free high coercivity Nd-Fe-B permanent magnets. Scr. Mater. 2018, 151, 6–13. [Google Scholar] [CrossRef]

- Hono, K.; Sepehri-Amin, H. Strategy for high-coercivity Nd–Fe–B magnets. Scr. Mater. 2012, 67, 530–535. [Google Scholar] [CrossRef]

- Li, J.; Tang, X.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Hono, K. On the temperature-dependent coercivities of anisotropic Nd-Fe-B magnet. Acta Mater. 2020, 199, 288–296. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, Z.W.; Zhong, X.C.; Zhang, G.Q. Properties improvement and structural optimization of sintered NdFeB magnets by non-rare earth compound grain boundary diffusion. Mater. Des. 2015, 86, 114–120. [Google Scholar] [CrossRef]

- Wang, E.H.; Peng, L.X.; Chen, P.Y.; Wang, M.; Zeng, W.W.; Xiao, C.H.; Lu, C.F.; Tang, R.H.; Zheng, Z.G.; Zhou, Q. Microstructure evolution and coercivity enhancement in Nd-Zn alloy-doped Nd-Fe-B powders. J. Magn. Magn. Mater. 2022, 556, 169427. [Google Scholar] [CrossRef]

- Liu, J.; Sepehri-Amin, H.; Ohkubo, T.; Hioki, K.; Hattori, A.; Schrefl, T.; Hono, K. Grain size dependence of coercivity of hot-deformed Nd–Fe–B anisotropic magnets. Acta Mater. 2015, 82, 336–343. [Google Scholar] [CrossRef]

- Hirosawa, S.; Matsuura, Y.; Yamamoto, H.; Fujimura, S.; Sagawa, M.; Yamauchi, H. Single Crystal Measurements of Anisotropy Constants of R2Fe14B (R= Y, Ce, Pr, Nd, Gd, Tb, Dy and Ho). Jpn. J. Appl. Phys. 1985, 24, L803–L805. [Google Scholar] [CrossRef]

- Liang, L.; Ma, T.; Wu, C.; Zhang, P.; Liu, X.; Yan, M. Coercivity enhancement of Dy-free Nd–Fe–B sintered magnets by intergranular adding Ho63.4Fe36.6 alloy. J. Magn. Magn. Mater. 2016, 397, 139–144. [Google Scholar] [CrossRef]

- Hirosawa, S.; Matsuura, Y.; Yamamoto, H.; Fujimura, S.; Sagawa, M.; Yamauchi, H. Magnetization and Magnetic-Anisotropy of R2Fe14B Measured on Single-Crystals. J. Appl. Phys. 1986, 59, 873–879. [Google Scholar] [CrossRef]

- Brown, D.N.; Lau, D.; Chen, Z. Substitution of Nd with other rare earth elements in melt spun Nd2Fe14B magnets. AIP Adv. 2016, 6, 056019. [Google Scholar] [CrossRef]

- Li, S.; Zhou, B.; Liao, X.; Liu, Z. Tuning the hard magnetic properties of nanocrystalline Ce-Fe-B alloys by Ho substitution. Mater. Lett. 2022, 323, 132569. [Google Scholar] [CrossRef]

- Tokunaga, M.; Nozawa, Y.; Iwasaki, K. Ga added Nd-Fe-B sintered and die-upset magnets. IEEE Trans. Magn. 1989, 25, 3561–3566. [Google Scholar] [CrossRef]

- Strzeszewski, J.; Hadjipanayis, G.; Kim, A. The effect of Al substitution on the coercivity of Nd-Fe-B magnets. J. Appl. Phys. 1988, 64, 5568–5570. [Google Scholar] [CrossRef]

- Fuerst, C.; Brewer, E.; Mishra, R. Die-upset Pr-Fe-B-type magnets from melt-spun ribbons. J. Appl. Phys. 1994, 75, 4208–4213. [Google Scholar] [CrossRef]

- Kwon, H.; Yu, J. Effect of Cu-Addition and Die-Upset Temperature on Texture in Die-Upset Nd-Lean Nd-Fe-B Alloys. J. Magn. 2010, 15, 32–35. [Google Scholar] [CrossRef][Green Version]

- Coey, J.M.D.; Parkin, S.S.P. Handbook of Magnetism and Magnetic Materials; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Wang, E.H.; Xiao, C.H.; He, J.Y.; Lu, C.F.; Hussain, M.; Tang, R.H.; Zhou, Q.; Liu, Z.W. Grain boundary modification and properties enhancement of sintered Nd-Fe-B magnets by ZnO solid diffusion. Appl. Surf. Sci. 2021, 565, 150545. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, Y.Q.; Kramer, M.J.; Smith, B.R.; Ma, B.-M.; Huang, M.-Q. A study on the role of Nb in melt-spun nanocrystalline Nd–Fe–B magnets. J. Magn. Magn. Mater. 2004, 268, 105–113. [Google Scholar] [CrossRef]

- Li, R.; Shang, R.X.; Xiong, J.F.; Liu, D.; Kuang, H.; Zuo, W.L.; Zhao, T.Y.; Sun, J.R.; Shen, B.G. Magnetic properties of (misch metal, Nd)-Fe-B melt-spun magnets. AIP Adv. 2017, 7, 056207. [Google Scholar] [CrossRef]

- Temperature Effects on Neodymium Iron Boron, Ndfeb, Magnets. Available online: https://e-magnetsuk.com/introduction-to-neodymium-magnets/temperature-ratings/ (accessed on 20 September 2022).

- Liao, X.F.; Zhao, L.Z.; Zhang, J.S.; Zhong, X.C.; Jiao, D.L.; Liu, Z.W. Enhanced formation of 2:14:1 phase in La-based rare earth-iron-boron permanent magnetic alloys by Nd substitution. J. Magn. Magn. Mater. 2018, 464, 31–35. [Google Scholar] [CrossRef]

- Liao, X.F.; Zhang, J.S.; He, J.Y.; Fan, W.B.; Yu, H.Y.; Zhong, X.C.; Liu, Z.W. Development of cost-effective nanocrystalline multi-component (Ce,La,Y)-Fe-B permanent magnetic alloys containing no critical rare earth elements of Dy, Tb, Pr and Nd. J. Mater. Sci. Technol. 2021, 76, 215–221. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, C.; Zeng, W.; Tang, Y.; Lu, C.; Tang, R.; Zheng, Z.; Liao, X.; Zhou, Q. Effect of Ho Substitution on Magnetic Properties and Microstructure of Nanocrystalline Nd-Pr-Fe-B Alloys. Metals 2022, 12, 1922. https://doi.org/10.3390/met12111922

Xiao C, Zeng W, Tang Y, Lu C, Tang R, Zheng Z, Liao X, Zhou Q. Effect of Ho Substitution on Magnetic Properties and Microstructure of Nanocrystalline Nd-Pr-Fe-B Alloys. Metals. 2022; 12(11):1922. https://doi.org/10.3390/met12111922

Chicago/Turabian StyleXiao, Caihai, Weiwei Zeng, Yongli Tang, Cifu Lu, Renheng Tang, Zhigang Zheng, Xuefeng Liao, and Qing Zhou. 2022. "Effect of Ho Substitution on Magnetic Properties and Microstructure of Nanocrystalline Nd-Pr-Fe-B Alloys" Metals 12, no. 11: 1922. https://doi.org/10.3390/met12111922

APA StyleXiao, C., Zeng, W., Tang, Y., Lu, C., Tang, R., Zheng, Z., Liao, X., & Zhou, Q. (2022). Effect of Ho Substitution on Magnetic Properties and Microstructure of Nanocrystalline Nd-Pr-Fe-B Alloys. Metals, 12(11), 1922. https://doi.org/10.3390/met12111922