Industrial X-ray Image Analysis with Deep Neural Networks Robust to Unexpected Input Data

Abstract

1. Introduction

2. Background

3. Materials and Methods

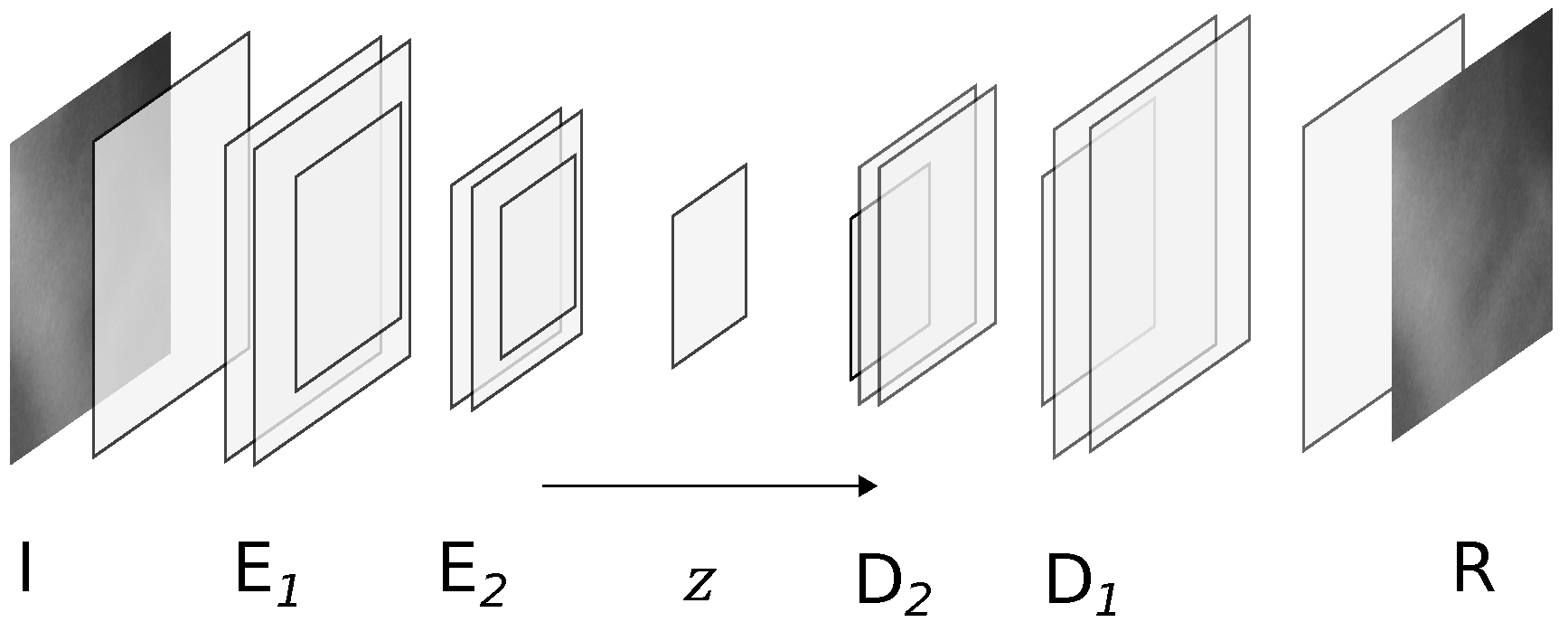

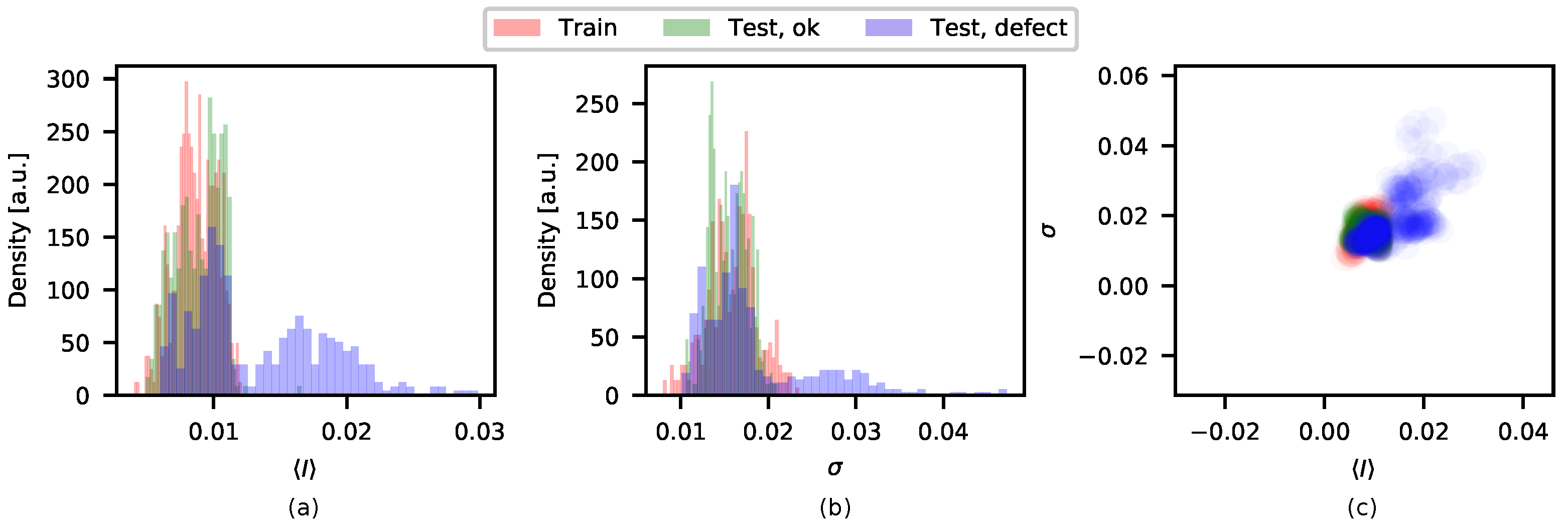

3.1. OOD Detector Model

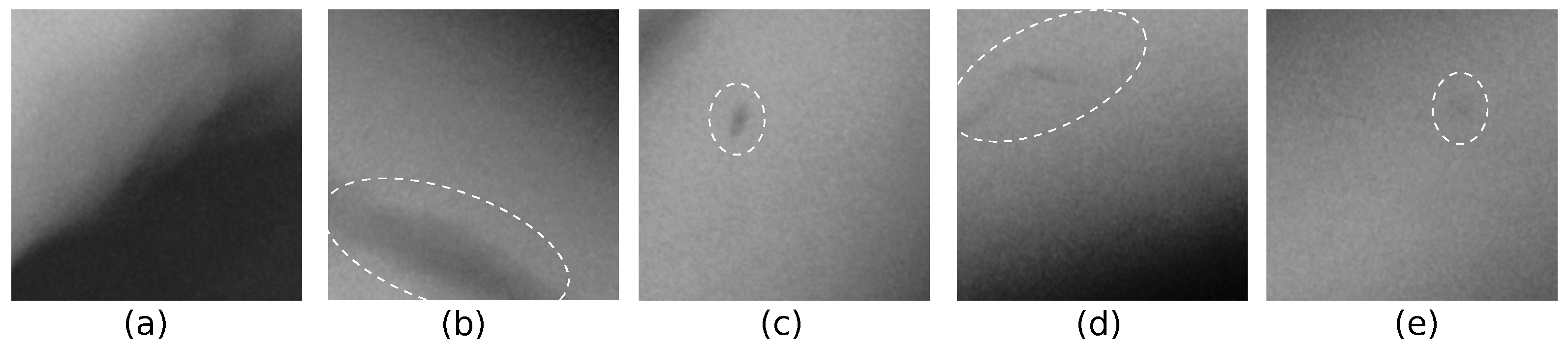

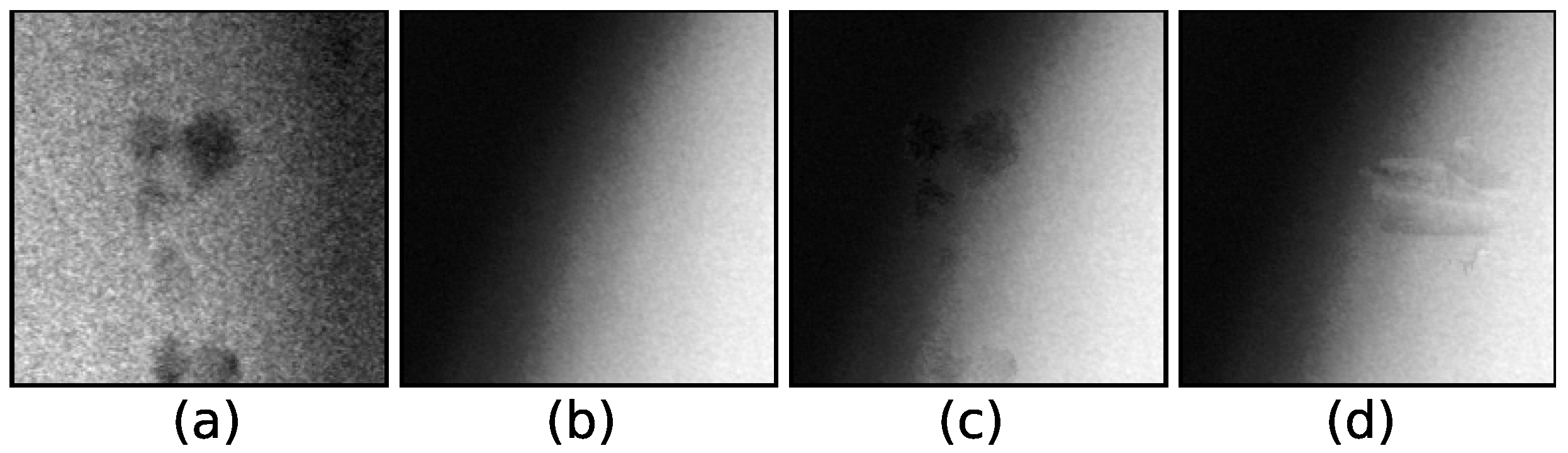

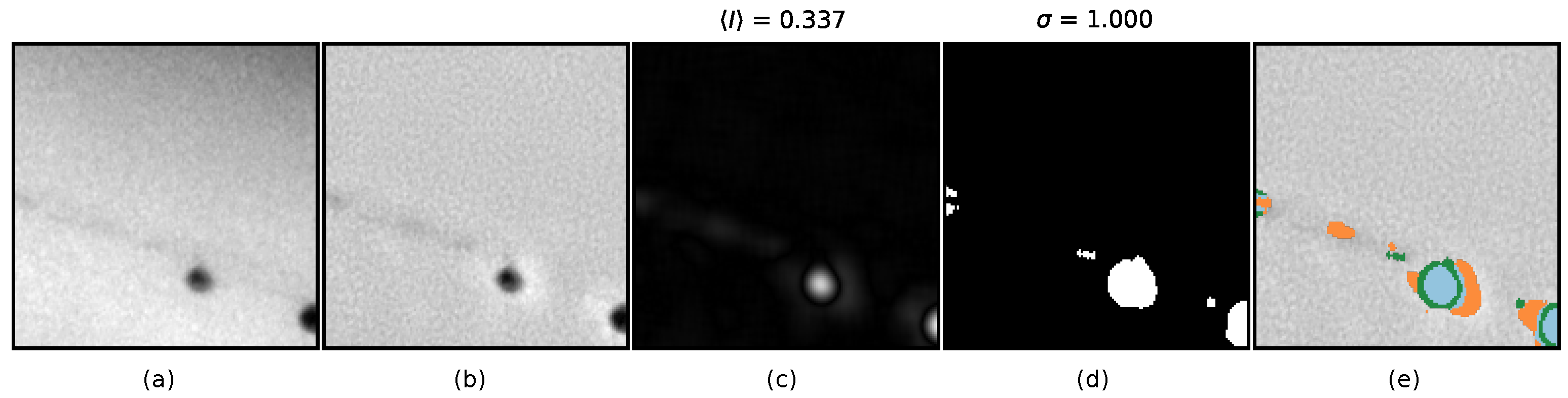

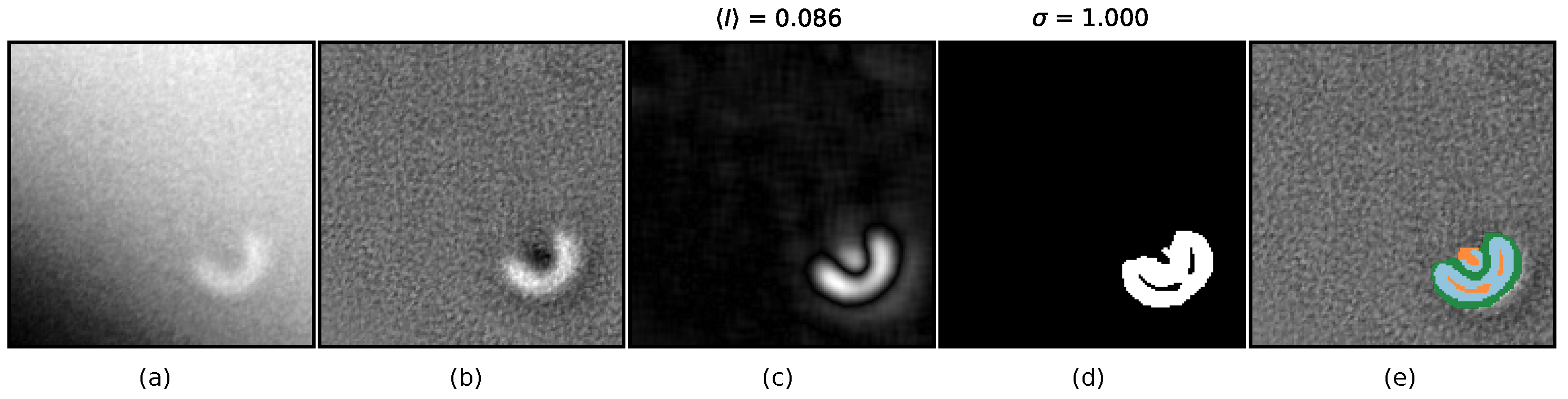

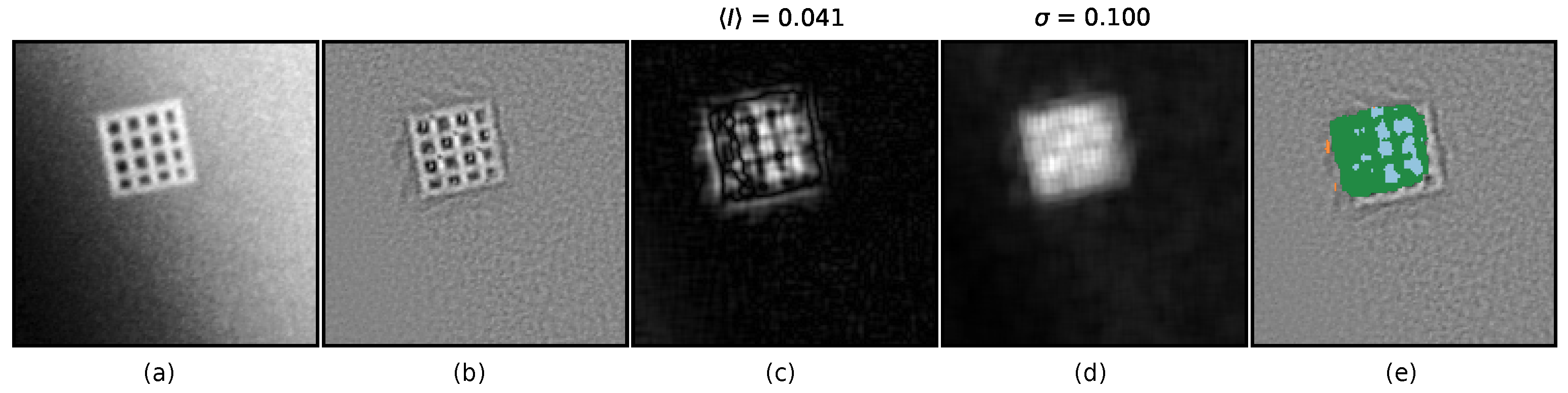

Residual Image Analysis

3.2. Binary Classifier Model Trained with Supervised-Learning

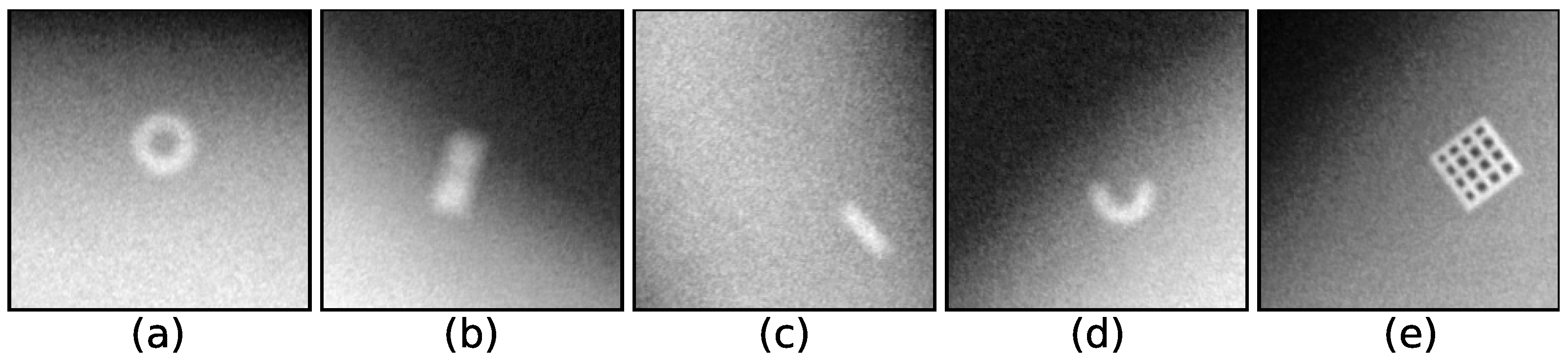

3.3. Datasets

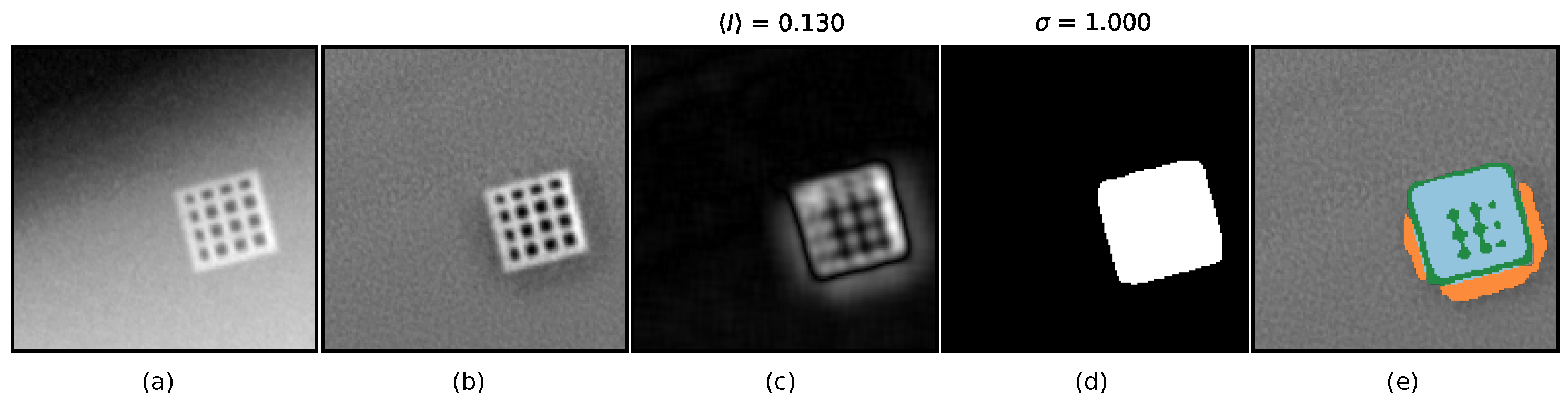

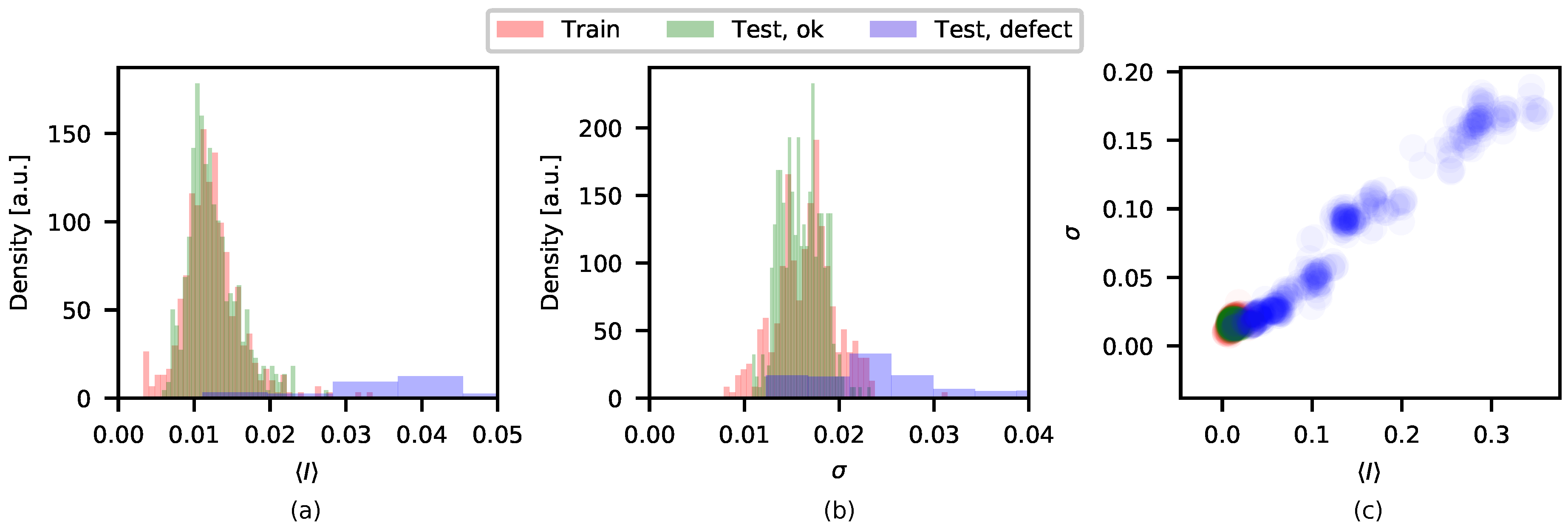

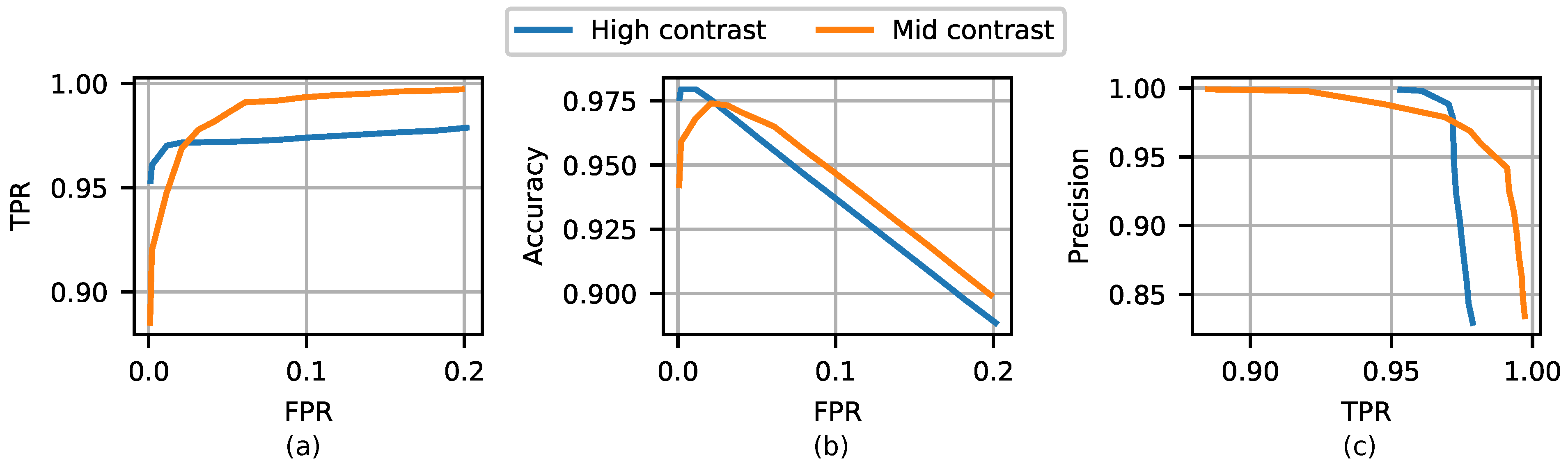

4. Results

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Liao, W. Automatic identification of different types of welding defects in radiographic images. NDT&E Int. 2002, 35, 519–528. [Google Scholar]

- Dang, C.; Gao, J.; Wang, Z.; Xiao, Y.; Zhao, Y. A novel method for detecting weld defects accurately and reliably in radiographic images. Insight-Non-Destr. Test. Cond. Monit. 2016, 58, 28–34. [Google Scholar] [CrossRef]

- Silva, R.R.; Mery, D. State-ofthe-Art of Weld Seam Inspection by Radiographic Testing: Part I—Image Processing. Mater. Eval. 2007, 65, 643–647. [Google Scholar]

- Rathod, V.; Anand, R. A Comparative Study of Different Segmentation Techniques for Detection of Flaws in NDE Weld Images. J. Nondestruct. Eval. 2011, 31, 1–16. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Kaftandjian, V.; Dupuis, O.; Babot, D.; Min Zhu, Y. Uncertainty modelling using Dempster–Shafer theory for improving detection of weld defects. Pattern Recognit. Lett. 2003, 24, 547–564. [Google Scholar] [CrossRef]

- Lashkia, V. Defect detection in X-ray images using fuzzy reasoning. Image Vis. Comput. 2001, 19, 261–269. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Y.; Lv, P.; Wang, H. Detection of line weld defects based on multiple thresholds and support vector machine. NDT&E Int. 2008, 41, 517–524. [Google Scholar]

- Vilar, R.; Zapata, J.; Ruiz, R. An automatic system of classification of weld defects in radiographic images. NDT&E Int. 2009, 42, 467–476. [Google Scholar]

- Kumar, J.; Anand, R.; Srivastava, S. Flaws Classification using ANN for Radiographic Weld Images. In Proceedings of the International Conference on Signal Processing and Integrated Networks, Noida, India, 20–21 February 2014; pp. 145–150. [Google Scholar]

- Dong, X.; Taylor, C.J.; Cootes, T.F. Automatic Inspection of Aerospace Welds Using X-ray Images. In Proceedings of the 2018 24th International Conference on Pattern Recognition (ICPR), Beijing, China, 20–24 August 2018; pp. 2002–2007. [Google Scholar]

- Nacereddine, N.; Goumeidane, A.B.; Ziou, D. Unsupervised weld defect classification in radiographic images using multivariate generalized Gaussian mixture model with exact computation of mean and shape parameters. Comput. Ind. 2019, 108, 132–149. [Google Scholar] [CrossRef]

- Mery, D.; Arteta, C. Automatic Defect Recognition in X-ray Testing using Computer Vision. In Proceedings of the 2017 IEEE Winter Conference on Applications of Computer Vision (WACV), Santa Rosa, CA, USA, 24–31 March 2017; pp. 1026–1035. [Google Scholar]

- Mu, Y.; Yan, S.; Liu, Y.; Huang, T.; Zhou, B. Discriminative local binary patterns for human detection in personal album. In Proceedings of the 2008 IEEE Conference on Computer Vision and Pattern Recognition, Anchorage, AK, USA, 23–28 June 2008; pp. 1–8. [Google Scholar]

- Hou, W.; Wei, Y.; Guo, J.; Jin, Y.; Zhu, C. Automatic Detection of Welding Defects using Deep Neural Network. J. Physics Conf. Ser. 2018, 933, 012006. [Google Scholar] [CrossRef]

- Hou, W.; Wei, Y.; Jin, Y.; Zhu, C. Deep features based on a DCNN model for classifying imbalanced weld flaw types. Measurement 2019, 131, 482–489. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. arXiv 2015, arXiv:cs.CV/1505.04597. Available online: https://arxiv.org/abs/1505.04597 (accessed on 14 November 2022).

- Tokime, R.B.; Maldague, X.; Perron, L. Automatic Defect Detection for X-ray inspection: Semantic segmentation with deep convolutional network. In Proceedings of the International Industrial Radiology and Computed Tomography DIR2019, Fürth, Germany, 2–4 July 2019. [Google Scholar]

- Tyystjärvi, T.; Virkkunen, I.; Fridolf, P.; Rosell, A.; Barsoum, Z. Automated defect detection in digital radiography of aerospace welds using deep learning. Weld. World 2022, 66, 643–671. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, H. Weld defect classification in radiographic images using unified deep neural network with multi-level features. J. Intell. Manuf. 2021, 32, 459–469. [Google Scholar] [CrossRef]

- Mery, D. Aluminum Casting Inspection Using Deep Learning: A Method Based on Convolutional Neural Networks. J. Nondestruct. Eval. 2020, 39, 12. [Google Scholar] [CrossRef]

- Fuchs, P.; Kröger, T.; Dierig, T.; Garbe, C. Generating Meaningful Synthetic Ground Truth for Pore Detection in Cast aluminum Parts. In Proceedings of the 9th Conference on Industrial Computed Tomography, Padova, Italy, 13–15 February 2019. [Google Scholar]

- Cogranne, R.; Retraint, F. Statistical detection of defects in radiographic images using an adaptive parametric model. Signal Process. 2014, 96, 173–189. [Google Scholar] [CrossRef]

- Grandin, R.; Gray, J. Implementation of automated 3D defect detection for low signa-to noise features in NDE data. Aip Conf. Proc. 2014, 1581, 1840–1847. [Google Scholar] [CrossRef]

- Kazantsev, I.; Lemahieu, I.; Salov, G.; Denys, R. Statistical detection of defects in radiographic images in nondestructive testing. Signal Process. 2002, 82, 791–801. [Google Scholar] [CrossRef]

- Tošić, I.; Frossard, P. Dictionary Learning. IEEE Signal Process. Mag. 2011, 28, 27–38. [Google Scholar] [CrossRef]

- Chen, B.; Fang, Z.; Xia, Y.; Zhang, L.; Huang, Y.; Wang, L. Accurate defect detection via sparsity reconstruction for weld radiographs. NDT&E Int. 2018, 94, 62–69. [Google Scholar]

- Presenti, A.; Liang, Z.; Pereira, L.F.A.; Sijbers, J.; Beenhouwer, J.D. Automatic anomaly detection from X-ray images based on autoencoder. Nondestruct. Test. Eval. 2022, 37, 552–565. [Google Scholar] [CrossRef]

- Tang, W.; Vian, C.M.; Tang, Z.; Yang, B. Anomaly detection of core failures in die-casting X-ray inspection images using a convolutional autoencoder. Mach. Vis. Appl. 2021, 32, 102. [Google Scholar] [CrossRef]

- Meyendorf, N.G.; Bond, L.J.; Curtis-Beard, J.; Heilmann, S.; Pal, S.; Schallert, R.; Scholz, H.; Wunderlich, C. NDE 4.0—NDE for the 21st Century—The Internet of Things and Cyber Physical Systems will Revolutionize NDE. In Proceedings of the Proceedings of the 15th Asia Pacific Conference for Non-Destructive Testing (APCNDT 2017), Singapore, 13–17 November 2017. [Google Scholar]

- Rummel, W.D. Nondestructive inspection reliability history, status and future path. In Proceedings of the 18th World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2010. [Google Scholar]

- Lindgren, E.; Forsyth, D.; Aldrin, J.; Spencer, F. ASM Handbook, Volume 17, Nondestructive Evaluation of Materials; ASM International: Almere, The Netherlands, 2018. [Google Scholar]

- Ewert, U.; Zscherpel, U.; Jechow, M. Essential Parameters and Conditions for Optimum Image Quality in Digital Radiology. In Proceedings of the 18th World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012. [Google Scholar]

- Kanzler, D.; Ewert, U.; Müller, C.; Pitkänen, J. Observer POD for radiographic testing. AIP Conf. Proc. 2015, 1650, 562. [Google Scholar]

- Bertović, M. Human Factors in Non-Destructive Testing (NDT): Risks and Challenges of Mechanised NDT. PhD Thesis, Technische Universitaet Berlin, Berlin, Germany, 1 September 2015. [Google Scholar]

- Aldrin, J.C.; Lindgren, E.; Forsyth, D. Intelligence augmentation in nondestructive evaluation. Aip Conf. Proc. 2019, 2102, 020028. [Google Scholar]

- Lindgren, E.; Zach, C. Autoencoder-Based Anomaly Detection in Industrial X-ray Images. In Proceedings of the 2021 48th Annual Review of Progress in Quantitative Nondestructive Evaluation, Virtual, 28–30 July 2021. [Google Scholar] [CrossRef]

- Richter, C.; Roy, N. Safe Visual Navigation via Deep Learning and Novelty Detection. In Proceedings of the Robotics Science and Systems, Cambridge, MA, USA, 12–16 July 2017. [Google Scholar]

- Gal, Y.; Ghahramani, Z. Dropout as a Bayesian Approximation: Representing Model Uncertainty in Deep Learning. In Proceedings of the 33rd International Conference on Machine Learning, New York, NY, USA, 19–24 June 2016; Volume 48, pp. 1050–1059. [Google Scholar]

- Lakshminarayanan, B.; Pritzel, A.; Blundell, C. Simple and Scalable Predictive Uncertainty Estimation Using Deep Ensembles. In Proceedings of the 31st International Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; Curran Associates Inc.: Red Hook, NY, USA, 2017; pp. 6405–6416. [Google Scholar]

- Seeböck, P.; Waldstein, S.; Klimscha, S.; Gerendas, B.S.; Donner, R.; Schlegl, T.; Schmidt-Erfurth, U.; Langs, G. Identifying and Categorizing Anomalies in Retinal Imaging Data. arXiv 2016, arXiv:cs.LG/1612.00686. Available online: https://arxiv.org/abs/1612.00686 (accessed on 14 November 2022).

- Schölkopf, B.; Platt, J.C.; Shawe-Taylor, J.C.; Smola, A.J.; Williamson, R.C. Estimating the Support of a High-Dimensional Distribution. Neural Comput. 2001, 13, 1443–1471. [Google Scholar] [CrossRef]

- Schlegl, T.; Seeböck, P.; Waldstein, S.M.; Schmidt-Erfurth, U.; Langs, G. Unsupervised Anomaly Detection with Generative Adversarial Networks to Guide Marker Discovery. arXiv 2017, arXiv:cs.CV/1703.05921. Available online: https://arxiv.org/abs/1703.05921 (accessed on 14 November 2022).

- Goodfellow, I.J.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative Adversarial Networks. arXiv 2014, arXiv:stat.ML/1406.2661. Available online: https://arxiv.org/abs/1406.2661 (accessed on 14 November 2022). [CrossRef]

- Schlegl, T.; Seeböck, P.; Waldstein, S.M.; Langs, G.; Schmidt-Erfurth, U. f-AnoGAN: Fast unsupervised anomaly detection with generative adversarial networks. Med. Image Anal. 2019, 54, 30–44. [Google Scholar] [CrossRef]

- Tang, Y.; Tang, Y.; Han, M.; Xiao, J.; Summers, R.M. Abnormal Chest X-ray Identification With Generative Adversarial One-Class Classifier. arXiv 2019, arXiv:cs.CV/1903.02040. Available online: https://arxiv.org/abs/1903.02040 (accessed on 14 November 2022).

- Akcay, S.; Atapour-Abarghouei, A.; Breckon, T.P. GANomaly: Semi-Supervised Anomaly Detection via Adversarial Training. arXiv 2018, arXiv:cs.CV/1805.06725. Available online: https://arxiv.org/abs/1805.06725 (accessed on 14 November 2022).

- Lindgren, E.; Zach, C. Analysis of industrial x-ray computed tomography data with deep neural networks. In Proceedings of the Developments in X-ray Tomography XIII. International Society for Optics and Photonics, San Diego, CA, USA, 1–5 August 2021; SPIE: Bellingham, WA, USA, 2021; Volume 11840, p. 118400B. [Google Scholar] [CrossRef]

- Springenberg, J.T.; Dosovitskiy, A.; Brox, T.; Riedmiller, M. Striving for Simplicity: The All Convolutional Net. arXiv 2015, arXiv:cs.LG/1412.6806. [Google Scholar]

- Hou, X.; Shen, L.; Sun, K.; Qiu, G. Deep feature consistent variational autoencoder. In Proceedings of the 2017 IEEE Winter Conference on Applications of Computer Vision (WACV), Santa Rosa, CA, USA, 24–31 March 2017; pp. 1133–1141. [Google Scholar]

- Vincent, P. A connection between score matching and denoising autoencoders. Neural Comput. 2011, 23, 1661–1674. [Google Scholar] [CrossRef] [PubMed]

- Hyvärinen, A.; Dayan, P. Estimation of non-normalized statistical models by score matching. J. Mach. Learn. Res. 2005, 6, 95–709. [Google Scholar]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Systems. 2015. Available online: tensorflow.org (accessed on 14 November 2022).

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. arXiv 2017, arXiv:cs.LG/1412.6980. [Google Scholar]

- Eckel, S.; Huthwaite, P.; Zscherpel, U.; Schumm, A.; Paul, N. Realistic Film Noise Generation Based on Experimental Noise Spectra. Trans. Imge Proc. 2020, 29, 2987–2998. [Google Scholar] [CrossRef]

- Lindgren, E.; Wirdelius, H. X-ray modeling of realistic synthetic radiographs of thin titanium welds. Ndt&E Int. 2012, 51, 111–119. [Google Scholar]

- Mery, D.; Riffo, V.; Zscherpel, U.; Mondragón, G.; Lillo, I.; Zuccar, I.; Lobel, H.; Carrasco, M. GDXray: The Database of X-ray Images for Nondestructive Testing. J. Nondestruct. Eval. 2015, 34, 42. [Google Scholar] [CrossRef]

- Roy, P.; Ghosh, S.; Bhattacharya, S.; Pal, U. Effects of Degradations on Deep Neural Network Architectures. arXiv 2018, arXiv:1807.10108. Available online: https://arxiv.org/abs/1807.10108 (accessed on 14 November 2022).

| Dataset | Original Sample Count | Augmented Sample Count |

|---|---|---|

| Train weld okay | 27,454 | 164,724 |

| Train defects | 11,705 | 70,230 |

| Train synthetic natural image indications | 112,000 | |

| Train synthetic, circular indication | 5000 | |

| Train synthetic, partial circle inclusion | 5000 | |

| Test weld okay | 3480 | |

| Test defect, high contrast | 3396 | |

| Test defect, mid-contrast | 2898 | |

| Test defect, low contrast | 1830 | |

| Test, synthetic, five different types | 200 |

| TPR Average and Spread | ||||

|---|---|---|---|---|

| Training Data | D | D + SC | D + SC + SPC | D + SNI |

| Test Dataset | ||||

| Defects high contrast | ||||

| Defects mid-contrast | ||||

| Defects low contrast | ||||

| Synthetic circular hollow inclusion | ||||

| Synthetic dogbone inclusion | ||||

| Synthetic elongated inclusion | ||||

| Synthetic partial circle inclusion | ||||

| Synthetic raster | ||||

| TPR Average and Spread | |||

|---|---|---|---|

| Perturbation Dataset | None | D | SNI |

| Test Dataset | |||

| Defects high contrast | |||

| Defects mid-contrast | |||

| Defects low contrast | |||

| Synthetic circular hollow inclusion | |||

| Synthetic dogbone inclusion | |||

| Synthetic elongated inclusion | |||

| Synthetic partial circle inclusion | |||

| Synthetic raster | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindgren, E.; Zach, C. Industrial X-ray Image Analysis with Deep Neural Networks Robust to Unexpected Input Data. Metals 2022, 12, 1963. https://doi.org/10.3390/met12111963

Lindgren E, Zach C. Industrial X-ray Image Analysis with Deep Neural Networks Robust to Unexpected Input Data. Metals. 2022; 12(11):1963. https://doi.org/10.3390/met12111963

Chicago/Turabian StyleLindgren, Erik, and Christopher Zach. 2022. "Industrial X-ray Image Analysis with Deep Neural Networks Robust to Unexpected Input Data" Metals 12, no. 11: 1963. https://doi.org/10.3390/met12111963

APA StyleLindgren, E., & Zach, C. (2022). Industrial X-ray Image Analysis with Deep Neural Networks Robust to Unexpected Input Data. Metals, 12(11), 1963. https://doi.org/10.3390/met12111963