Characterization of Hot Workability in AISI 4340 Based on a 3D Processing Map

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

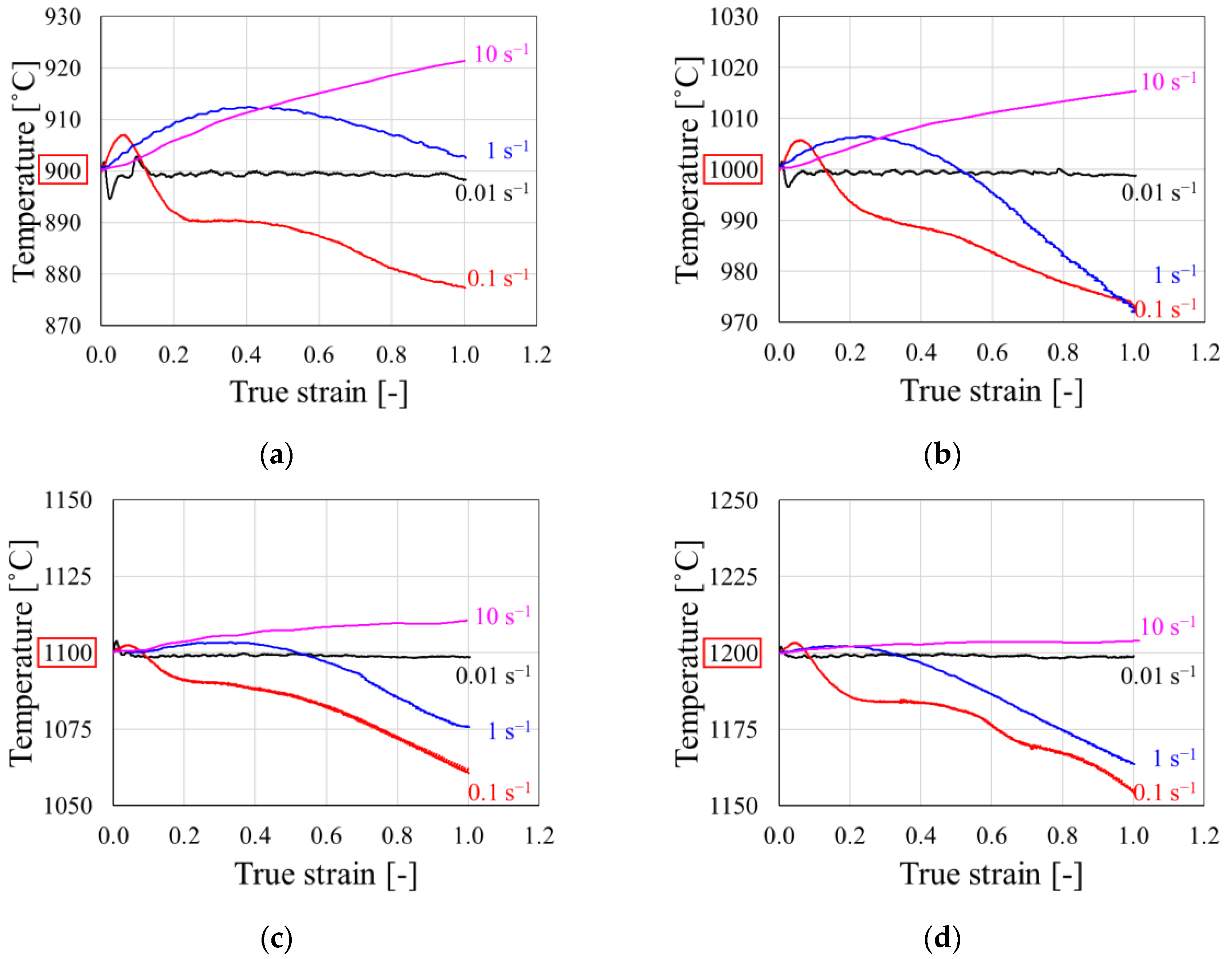

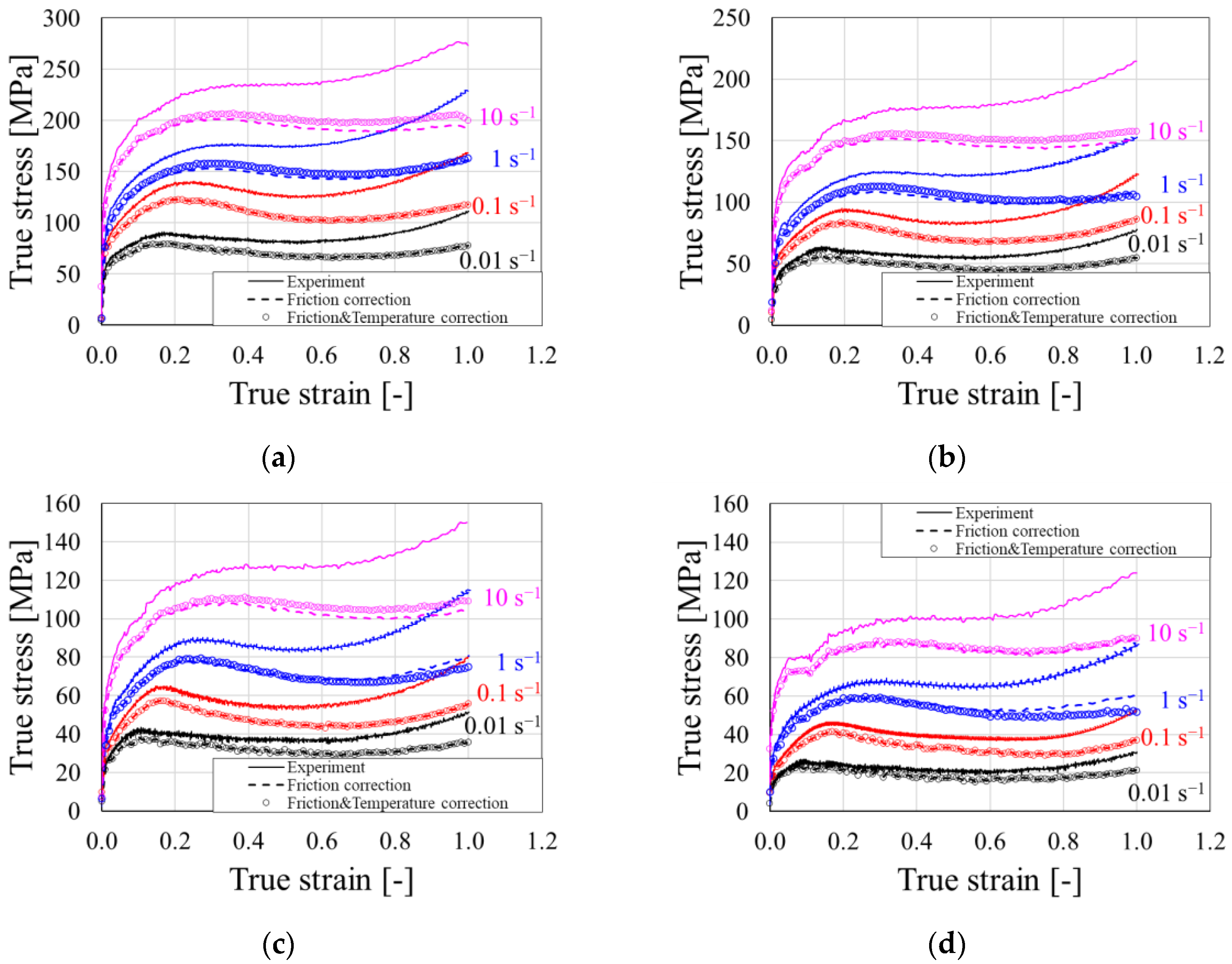

3.1. Friction and Temperature Correction

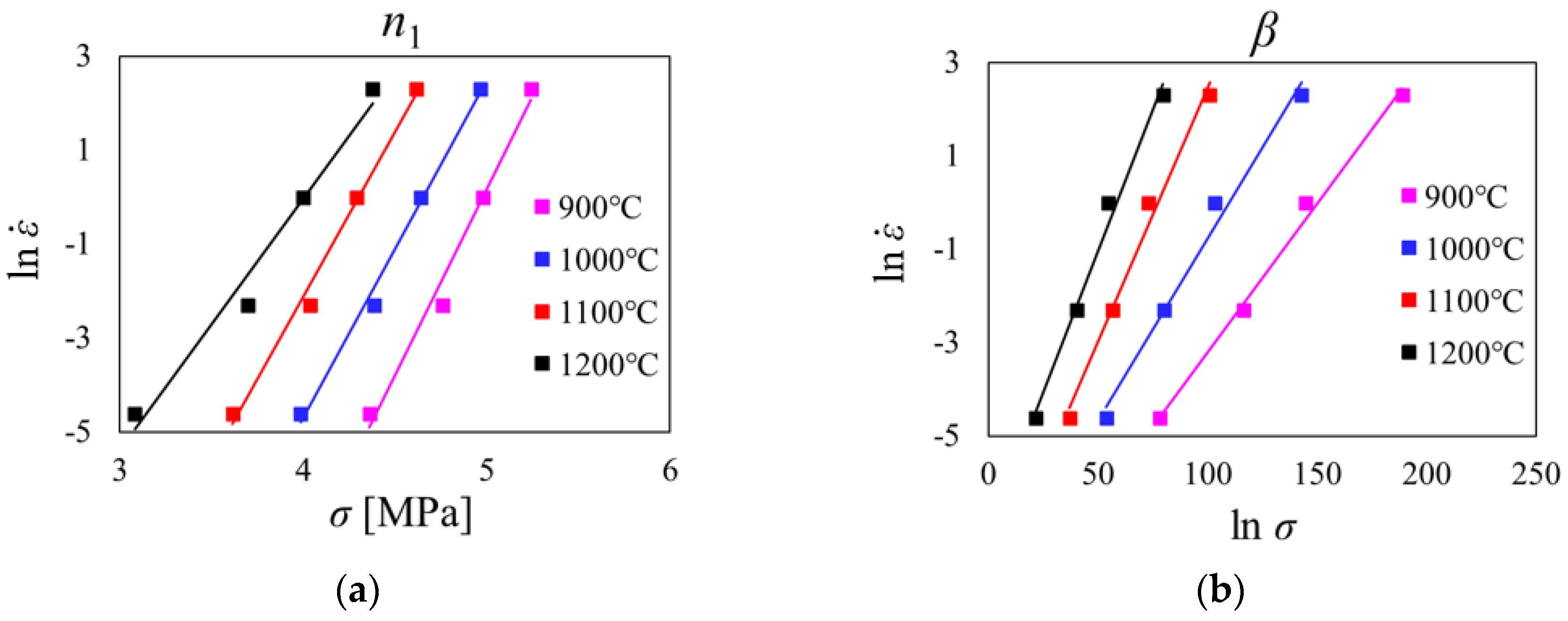

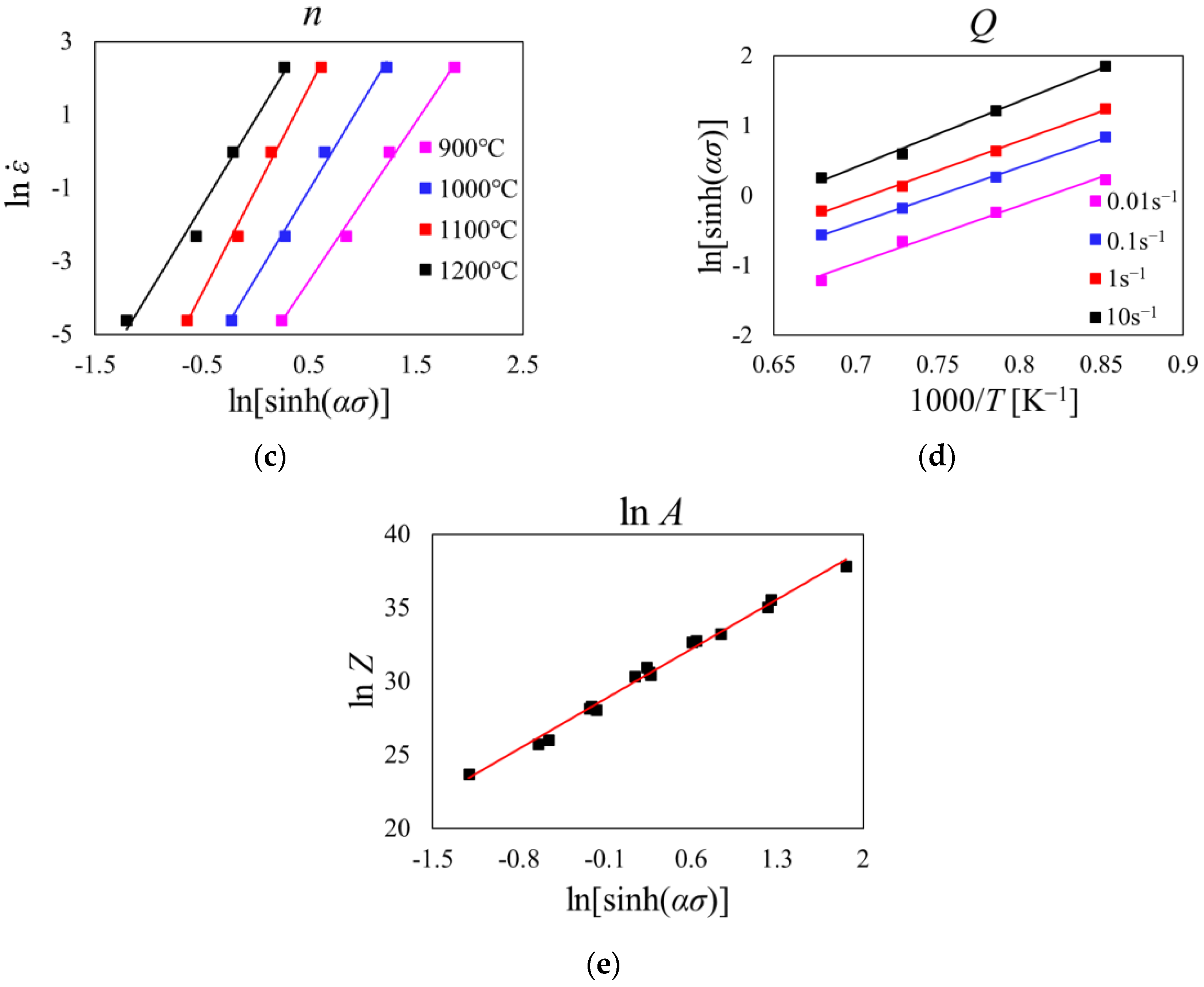

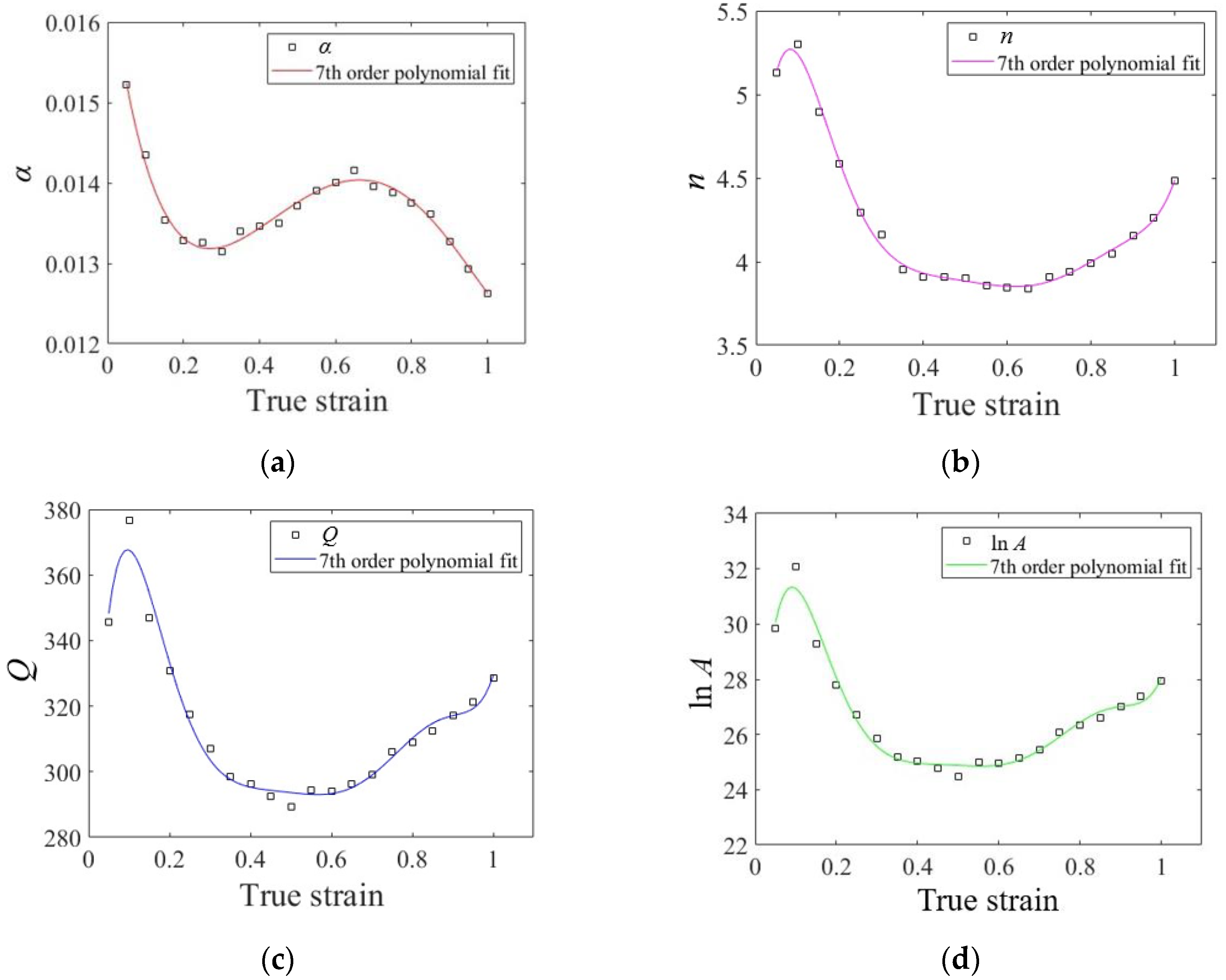

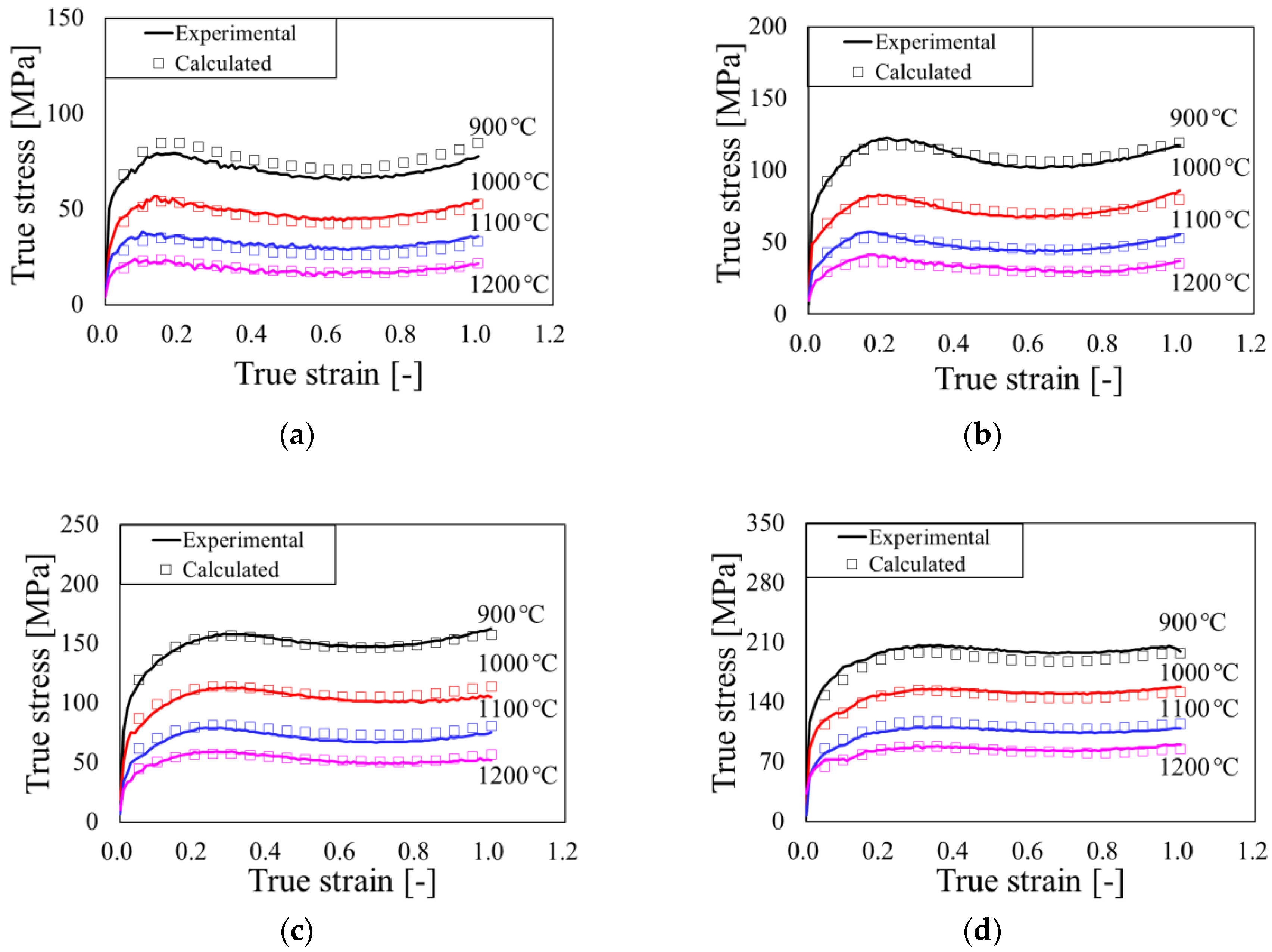

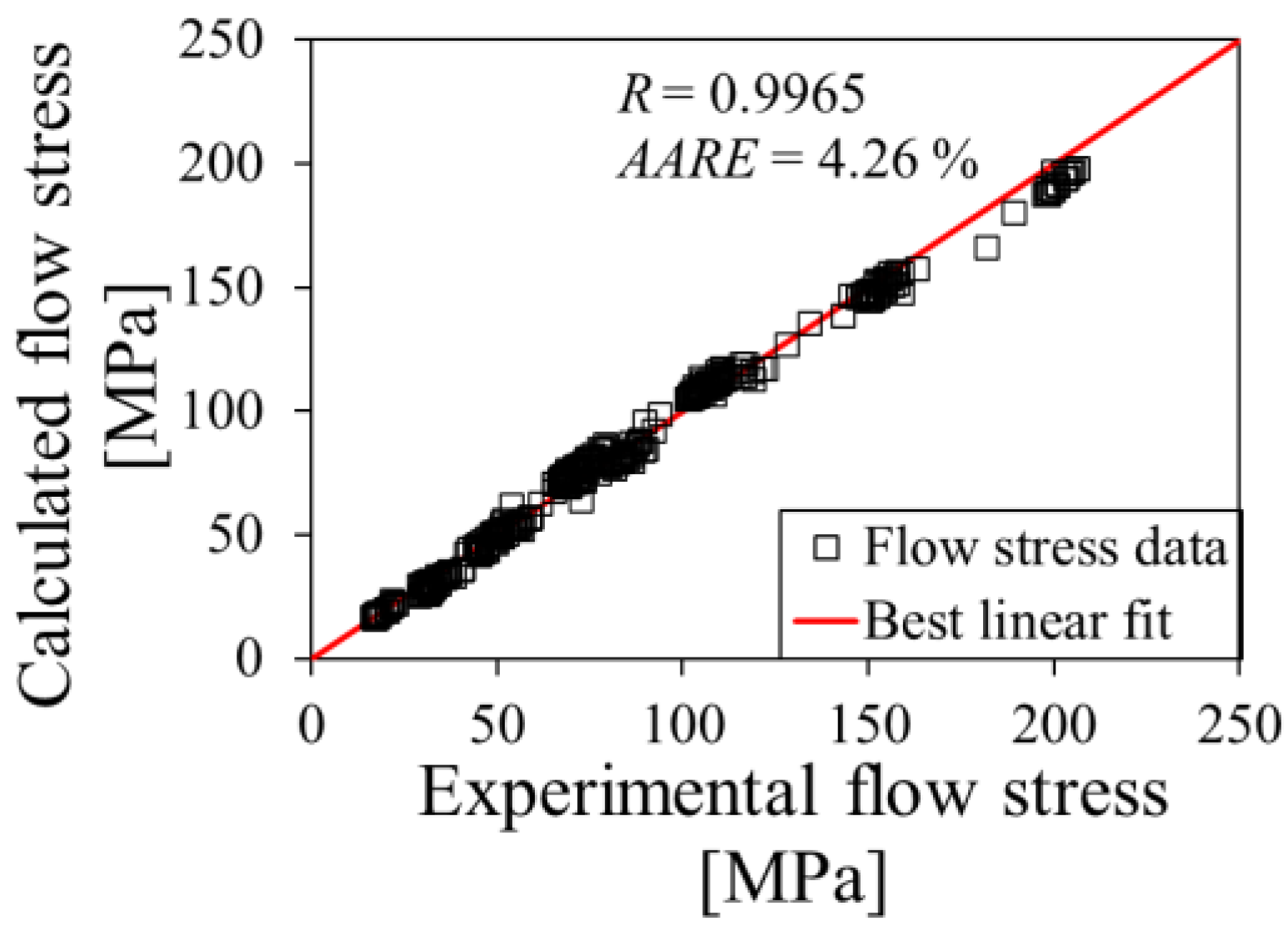

3.2. Derivation of Arrhenius Constitutive Equation

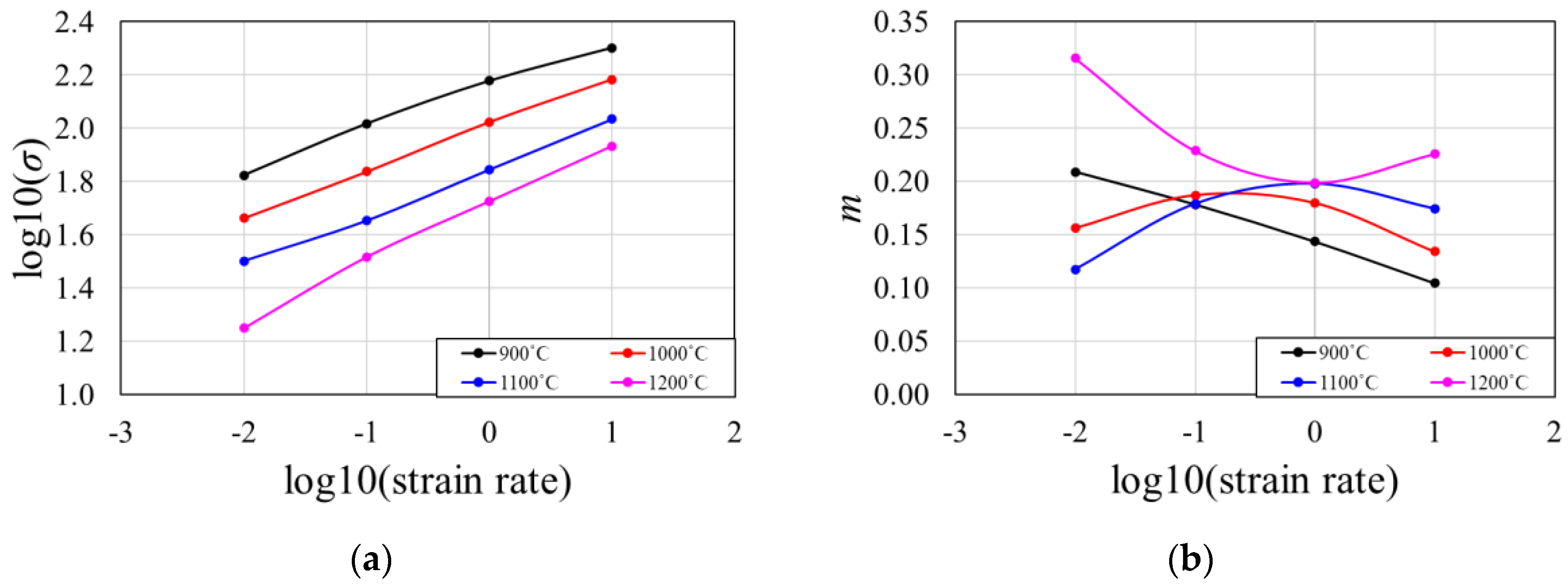

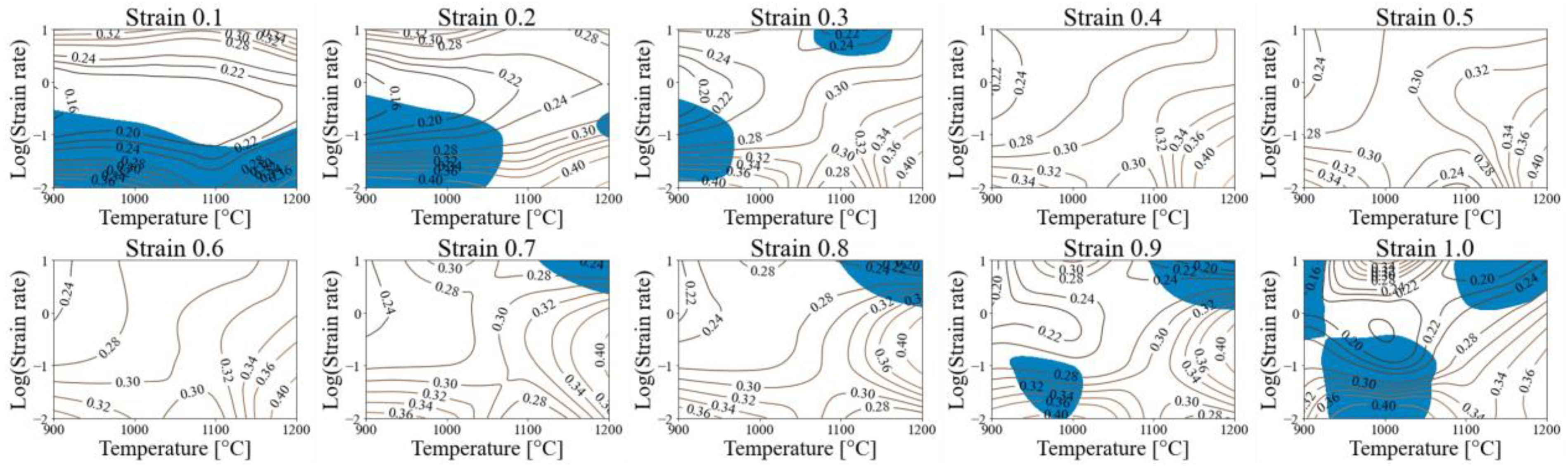

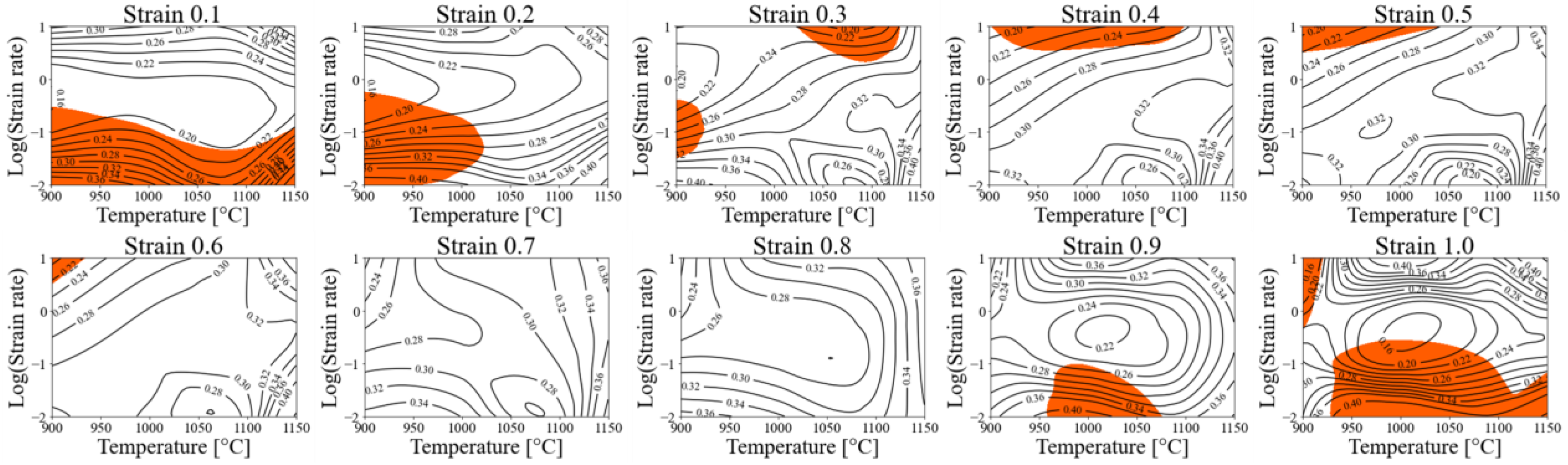

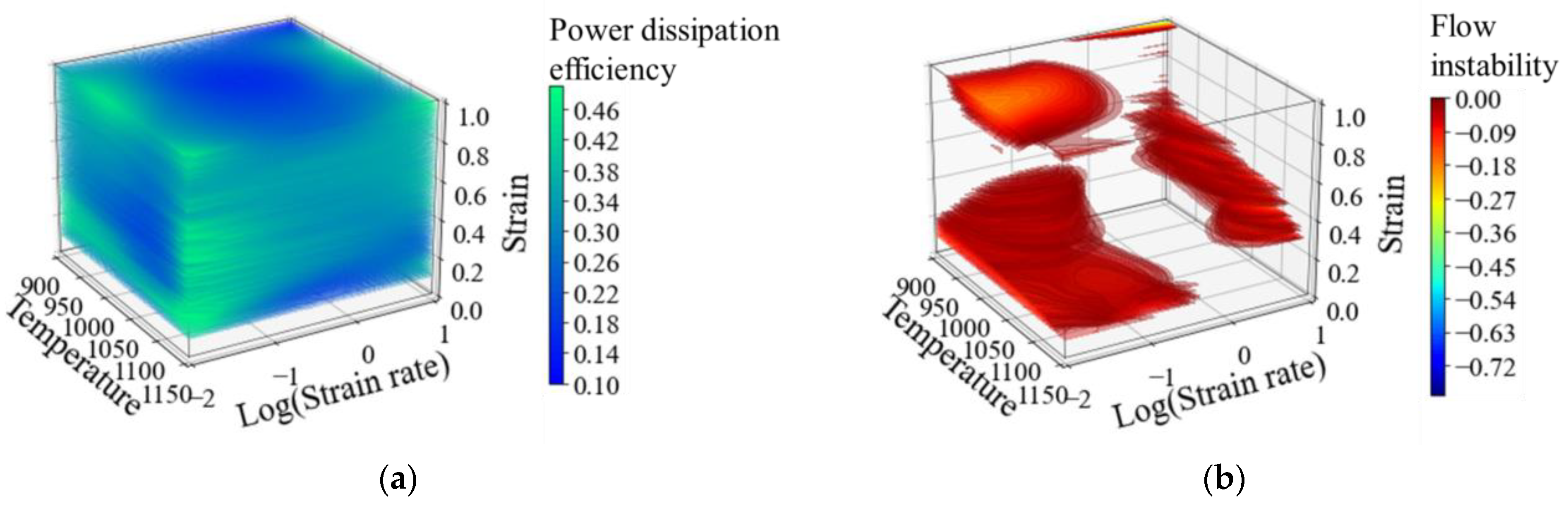

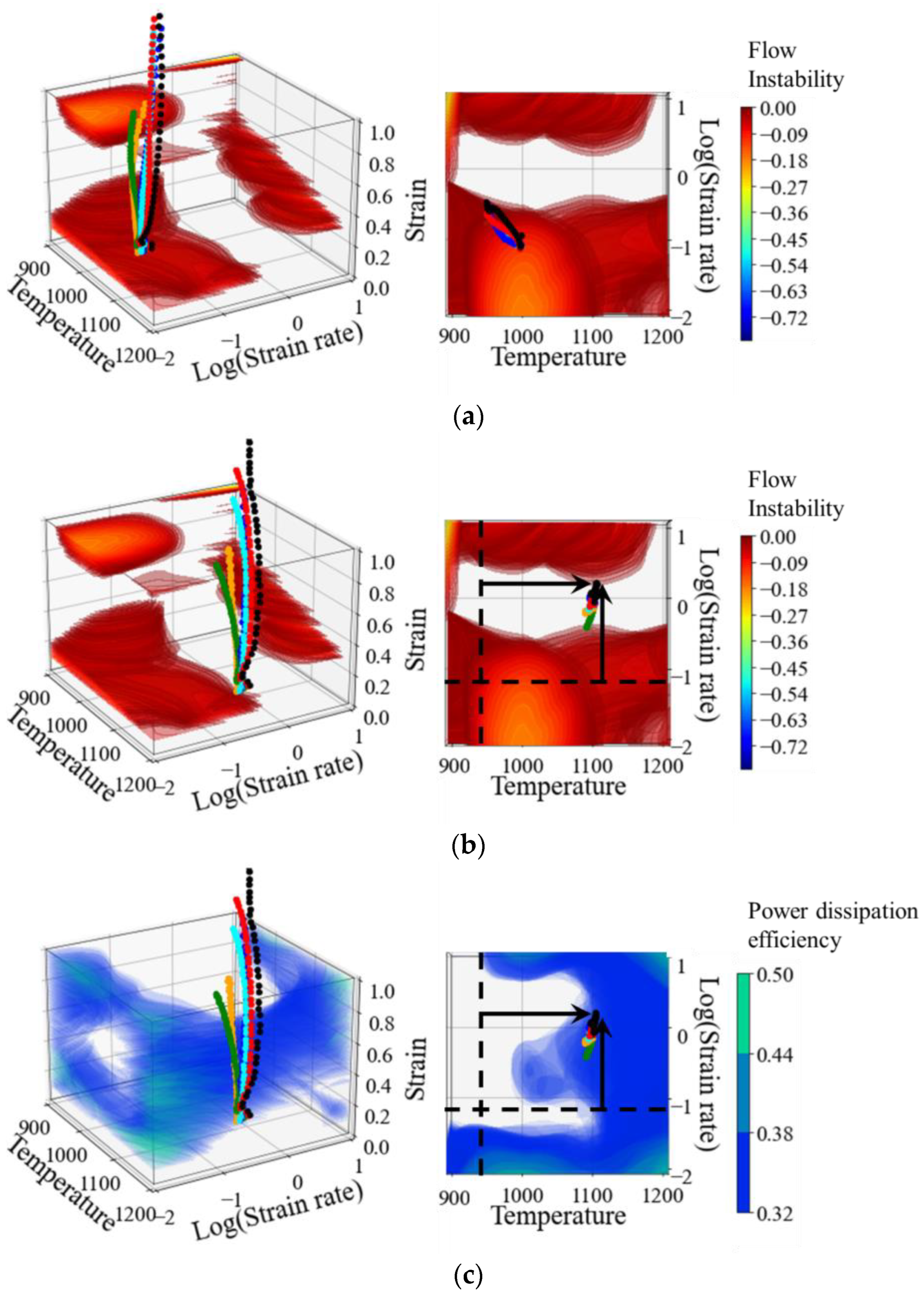

3.3. Processing Map

3.3.1. Processing Map Theory

3.3.2. Analysis of Processing Map

3.4. Hot Forging Process Temperature and Speed Controls Based on a 3D Processing Map

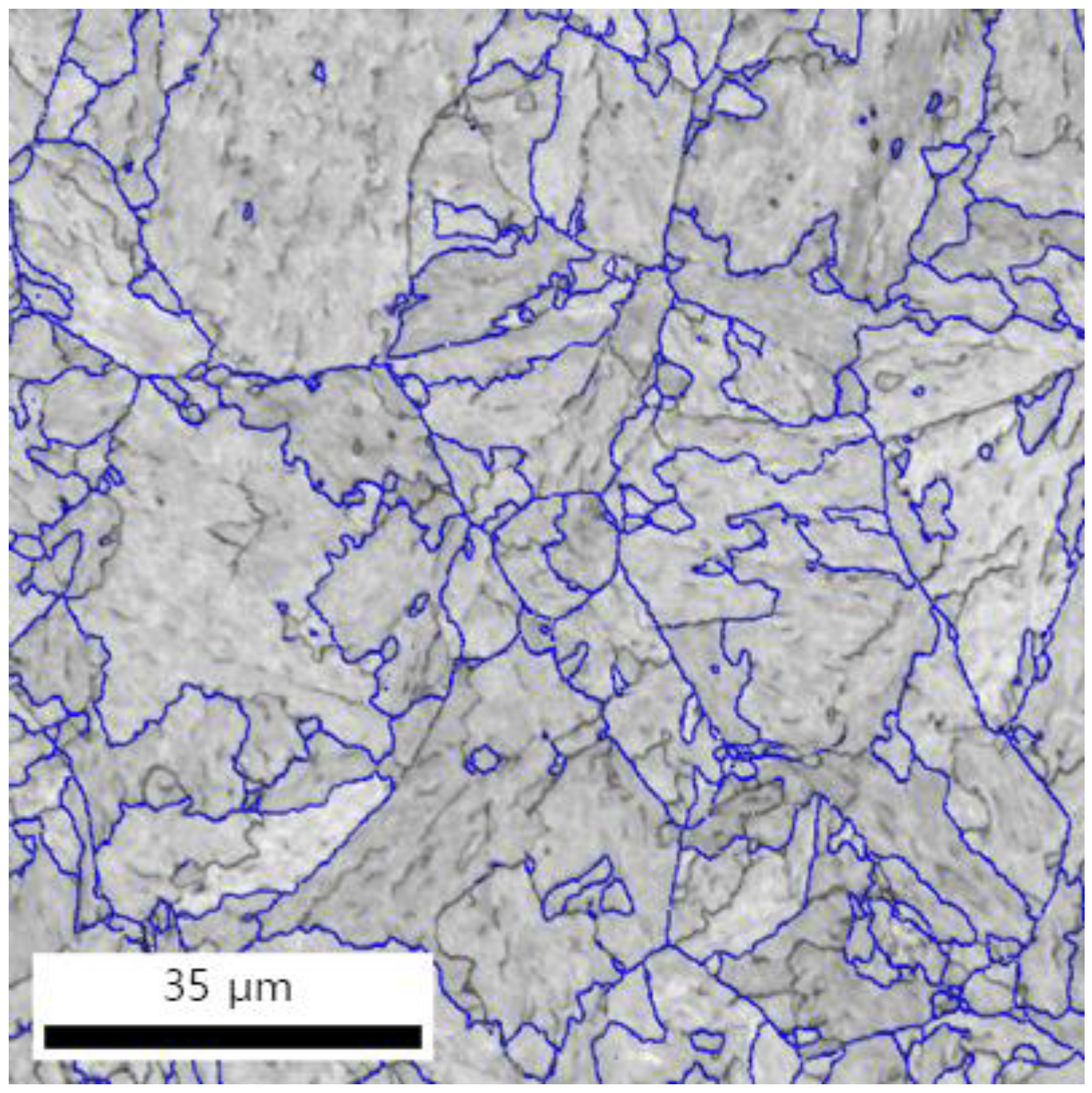

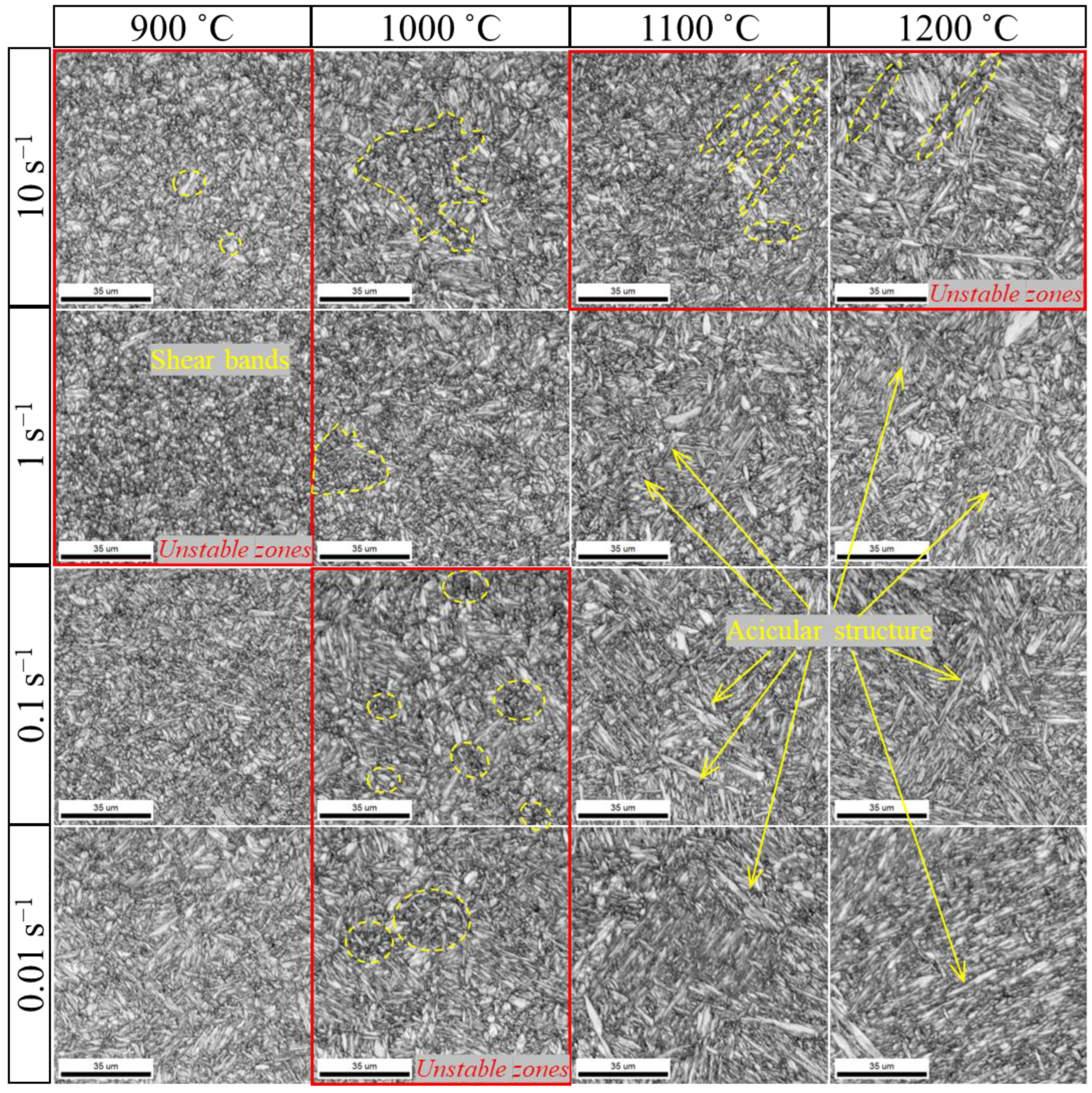

3.5. Microstructure Analysis

Microstructure Analysis of Processing Map

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oh, S.; Semiatin, S.; Jonas, J. An analysis of the isothermal hot compression test. Metall. Trans. A 1992, 23, 963–975. [Google Scholar] [CrossRef]

- Sanrutsadakorn, A.; Uthaisangsuk, V.; Suranuntchai, S.; Thossatheppitak, B. Investigation of hot deformation characteristics of AISI 4340 steel using processing map. Adv. Mater. Res. 2013, 683, 301–306. [Google Scholar] [CrossRef]

- Sun, S.L.; Zhang, M.G.; He, W.W. Hot deformation behavior and hot processing map of P92 steel. Adv. Mater. Res. 2010, 97–101, 290–295. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Jonas, J.J. Formability and Workability of Metals: Plastic Instability and Flow Localization; American Society for Metals: Materials Park, OH, USA, 1984; Volume 299. [Google Scholar]

- Kumar, N.; Kumar, S.; Rajput, S.K.; Nath, S.K. Modelling of flow stress and prediction of workability by processing map for hot compression of 43CrNi steel. ISIJ Int. 2017, 57, 497–505. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Liu, G.; Zhang, Q.; Li, R.; Wang, L. Determination of hot deformation behavior and processing maps of IN 028 alloy using isothermal hot compression test. Mater. Sci. Eng. A 2014, 595, 92–98. [Google Scholar] [CrossRef]

- Zhao, H.; Qi, J.; Su, R.; Zhang, H.; Chen, H.; Bai, L.; Wang, C. Hot deformation behaviour of 40CrNi steel and evaluation of different processing map construction methods. J. Mater. Res. Technol. 2020, 9, 2856–2869. [Google Scholar] [CrossRef]

- Maarefdoust, M. Simulation of finite volume of hot forging process of industrial gear. Int. Proc. Comput. Sci. Inf. Technol. 2012, 57, 111. [Google Scholar]

- Sellars, C.M.; McTegart, W. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Li, H.-Y.; Li, Y.-H.; Wang, X.-F.; Liu, J.-J.; Wu, Y. A comparative study on modified Johnson Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict the hot deformation behavior in 28CrMnMoV steel. Mater. Des. 2013, 49, 493–501. [Google Scholar] [CrossRef]

- He, A.; Chen, L.; Hu, S.; Wang, C.; Huangfu, L. Constitutive analysis to predict high temperature flow stress in 20CrMo continuous casting billet. Mater. Des. 2013, 46, 54–60. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Flow stress prediction at hot working conditions. Mater. Sci. Eng. A 2010, 527, 1160–1164. [Google Scholar] [CrossRef]

- Jonas, J.J.; Quelennec, X.; Jiang, L.; Martin, É. The Avrami kinetics of dynamic recrystallization. Acta Mater. 2009, 57, 2748–2756. [Google Scholar] [CrossRef]

- McQueen, H.; Jonas, J. Recent advances in hot working: Fundamental dynamic softening mechanisms. J. Appl. Metalwork. 1984, 3, 233–241. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 1996, 44, 127–136. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, P.; Luo, A.A.; She, J.; Tang, A.; Pan, F. Dynamic precipitation and enhanced mechanical properties of ZK60 magnesium alloy achieved by low temperature extrusion. Mater. Sci. Eng. A 2022, 829, 142143. [Google Scholar] [CrossRef]

- Bembalge, O.; Panigrahi, S. Hot deformation behavior and processing map development of cryorolled AA6063 alloy under compression and tension. Int. J. Mech. Sci. 2021, 191, 106100. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Tang, H.; Liu, T.; Li, Z.; Jiang, H.; Wang, K.; Ebrahimi, M.; Ding, W. Hot deformation constitutive model and processing maps of homogenized Al–5Mg–3Zn–1Cu alloy. J. Mater. Res. Technol. 2021, 14, 324–339. [Google Scholar] [CrossRef]

- Frost, H.; Ashby, M. Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Book); Pergamon Press: Oxford, UK, 1982; 165p. [Google Scholar]

- Prasad, Y.; Gegel, H.; Doraivelu, S.; Malas, J.; Morgan, J.; Lark, K.; Barker, D. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Prasad, Y.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Wan, Z.; Hu, L.; Sun, Y.; Wang, T.; Li, Z. Hot deformation behavior and processing workability of a Ni-based alloy. J. Alloys Compd. 2018, 769, 367–375. [Google Scholar] [CrossRef]

- Gholamzadeh, A.; Taheri, A.K. The prediction of hot flow behavior of Al–6% Mg alloy. Mech. Res. Commun. 2009, 36, 252–259. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Najafizadeh, A. A new method for evaluation of friction in bulk metal forming. J. Mater. Process. Technol. 2004, 152, 136–143. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Mandal, S.; Rakesh, V.; Sivaprasad, P.V.; Venugopal, S.; Kasiviswanathan, K.V. Constitutive equations to predict high temperature flow stress in a Ti-modified austenitic stainless steel. Mater. Sci. Eng. A 2009, 500, 114–121. [Google Scholar] [CrossRef]

- Sarkar, J.; Prasad, Y.; Surappa, M. Optimization of hot workability of an Al-Mg-Si alloy using processing maps. J. Mater. Sci. 1995, 30, 2843–2848. [Google Scholar] [CrossRef]

- Lin, Y.; Zhao, C.-Y.; Chen, M.-S.; Chen, D.-D. A novel constitutive model for hot deformation behaviors of Ti–6Al–4V alloy based on probabilistic method. Appl. Phys. A 2016, 122, 1–9. [Google Scholar] [CrossRef]

- Peng, X.; Guo, H.; Shi, Z.; Qin, C.; Zhao, Z.; Yao, Z. Study on the hot deformation behavior of TC4-DT alloy with equiaxed α+ β starting structure based on processing map. Mater. Sci. Eng. A 2014, 605, 80–88. [Google Scholar] [CrossRef]

- Kumar, B.; Saxena, K.K.; Dey, S.R.; Pancholi, V.; Bhattacharjee, A. Processing map-microstructure evolution correlation of hot compressed near alpha titanium alloy (TiHy 600). J. Alloys Compd. 2017, 691, 906–913. [Google Scholar]

- Prasad, Y.; Seshacharyulu, T. Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 1998, 243, 82–88. [Google Scholar] [CrossRef]

- Prasad, Y.; Rao, K. Processing maps and rate controlling mechanisms of hot deformation of electrolytic tough pitch copper in the temperature range 300–950 C. Mater. Sci. Eng. A 2005, 391, 141–150. [Google Scholar] [CrossRef]

- Sivakesavam, O.; Prasad, Y. Hot deformation behaviour of as-cast Mg–2Zn–1Mn alloy in compression: A study with processing map. Mater. Sci. Eng. A 2003, 362, 118–124. [Google Scholar] [CrossRef]

- Prasad, Y. Processing maps: A status report. J. Mater. Eng. Perform. 2003, 12, 638–645. [Google Scholar] [CrossRef]

- Prasad, Y.; Rao, K.; Sasidhar, S. Hot Working Guide: A Compendium of Processing Maps; ASM International: Almere, The Nertherlands, 2015. [Google Scholar]

- Ziegler, H. Some extremum principles in irreversible thermodynamics, with application to continuum mechanics. Prog. Solid Mech. 1963, 4, 93–193. [Google Scholar]

- Kumar, A.K. Criteria for Predicting Metallurgical Instabilities in Processing. Master’s Thesis, Indian Institute of Science, Bangalore, India, 1987. [Google Scholar]

- Prasad, M.; Inamdar, J. Effect of cement kiln dust pollution on black gram (Vigna mungo (L.) Hepper). Proc. Plant Sci. 1990, 100, 435–443. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A. Characterization of deformation instability in modified 9Cr–1Mo steel during thermo-mechanical processing. Mater. Des. 2011, 32, 716–722. [Google Scholar] [CrossRef]

- Joon Hee, P.; Dong Hwi, P.; Sang Yun, S.; Naksoo, K. Temperature and Strain Rate Controls of AISI 4340 based on a 3D Processing Map in a Hot Forging Process. J. Korean Soc. Precis. Eng. 2022, 38, 691–700. [Google Scholar] [CrossRef]

- Han, J.; Sun, J.-P.; Han, Y.; Liu, H. Hot workability of the as-cast 21Cr economical duplex stainless steel through processing map and microstructural studies using different instability criteria. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 1080–1088. [Google Scholar] [CrossRef]

- Li, J.-Q.; Liu, J.; Cui, Z.-S. Hot deformation stability of extruded AZ61 magnesium alloy using different instability criteria. Acta Metall. Sin. (Engl. Lett.) 2015, 28, 1364–1372. [Google Scholar] [CrossRef] [Green Version]

- Łukaszek-Sołek, A.; Krawczyk, J.; Śleboda, T.; Grelowski, J. Optimization of the hot forging parameters for 4340 steel by processing maps. J. Mater. Res. Technol. 2019, 8, 3281–3290. [Google Scholar] [CrossRef]

- Murty, S.N.; Rao, B.N.; Kashyap, B. Identification of flow instabilities in the processing maps of AISI 304 stainless steel. J. Mater. Process. Technol. 2005, 166, 268–278. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Zhao, M.-C.; Yang, K.; Shan, Y.-Y. Comparison on strength and toughness behaviors of microalloyed pipeline steels with acicular ferrite and ultrafine ferrite. Mater. Lett. 2003, 57, 1496–1500. [Google Scholar] [CrossRef]

- Byun, J.-S.; Shim, J.-H.; Suh, J.-Y.; Oh, Y.-J.; Cho, Y.W.; Shim, J.-D.; Lee, D.N. Inoculated acicular ferrite microstructure and mechanical properties. Mater. Sci. Eng. A 2001, 319, 326–331. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass fraction (wt. %) | 0.42 | 0.18 | 0.84 | 0.018 | 0.006 | 1.6 | 0.79 | 0.15 | 0.1 | Bal. |

| α (MPa−1) | n | Q (kJ/mol) | lnA |

|---|---|---|---|

| 0.013 | 4.89 | 346.79 | 29.29 |

| Coefficient | α (MPa−1) | n | Q (kJ/mol) | lnA |

|---|---|---|---|---|

| 1 | 0.0168 | 4.12 | 252 | 22.5 |

| 2 | −0.0372 | 35.1 | 3.12 × 103 | 250 |

| 3 | 0.143 | −358 | −2.93 × 104 | −2.44 × 103 |

| 4 | −0.274 | 1.47 × 103 | 1.20 × 105 | 1.01 × 104 |

| 5 | 0.323 | −3.17 × 103 | −2.59 × 105 | −2.23 × 104 |

| 6 | −0.242 | 3.75 × 103 | 3.11 × 105 | 2.70 × 104 |

| 7 | 0.0943 | −2.32 × 103 | −1.95 × 105 | −1.70 × 104 |

| 8 | −0.0118 | 583 | 4.96 × 104 | 4.36 × 103 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Kim, Y.; Shin, S.; Kim, N. Characterization of Hot Workability in AISI 4340 Based on a 3D Processing Map. Metals 2022, 12, 1946. https://doi.org/10.3390/met12111946

Park J, Kim Y, Shin S, Kim N. Characterization of Hot Workability in AISI 4340 Based on a 3D Processing Map. Metals. 2022; 12(11):1946. https://doi.org/10.3390/met12111946

Chicago/Turabian StylePark, Joonhee, Yosep Kim, Sangyun Shin, and Naksoo Kim. 2022. "Characterization of Hot Workability in AISI 4340 Based on a 3D Processing Map" Metals 12, no. 11: 1946. https://doi.org/10.3390/met12111946

APA StylePark, J., Kim, Y., Shin, S., & Kim, N. (2022). Characterization of Hot Workability in AISI 4340 Based on a 3D Processing Map. Metals, 12(11), 1946. https://doi.org/10.3390/met12111946