Effects of Build Orientations on Microstructure Evolution, Porosity Formation, and Mechanical Performance of Selective Laser Melted 17-4 PH Stainless Steel

Abstract

1. Introduction

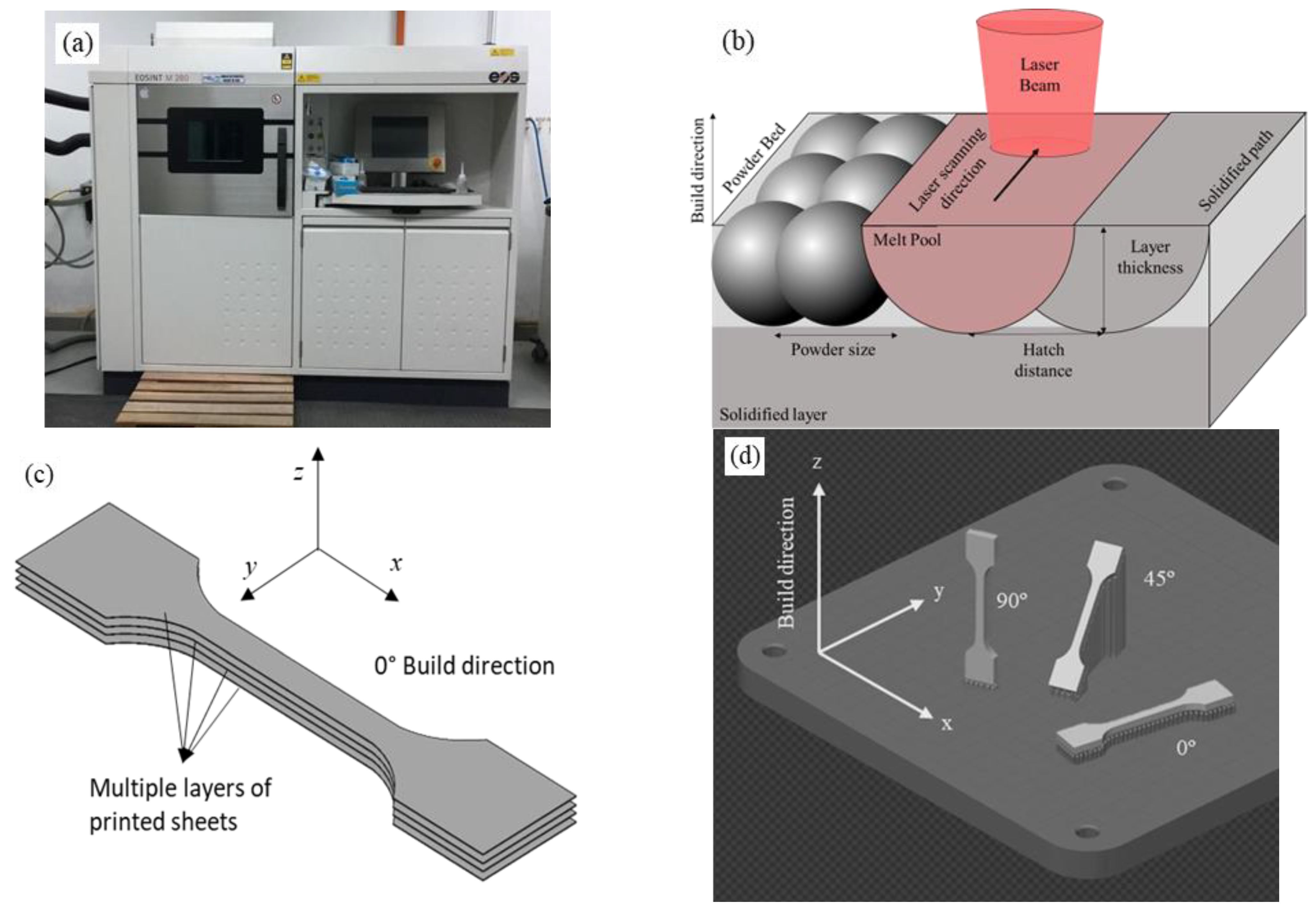

2. Methodology

3. Results and Discussion

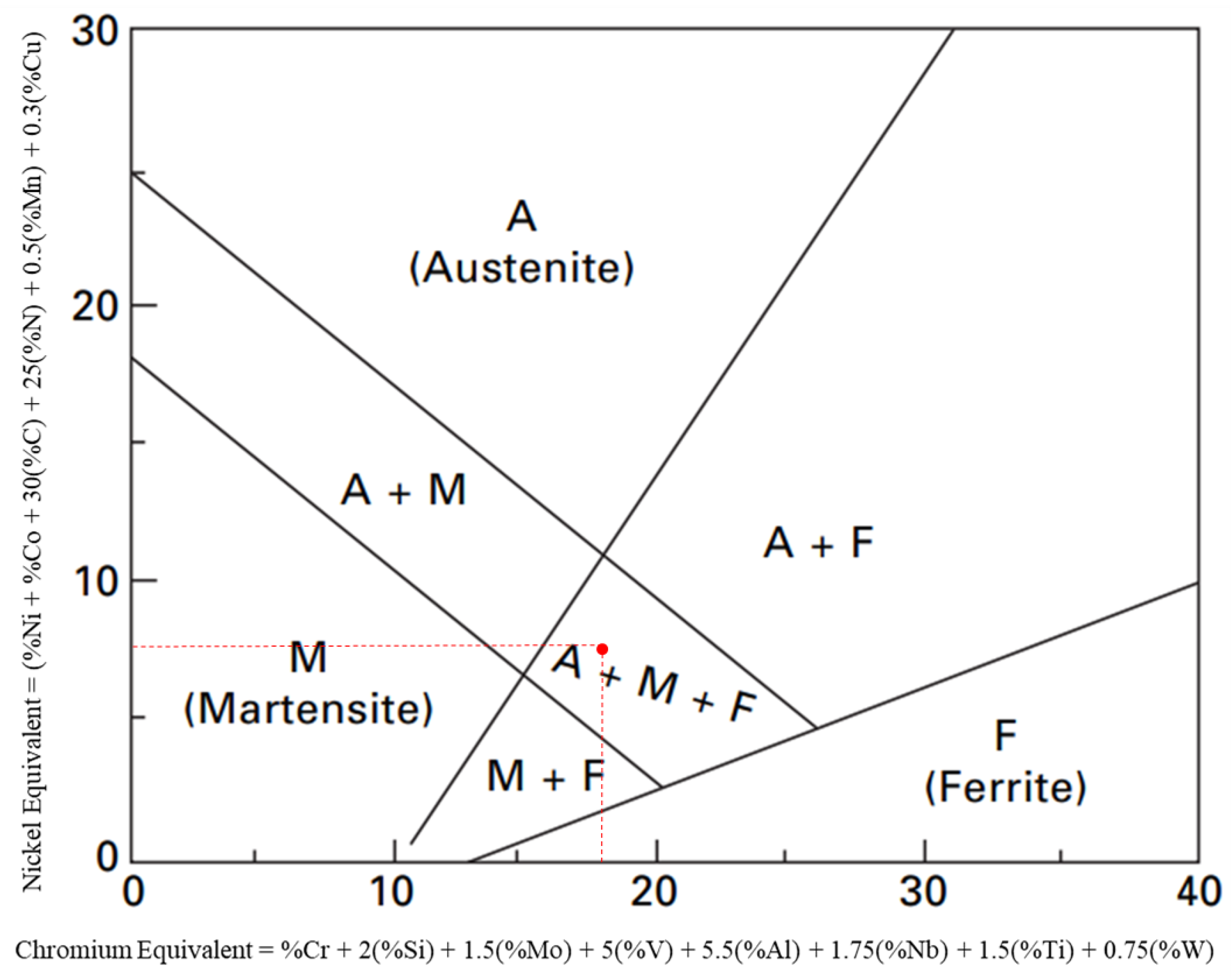

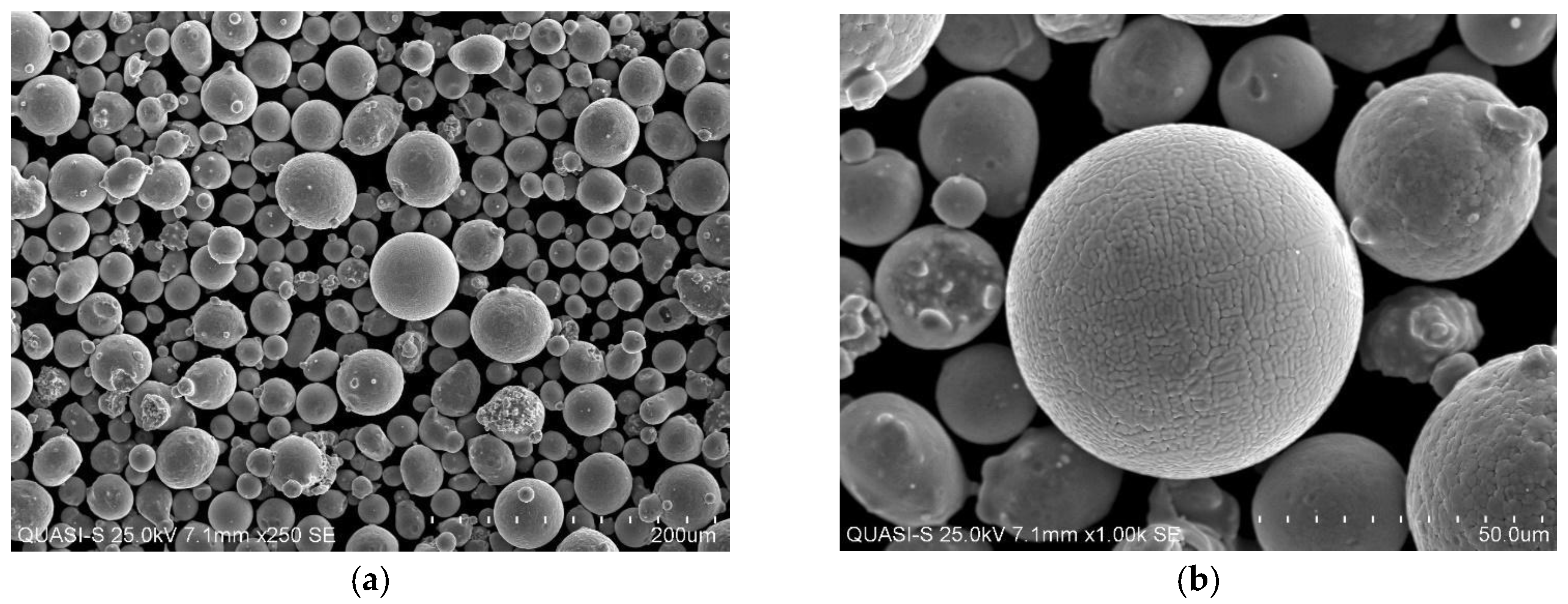

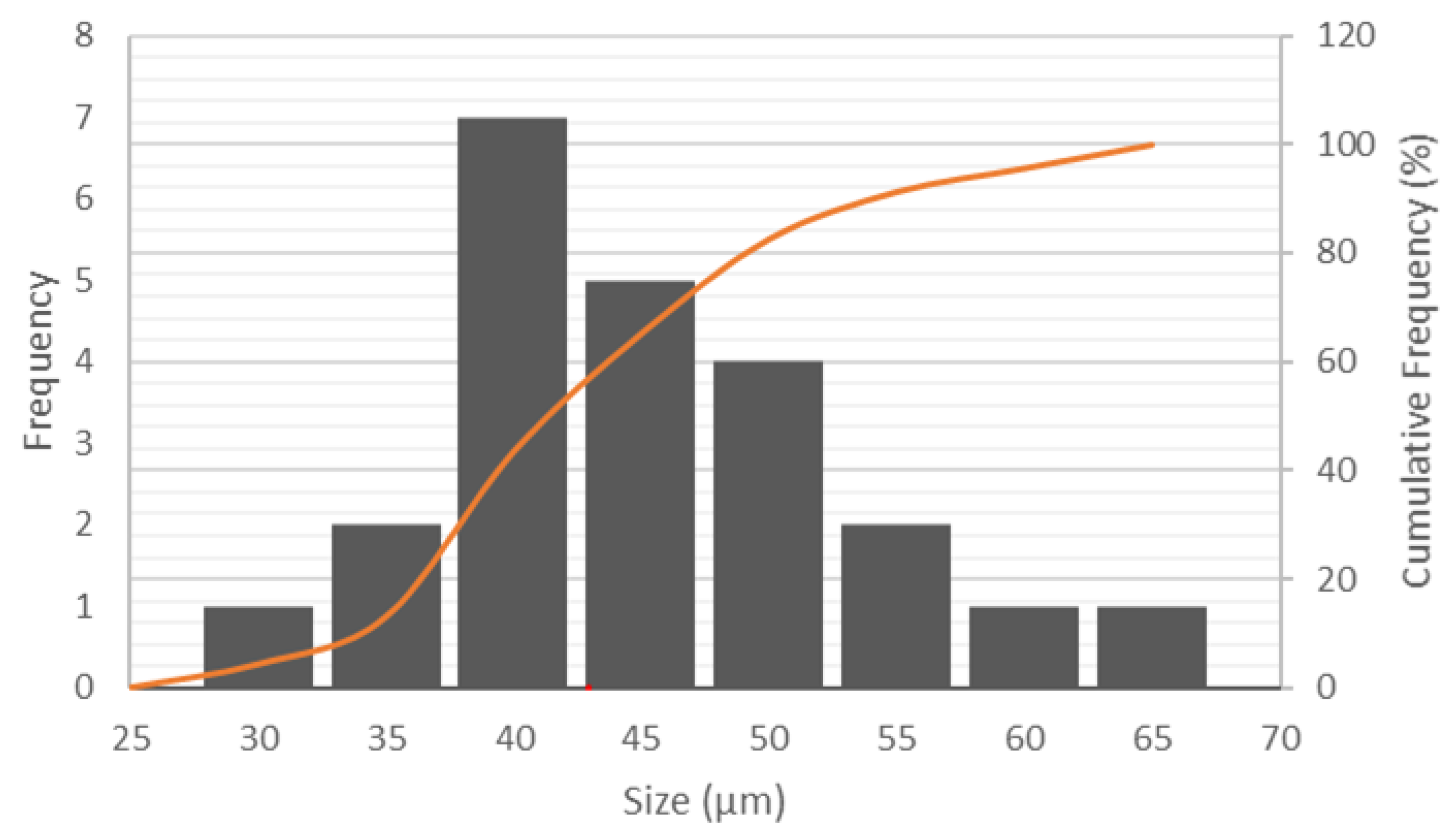

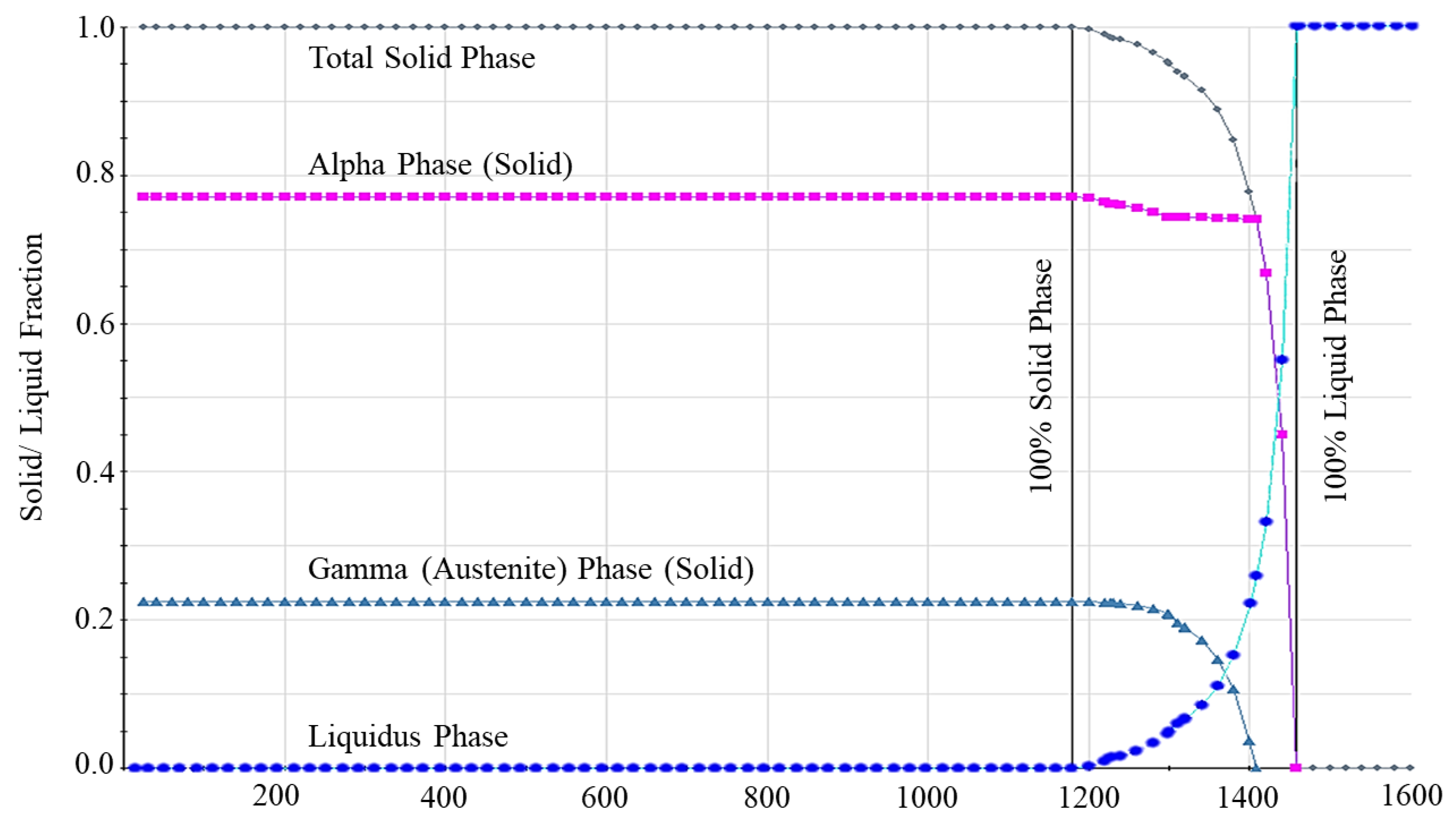

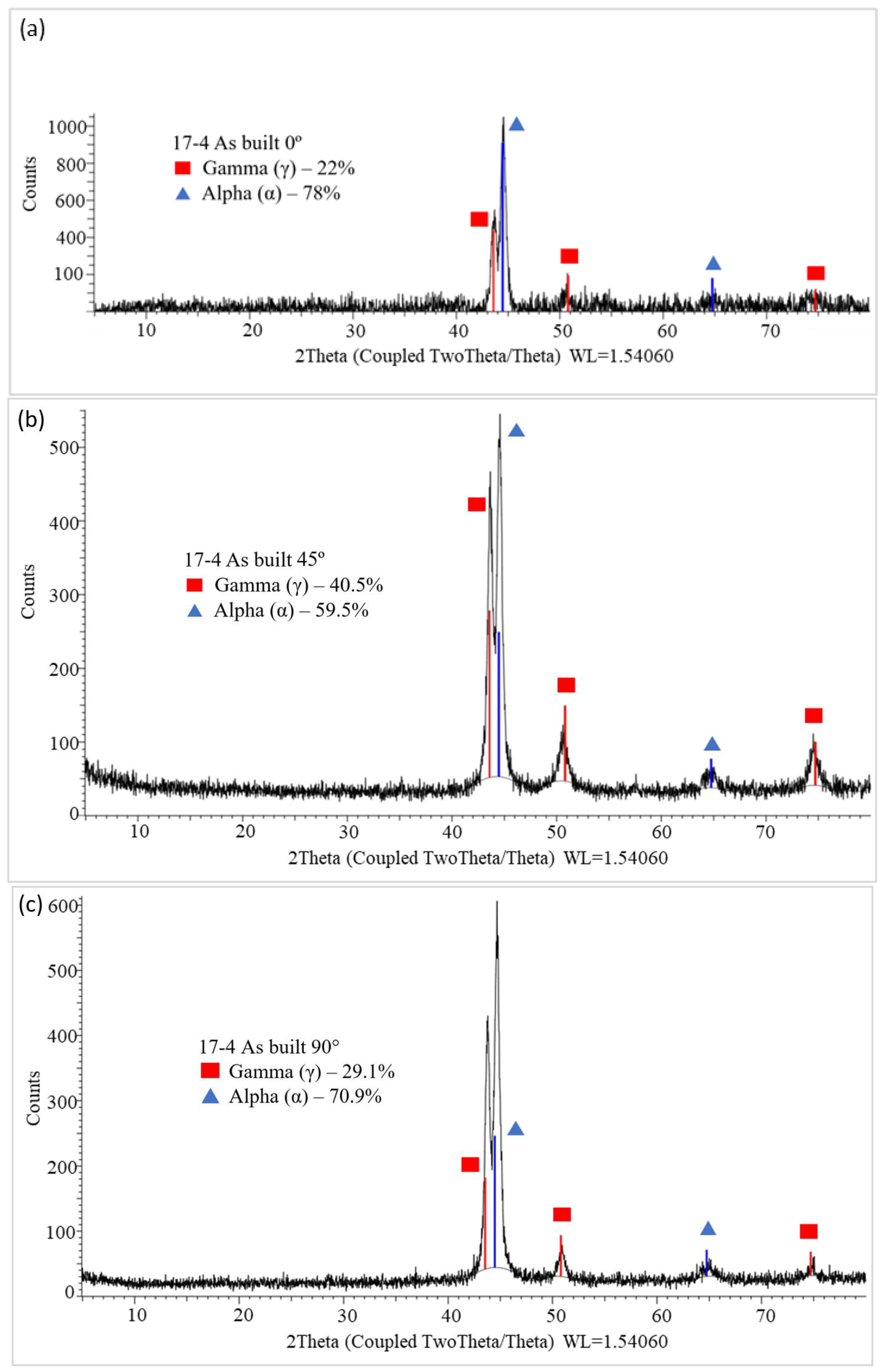

3.1. Powder and Phase Profiling

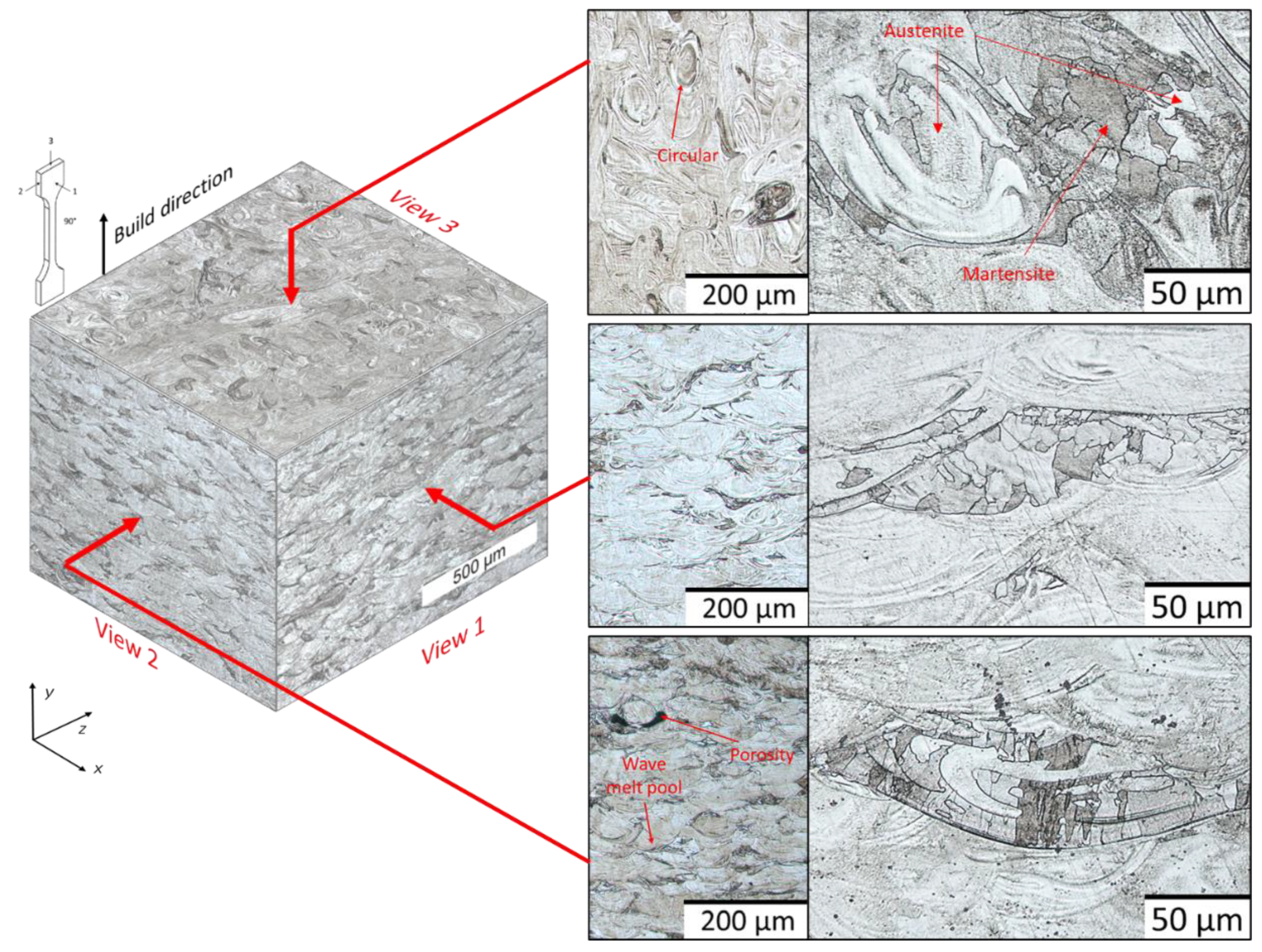

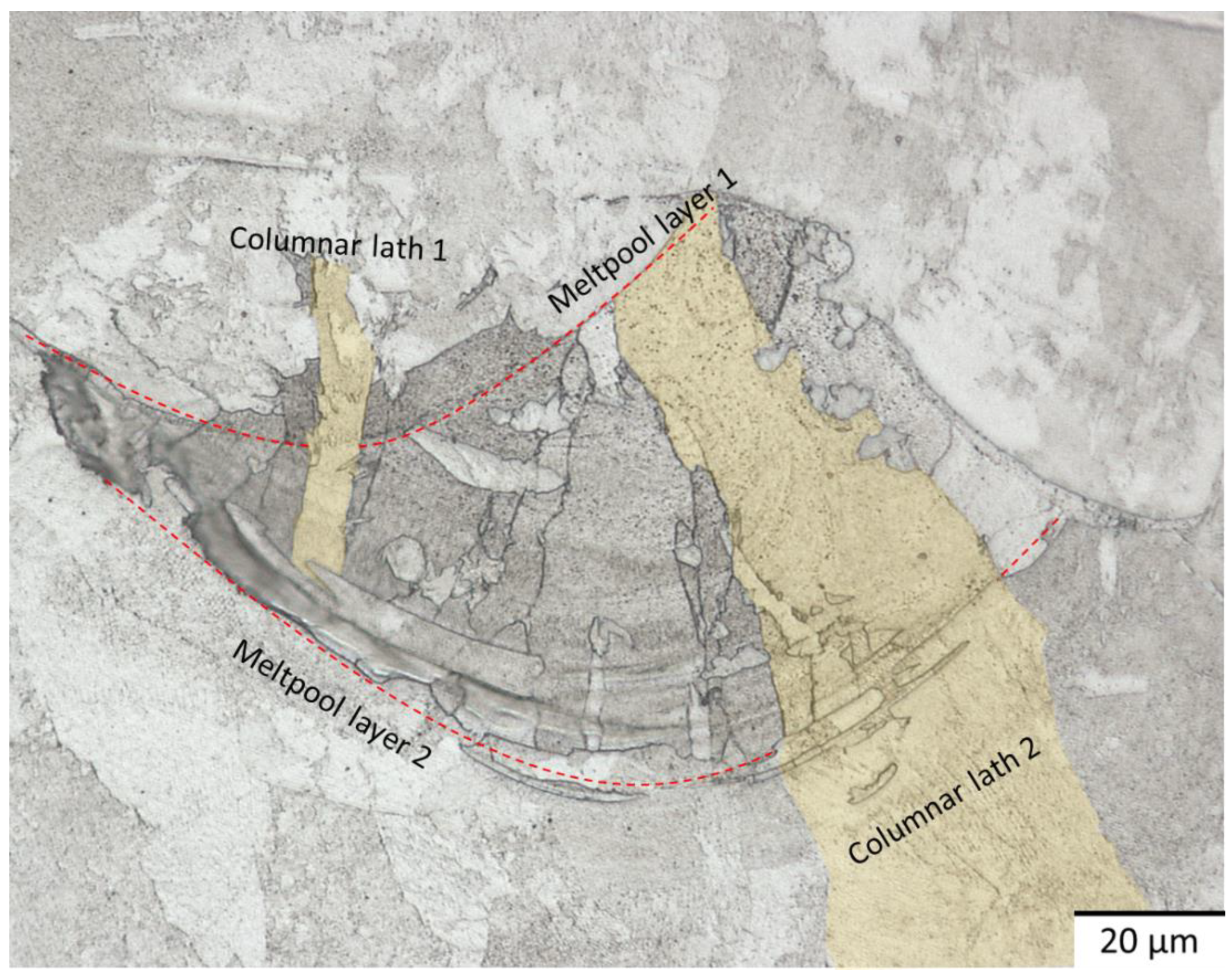

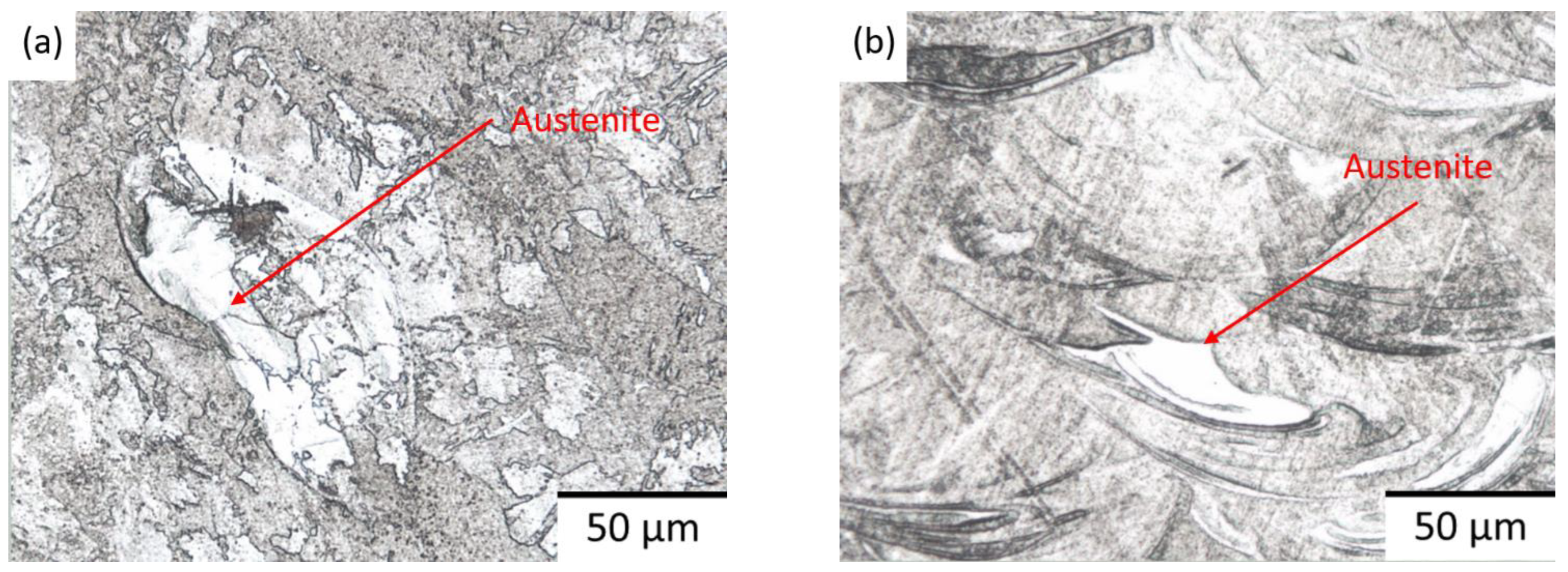

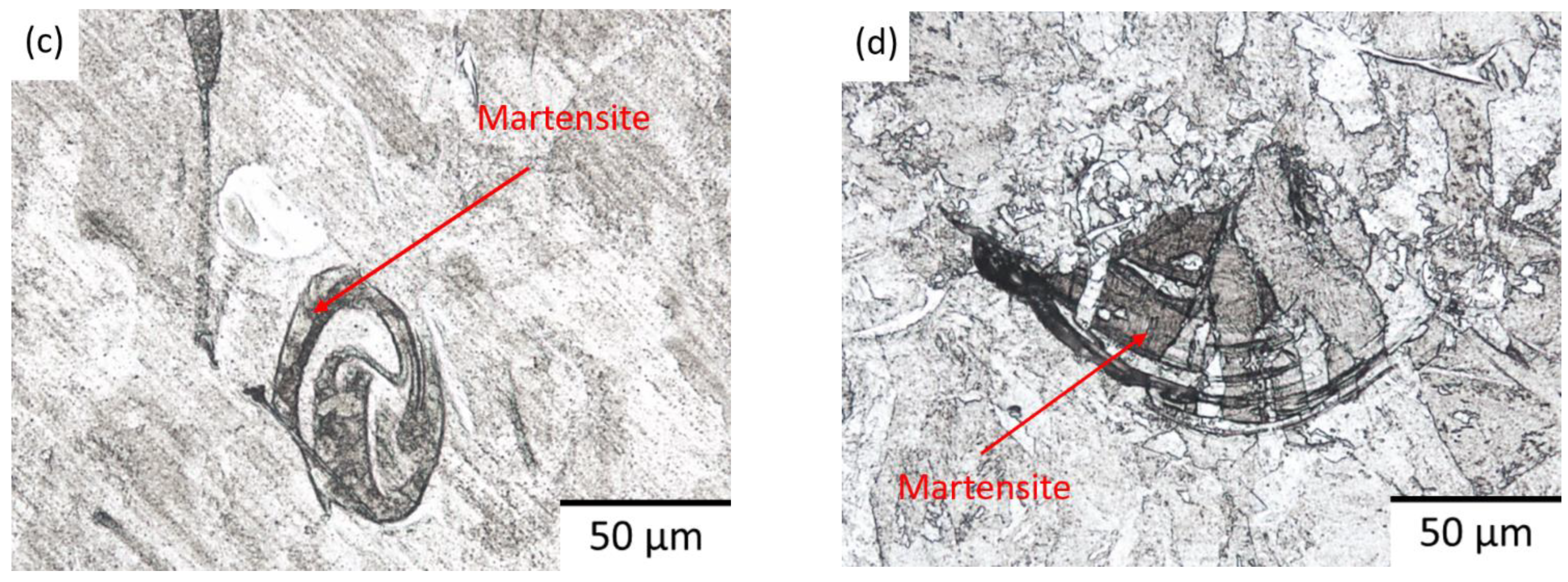

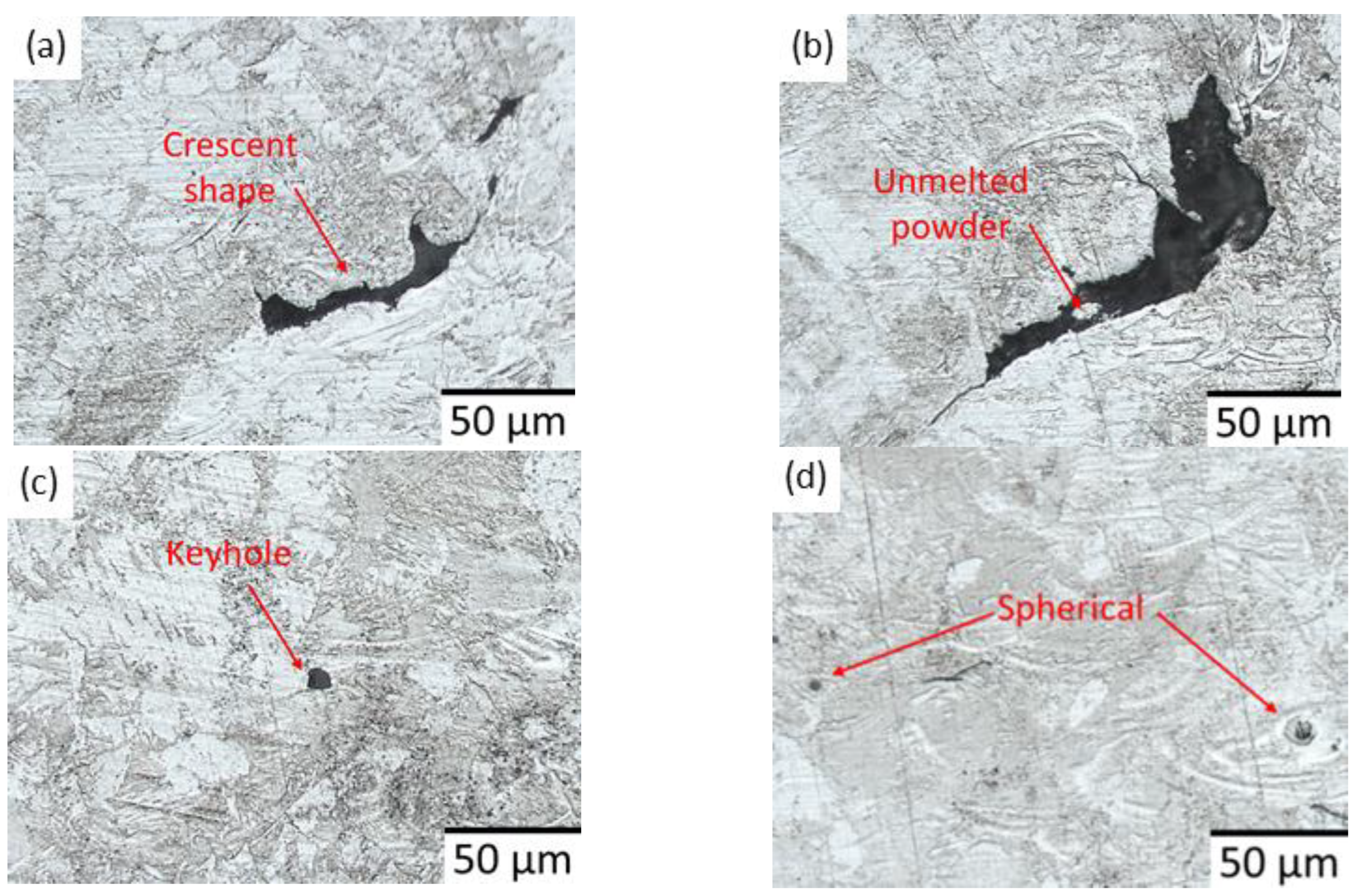

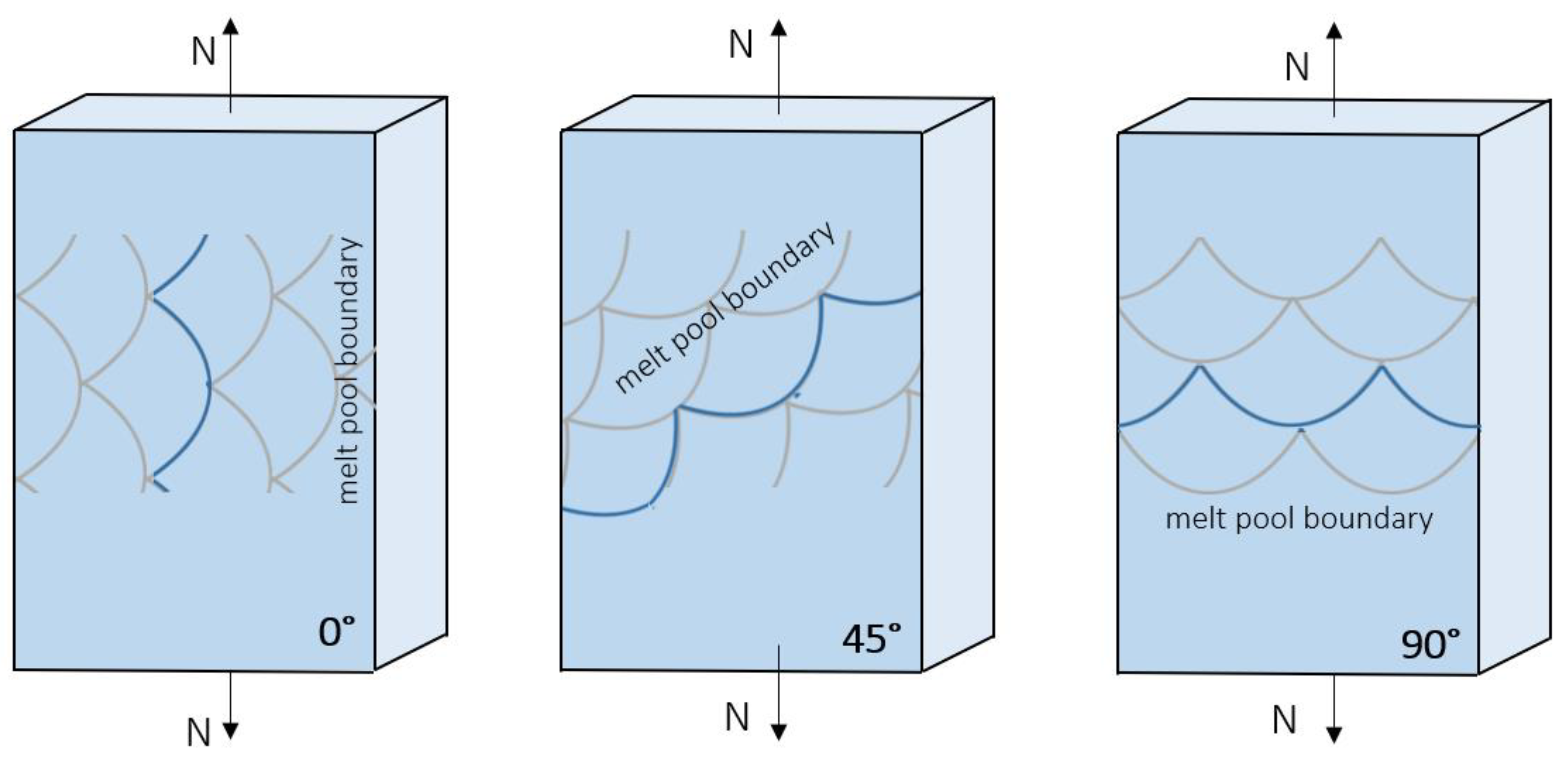

3.2. Microstructure Profiling and Hardness Test

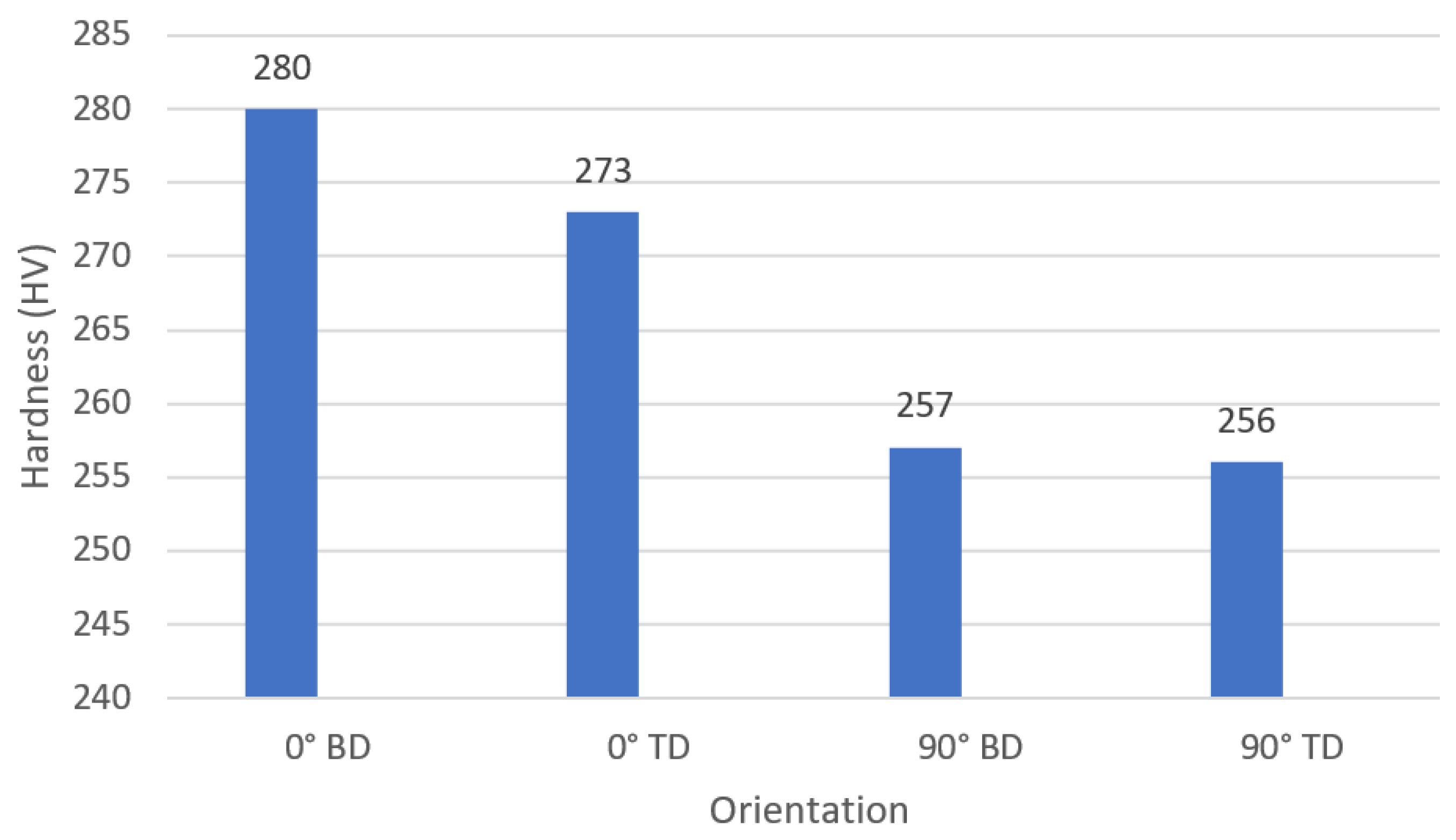

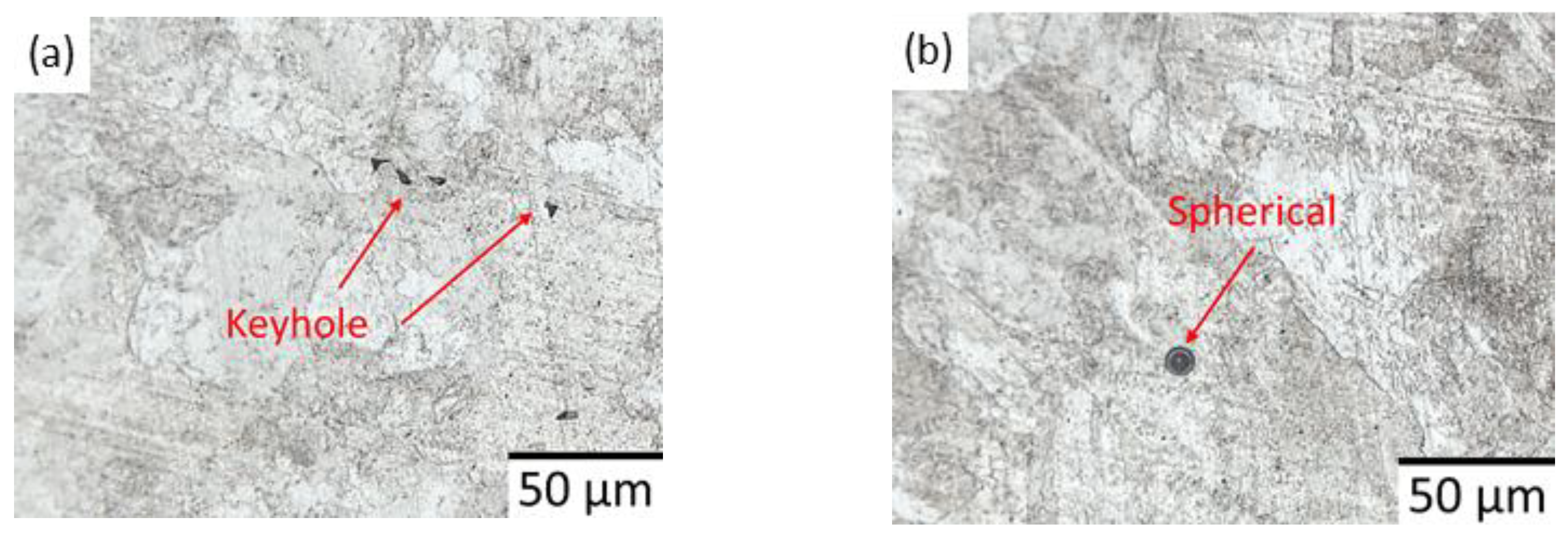

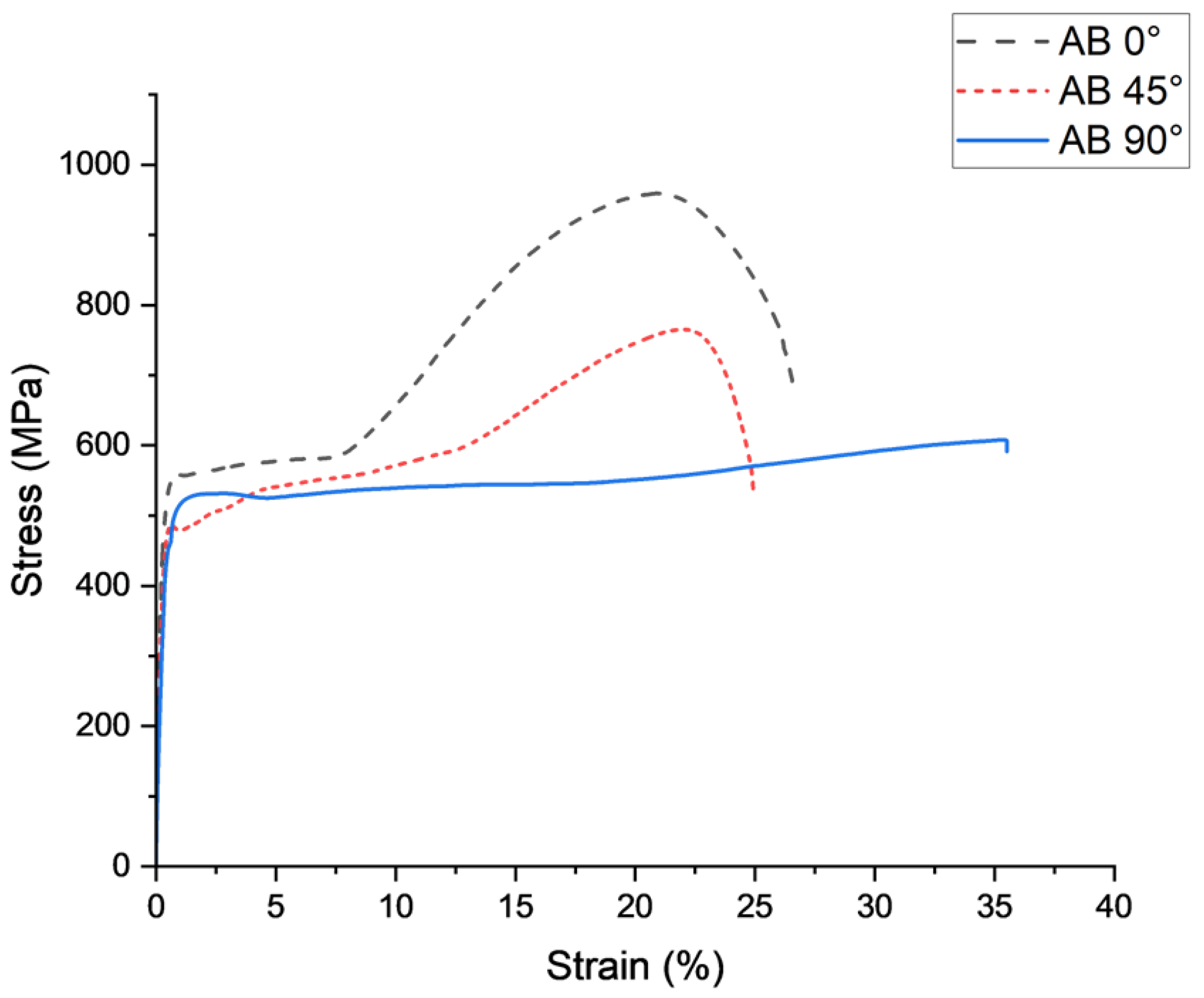

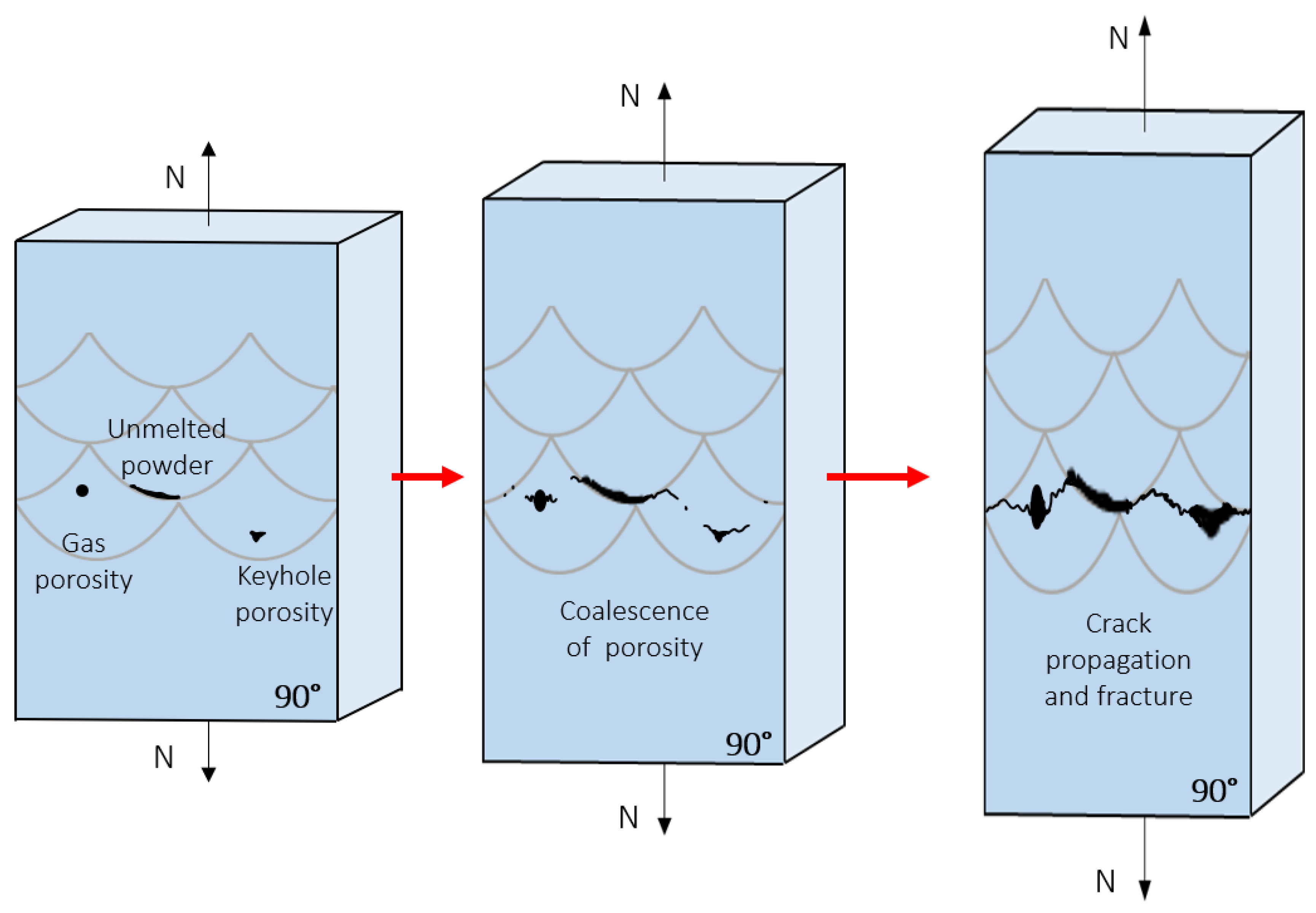

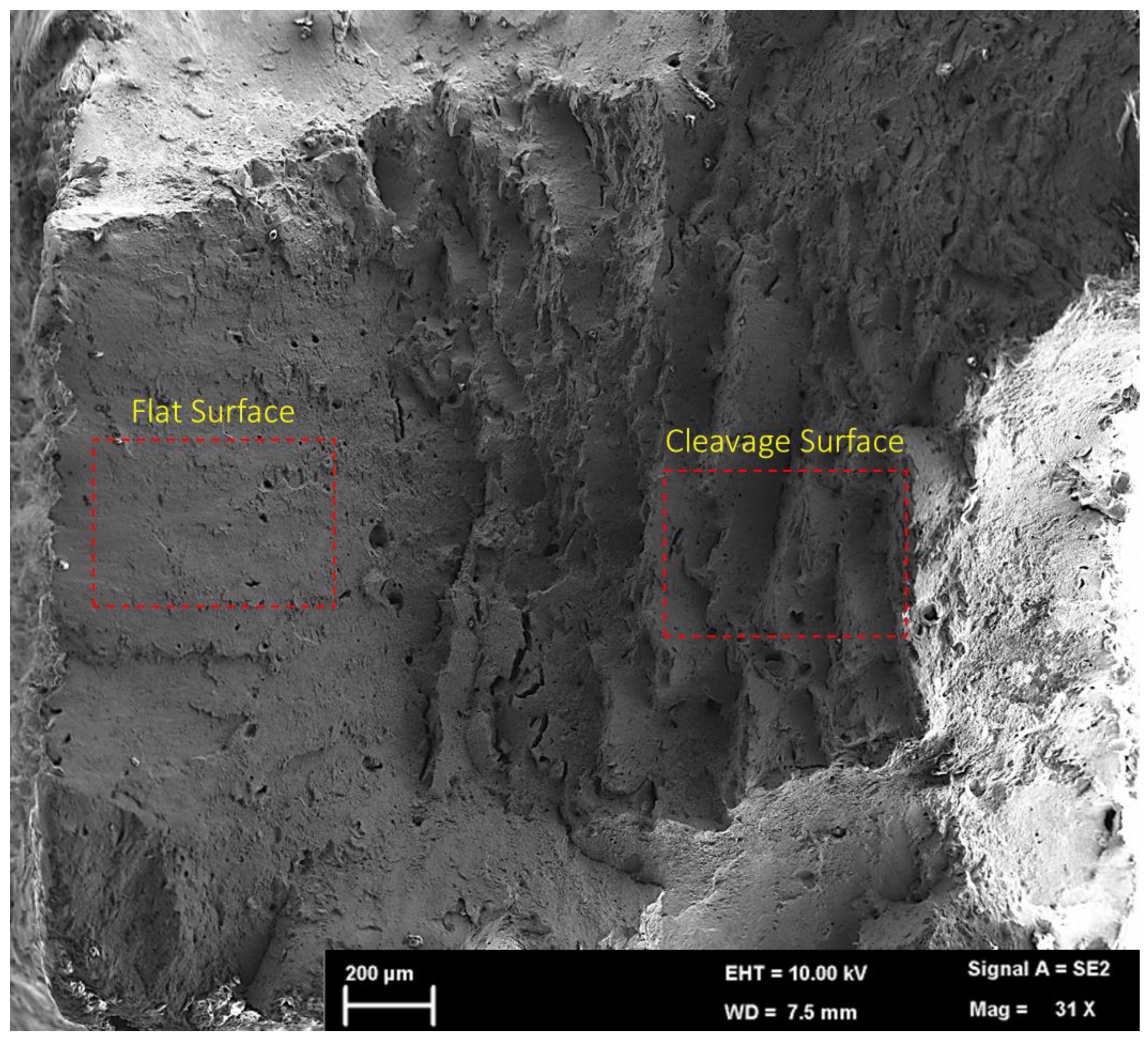

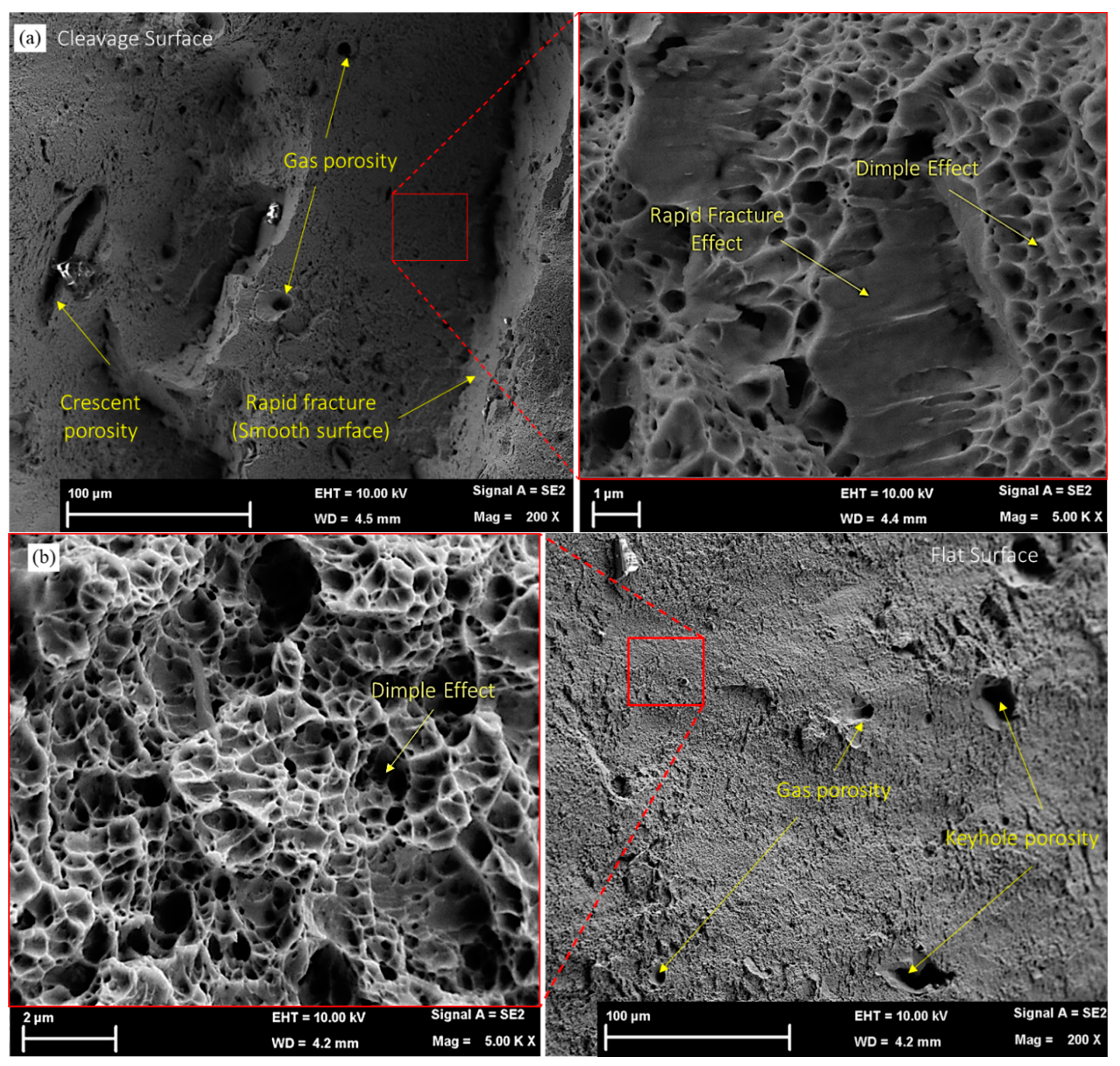

3.3. Porosity Distribution and Tensile Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, P.; Li, W.; Liang, Y.; Liang, Y. Microstructure and anisotropy of the mechanical properties of 316l stainless steel fabricated by selective laser melting. Metals 2021, 11, 775. [Google Scholar] [CrossRef]

- Babaev, A.; Promakhov, V.; Schulz, N.; Semenov, A.; Bakhmat, V.; Vorozhtsov, A. Processes of Physical Treatment of Stainless Steels Obtained by Additive Manufacturing. Metals 2022, 12, 1449. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Ansari, P.; Rehman, A.U.; Pitir, F.; Veziroglu, S.; Mishra, Y.K.; Aktas, O.C.; Salamci, M.U. Selective laser melting of 316l austenitic stainless steel: Detailed process understanding using multiphysics simulation and experimentation. Metals 2021, 11, 1076. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol. 2018, 327, 128–151. [Google Scholar] [CrossRef]

- American Iron and Steel Institute. Design Guidelines for the Selection and Use of Stainless Steel; Specialty Steel Industry of the United States; American Iron and Steel Institute: Detroit, MI, USA, 1993. [Google Scholar]

- Ko, G.; Kim, W.; Kwon, K.; Lee, T.K. The Corrosion of Stainless Steel Made by Additive Manufacturing: A Review. Metals 2021, 11, 516. [Google Scholar] [CrossRef]

- Jiao, Z.H.; Xu, R.D.; Yu, H.C.; Wu, X.R. Evaluation on Tensile and Fatigue Crack Growth Performances of Ti6Al4V Alloy Produced by Selective Laser Melting. Procedia Struct. Integr. 2017, 7, 124–132. [Google Scholar] [CrossRef]

- Waller, J.M.; Parker, B.H.; Hodges, K.L.; Burke, E.R.; Walker, J.L. Nondestructive Evaluation of Additive Manufacturing State-of-the-Discipline Report; Nasa/Tm-2014-218560; Langley Research Center, National Aeronautics and Space Administration: Hampton, VA, USA, 2014; pp. 1–36. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. Selective laser melting of TiB2/316L stainless steel composites: The roles of powder preparation and hot isostatic pressing post-treatment. Powder Technol. 2017, 309, 37–48. [Google Scholar] [CrossRef]

- Facchini, L.; Vicente, N.; Lonardelli, I.; Magalini, E.; Robotti, P.; Alberto, M. Metastable austenite in 17-4 precipitation-hardening stainless steel produced by selective laser melting. Adv. Eng. Mater. 2010, 12, 184–188. [Google Scholar] [CrossRef]

- Coulson, S. Analysis of Additively Manufactured 17-4ph Stainless Steel; McMaster University: Hamilton, ON, Canada, 2018; 4p. [Google Scholar]

- Syarif, J.; Yousuf, M.H.; Sajuri, Z.; Baghdadi, A.H.; Merabtene, M.; Omar, M.Z. Effect of partial solution treatment temperature on microstructure and tensile properties of 440C martensitic stainless steel. Metals 2020, 10, 694. [Google Scholar] [CrossRef]

- Khuenkaew, T.; Kanlayasiri, K. Resistance spot welding of SUS316L austenitic/SUS425 ferritic stainless steels: Weldment characteristics, mechanical properties, phase transformation and solidification. Metals 2019, 9, 710. [Google Scholar] [CrossRef]

- Kain, V. Stress Corrosion Cracking (SCC) in Stainless Steels; Woodhead Publishing Limited: Sawston, UK, 2011. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Elwany, A.; Yadollahi, A.; Thompson, S.M. Mechanical and microstructural characterization of selective laser melted 17-4 PH stainless steel. Rapid Prototyp. J. 2017, 23, 280–294. [Google Scholar] [CrossRef]

- Fauzi, F.M.; Jamhari, F.I.; Ahmad Buhairi, M. Pencirian dan Perbandingan Serbuk Aloi Titanium (Ti6Al4V) yang Digunakan dalam Peleburan Laser Selektif (SLM). Sains Malaysiana 2022, 51, 1885–1894. [Google Scholar]

- Gorsse, S.; Hutchinson, C.; Gouné, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef] [PubMed]

- Aripin, M.A.; Sajuri, Z.; Junaidi, S.; Baghdadi, A.H.; Mohamed, I.F. Evaluation of Microstructure and Porosity for 3D Printed Stainless Steel. Mater. Today Proc. 2022, 66, 3082–3086. [Google Scholar] [CrossRef]

- Ahmad Buhairi, M.; Mohd Foudzi, F.; Jamhari, F.I.; Sulong, A.B.; Mohd Radzuan, N.A.; Muhamad, N.; Mohamed, I.F.; Azman, A.H.; Wan Harun, W.S.; Al-Furjan, M.S.H. Review on volumetric energy density: Influence on morphology and mechanical properties of Ti6Al4V manufactured via laser powder bed fusion. Prog. Addit. Manuf. 2022. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. Engl. Ed. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.J.S.; Pal, D.; Stucker, B. Melt pool characterization for selective laser melting of Ti-6Al-4V pre-alloyed powder. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium: An Additive Manufacturing Conference, Austin, TX, USA, 4–6 August 2014; pp. 256–267. [Google Scholar]

- Jacob, G. Prediction of Solidification Phases in Cr-Ni Stainless Steel Alloys Manufactured by Laser Based Powder Bed Fusion Process; National Institute of Standards and Technology, US Department of Commerce: Washington, DC, USA, 2018; pp. 1–38. [Google Scholar]

- Yusuf, S.M.; Gao, N. Influence of energy density on metallurgy and properties in metal additive manufacturing. Mater. Sci. Technol. 2017, 33, 1269–1289. [Google Scholar] [CrossRef]

- Mfusi, B.J.; Tshabalala, L.C.; Popoola, A.P.I.; Mathe, N.R. The effect of selective laser melting build orientation on the mechanical properties of AlSi10Mg parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012028. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Adeyemi, A.; Akinlabi, E.T.; Mahamood, R.M. Powder bed based laser additive manufacturing process of stainless steel: A review. Mater. Today Proc. 2018, 5, 18510–18517. [Google Scholar] [CrossRef]

- ASTM. E975 Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Slotwinski, J.A.; Garboczi, E.J.; Stutzman, P.E.; Ferraris, C.F.; Watson, S.S.; Peltz, M.A. Characterization of metal powders used for additive manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 460–493. [Google Scholar] [CrossRef]

- Gu, H.; Gong, H.; Pal, D.; Rafi, K.; Starr, T.; Stucker, B. Influences of energy density on porosity and microstructure of selective laser melted 17-4PH stainless steel. In Proceedings of the 2013 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013; pp. 474–489. [Google Scholar]

- Vander Voort, G.F.; Lucas, G.M.; Manilova, E.P. Metallography and Microstructures of Stainless Steels and Maraging Steels. Metallogr. Microstruct. 2004, 9, 670–700. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An investigation of the microstructure and fatigue behavior of additively manufactured AISI 316L stainless steel with regard to the influence of heat treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef]

- ASTM. A 240/A 240Ma: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Irrinki, H.; Jangam, J.S.D.; Pasebani, S.; Badwe, S.; Stitzel, J.; Kate, K.; Gulsoy, O.; Atre, S.V. Effects of particle characteristics on the microstructure and mechanical properties of 17-4 PH stainless steel fabricated by laser-powder bed fusion. Powder Technol. 2018, 331, 192–203. [Google Scholar] [CrossRef]

- Bhaduri, A.K.; Gill, T.P.S.; Srinivasan, G.; Sujith, S. Optimised post-weld heat treatment procedures and heat input for welding 17-4PH stainless steel. Sci. Technol. Weld. Join. 1999, 4, 295–301. [Google Scholar] [CrossRef]

- Zai, L.; Zhang, C.; Wang, Y.; Guo, W.; Wellman, D.; Tong, X.; Tian, Y. Laser powder bed fusion of precipitation-hardened martensitic stainless steels: A review. Metals. 2020, 10, 255. [Google Scholar] [CrossRef]

- Gorni, A.A. Steel Forming and Heat Treating Handbook; Sao Vicente, Cape Verde, 2018; Available online: http://www.chte.org/d/file/p/2013-01-22/bbf30bc70b449796e79d568fe864a802.pdf (accessed on 15 April 2019). [CrossRef]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and properties of 17-4 PH stainless steel fabricated by selective laser melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef]

- Donik; Kraner, J.; Paulin, I.; Godec, M. Influence of the Energy Density for Selective Laser Melting on the Microstructure and Mechanical Properties of Stainless Steel. Metals 2020, 10, 919. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Mohamed, O.A. Mechanical performance of selective laser melted 17-4 PH stainless steel under compressive loading. In Proceedings of the 2017 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; pp. 321–331. [Google Scholar]

- Pilehrood, A.E.; Mashhuriazar, A.; Baghdadi, A.H.; Sajuri, Z.; Omidvar, H. Effect of Laser Metal Deposition Parameters on the Characteristics of Stellite 6 Deposited Layers on. Materials 2021, 14, 5662. [Google Scholar] [CrossRef] [PubMed]

- Condruz, M.R.; Paraschiv, A.; Puscasu, C. Heat Treatment Influence on Hardness and Microstructure of Adam Manufactured 17-4 Ph. Turbo 2018, 5, 4–11. Available online: https://www.researchgate.net/publication/332423408 (accessed on 15 April 2019).

- Lass, E.A.; Zhang, F.A.N.; Campbell, C.E. Nitrogen Effects in Additively Manufactured Martensitic Stainless Steels: Conventional Thermal Processing and Comparison with Wrought. Metall. Mater. Trans. A 2020, 51, 2318–2332. [Google Scholar] [CrossRef]

- Sabooni, S.; Chabok, A.; Feng, S.C.; Blaauw, H.; Pijper, T.C.; Yang, H.J.; Pei, Y.T. Laser powder bed fusion of 17–4 PH stainless steel: A comparative study on the effect of heat treatment on the microstructure evolution and mechanical properties. Addit. Manuf. 2021, 46, 102176. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Perulli, P.; Sastre, M.A.C.; Fernández-Abia, A.I.; Barreiro, J. Analysis of microstructure and defects in 17-4 PH stainless steel sample manufactured by Selective Laser Melting. Procedia Manuf. 2019, 41, 66–73. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel. Int. J. Fatigue 2017, 94, 218–235. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, H.; Zhang, H.; Zeng, X. Experimental investigation on selective laser melting of 17-4PH stainless steel. Opt. Laser Technol. 2017, 87, 17–25. [Google Scholar] [CrossRef]

- Kamariah, M.S.I.N.; Harun, W.S.W.; Khalil, N.Z.; Ahmad, F.; Ismail, M.H.; Sharif, S. Mechanical Behaviours of Selective Laser Melting 316L Stainless Steel. J. Addit. Manuf. Adv. Mater. 2020, 257, 012021. [Google Scholar] [CrossRef]

- Li, L. Repair of directionally solidified superalloy GTD-111 by laser-engineered net shaping. J. Mater. Sci. 2006, 41, 7886–7893. [Google Scholar] [CrossRef]

- Cegan, T.; Pagac, M.; Jurica, J.; Skotnicova, K.; Hajnys, J.; Horsak, L.; Soucek, K.; Krpec, P. Effect of hot isostatic pressing on porosity and mechanical properties of 316L stainless steel prepared by the selective laser melting method. Materials 2020, 13, 4377. [Google Scholar] [CrossRef] [PubMed]

- Tascioglu, E.; Karabulut, Y.; Kaynak, Y. Correction to: Influence of heat treatment temperature on the microstructural, mechanical, and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 1957. [Google Scholar] [CrossRef]

- Vallejo, N.D.; Lucas, C.; Ayers, N.; Graydon, K.; Hyer, H.; Sohn, Y. Process optimization and microstructure analysis to understand laser powder bed fusion of 316L stainless steel. Metals 2021, 11, 832. [Google Scholar] [CrossRef]

| Process Parameters | Parameters Value |

|---|---|

| Laser power | 200 W |

| Laser scanning speed | 800 mm/s |

| Layer thickness | 30 µm |

| Hatching distance | 100 ± 10 μm |

| Temperature range | 1075–1125 °C |

| Heat Treatment | Air-cooled |

| Average powder size | 43 µm |

| Element | Fe | Cr | Ni | Cu | C | Si | Mn |

|---|---|---|---|---|---|---|---|

| wt. % | Bal. | 15.76 | 4.02 | 4.08 | 0.07 | 1.23 | 0.59 |

| Build Orientation | Tensile Strength (MPa) | Elongation (%) | Yield Strength (MPa) | Strain Energy (J) |

|---|---|---|---|---|

| 0° | 958 ± 1 | 26 ± 0.6 | 472 ± 9 | 68 ± 1.5 |

| 45° | 744 ± 9 | 25 ± 0.6 | 481 ± 5 | 54 ± 0.8 |

| 90° | 615 ± 7 | 38 ± 1.5 | 442 ± 5 | 77 ± 4.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aripin, M.A.; Sajuri, Z.; Jamadon, N.H.; Baghdadi, A.H.; Syarif, J.; Mohamed, I.F.; Aziz, A.M. Effects of Build Orientations on Microstructure Evolution, Porosity Formation, and Mechanical Performance of Selective Laser Melted 17-4 PH Stainless Steel. Metals 2022, 12, 1968. https://doi.org/10.3390/met12111968

Aripin MA, Sajuri Z, Jamadon NH, Baghdadi AH, Syarif J, Mohamed IF, Aziz AM. Effects of Build Orientations on Microstructure Evolution, Porosity Formation, and Mechanical Performance of Selective Laser Melted 17-4 PH Stainless Steel. Metals. 2022; 12(11):1968. https://doi.org/10.3390/met12111968

Chicago/Turabian StyleAripin, Mohammad Azlan, Zainuddin Sajuri, Nashrah Hani Jamadon, Amir Hossein Baghdadi, Junaidi Syarif, Intan Fadhlina Mohamed, and Ahmad Muhammad Aziz. 2022. "Effects of Build Orientations on Microstructure Evolution, Porosity Formation, and Mechanical Performance of Selective Laser Melted 17-4 PH Stainless Steel" Metals 12, no. 11: 1968. https://doi.org/10.3390/met12111968

APA StyleAripin, M. A., Sajuri, Z., Jamadon, N. H., Baghdadi, A. H., Syarif, J., Mohamed, I. F., & Aziz, A. M. (2022). Effects of Build Orientations on Microstructure Evolution, Porosity Formation, and Mechanical Performance of Selective Laser Melted 17-4 PH Stainless Steel. Metals, 12(11), 1968. https://doi.org/10.3390/met12111968